Patents

Literature

125results about How to "Suitable for small batch production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

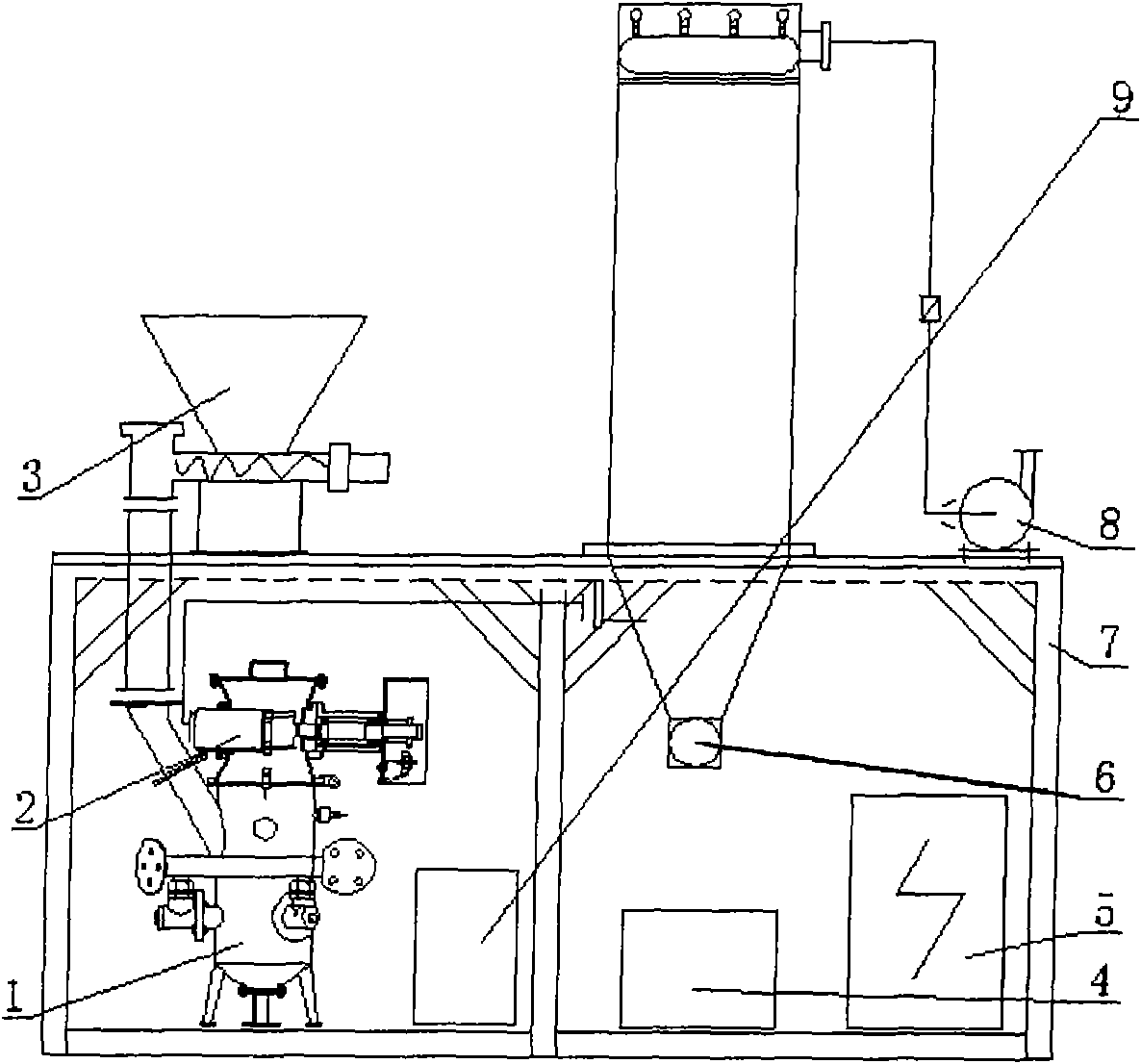

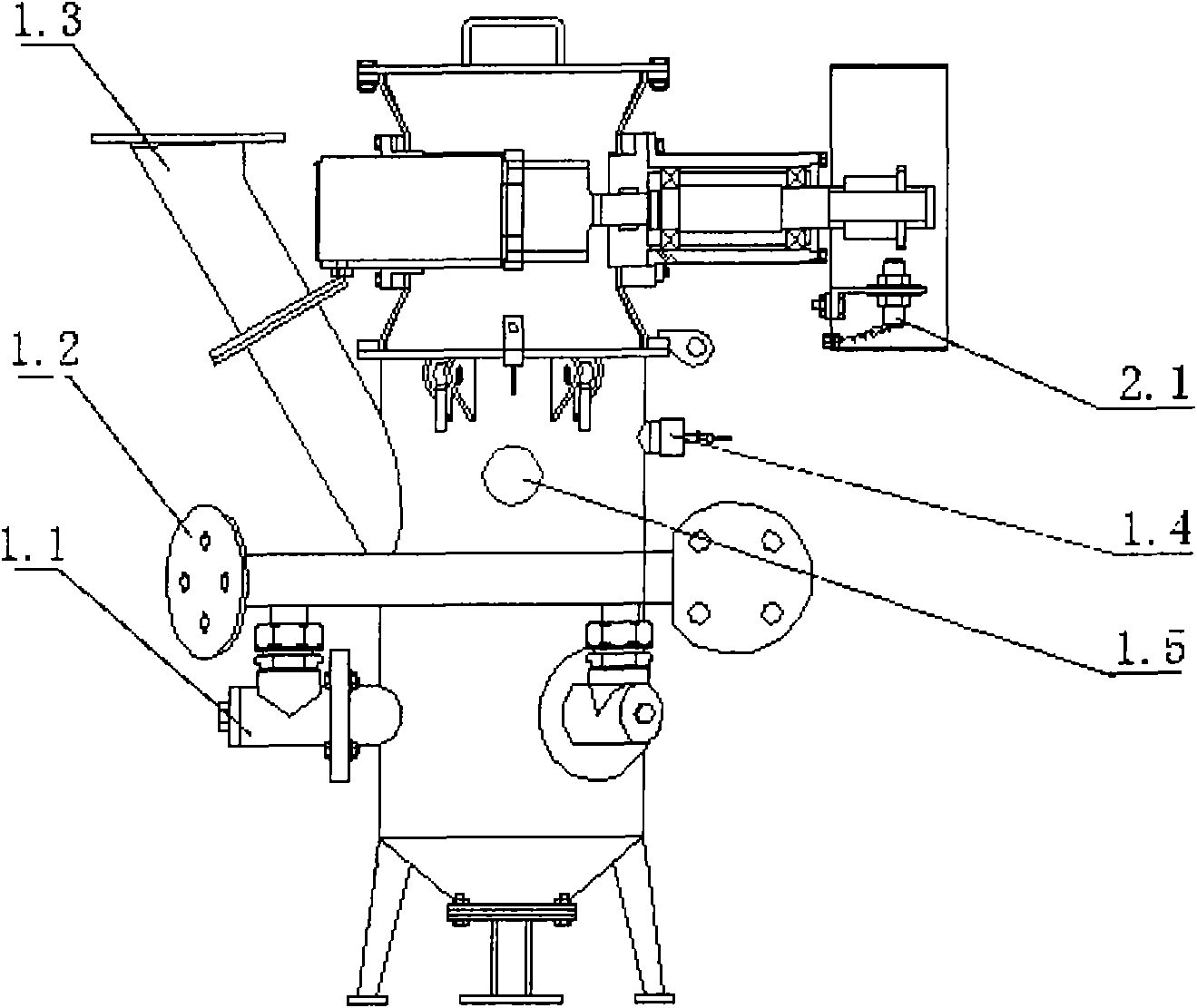

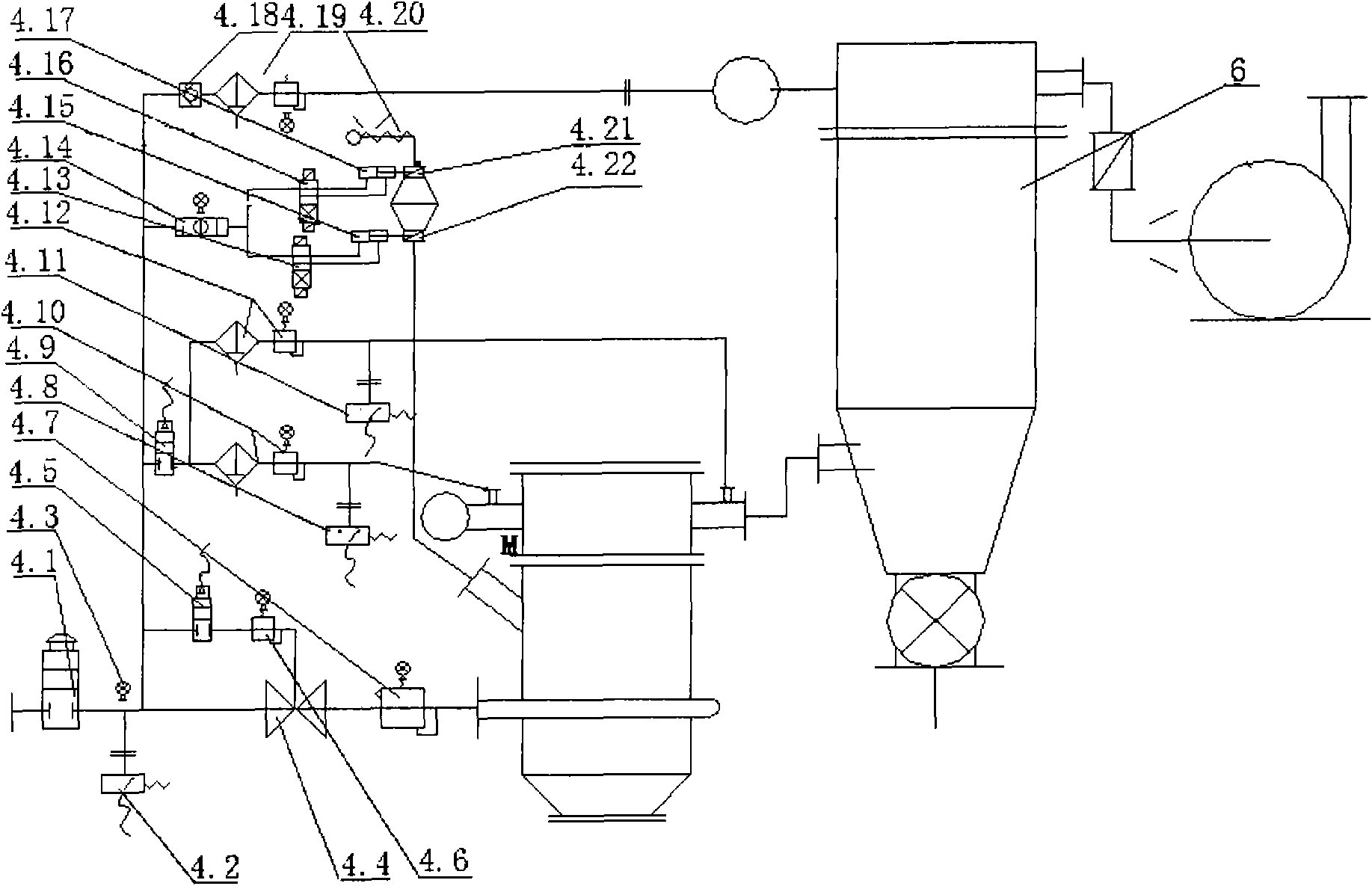

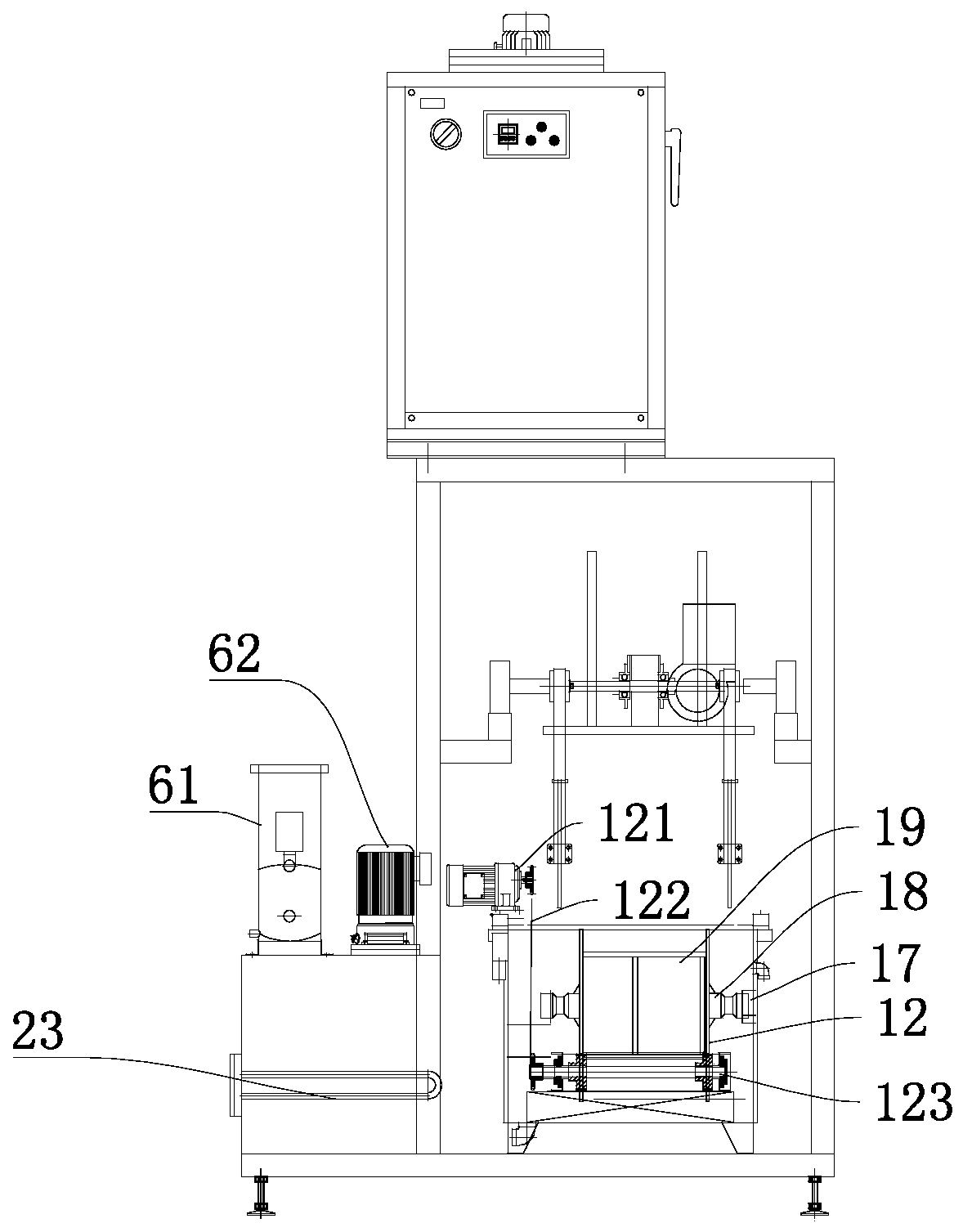

Ultra-fine powder processing device

The invention discloses an ultra-fine powder processing device which comprises an air flow crushing mechanism, a turbine grading mechanism, a screw feeder, an automatic sack packer, an automatic controller, a bag type dust collector, an integrated platform, an induced draft fan and a gas path controller, wherein the air flow crushing mechanism connected with the turbine grading mechanism is located below the turbine grading mechanism, the feed port of the screw feeder is connected with a feed taper pipe in the air flow crushing mechanism, the bag type dust collector is connected with the turbine grading mechanism through a pipeline, the automatic sack packer is located below the bag type dust collector and the induced draft fan is connected with the bag type dust collector. The ultra-fine powder processing device can process materials in a fully-closed condition without producing dust. The ultra-fine powder processing device uses a PLC control system to intelligentize the production process and adjusts the parameters of crushing, grading and other devices according to the factory production requirements so as to meet the crushing requirements of different raw materials. The processing device is built on a stand, and the position of the processing device can be adjusted according to the factory production requirement.

Owner:SOUTH CHINA UNIV OF TECH

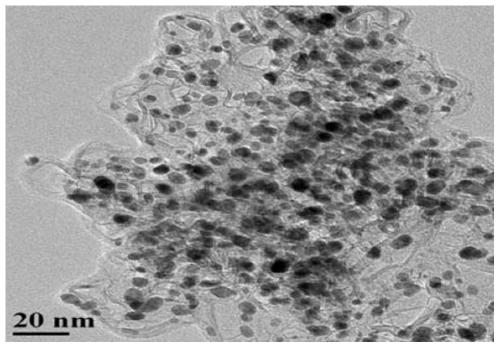

Preparation method for anti-settling fuel cell catalyst slurry

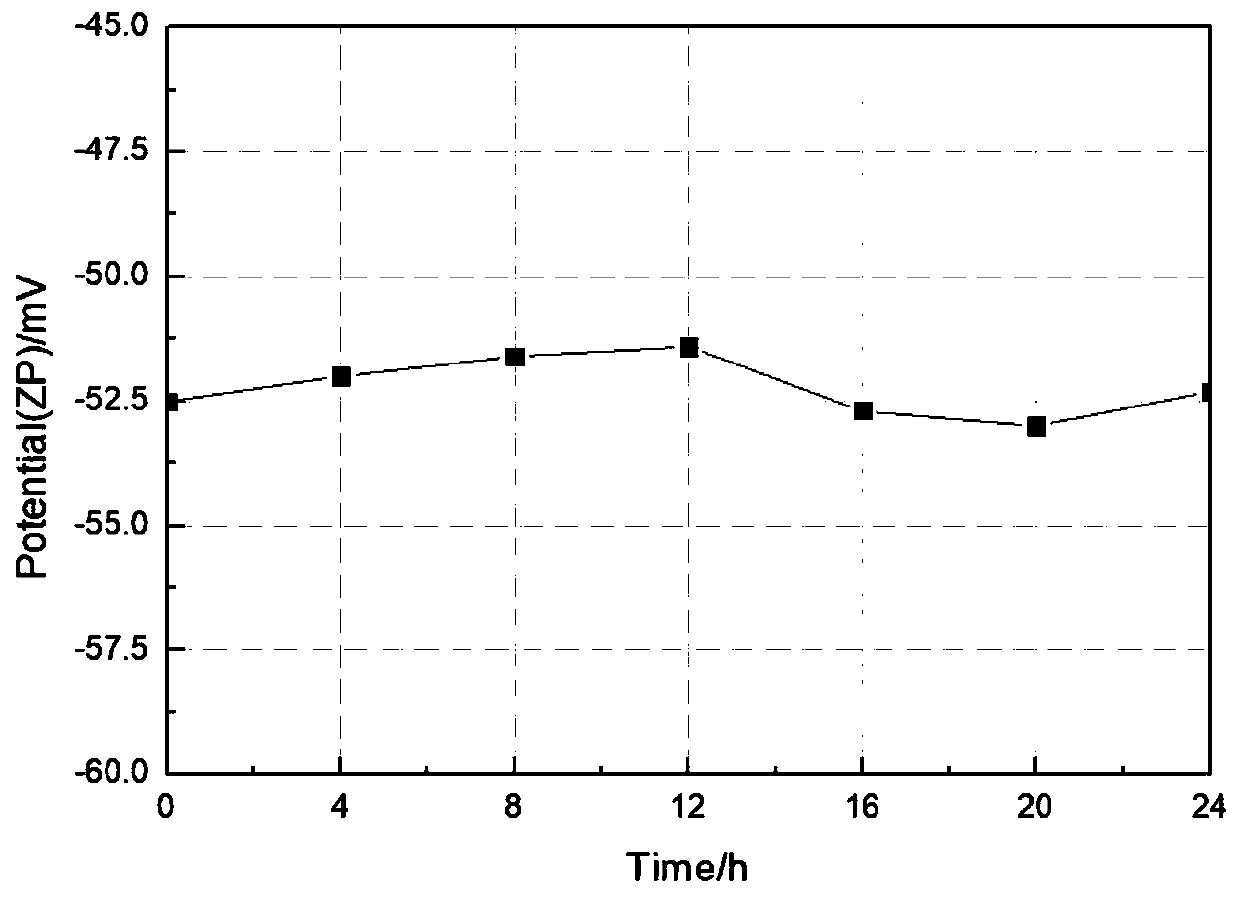

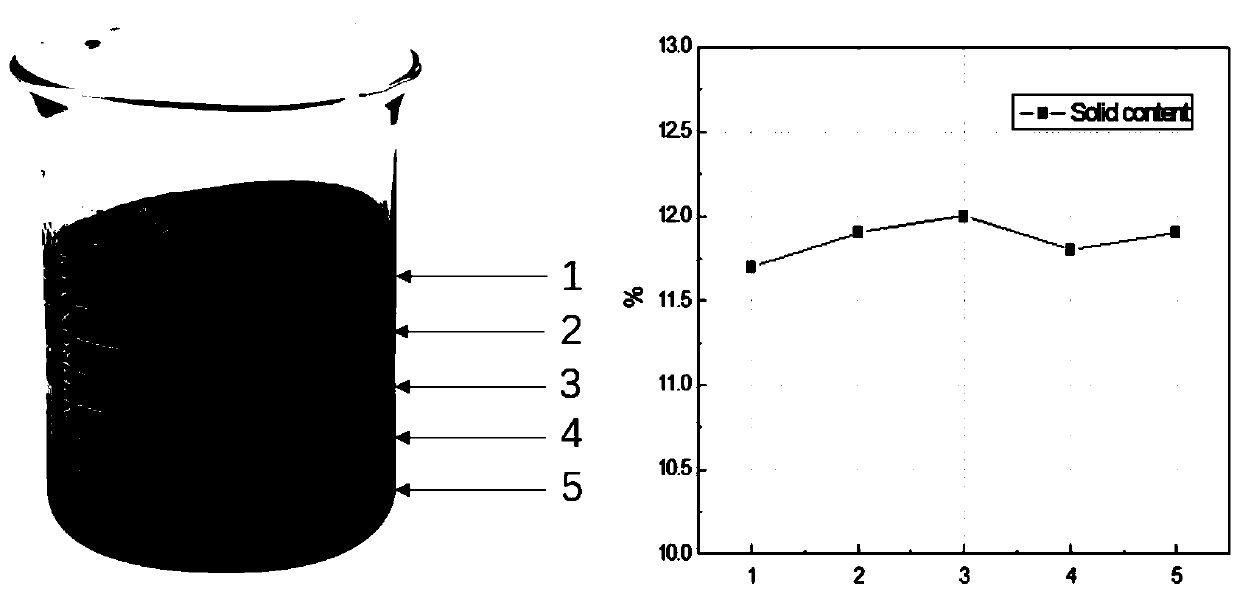

InactiveCN111135761AImprove stabilityImprove consistencyTransportation and packagingMixing methodsPtru catalystPhysical chemistry

