Patents

Literature

235results about How to "Evenly lubricated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

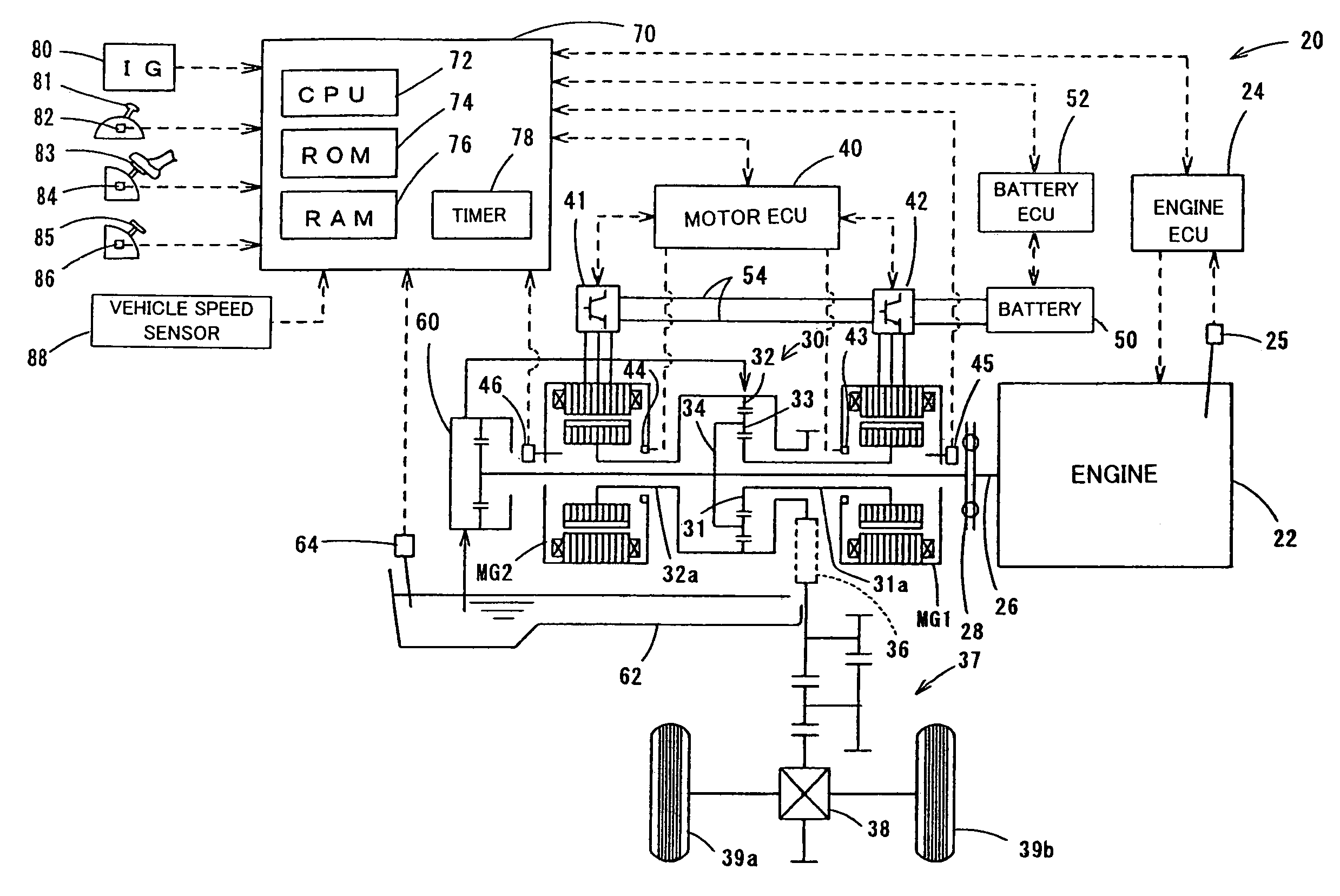

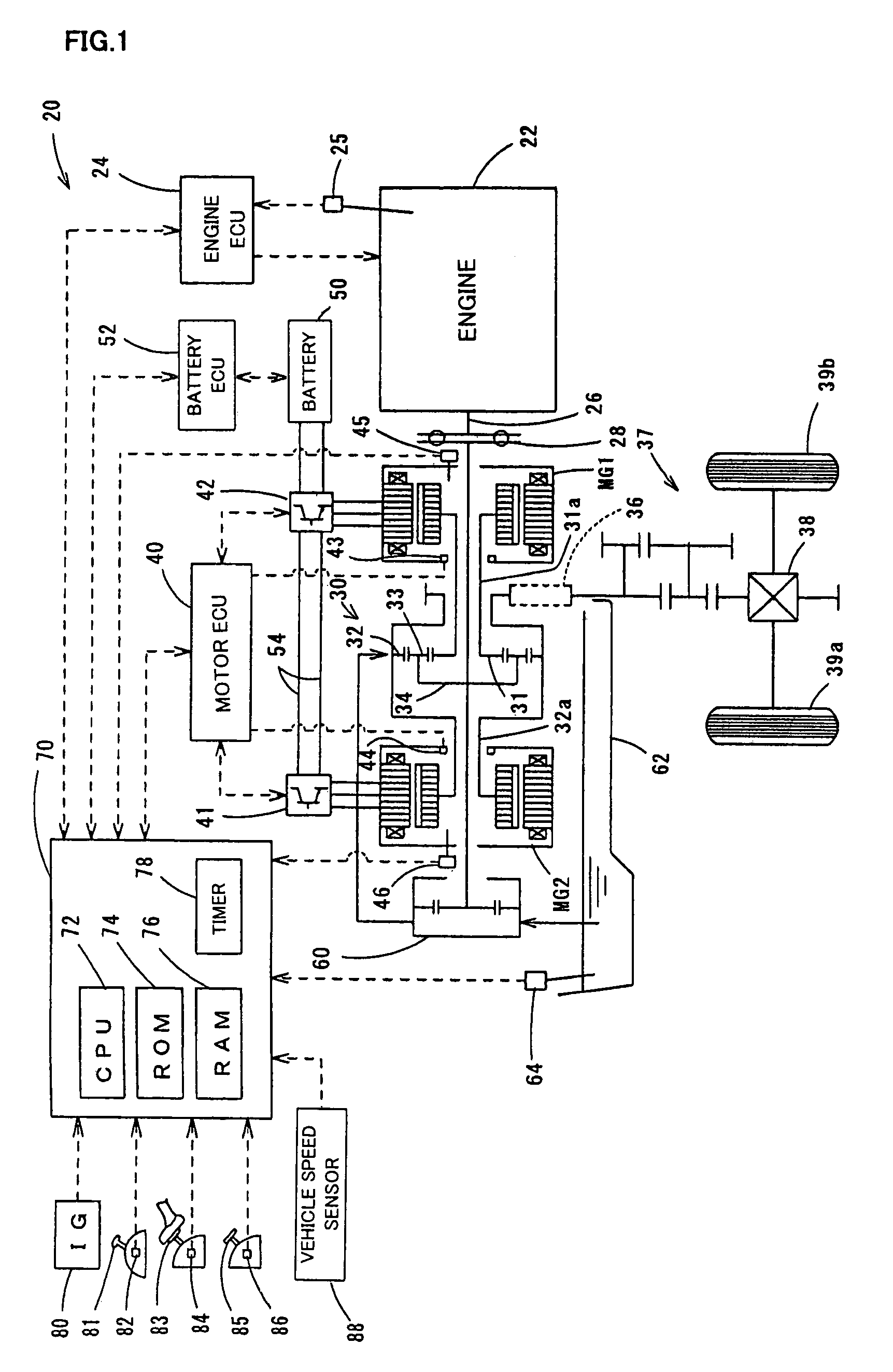

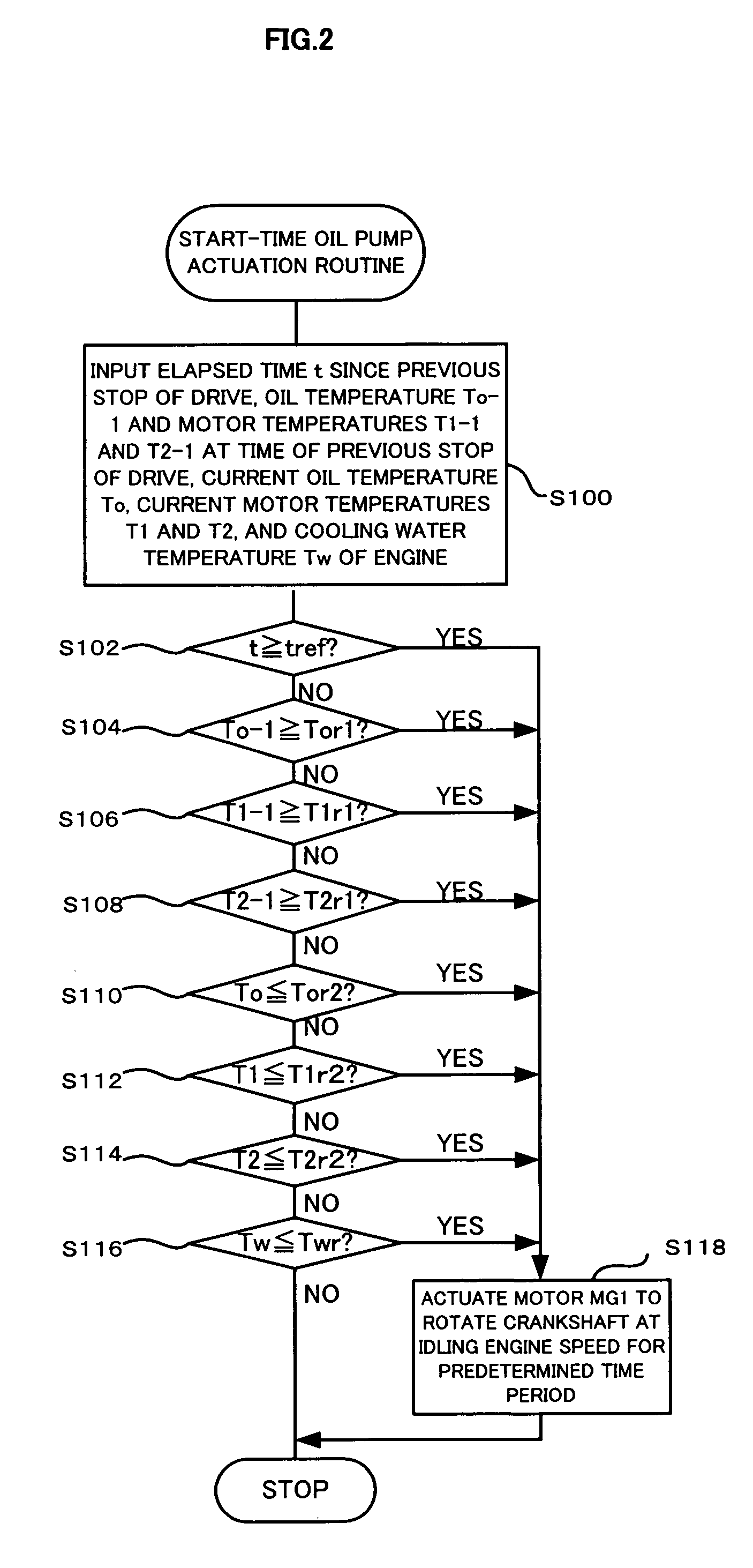

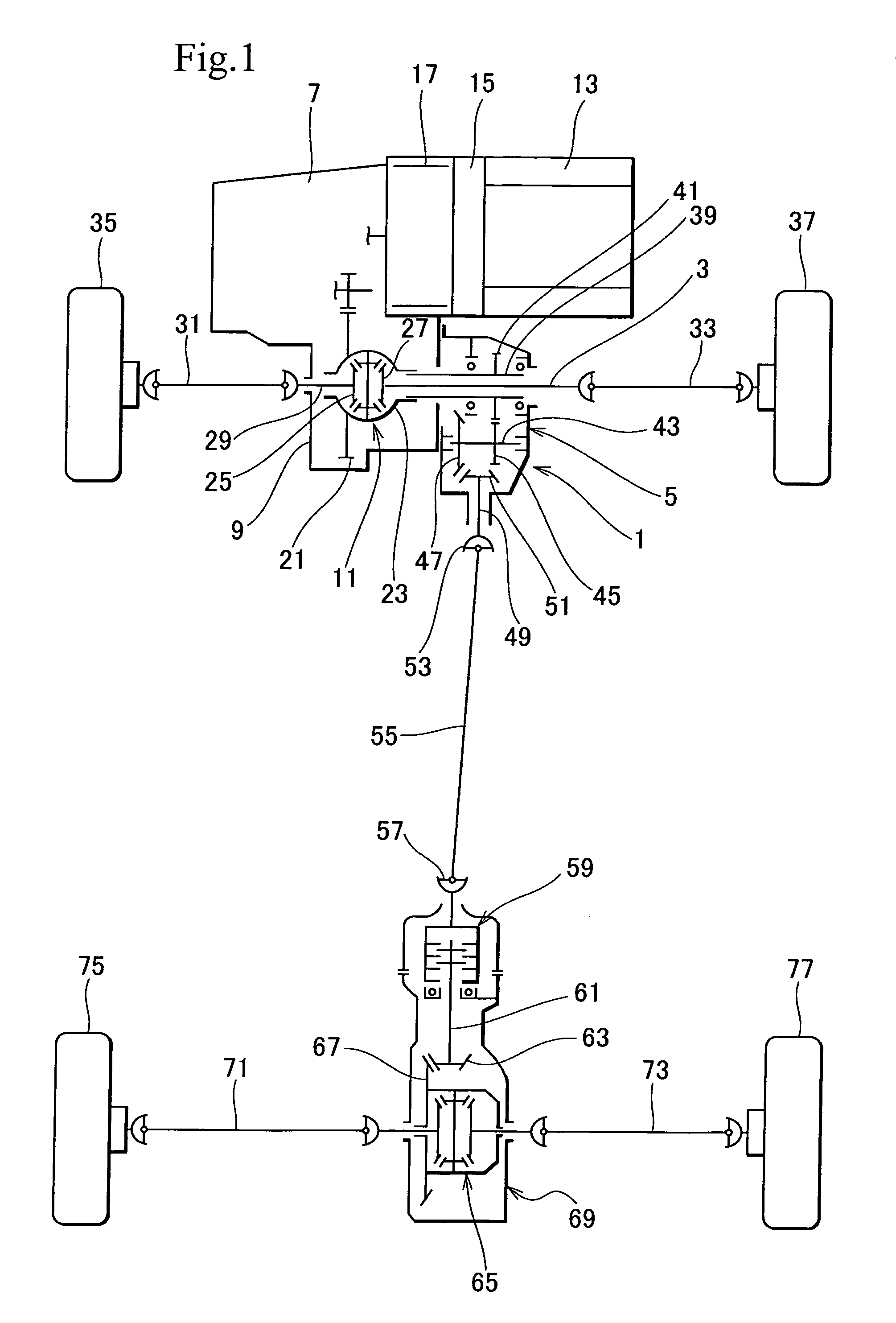

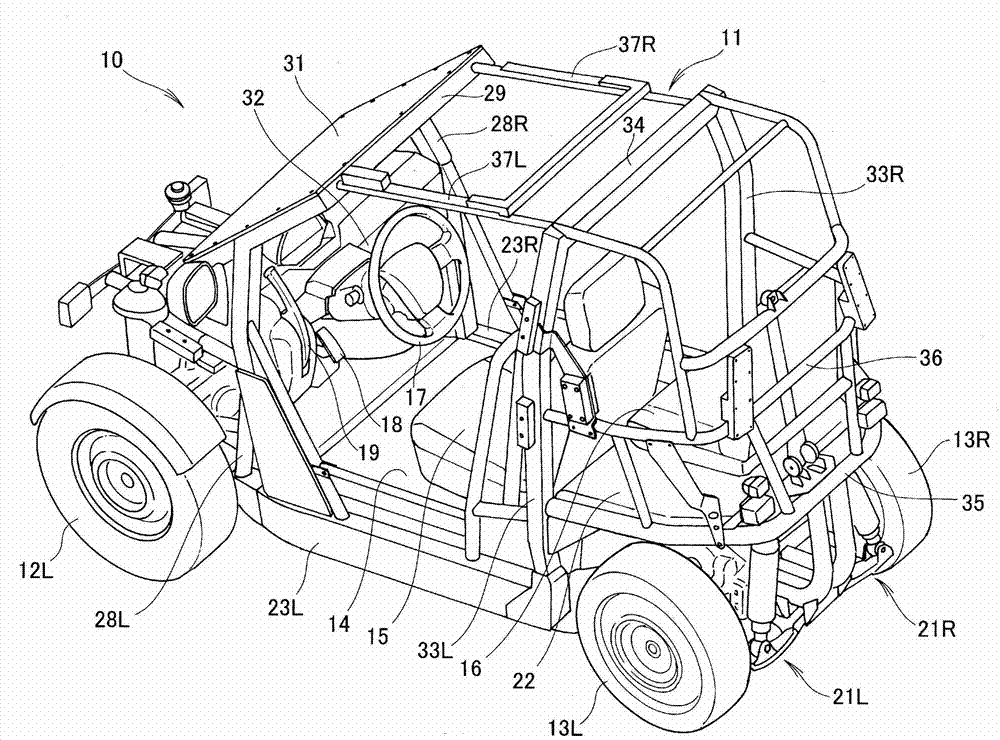

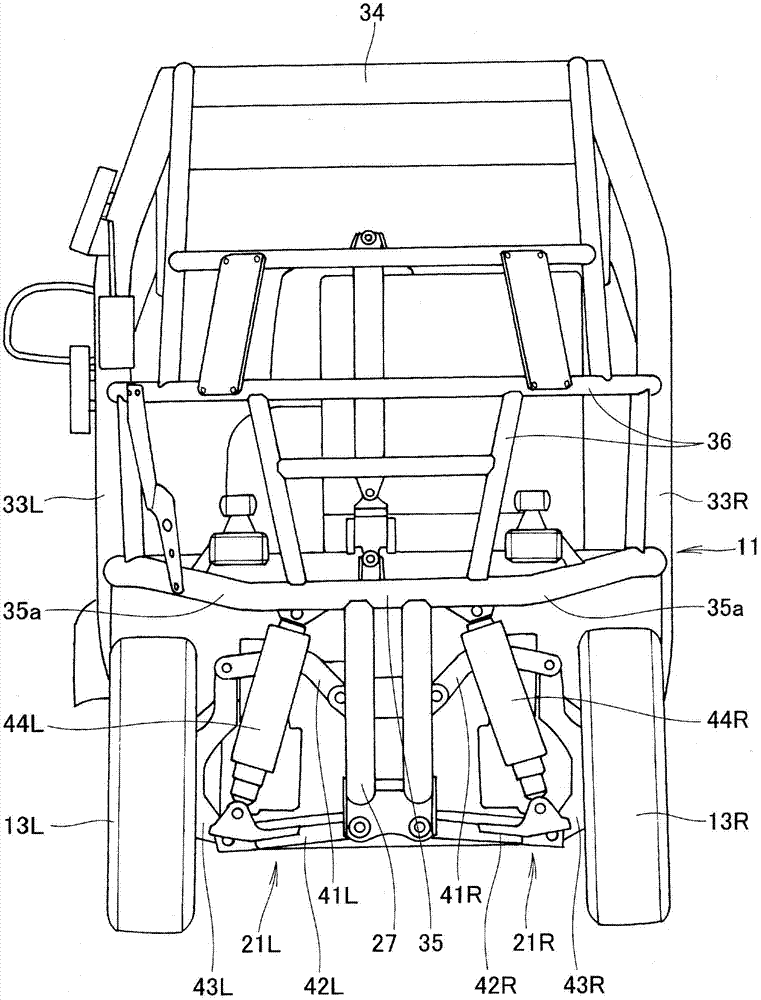

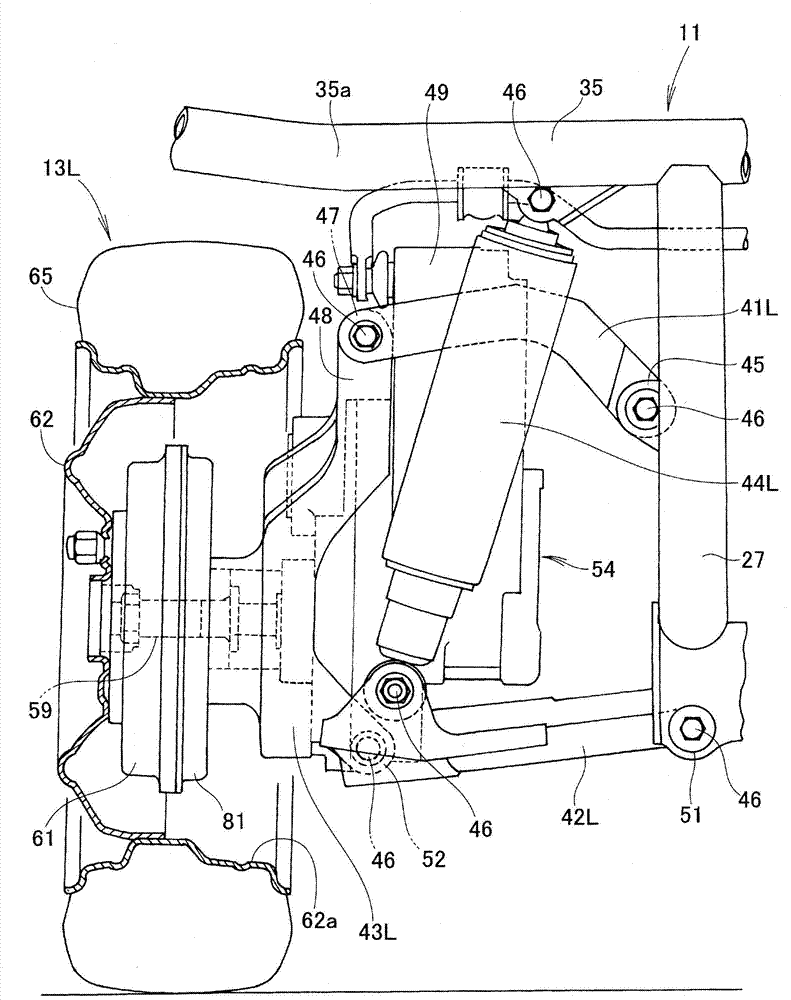

Power output apparatus and hybrid vehicle with power output apparatus mounted thereon

InactiveUS7000718B2Additional mechanical partIncrease temperatureHybrid vehiclesElectric propulsion mountingHybrid vehicleCrankshaft

A hybrid vehicle may run with only the power from a motor MG2, while an engine is at a stop. In this state, the control procedure drives a motor MG1 to rotate a crankshaft at an idling engine speed for a predetermined time period, when at least one of an observed oil temperature in a sump, an observed temperature of the motor MG1, an observed temperature of the motor MG2, an observed revolving speed of the motor MG1, and an observed revolving speed of the motor MG2 is not less than a corresponding preset value. Rotation of the crankshaft at the idling engine speed results in driving an oil pump to feed a supply of lubricating oil to mechanical part of the power output apparatus including a power distribution integration mechanism.

Owner:TOYOTA JIDOSHA KK

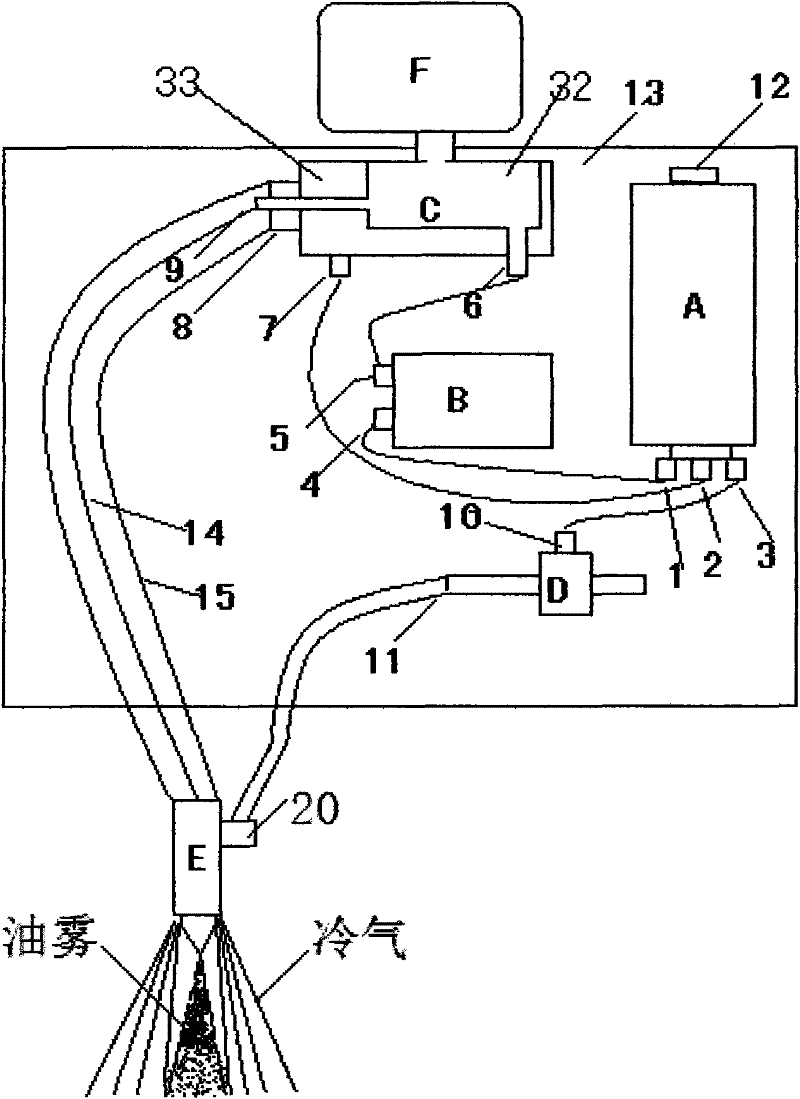

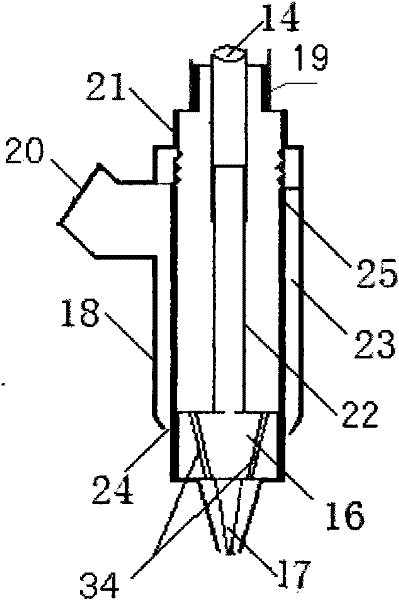

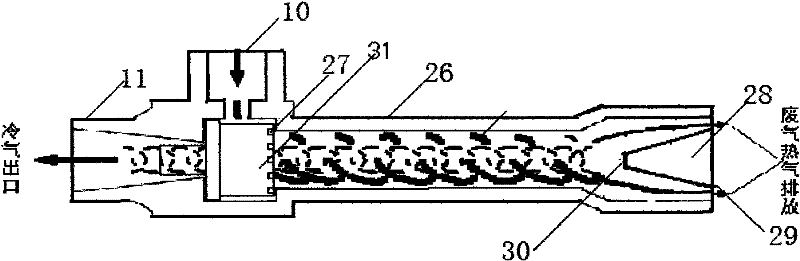

Low temperature atomization lubrication cooling system

InactiveCN102275088AReduce pollutionReduce volumeMaintainance and safety accessoriesCold airSpray nozzle

The invention provides a low-temperature atomized lubrication cooling system, aiming at providing a lubrication cooling system which can be used for reducing the using amount of a cooling lubricant and effectively improving the cooling lubrication effect and has small size and no oil deposit at a spray nozzle. The low-temperature atomized lubrication cooling system is