Patents

Literature

36 results about "Form constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A form constant is one of several geometric patterns which are recurringly observed during hallucinations and altered states of consciousness.

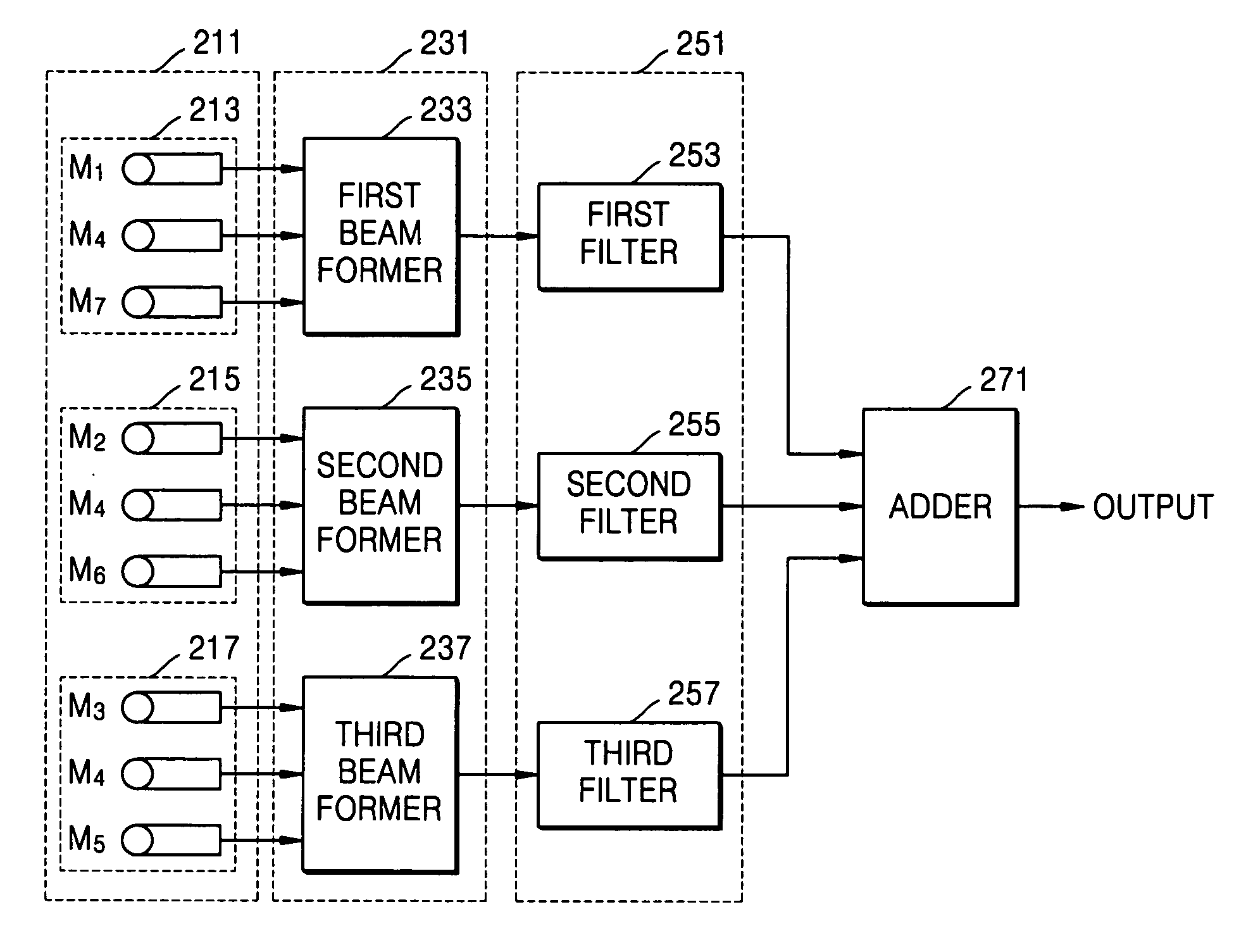

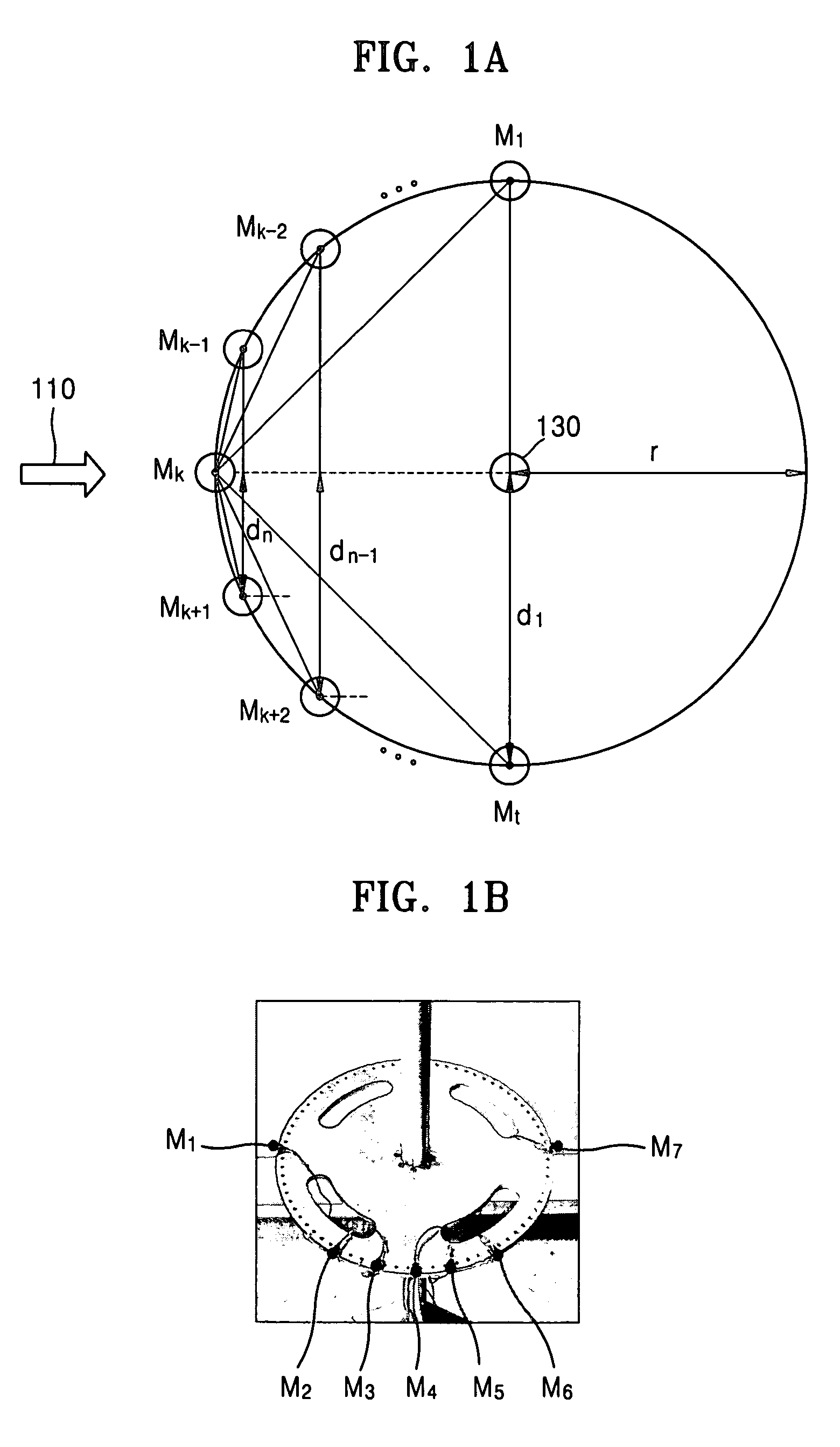

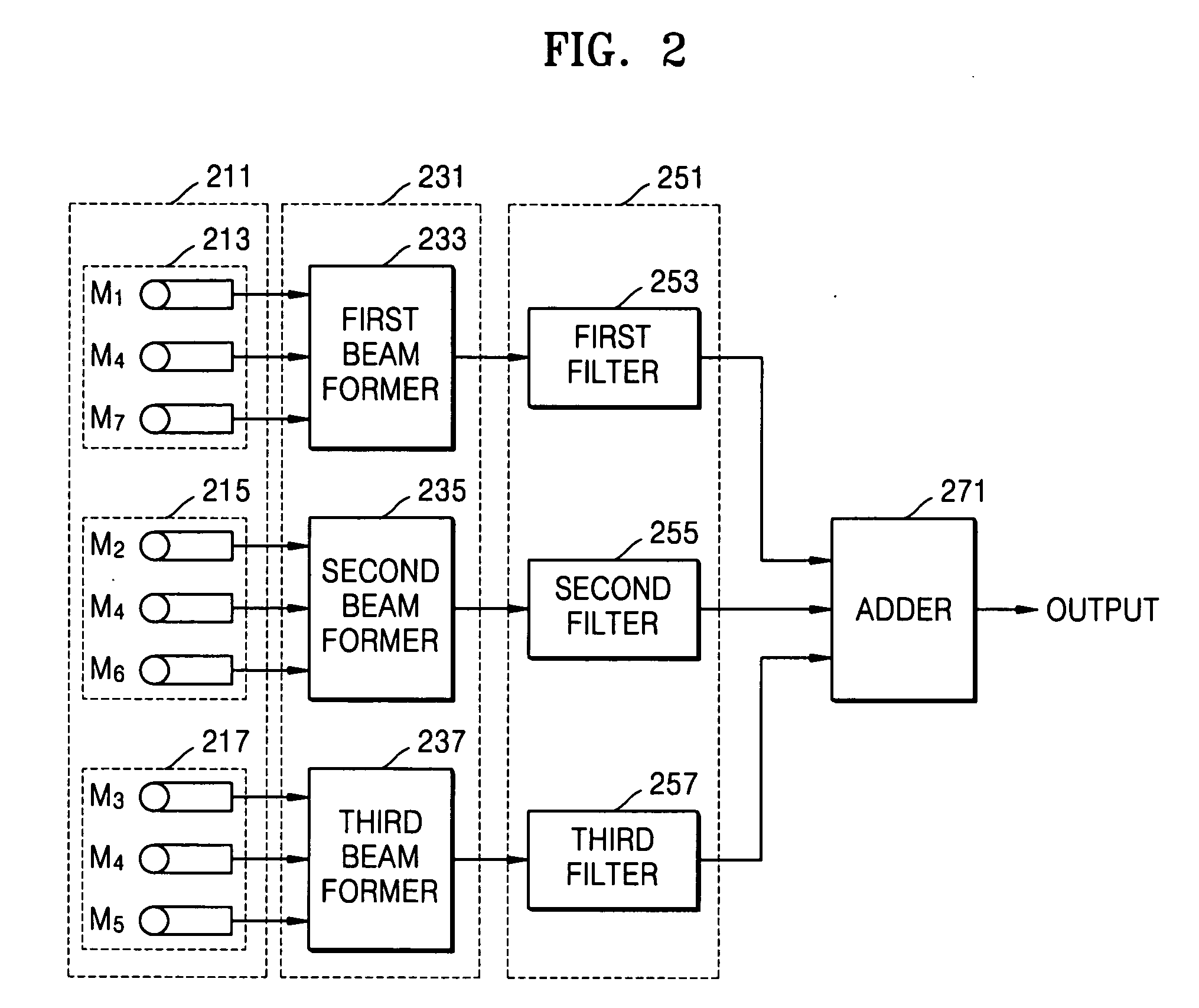

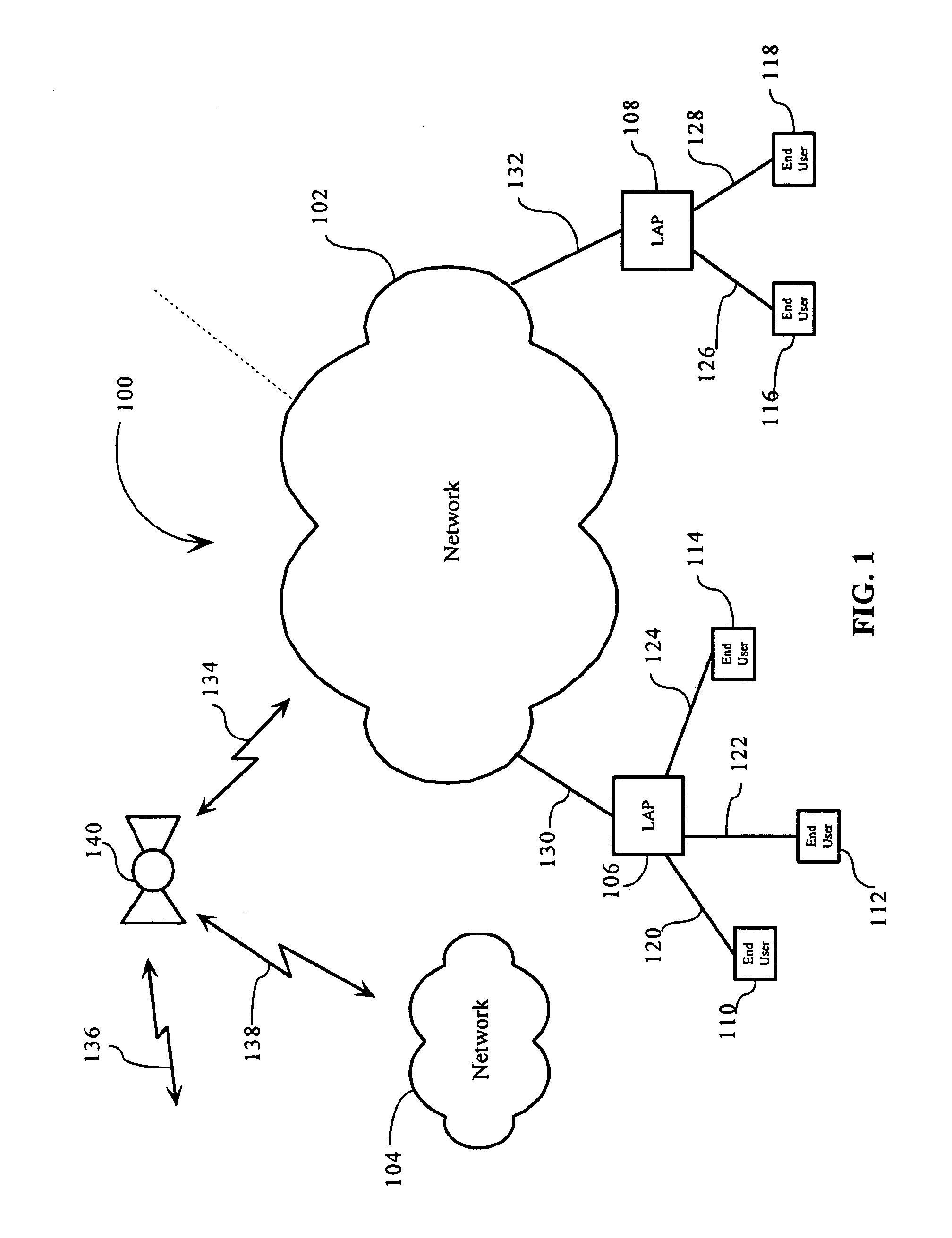

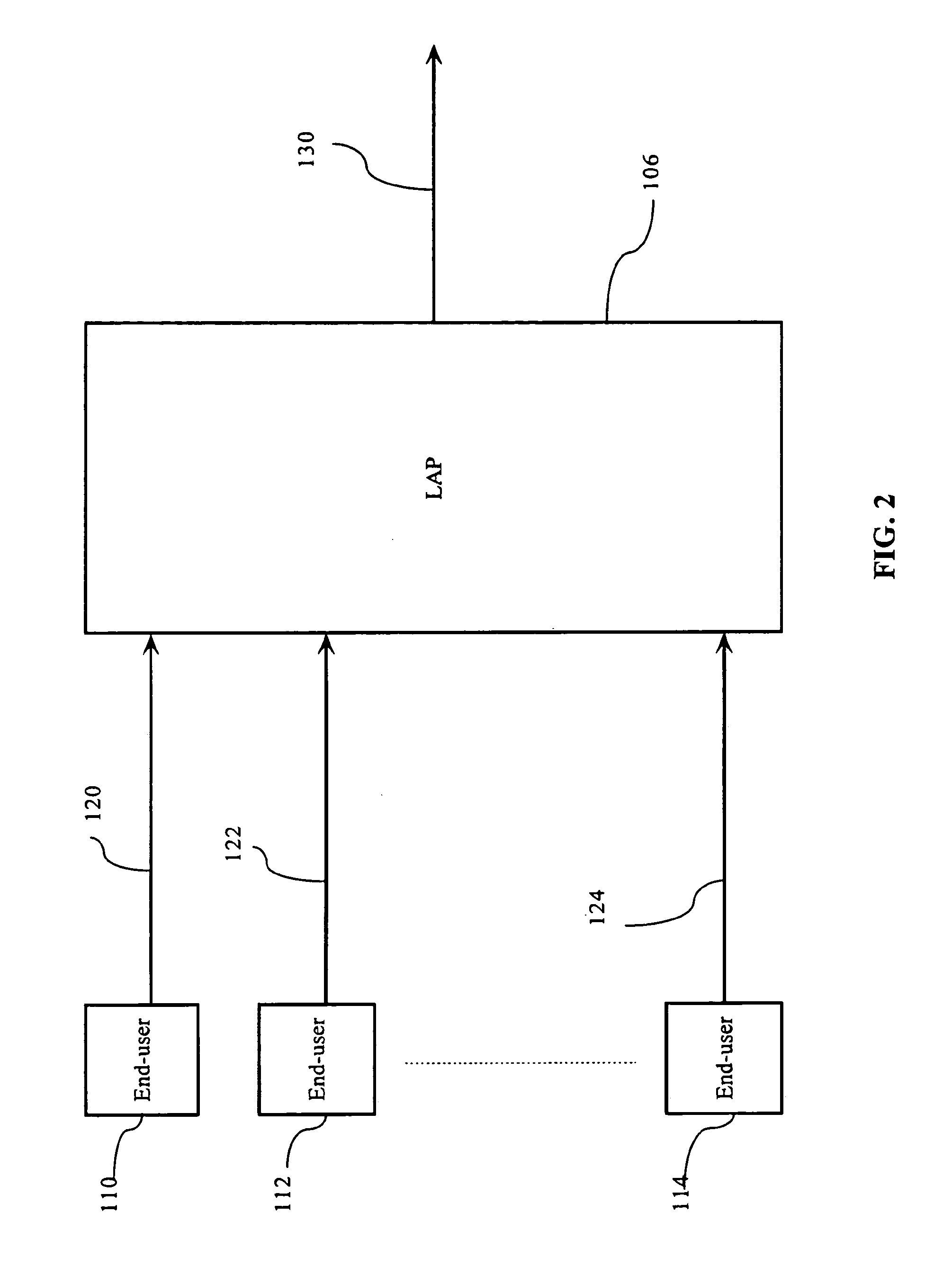

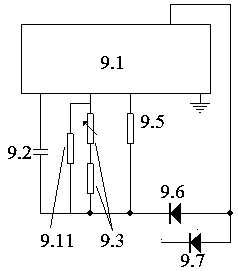

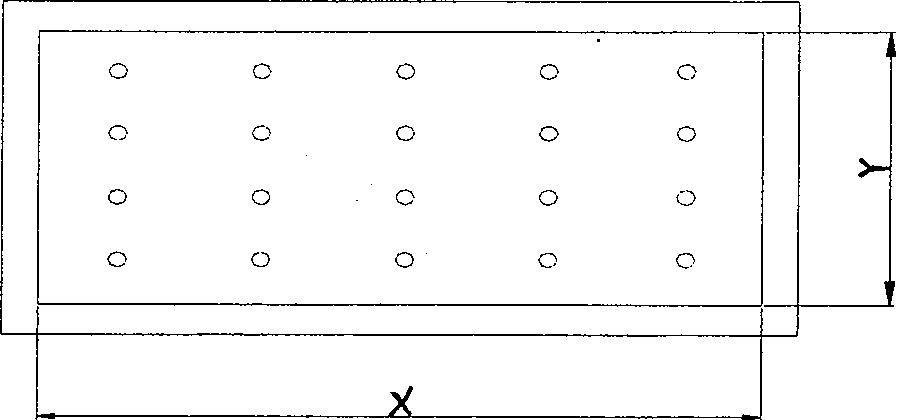

Microphone array, method and apparatus for forming constant directivity beams using the same, and method and apparatus for estimating acoustic source direction using the same

A microphone array, beam forming method and apparatus using the microphone array, and a method and apparatus for estimating an acoustic source direction using the microphone array are provided. The apparatus for forming constant directivity beams comprising: a microphone array, which is comprised of first through n-th microphone sub-arrays, wherein each of the microphone sub-arrays comprises: a first microphone placed at a predetermined location on a flat plate, which commonly belongs to each of the microphone sub-arrays; and second and third microphones placed at locations perpendicularly spaced by a predetermined segment from a straight line connecting the first microphone and the center of the flat plate, the predetermined segment being determined depending on a target frequency allotted to reach of the microphone sub-arrays, a beam formation unit receiving voice signals output from the first through n-th microphone sub-arrays and generating a beam for each of the first through n-th microphone sub-arrays; a filtering unit filtering the beams output from the beam formation unit; and an adding unit adding the filtered signals output from the filtering unit.