The invention relates to a preparation method for an anti-settling fuel cell catalyst slurry. The preparation method comprises the following steps: (1) weighing a perfluorosulfonic acid solution, isopropanol and water for mixing, then carrying out sealing, and carrying out magnetic stirring so as to form a dispersion solution; (2) mixing a catalyst with the dispersion solution, and carrying out ultrasonic dispersion so as to obtain a primarily dispersed catalyst slurry; (3) continuously carrying out high-shear dispersion on the primarily dispersed catalyst slurry by using a stator and rotor stirrer so as to obtain a secondarily dispersed catalyst slurry; and (4) carrying out homogeneous dispersion on the secondarily dispersed catalyst slurry under a vacuum condition by using a homogenizerso as to obtain a stable catalyst slurry. Compared with the prior art, the fuel cell catalyst slurry prepared by using the preparation method provided by the invention is high in stability and betterin consistency; different types of catalyst slurry can be prepared according to different fuel cell membrane electrode preparation processes; and the fuel cell catalyst slurry provided by the invention is applicable to being used in domestic fuel cell stacks.

Owner:上海亮仓能源科技有限公司

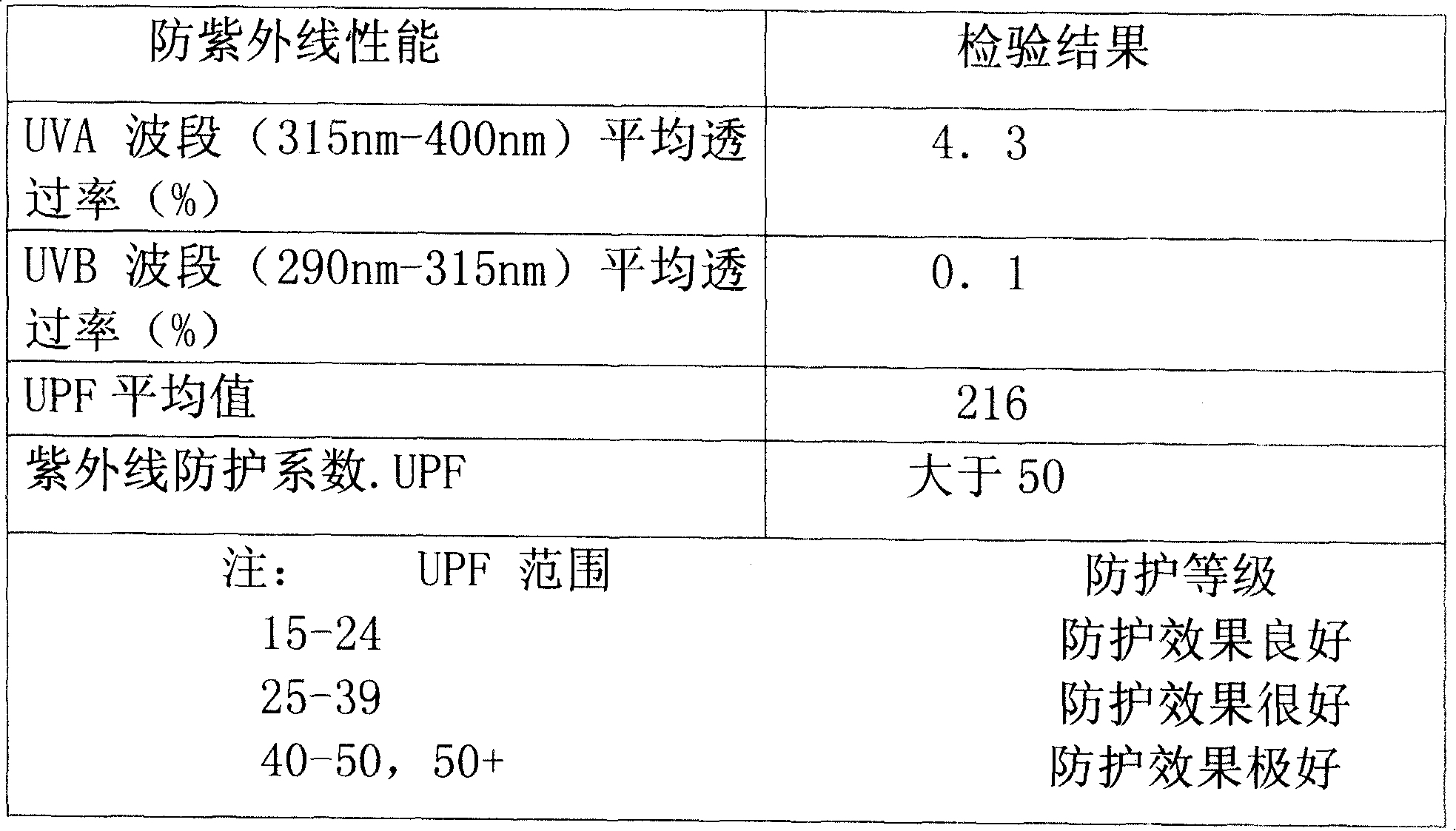

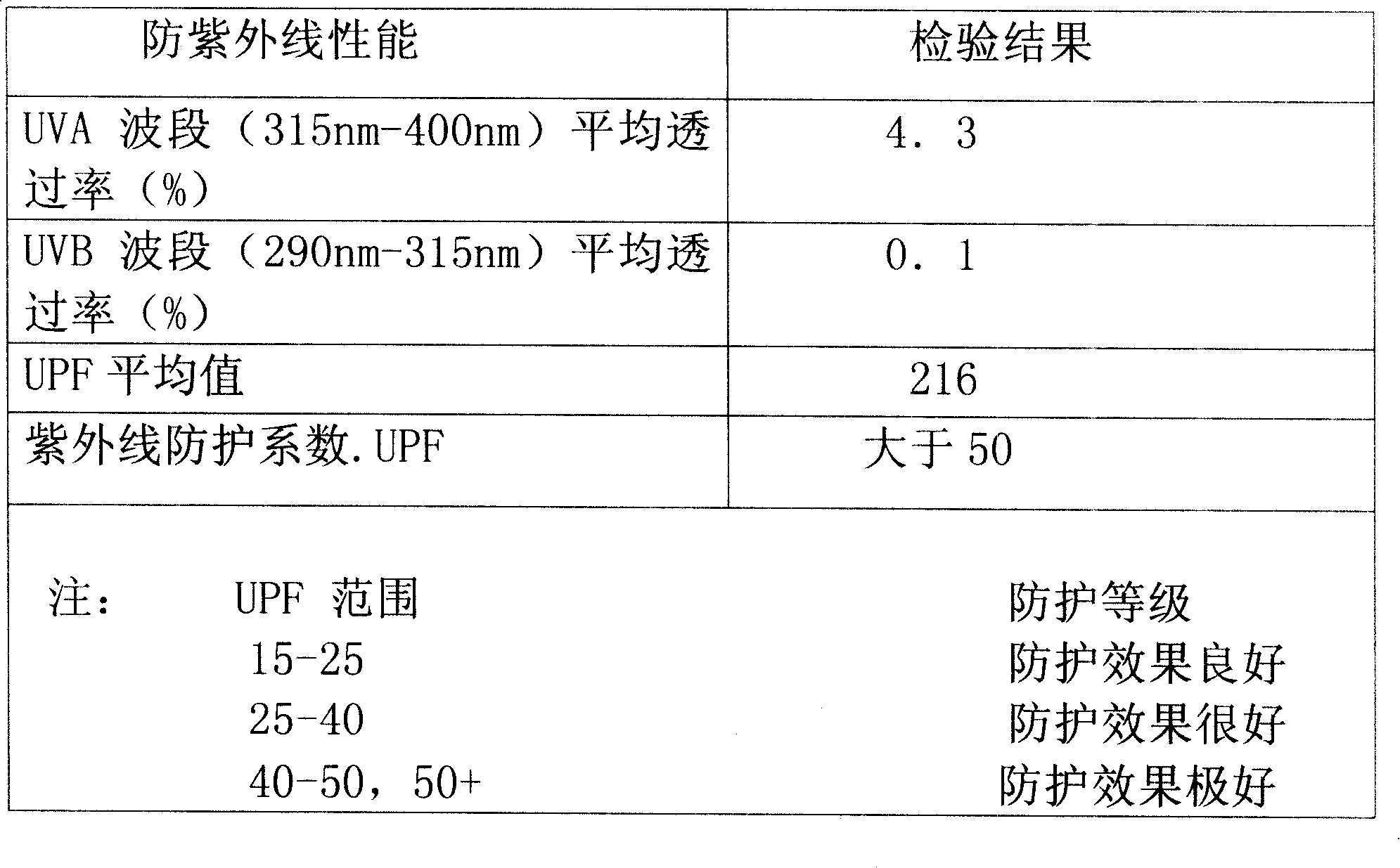

Method for making fabric containing nano particles

InactiveCN101205689APurifyHas bactericidal effectBleaching apparatusDyeing processPhysical chemistryBleach

The invention relates to an antibiosis fabric making method, in particular to an antibiosis fabric making method which adopts specialized nanometer material as additive. The invention adopts the following procedures that: (1) the addition of nanometer particles: nano-sized titanium dioxide particles and argentine particles are added to dye or bleacher and fully mixed; (2) the fabric is dyed and bleached by the fully mixed dye or bleacher under the high-temperature condition. The fabric achieved by the invention has the functions of long lasting antibiosis, deodorization, ultraviolet resistance, etc. The invention is suitable for clothes, undergarments, hoses, towels, bath towels, facemasks, napkins, knitting, home textile, etc.