characterized in that: a diverter pump and a pulser which are communicated with a rectifying and atomizing nozzle and an oil cup are arranged between a pressurizer and the oil cup; three groups of diverter air nozzles are arranged on the pressurizer, wherein an intermitted airflow is formed at one group of diverter air nozzles through the pulser and enters the diverter pump, and the other tow groups of diverter air nozzles are respective and directly communicated into an interlayer port of the diverter pump and an air inlet nozzle of a vortex generator; and a double-core outlet which is communicated with an interlayer ofthe diverter pump and a main cavity of the diverter pump is also arranged on the output end of the diverter pump, and vertex cold air which is generated at the double-core outlet through a double-core air pipe and a vertex generator that are connected flows into the rectifying and atomizing nozzle. According to the invention, the problems of large lubrication cooling quantity and pollution causedby waste oil discharge in the traditional machining operation are solved, oil is saved, and the using amount of cutting fluid for atomizing and lubricating is only 0.03-0.2L / h generally.

Owner:成都三洪高科科技有限公司

Glass lubricant for hot extrusion of titanium alloy section bar

ActiveCN103602361AGood instant meltingSmall specific surface areaBase-materialsSurface roughnessTitanium alloy

The invention provides a glass lubricant combination for hot extrusion of a titanium alloy section bar at a temperature of 900 DEG C-1,200 DEG C. The lubricant is composed of glasses being powder-coated glass and glass-pad glass with novel glass formulas. The two types of glass are used in a roller coating stage and an extruding stage respectively. Compared with conventional products, the lubricant provided by the invention has better protective and lubricative performances. With the products provided by the invention, surface roughness of the titanium alloy section bar is low; defects are few; and coping rate can be significantly reduced.

