Pipe barrel sizing device

A tube and leather tube technology, applied in the field of tube sizing devices, can solve the problems of high cost, high power, complex structure, etc., and achieve the effects of small batch production, simple structure, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with embodiment the present invention is further described:

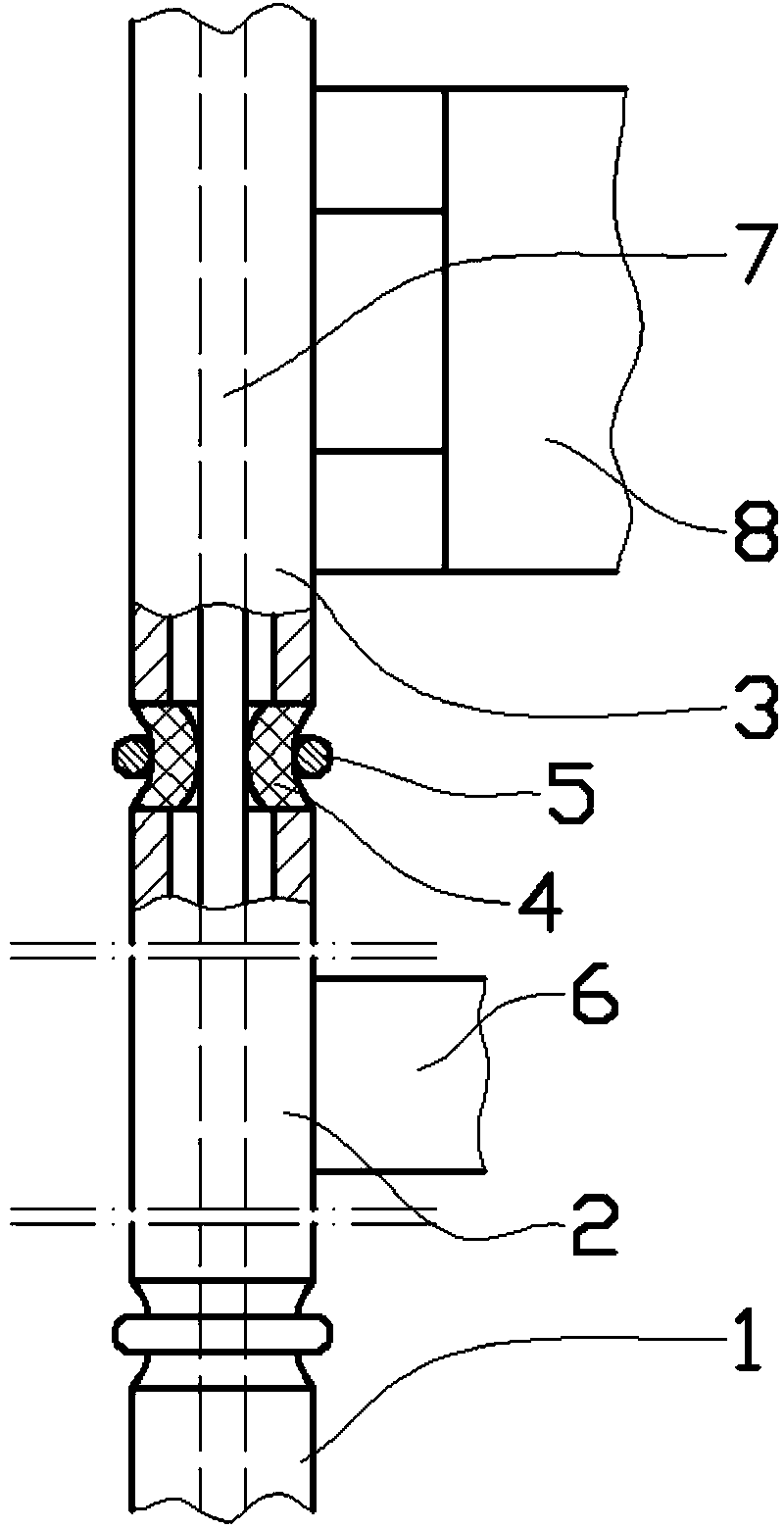

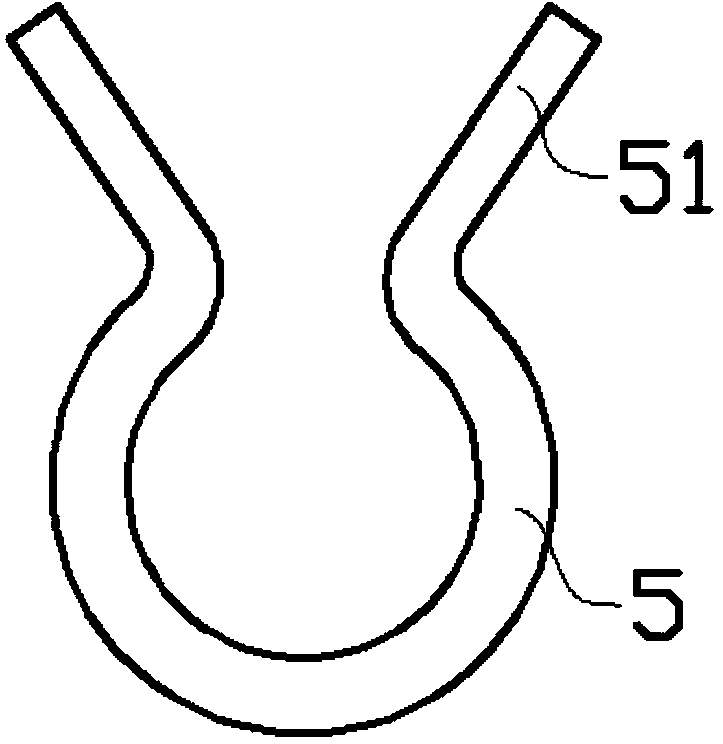

[0011] Such as figure 1 As shown in the embodiment, the tube sizing device includes a yarn inlet tube 1, a size tube 2, and a yarn output tube 3 which are assembled vertically and sequentially from bottom to top; the two ends of the size tube 2 respectively pass through A leather tube 4 made of elastic material is connected to the yarn inlet tube 1 and the yarn outlet tube 3, and the leather tube 4 is covered with an elastic hoop 5, and the slurry tube 2 is filled with slurry. The slurry pipe 2 is connected with a horizontal feeding pipe 6, and the feeding pipe 6 can be used to connect with the slurry supply equipment. The yarn 7 to be sized passes through the yarn inlet tube 1, the size tube 2 and the yarn outlet tube 3 in sequence, and is elastically attached to the inner side of the leather tube 4.

[0012] The tube sizing device has a simple structure and can be used in special sizi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com