Owner:杨文剑

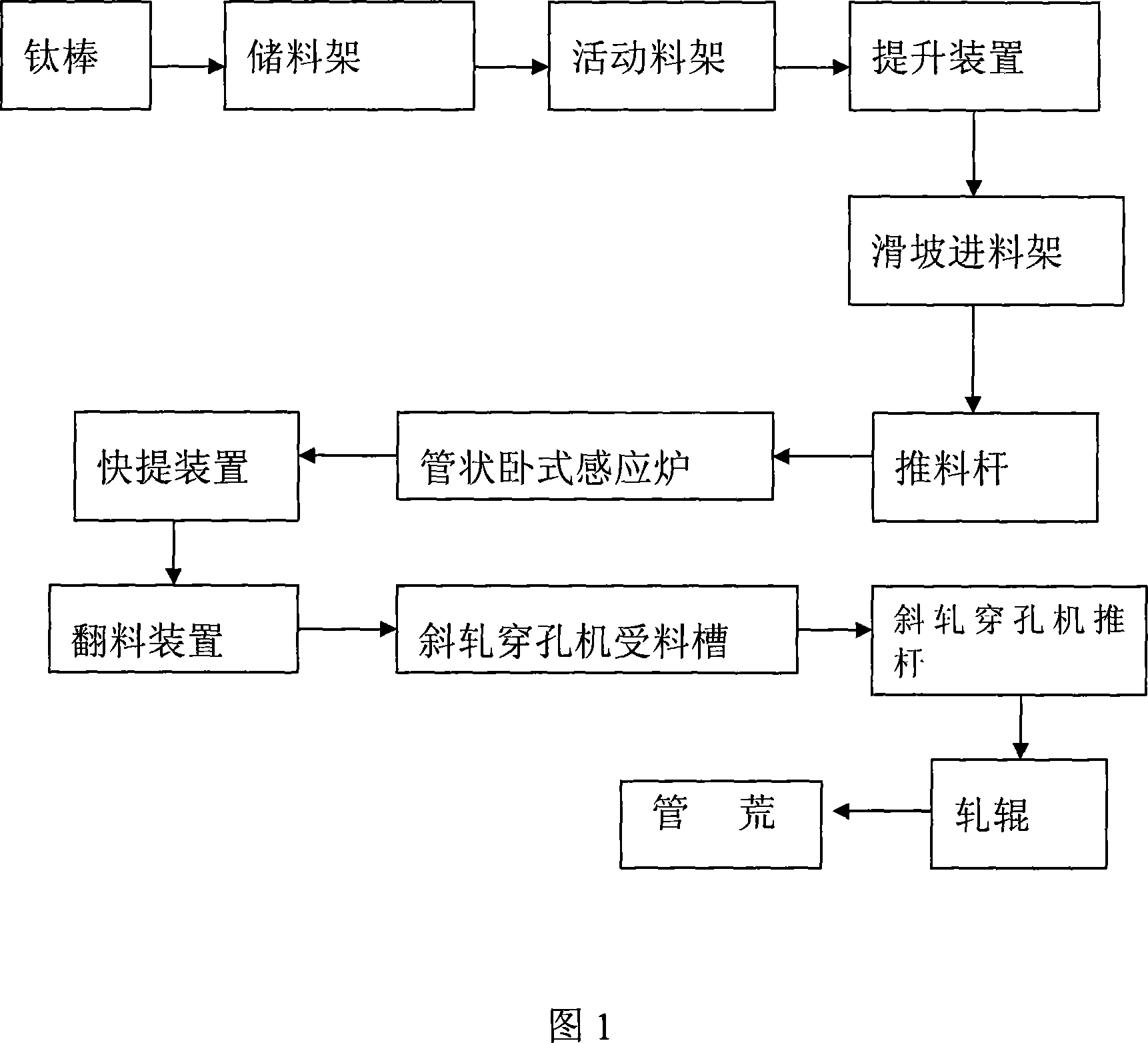

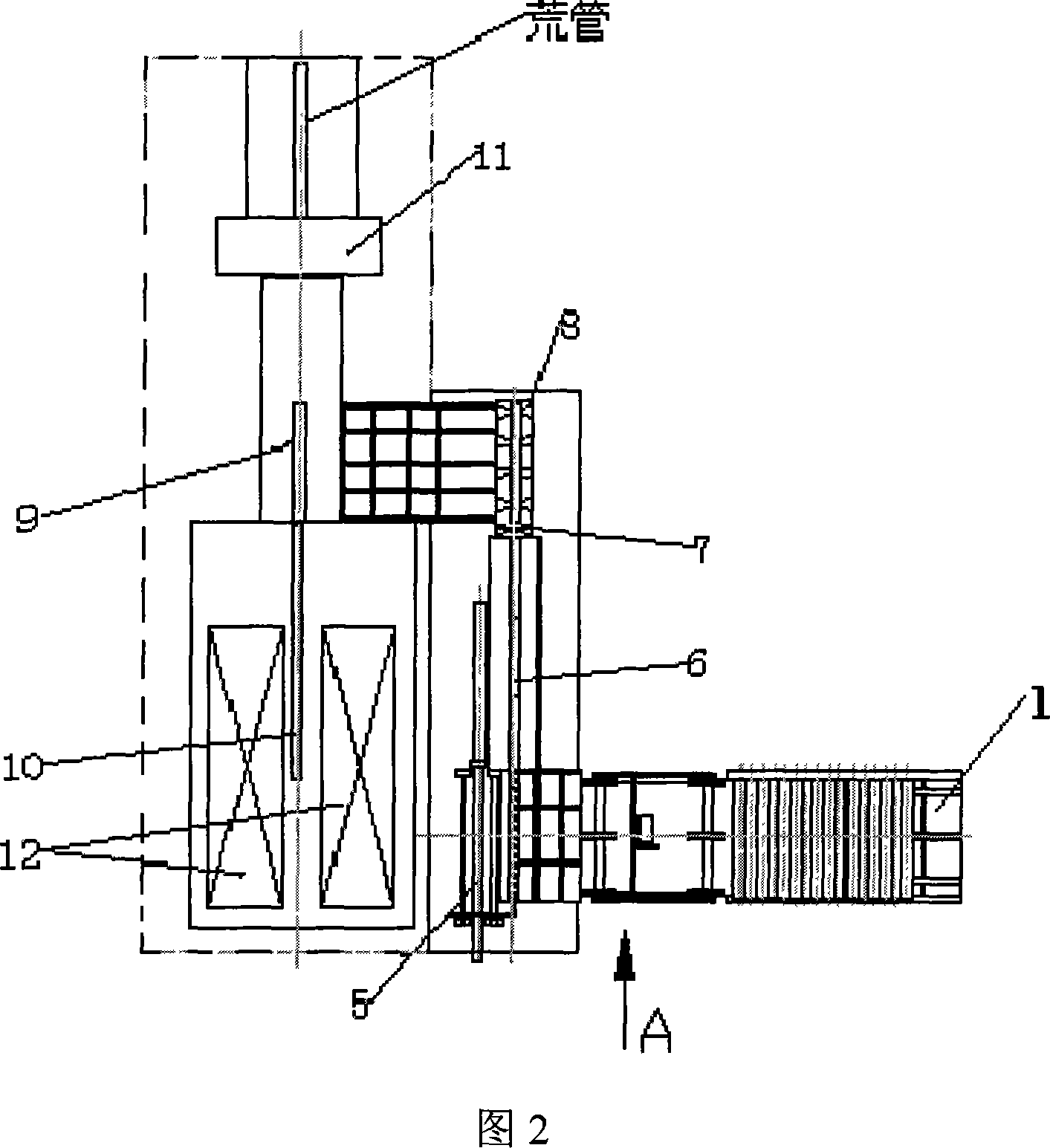

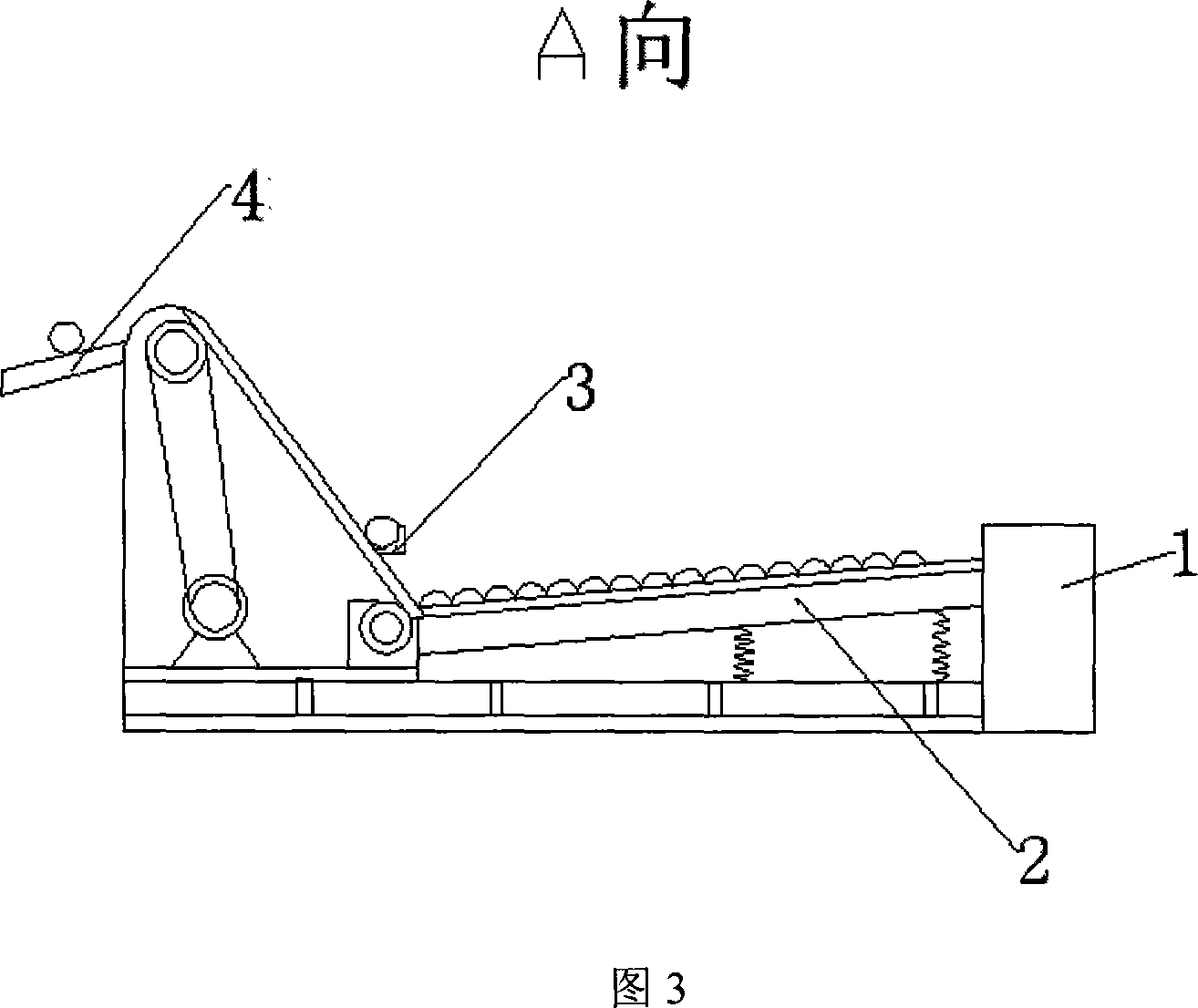

Process for heating titanium oblique perforating rod ingot

InactiveCN101029348AHeating fastReduce oxidationTemperature control deviceFurnace typesPunchingMonitoring system

Process for heating titanium-oblique rolling punch rod blank adopts horizontal step-by-step medium-frequency induction heating finance as tool. The heating furnace consists of automatic skip mechanism, core-watch temperature differential monitoring system and fast-extraction discharge mechanism. The process is carried out by hoisting titanium rod onto bedding rack by overhead traveling crane, arranging on movable bedding rack paralleled, lifting titanium-rod onto charge rack on slop by production beat, entering into horizontal step-by-step medium-frequency induction heating furnace successively, moving titanium-rod forwardly by step-by-step mode, raising temperature while homogeneous heating, discharging, entering into blow tank of oblique-rolling punch, nipping and punching to raw pipe. It's simple, safe and cheap and has no environmental pollution.

Owner:WESTERN TITANIUM TECH

Production method of alloy plate

The invention discloses a production method of an alloy plate, and belongs to the technical field of alloy plates. The production method comprises the following steps of (1) centrifugally casting an alloy tube blank; (2) mechanically processing the inner and outer walls of a hollow blank; (3) equally cutting the hollow blank to be arc plates along a longitudinal axis direction; (4) heating the preheated arc plates to 1180-1230 DEG C, and flattening the arc plates by using a rolling mill or a forging machine; and (5) hot rolling the flattened arc plates to be the alloy plate. According to the production method of the alloy plate, the alloy plate is produced by using a centrifugal casting technology; the metal use ratio is high; the production cost is low; the operation is simple; the equipment investment is small; the production efficiency is high; the performance after rolling is relatively high; use requirements can be met; and the production method is applicable to small scale production of the alloy plate.

Owner:XINXING DUCTILE IRON PIPES CO LTD

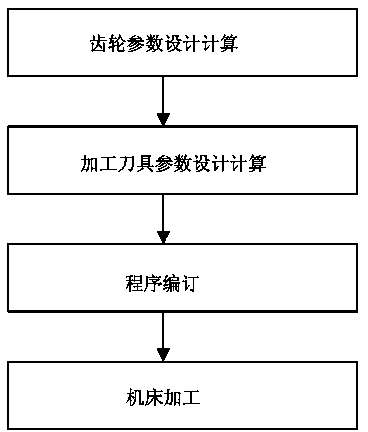

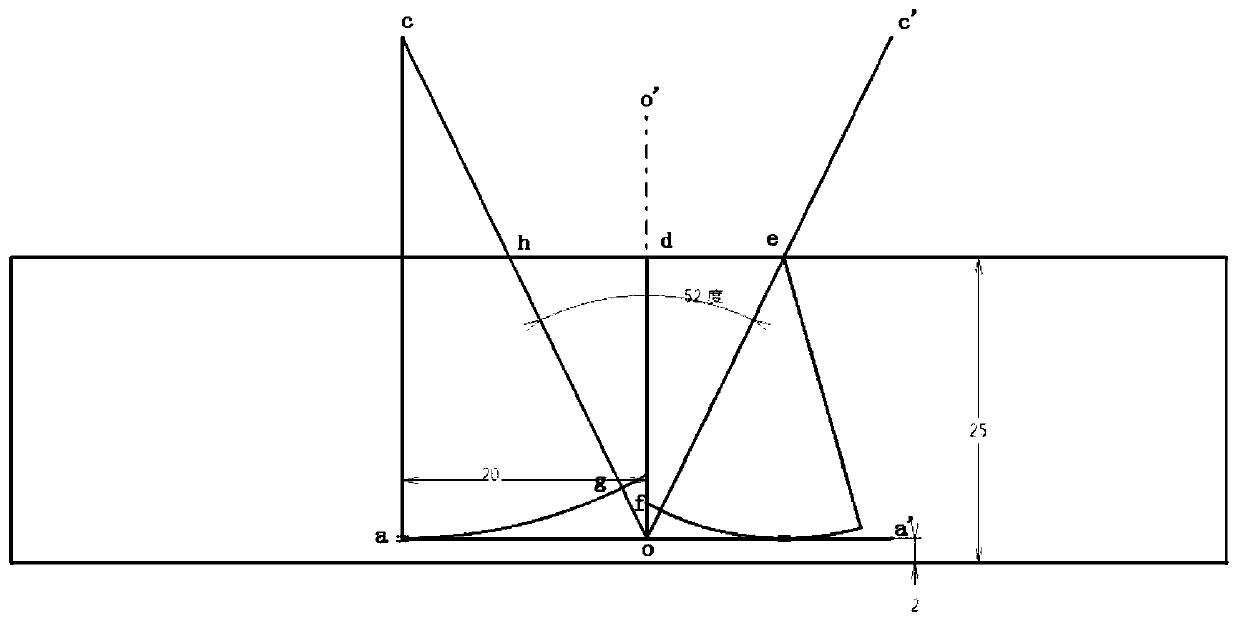

Small-module straight bevel gear forming method numerical control machining process

InactiveCN104070333ALess varietyImprove processing efficiencyGear teethNumerical controlAxial displacement

The invention discloses a small-module straight bevel gear forming method numerical control machining process. The small-module straight bevel gear forming method numerical control machining process comprises the following steps of gear parameter design calculation, machining cutting tool parameter design calculation, program scheduling and machine tool machining. According to the small-module straight bevel gear forming method numerical control machining process, a tooth profile angle of a large end and a tooth profile angle of a small end are continuously modified through the angular displacement of a C axis of a numerical control gear hobbing machine and the axial displacement of a Y axis of the numerical control gear hobbing machine to obtain the tooth profile which is approximate to the spherical involute. The small-module straight bevel gear forming method numerical control machining process is less in cutting tool change type, high in machining efficiency and suitable for small batch production and mass production.