Owner:BEIJING TIAN LICHUANG SCI & TECH OF GLASS DEV +2

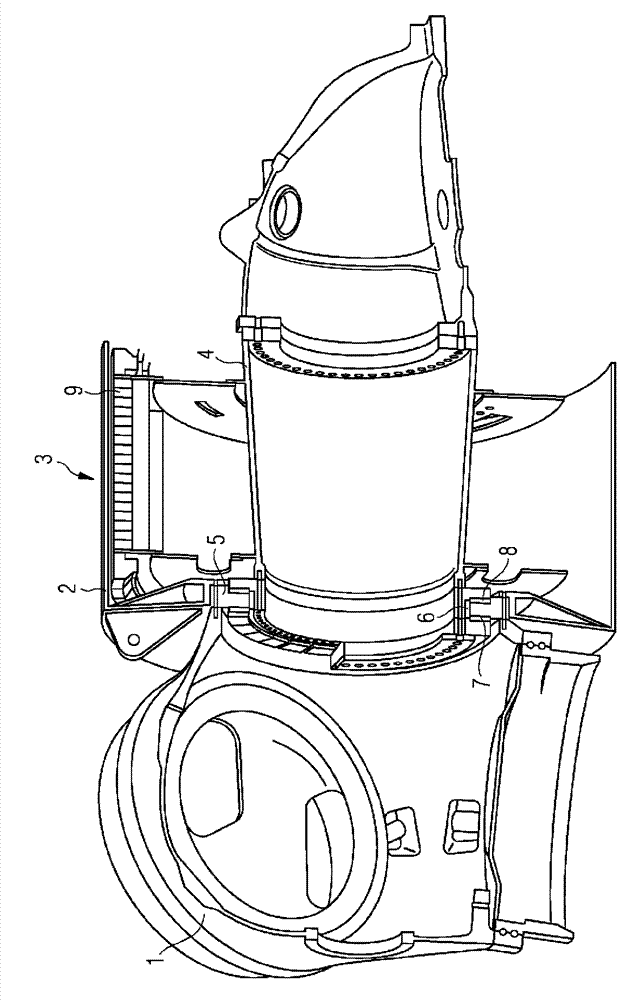

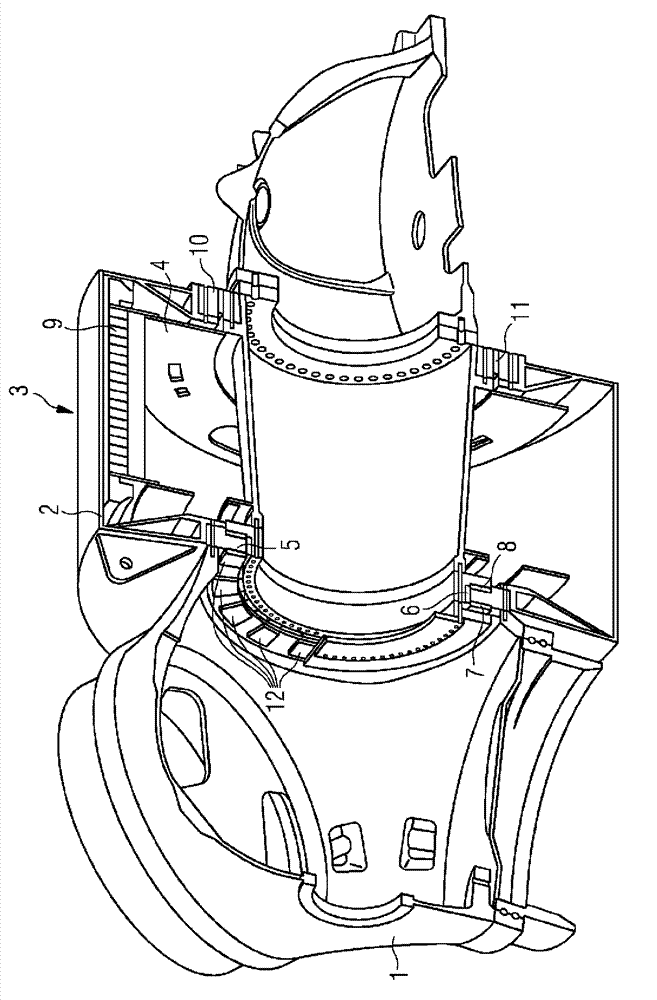

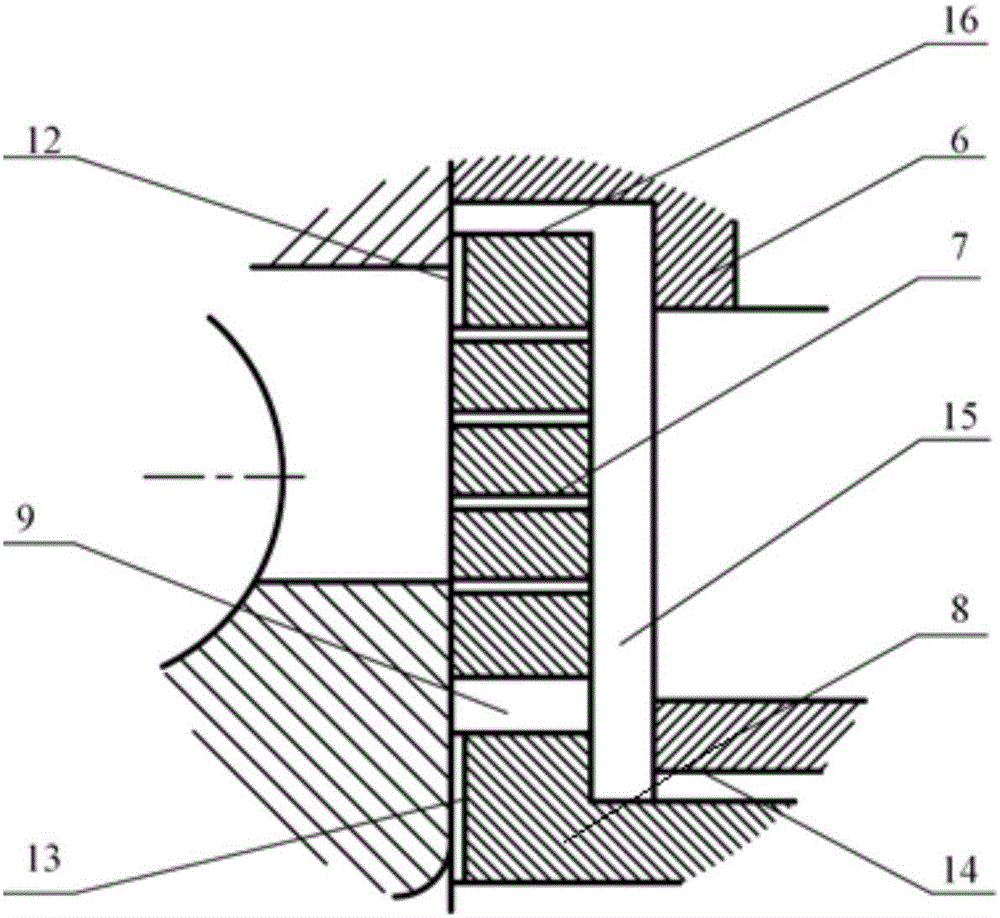

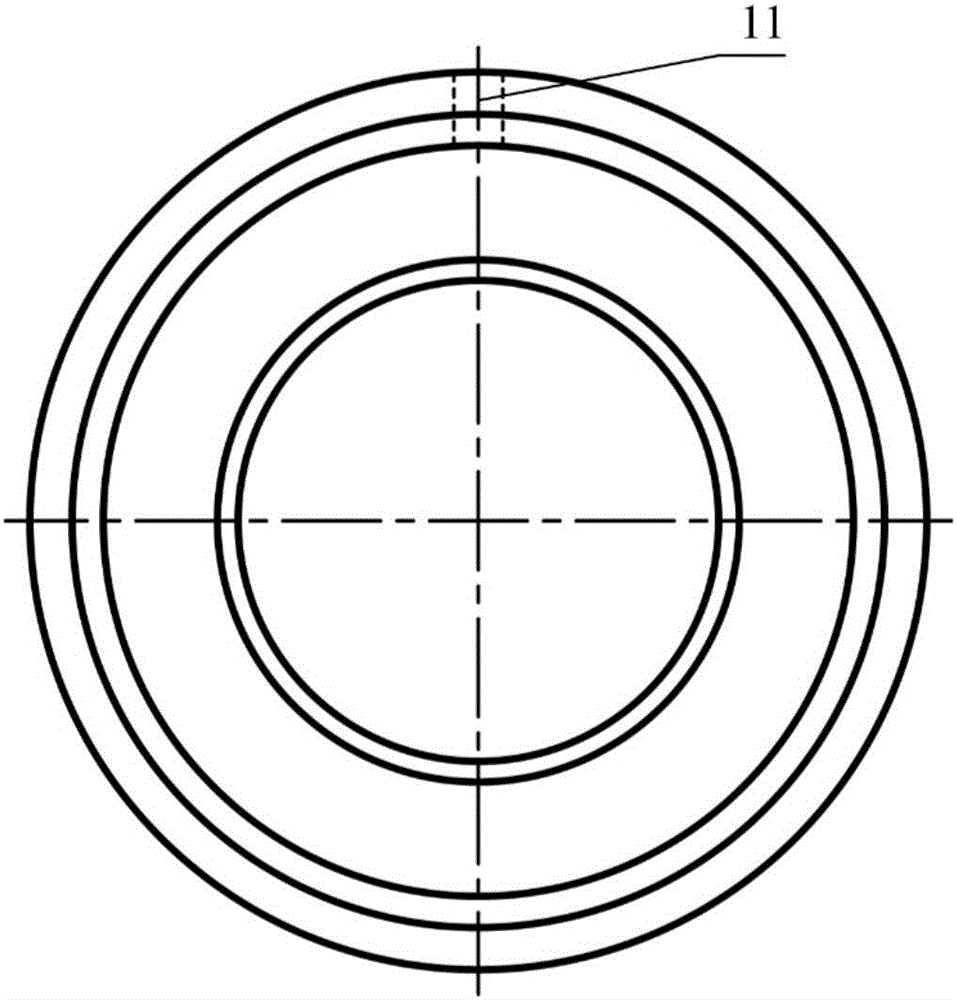

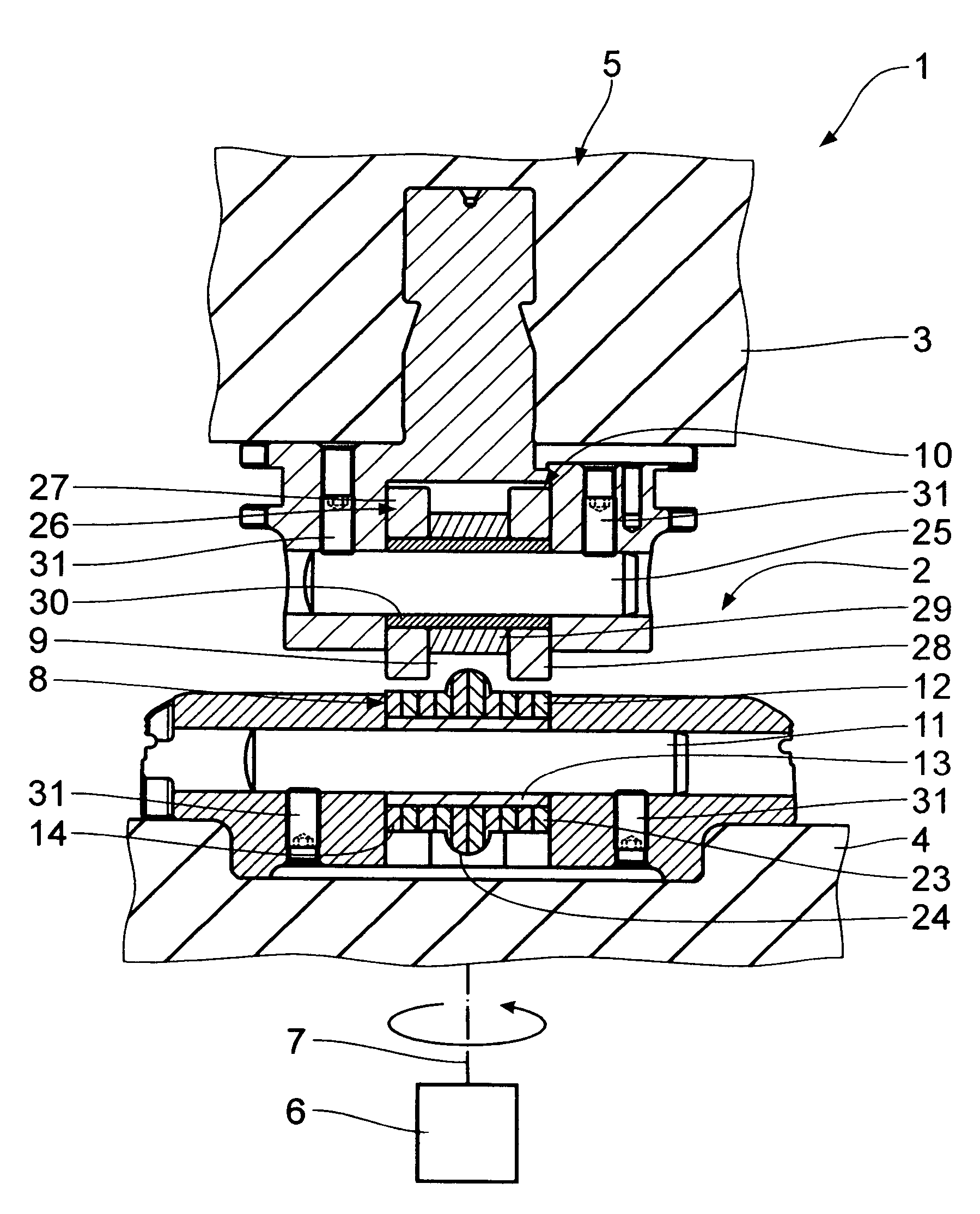

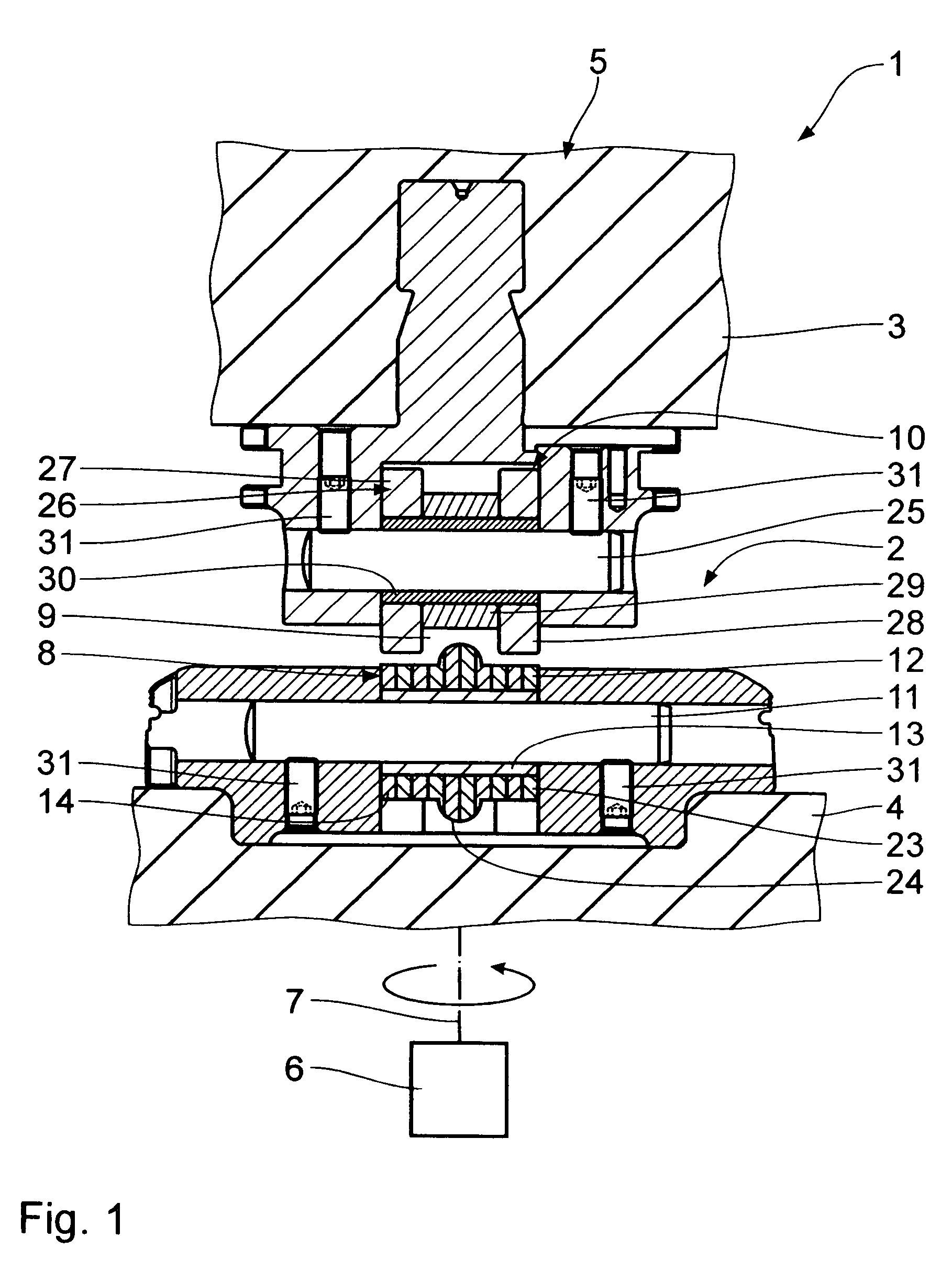

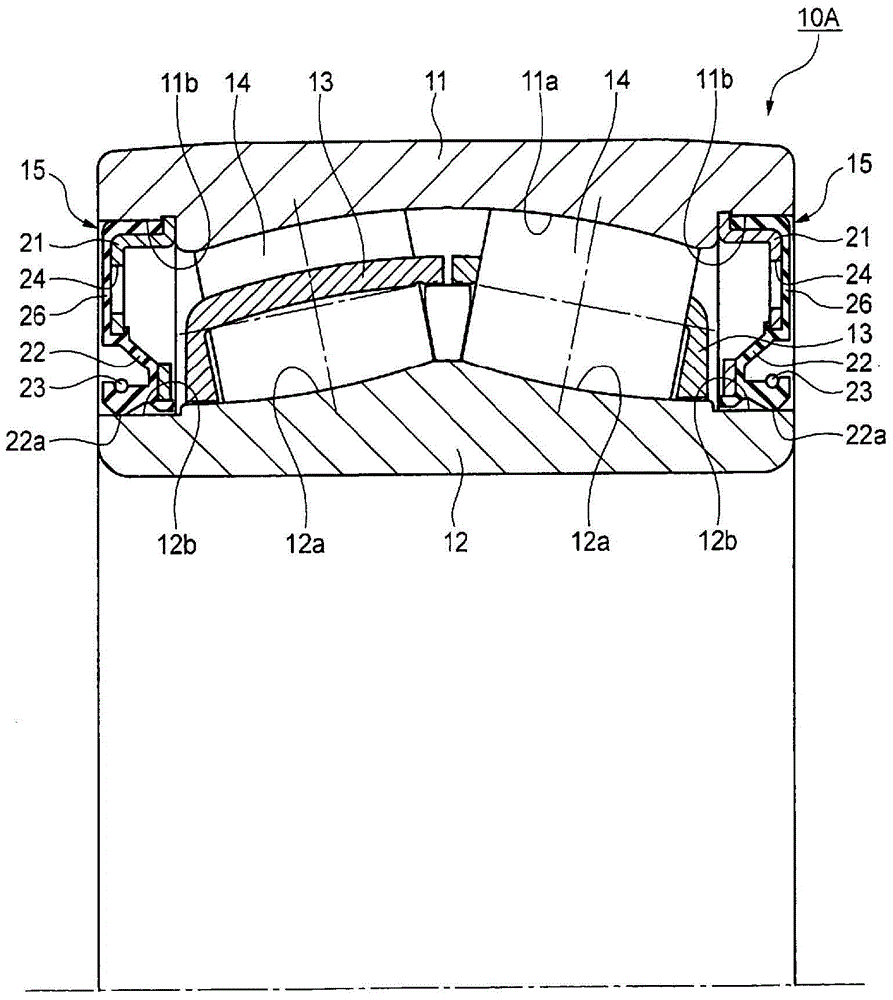

Direct-drive wind turbine

InactiveCN103765005AEvenly distributedReduce the risk of injuryShaftsBearing componentsTurbineBearing surface

The invention relates to a direct-drive wind turbine and the main bearing used in such a wind turbine. The rotating drive train is connected with a stationary part of the wind turbine via at least one bearing (5), which allows the rotation of the drive train in relation to the stationary part. The at least one bearing (5) is a plain bearing; the bearing comprises at least one cylindrical sliding surface (6) constructed to support radial loads present in the drive train. The bearing comprises at least two radial bearing surfaces (7, 8) constructed to support axial loads and bending moments present in the drive train. The surface areas of the radial bearing surfaces (7, 8) are dimensioned proportional to a predetermined maximum total load of the bending moments expected in the drive train.

Owner:SIEMENS AG

Drawing lubricant for titanium and titanium alloy tubes and application method of such drawing lubricant

ActiveCN106811277AImprove bindingReduce frictionLubricant compositionSodium phosphatesSurface cleaning

The invention belongs to the field of lubricating materials and application thereof and discloses a drawing lubricant for titanium and titanium alloy tubes and an application method of such drawing lubricant. The drawing lubricant comprises 1) any two of glass powder, graphite fluoride and boron nitride, 2) any two of borax, sodium phosphate and sodium fluoride, and 3) water. A lubricating treatment process includes subjecting the titanium and titanium alloy tubes to surface cleaning, conducting oxidizing annealing, spraying, drying and drawing practically to enable the surface roughness of drawn products to be below Ra 0.8 micrometers. The drawing lubricant has the advantages that a lubricating coating is formed on the surfaces of titanium and titanium alloy blanks through the drawing lubricant, so that lubricating conditions between the tube blanks and drawing dies are improved effectively, adhesion between the blanks and the dies is prevented, the service lives of the dies are prolonged and the tube surface quality is improved.

