Multi-groove ultrasonic cleaning machine

An ultrasonic and washing machine technology, applied in dryers, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of the need to improve the cleaning efficiency and the low degree of automation of the cleaning machine, and achieve a beautiful structure and clean Consistent quality and the effect of avoiding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

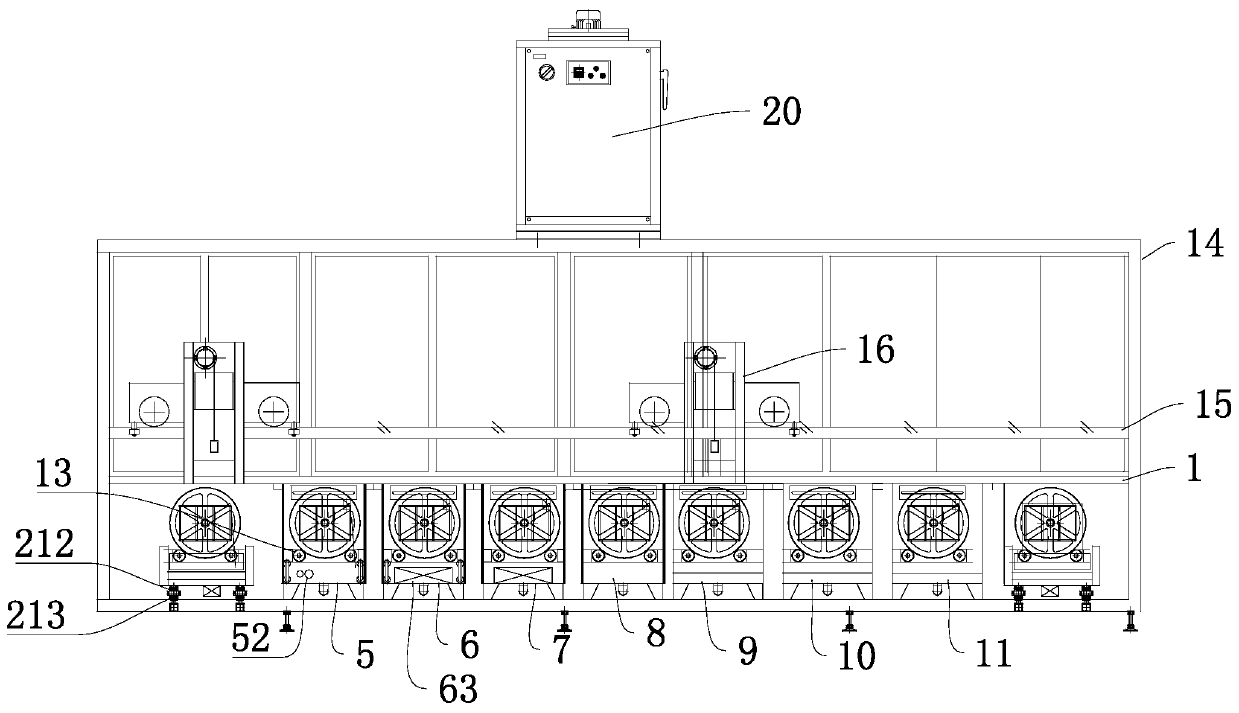

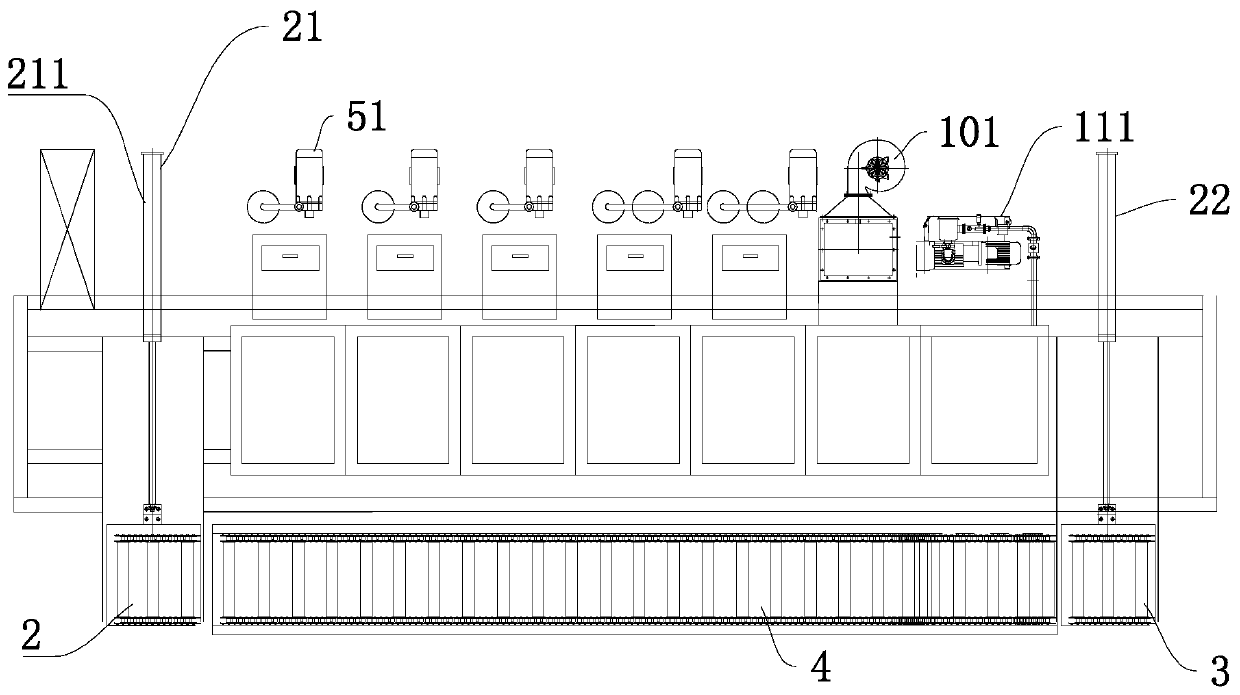

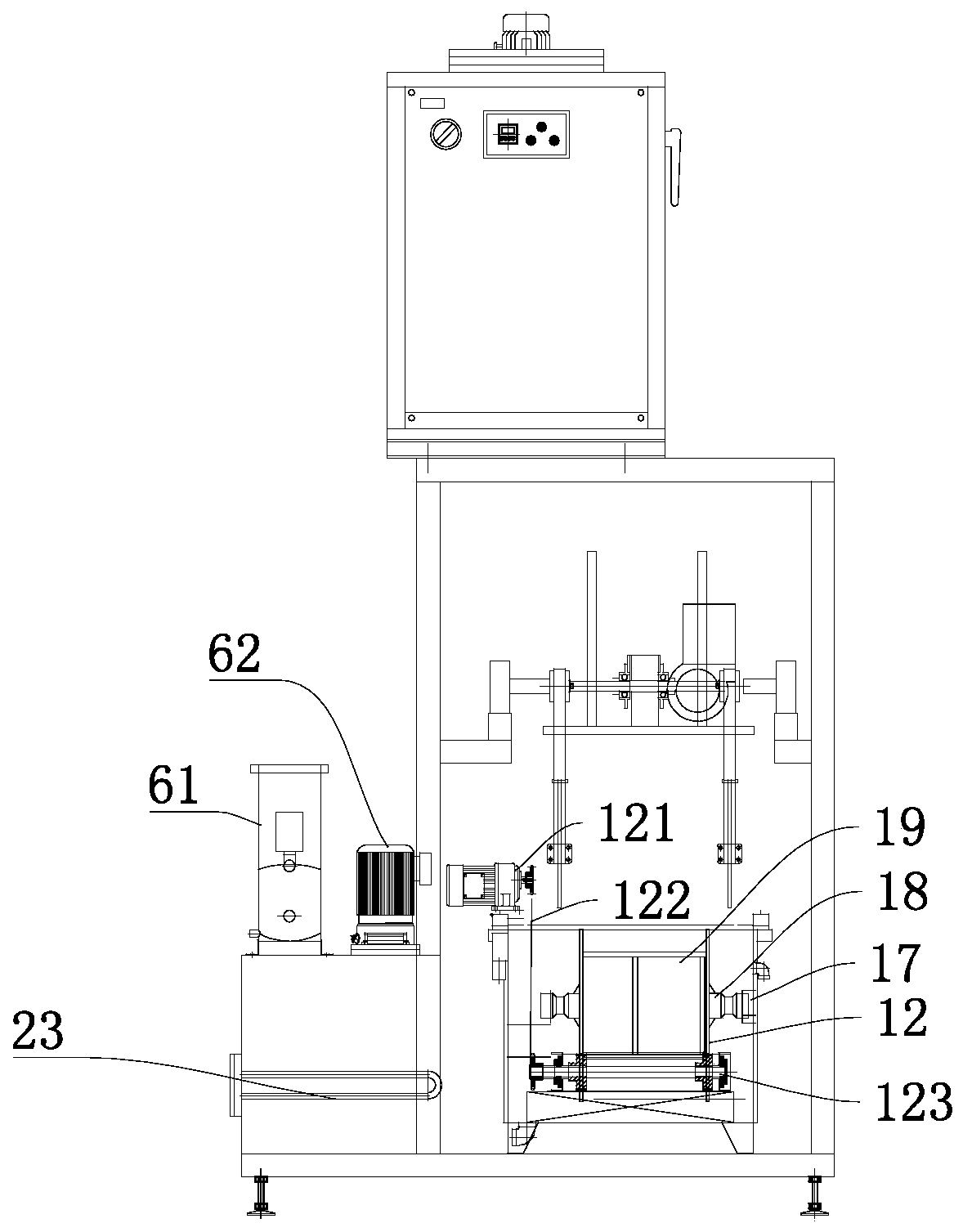

[0025] Example 1: Such as figure 1 , figure 2 and image 3 As shown, a multi-tank ultrasonic cleaning machine is provided with a total of seven main cleaning procedures in the cleaning box 1. One end of the cleaning box 1 is provided with a first pushing mechanism 21. The first pushing mechanism 21 includes a conveying cylinder 211, The rail 212 and the guide rail 213, two parallel guide rails 213 are fixed on the ground, the slide rail 212 is located on the guide rail 213 and slides along the guide rail 213, the feeding roller 2 is fixed on the top of the guide rail 213, and the feeding roller 2 follows the guide rail. 213 slides, the conveying cylinder 211 is arranged on one side of the feeding roller table 2, and the feeding roller table 2 is pushed by the conveying cylinder 211 to slide on the top of the guide rail 213.

[0026] A rail bracket 14 is fixedly connected to the top of the cleaning box 1 side. The rail bracket 14 is provided with a moving rail 15. The moving rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com