Owner:河南平原光电有限公司

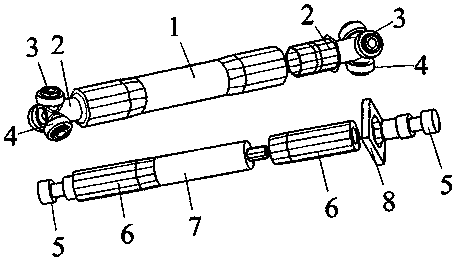

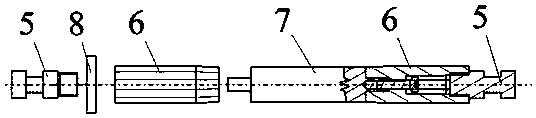

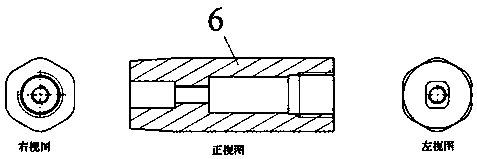

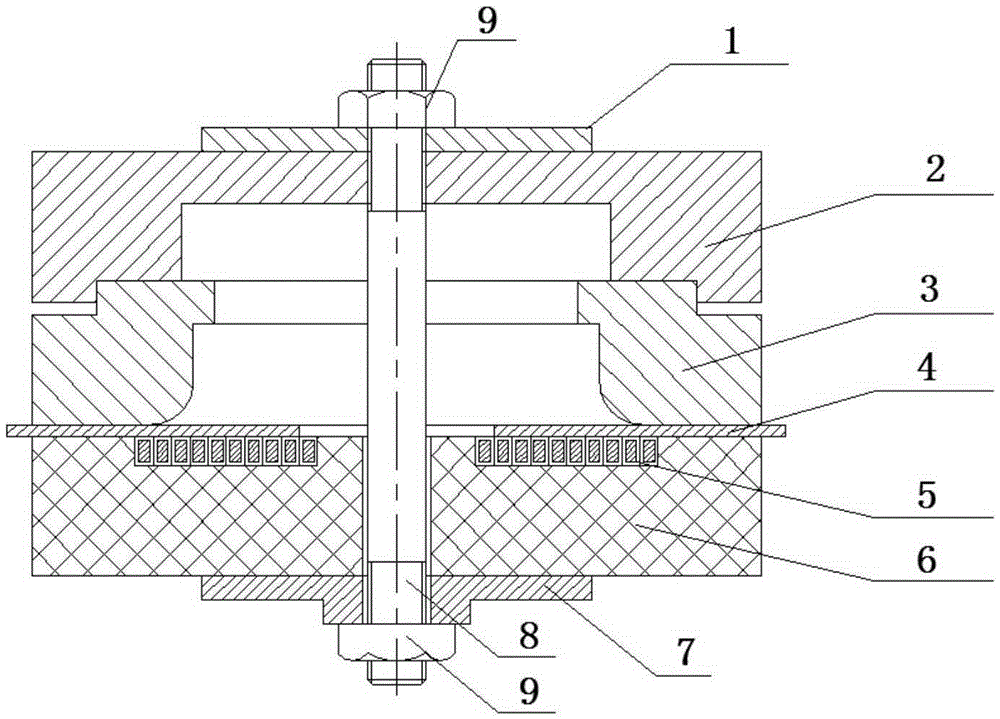

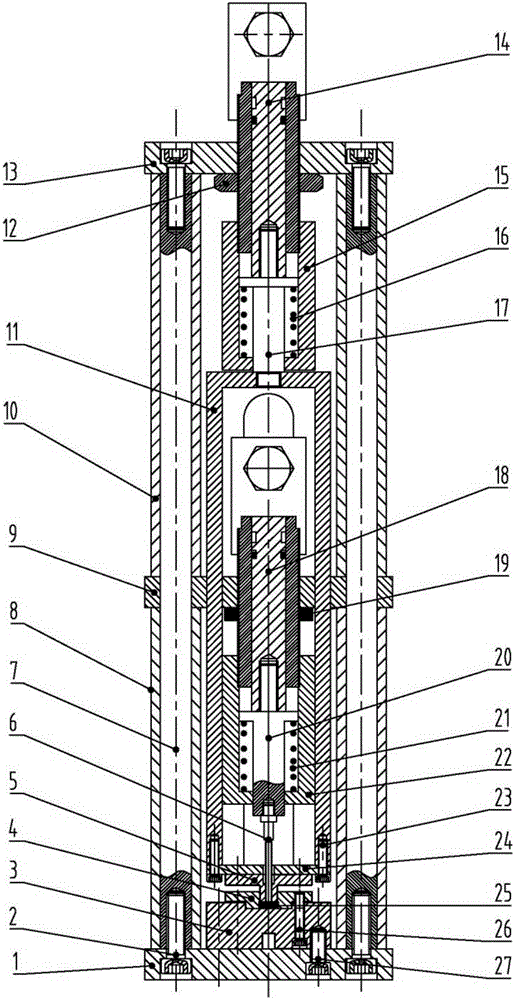

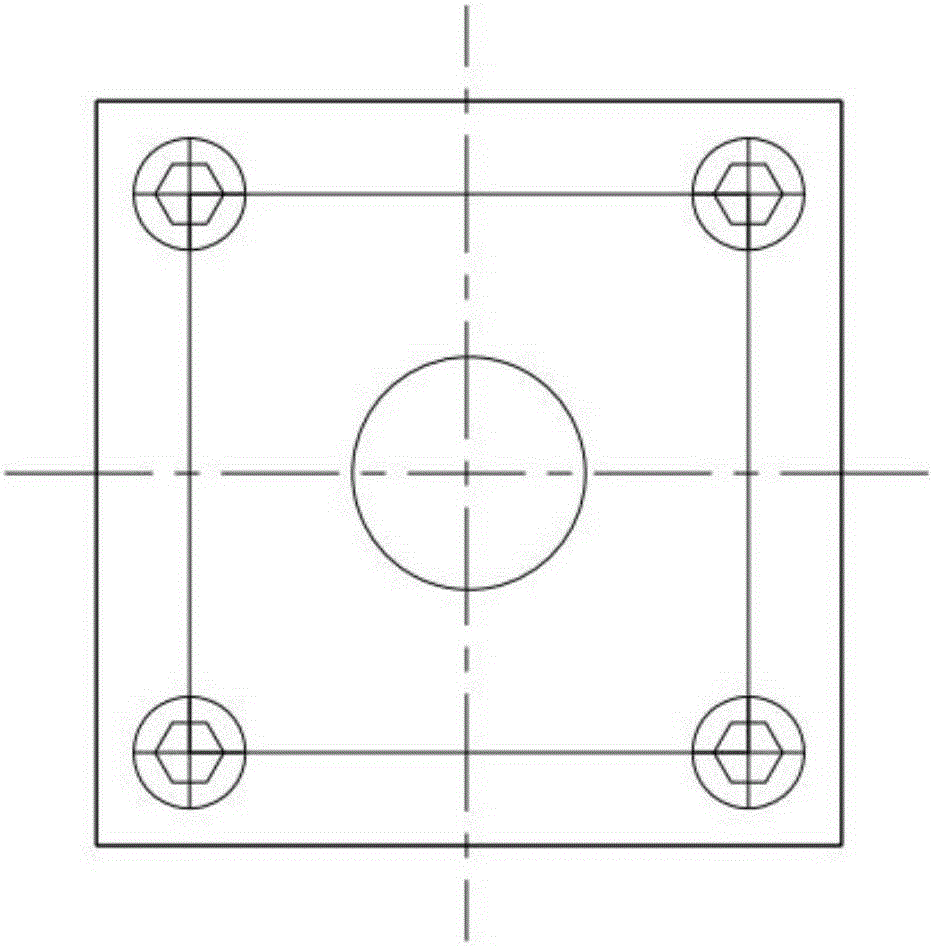

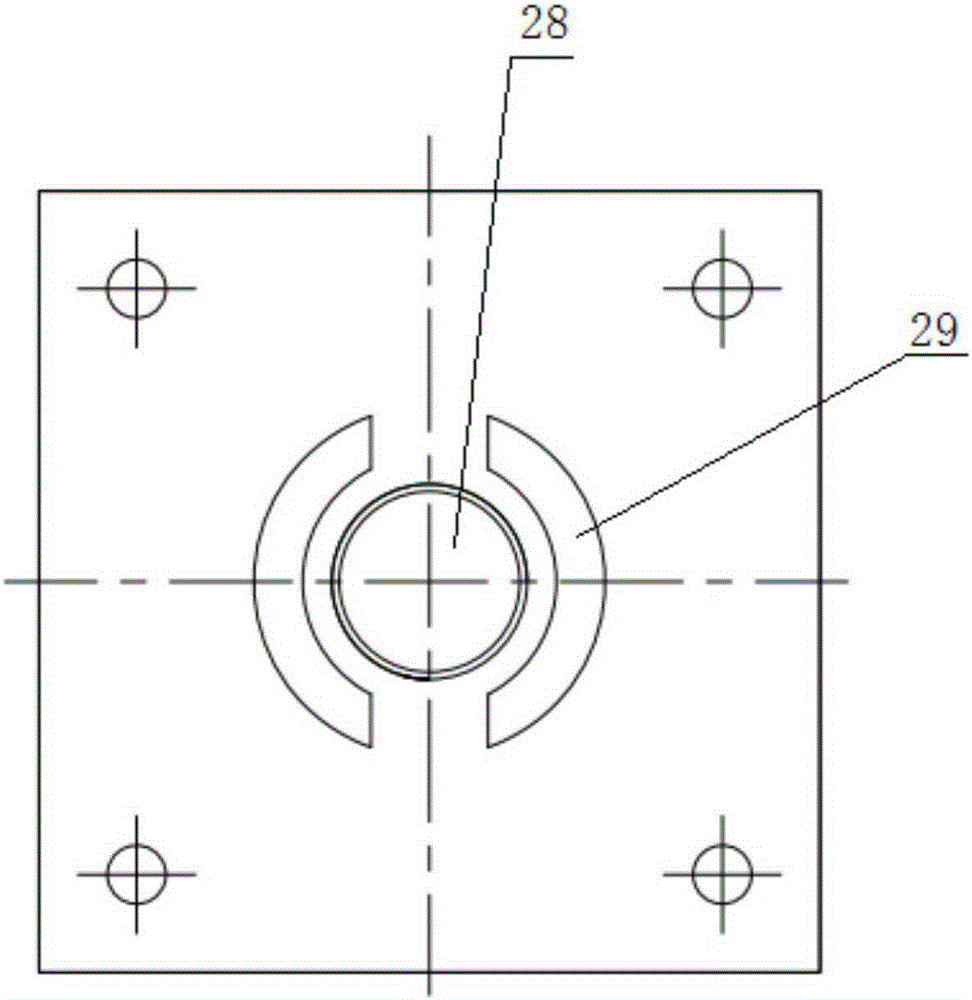

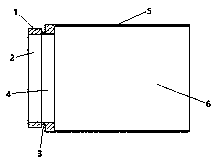

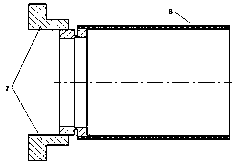

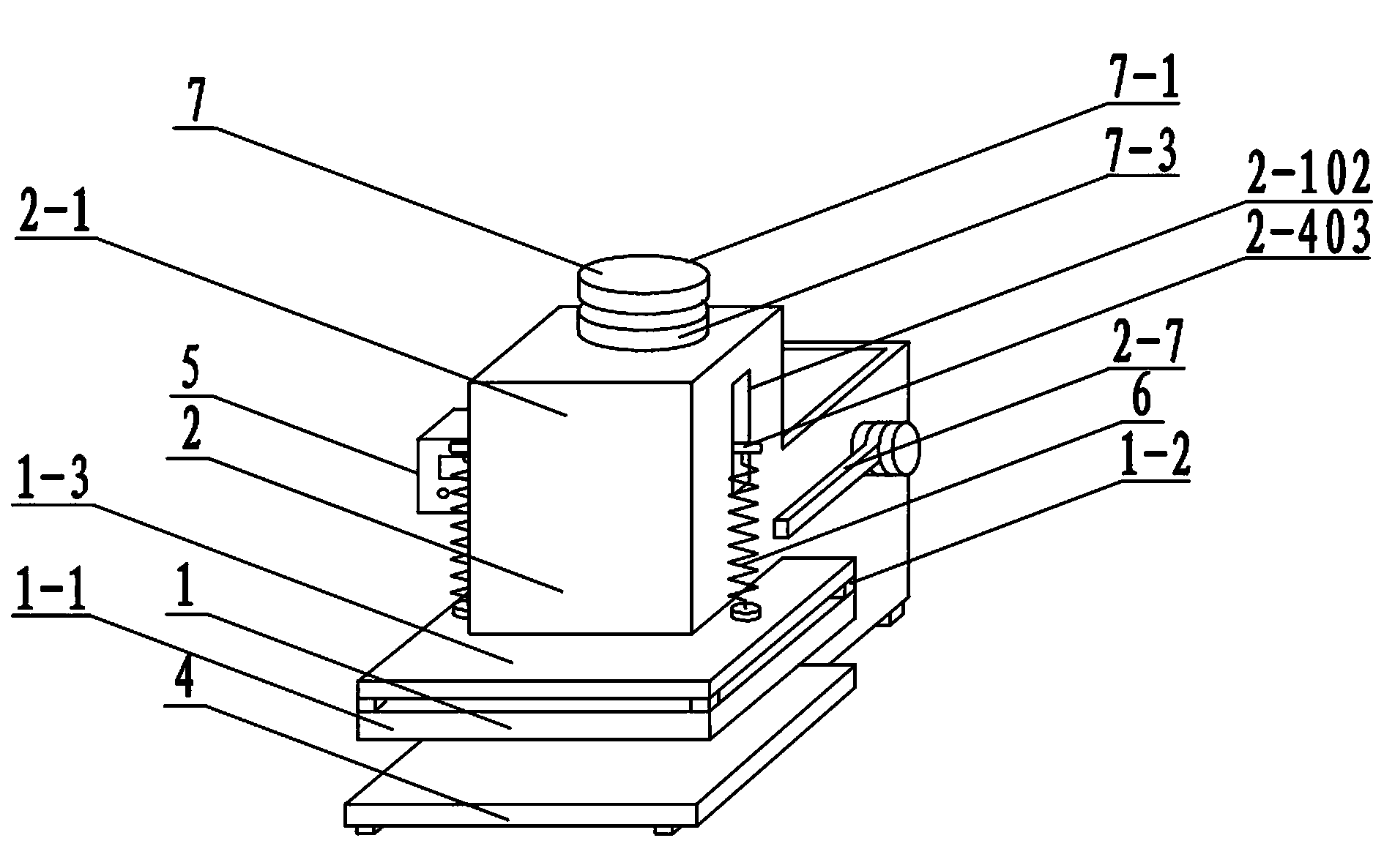

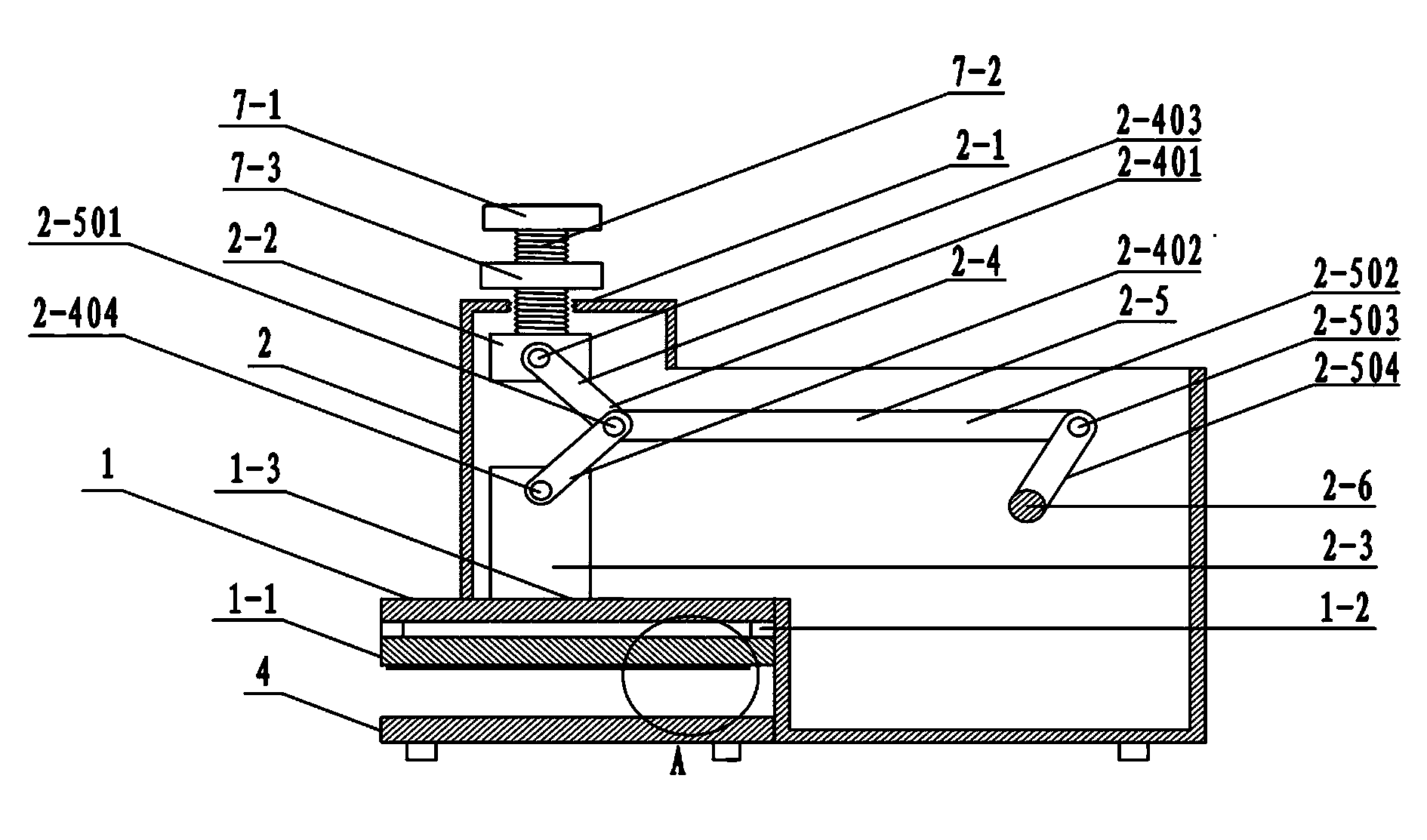

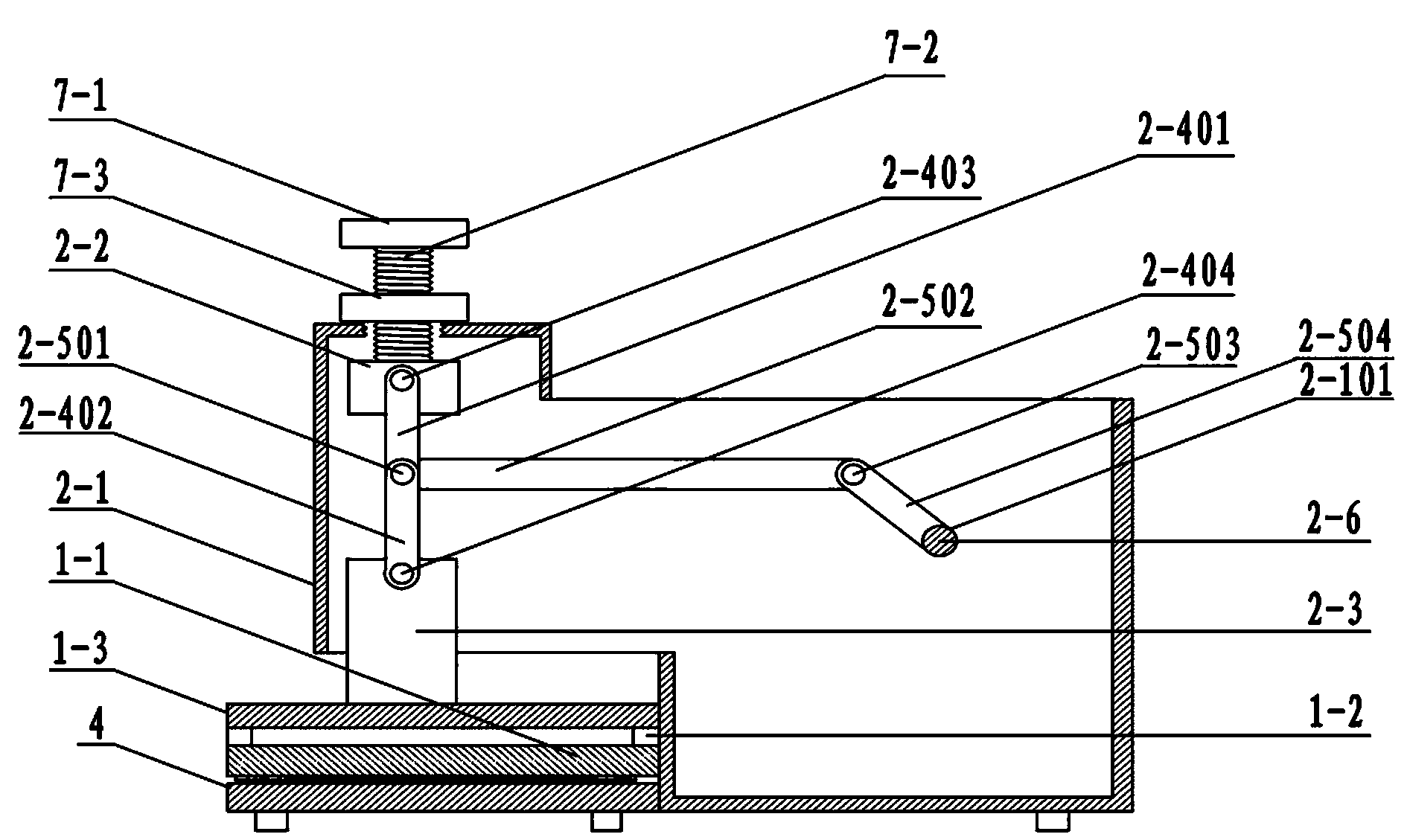

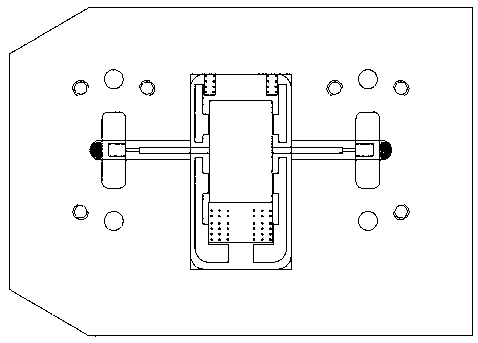

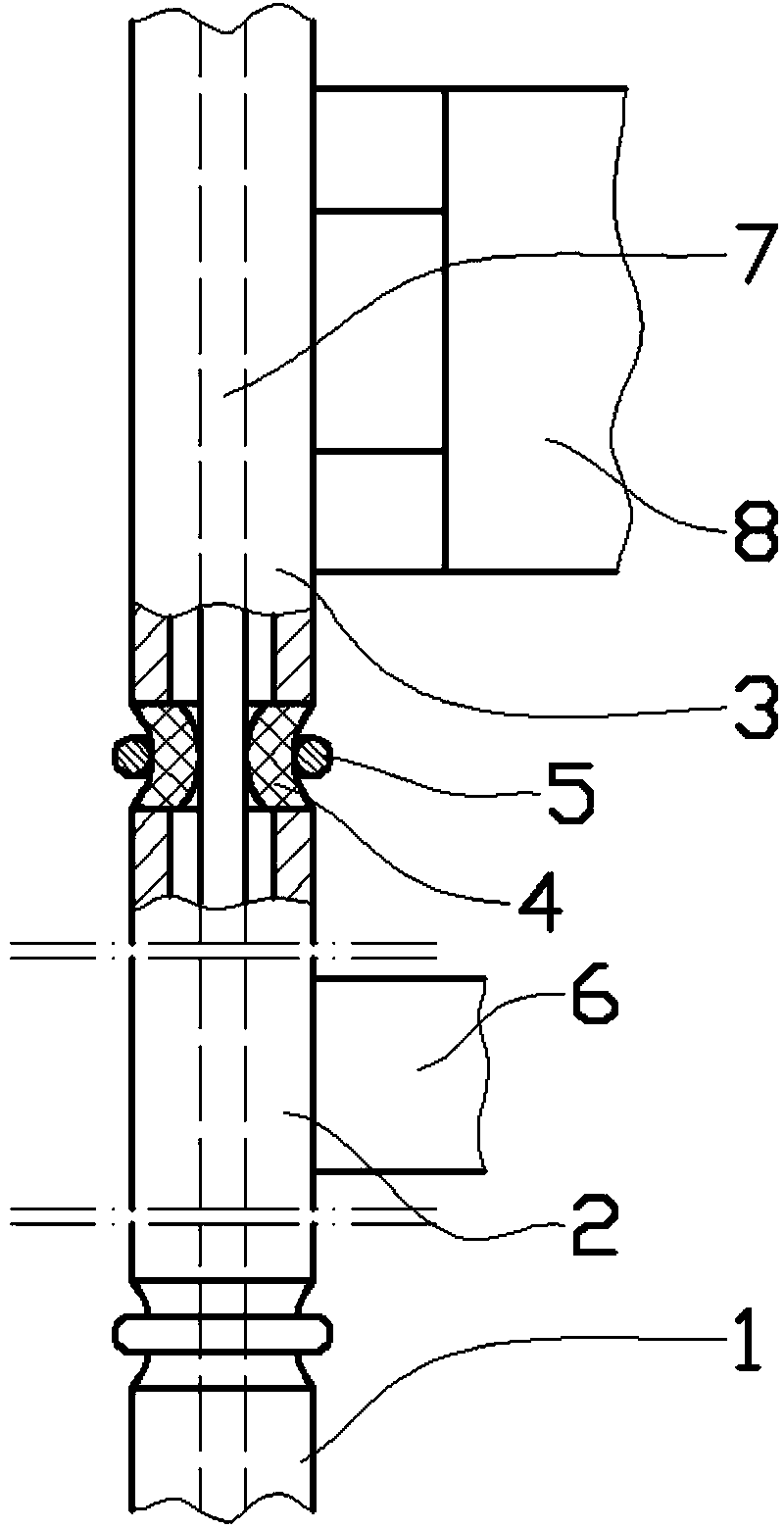

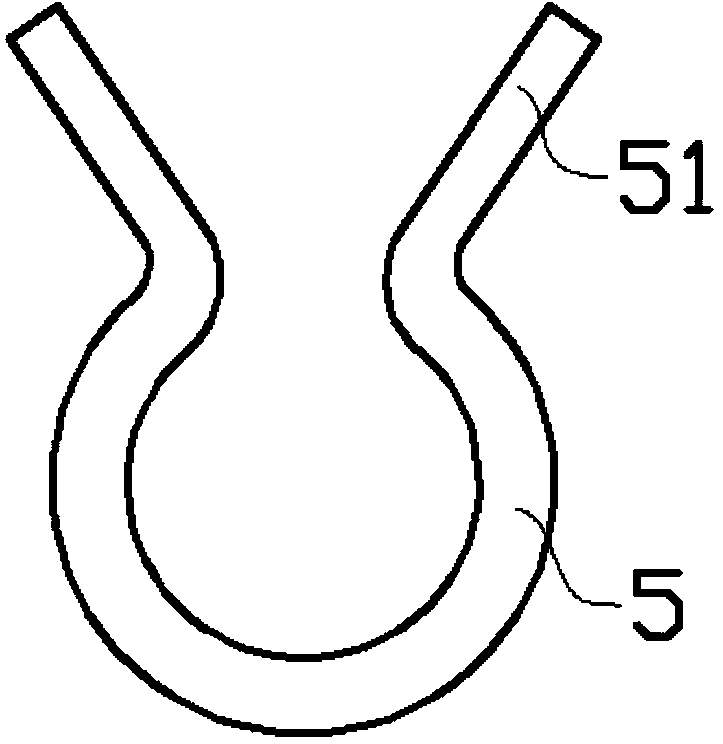

Carbon fiber winding paving variable cross-section adhesive transmission shaft and combined type mould thereof

PendingCN107605928AHigh adhesive strengthEasy to assemble and disassembleYielding couplingShaftsNeedle roller bearingEngineering

The invention relates to a carbon fiber winding paving variable cross-section adhesive transmission shaft and a combined type mould thereof. The carbon fiber transmission shaft comprises a carbon fiber tube 1, an integrated joint 2 and the combined type mould. The two ends of the carbon fiber tube 1 are bonded on the integrated joint 2, a three-ball pin column at the other end of the integrated joint 2 is matched with a needle bearing 3 and a ball ring 4 to form constant-speed universal connection, and the needle bearing is limited by a clamp spring. A clamp 5 is in a cylindrical shape, and the mold and machining equipment are connected by the clamp 5. The combined type mould comprises a mould body 6 with the two ends being hexagon-like cross sections (including a transition section) and amould body 7 with the middle being circular cross section, and the combined type mould is positioned and matched by a groove and a boss on the mould and then connected with the cylindrical clamp 5. Acenter hole of a square block 8 is used for assisting demoulding. According to the carbon fiber winding paving variable cross-section adhesive transmission shaft and the combined type mould thereof,the design is reasonable, assembly and disassembly of the mould are convenient, the paving scheme is flexible, the problem that demoulding is difficult is solved, the material performance is sufficiently utilized, the transmission shaft and the combined type mould can adapt to different machining equipment and working conditions, the feasibility and operability are high, the weight is lowered by about 53% compared with steel, the inertia is reduced, and energy is saved.

Owner:HARBIN INST OF TECH AT WEIHAI

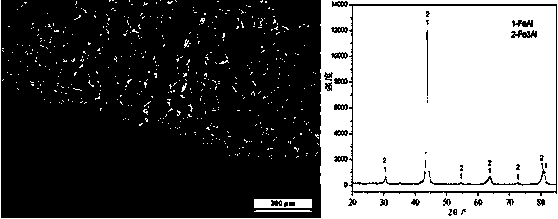

Corrosion resistant surface treatment method of chain parts

ActiveCN103628015AImprove corrosion resistanceStrong coating adhesionHot-dipping/immersion processesTemperingMetallurgy

The invention relates to surface treatment of chain parts, and particularly relates to a corrosion resistant surface treatment method of chain parts. A Fe-Al intermetallic compound corrosion resistant coating is obtained by adopting liquid state aluminum impregnation and following diffusion treatment for parts of a chain, such as a chain plate, a pin roll, a sleeve and a roller. The process flow comprises the following steps: pretreatment, aluminum impregnation, diffusion treatment and following quenching and tempering, wherein aluminum impregnation is performed in an aluminum liquid for 1-5 minutes at 720-750 DEG C; diffusion annealing is performed for 30 minutes to 2 hours at 850-1000 DEG C in a protective atmosphere; the intermetallic compound corrosion resistant coatings with different thicknesses are obtained by adjusting the temperature and time of diffusion treatment; after diffusion treatment, oil quenching is performed, and then tempering is performed for 2 hours at an intermediate temperature of 400-450 DEG C or a low temperature of 180-220 DEG C. The method provided by the invention has the characteristics of simple and convenient process, low cost, strong binding force of the coating, adaptability to batch production of small pieces and the like, can be used for producing chains in a corrosive environment, the treated chain can replace common chains or stainless steel chains, the performance and service life can be improved, and the alloy resources can be saved.