Owner:GRIMAT ENG INST CO LTD

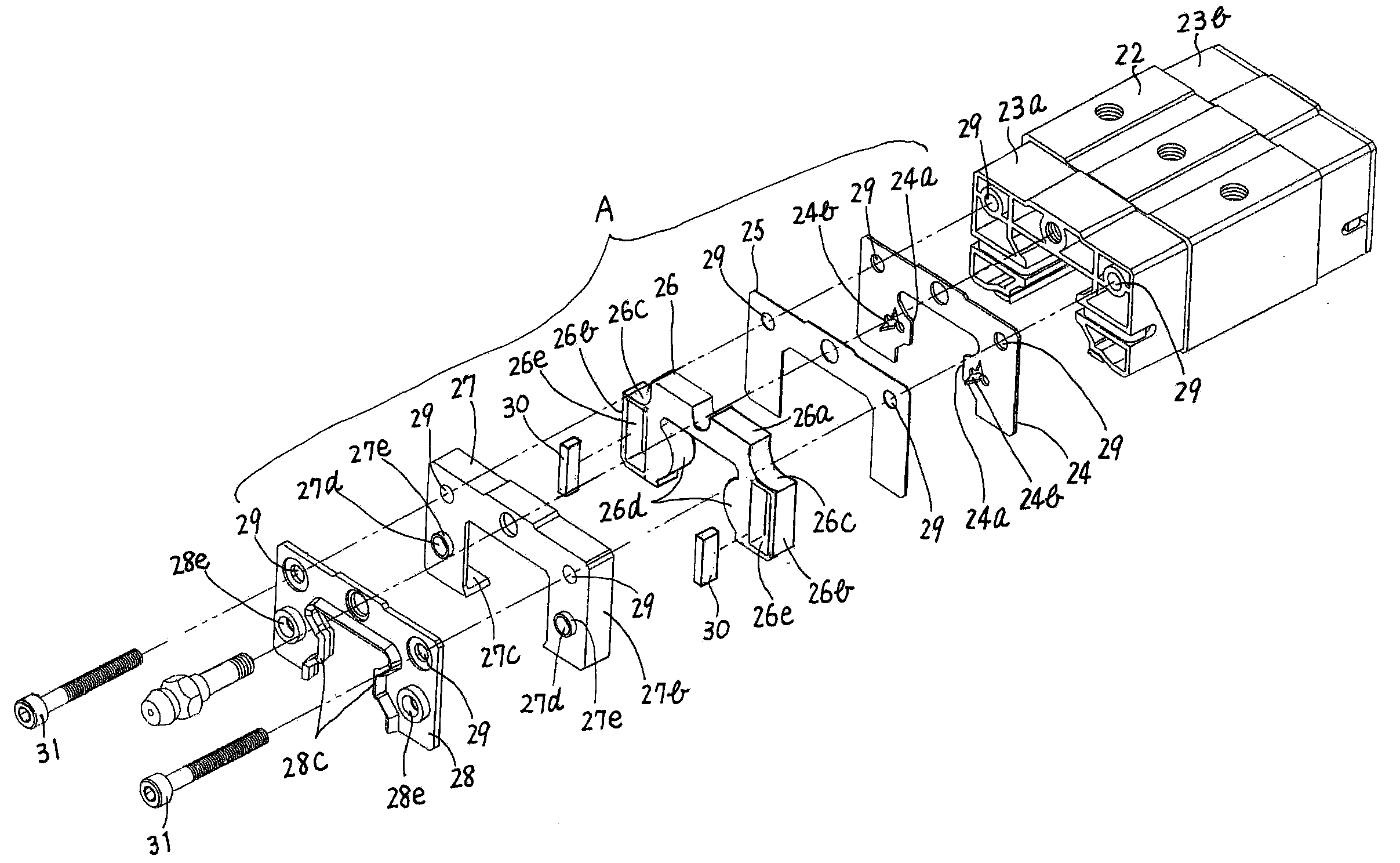

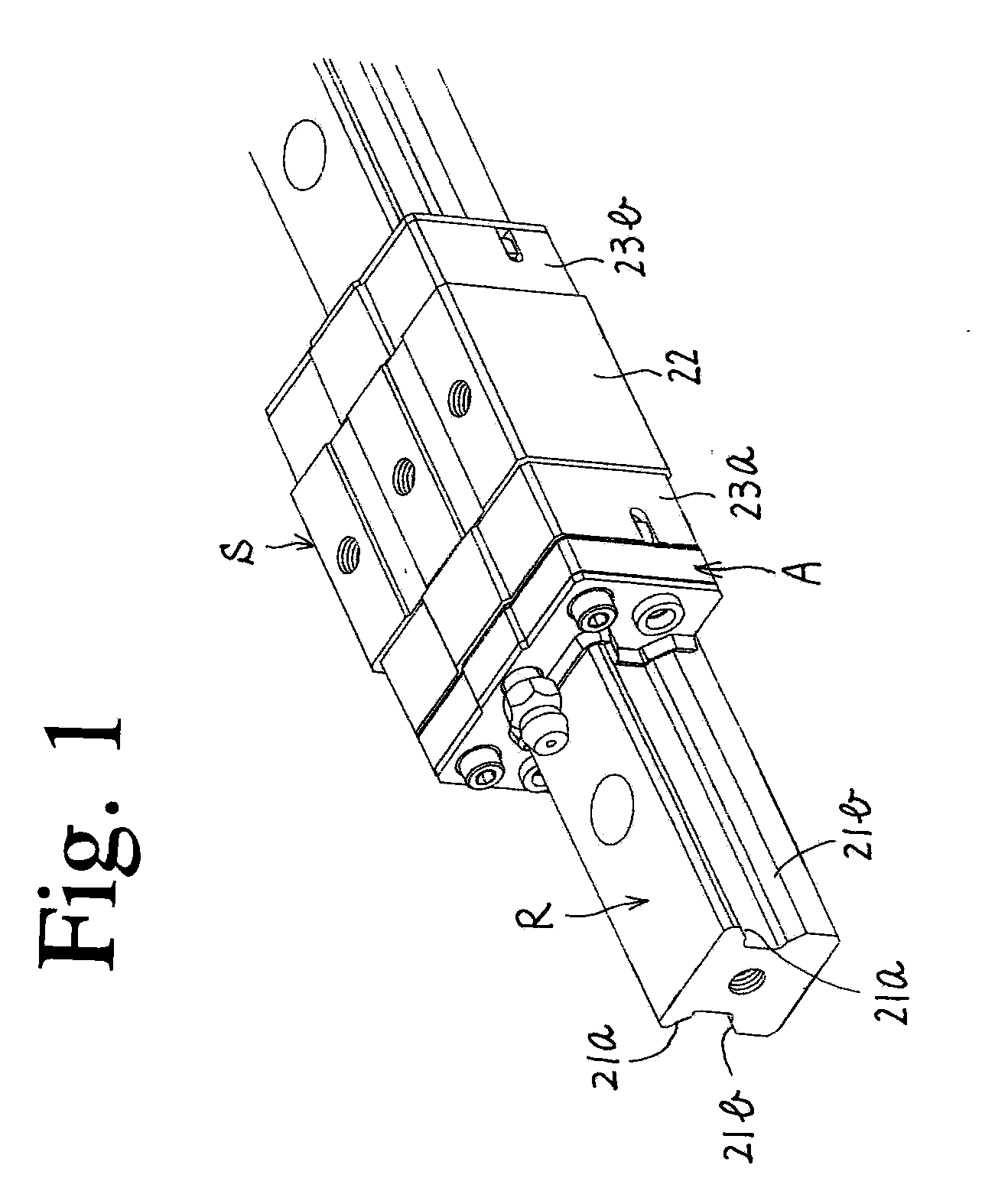

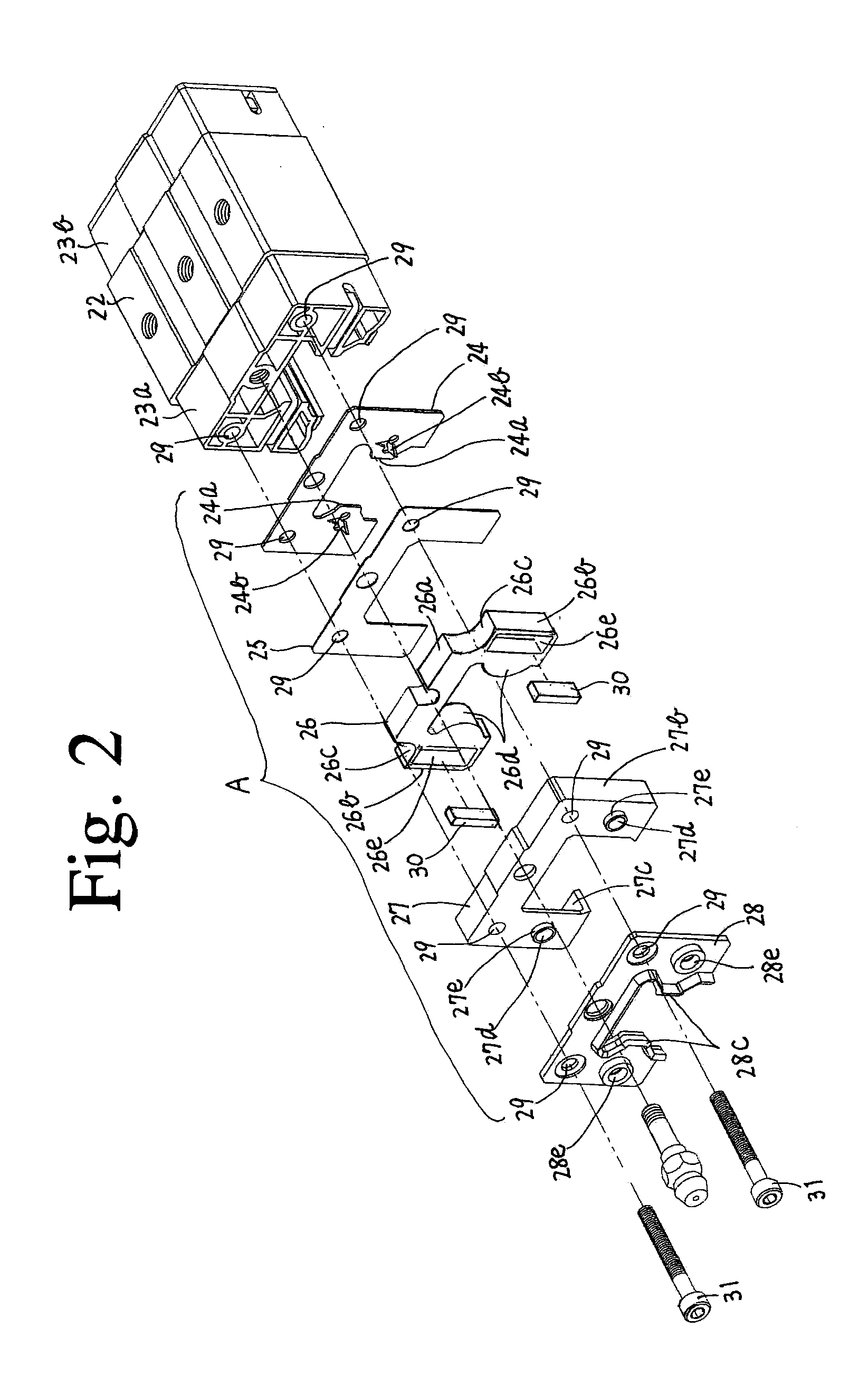

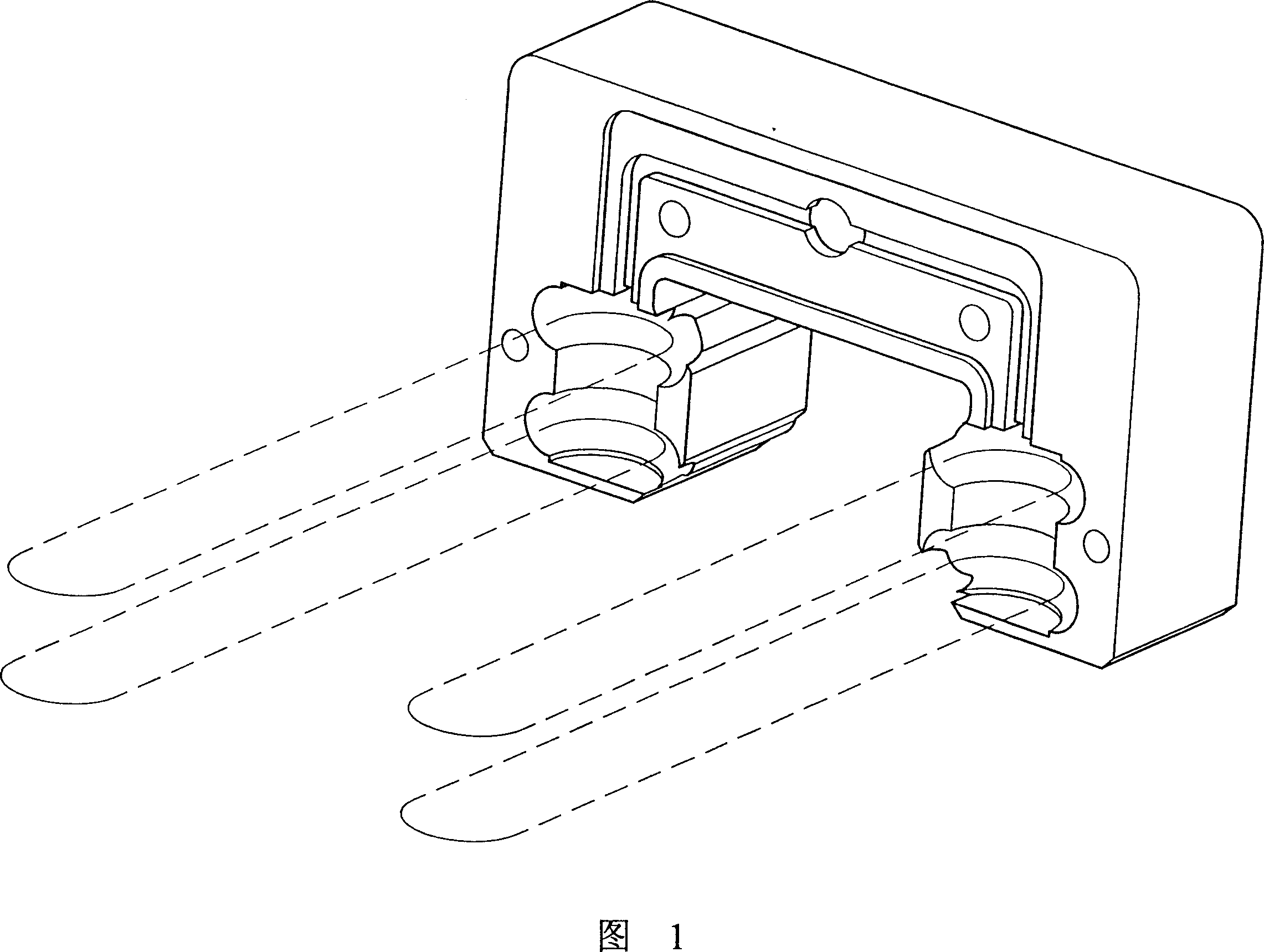

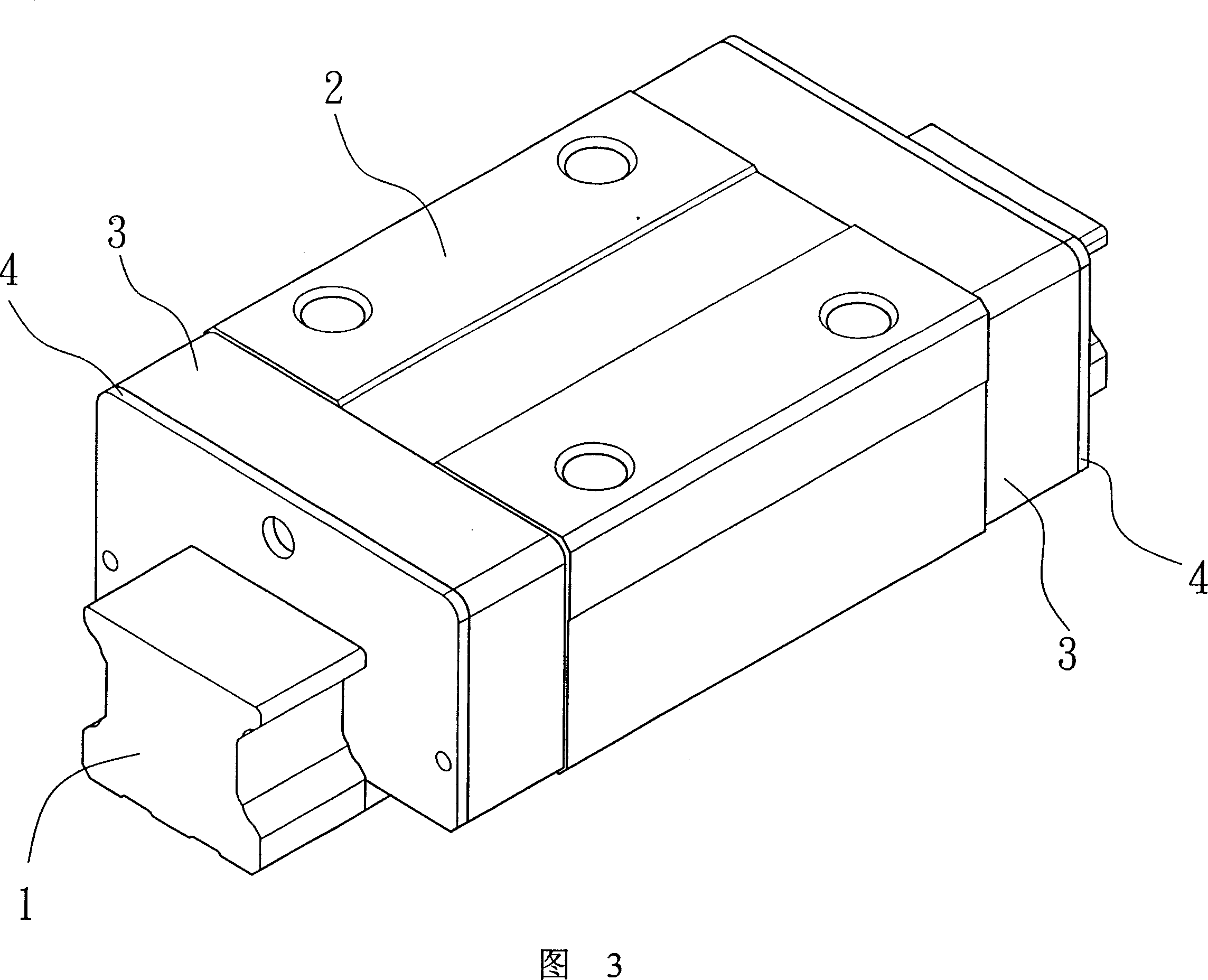

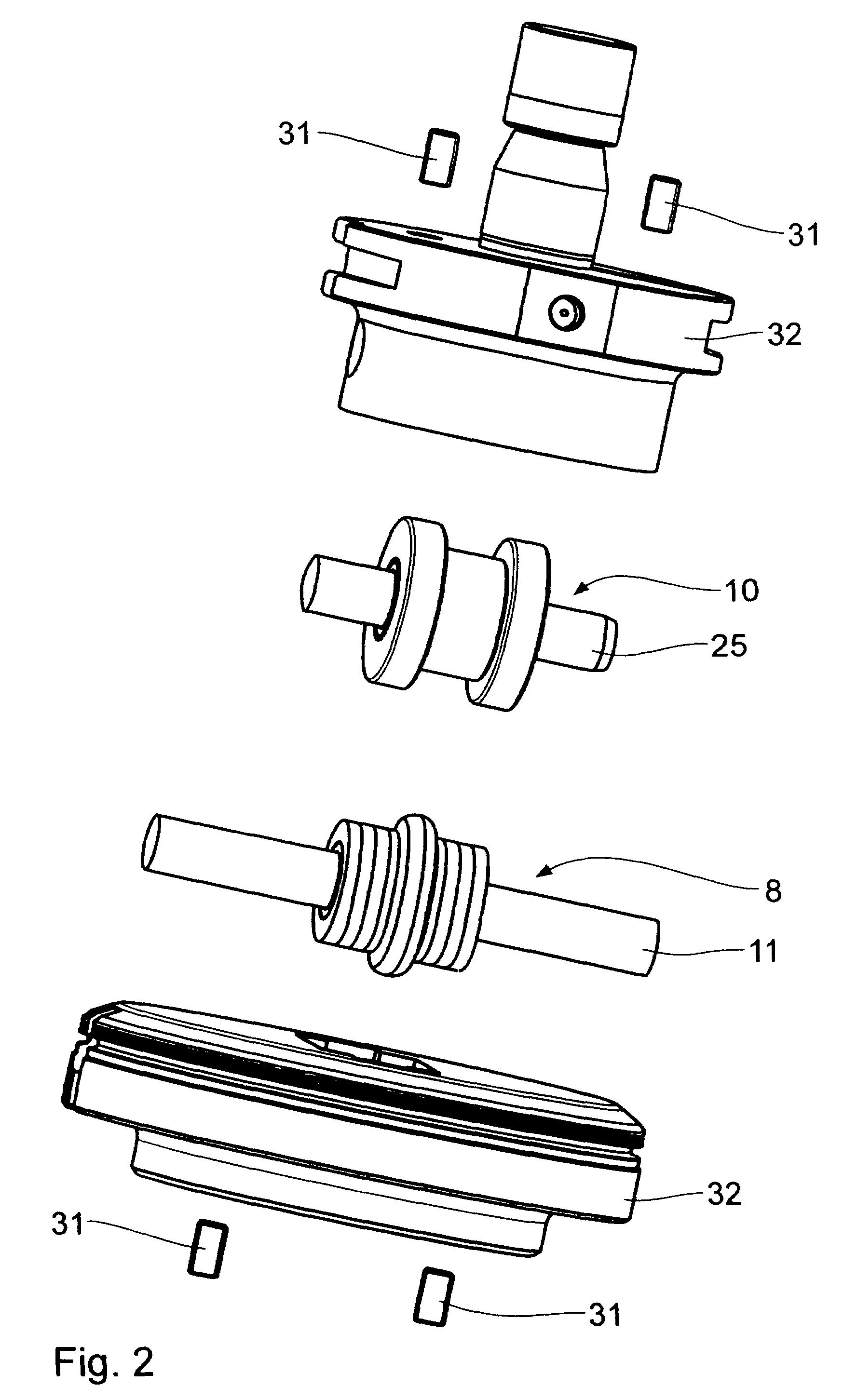

Lubricating Member For Linear Motion Rolling Guide Unit And Slider For Linear Motion Rolling Guide Unit

ActiveUS20100002965A1Operation be completeMaintaining lubricating capability of lubricatingRotary combination bearingsLinear bearingsLinear motionEngineering

A lubricant can be evenly applied onto raceway faces or raceway grooves of a rail even when fixed to a horizontal, vertical, tilted, or ceiling surface. One or a plurality of embedding portions 26e having a recess or a hole is formed in a member body 26 straddling the rail R. An impregnation holding member 30 holding a lubricant is embedded in the embedding portion. The lubricating member supplies the impregnating lubricant onto the rail raceway faces while making contact with them. Even when the rail is fixed to a horizontal, vertical, tilted or a ceiling surface, the embedding portion of the member body straddling the rail has at least a part maintained in position at a level equal to or higher than the level of at least a part of one of the raceway sections 21a, 21b of the rail located higher relative to the other raceway section.