Owner:SAMSUNG ELECTRONICS CO LTD

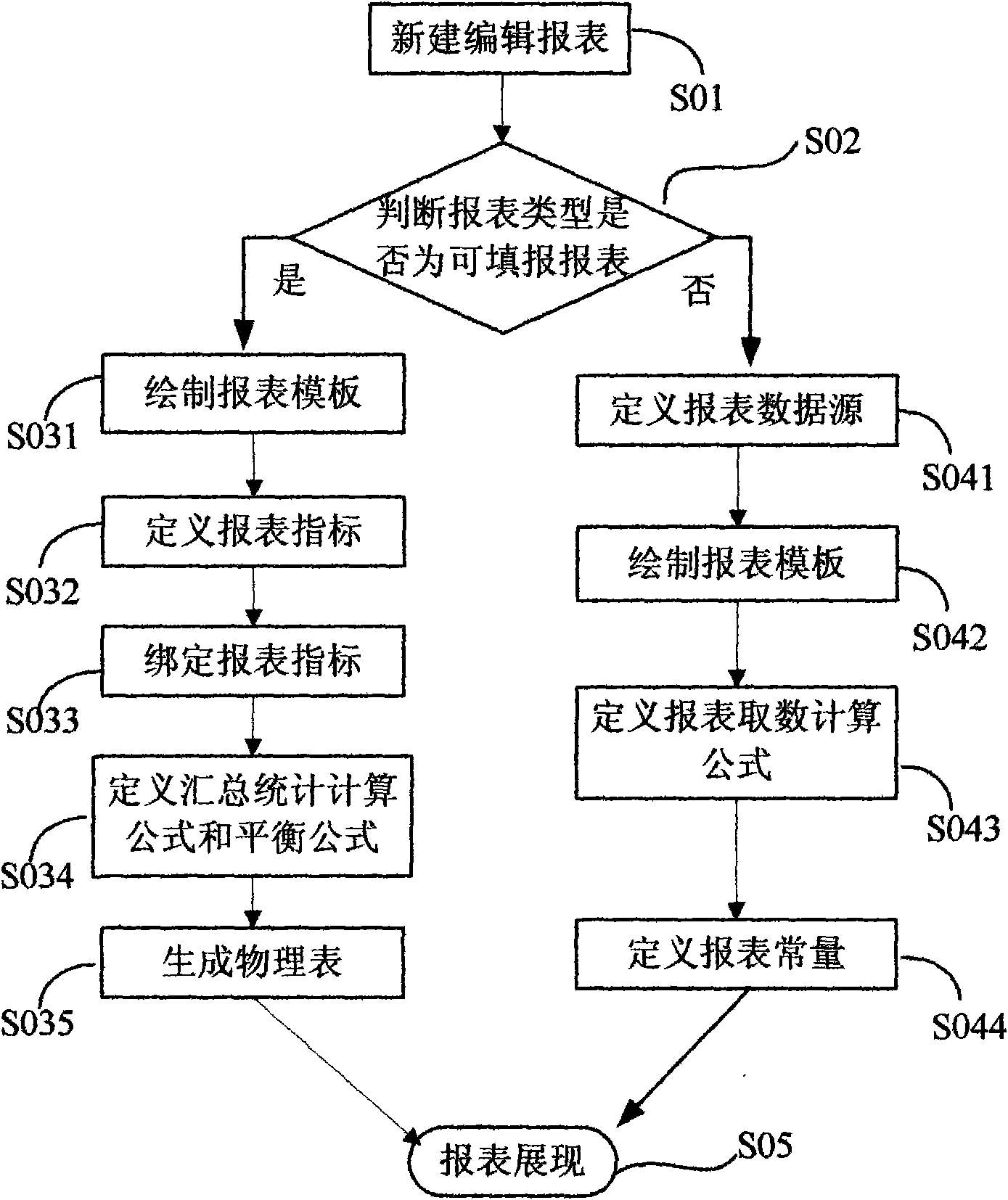

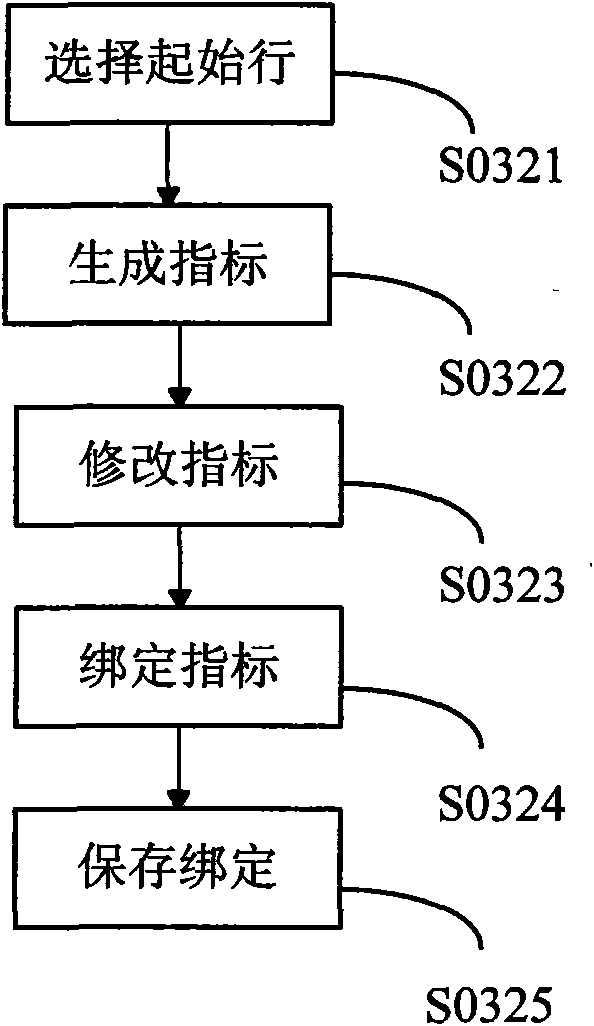

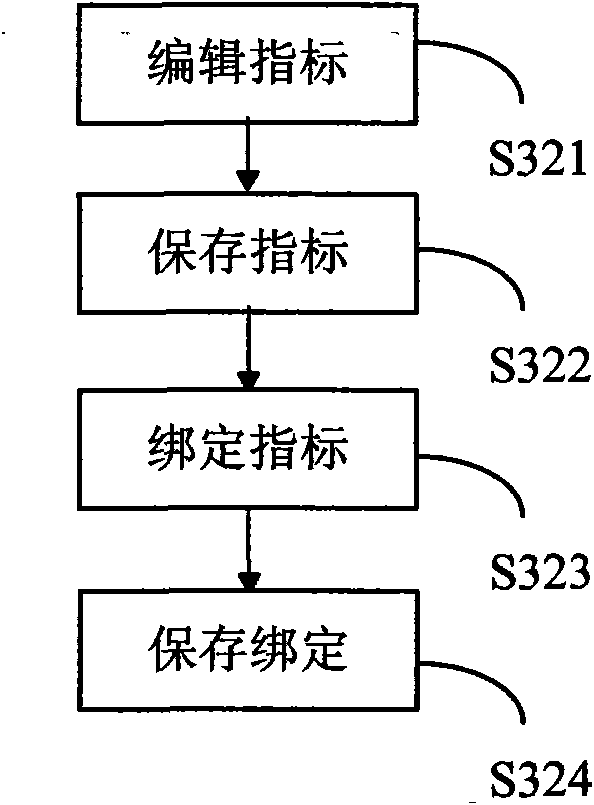

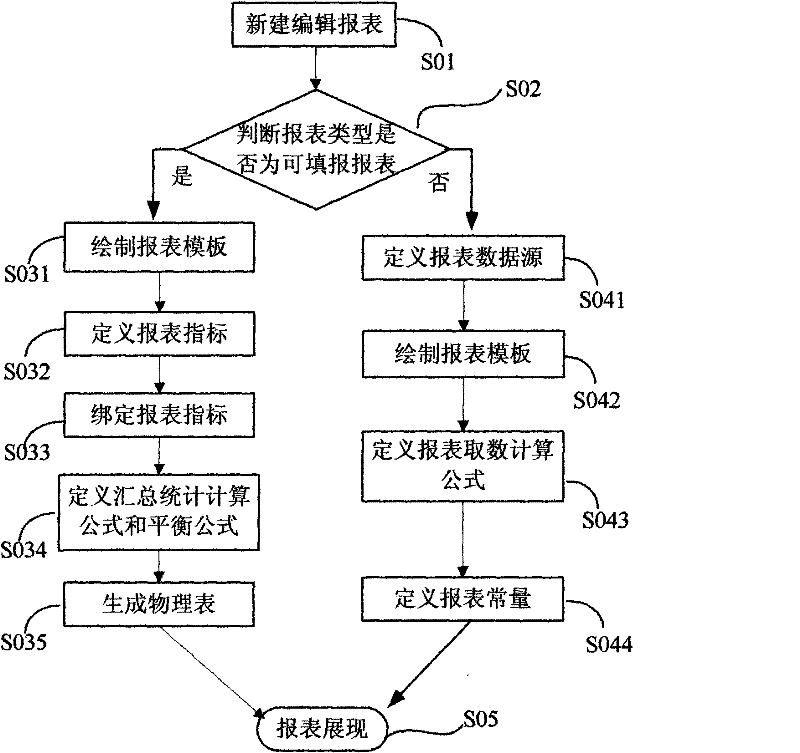

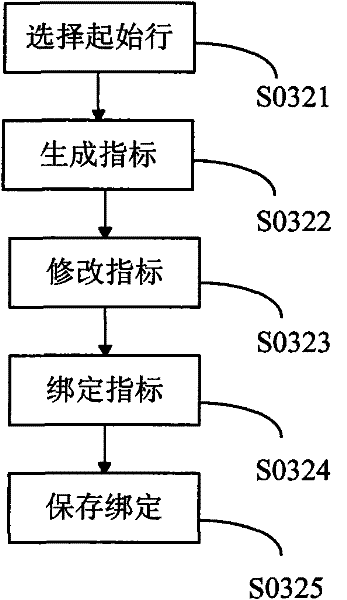

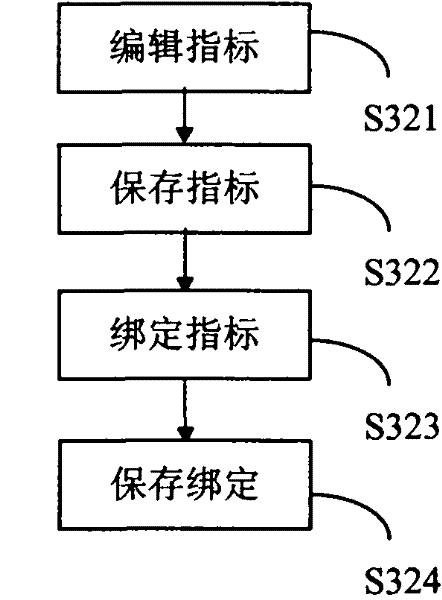

Method of self-customizing report forms for users

InactiveCN101599067ASolve problems that cannot be customized by usersTroubleshoot custom reportsSpecial data processing applicationsForm constantForm analysis

The invention discloses a method of self-customizing report forms for users, comprising the following steps: A, establishing a new report form and selecting the type of the report form; B1, if the selected report form type is a report form in which an user can fill and submit, drawing a report form template firstly and saving the report form template to a database after finishing drawing; then defining a report form index and binding the report form index and the table cell of the report form; and then defining a summary statistical formula and a calculation formula, carrying out summary statistical calculation according to the summary statistical formula and the calculation formula, showing the report form analysis; B2, if the selected report form type is a report form in which an user can not fill and submit, firstly defining a report form data source, drawing the report form template and saving the report form template to the database; and then defining a report form figure selection formula, a calculation formula, and a report form constant; finally, showing the report form analysis. The invention transforms the complex report form figure selection and formulas into a perceivable and understandable operation mode for users, so that the report forms can be self-customized by users.

