Preparation method for anti-settling fuel cell catalyst slurry

A catalyst slurry, fuel cell technology, applied in chemical instruments and methods, mixing methods, chemical/physical processes, etc., to achieve the effect of high consistency and high stability of the slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

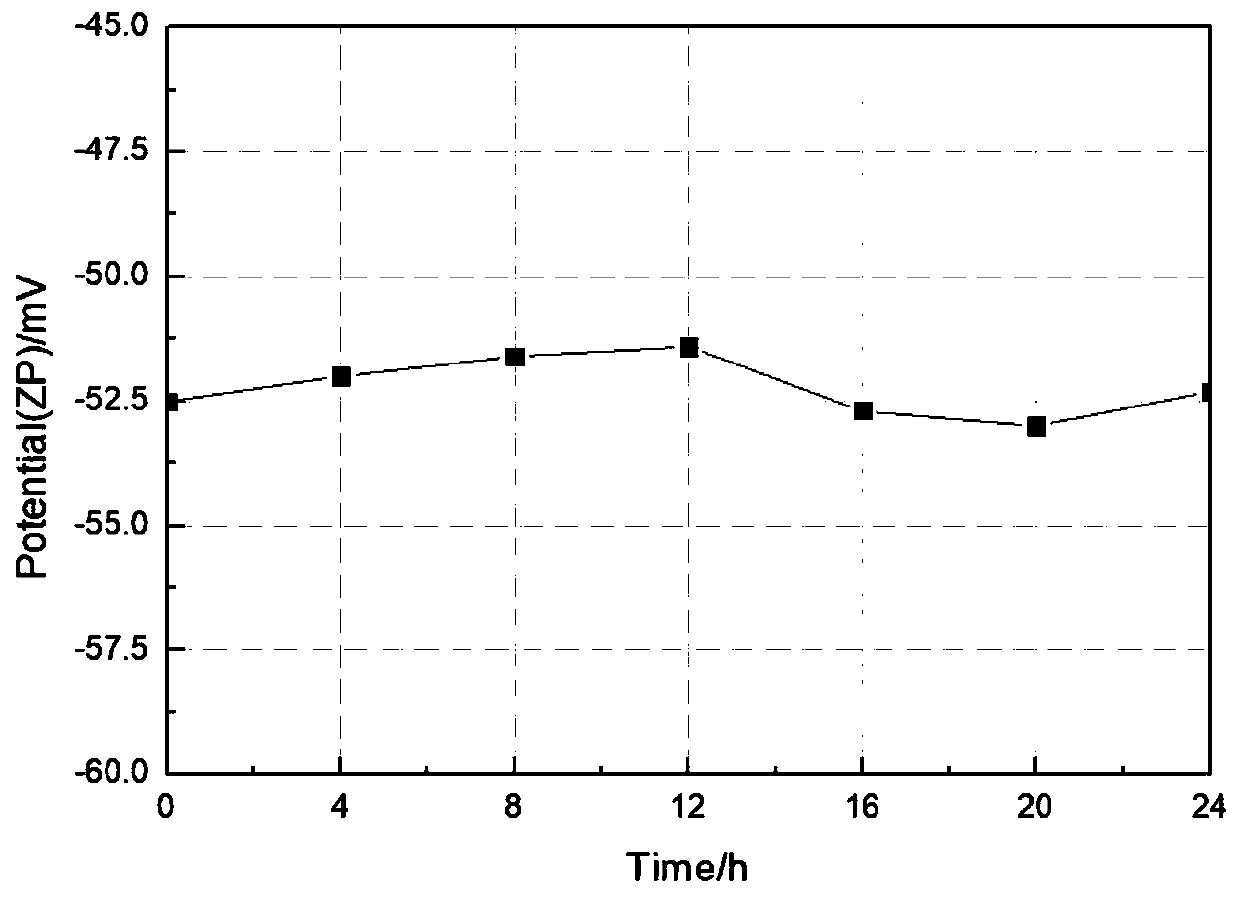

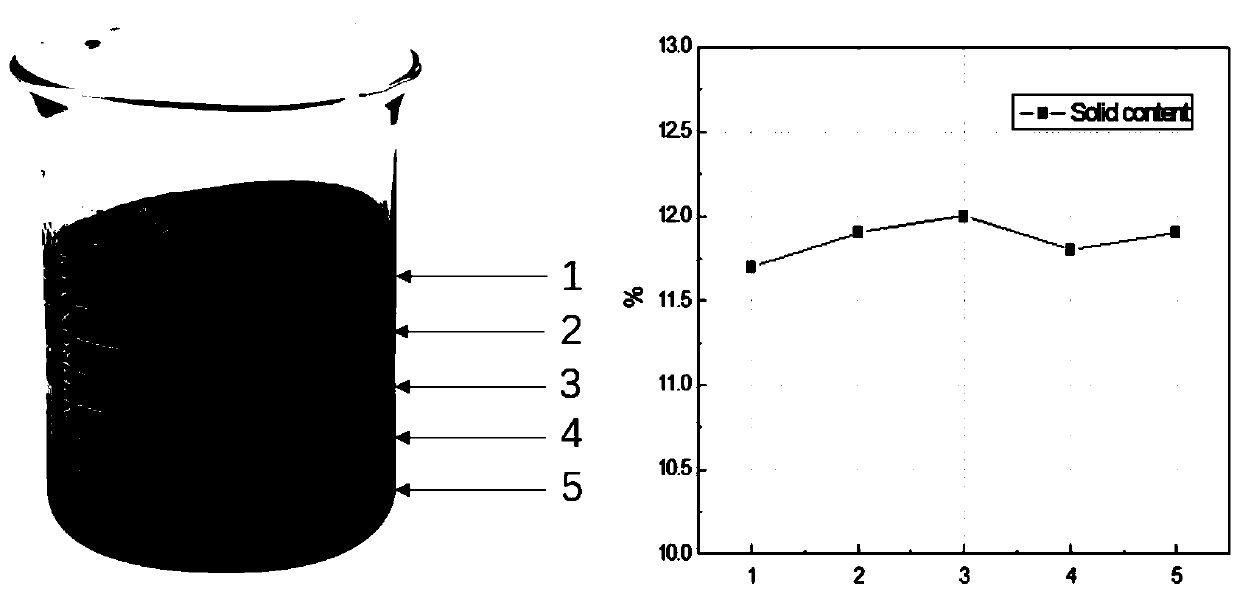

[0041] Configure Catalyst Slurry A

[0042] Will The monomer solution is dispersed in a mixed solvent by magnetic stirring, and the mixed solvent includes two components of isopropanol and deionized water, and placed in a vacuumable container and stirred for 24 hours to obtain a dispersed solution; wherein, by mass ratio , Monomer solution: isopropanol: deionized water = (3-10): (33-50): (30-45) preparation.

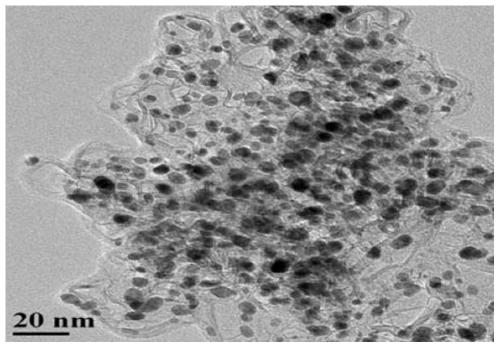

[0043] Mix 50% Pt / C catalyst with the dispersion solution, vacuumize the container after mixing, start the constant temperature water bath of the ultrasonic disperser, set the temperature at 17°C, the ultrasonic frequency at 25KHz, and the set power at 700W for 30min Ultrasonic dispersion, preliminarily prepared catalyst slurry; wherein, by mass ratio, the catalyst: Monomer solution: isopropanol: deionized water = (9-25): (3-10): (33-50): (30-45) preparation (this embodiment limits the mass ratio of the three to 15:5 :40).

[0044] Use a stator-rotor mixer to car...

Embodiment 2

[0060] Compared with Example 1, most of them are the same, except in this example: Catalyst: Monomer solution: isopropanol: deionized water = 9:10:33:30.

Embodiment 3

[0062] Compared with Example 1, most of them are the same, except in this example: Catalyst: Monomer solution: isopropanol: deionized water = 25:3:50:45.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com