Owner:NIPPON THOMPSON

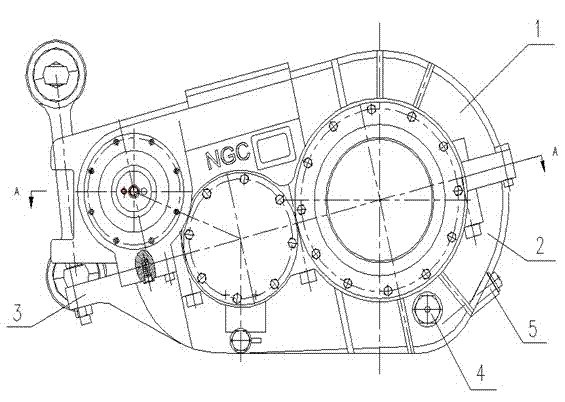

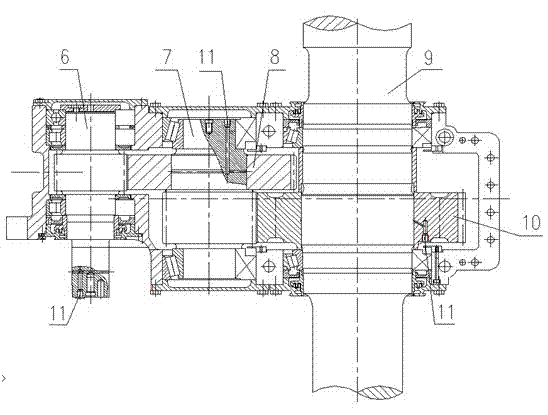

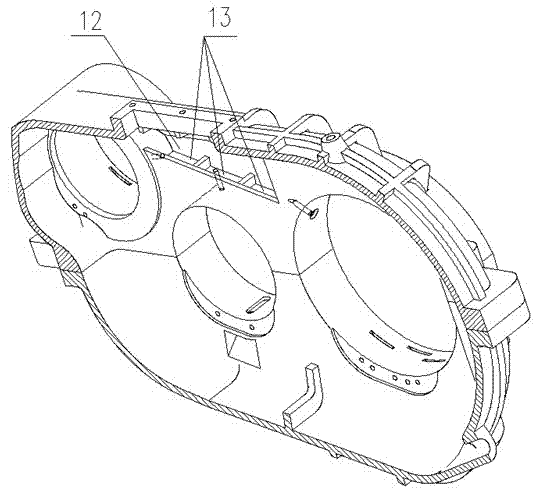

Rail transit gearbox

The invention relates to a rail transit gearbox, the box body of which comprises an upper box body and a lower box body, the lower box body is provided with a boom mounting seat, shaft axes of an input gear shaft, an intermediate gear shaft and a main shaft are parallel to each other, and a joint face between the upper box body and the lower box body passes through axes of the intermediate gear shaft and the main shaft and is parallel to the top of the upper box body. The input gear shaft is installed on the upper box body, an external shaft neck of the input gear shaft and both ends of the main shaft extend out of the box body, and the upper surface of the boom mounting seat in the lower box body and the joint face between the upper box body and the lower box body are on the same plane. The input gear shaft engages with a big intermediate gear and the intermediate gear shaft engages with a big output gear. The taper of the external shaft neck of the input gear shaft is 1:50. Assembly area of the external shaft neck of the input gear shaft is provided with a ring groove, the mounting shaft diameter of the intermediate gear shaft and the central mounting hole of the big output gear are provided with a ring groove, and the external shaft neck of the input gear shaft, the intermediate gear shaft and the big output gear are all provided with a high-pressure oil passage.