Owner:广东金宇恒软件科技有限公司

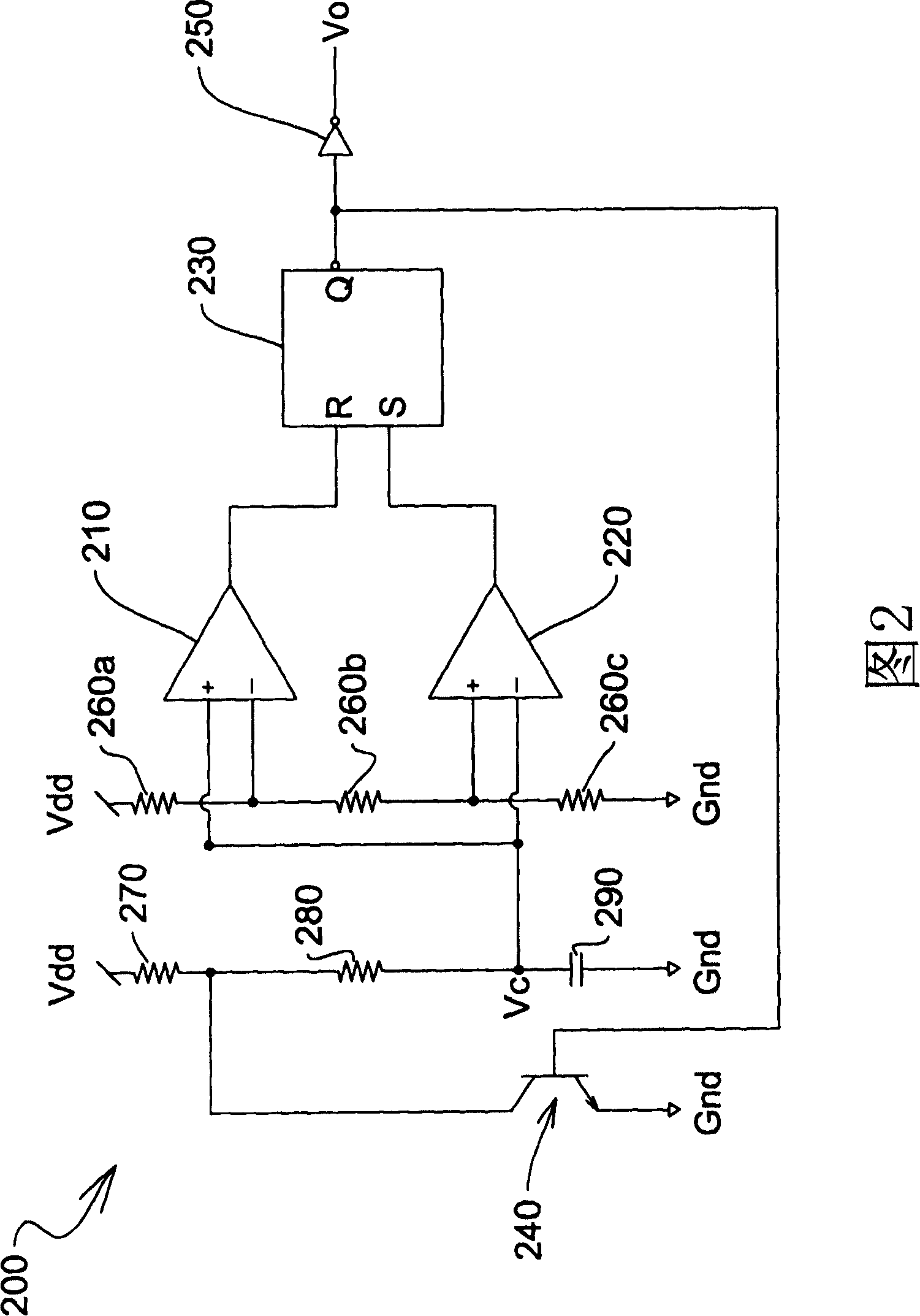

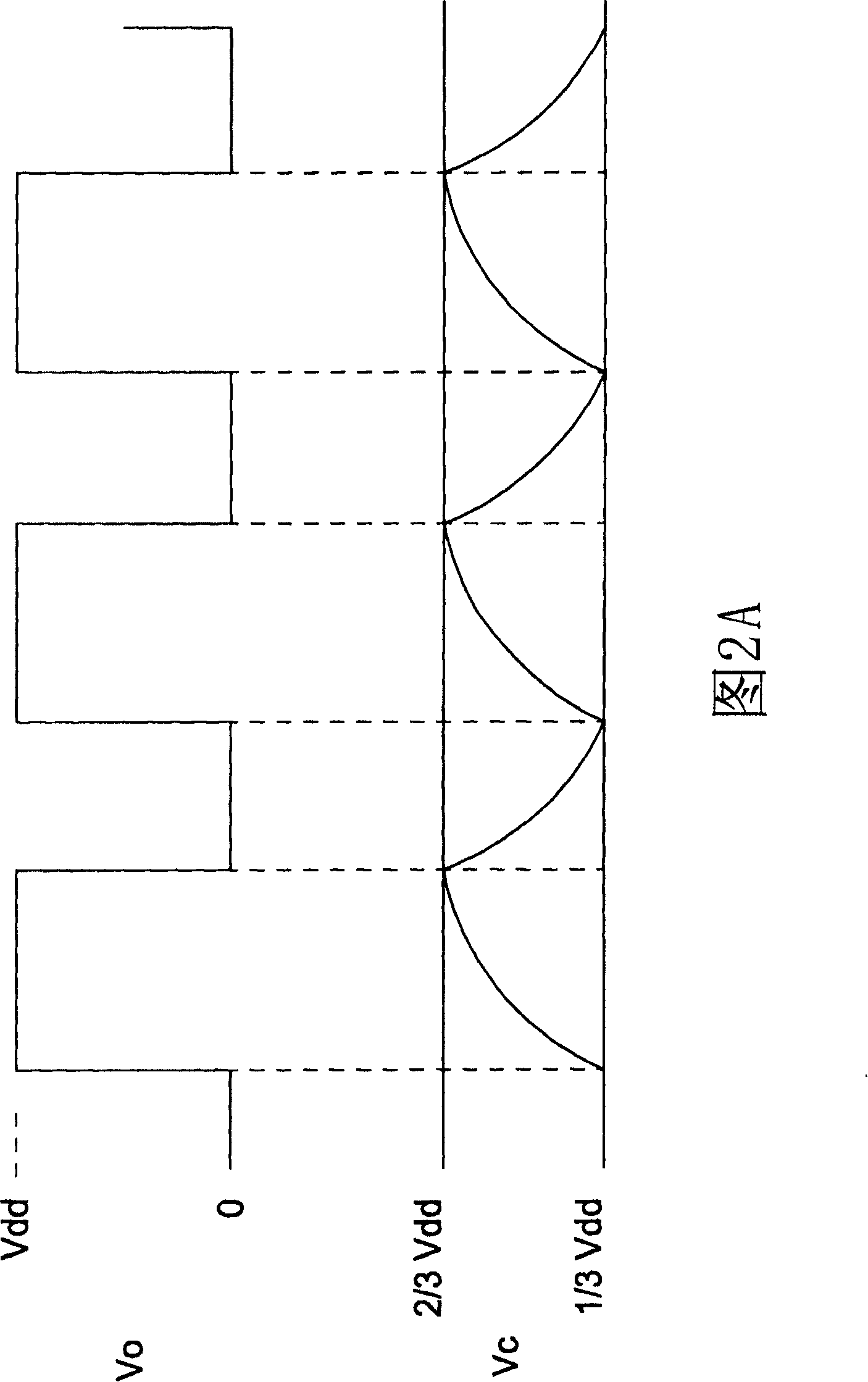

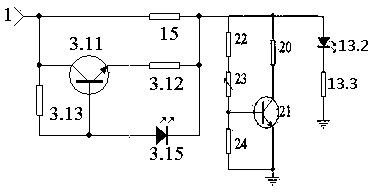

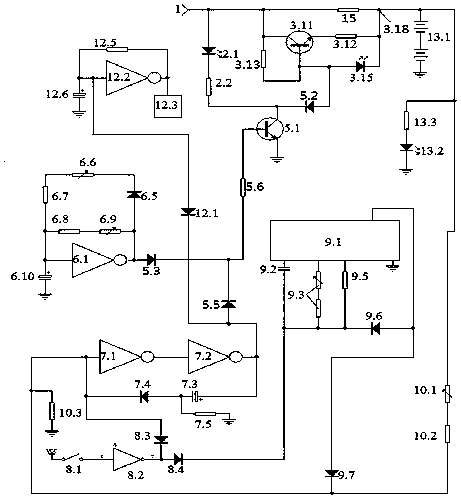

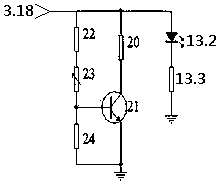

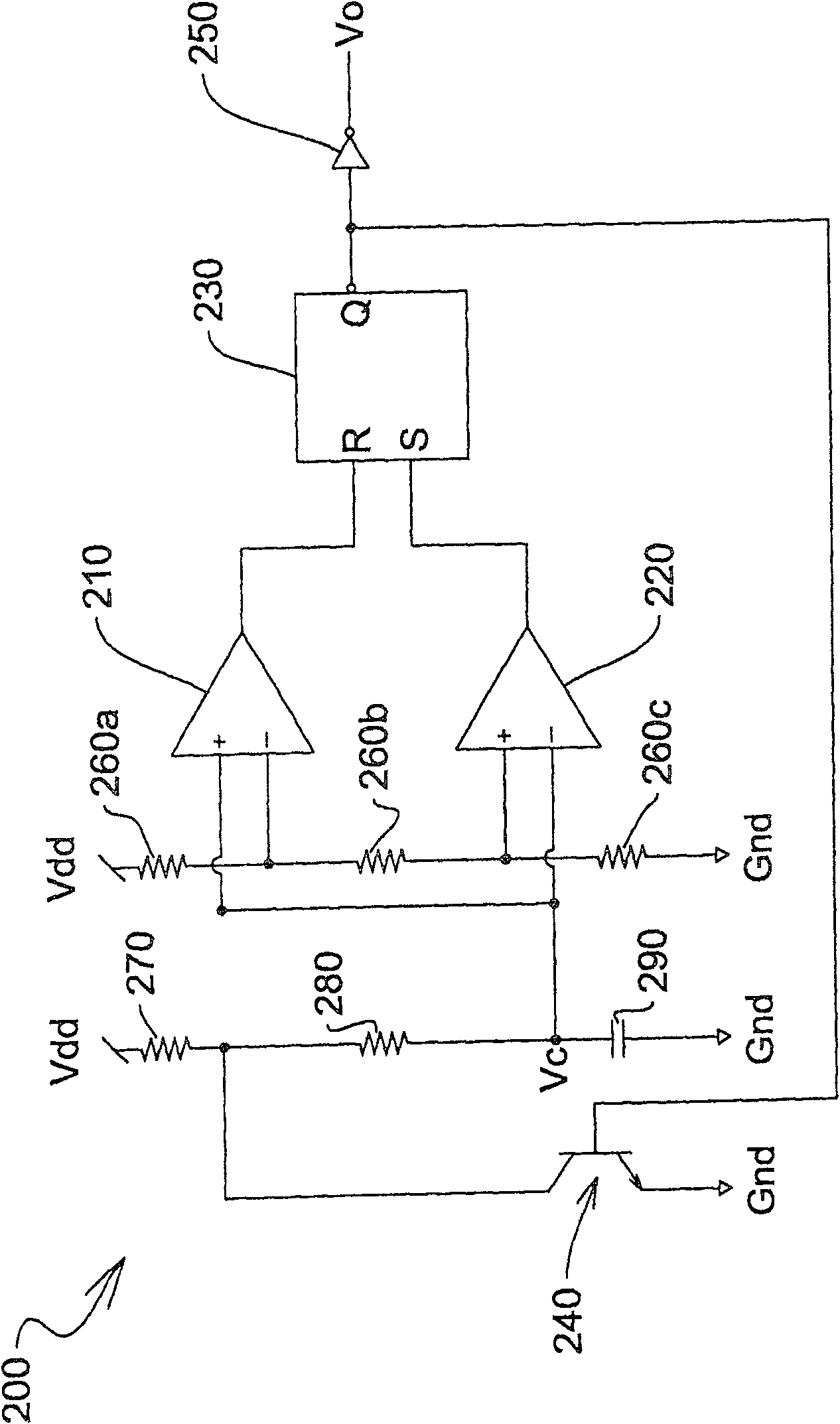

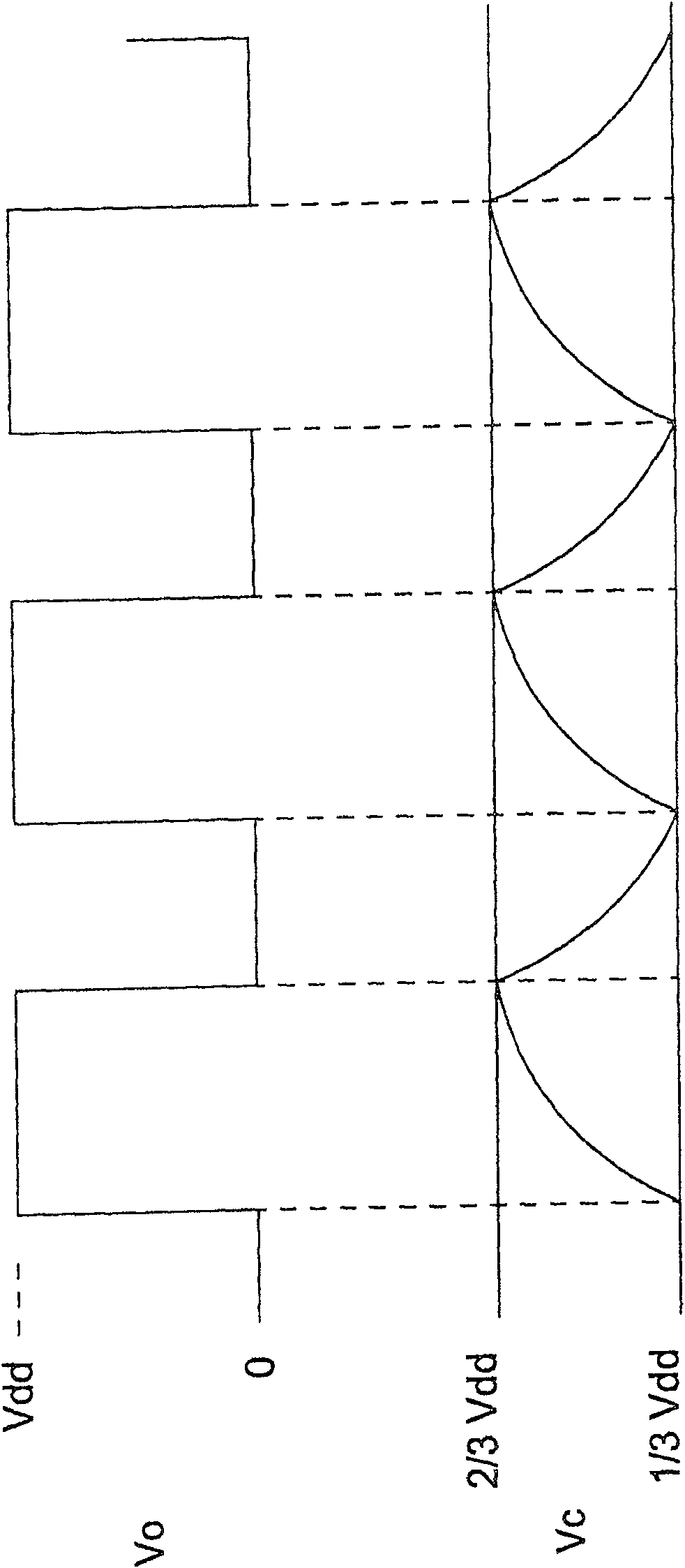

Stable oscillator without influence of temperature variation and power supply voltage variation

InactiveCN101179266AStable characteristicsMultiple input and output pulse circuitsOscillations generatorsVoltage referenceVoltage source

The invention provides a comparator for a oscillator circuit with a self bias reference voltage. The comparator includes: a depleted metal oxide semiconductor transistor network which forms constant current equivalent connection, wherein a gate electrode and a source electrode which belong to the depleted metal oxide semiconductor transistor are connected; a enhanced metal oxide semiconductor transistor network, wherein a drain electrode or a source electrode of the enhanced metal oxide semiconductor transistor is connected with the depleted metal oxide semiconductor transistor in series, and a gate electrode terminal can receive a input voltage. The comparator outputs a high level signal when the input voltage is lower than the reference voltage and a low level signal when the input voltage is higher than the reference voltage. Moreover, the oscillator circuit with the comparator ensures that the reference voltage is independent from changes of external voltage source and temperature.

Owner:G TIME ELECTRONICS

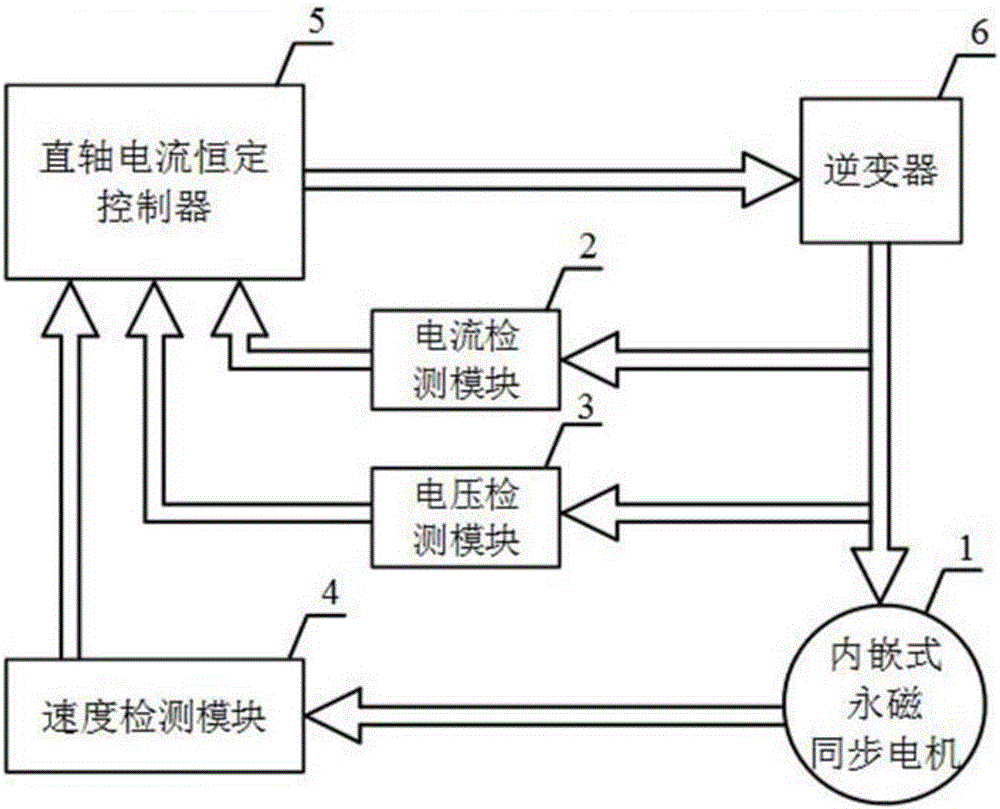

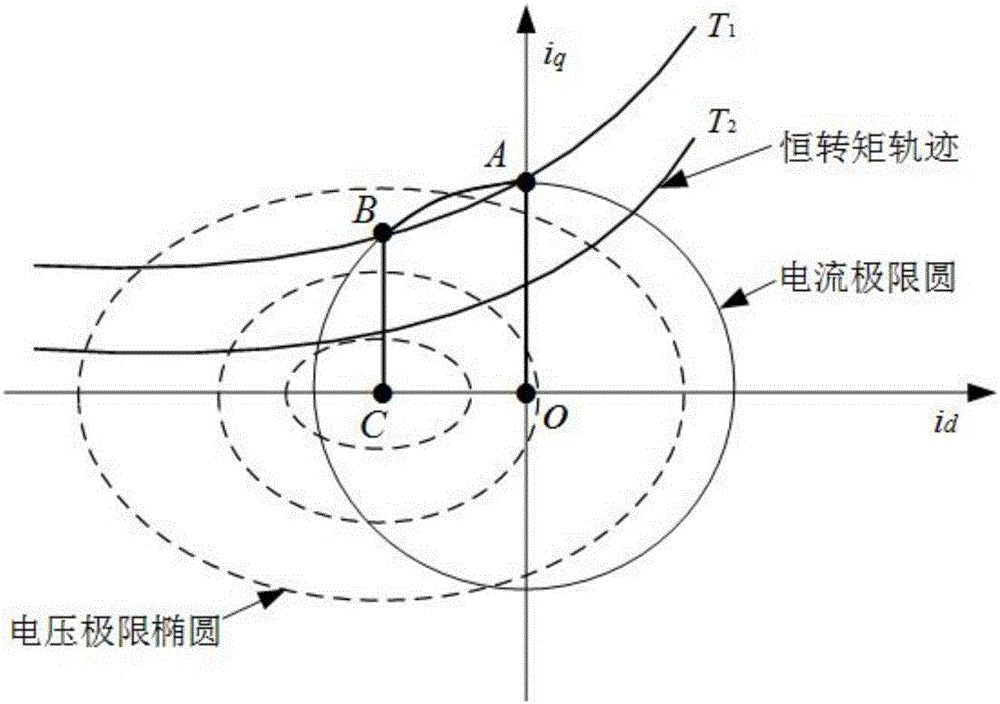

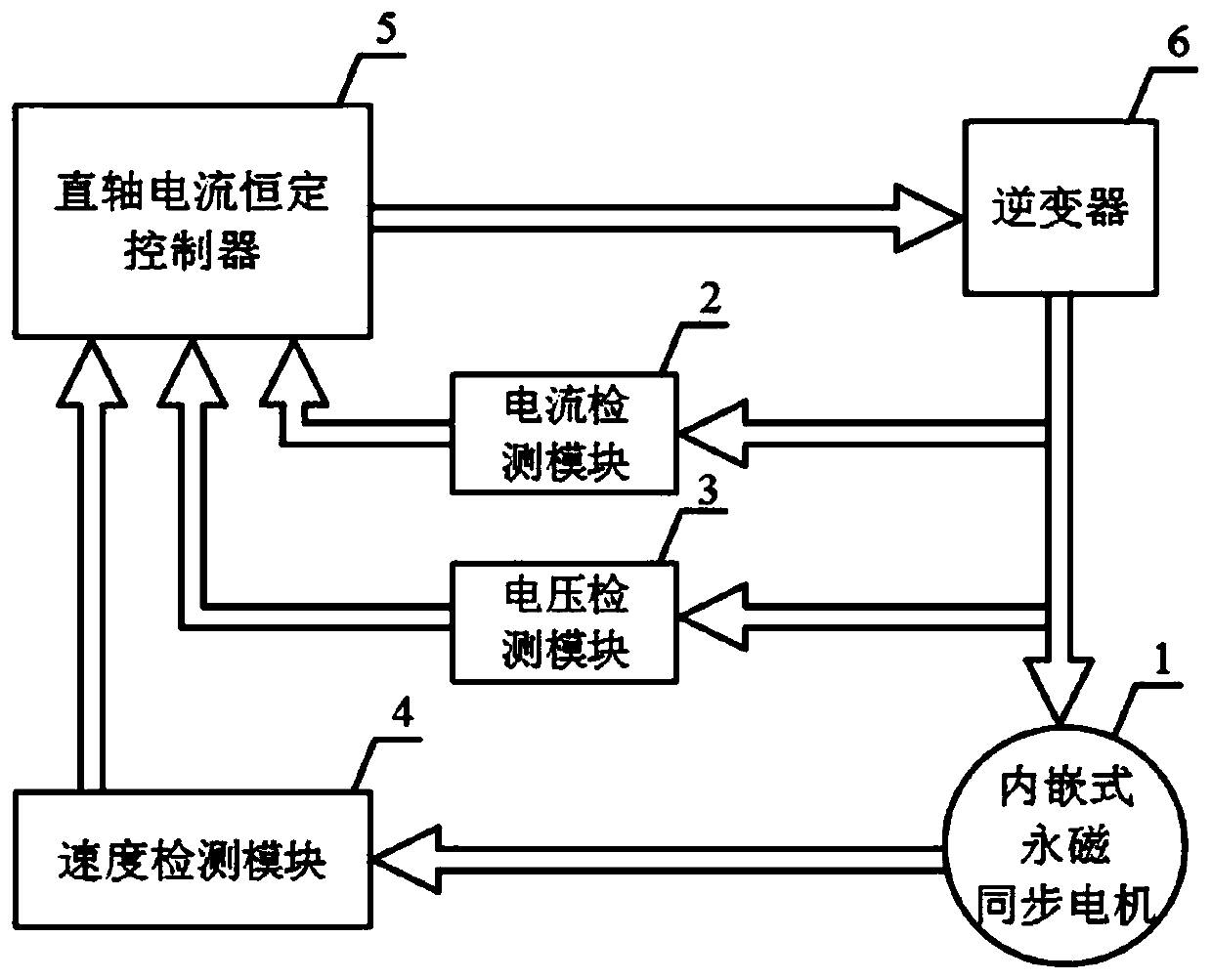

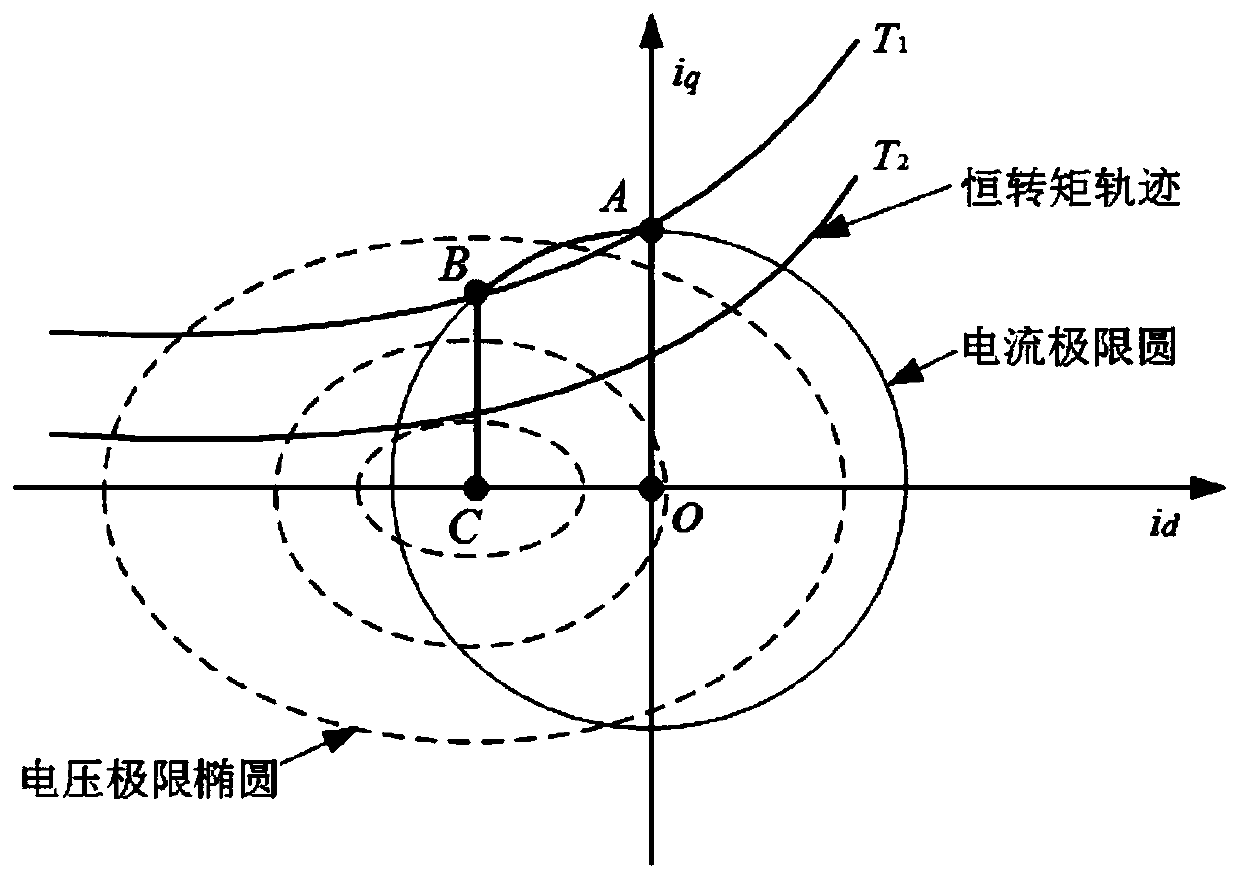

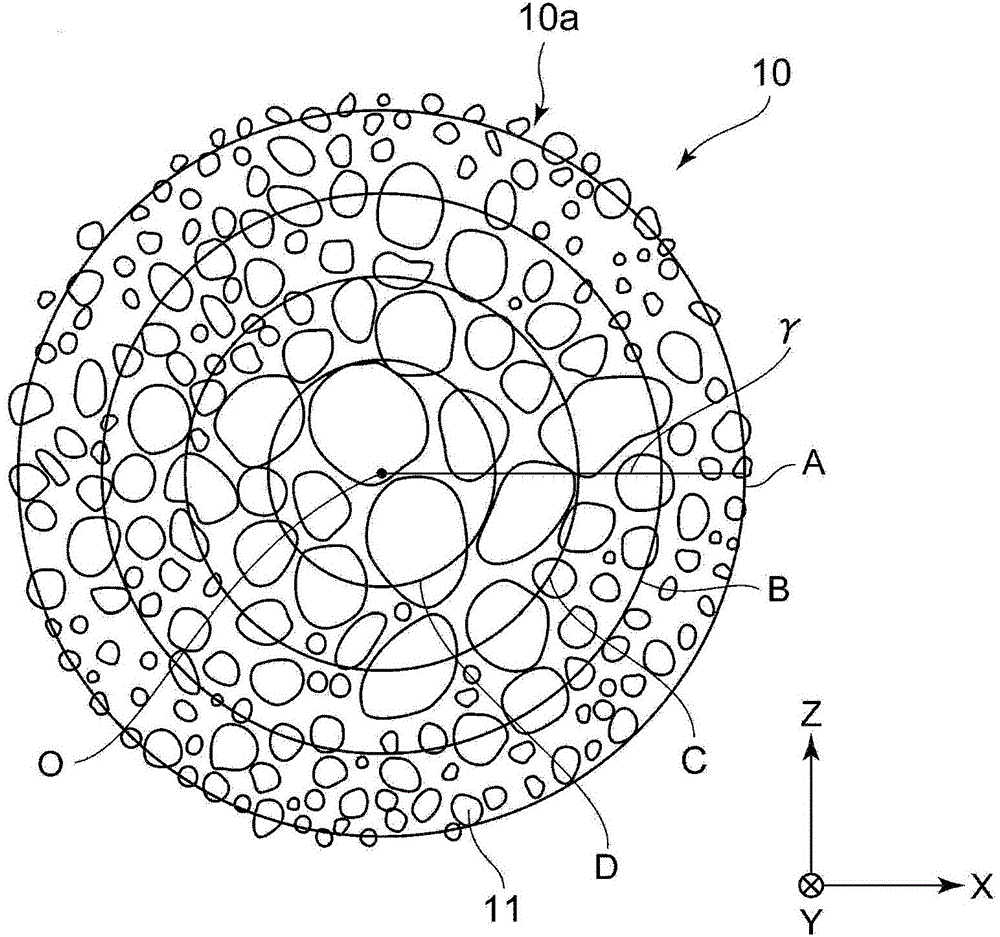

Constant direct-axis current control method and system of embedded permanent magnet synchronous motor

ActiveCN106301128ARealize linear controlAchieve unlimited speed controlElectronic commutation motor controlVector control systemsPhase currentsConstant power

The invention discloses a constant direct-axis current control method and system of an embedded permanent magnet synchronous motor, and belongs to the technical field of motors. According to the constant direct-axis current control method and system disclosed by the invention, a coordinate original point O and an intersection point A of a limited current circle and a quadrature-axis current form constant direct-axis current control of a constant torque output region, an intersection point of a straight line perpendicular to a direct-axis current and extending from a center C of a voltage limited oval of a control region of the embedded permanent magnet synchronous motor and a center point B of the voltage limited oval form constant direct-axis current control of a constant power output region, a phase current, a phase voltage and a rotational speed of the embedded permanent magnet synchronous motor are detected according to a target rotational speed of the embedded permanent magnet synchronous motor, and the embedded permanent magnet synchronous motor is driven to work by utilization of the constant and invariable direct-axis current and an inverse relation between the quadrature-axis current and the rotational speed of the motor. The constant direct-axis current control method and system have the characteristics of fast response speed, high reliability and no speed limit control, and have good application prospects in the fields of new energy automobiles and the like.

