Composite magnetic powder and compaction magnet core using the same

A composite magnetic powder and soft magnetic technology, which is applied in the field of dust cores, can solve the problems of iron loss reduction and achieve the effect of improving contact resistance and high resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

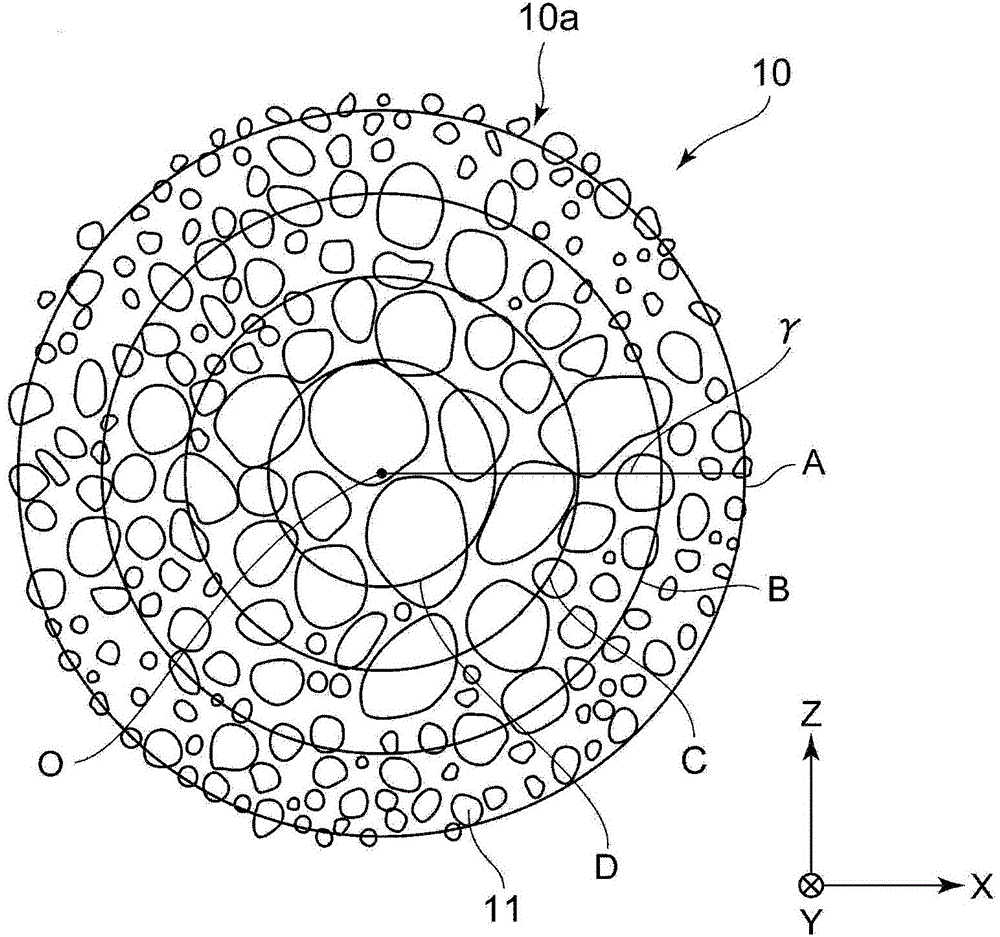

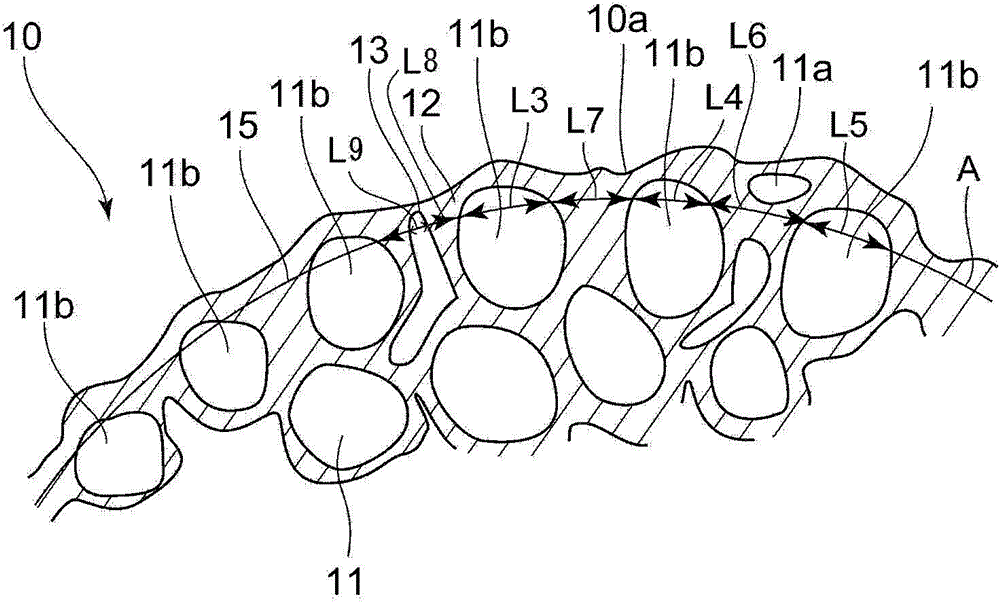

[0069] figure 1 It is a schematic diagram showing the cross section of the composite magnetic powder of this embodiment, figure 2 will be figure 1 A schematic diagram of a composite magnetic powder according to the present embodiment shown enlarged.

[0070] figure 1 The composite magnetic powder (granulated powder) 10 of the present embodiment shown is obtained by using a binder resin ( figure 1 Not shown in ) by bonding soft magnetic particles 11 together. Among them, in figure 1 In , only one soft magnetic particle 11 is given a symbol 11 .

[0071] figure 1 A cross section passing through the approximate center O of the composite magnetic powder 10 is shown. Here, "center" may be defined as the geometric center point. If the composite magnetic powder 10 is approximately spherical or approximately ellipsoidal, the point where the midpoints in the X, Y, and Z directions intersect is the center. In addition, "center" may be defined as "center of gravity".

[0072] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com