Owner:南京高精轨道交通设备有限公司

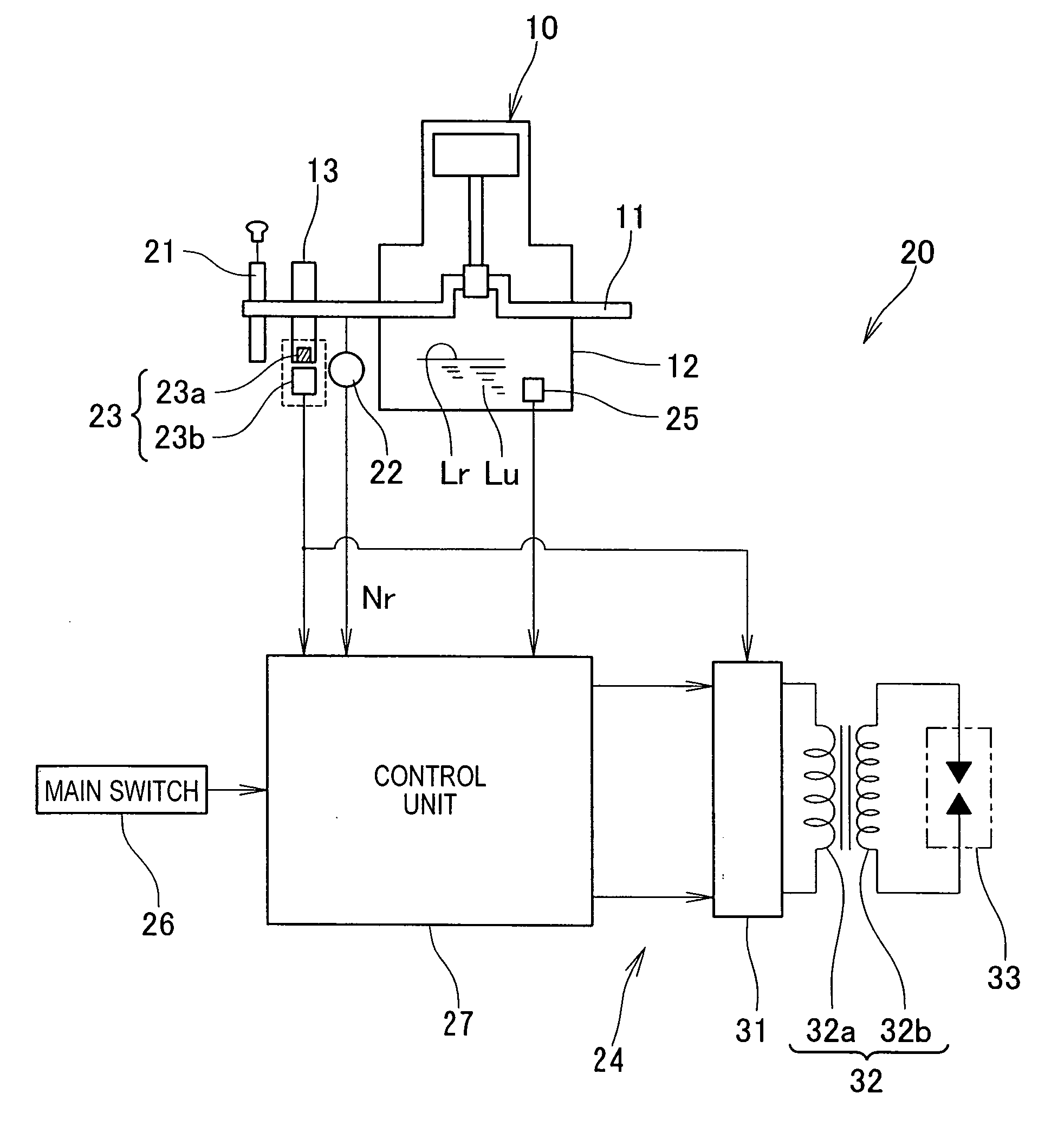

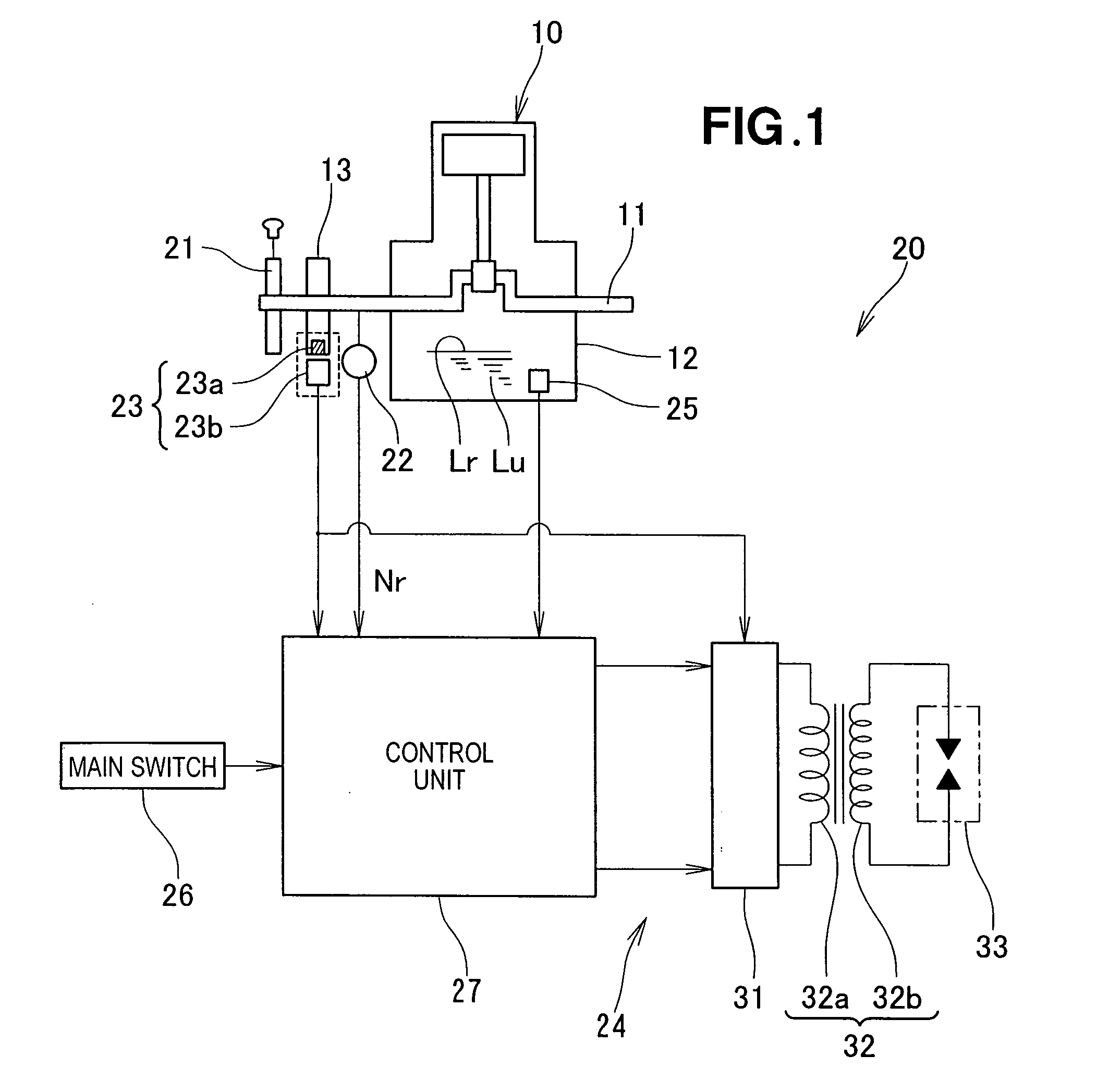

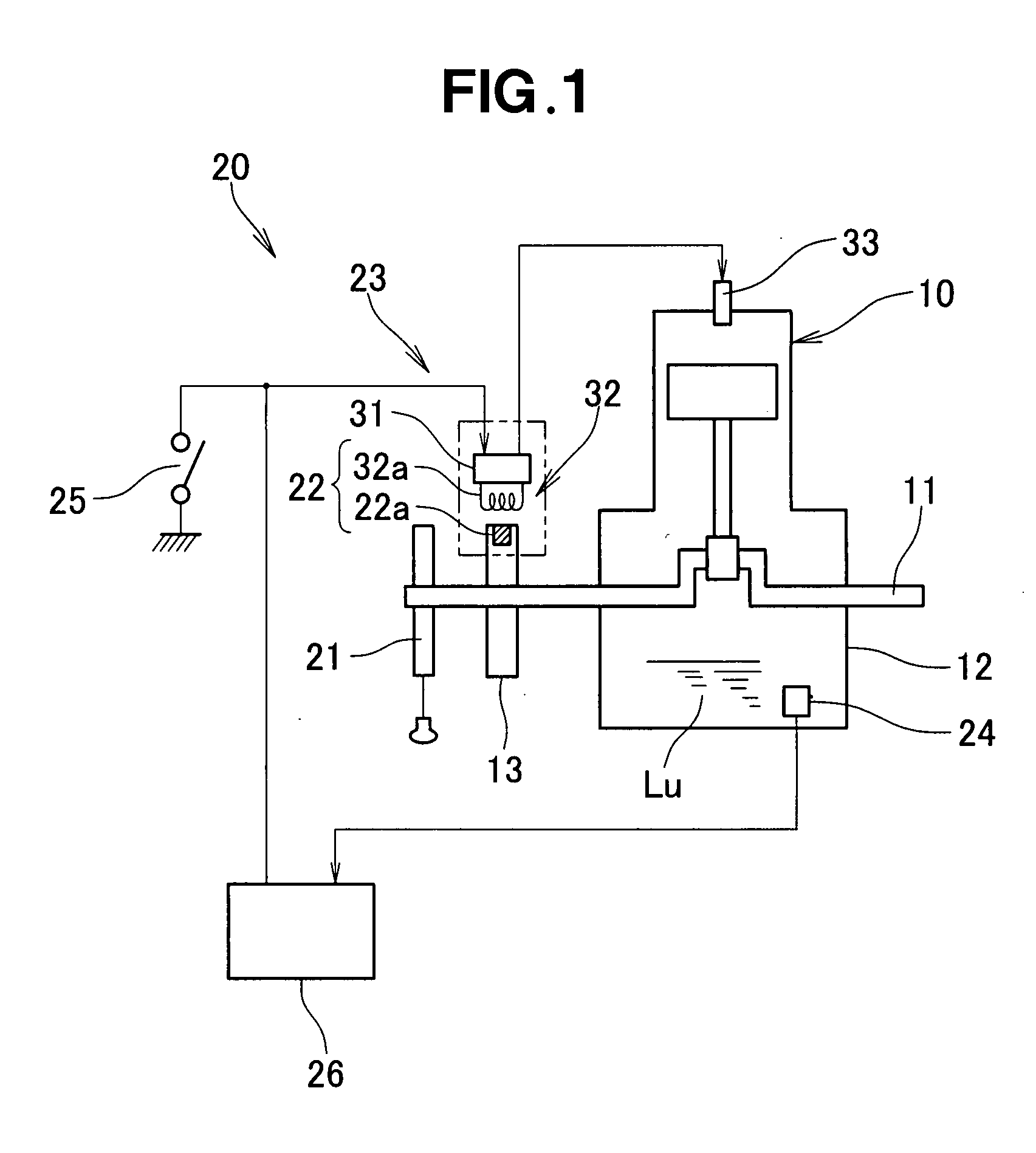

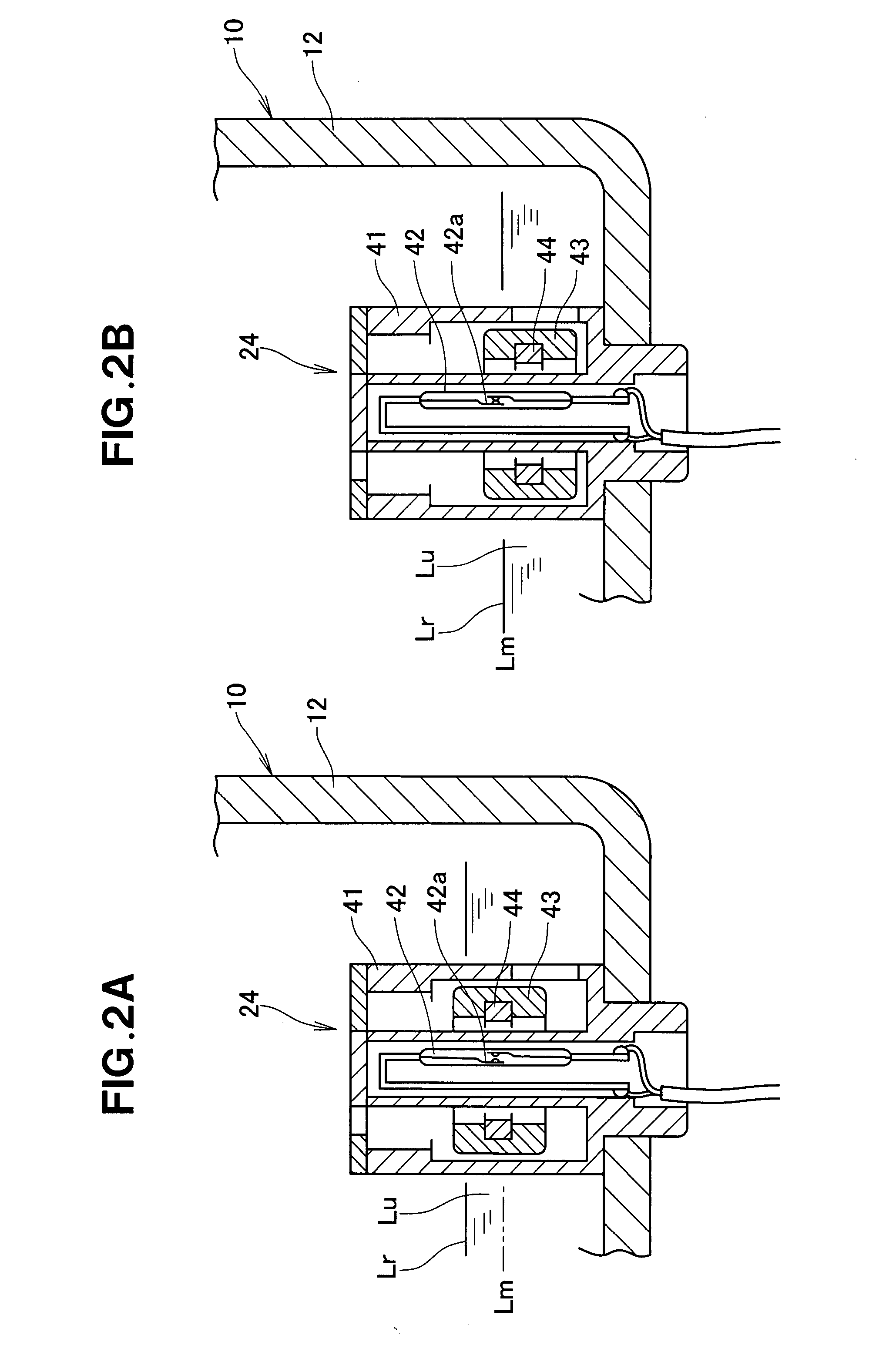

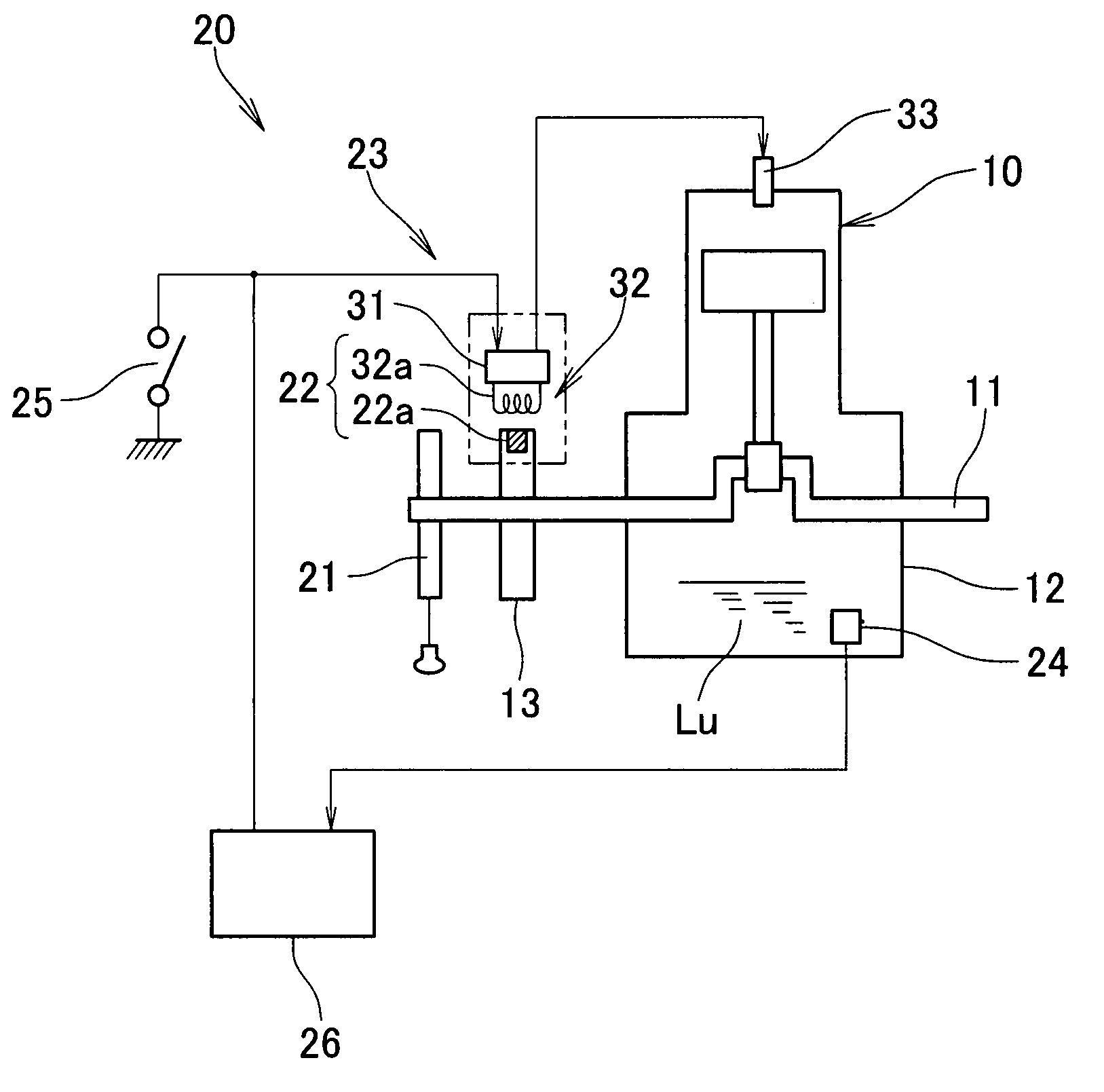

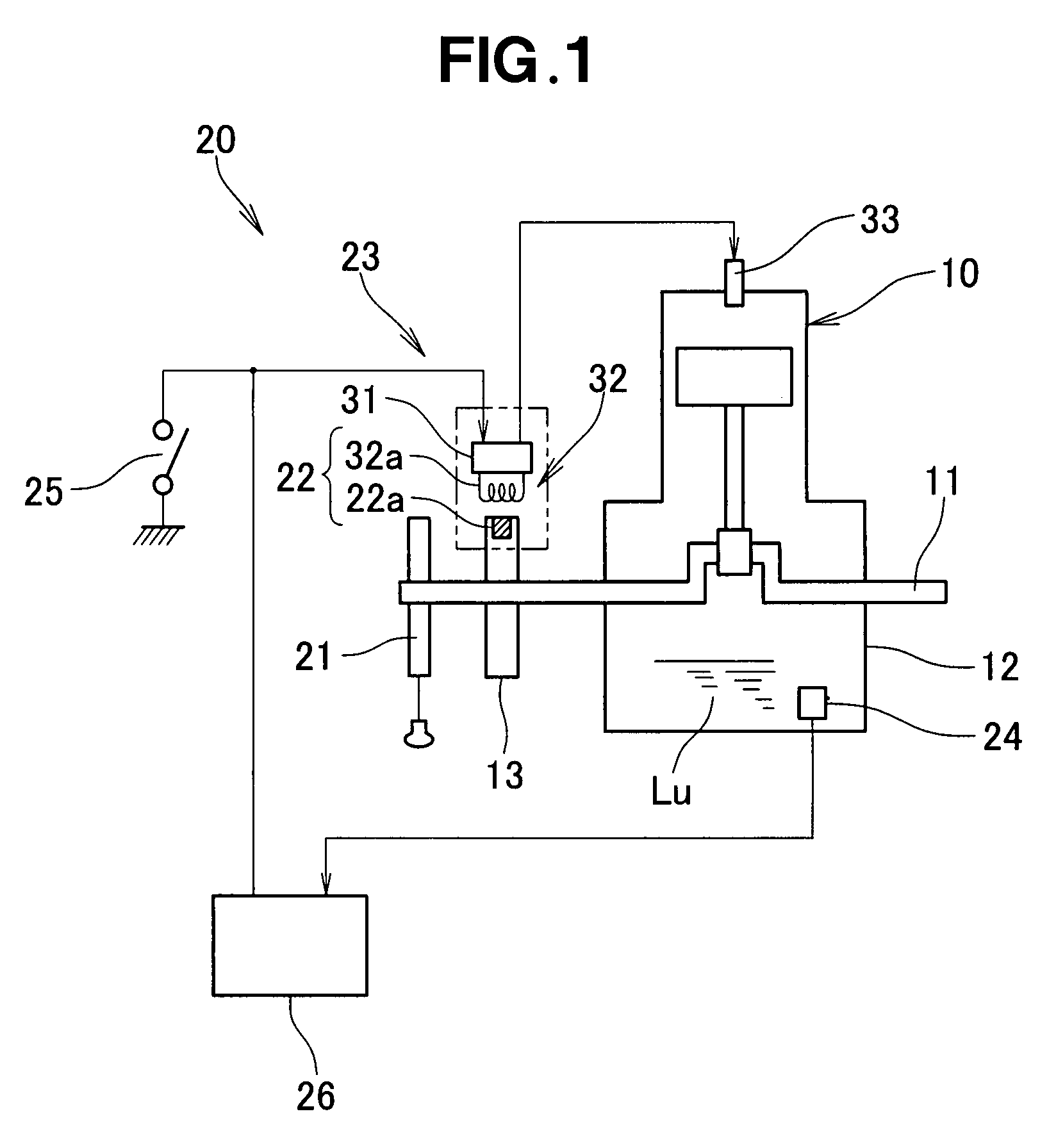

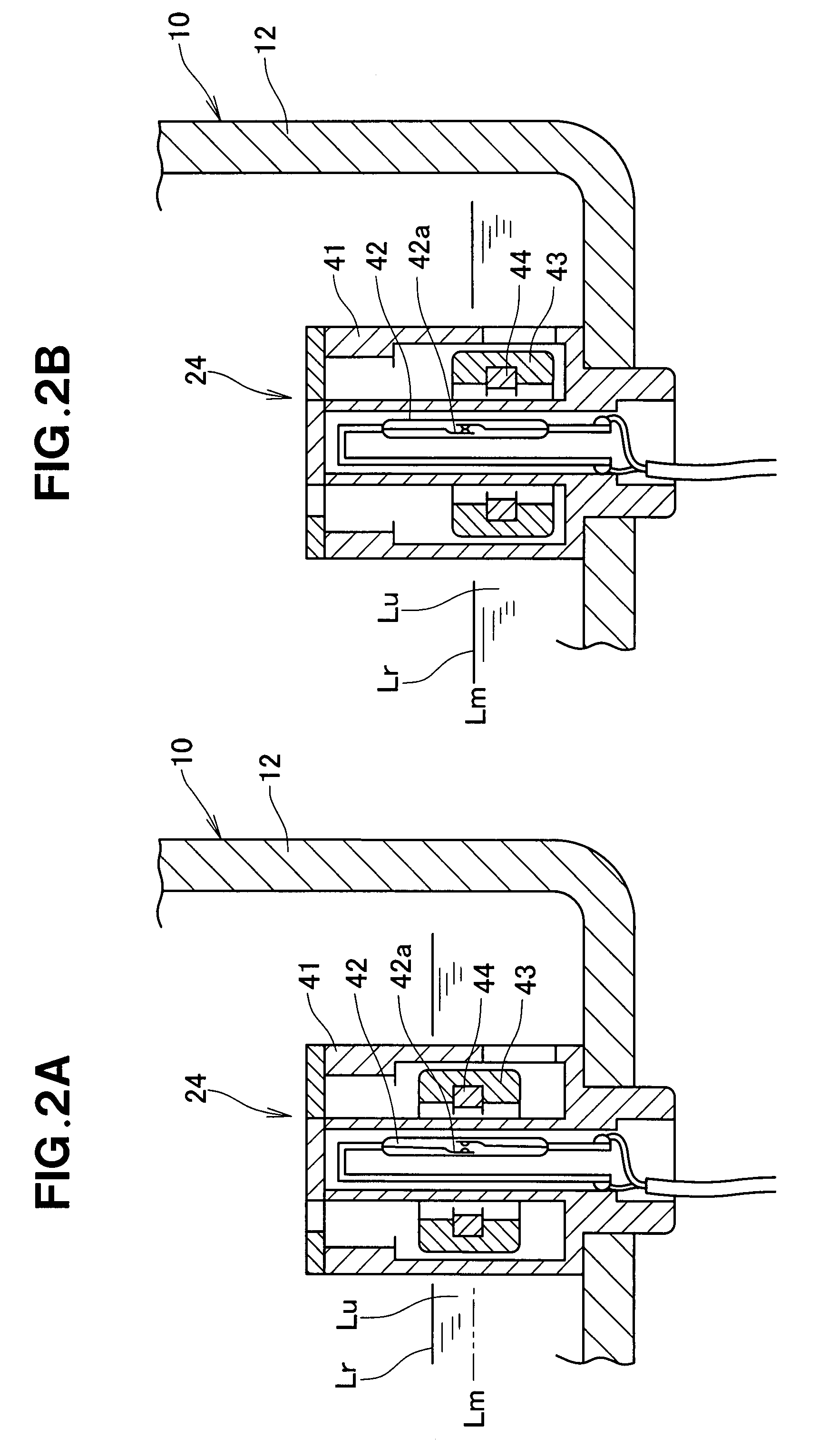

Multipurpose engine controller

ActiveUS20070182251A1Evenly lubricatedDurability is assuredAnalogue computers for vehiclesElectrical apparatusLevel sensorCrankcase

A multipurpose engine controller comprises a control unit for switching between supplying and stopping power supplied from an ignition circuit to a spark plug on the basis of two states, i.e., the operating state of the multipurpose engine determined based on a detection signal from the engine speed sensor, and the state of the level of the oil inside the crankcase determined based on a detection signal from the float-type oil level sensor.