Owner:JIANGSU UNIV

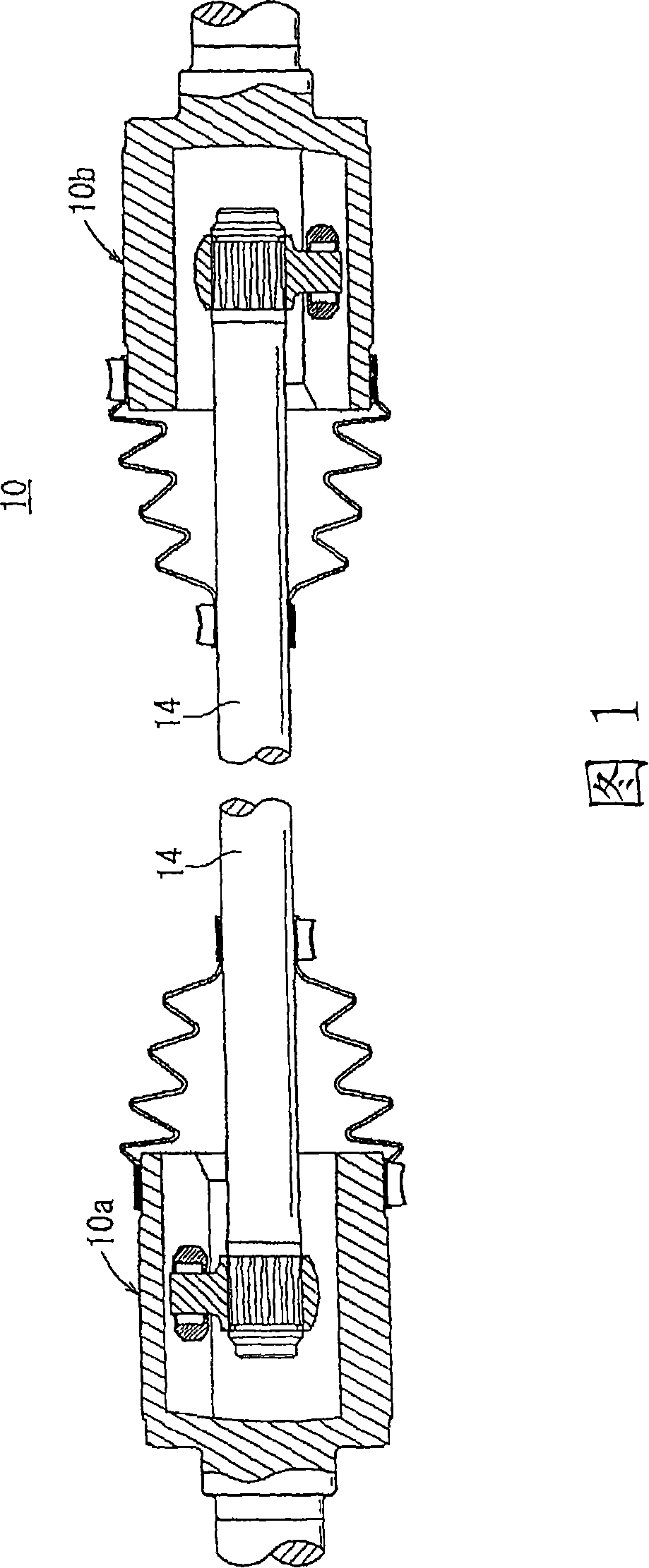

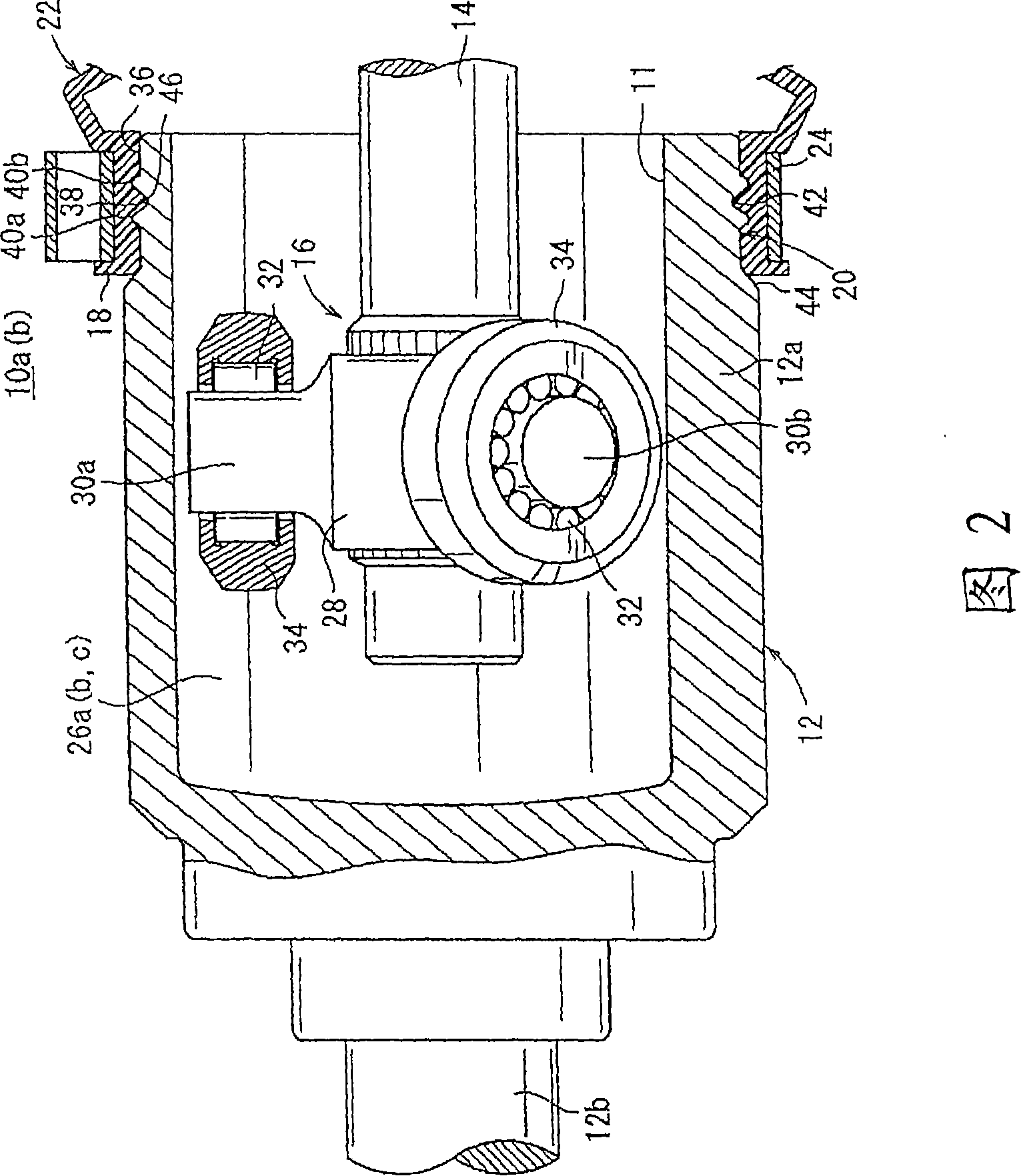

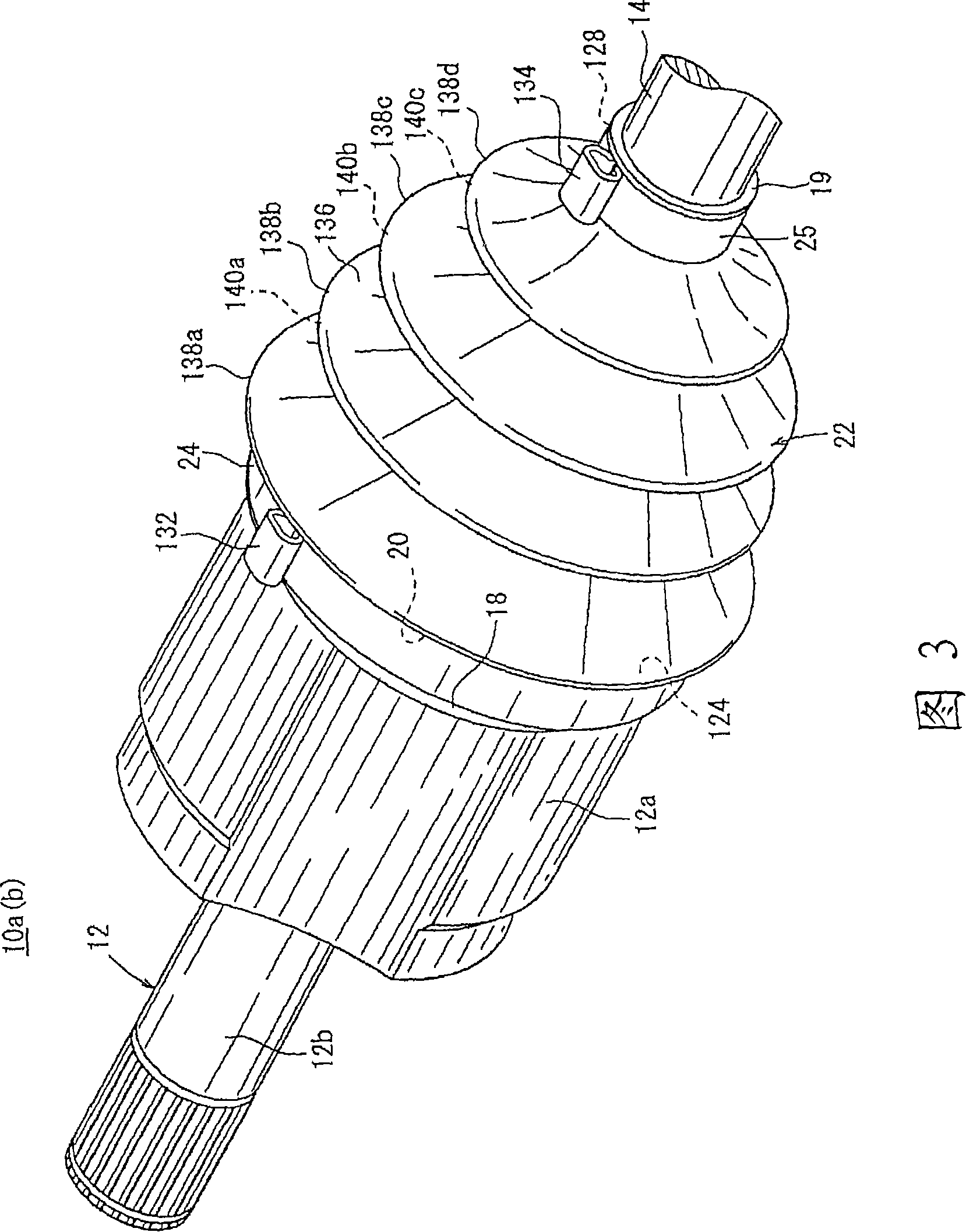

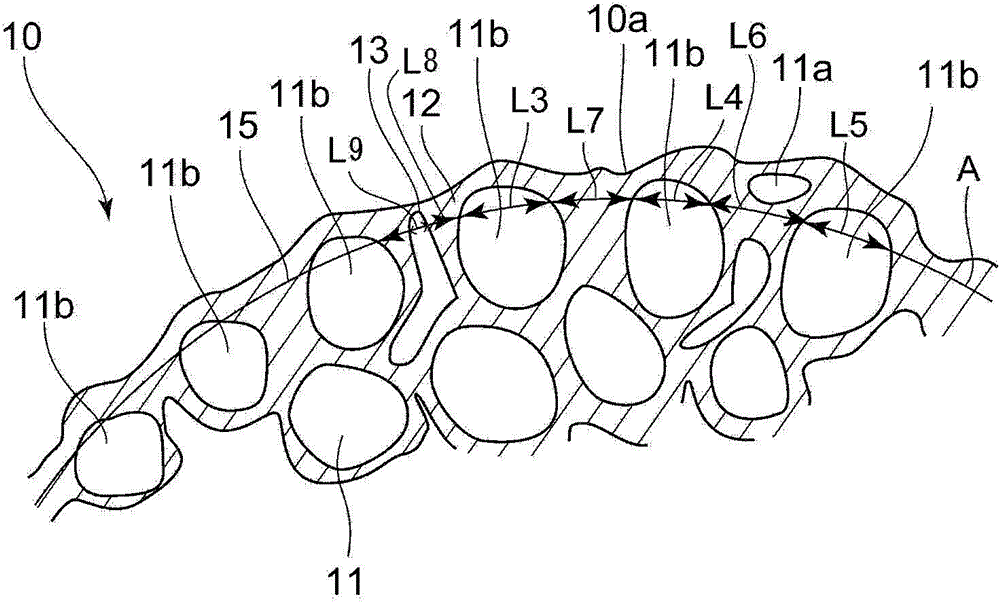

Rotation drive force transmission mechanism, constant velocity universal joint and resin joint boot constructing the mechanism, and method of tightening clamp band for constant velocity universal join

The present invention relates to a rotation drive force transmission mechanism (10), method for forming constant speed universal joint and resin joint covering as well as holding belt tensioning for the constant speed universal joint. Where tripod constant velocity universal joints (10a, 10b) are connected in phases opposite to each other to the ends of a shaft (14), and a boot (22) covers from an outer member (12) of each tripod constant velocity universal joint (10a, 10b) to the shaft (14). When a large diameter tube section (18) of the boot (22) is tightened around the outer member (12) by a first clamp band (24), a band tightening rate is controlled to be in a predetermined region. Further, the shape of a boot installation section (20) of the outer member (12) is formed so as to satisfy a predetermined relational expression.

Owner:HONDA MOTOR CO LTD

Strong wear-resistant arc spraying wire containing Ti(C,N) hard phase

InactiveCN101492801AImprove anti-corrosion performanceImprove wettabilityMolten spray coatingWear resistantMetallic substrate

The invention relates to a strong abrasion resisting electric arc spraying powder core wire containing Ti (C, N) hard phase and a preparation method thereof. The wire comprises the following powder core raw materials by mass percentage: 13-17% of Ti (C, N) powder, 16-20% of Cr powder, 17-23% of Cr2C3 powder, 9-13% of Ni powder, 1-3% of Mo powder, 15-17% of Si-Fe powder, and the rest being Mn-Fe powder. The preparation method comprises the following steps: (1) the powder core raw materials are weighed in proportion; (2) the powder core raw materials are mixed; (3) steel strips are used to wrap the mixed powder core raw materials to form thick wires; (5) the diameter of the thick wires is reduced grade by grade to form finished wire products. The wires can form constant dense protective coating on metal substrates by electric arc spraying, especially supersonic electric arc spraying, the protective coating has Ti(C, N)-based metal ceramic texture and performance, and has the characteristics of stainless steels, has higher hardness, red hardness, abrasion resistance, crater wear resistance and high pyrochemical stability, and is mainly used in surface protection for equipment such as boiler three pipes under high temperature and high abrasion and corrosion.

Owner:北京球冠科技有限公司

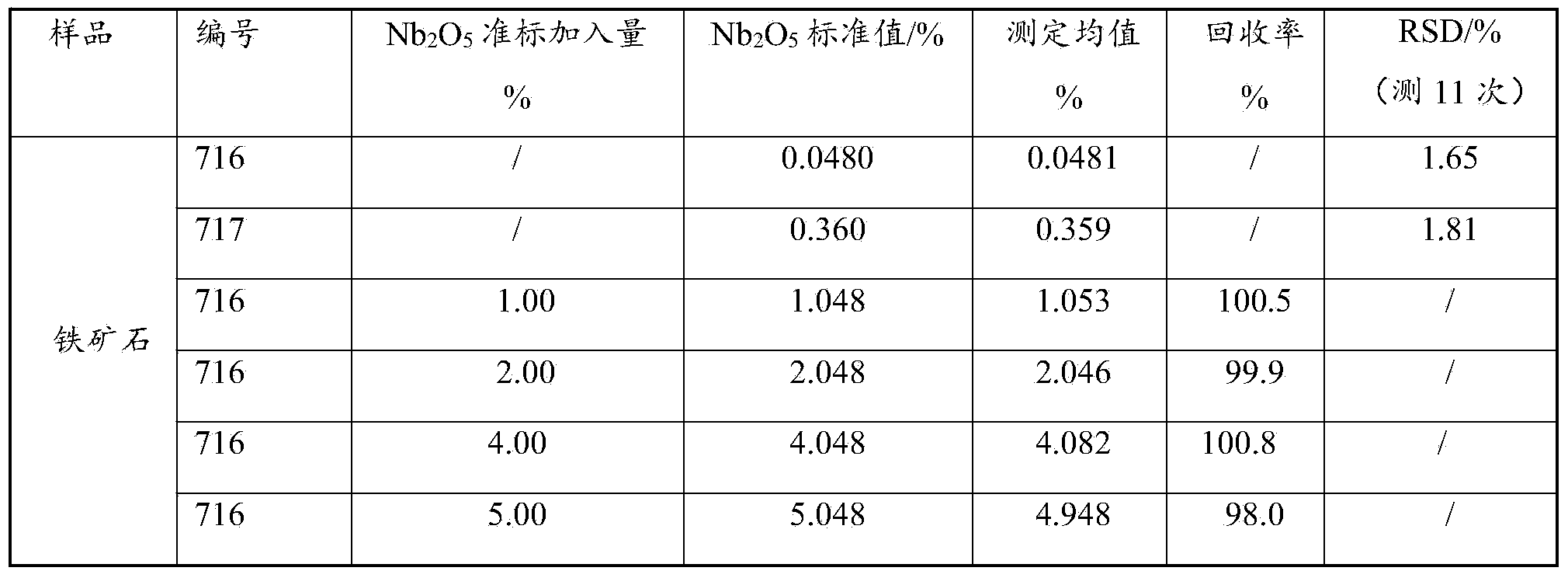

Method for measuring niobium content in iron ore

InactiveCN104237208ALow costEasy to operatePreparing sample for investigationAnalysis by thermal excitationIronstoneNiobium

The invention discloses a method for measuring niobium content in iron ore. The method comprises the steps as follows: an iron ore sample is weighed and fused by a mixed fusing agent; the sample is subjected to leaching by tartaric acid and hydrochloric acid at the low temperature and dissolved to form constant volume, and a to-be-tested liquid is shaken well; a niobium standard solution is adopted to prepare at least four working curve standard solutions for measuring the niobium content in a volumetric flask under the condition of selected same acid medium, and the niobium content of the to-be-tested liquid is in the working curve range; and a niobium 269.706 nm analytical spectral line is selected for measuring spectral line intensity of niobium in the working curve standard solutions and the to-be-tested liquid simultaneously on an inductive coupling plasma emission spectrometer, and an analysis result is obtained. According to the method for measuring the niobium content in the iron ore, the operation process is simple and fast, and accurate data can be provided for component control in the smelting process.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

