Framework type driving cab of fire fighting truck

A technology for fire trucks and cabs, which is applied to vehicle components, upper structures of trucks, and upper structures. It can solve the problems of high cost and high price, and achieve the effects of short production cycle, low development cost and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

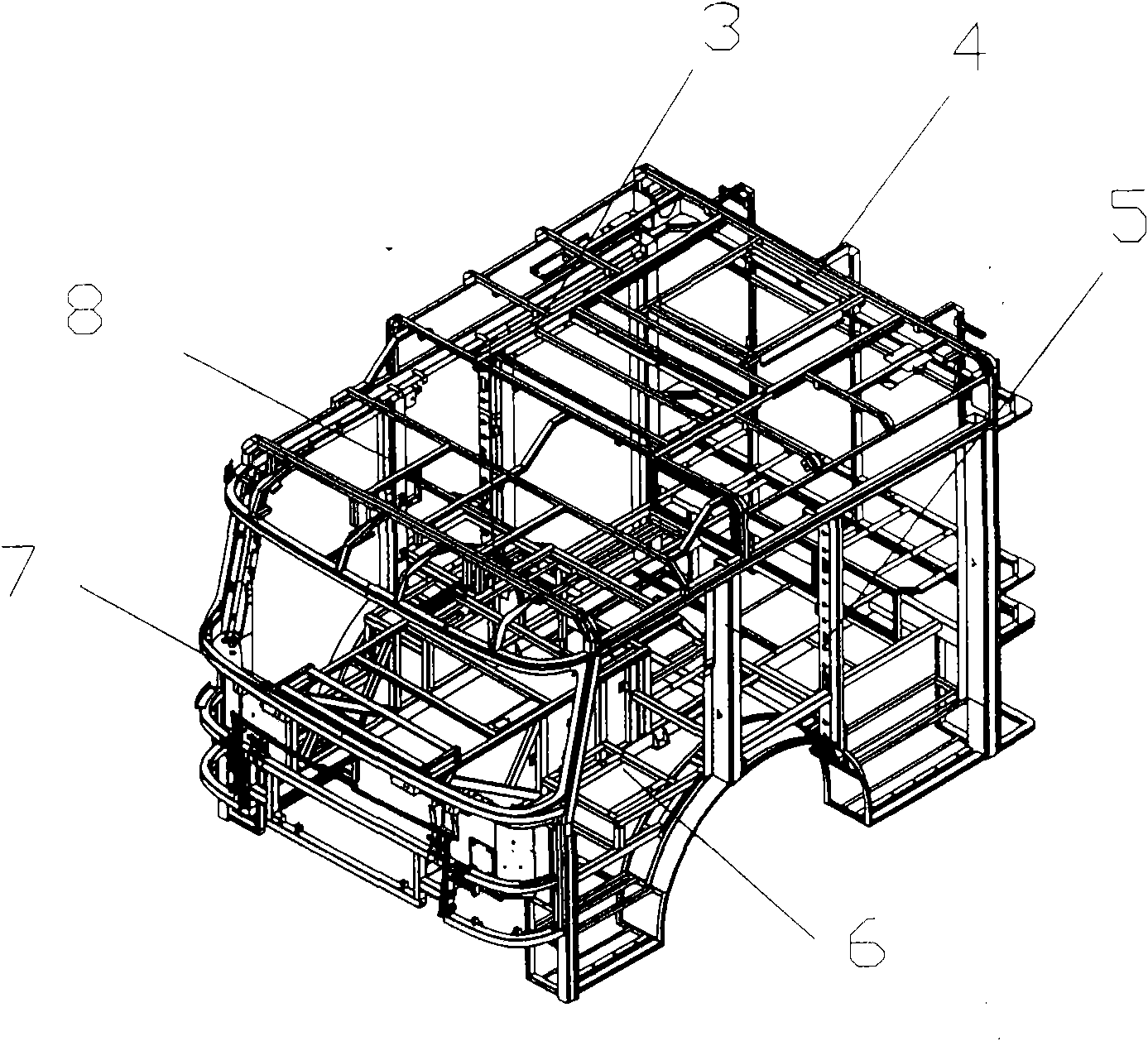

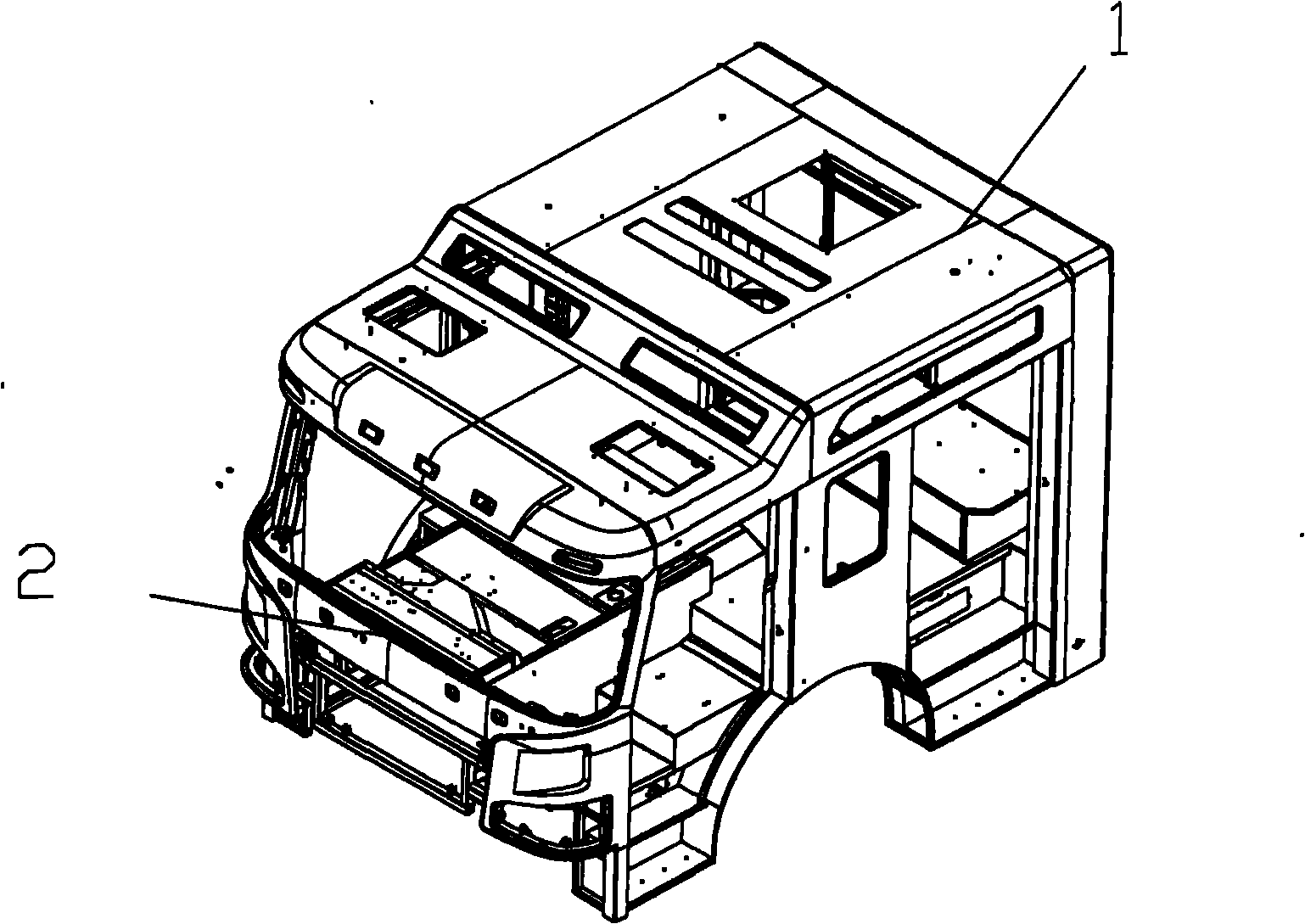

[0008] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 As shown in -3, the frame-type fire truck cab is composed of a body frame 2 and an outer skin 1, and is characterized in that: the body frame 2 is divided into a floor frame 6, a left side frame 8, a right side frame 5, and a top cover Frame 3, front wall frame 7 and rear wall frame 4 have six parts, and the metal profiles between the six parts are welded by square steel pipe, angle steel and channel steel, and the outer skin 1 is fixed with the skeleton 2 by welding or bonding.

[0009] Compared with the cab of the conventional modified fire truck, the present invention has larger internal space and convenience of getting on and off. It can pull fire fighters of a combat team into the fire scene in time for fire fighting, which can satisfy the fire fighters to enter and exit the cab more quickly in the fire fighting battle, and can ensure the personal safety and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com