Ultra-fine powder processing device

A processing device and ultra-fine powder technology, applied in the field of ultra-fine powder processing devices, can solve the problems of incomplete functions, poor self-sealing and automation, and inability to realize a processing system, so as to avoid manual intervention and achieve good repetition. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

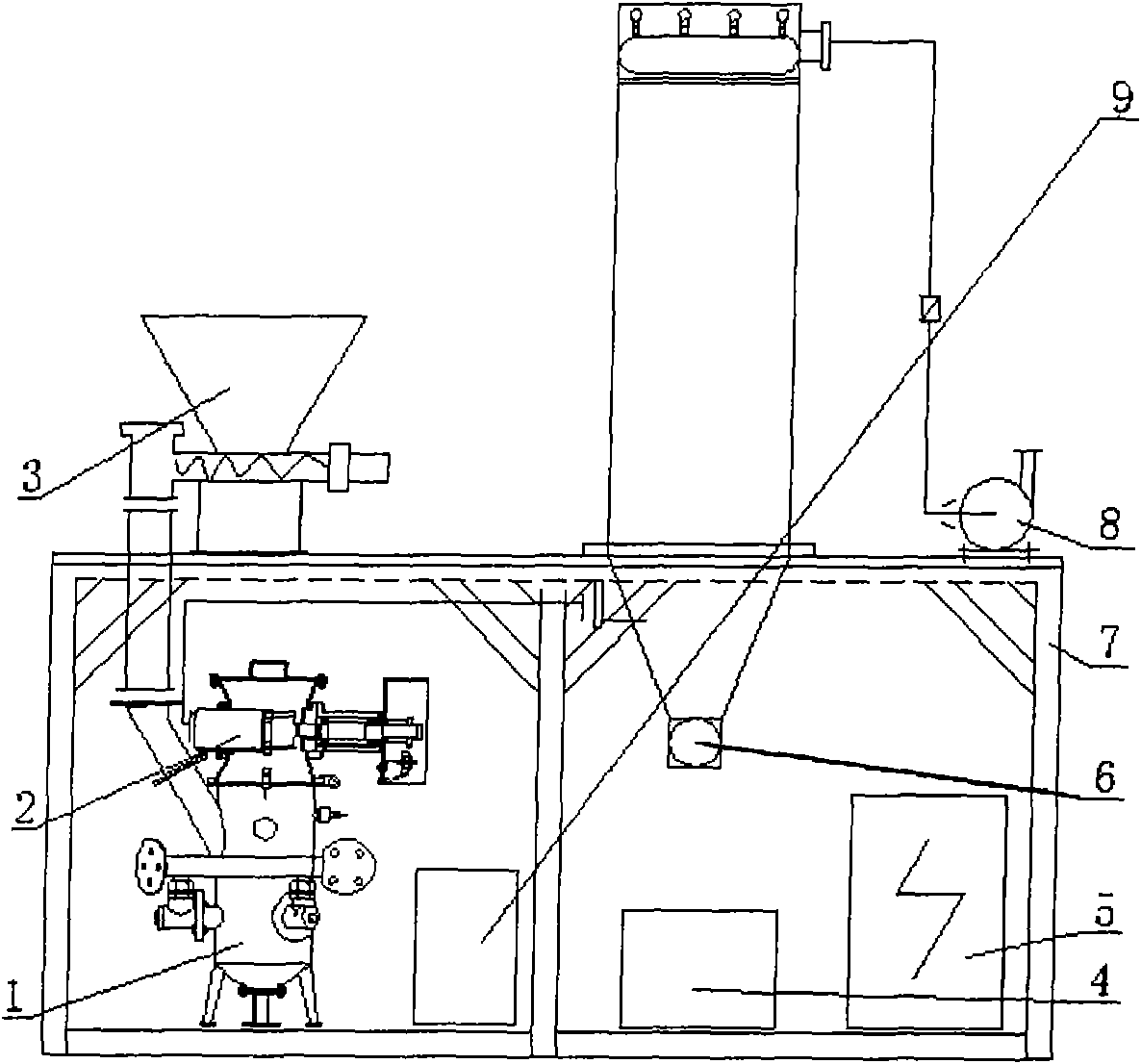

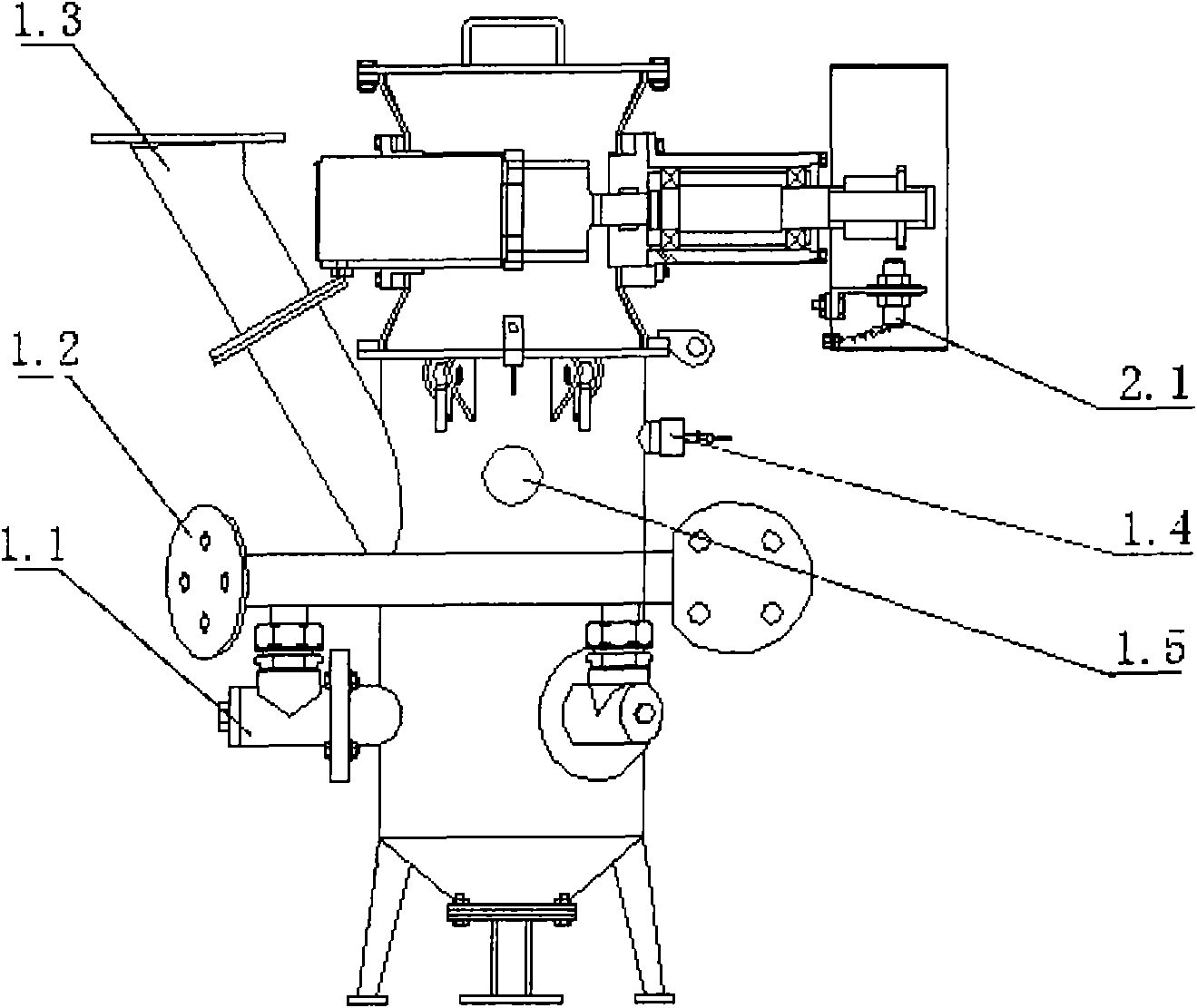

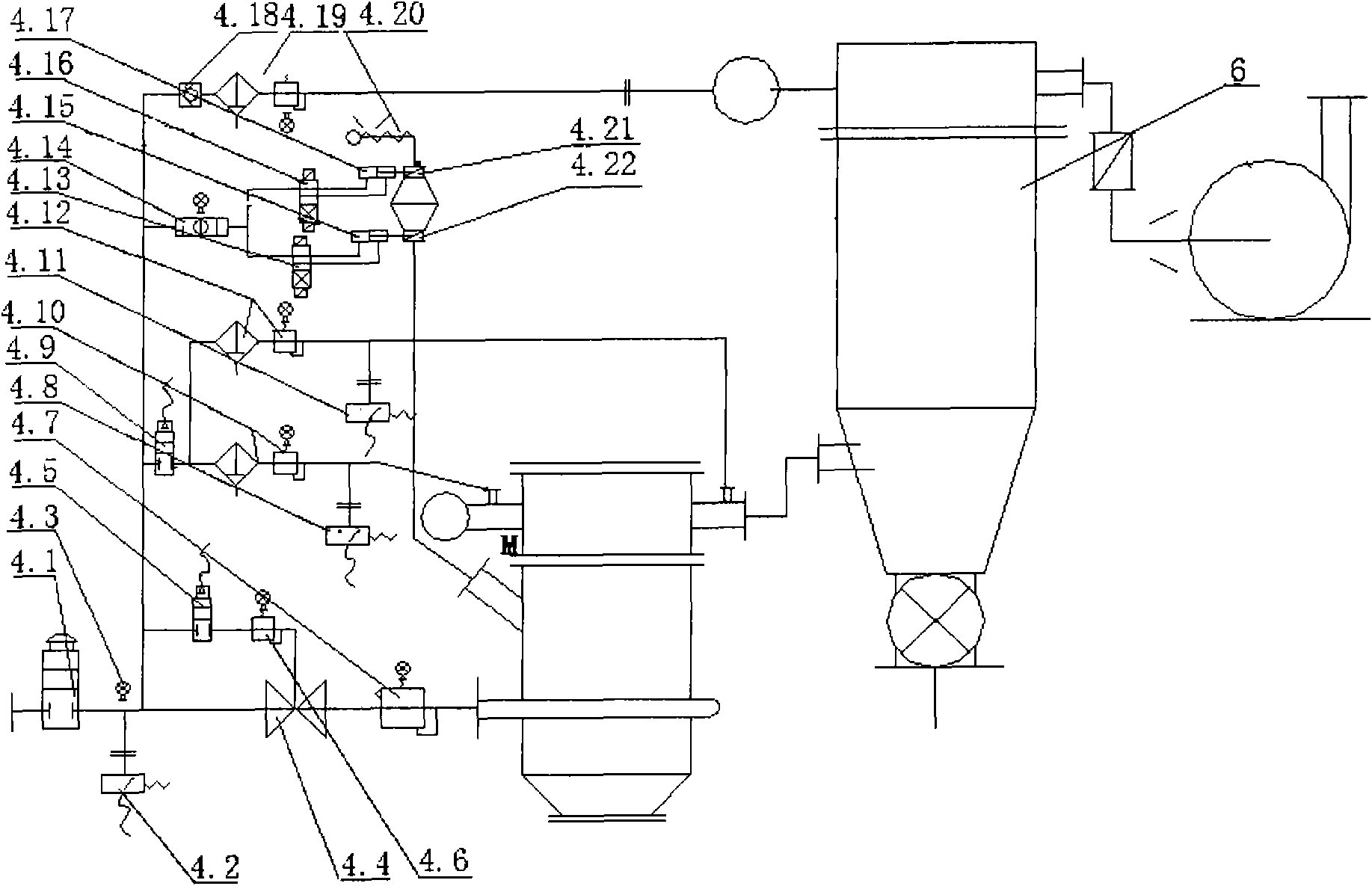

[0030] Such as figure 1 , 2 As shown, the ultrafine powder processing device includes an airflow crushing mechanism 1, a turbine classifying mechanism 2, a screw feeder 3, an automatic bagging machine 4, an automatic controller 5, a bag filter 6, an integrated platform 7, and an induced draft fan 8 and air path controller 9. Airflow crushing mechanism 1, turbine classifying mechanism 2, screw feeder 3, automatic bagging machine 4, bag filter 6, induced draft fan 8 and air circuit controller 9 are all integrated on the integrated platform 7; With a movable pulley, the entire ultrafine powder processing device can rely on the pulley to adjust its position according to the production needs of the factory. Among them, the airflow milling mechanism 1 is connected with the turbine classifying mechanism 2 through a flange, and is located below the turbine classifying mechanism 2; the feeding port of the screw feeder 3 is connected with the feeding cone pipe 1.3 in the airflow milli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com