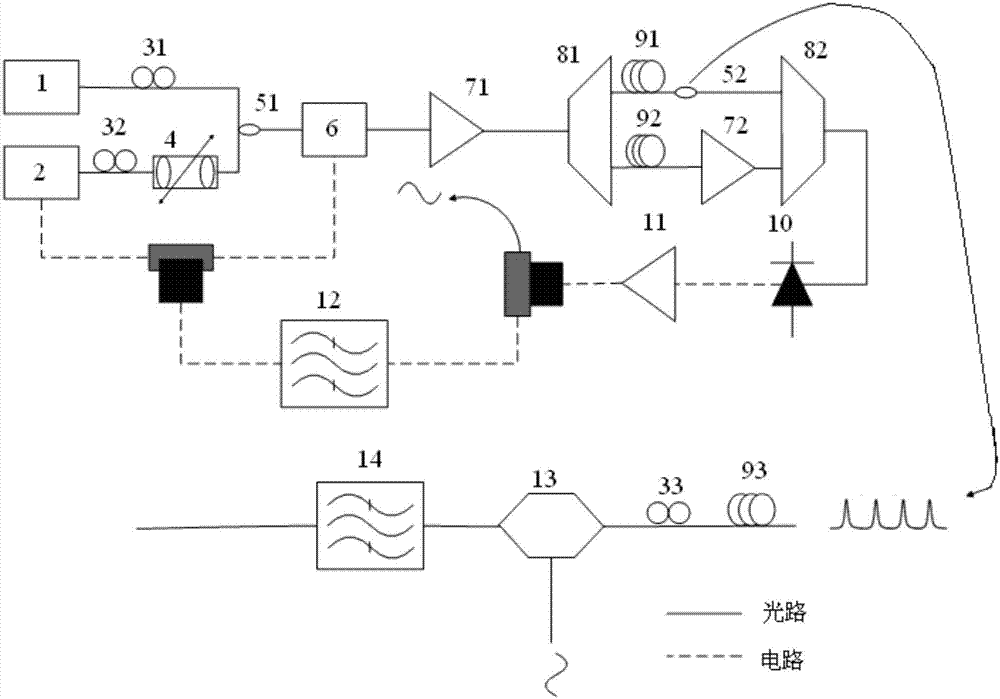

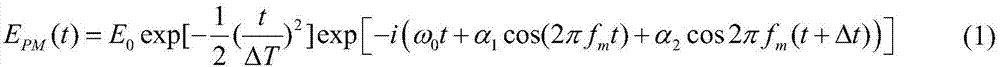

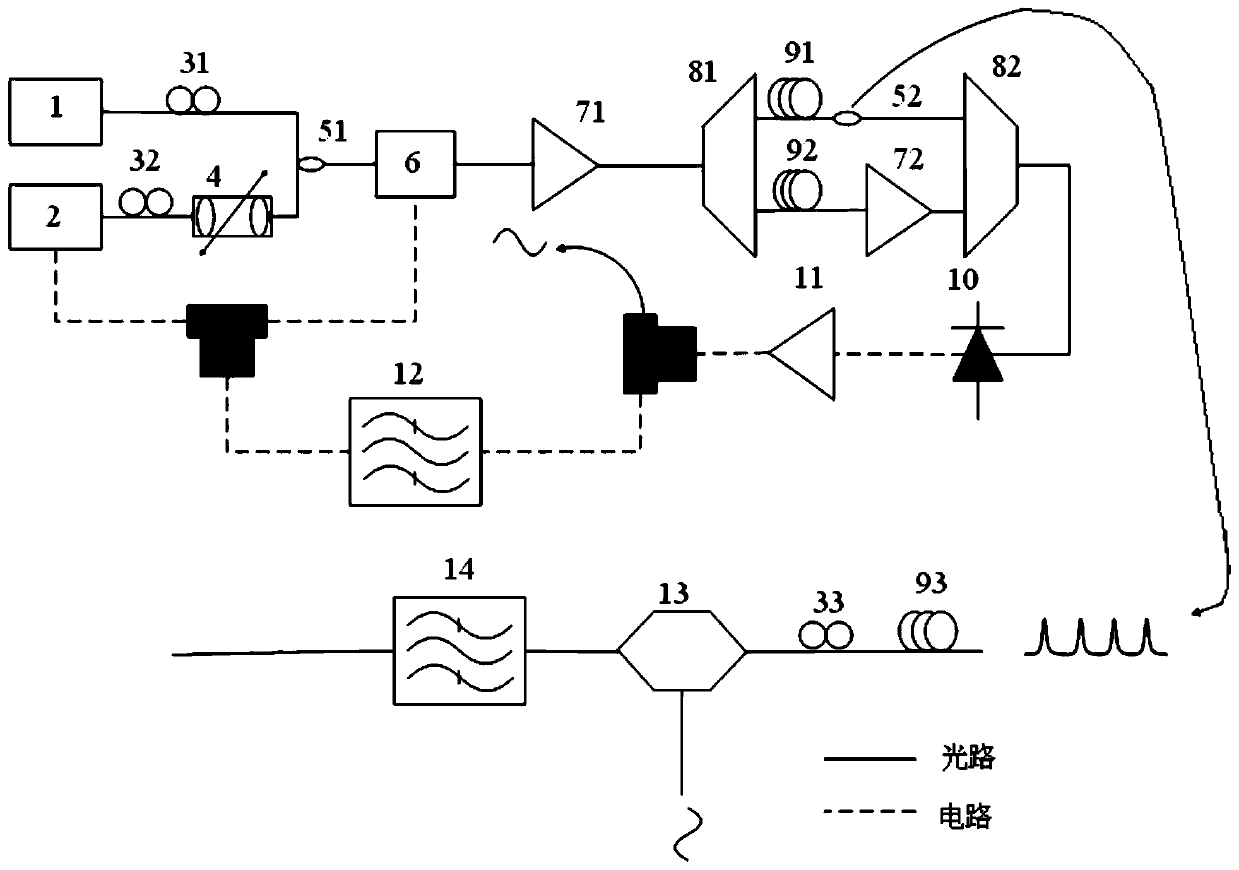

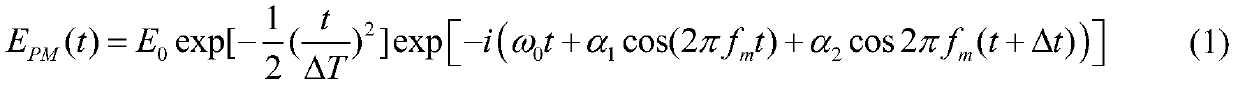

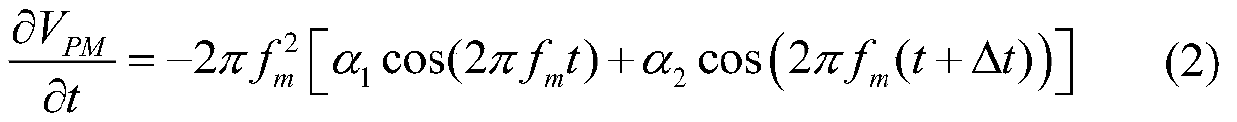

System and method for photon sampling based on OEO

InactiveCN107887783ASimplified generation structureReduce time jitterActive medium shape and constructionFiber chromatic dispersionPhase noise

The present invention discloses a system for photon sampling based on an OEO. The system for photon sampling based on the OEO comprises an optical narrow pulse source based on the OEO and a time domain Fourier transform system. The optical narrow pulse source based on the OEO is generated by a wavelength double-ring OEO structure, a directly modulated laser and a phase modulator are integrated into the wavelength double-ring OEO structure, microwave signals are generated by the OEO structure, the directly modulated laser is modulated to generate optical narrow pulses, the phase modulator is employed to broaden the pulse width to obtain wide-spectrum narrow pulses, and a long fiber dispersive medium is employed to perform dispersion walk-off of the narrow pulses to form constant-amplitude chirped narrow pulses and perform signal sampling. The system and the method employ a characteristic that the OEO structure directly generates signals with high repetition frequency and low phase noise, and combine the time domain Fourier transform system to simplify a production process and an optical serial-parallel converting process of the pulse source with a high repeat rate in photon samplingand have a characteristic of ultralow jittering. The system and the method for photon sampling based on the OEO can be widely applied to the fields of optical communication, optical analog-digital conversion, laser radar, microwave photonics, etc.

Owner:TIANJIN UNIV

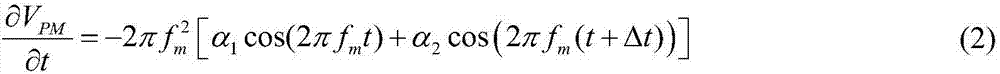

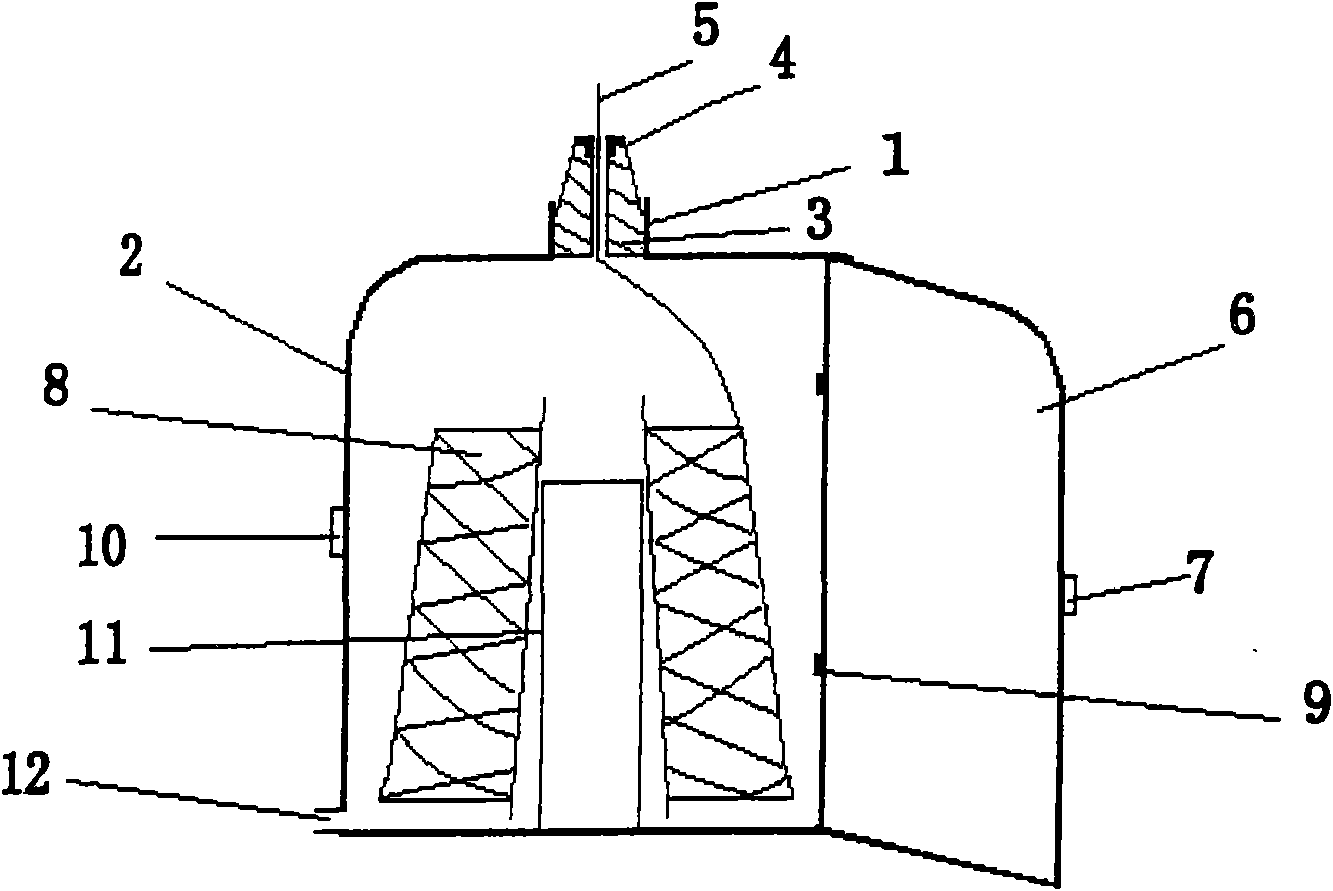

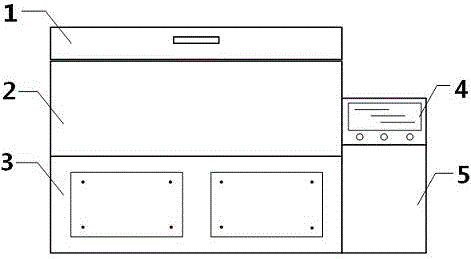

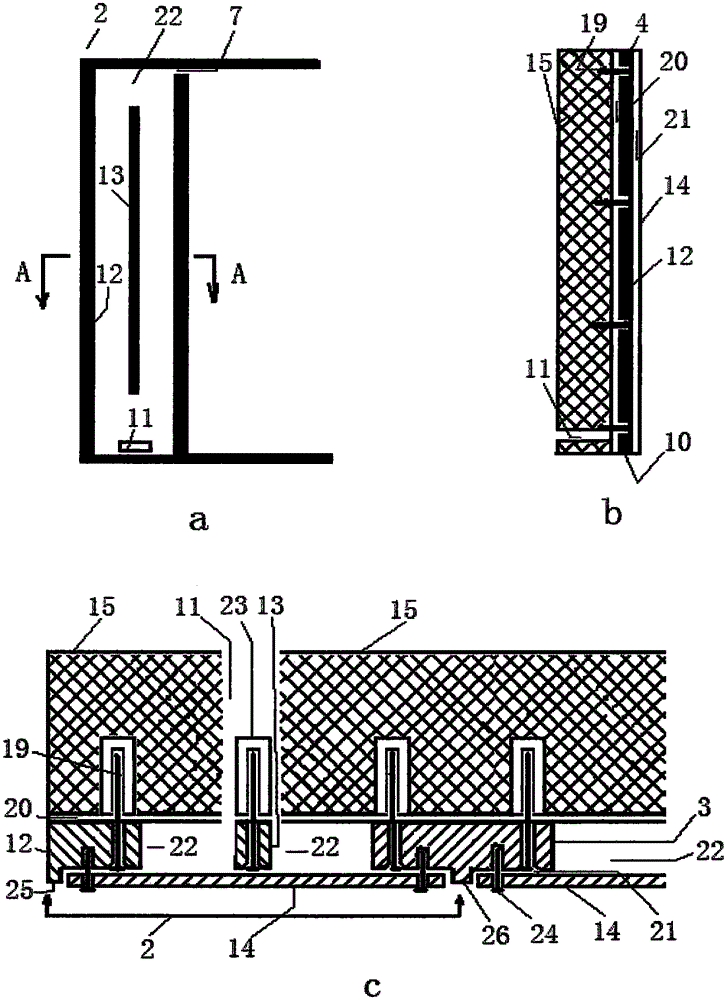

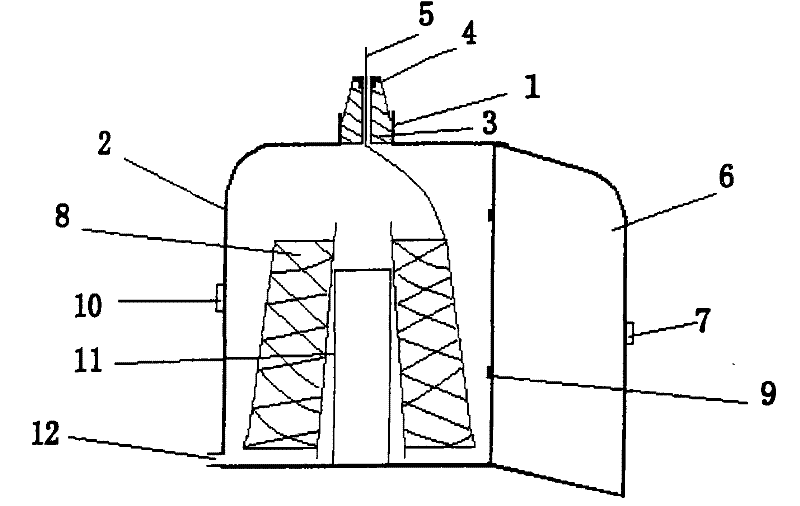

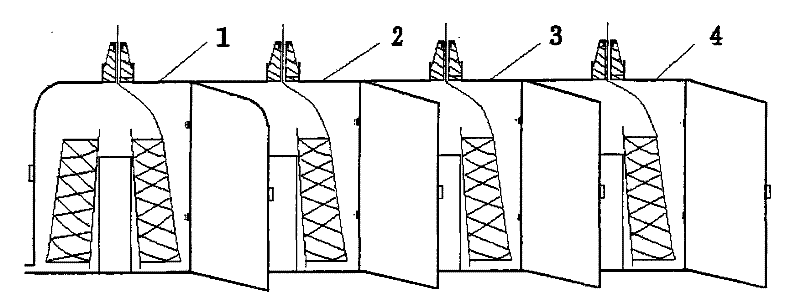

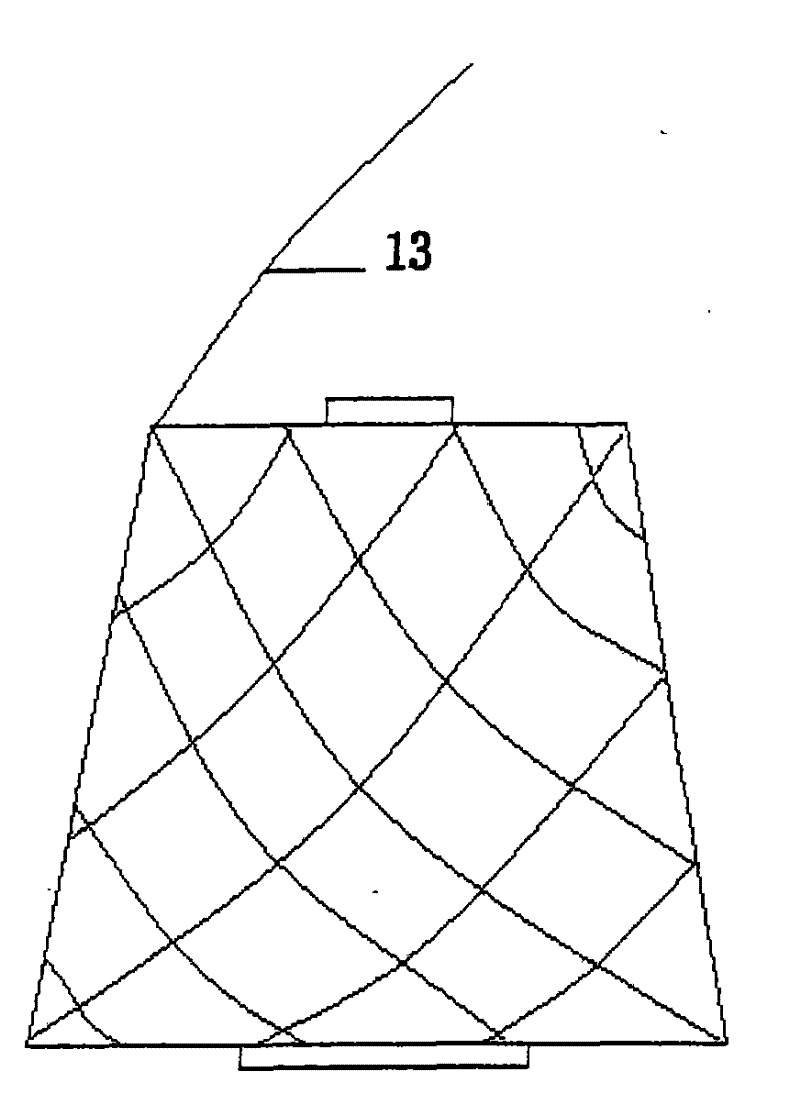

Integral yarn automatic lubricating device

InactiveCN101775681AReasonable structureEasy to operateTextiles and paperForm constantIntegrated design

Technical field: the invention relates to the field of textile, in particular to an integral yarn automatic lubricating device used in textile industry for mitigating friction between yarn and machine. The aims of the invention are realized by the following measures: a lubricating box (1) is connected with a transparent dust cover (2), a cone-shaped lubricating block (3) is plugged in the lubricating box (1), a porcelain eye (4) is connected on the top central hole of the cone-shaped lubricating block (3) in a plugging way, yarns (5) are led out through the central hole of the porcelain eye (4), a central tube (11) of the dust cover is plugged in a yarn ball (8), a door of dust cover door (6) is connected with a hinge (9), clasp (7) and clasp (10) are locked when closing the door, and a dust discharge port (12) is connected with a dust collector for dedusting. The device can be applied to integrated design of multiple storehouses numbering 1, 2, 3, 4...12, mainly used in textile industry, and on equipments such as braiding machine, strand combining machine, weaving machine, warp knitting machine, beam-warping, spinning machine, yarn forming machine and the like. The structure is characterized in that natural air ring is generated when a yarn roll is unwinded during beam-warping to form constant corkscrew force to straighten hairfeather, yarns rotate 360 degrees to be uniform and smooth. The invention is defined as: uniformity and smoothness are achieved while straightening hairfeather by rotating 360 degrees.

