Electro-welding additive manufacturing method of nuclear power station SAP refrigerator end covers

An additive manufacturing and refrigerator technology, which is applied in the field of electrofusion additive manufacturing of end caps of SAP refrigerators in nuclear power plants, can solve the problems of coarse grains of end caps, short service cycles, and difficult repairs, and achieves excellent mechanical properties and heat treatment. The effect of uniform and simplified processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

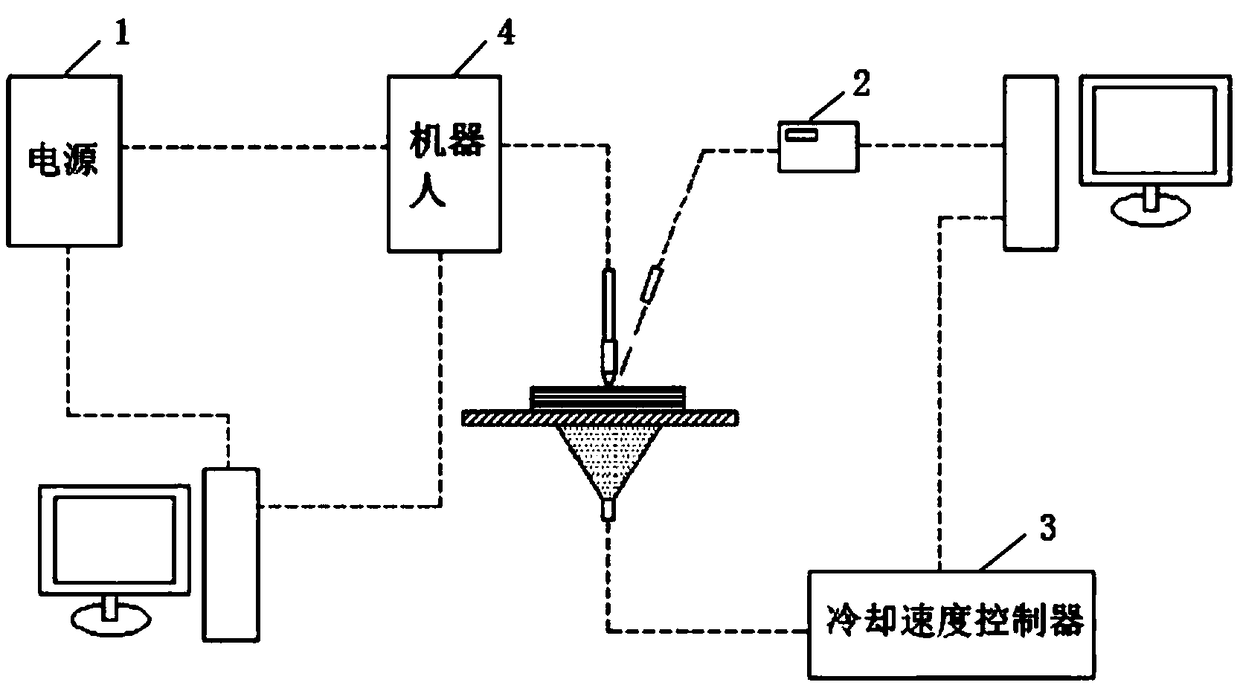

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] The invention provides a method for manufacturing an end cover of a SAP refrigerator in a nuclear power plant by electrofusion and additive manufacturing, comprising:

[0033] (1) Connect the two poles of the power supply to the electrofusion head and the substrate respectively, and the metal raw wire is sent to the surface of the substrate through the conveying mechanism and the electrofusion head. Under the protection of the accumulation of auxiliary agents, an arc is generated between the metal raw wire and the substrate, and the melting part Heap auxiliary materials to form molten slag pool;

[0034] Wherein, the shape of the metal precursor wire can be round rod shape, ribbon shape, solid core or drug core, and its diameter is 2-5 mm. The length (that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com