Owner:东台市溱东科技发展有限公司 +1

Aluminum-alloy tank melon petal punching device and punching method

InactiveCN106676437AAvoid the risk of overheatingHigh tensile strengthPunchingManufacturing technology

The invention belongs to aerospace design and manufacturing technologies, and particularly discloses an aluminum-alloy tank melon petal punching device and punching method. The punching device comprises an upper pressing block, a molding female die, an insulating padding plate and a lower pressing block, wherein the upper pressing block, the molding female die, the insulating padding plate and the lower pressing block are coaxially installed, the molding female die is arranged on the upper portion of the insulating padding plate which is provided with an installing groove, an inductor coil is arranged in the installing groove, the upper pressing block is arranged on the molding female die, and the lower pressing block is arranged on the lower portion of the insulating padding plate. The punching method comprises the steps that plates are subjected to deep-drawing deformation, punching machining is conducted by means of a magnetic pulse technology, the restrictive use process of secondary solid solution treatment is eliminated, the risk that parts are prone to overburning due to multiple times of solid solution treatment is avoided, and meanwhile tensile strength and yield strength of the parts are improved.

Owner:CAPITAL AEROSPACE MACHINERY +1

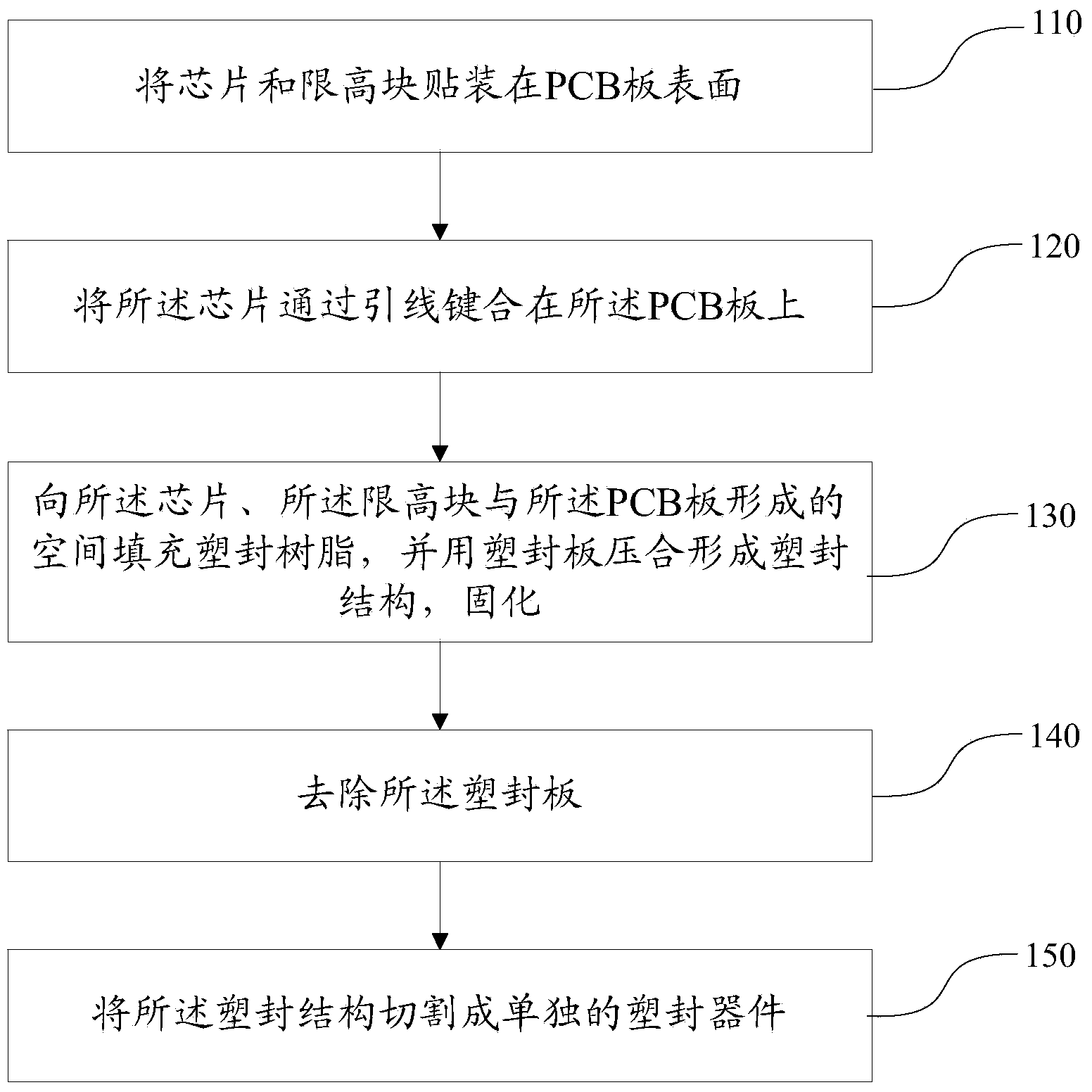

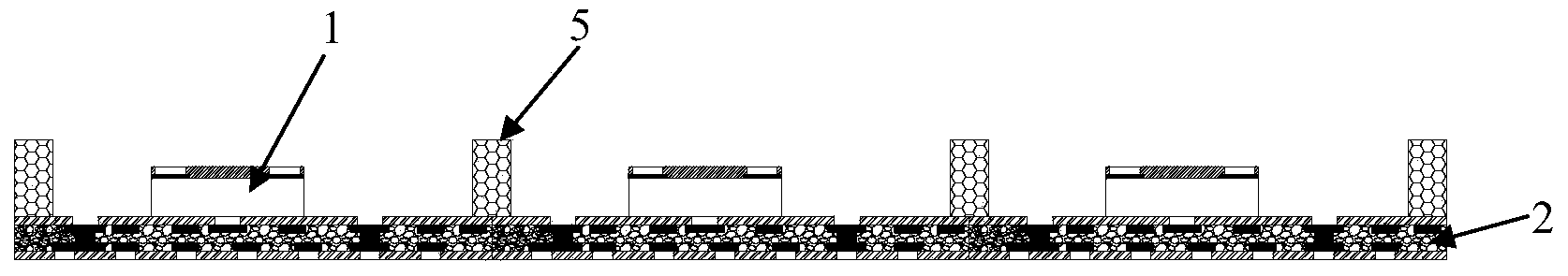

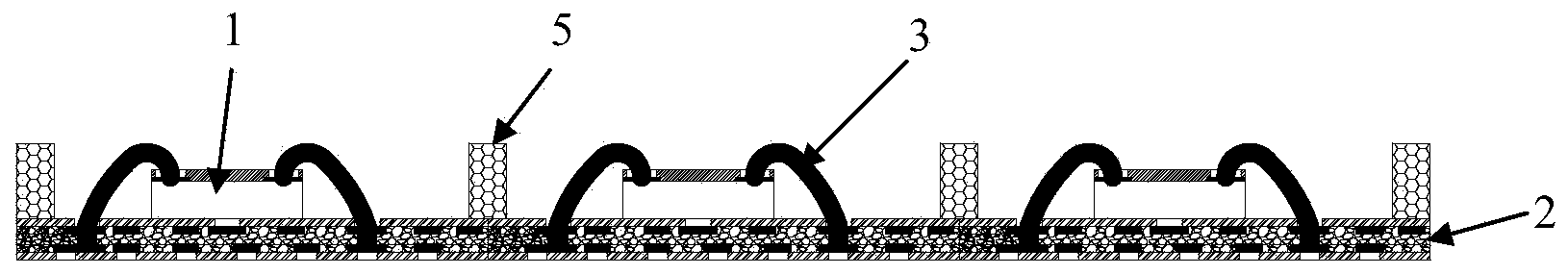

Chip plastic package structure manufacturing method

InactiveCN104241144ALow costSimple processSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention discloses a chip plastic package structure manufacturing method and relates to the technical field of semiconductors. The method includes the steps that a chip and height limiting blocks are attached to the surface of a PCB; the chip is arranged on the PCB in a bonding mode through a lead, the space formed by the chip, the height limiting blocks and the PCB is filled with plastic package resin, a plastic package structure is formed through press fit of a plastic package plate, and curing is performed; a plastic package plate is removed; the plastic package structure is cut to form independent plastic package devices. Due to the use of the height limiting blocks, a high-precision packaging mold is not needed, and the low-cost advantage is achieved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

Loquat scented tea and preparation method thereof

The invention discloses loquat scented tea and a preparation method thereof. The loquat scented tea prepared by the method can be directly eaten; impurities, such as fluff, are reliably removed; the tea has more healthy functions compared with single loquat; the preparation method also has the advantages of being simple and practical and being low in cost, thereby being very favorable for popularizing the loquat scented tea. Particularly, the preparation method of the loquat scented tea comprises the following steps: (1) drying raw materials in the sun; (2) drying the raw materials by distillation in a blast furnace and cooling; (3) crushing the cooled materials into powder; (4) vibrating and screening the powder by a vibration screen to remove the impurities, namely the fluff and flower bud seeds, to obtain effective raw materials; (5) adding dried and crushed chrysanthemums and dried and crushed cordyceps flowers into the effective raw materials to obtain a mixture; (6) rolling and frying the mixture, cooling the mixture, improving the aroma while removing the foreign flavors of the mixture, and cooling the tea again after the tea gets darker, thereby obtaining a fermentation raw material; and (7) fermenting the fermentation raw material.

Owner:ZHANGZHOU DERUNKANG FOOD CO LTD

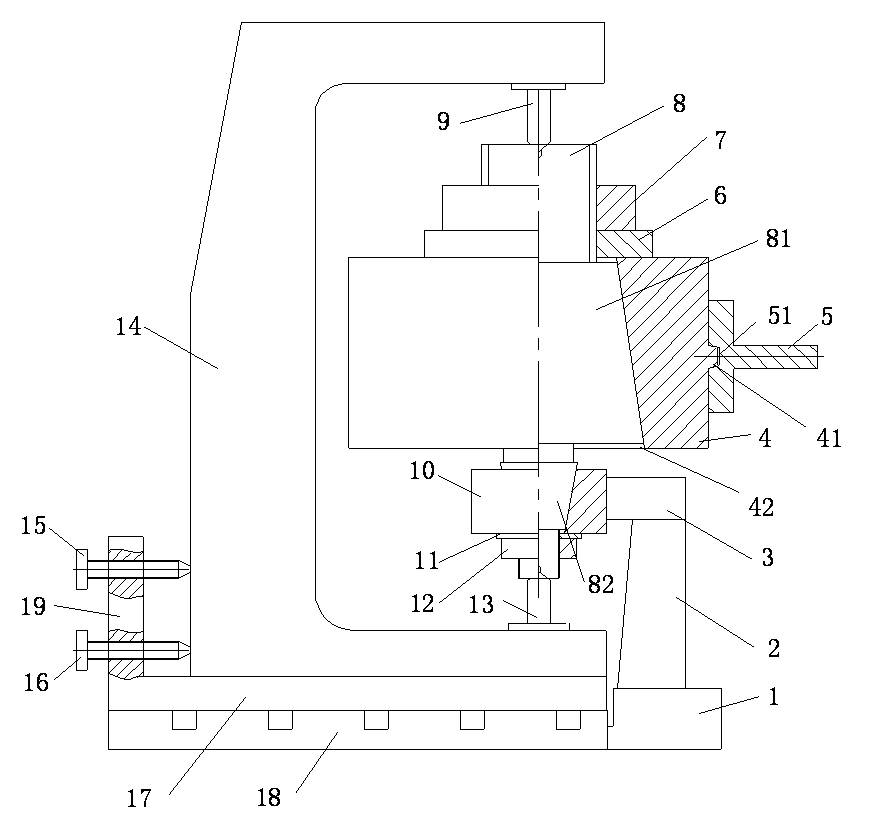

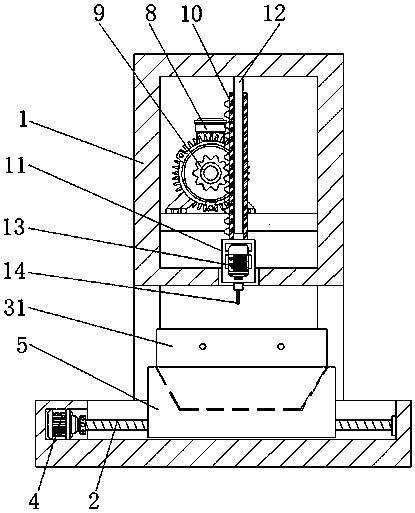

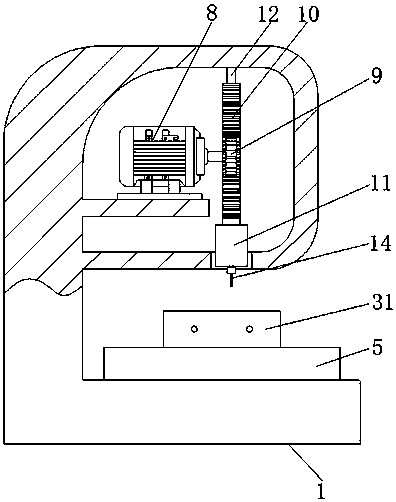

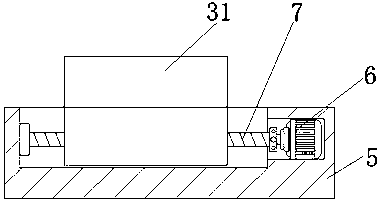

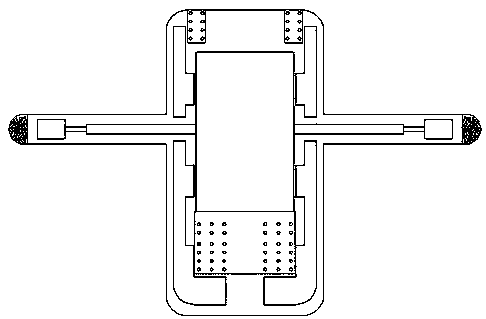

Miniature double-acting hydraulic machine and forming method

The invention discloses a miniature double-acting hydraulic machine and a forming method. The miniature double-acting hydraulic machine comprises an upper beam, a middle beam, a workbench, uprights, upper sleeves, lower sleeves, an upper oil cylinder, a lower oil cylinder, an upper piston rod connecting rod, a lower piston rod connecting rod and a guide sleeve. The upper beam and the workbench are connected through the four uprights. The middle beam is located through the upper sleeves and the lower sleeves, wherein the uprights are sleeved with the upper sleeves and the lower sleeves. The upper oil cylinder is fixed to the upper beam. The lower oil cylinder is fixed to the middle beam. The upper oil cylinder transmits power to a die through the upper piston rod connecting rod connected with the upper oil cylinder and the guide sleeve. The lower oil cylinder transmits power to the die directly through the lower piston rod connecting rod connected with the lower oil cylinder. The die is arranged on the workbench. The miniature double-acting hydraulic machine is tiny in size, stable in pressure, low in cost and capable of being matched with the miniature die to form a miniature part.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Novel technique for high-frequency heat treatment of lathe tool

InactiveCN103276182AThe process steps are simpleLow costIncreasing energy efficiencyFurnace typesNovel techniqueHardness

The invention relates to a novel technique for high-frequency heat treatment of a lathe tool. The technique comprises the following steps: (1) the lathe tool is placed into a chamber furnace for preheating, heat preservation is performed for 30 minutes at 580 DEG C in the first stage, and heat preservation is performed for 1-1.5 hours at 860 DEG C at the second stage; (2) a tool bit part of the lathe tool is heated in high-frequency induction heating equipment, the heating temperature is about 1280 DEG C-1300DEG C, after the temperature is maintained for 60 seconds, the heating is over; (3) the lathe tool is taken out of an induction coil of the high-frequency induction heating equipment, oil-quenched, cooled to 250 DEG C and then is taken out of oil, and air-cooled; and (4) tempering is performed twice at the temperature ranging from 550 DEG C to 560 DEG C, the heat preservation time is 2 hours for each time, and after quenching, the external hardness of the tool bit is 64-66 HRC, and the internal hardness is 50-55 HRC. The novel technique for high-frequency heat treatment of the lathe tool has convenient steps, the quality of the lathe tool after the heat treatment meets requirements, and the technique has the advantages of short period, low cost and the like.

Owner:SHENYANG AIRCRAFT CORP

Making method of case having pattern

The invention discloses a making method of a case having a pattern. The making method comprises the following steps: coating PC lightening oil on a PC film, printing the pattern onto the PC film, carrying out primary heating, compounding the PC film to an ABS sheet, carrying out secondary heating, carrying out plastic uptake, and molding to form the case having the pattern. The method is simple, and the making cost of the case is low.

Owner:SHANGHAI MENGYI IND CO LTD

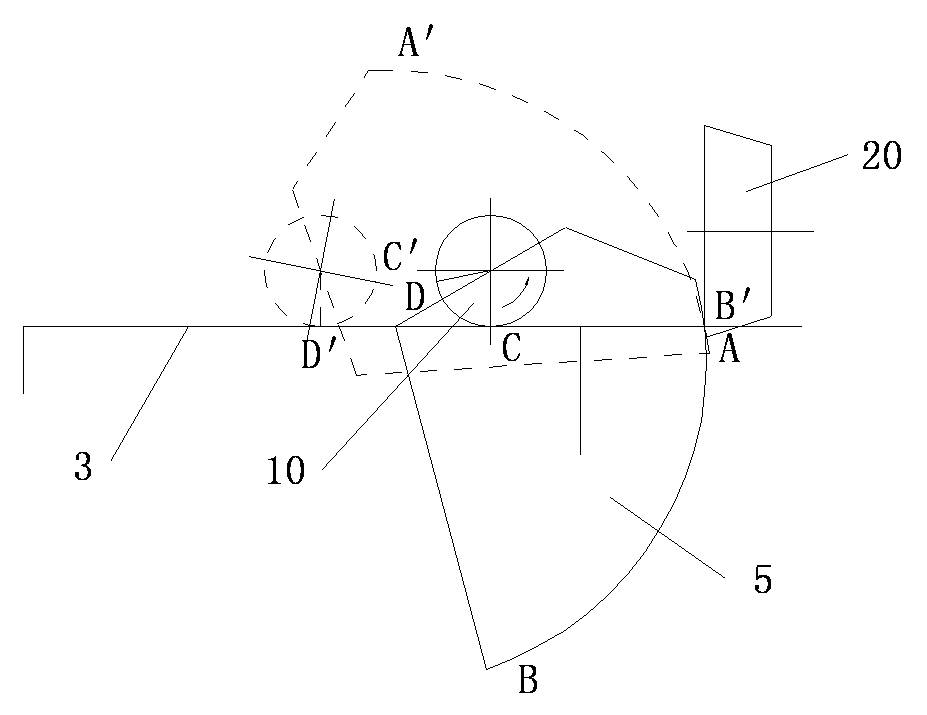

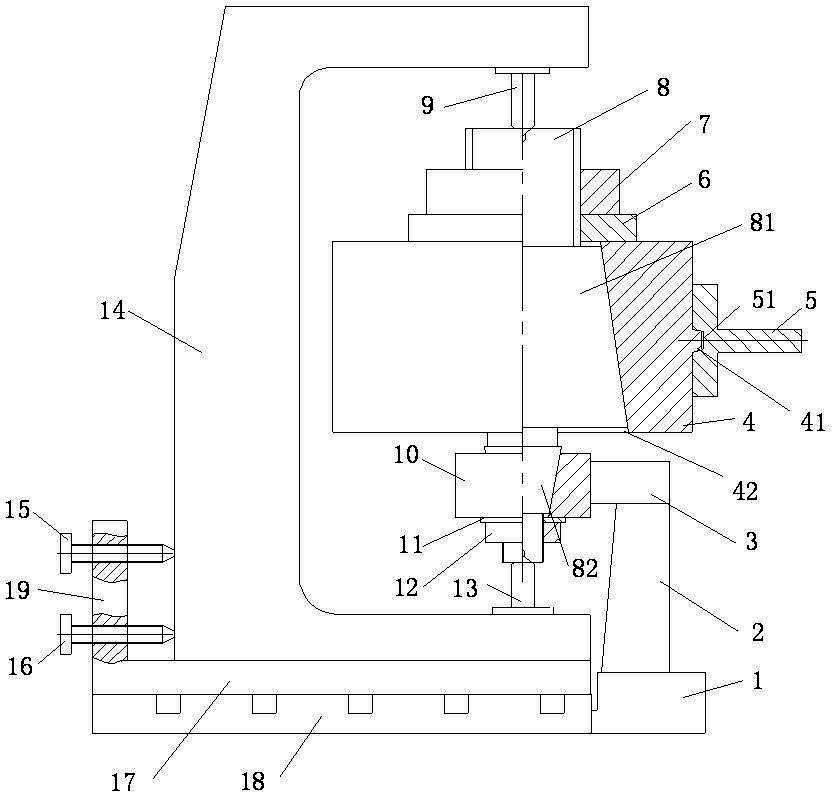

Involute cam processing device and processing method thereof

InactiveCN102423868AEasy to manufactureSimple structureBelt grinding machinesMilling equipment detailsCamGrinding wheel

The invention relates to an involute cam processing device comprising a clamp base which is arranged on a machine tool guide rail and a support body which is arranged on the clamp base; the support body is in a U shape; an upper top tip and a lower top tip are arranged on both side inner walls of the support body oppositely; a positioning mandrel is arranged between the upper top tip and the lower top tip; a base disc and a cam base are sleeved on the positioning mandrel; one side of the base disc is provided with a master plate; the master plate is fixedly arranged on a machine tool body; and a work pieces to be processed is arranged on the outer peripheral wall of the cam base. An involute cam processing method comprises the steps that: (1) the involute cam processing device is arranged; (2) the position of the master plate is corrected; (3) the position of the support body on the clamp base is adjusted; (4) the position of a grinding wheel is adjusted; and (5) a machine tool is started. The involute cam processing device not only has a simple structure but also does not need to preset the master plate with an involute curved surface, so that the implementation is convenient, and the involute cam processing device can be used on various machine tools.