Owner:崔建明

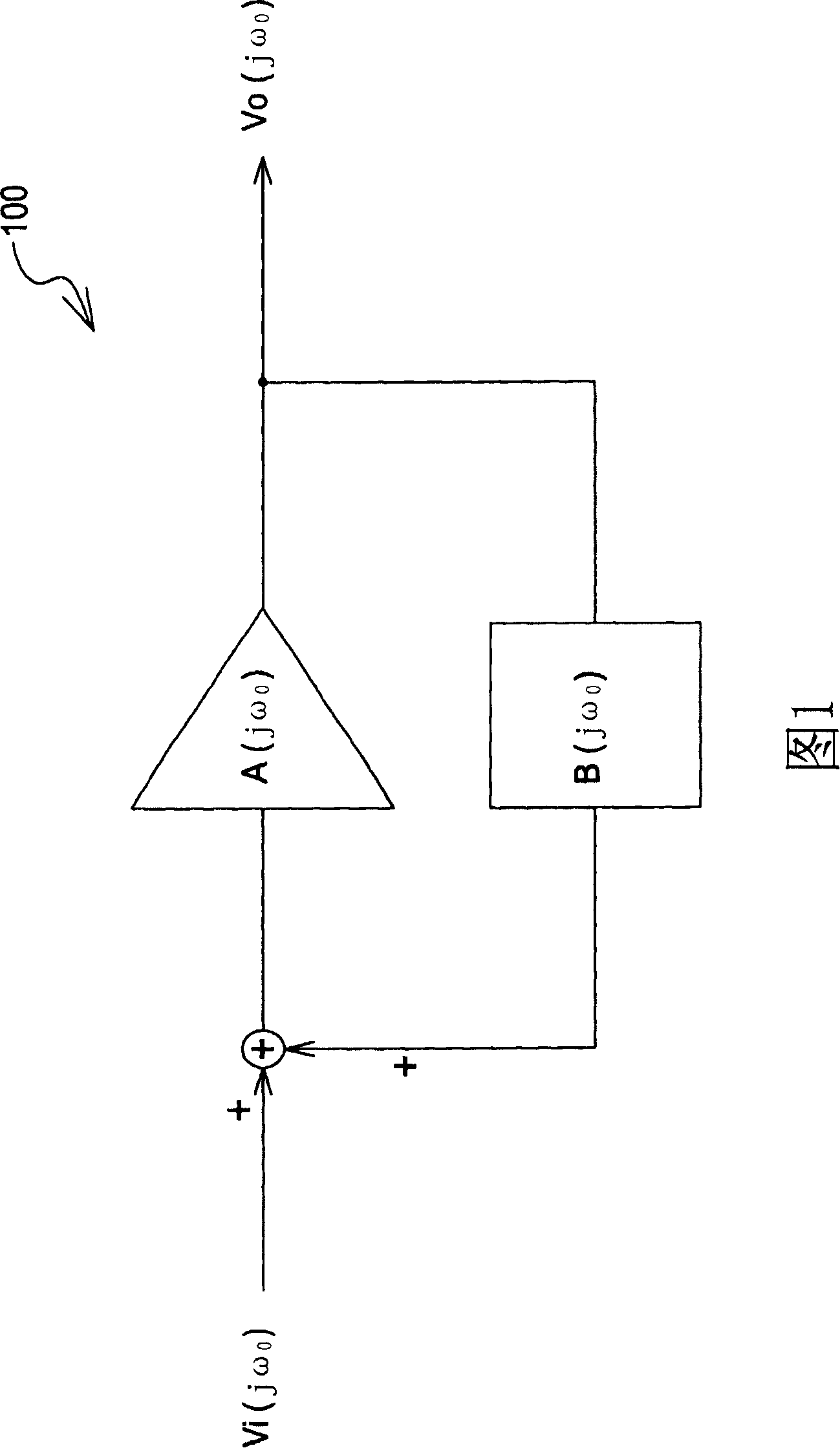

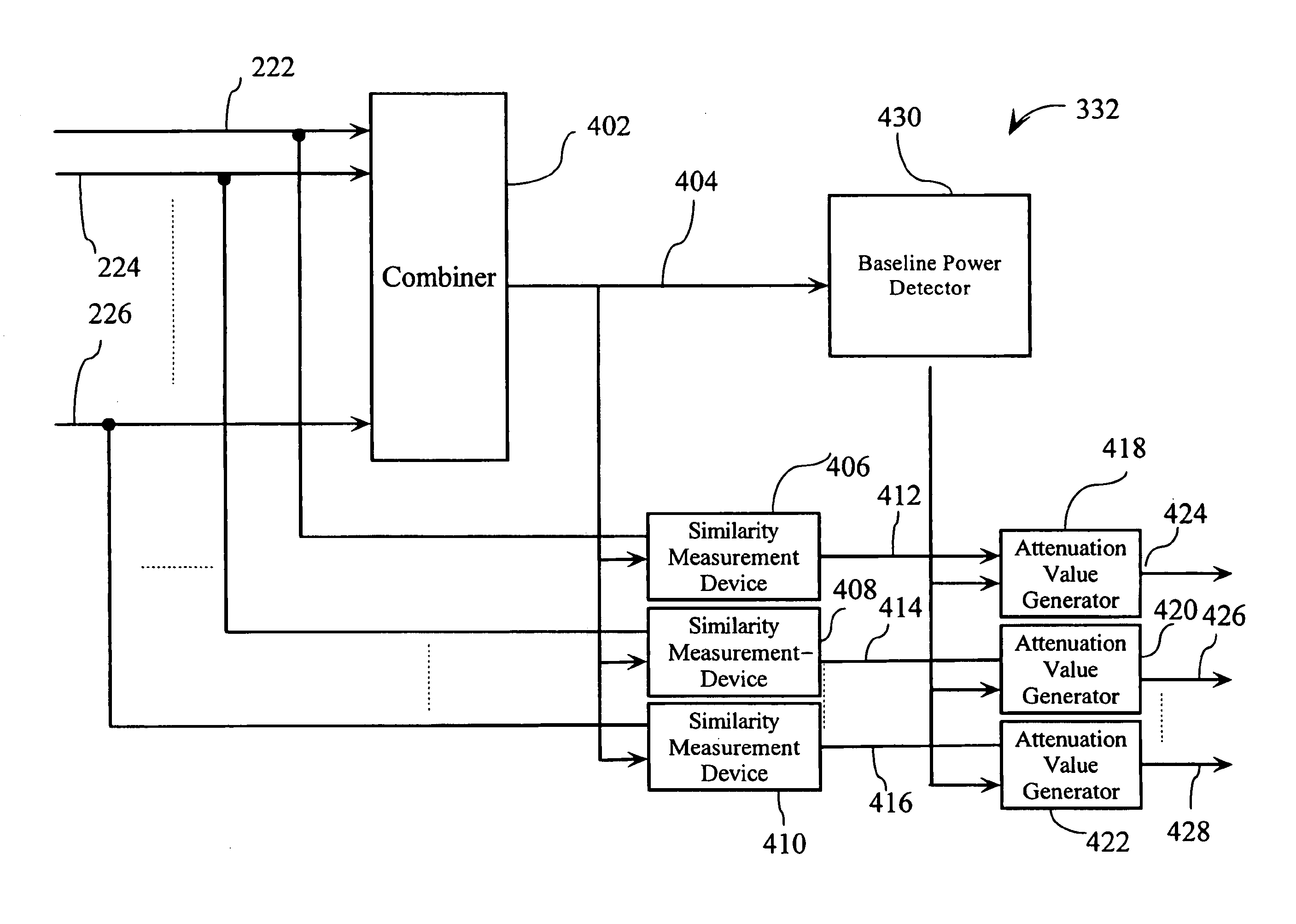

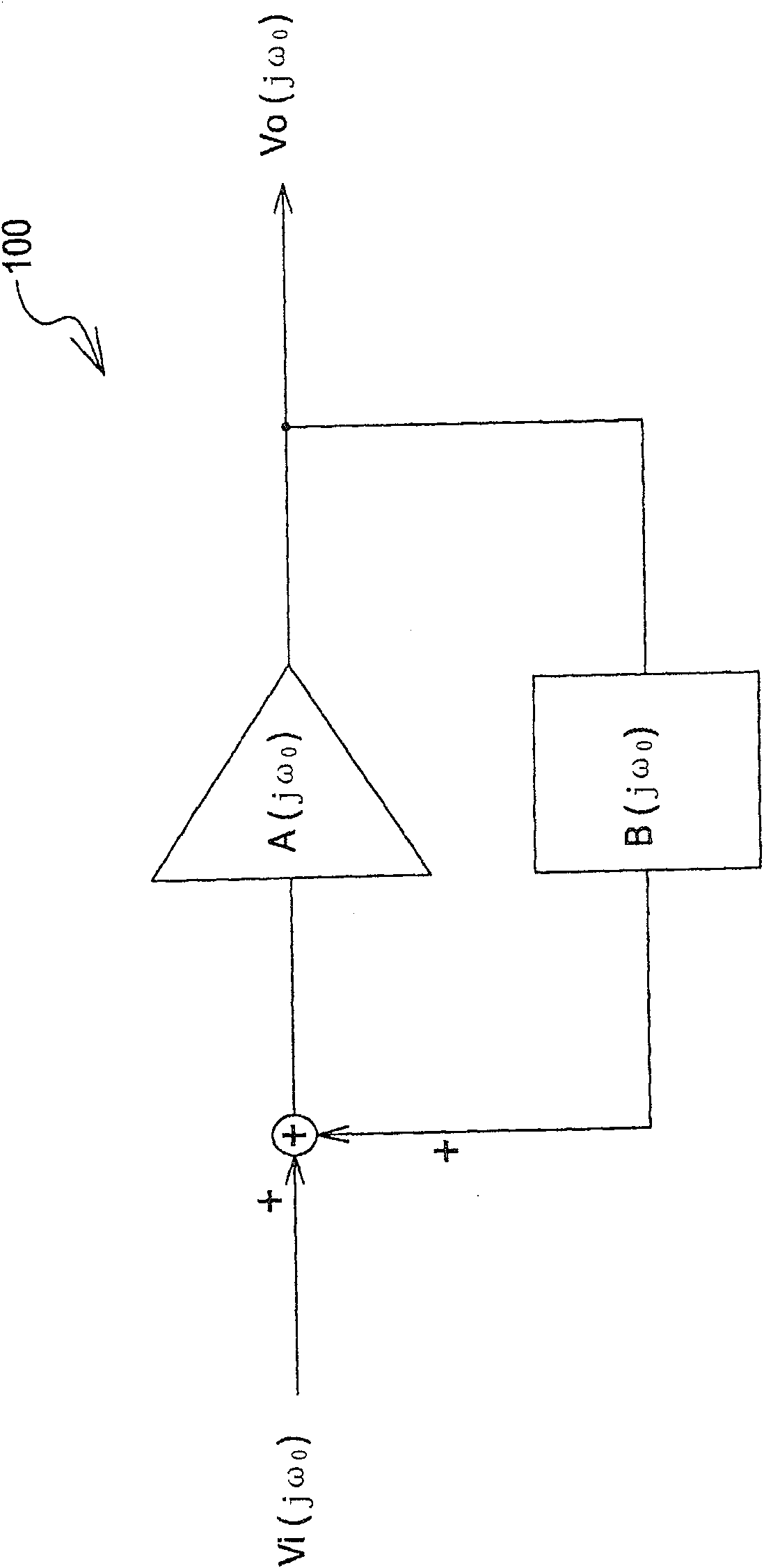

Pre-distortion of input signals to form constant envelope signal outputs

ActiveUS7046739B2Component resource requirementLower requirementAmplifier modifications to reduce non-linear distortionSecret communicationForm constantEngineering

A plurality of input signals are pre-distorted for combination into a first combined signal having a constant envelop. The input signals are combined into a second combined signal, and a similarity between each of the input signals and the second combined signal is measured. Ones of the input signals are selected and attenuated based on the similarity measurement. The attenuated input signals and non-attenuated signals are output for combination to form the first combined signal.

Owner:SOUTHWEST RES INST

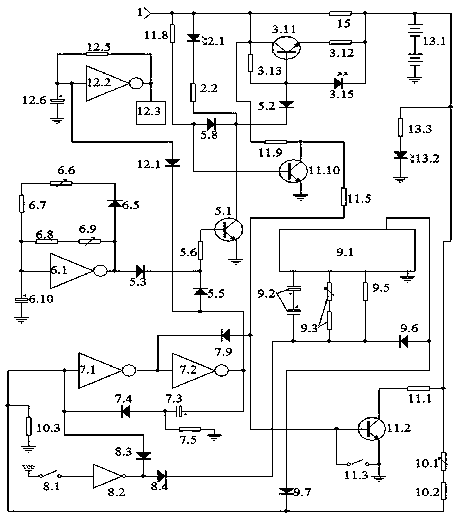

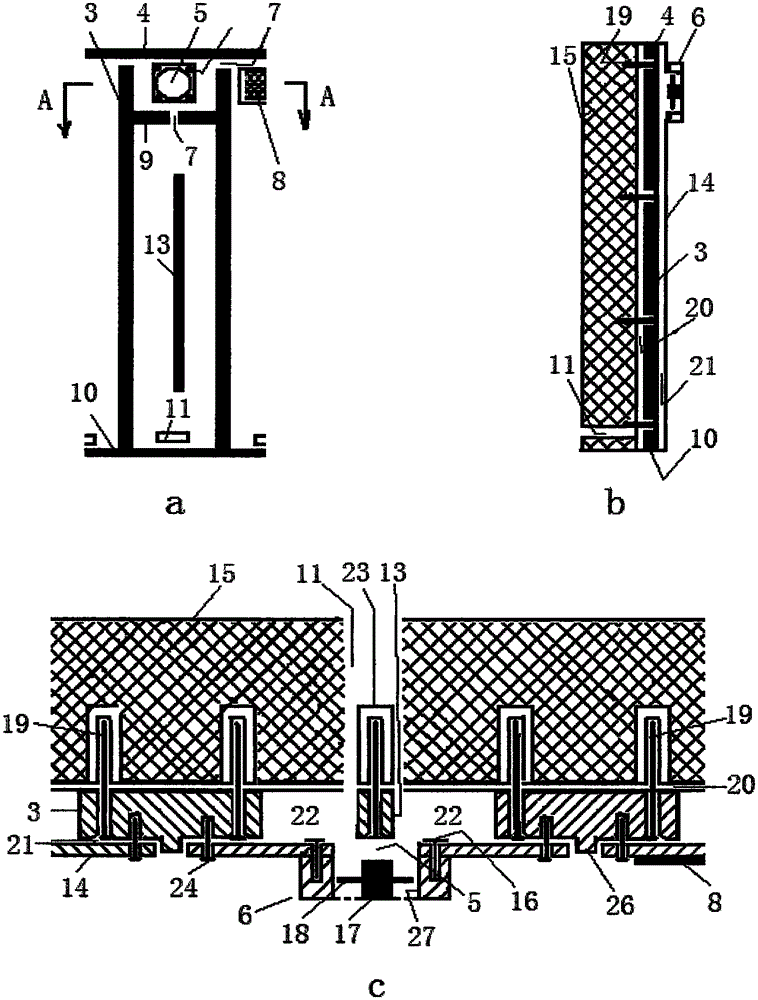

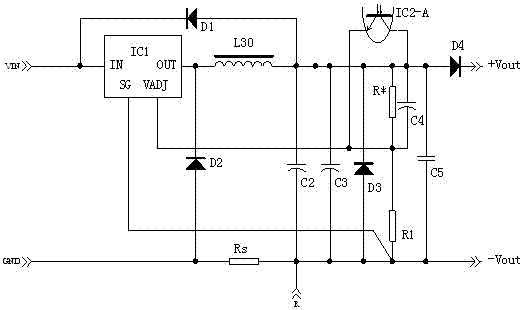

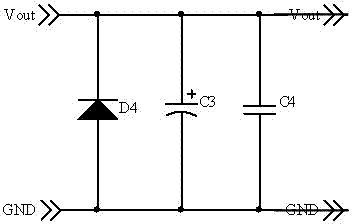

Constant current charging-discharging pulse charger

InactiveCN108075511AExtend your lifeReduce scrap rateElectric powerBattery load switchingElectricityForm constant

The invention discloses a constant current charging-discharging pulse charger, and belongs to the technical field of electronics. The constant current charging-discharging pulse charger is composed ofa process indicting unit, a voice prompt unit, an N-type charging unit, an N-type discharging unit, an interface unit, a pulse unit, a double-selection termination unit, a load unit, and a trickle resistor. The N-type charging unit, the N-type discharging unit and the pulse unit, and the interface unit form a pulse charging form that is capable of charging and discharging and having a charging time longer than the discharging time. A constant current triode of the N-type charging unit is connected in the form of constant current, therefore forming constant current charging. The constant current charging-discharging pulse charger has termination after the full charging of the battery and termination after the end of the timing countdown which can easily switch. After the end of charging ordischarging, the trickle resistor provides required trickle current to a to-be-charged battery, the inverter in each unit is formed of a gate circuit that has mutation input and output. The constantcurrent charging-discharging pulse charger has strong loading capability. After the implementation, the constant current charging-discharging pulse charger can flexibly adjust the charging and discharging time of the to-be-charged power supply and is suitable to to-be-charged batteries of different types.

Owner:CHONGQING NINGLAI SCI & TRADE

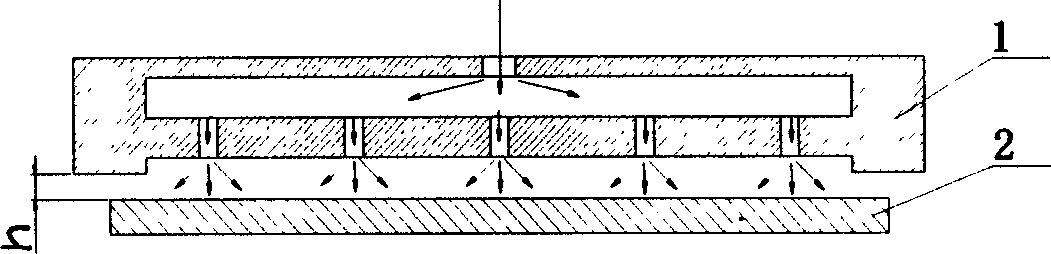

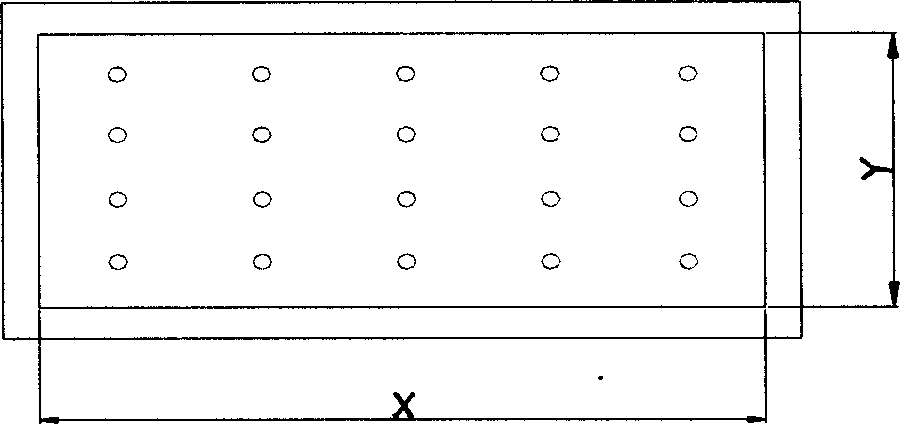

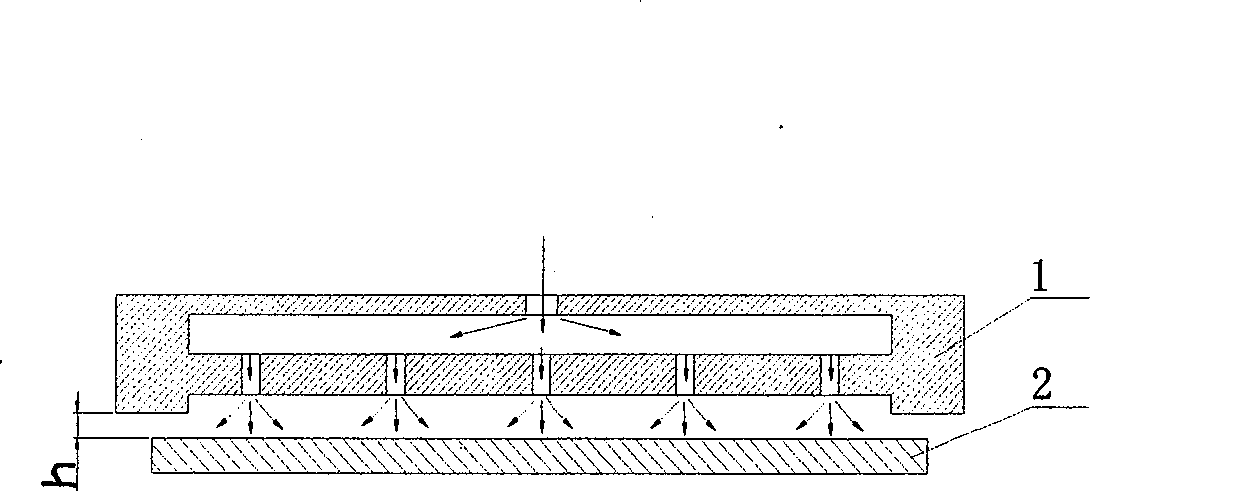

Space solar cell string non-contact pressing method

InactiveCN1588648AConsistent pressureImprove the quality of cloth stickersFinal product manufactureSemiconductor devicesContact pressureForm constant

In the space solar battery string non-contact pressure exerting method used is pressure exerting device with corresponding shape and size to space solar battery string. There is a gas storage cell inside the pressure exerting device, and gas entrnace is at top end of the gas storage cell, some small gas exit are arranged at the bottom end of the gas storage cell. The pressure exerting device is fixed on robot which drives pressure exerting device moving straight above the solar battery, controlls relative space between pressure exerting device and space solar battery, makes gas into gap of space solar battery and pressure exerting device through the small hole on pressure exerting device after gas source is put-through to form constant pressure space to make solar battery be firm fixed on said board.

Owner:SHANGHAI JIAO TONG UNIV

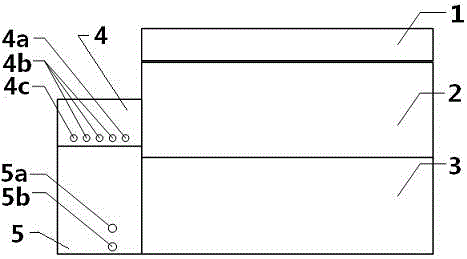

Pavement semi-rigid base material freeze thawing test machine

PendingCN106525893AFully automatedTimely and accurate frost resistance dataMaterial thermal analysisForm constantWater discharge

The invention discloses a pavement semi-rigid base material freeze thawing test machine. The test machine comprises a test piece box, a water circulation system, a controller, a refrigeration system and a computer; an evaporator is arranged on the sidewall of the test piece box; a condenser, a compressor and the evaporator are connected through a pipeline; a water inlet is arranged on the sidewall of the test piece box, and a water outlet is arranged at the bottom of the test piece box; a water tank is arranged under the test piece box; a heating pipe and a water tank temperature sensor are arranged on the water tank apart; the water inlet is connected with a tap water pipe, a water discharging valve and a water overflow opening are connected with a floor drain, and the evaporator refrigerates the test piece box in the refrigeration working process; circulation fans realize air convection in the box; water in the water tank is heated by the heating pipe after the refrigeration ends to form constant temperature water circulation; and a test piece is thawed in water. The test machine realizes full automation of pavement semi-rigid base material freeze thawing cycle test; freeze thawing parameters are autonomously set according to test needs, so the test machine is convenient and flexible; the test machine reduces labor and has high efficiency; the circulation fans are arranged to enhance air convection in order to make the temperature in the box rapidly and uniformly reach a preset temperature, so the test precision is high; and the freezing resistance data of a semi-rigid base material can be timely and accurately obtained, and the construction quality of a semi-rigid base in the northern region is improved.

