Local indentator for fiber towel, and manufacturing method of indentation in specific position of the fiber towel

A technology with a specific location and production method, applied in textile and papermaking, fabric surface trimming, thorn patterns, etc., can solve the problems of small production batch, high printing fee, high cost, fill the gap in the industry, reduce production cost, and be easy to operate. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] 1. Equipment used:

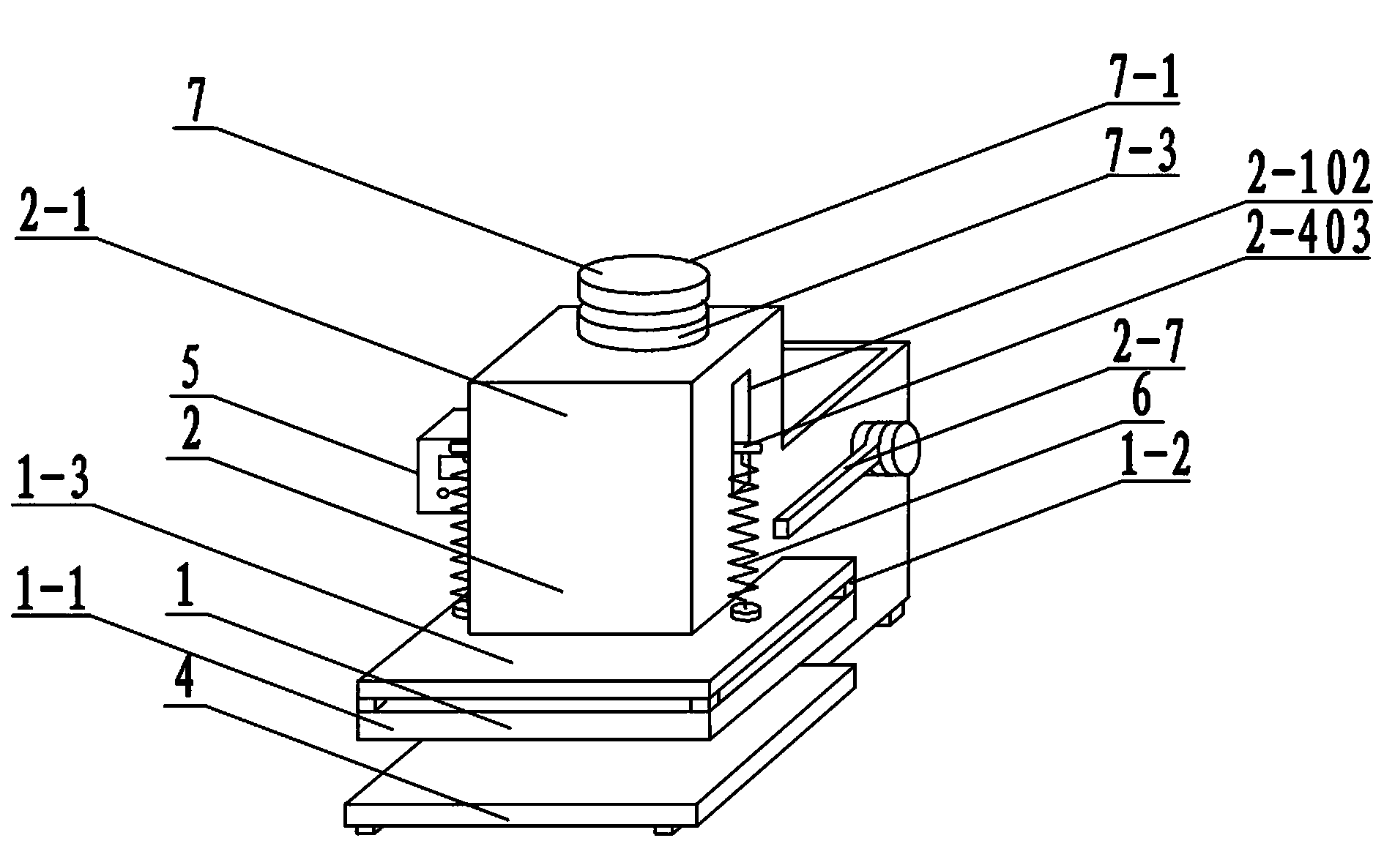

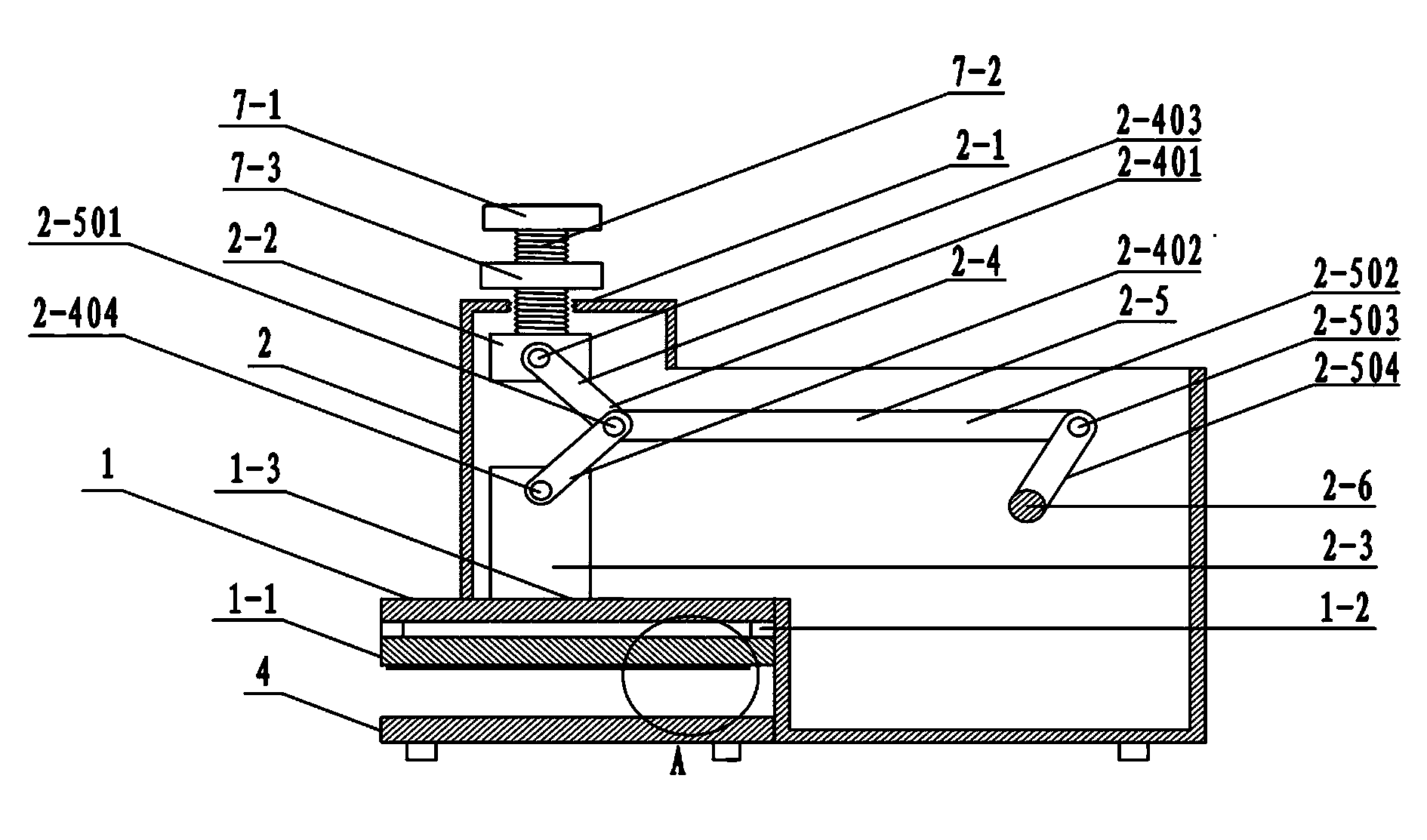

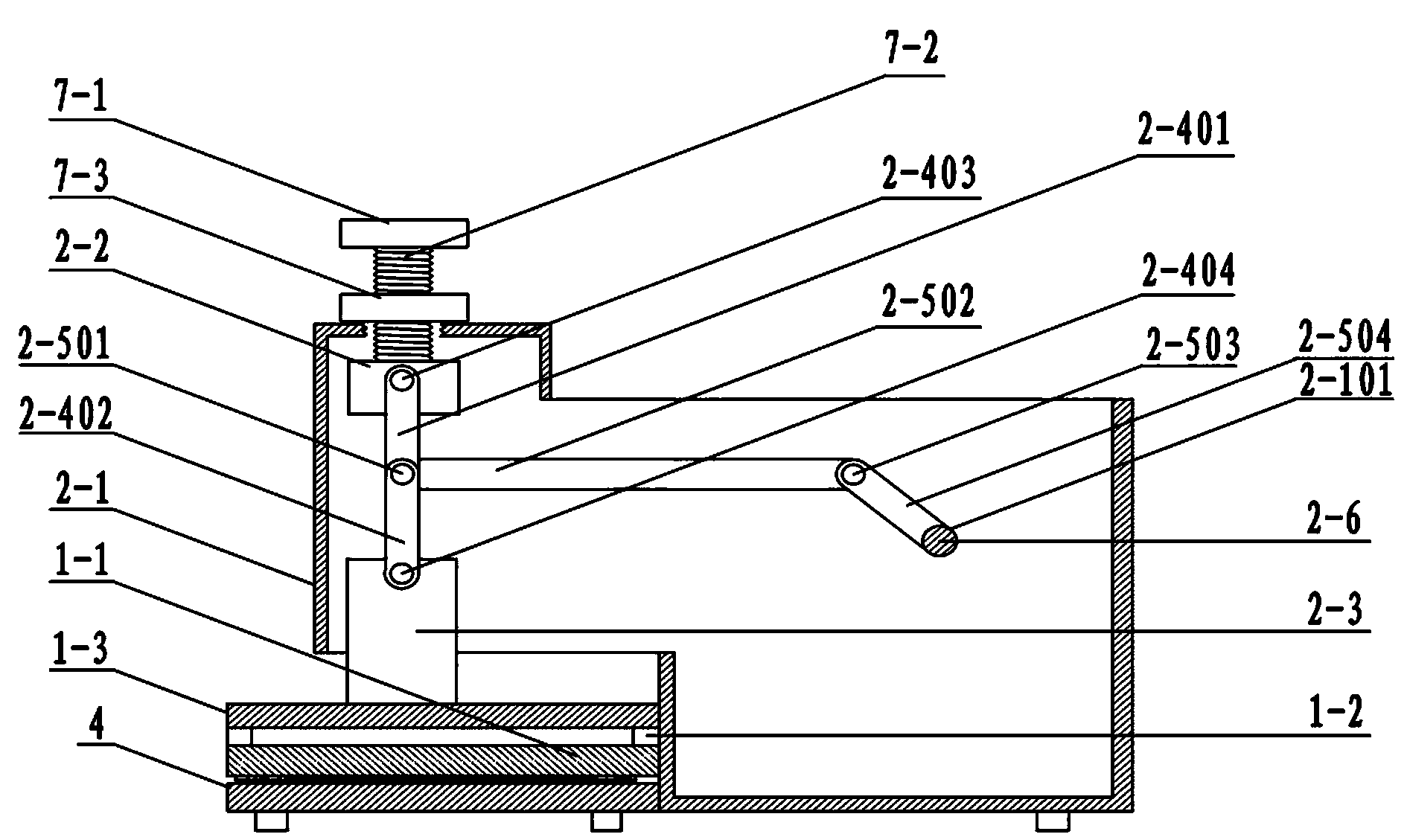

[0060] as attached Figure 1~5 As shown, this embodiment adopts a fiber towel partial indentation machine, including a heating plate 1, a pattern plate 3 installed under the heating plate 1 and closely attached to the heating plate 1, and located under the