Owner:重庆工具厂有限责任公司

Turning method for cylindrical stepped thin-wall part

The invention discloses a turning method for a cylindrical stepped thin-wall part. According to the method, during rough machining, an outer circular groove and an inner hole step are reserved; when asmall outer circle is clamped, a large hole is finely bored, and a large outer circle is finely turned; when the large outer circle is clamped, a small hole is finely bored, the small outer circle isfinely turned, and cotton adhesive tape, high-density foam blocks and other materials are utilized for achieving a cushioning effect when the cylindrical stepped thin-wall part is turned; stress canbe released in advance through the reserved outer circular groove and inner hole step, the influence on the size precision of the other end can be reduced when one end is finely machined, and therefore part deformation is reduced, and the size precision is improved; and the turning method is economical and suitable for small-scale production of new products.

Owner:LANDING GEAR ADVANCED MFG

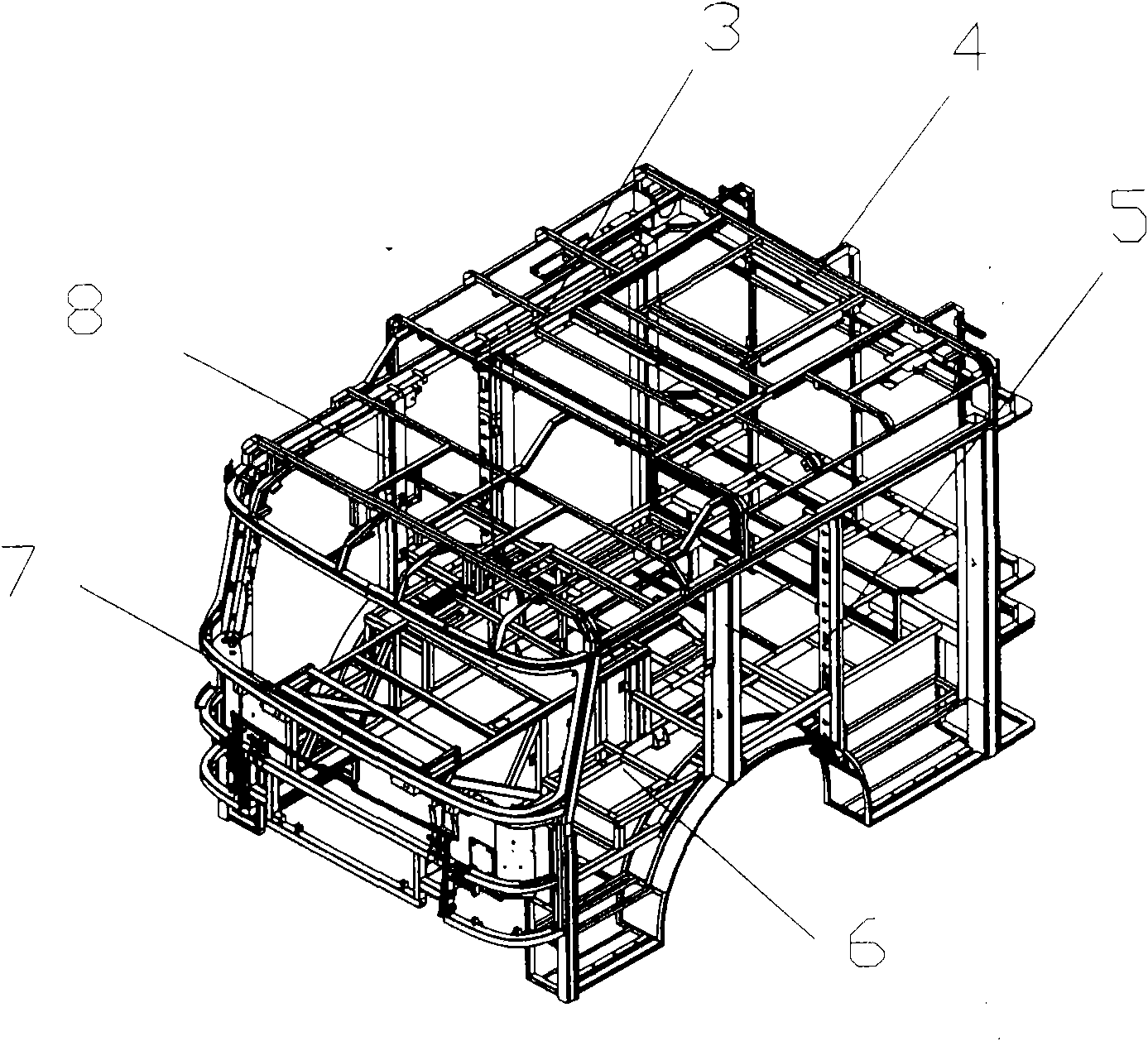

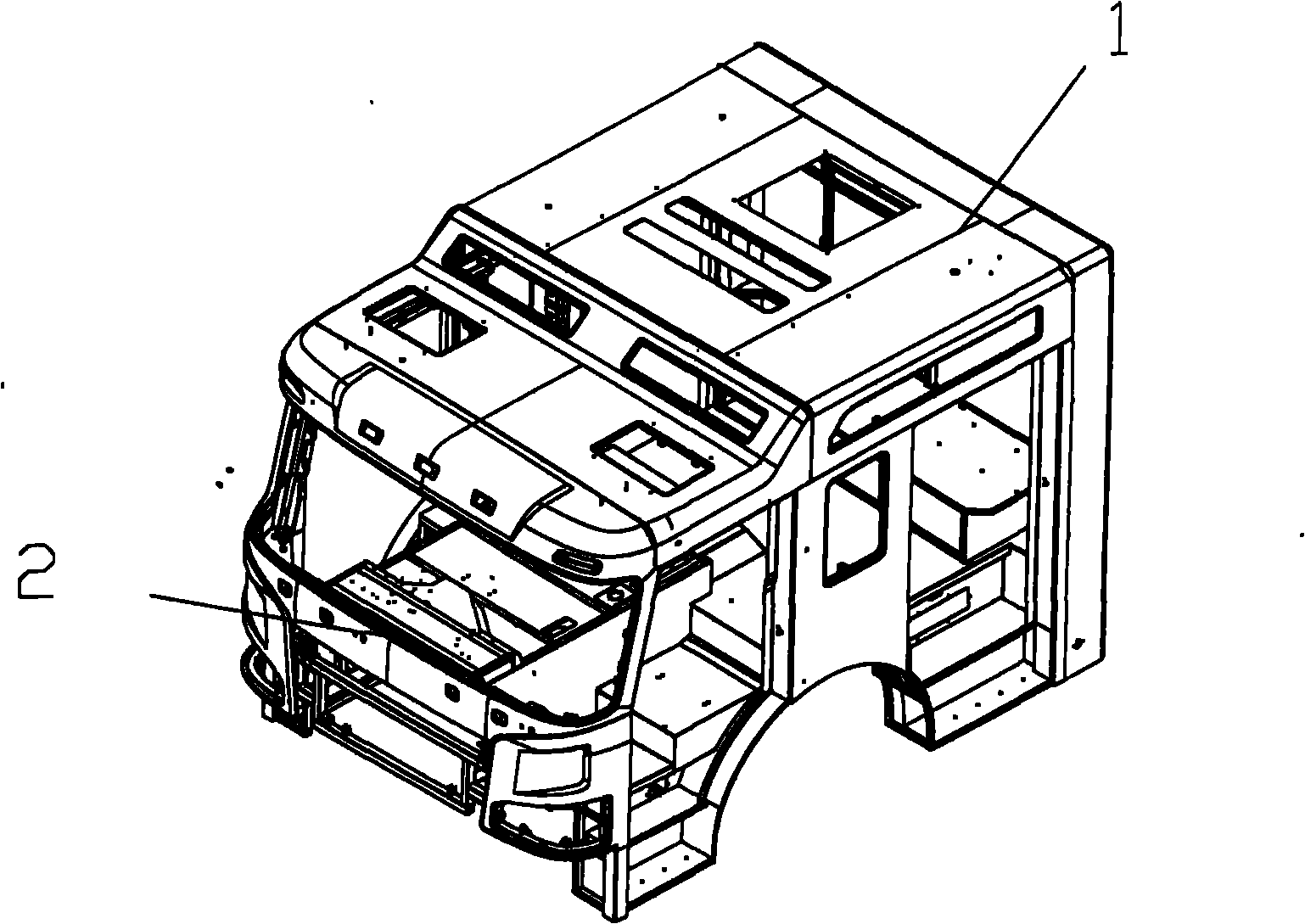

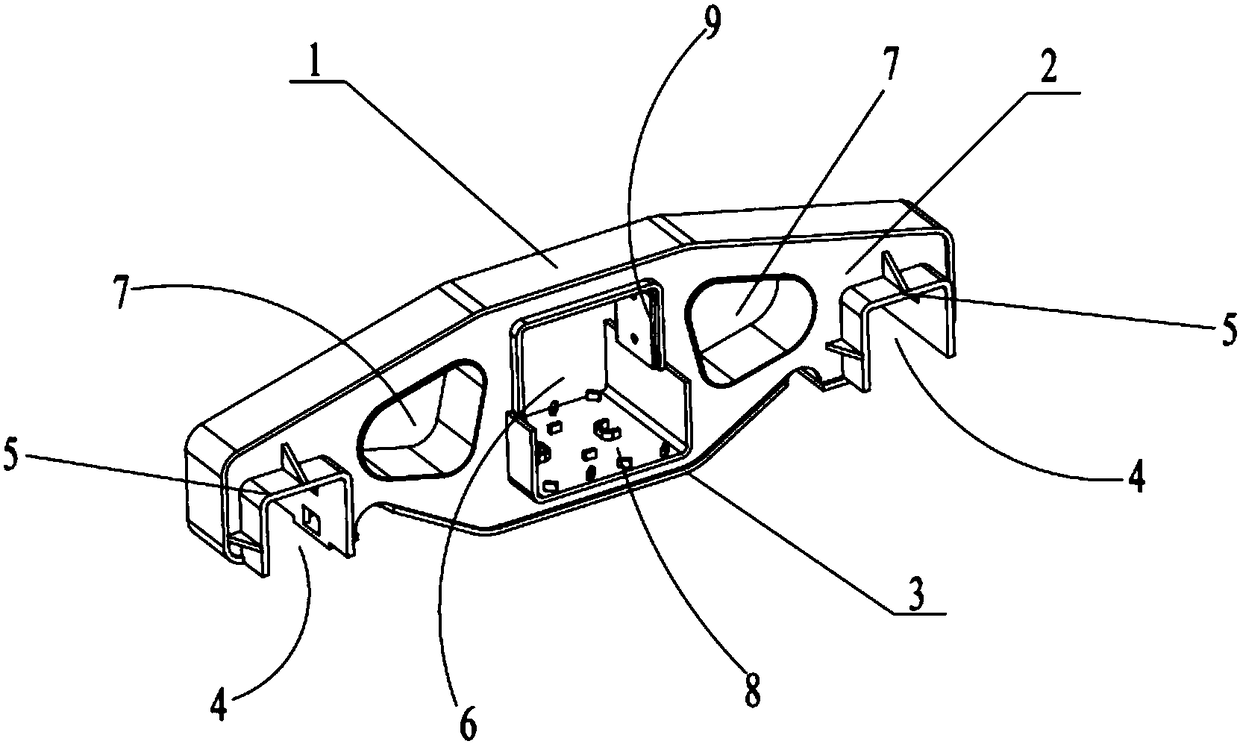

Framework type driving cab of fire fighting truck

InactiveCN102372036AMeet requirements for bending torsional stiffnessFulfil requirementsFire rescueLoading-carrying vehicle superstructuresEngineeringTruck

The invention relates to a framework type driving cab of a fire fighting truck, which consists of a truck body framework and an outer cover. The framework type driving cab is characterized in that the framework of the truck body comprises six parts, namely a floor framework, a left-side enclosure framework, a right-side enclosure framework, a top cover framework, a front enclosure framework and a rear enclosure framework, wherein the six parts are formed by welding metal sections such as square steel tubes, angle steel and channel steel; and the outer cover arranged outside the framework type driving cab is fixedly connected with the framework by welding or bonding. The framework type driving cab has the advantages of favorable integral rigidity, reliable performance, low development cost, short production period and suitability for small-batch production; the requirement of a traditional driving cab on the flexion torsion rigidity can be met; and the requirement of ECE (Economic Commission for Europe) R29 safety legislation on the driving cab can be met.

Owner:FAW GROUP

Cleaning agent for silicon wafer of solar cell and using method thereof

InactiveCN102199499AHigh operating costsEasy to cleanFinal product manufactureInorganic non-surface-active detergent compositionsSodium phosphatesElectrical battery

The invention provides a cleaning agent for a silicon wafer of a solar cell and a using method thereof, belonging to the technical field of solar cell production. The cleaning agent for the silicon wafer of the solar cell comprises the following components: sodium hypochlorous, sodium tripolyphosphate, sodium phosphate and water at a mol ratio of (5-15):(5-10):(1-5):(10-100). The cleaning agent provided by the invention can effectively remove the surface oil generated by wire cutting of monocrystalline silicon, metal impurities inside the silicon wafer, and dust and other granules attaching to the surfaces of the silicon wafer, improve the utilization rate of cell wafer assembly to more than 97%, improve the conversion efficiency of cell wafer to more than 18.2%, and improve the open-circuit voltage of the cell wafer to more than 632 mv.

Owner:浙江向日葵聚辉新能源科技有限公司

Local indentator for fiber towel, and manufacturing method of indentation in specific position of the fiber towel

The invention relates to a local indentator for a fiber towel. The local indentator comprises a heating plate, a pattern plate disposed below the heating plate and tightly adhered to the heating plate, a fixed plate disposed below the heating plate and used for disposing the fiber towel, a supercharging device disposed above the heating plate and used for driving the heating plate to drop, and a temperature controller. An electrical heating element and a temperature sensor are disposed in the heating plate. The electrical heating element is electrically connected to the temperature controller. The temperature sensor and the temperature controller are electrically connected. The invention also provides a manufacturing method of indentation in a specific position of the fiber towel by utilization of the local indentator. According to the manufacturing method, the local indentation can be formed selectively in the specific position of the single fiber towel and pictorial trademarks, telephones, and the like can be printed on the fiber towel. The local indentator and the manufacturing method overcome limitation that the indentation of the fiber towel at present must be whole-area indentation. The local indentation can be formed selectively in the specific position of a single finished-product fiber towel. The local indentator and the manufacturing method are mainly used for indentation on catering moist wipes.

Owner:王立民

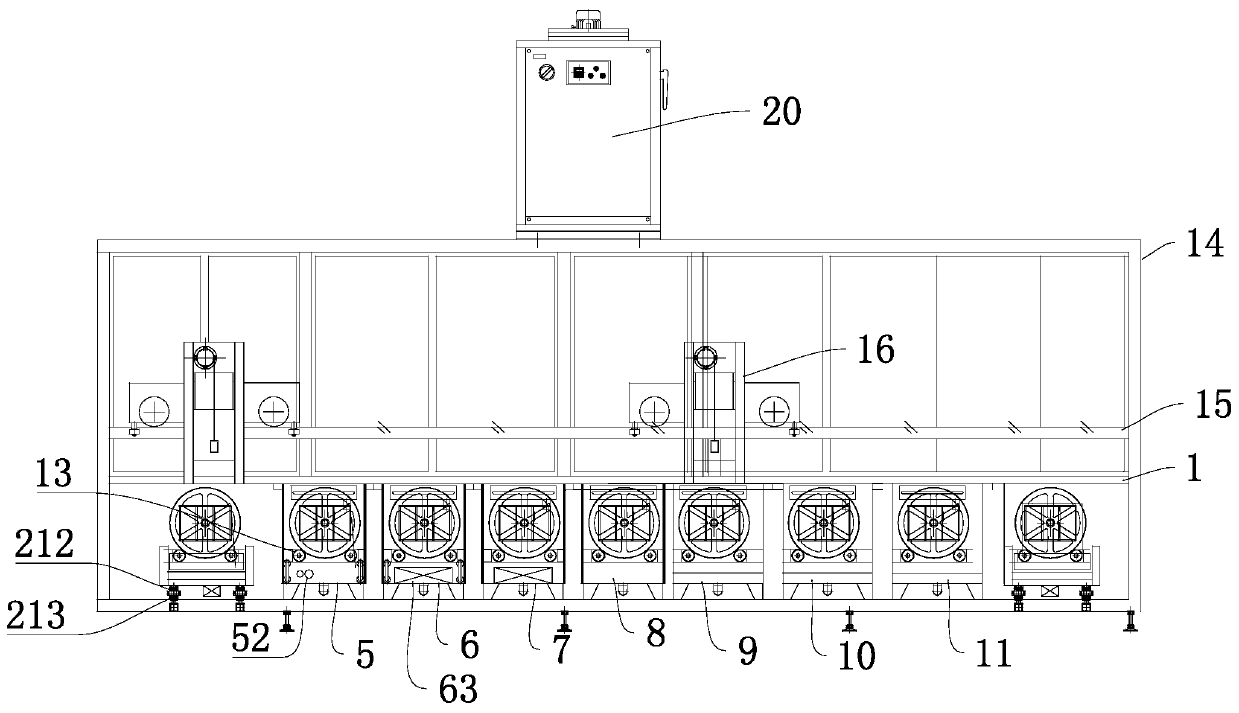

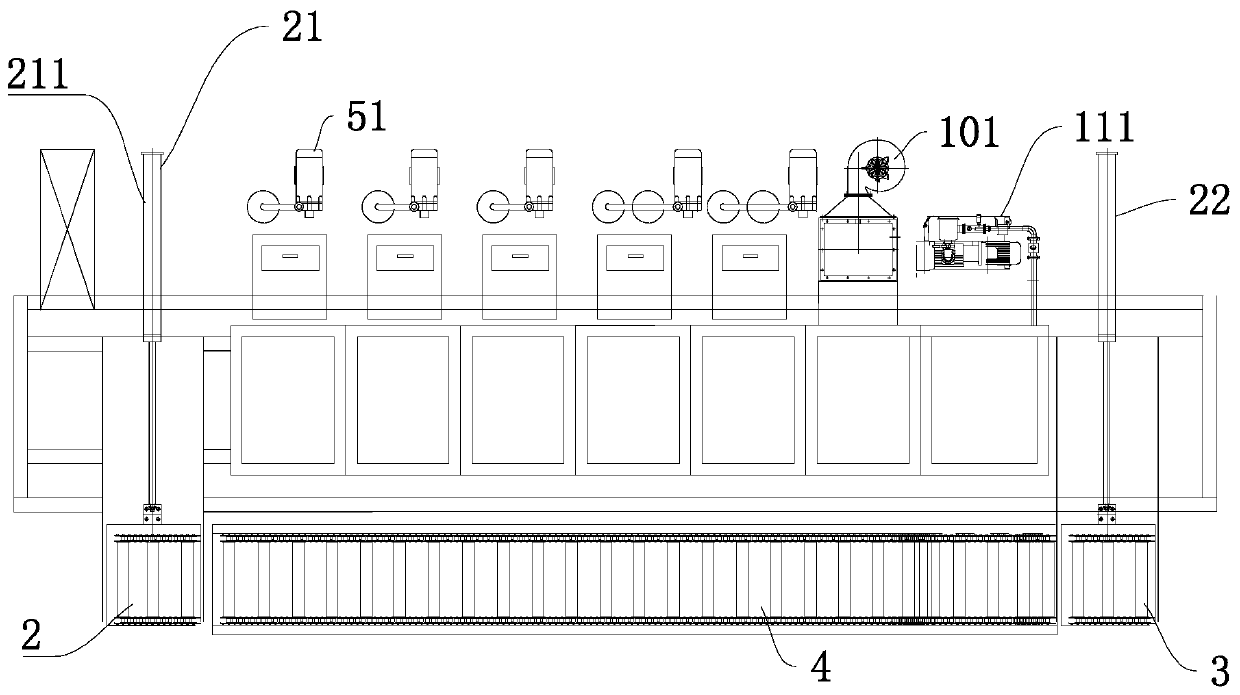

Multi-groove ultrasonic cleaning machine

PendingCN110681639AImprove cleaning efficiencyConsistent qualityDrying gas arrangementsCleaning using liquidsMegasonic cleaningEngineering

The invention discloses a multi-groove ultrasonic cleaning machine. The multi-groove ultrasonic cleaning machine comprises a cleaning box, a loading roller way, and an unloading roller way arranged onone side of the loading roller way; a material frame return roller way is formed between the loading roller way and the unloading roller way; a spray cleaning system is arranged at one end of the material frame return roller way; a first ultrasonic cleaning system, a second ultrasonic cleaning system, a first spray rinsing system, a second spray rinsing system, a hot air drying system and a vacuum drying system are arranged on one side of the spray cleaning system in sequence; and rotating devices with the same structures are arranged in the spray cleaning system, the first ultrasonic cleaning system, the second ultrasonic cleaning system, the first spray rinsing system, the second spray rinsing system, the hot air drying system and the vacuum drying system on one side of the material frame return roller way.