Owner:吉林省交通科学研究所

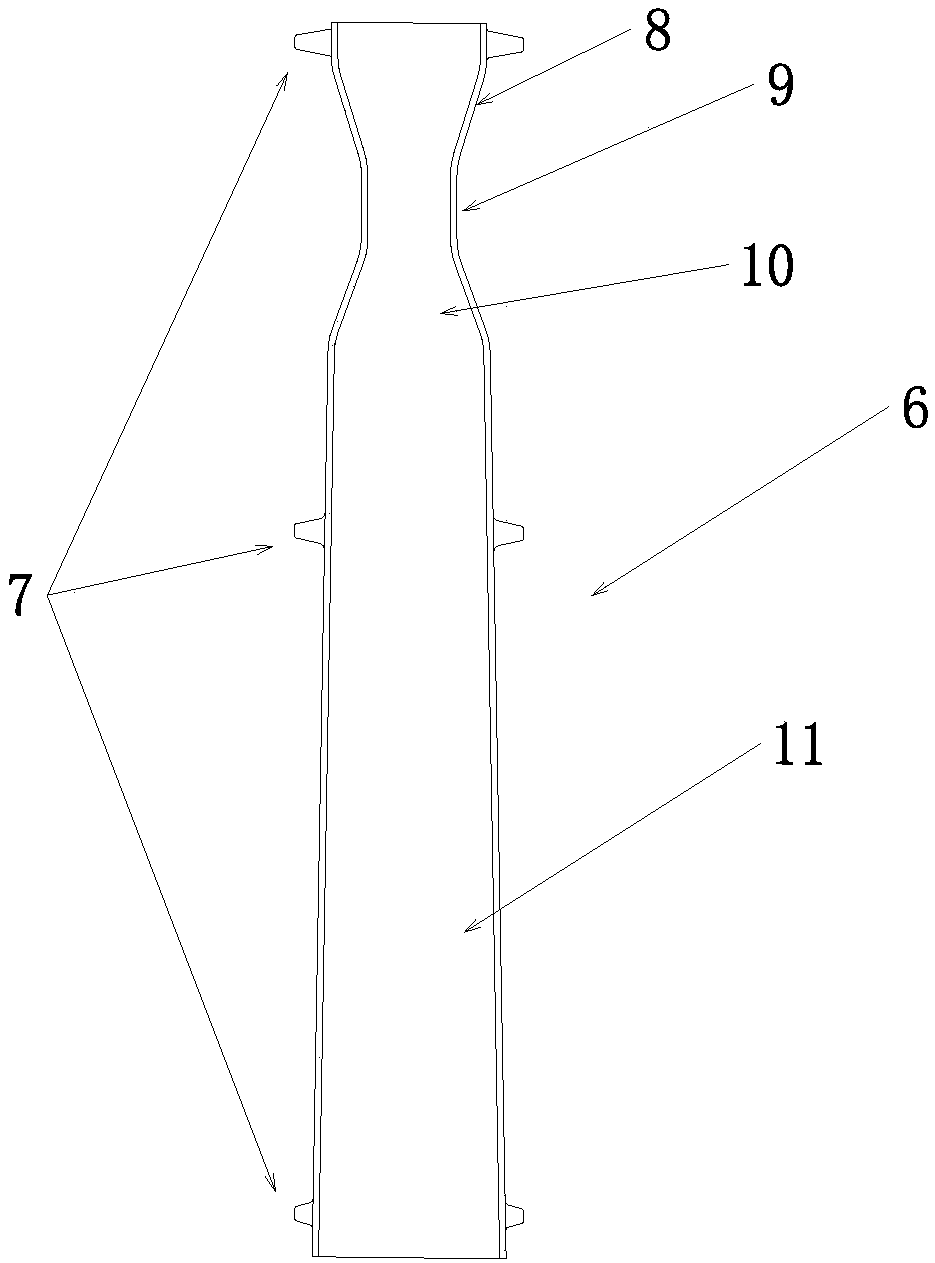

Inner flame tube applicable to radiant tube and radiant tube

PendingCN109404913AImprove temperature uniformityReduce flow rateGaseous fuel burnerLow speedForm constant

The invention discloses an inner flame tube applicable to a radiant tube and the radiant tube. The inner flame tube is provided with a shrinkage pipe section, a straight pipe section and an expansionpipe section in sequence in the extension direction from the inlet end to the outlet end. After smoke generated by combustion in a nozzle passes through the inner flame tube, high-speed airflow can inject surrounding low-speed airflow through the shrinkage pipe section, the airflows mix and transfer energy, and accordingly an injection area is formed; afterwards, the injecting airflow passes through the straight pipe section to be mixed with the injected airflow so as to form constant-speed and constant-pressure airflow; and finally, the airflow passes through the expansion pipe section, so that the flow speed is reduced and the static pressure is increased. After the inner flame tube is applied to a self preheating nozzle in cooperation with the closed radiant tube with a single-end inlet, backflow of smoke inside can be achieved to the maximum extent, the smoke is mixed with gas and combustion air to form a mixture for a mild and more uniform combustion way, and the temperature uniformity of the surface of the whole radiant tube is improved.

Owner:FOSHAN KEHAO COMBUSTION EQUIP MFG

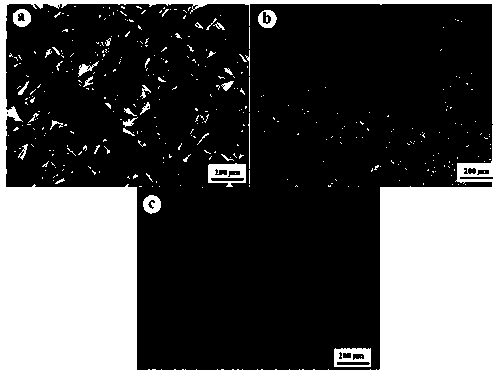

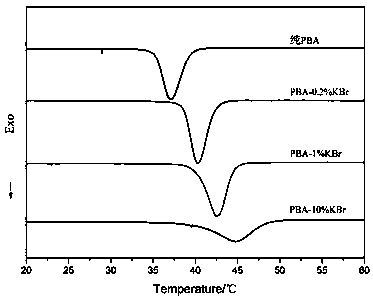

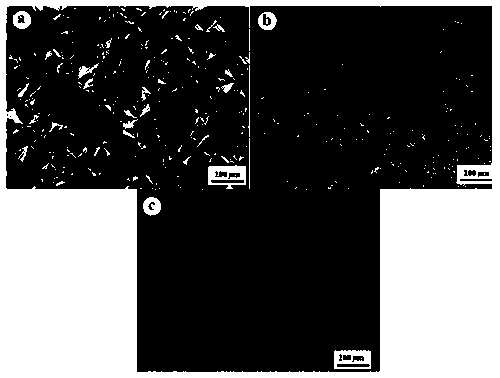

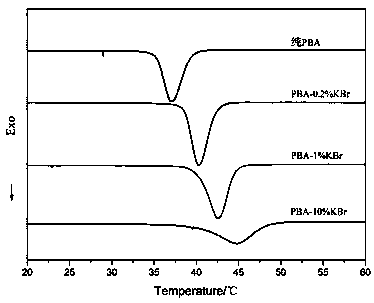

Preparation method of degradable polybutylene adipate/potassium bromide composite

The invention relates to a preparation method of a degradable polybutylene adipate / potassium bromide composite. The preparation method includes: (1) grinding potassium bromide particles prior to vacuum drying for standby; (2) putting PBA into a volumetric flask, and forming constant volume with a good solvent CHCl3 to enable PBA to dissolve completely; (3) adding KBr into prepared PBA solution to obtain KBr blended solution; (4) adding ionized water into the PBA solution different in KBr content, performing room-temperature ultrasonic treatment on the volumetric flask to prepare PBA / KBr membrane casting suspension; (5) subjecting the prepared PBA membrane casting suspension to spin coating to obtain a composite film, and performing vacuum drying for 6 hours after solvent CHCl3 completely volatilizes at room temperature; (6) subjecting the prepared composite film to constant temperature culture to eliminate thermal history; (7) subjecting the composite film with thermal history eliminated to constant temperature culture till fully recrystallized; (8) cooling the fully crystallized product in the step (3) to room temperature for under test. The preparation method is simple and scientific in process, low in cost, controllable in procedure and hopeful in industrial production, and has tremendous potential application prospect and economic benefit.

Owner:SHAANXI UNIV OF SCI & TECH

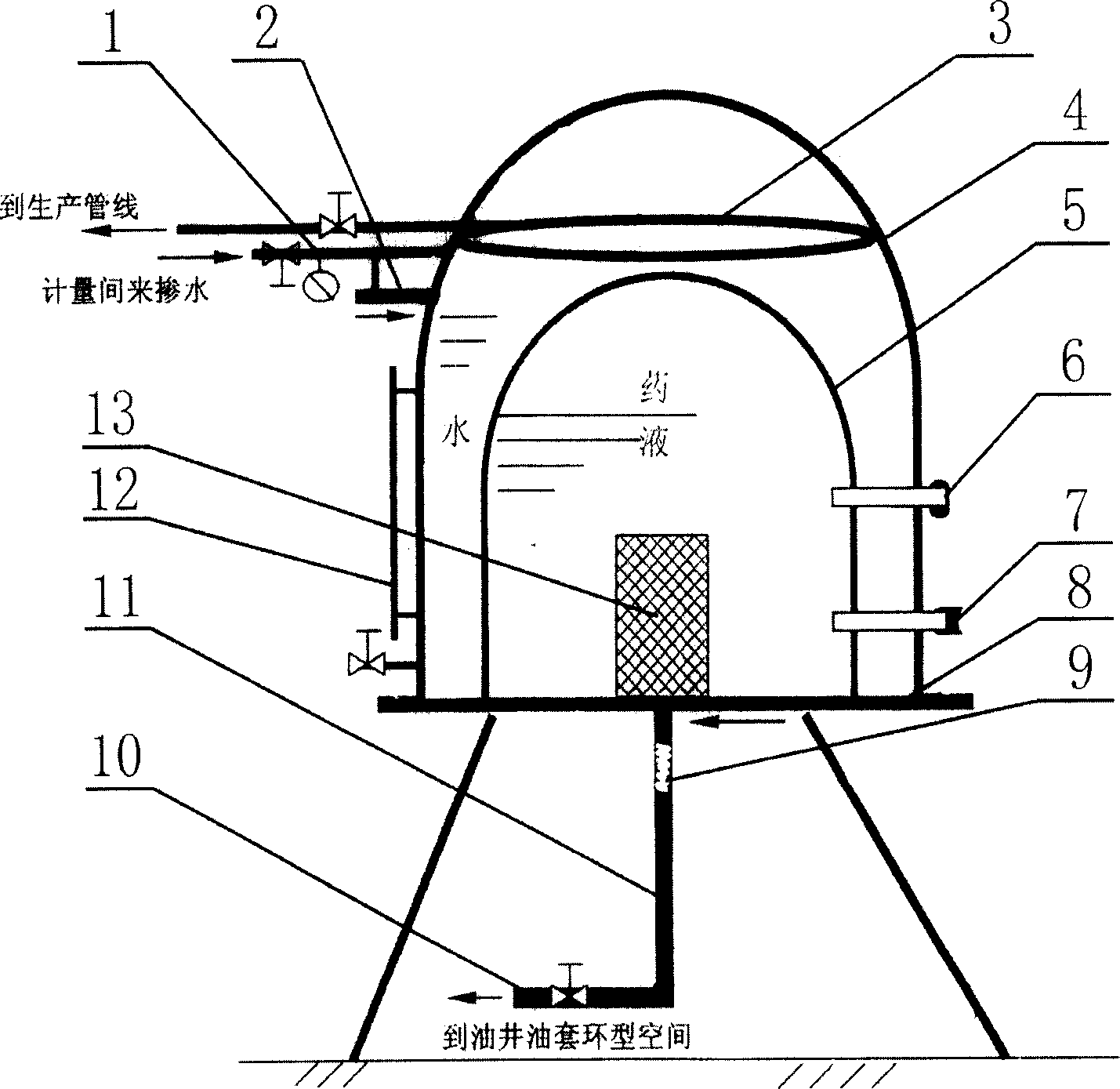

Wellhead drip medicament charging method by using water pressure to retain constant medicament charging differential pressure

ActiveCN1730900AIncrease the amount of diluentSimple structureCleaning apparatusWater bathsDifferential pressure

The well head chemical dropping method of utilizing water pressure to maintain constant chemical adding pressure aims at providing sufficient chemical adding amount to maintain constant chemical concentration and features that water is shunt with controlling tap from the water adding pipeline to the chemical adding tank to form constant pressure difference on the chemical storing capsule so as to control the chemical adding amount accurately, and the capsule is provided with filter and capillary for chemical to be dropped into water adding mixing pipe and added to oil jacket annular space connecting valve continuously and stably under relatively small pressure difference. The chemical adding tank has temperature maintained with water adding temperature maintaining pipe and water flows out through capillary in temperature maintaining water bath. The method has stable chemical concentration within the effective wax-preventing and antifreezing range.

Owner:DAQING OILFIELD CO LTD +1

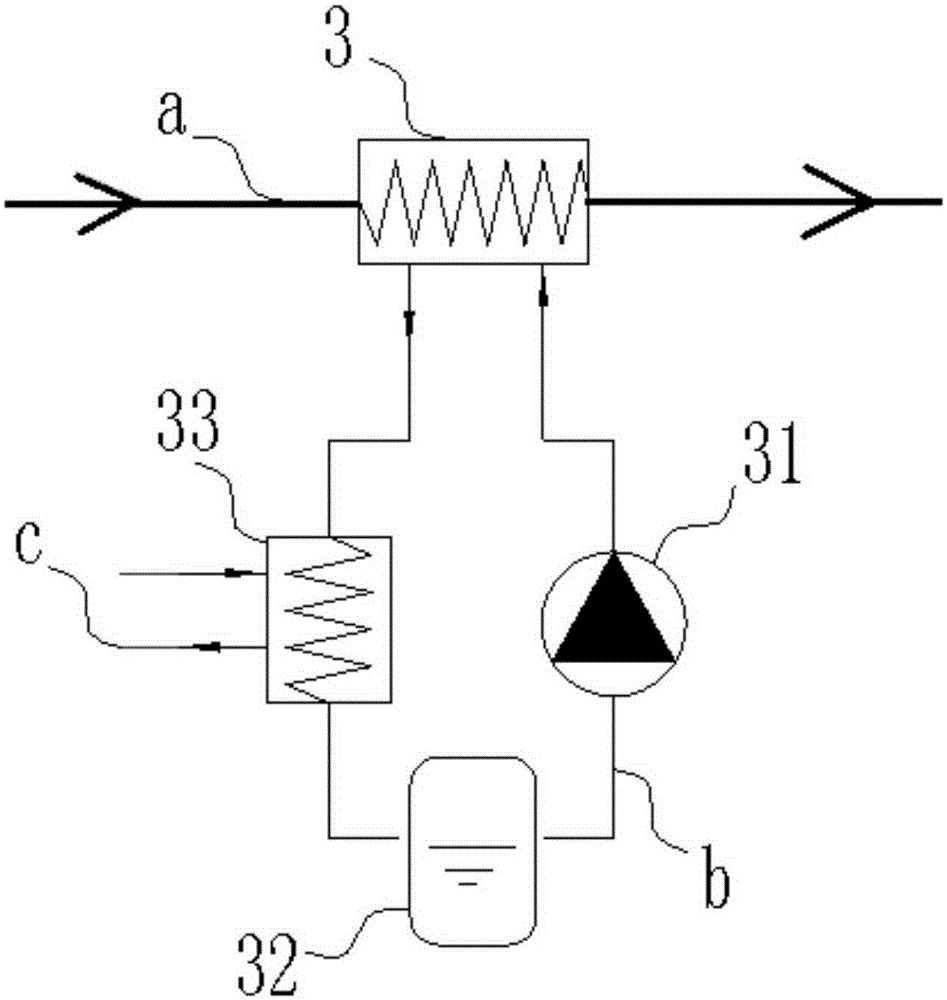

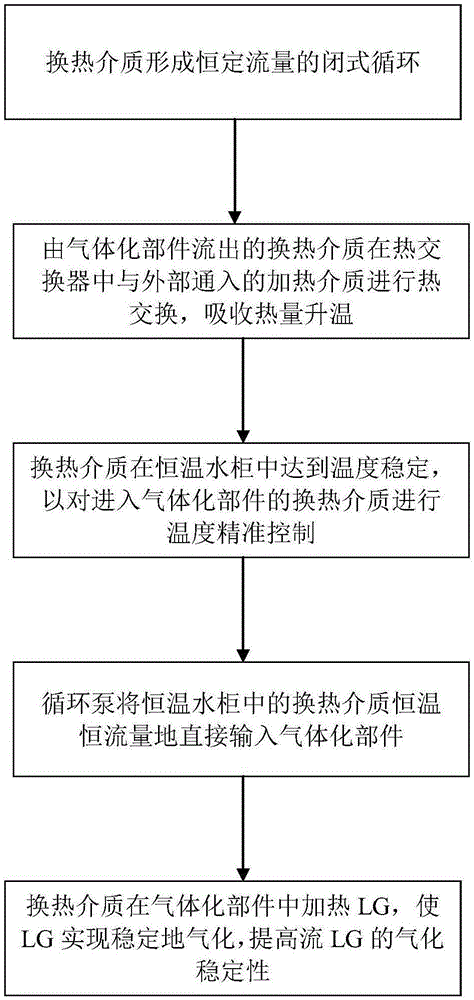

High-stability gasification method for LG

InactiveCN105202364AChange the connection arrangement orderModify the process flowContainer filling methodsPressure vesselsTemperature controlForm constant

A high-stability gasification method for LG is related to a gasification part, a heat exchanger, a constant-temperature water tank and a circulating pump which are connected in sequence through a heat exchange medium pipeline, wherein a heat exchange medium passes through the heat exchanger, the constant-temperature water tank, the circulating pump and the gasification part in sequence to form constant-flow closed circulation, heat exchange is conducted between the heat exchange medium flowing out of the gasification part and a heating medium introduced from the outside in the heat exchanger, the heated heat exchange medium is fed into the constant-temperature water tank after absorbing heat and obtains a constant temperature in the constant-temperature water tank so that accurate temperature control can be conducted on the heat exchange medium entering the gasification part, the heat exchange medium in the constant-temperature water tank is directly input into the gasification part through the circulating pump in a constant-temperature and constant-flow mode, and LG is heated by the heat exchange medium in the gasification part so as to be gasified stably. By the adoption of the method, constant temperature and constant flow of the heat exchange medium entering the gasification part are guaranteed, so that gasification stability of LG is improved, LG leakage risks are reduced, and system safety is improved.

Owner:HUDONG HEAVY MACHINERY +1

A method and system for controlling constant direct axis current of an embedded permanent magnet synchronous motor

ActiveCN106301128BRealize linear controlAchieve unlimited speed controlElectronic commutation motor controlVector control systemsPhase currentsConstant power

