Deburring device for wood board processing

A technique of burrs, planks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

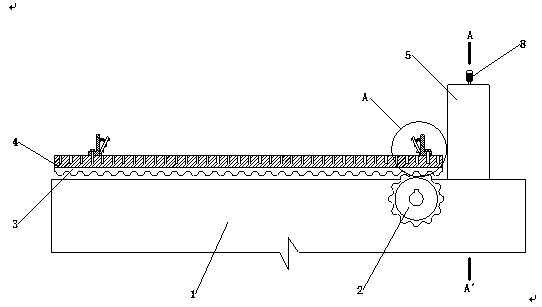

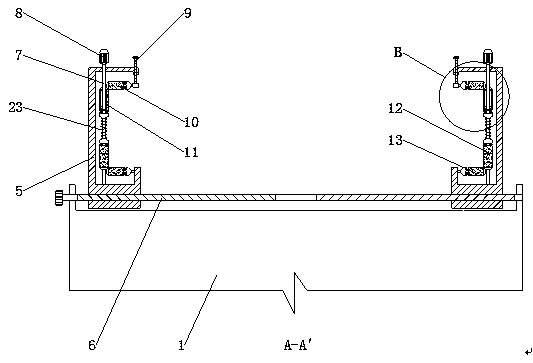

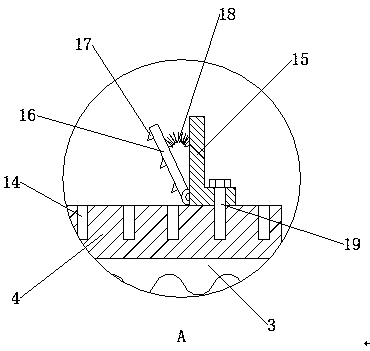

[0028] as attached figure 1 to attach Figure 9 Shown:

[0029] The invention provides a deburring device for wood processing, which includes a workbench 1, a gear 2, a rack 3, a feeding plate 4, a deburring frame 5, a two-way screw rod 6, a rotating shaft 7, a motor 8, an adjusting screw rod 9, a moving Horizontal grinding roller 10, mobile vertical grinding roller 11, fixed vertical grinding roller 12, fixed horizontal grinding roller 13, threaded hole 14, L-shaped support plate 15, elastic splint 16, check bar 17, clamping spring 18, screw 19, Connecting block 20, bevel gear 21, slider 22, telescopic spring 23, gear 2 is installed inside the workbench 1 for rotation, a feeding plate 4 is slidably arranged above the workbench 1, and a rack 3 is fixedly connected to the bottom of the feeding plate 4 , the rack 3 meshes with the gear 2, the surface of the feed plate 4 is provided with a threaded hole 14, the top of the feed plate 4 is fixedly connected with two L-shaped supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com