Owner:无锡华伟机电设备有限公司

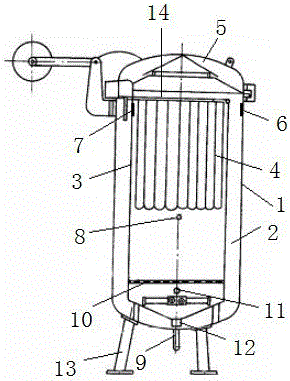

Cylindrical real silk steaming box

InactiveCN106367906ASimple structureLow costLiquid/gas/vapor textile treatmentEngineeringMoisture sensor

The invention discloses a cylindrical real silk steaming box which comprises an outer cylindrical barrel and an inner cylindrical barrel arranged in the outer barrel. An interlayer is formed between the outer barrel and the inner barrel, top covers capable of sealing are arranged at the top of the outer barrel and the top of the inner barrel, and the inner barrel is provided with a silk hanging rack for supporting a real silk fabric. The cylindrical real silk steaming box is characterized in that an outer side temperature and humidity sensor is arranged at the top of the inner wall of the outer barrel, an inner side temperature and humidity sensor is arranged at the top of the inner wall of the inner barrel, an interlayer air inlet pipe is arranged at the central position of the outer barrel, an interlayer exhausting pipe is arranged at the bottom, the inner barrel is provided with an inner barrel air inlet pipe, a partition plate is arranged between the inner barrel air inlet pipe and the real silk fabric, a plurality of holes are formed in the partition plate, and an inner barrel exhausting pipe is arranged at the bottom of the inner barrel. The cylindrical real silk steaming box is simple in structure, low in cost, convenient to adjust and control and suitable for small-batch production.

Owner:SUZHOU WEIDU SILK

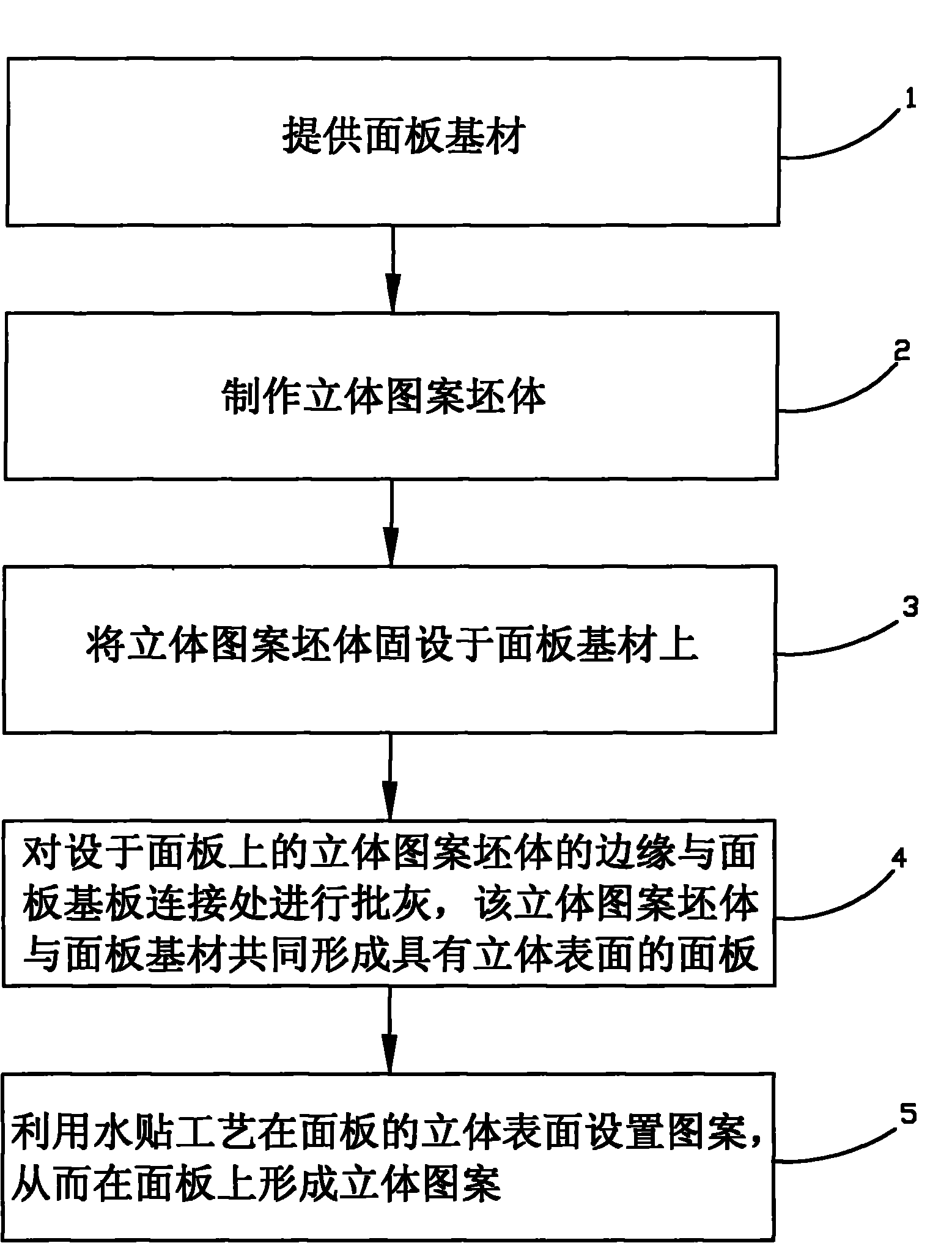

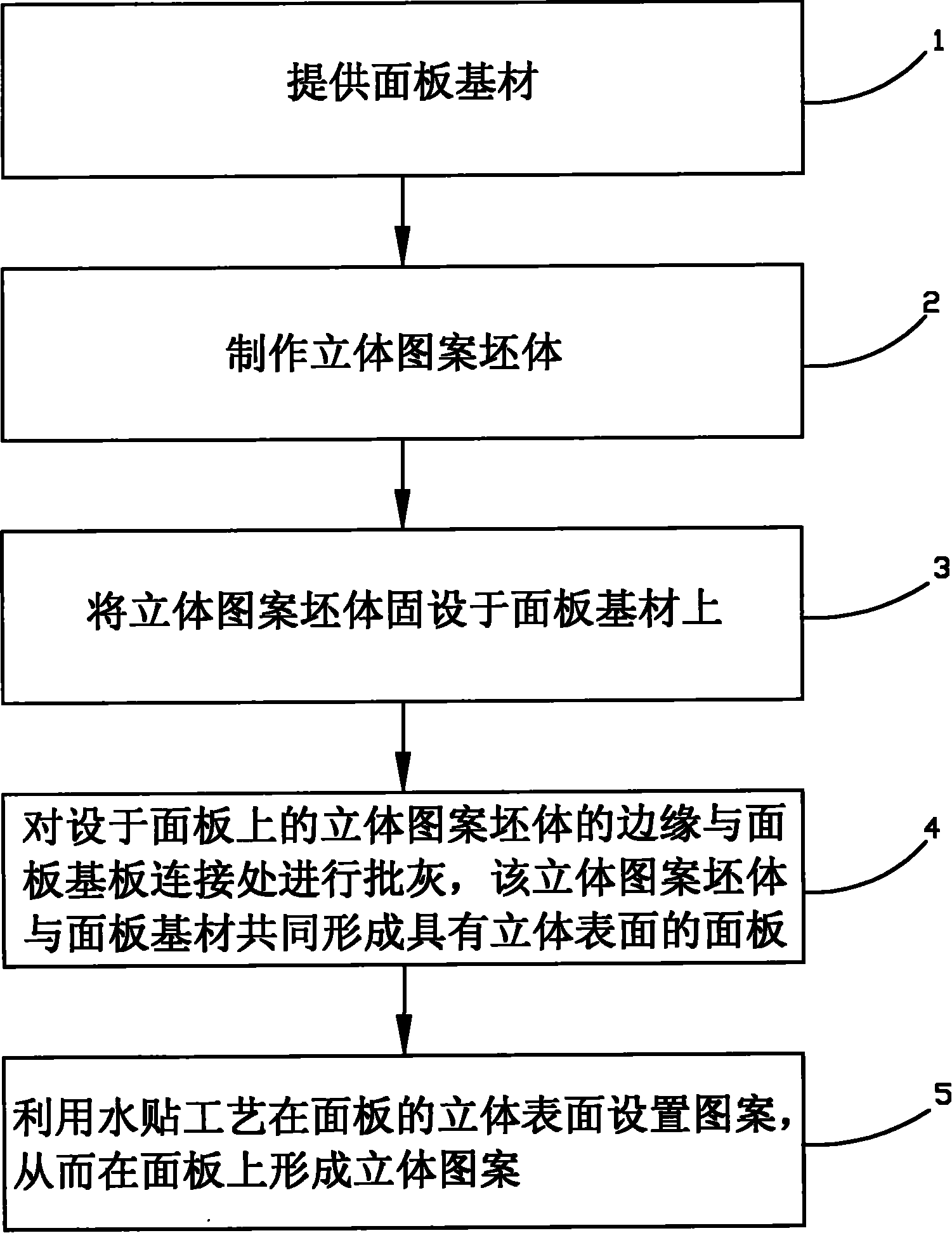

Method for manufacturing embossed pattern on metal panel

InactiveCN101804761AFirmly connectedSimple preparation processDecorative surface effectsHigh volume manufacturingEngineering

The invention relates to a method for manufacturing an embossed pattern on a metal panel, which comprises the following steps: 1, providing a metal panel base material; 2, preparing an embossed pattern blank on the metal panel; 3, fixing the embossed pattern blank on the panel base material; 4, plastering the connecting place of the edge of the embossed pattern blank body on the panel and a panel base plate, wherein the embossed pattern blank body and the panel base material form the panel with a stereo surface; and 5, making a pattern on the stereo surface of the panel by a water paste process so as to form the embossed pattern on the panel. A mould is used for pressing a sheet so as to form the embossed pattern blank; the embossed pattern blank and the panel base material form the panel with the stereo surface; and the water paste process is adopted to make the pattern on the stereo surface of the panel so as to form the embossed pattern on the panel. The manufacturing process is simple; the connection between the embossed pattern and the panel is firm; and the manufacturing method is suitable for both small scale production and large scale production and can effectively reduce production cost to a certain degree.

Owner:林其武

Full-automatic intelligent plastic plate surface drilling equipment

The invention discloses full-automatic intelligent plastic plate surface drilling equipment which comprises a box body and a clamping device. The bottom of the box body is in sliding connection with afirst lead screw. The left end of the first lead screw and an output shaft of a first motor fixedly mounted at the bottom of the box body are fixedly connected through a coupling. A base is arrangedon the surface of the first lead screw in a sleeving manner. A second motor is fixedly mounted at the front end in the base. The invention relates to the technical field of plastic processing. By means of the full-automatic intelligent plastic plate surface drilling equipment, the first lead screw is driven by the first motor to rotate, the base can move left and right along the first lead screw,a second lead screw is driven by the second motor to rotate, and the clamping device can move front and back along the second lead screw on the basis of the base; the structure is simple, and operation is convenient; the production cost is low; the full-automatic intelligent plastic plate surface drilling equipment is suitable for small-batch production; and the position of the clamping device iscontrolled through the first motor and the second motor, and the automation degree and the processing precision are high.

Owner:FOSHAN HIGH GRADE ROBOT INTELLIGENT EQUIP CO LTD

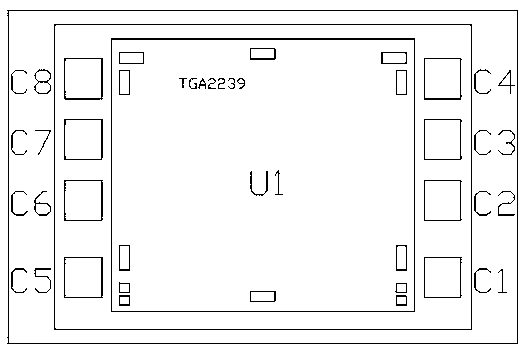

Processing method of 35W (Watt) power amplification module in the field of satellite communications

InactiveCN109451677AReduce volumeFlexible installationPrinted circuit assemblingFinal product manufactureCapacitanceAudio power amplifier

The invention provides a processing method of a 35W (Watt) power amplification module in the field of satellite communications. A microwave circuit board and an amplifier module are comprised. The processing method comprises the following steps of S1, sintering a microwave circuit board on a soldering lug; S2, eutecticizing a power amplifier chip U1 to a corresponding molybdenum-copper carrier toform a power amplifier eutectic subassembly G1; S3, sintering the power amplifier eutectic subassembly G1 and a capacitor onto the microwave circuit board; S4, cleaning the sintered microwave circuitboard by use of a gas phase cleaning machine; S5, performing gold wire bonding on the power amplifier chip U1 and the capacitor; and S6, debugging, testing, capping and marking the assembled subassembly. According to the processing method of the 35W power amplification module, the 35W power amplification module in the field of satellite communications is manufactured by virtue of the microelectronic package processing technology, and the 35W power amplifying module in the field of satellite communications has the characteristics of small size, flexible installation and high reliability and issuitable for small batch production.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

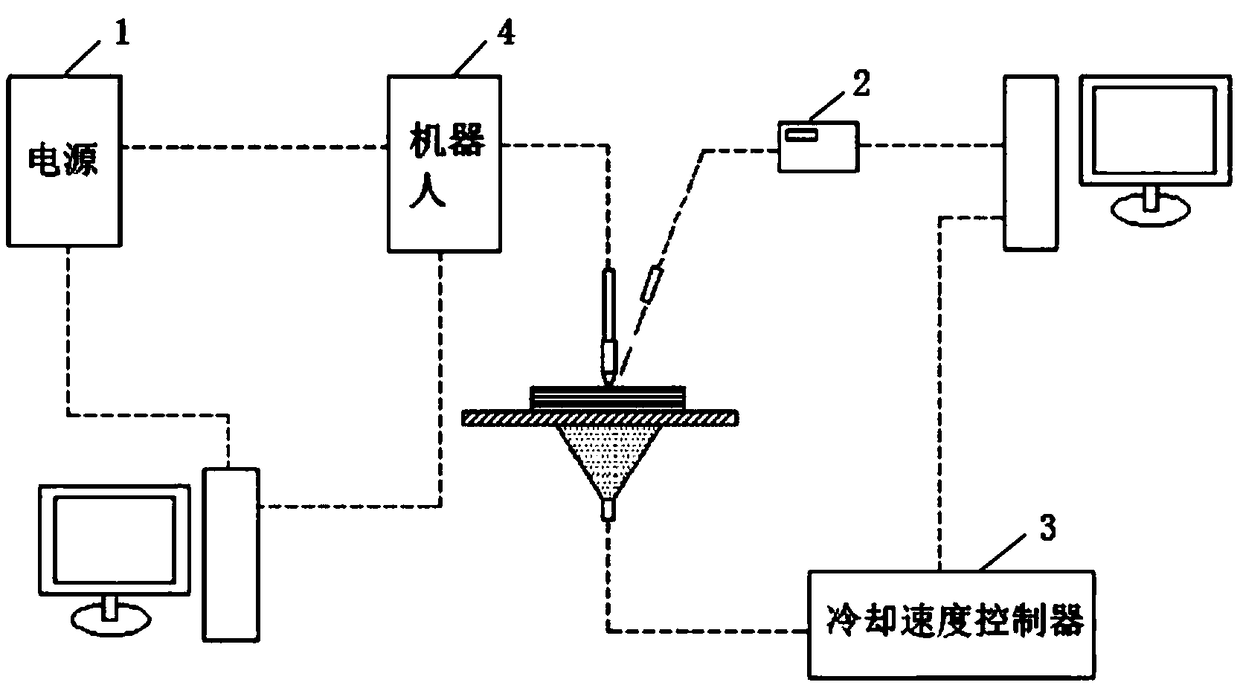

Electro-welding additive manufacturing method of nuclear power station SAP refrigerator end covers

InactiveCN108971697ALower requirementEasy to processNuclear energy generationReactors manufactureMelting tankHigh energy

The invention discloses an electro-welding additive manufacturing method of nuclear power station SAP refrigerator end covers. The method herein comprises: I, conveying raw metal wires to the surfaceof a base via a conveying mechanism and an electro-welding head, allowing the raw metal wires and the base to generate electric arcs under overlaying protection of an aid so that part of the overlaying aid is melted into a molten slag bath; II, allowing current to pass through the raw metal wires and the molten slag bath to generate resistance heat and slag heat, melting the raw metal wires underthe thermal composite high-energy heat action of arc heat, the resistance heat and the slag heat so that a local bath is formed in the surface of the base; III, conveying the raw metal wires and the aid continuously, controlling the welding head to move by a computer according to hierarchical slicing data so that layerwise overlaying of the bath is performed on the base to obtain a finished product. The method herein has high efficiency and good stability, and has no need for remanufacturing of molds; a manufactured end cover has good tissue characteristics and excellent mechanical properties.