Owner:JIANGSU UNIV

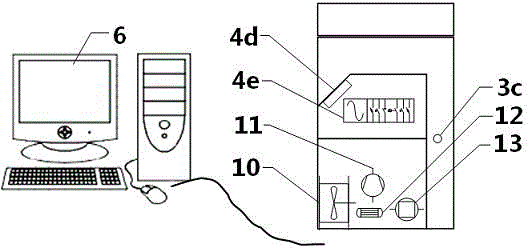

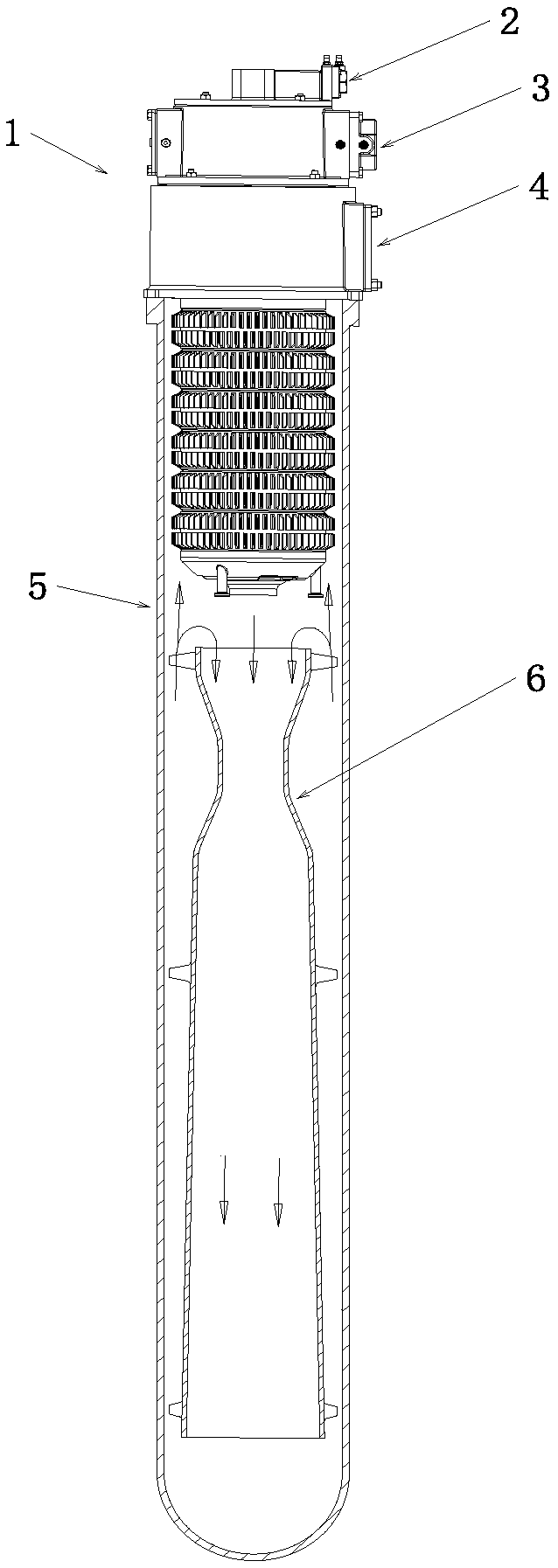

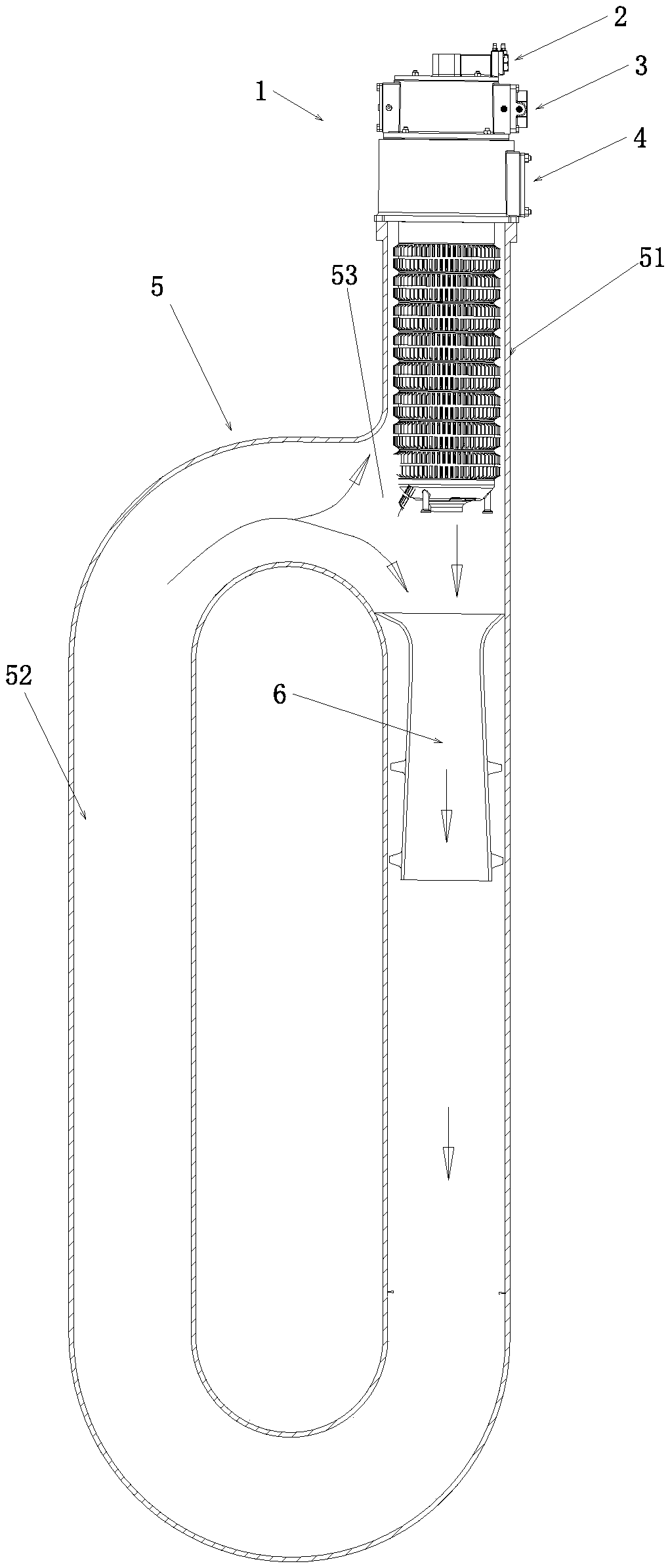

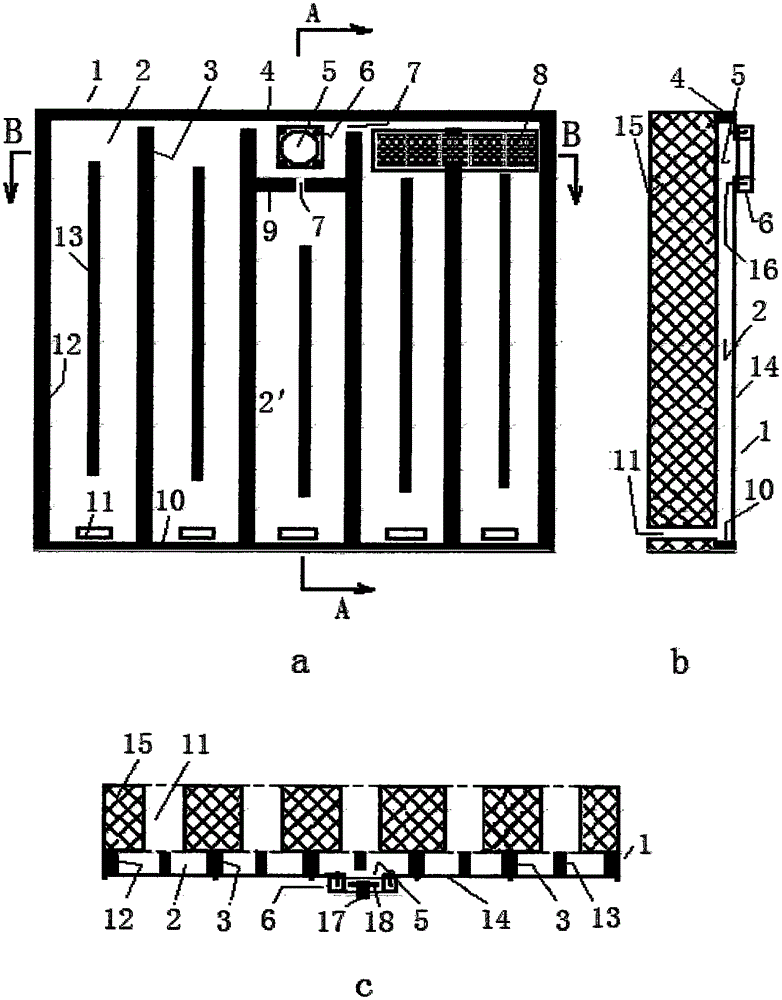

House external wall air-suction type solar indoor cooling device

ActiveCN105350683ARealize indoor coolingOvercome the many deficiencies that existLighting and heating apparatusWallsInsulation layerForm constant

The invention relates to a house external wall air-suction type solar indoor cooling device which achieves a novel solar energy utilization mode for an external wall of a house to achieve indoor cooling. The house external wall air-suction type solar indoor cooling device is characterized in that air in a heat insulation layer 1 arranged on the external wall 15 of the house is adopted to be communicated with indoor air, no energy resources are consumed, a solar cell panel 8 serves as a power supply for rotation of an air suction fan 6, the air in the heat insulation layer is constantly absorbed and exhausted through rotation of the air suction fan 6 to form constant exchange and flow of the air in the whole heat insulation layer from bottom to top, solar heat radiation has no chance to heat air in the heat insulation layer 1, and thus a heat conduction medium is lost, so that the effect of blocking the heat conduction effect of solar heat radiation on a wall body of the external wall 15 is achieved, indoor cooling is achieved, the defect that an air conditioner is adopted for cooling in the prior art, and the human body health is influenced is overcome, and the blank that the heat insulation layer is arranged on the external wall of the house and solar energy is used for achieving indoor cooling home and abroad is filled up.

Owner:徐州天骋智能科技有限公司

Simplified double selection pulse float charger

InactiveCN108075512AExtend your lifeReduce scrap rateCircuit monitoring/indicationDifferent batteries chargingElectrical resistance and conductanceElectricity

The invention discloses a simplified double selection pulse float charger, and belongs to the technical field of electronics. The simplified double selection pulse float charger is composed of a process indicting unit, a voice prompt unit, an N-type charging unit, an N-type discharging unit, an interface unit, a pulse unit, a double-selection termination unit, a load unit, and a trickle resistor.The N-type charging unit and the interface unit, and the pulse unit cooperate so as to form a pulse-type scientific charging method. A constant current triode of the N-type charging unit is connectedin the form of constant current, therefore forming constant current charging. The double selection termination unit has termination after the full charging of the battery and termination after the endof the timing countdown which can easily switch. After the end of charging or discharging, the trickle resistor provides required trickle current to a to-be-charged battery. In the line, the constantcurrent triode serves to control the on and off in charging and provides double functions of a constant current source, thus simplifying the line. The constant current charging apparatus can performcharging in a more scientific manner and provide maximum charging, so that the constant current charging apparatus can increase the service life and capacity of a charger and the to-be-charged batteryat the maximum and protect environment.

Owner:CHONGQING NINGLAI SCI & TRADE

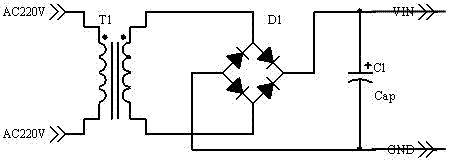

On-line integrated integrated switching constant current charger

ActiveCN104753155BEnsure charging safetyResistant to harsh environmentsBatteries circuit arrangementsElectric powerCapacitanceTransformer

Owner:AEROSPACE CHANGFENG CHAOYANG POWER SUPPLY

A kind of preparation method of degradable polybutylene adipate/potassium bromide composite material

The invention relates to a preparation method of a degradable polybutylene adipate / potassium bromide composite. The preparation method includes: (1) grinding potassium bromide particles prior to vacuum drying for standby; (2) putting PBA into a volumetric flask, and forming constant volume with a good solvent CHCl3 to enable PBA to dissolve completely; (3) adding KBr into prepared PBA solution to obtain KBr blended solution; (4) adding ionized water into the PBA solution different in KBr content, performing room-temperature ultrasonic treatment on the volumetric flask to prepare PBA / KBr membrane casting suspension; (5) subjecting the prepared PBA membrane casting suspension to spin coating to obtain a composite film, and performing vacuum drying for 6 hours after solvent CHCl3 completely volatilizes at room temperature; (6) subjecting the prepared composite film to constant temperature culture to eliminate thermal history; (7) subjecting the composite film with thermal history eliminated to constant temperature culture till fully recrystallized; (8) cooling the fully crystallized product in the step (3) to room temperature for under test. The preparation method is simple and scientific in process, low in cost, controllable in procedure and hopeful in industrial production, and has tremendous potential application prospect and economic benefit.

Owner:SHAANXI UNIV OF SCI & TECH

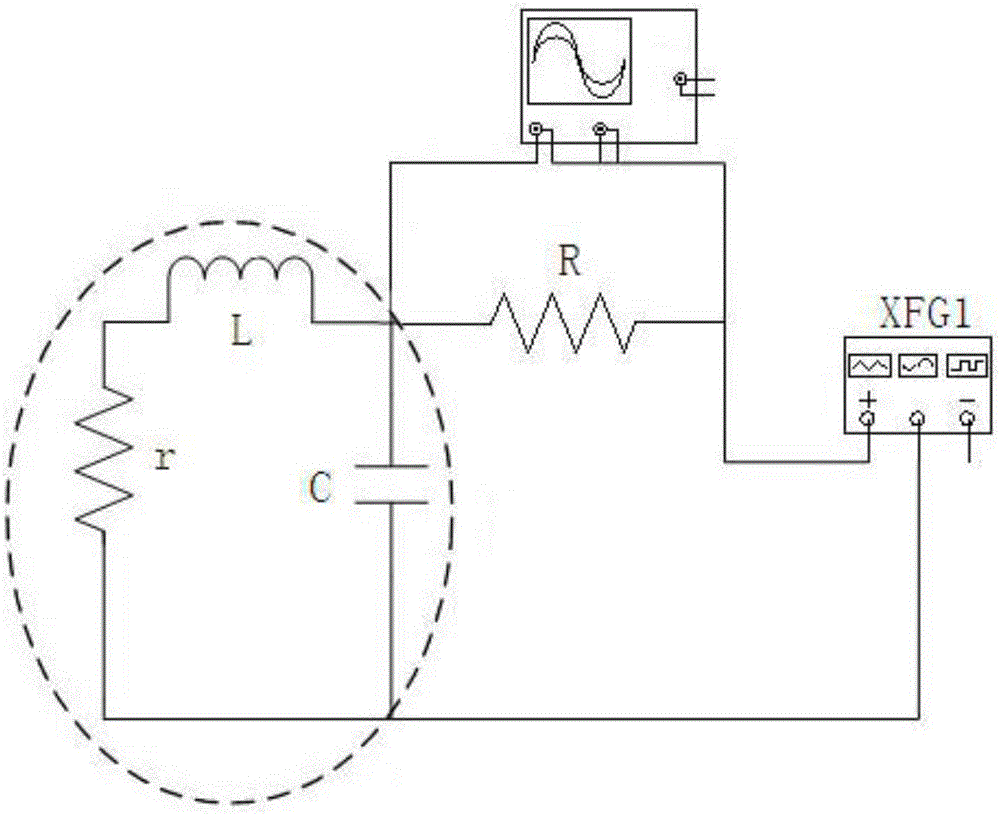

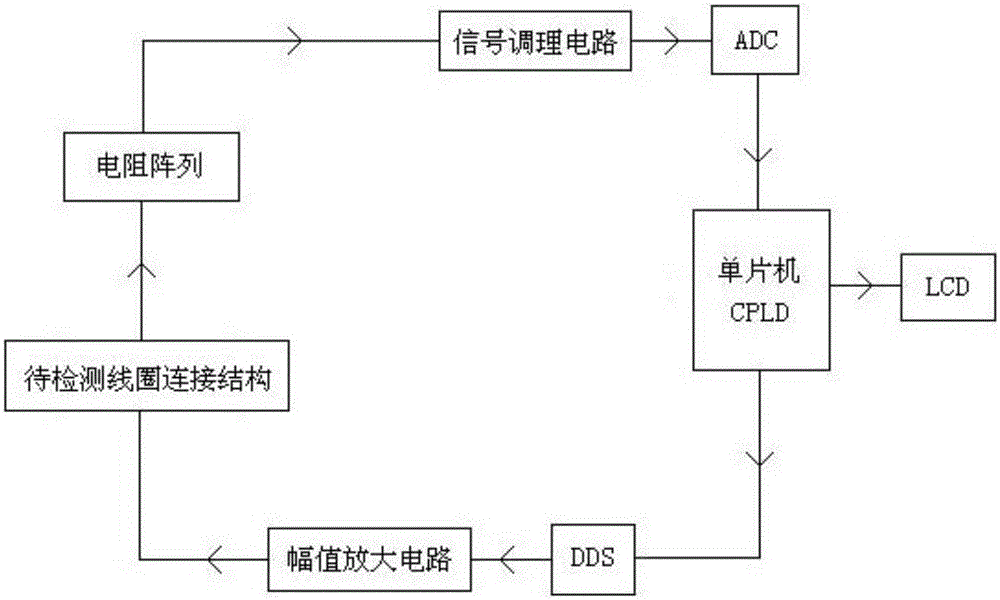

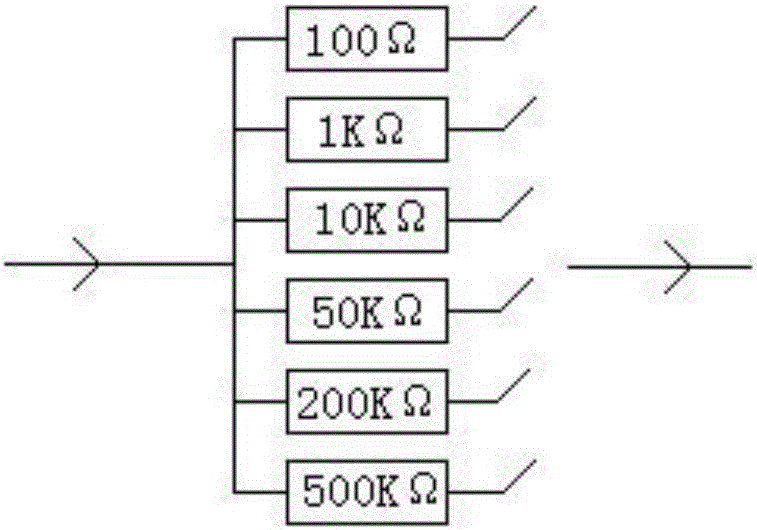

Coil sensor resonance parameter measurement method and device

ActiveCN106019200AHigh degree of intelligenceReduce volumeElectrical measurementsMicrocontrollerData acquisition

The invention provides a coil sensor resonance parameter measurement method and device. Frequency-adjustable signals generated by a DDS are controlled by a core part composed of a single-chip microcomputer and a CPLD, the amplitude of the signals is amplified to form constant-voltage signals, then the constant-voltage signals are input into a serial circuit composed of a to-be-detected coil and a resistor array, voltage signals at the two ends of series resistors are connected into an ADC through a signal conditioning circuit for data acquisition, the CPLD conducts multiple times of absolute value addition on voltage data at the same signal frequency, an average value is obtained, accordingly a stable voltage value corresponding to the signal frequency is obtained, finally the minimum voltage value is obtained by comparing stable voltage values at different signal frequencies, and signal frequency corresponding to the minimum voltage value is resonance frequency of the to-be-detected coil. The method and device are high in intelligence degree, simple in equipment structure and low in cost, and measuring precision is improved by improving frequency change precision and reducing interference.

Owner:HUNAN ZHONGDA CONSTR ENG TESTING TECH

Method of self-customizing report forms for users

InactiveCN101599067BSolve problems that cannot be customized by usersTroubleshoot custom reportsSpecial data processing applicationsForm constantForm analysis

The invention discloses a method of self-customizing report forms for users, comprising the following steps: A, establishing a new report form and selecting the type of the report form; B1, if the selected report form type is a report form in which an user can fill and submit, drawing a report form template firstly and saving the report form template to a database after finishing drawing; then defining a report form index and binding the report form index and the table cell of the report form; and then defining a summary statistical formula and a calculation formula, carrying out summary statistical calculation according to the summary statistical formula and the calculation formula, showing the report form analysis; B2, if the selected report form type is a report form in which an user can not fill and submit, firstly defining a report form data source, drawing the report form template and saving the report form template to the database; and then defining a report form figure selection formula, a calculation formula, and a report form constant; finally, showing the report form analysis. The invention transforms the complex report form figure selection and formulas into a perceivable and understandable operation mode for users, so that the report forms can be self-customized by users.

Owner:广东金宇恒软件科技有限公司

A photon sampling system and method based on oeo

InactiveCN107887783BSimplified generation structureReduce time jitterActive medium shape and constructionFiber chromatic dispersionPhase noise

The present invention discloses a system for photon sampling based on an OEO. The system for photon sampling based on the OEO comprises an optical narrow pulse source based on the OEO and a time domain Fourier transform system. The optical narrow pulse source based on the OEO is generated by a wavelength double-ring OEO structure, a directly modulated laser and a phase modulator are integrated into the wavelength double-ring OEO structure, microwave signals are generated by the OEO structure, the directly modulated laser is modulated to generate optical narrow pulses, the phase modulator is employed to broaden the pulse width to obtain wide-spectrum narrow pulses, and a long fiber dispersive medium is employed to perform dispersion walk-off of the narrow pulses to form constant-amplitude chirped narrow pulses and perform signal sampling. The system and the method employ a characteristic that the OEO structure directly generates signals with high repetition frequency and low phase noise, and combine the time domain Fourier transform system to simplify a production process and an optical serial-parallel converting process of the pulse source with a high repeat rate in photon samplingand have a characteristic of ultralow jittering. The system and the method for photon sampling based on the OEO can be widely applied to the fields of optical communication, optical analog-digital conversion, laser radar, microwave photonics, etc.

Owner:TIANJIN UNIV

Integral yarn automatic lubricating device

InactiveCN101775681BReasonable structureEasy to operateTextiles and paperForm constantIntegrated design

Owner:崔建明

Strong wear-resistant arc spraying wire containing Ti(C,N) hard phase

InactiveCN101492801BImprove anti-corrosion performanceImprove wettabilityMolten spray coatingWear resistantMetallic substrate

The invention relates to a strong abrasion resisting electric arc spraying powder core wire containing Ti (C, N) hard phase and a preparation method thereof. The wire comprises the following powder core raw materials by mass percentage: 13-17% of Ti (C, N) powder, 16-20% of Cr powder, 17-23% of Cr2C3 powder, 9-13% of Ni powder, 1-3% of Mo powder, 15-17% of Si-Fe powder, and the rest being Mn-Fe powder. The preparation method comprises the following steps: (1) the powder core raw materials are weighed in proportion; (2) the powder core raw materials are mixed; (3) steel strips are used to wrapthe mixed powder core raw materials to form thick wires; (5) the diameter of the thick wires is reduced grade by grade to form finished wire products. The wires can form constant dense protective coating on metal substrates by electric arc spraying, especially supersonic electric arc spraying, the protective coating has Ti(C, N)-based metal ceramic texture and performance, and has the characteristics of stainless steels, has higher hardness, red hardness, abrasion resistance, crater wear resistance and high pyrochemical stability, and is mainly used in surface protection for equipment such asboiler three pipes under high temperature and high abrasion and corrosion.

Owner:北京球冠科技有限公司

Stable oscillator without influence of temperature variation and power supply voltage variation

InactiveCN100581056CStable characteristicsMultiple input and output pulse circuitsOscillations generatorsVoltage referenceVoltage source

The invention provides a comparator for a oscillator circuit with a self bias reference voltage. The comparator includes: a depleted metal oxide semiconductor transistor network which forms constant current equivalent connection, wherein a gate electrode and a source electrode which belong to the depleted metal oxide semiconductor transistor are connected; a enhanced metal oxide semiconductor transistor network, wherein a drain electrode or a source electrode of the enhanced metal oxide semiconductor transistor is connected with the depleted metal oxide semiconductor transistor in series, and a gate electrode terminal can receive a input voltage. The comparator outputs a high level signal when the input voltage is lower than the reference voltage and a low level signal when the input voltage is higher than the reference voltage. Moreover, the oscillator circuit with the comparator ensures that the reference voltage is independent from changes of external voltage source and temperature.

Owner:G TIME ELECTRONICS

Composite magnetic powder and compaction magnet core using the same

ActiveCN103021617BLow resistivityHigh resistivityInorganic material magnetismCores/yokesForm constantMaterials science

Owner:ALPS ALPINE CO LTD

Space solar cell string non-contact pressing method

InactiveCN100492677CCloth paste quality controlCloth paste quality assuranceFinal product manufactureSemiconductor devicesContact pressureForm constant

In the space solar battery string non-contact pressure exerting method used is pressure exerting device with corresponding shape and size to space solar battery string. There is a gas storage cell inside the pressure exerting device, and gas entrnace is at top end of the gas storage cell, some small gas exit are arranged at the bottom end of the gas storage cell. The pressure exerting device is fixed on robot which drives pressure exerting device moving straight above the solar battery, controlls relative space between pressure exerting device and space solar battery, makes gas into gap of space solar battery and pressure exerting device through the small hole on pressure exerting device after gas source is put-through to form constant pressure space to make solar battery be firm fixed on said board.

Owner:SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com