heating plate 1 for placing fiber towels. The fixed plate 4, the booster device 2 that drives the heating plate 1 to descend above the heating plate 1, and the temperature controller 5, wherein the heating plate 1 is equipped with an electric heating element 1-101 and a temperature sensor 1-102, and the electric heating element 1- 101 is electrically connected to the temperature controller 5, and the temperature sensor 1-102 is electrically connected to the temperature controller 5;

[0061] Wherein, the booster device 2 includes a chassis 2-1, a fixed module 2-2 fixed on the inner upper part of the chassis 2-1, a booster module 2-3 located above the heating plate 1, connected to the chassis thro...

Embodiment 2~6、 comparative example 1

[0084] The equipment used in Examples 2 to 6 and Comparative Examples 1 and 2 is the same as that of Example 1, and the manufacturing steps of indented fiber towels are different as follows, and the others are the same, see Table 1:

[0085] Table 1 Embodiment 2~6 and comparative example 1, 2 and embodiment 1 operation contrast

[0086] .

Embodiment 7

[0088] The indentation fiber towel quality evaluation that embodiment 1~6 and comparative example 1,2 make are shown in Table 2:

[0089] Table 2 Quality evaluation of indented fiber towels prepared in Examples 1-6 and Comparative Examples 1 and 2

[0090]

[0091] Conclusion: The above comparison shows that when the heating temperature of the heating plate is 180~280℃, preferably 235~265℃, the indentation is clear and beautiful, which meets the requirements of industrial production. In addition, the addition of anti-adhesion and heat insulation film can effectively reduce the defective rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com