Chip plastic package structure manufacturing method

A manufacturing method and chip technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of high manufacturing cost and low cost, and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In order to enable those skilled in the art to understand the present invention in more detail, the present invention will be described in detail below in conjunction with the accompanying drawings.

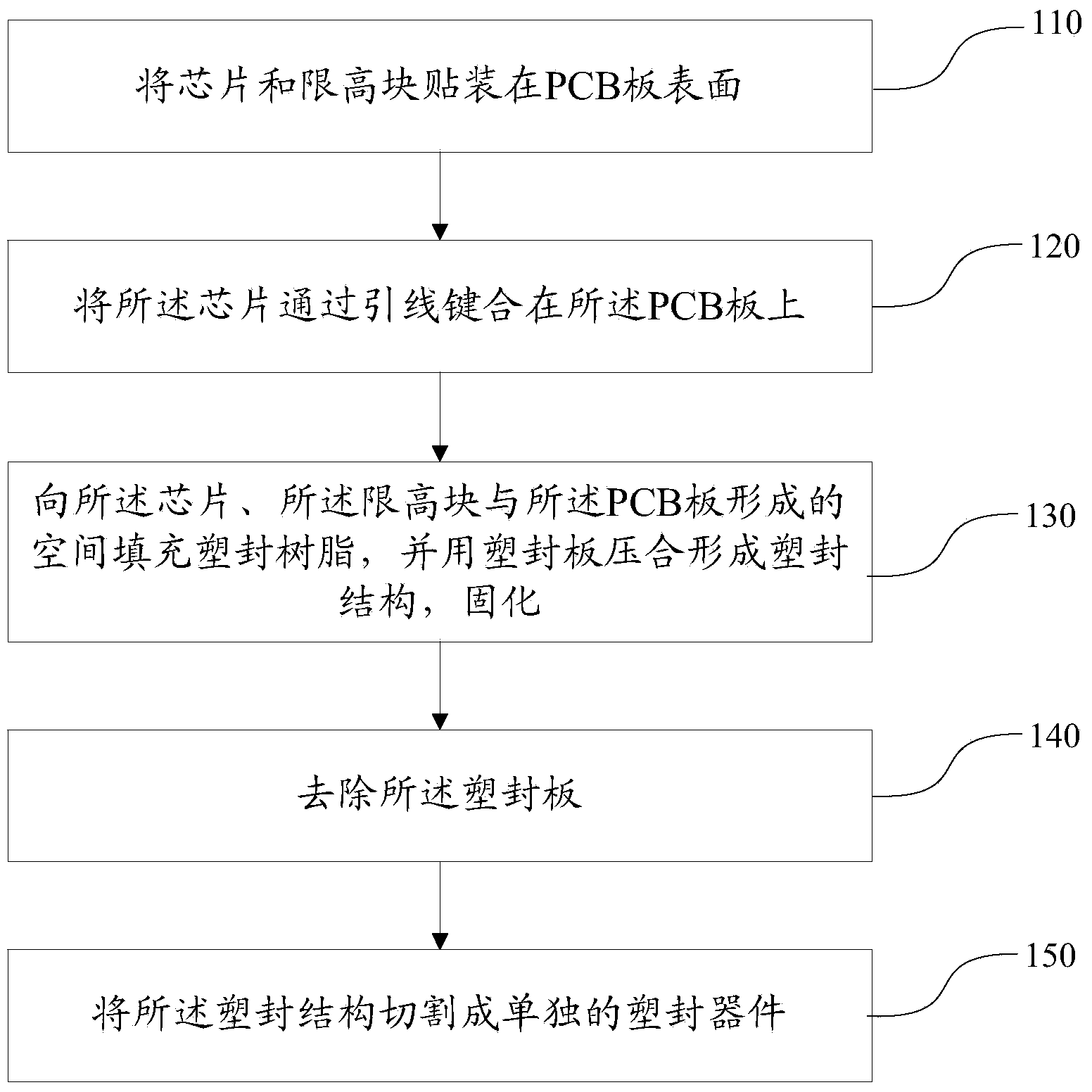

[0033] Such as Figure 2-6 As shown, the embodiment of the present invention also provides a method for manufacturing a chip plastic package structure, the method comprising:

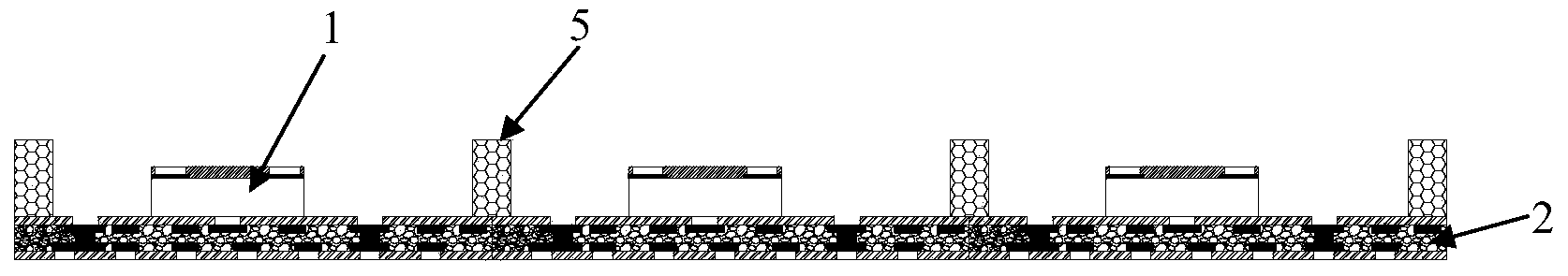

[0034] Step 110: mount the chip 1 and the height limiting block 5 on the surface of the PCB board 2;

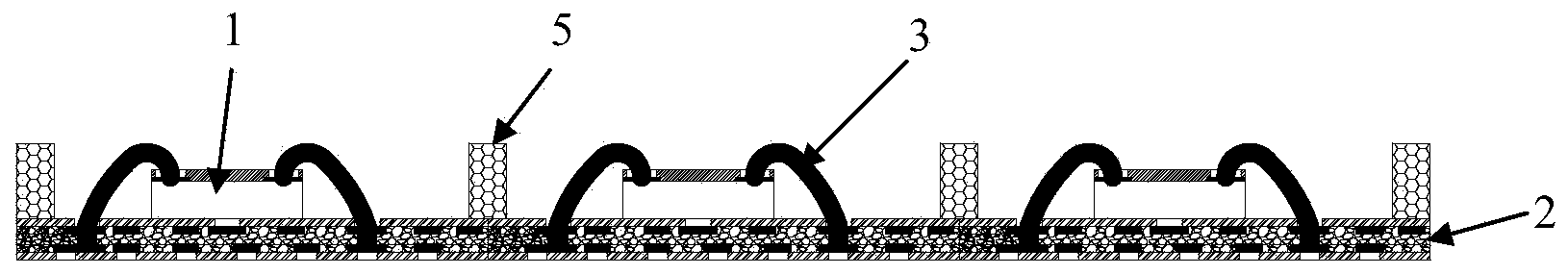

[0035] Step 120: bonding the chip 1 on the PCB 2 through the wire 3;

[0036] Step 130: Fill the space formed by the chip 1, the height limiting block 5 and the PCB board 2 with a plastic sealing resin 4, press the plastic sealing plate 6 to form a plastic sealing structure, and cure;

[0037] Step 140: removing the plastic sealing plate 6;

[0038] Step 150: Cut the molded structure into individual molded devices.

[0039] Further, filling the molding resin in step 130 also includes:

[0040]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com