Integral yarn automatic lubricating device

An automatic lubrication and yarn technology, applied in textiles and papermaking, etc., can solve the problems of increased product cost, increased consumption, fly, etc., and achieve the effects of reasonable structure, increased cohesion, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

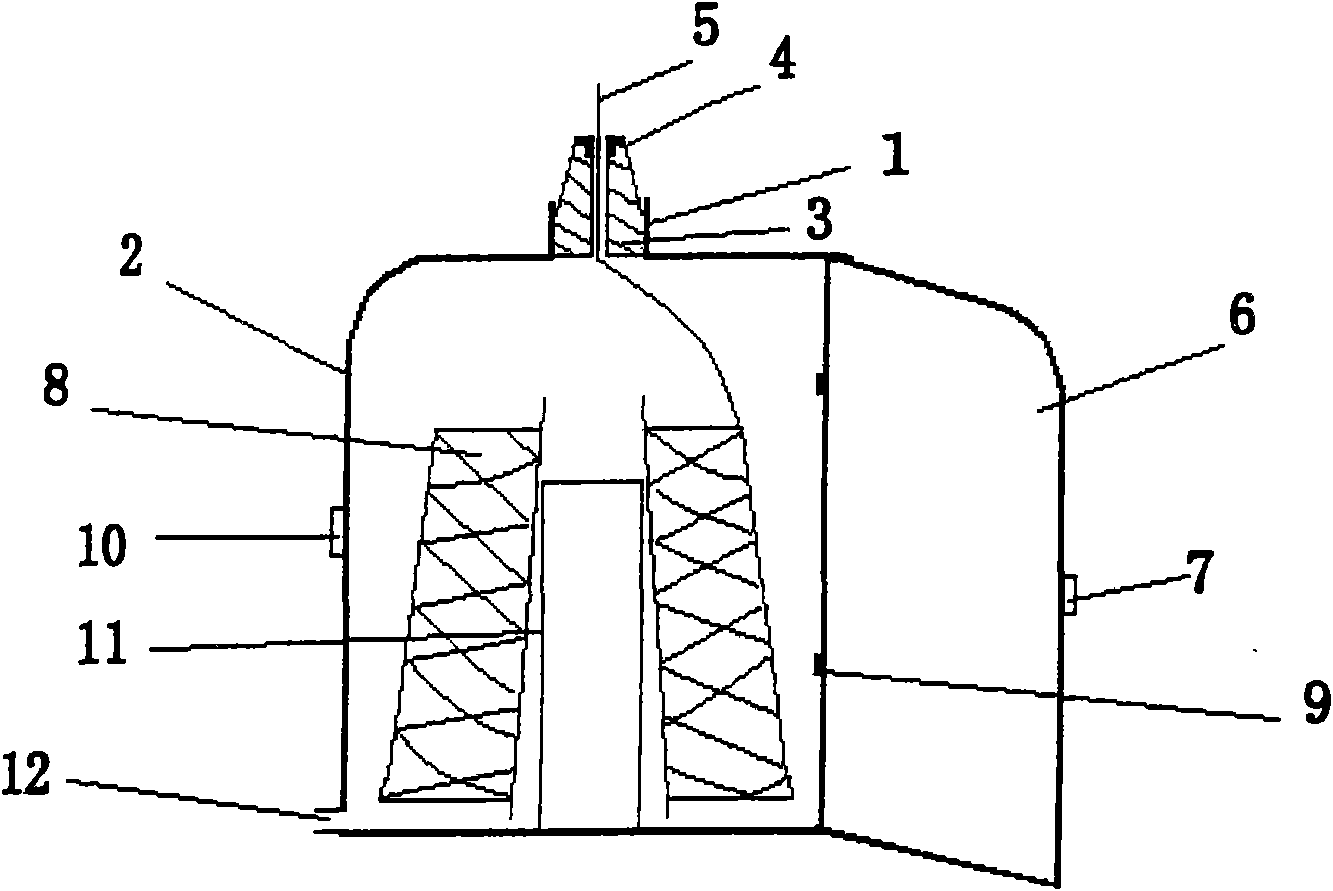

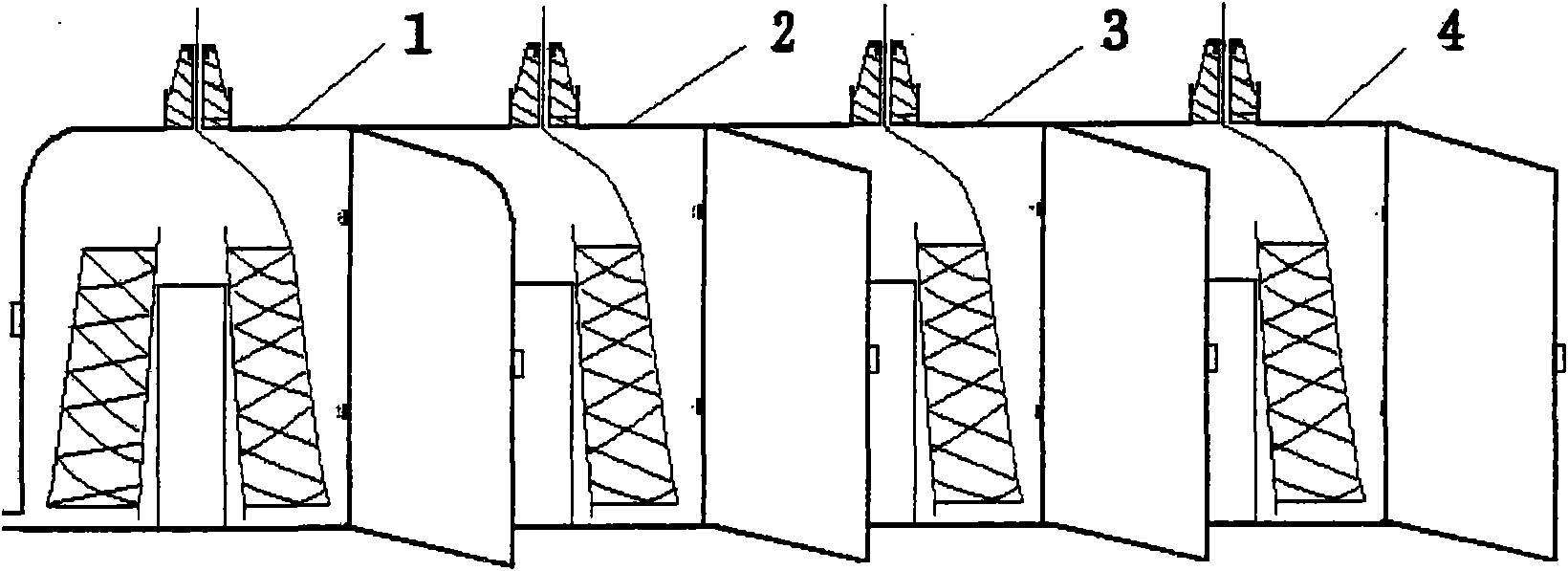

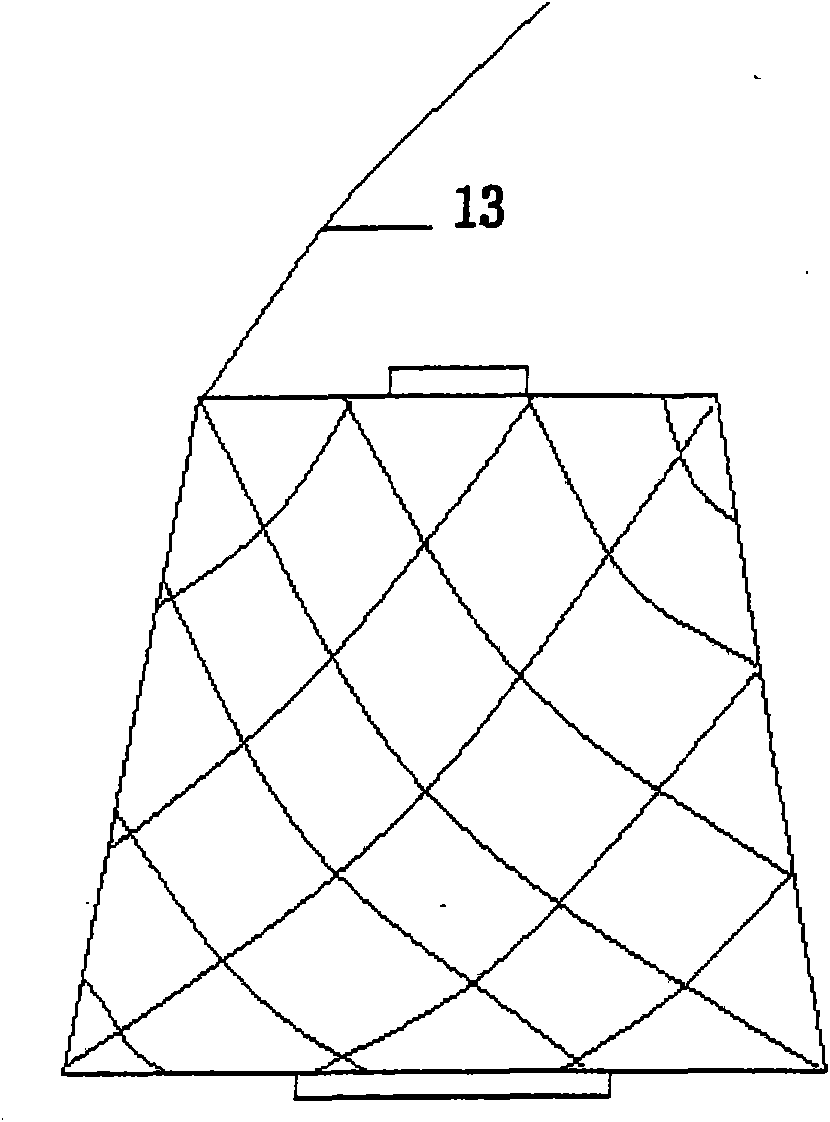

[0012] Referring to the accompanying drawings is an embodiment of the invention, the purpose of the present invention is achieved by the following measures: the lubricating box (1) is connected to the transparent dust cover (2), the tapered lubricating block (3) is inserted in the lubricating box (1), the porcelain The eye (4) is plugged into the top center hole of the conical lubricating block (3), the yarn (5) is drawn out from the center hole of the porcelain eye (4), and the center tube (11) of the dust cover is inserted into the yarn ball (8 ), the dust cover door (6) is connected to the hinge (9), and the clasp (7) is locked together with the clasp (10) when closing the door, and the dust outlet (12) is connected with the vacuum cleaner for dust removal. The device can be used in an integrated design of 1, 2, 3, 4...12, etc. multi-compartment. Realize the natural air circle generated when the yarn cluster is unwound, form a constant helical force to straighten out the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com