Owner:CHINA GENERAL NUCLEAR POWER OPERATION +1

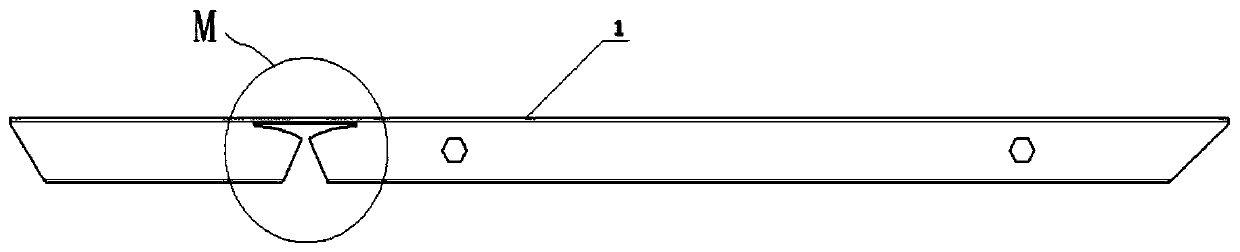

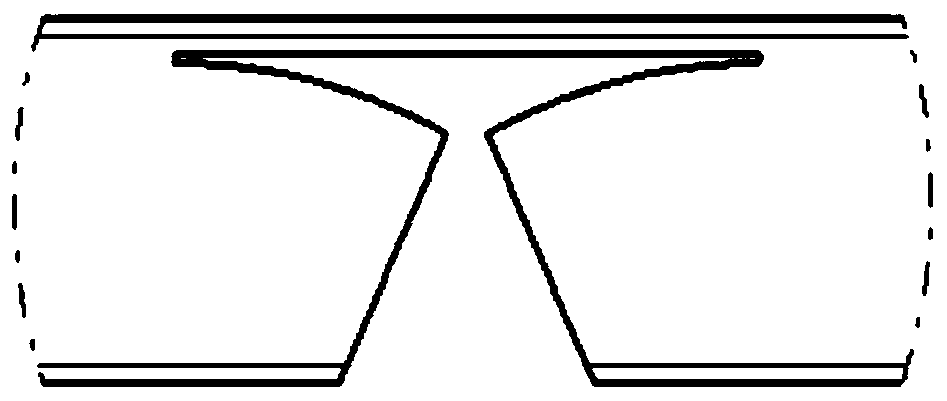

Pipe barrel sizing device

InactiveCN104032506ASimple structureReduce volumeAuxillary apparatusLiquid/gas/vapor yarns/filaments treatmentYarnPulp and paper industry

The invention provides a pipe barrel sizing device. The pipe barrel sizing device comprises a yarn inlet pipe, a sizing agent pipe and a yarn outlet pipe; the two ends of the sizing agent pipe are connected with the yarn inlet pipe and the yarn outlet pipe respectively through leather pipes made of elastic materials, each leather pipe is sleeved with an elastic tightening ring, and the sizing agent pipe is communicated with a horizontal feeding pipe; yarns sequentially penetrate through the yarn inlet pipe, the sizing agent pipe and the yarn outlet pipe and are elastically attached to the inner sides of the leather pipes. The main work part of the device is the pipe barrel structure, and a sizing process is completed when the yarns penetrate through the sizing agent pipe full of sizing agents. According to the device, the leather pipes and the tightening ring are adopted, the sizing agents are kept in the sizing agent pipe between the two leather pipes, the size is smaller, and cost is lower; few sizing agents are used in the sizing agent pipe in the sizing process of the device, and the device is very suitable for small-batch production.

Owner:WUJIANG XINHE WEAVING

Bending welding forming method for rectangular steel pipe

The invention discloses a bending welding forming method for a rectangular steel pipe. Before the rectangular steel pipe is bent, a T-shaped cutting track is drawn according to a target bending angle,a corresponding groove is cut in the side face of the rectangular steel pipe with a laser or plasma cutting method, then the corresponding groove of the steel pipe is bent, the bent T-shaped groove is welded, and then the rectangular steel pipe can be bent. The method has the beneficial effects that rapid forming is achieved, and dies are not needed, is suitable for small-scale production and manufacturing, and can meet the requirements of different bending angles within a certain range.

Owner:嘉兴速羽科技有限责任公司

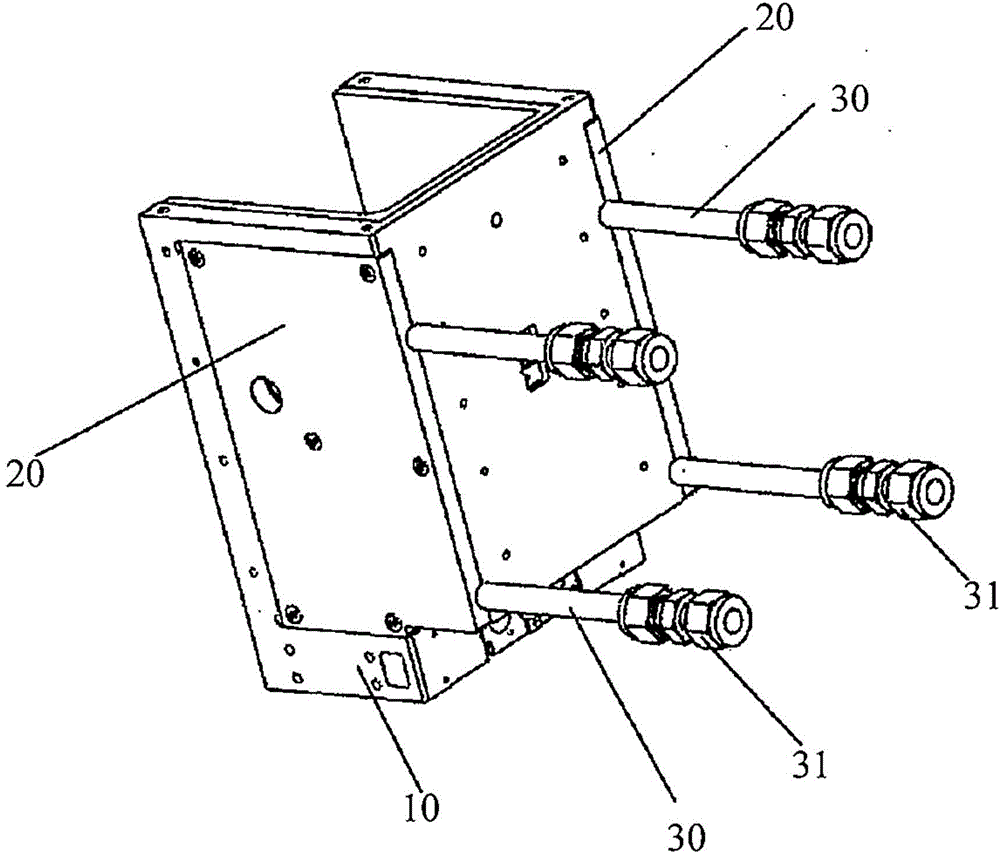

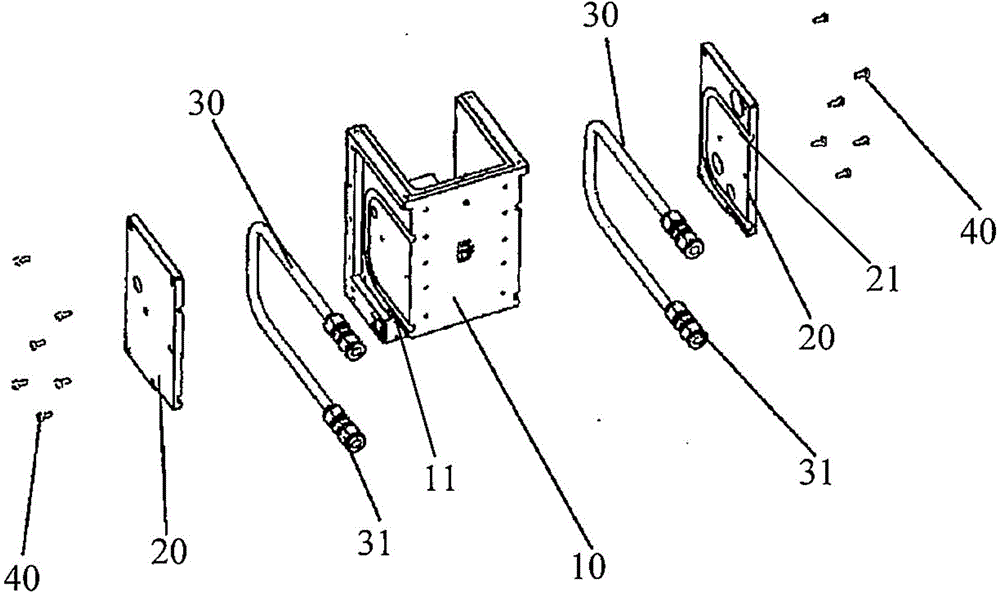

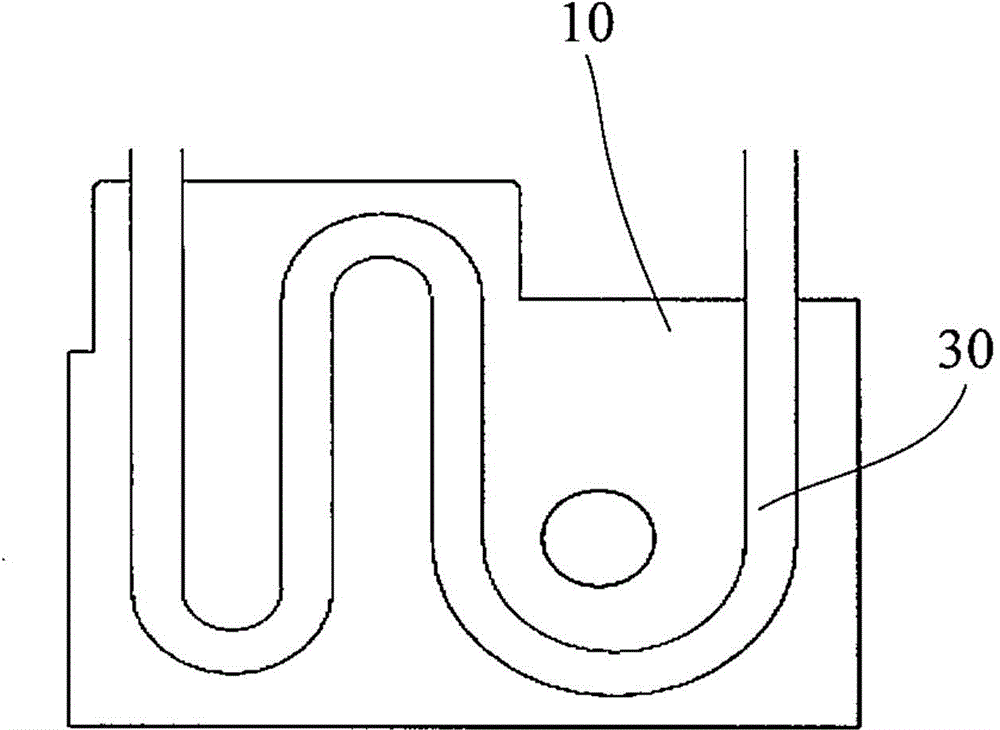

Water-cooled heat sink

InactiveCN104582422AWill not affect the sealMaintain securityCooling/ventilation/heating modificationsHeat sinkEngineering

The invention provides a water-cooled heat sink. The water-cooled heat sink comprises a water-cooling housing, splints and water-cooling pipes, wherein the water-cooling housing is used for accommodating an energy source, and an outer groove is formed in the outer side of at least one side wall of the water-cooling housing; an inner groove is formed in the inner side of each of the splints, and the outer grooves of the water-cooling housing and the inner grooves of the splints are in complimentary shapes and are matched to form a water-cooling pipe channel; a water-cooling joint is arranged at each of the two ends of each water-cooling pipe, and the water-cooling pipes are placed in the water-cooling pipe channel; heat conducting adhesive layers are respectively arranged in the outer grooves of the water-cooling housing and the inner grooves of the splints, the water-cooling pipes are connected to the interior of the water-cooling pipe channel through the heat conducting adhesive layers, and gaps between the water-cooling pipe channel and the water cooling pipes are filled with the heat conducting adhesive layers. According to the water-cooled heat sink, the water-cooled heat sink has favorable reliability and maintainability.

Owner:RAINTREE SCI INSTR SHANGHAI

Side frame of railway freight car bogie

PendingCN108382414AShorten the production cycleSuitable for small batch productionBogiesTruckBatch production

Owner:张家港保税区泰德瑞尔轨道科技有限公司

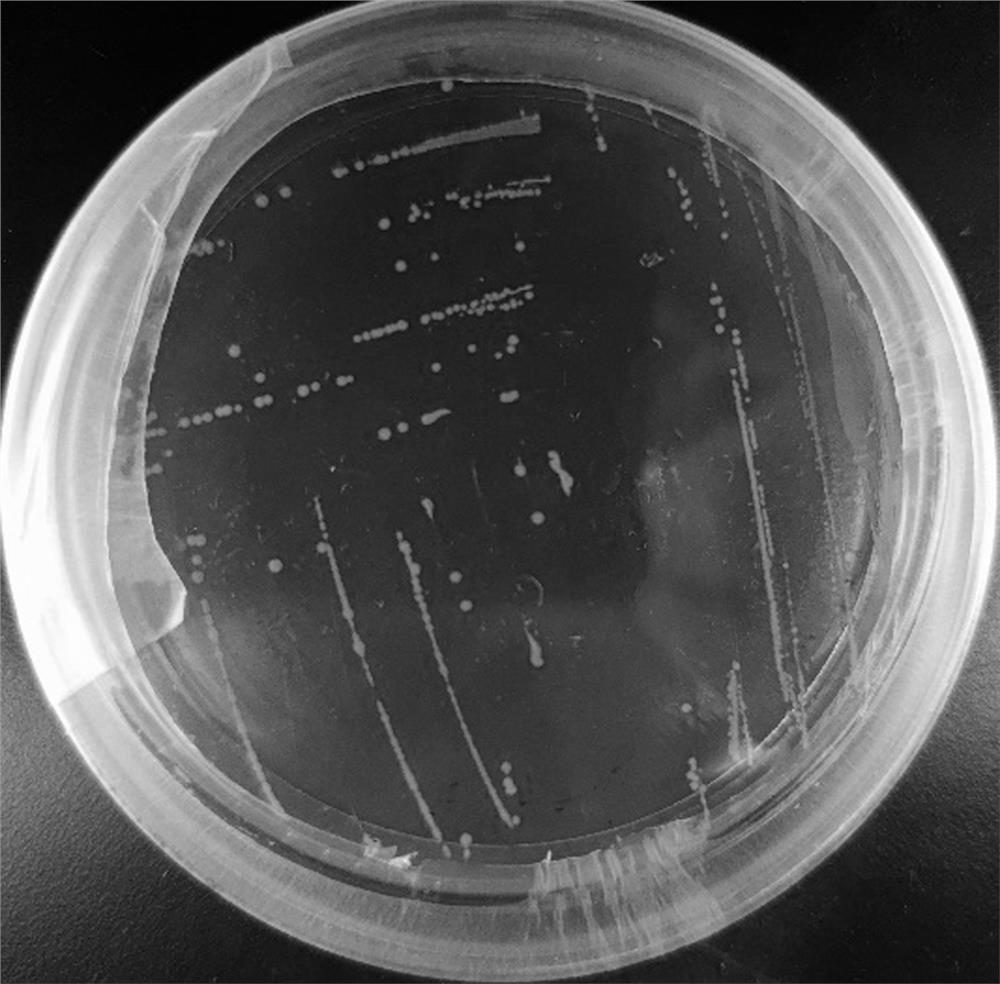

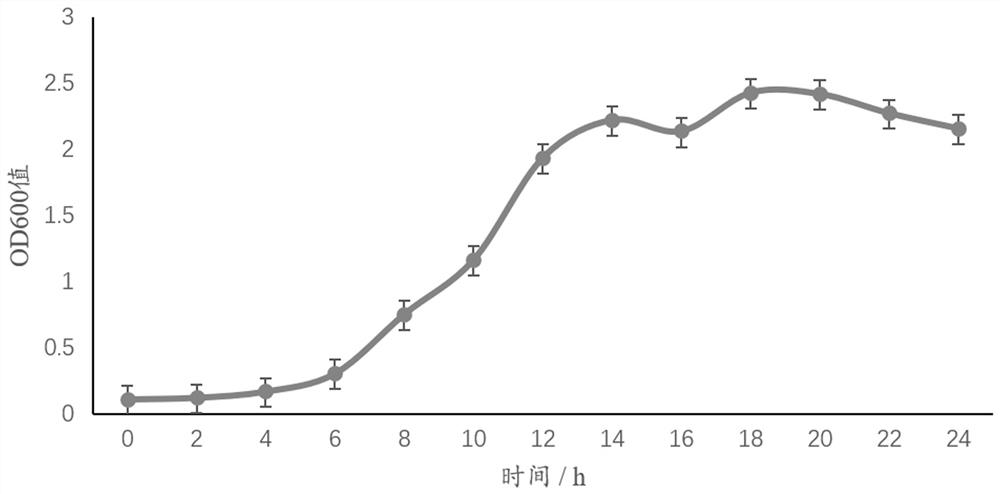

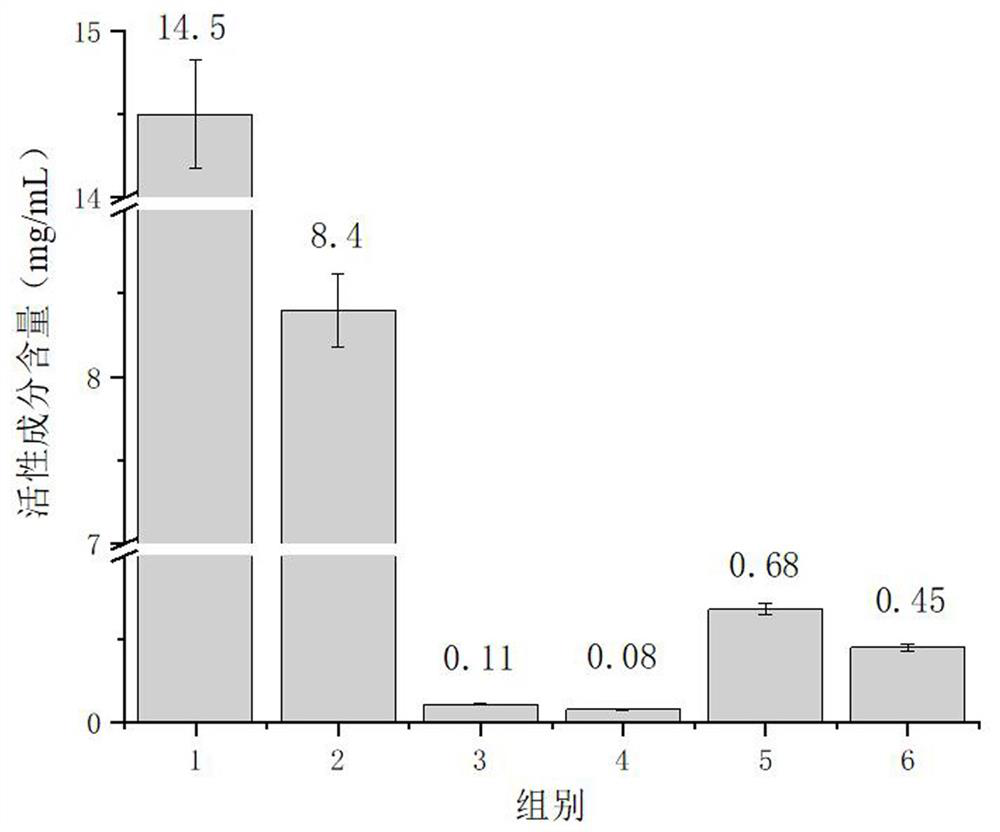

Enterococcus monteilii and application thereof in fermentation of Chinese herbal medicines

ActiveCN114196586AIncrease productionEfficient use ofBacteriaMicroorganism based processesBiotechnologyAstragalus polysaccharide

The invention belongs to the field of microorganisms, and relates to enterococcus monteilii, in particular to enterococcus monteilii and application thereof in fermentation of Chinese herbal medicines. The preservation number of the strain is CCTCC NO: M 20211504, the classification name is Enterococcus mudtii MY-YD-1, the preservation unit is China Center for Type Culture Collection, the preservation time is November 29, 2021, and the preservation address is Wuhan University, Wuhan, China. When the strain is used for fermenting the traditional Chinese herbal medicine astragalus membranaceus, the release amount of the effective components astragalus polysaccharide, flavonoid and saponin compounds in the astragalus membranaceus can be greatly increased. The method for fermenting Chinese herbal medicines by virtue of strains is an effective method for improving active ingredients. The enterococcus monteilii MY-YD-1 strain disclosed by the invention is good in astragalus mongholicus fermentation performance and high in yield of active ingredients, and can be used for small-scale and large-scale industrial production in the future, so that very strong economic benefits are brought.

Owner:ZHENGZHOU UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com