Owner:HONDA MOTOR CO LTD

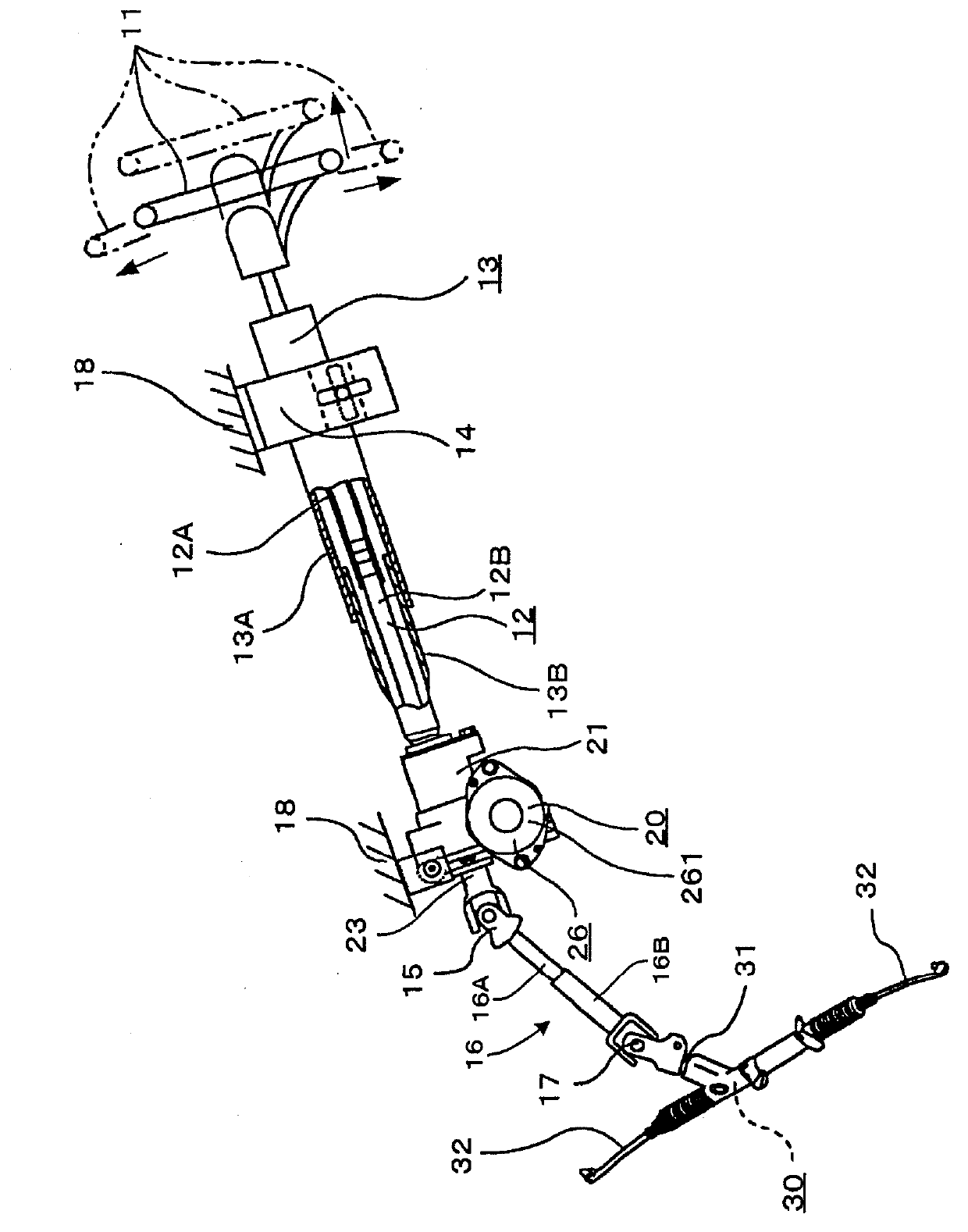

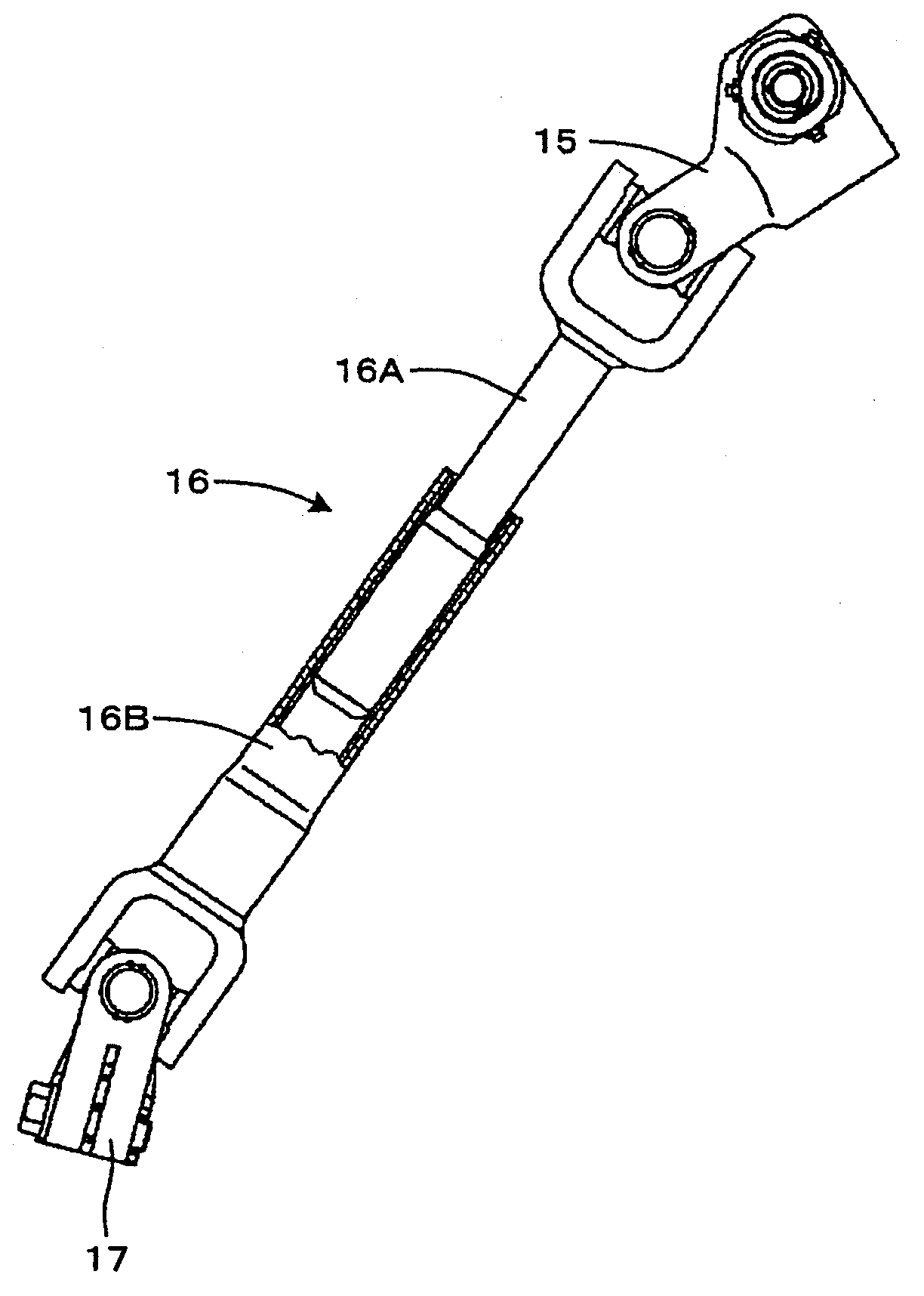

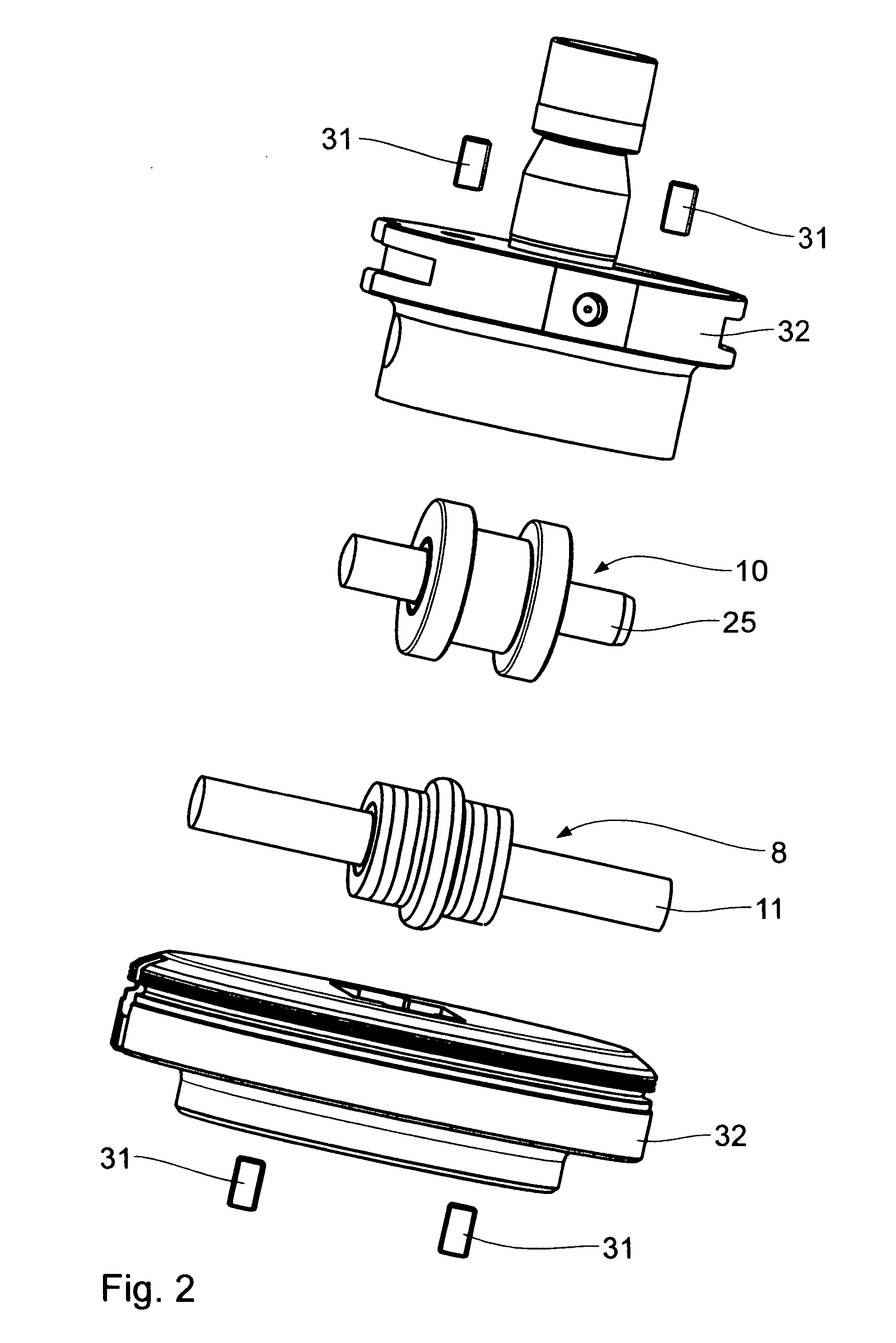

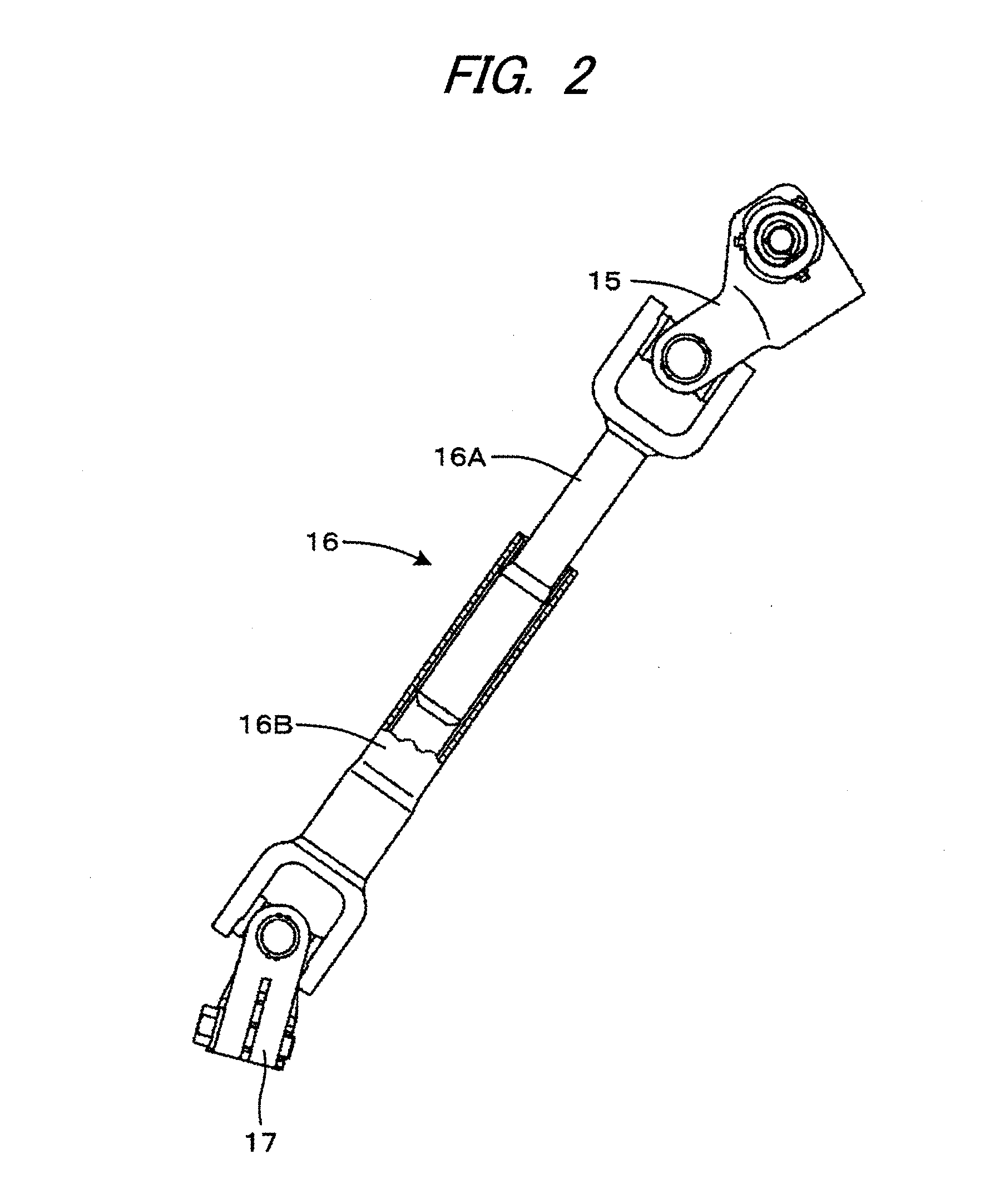

Telescopic shaft

Owner:NSK LTD

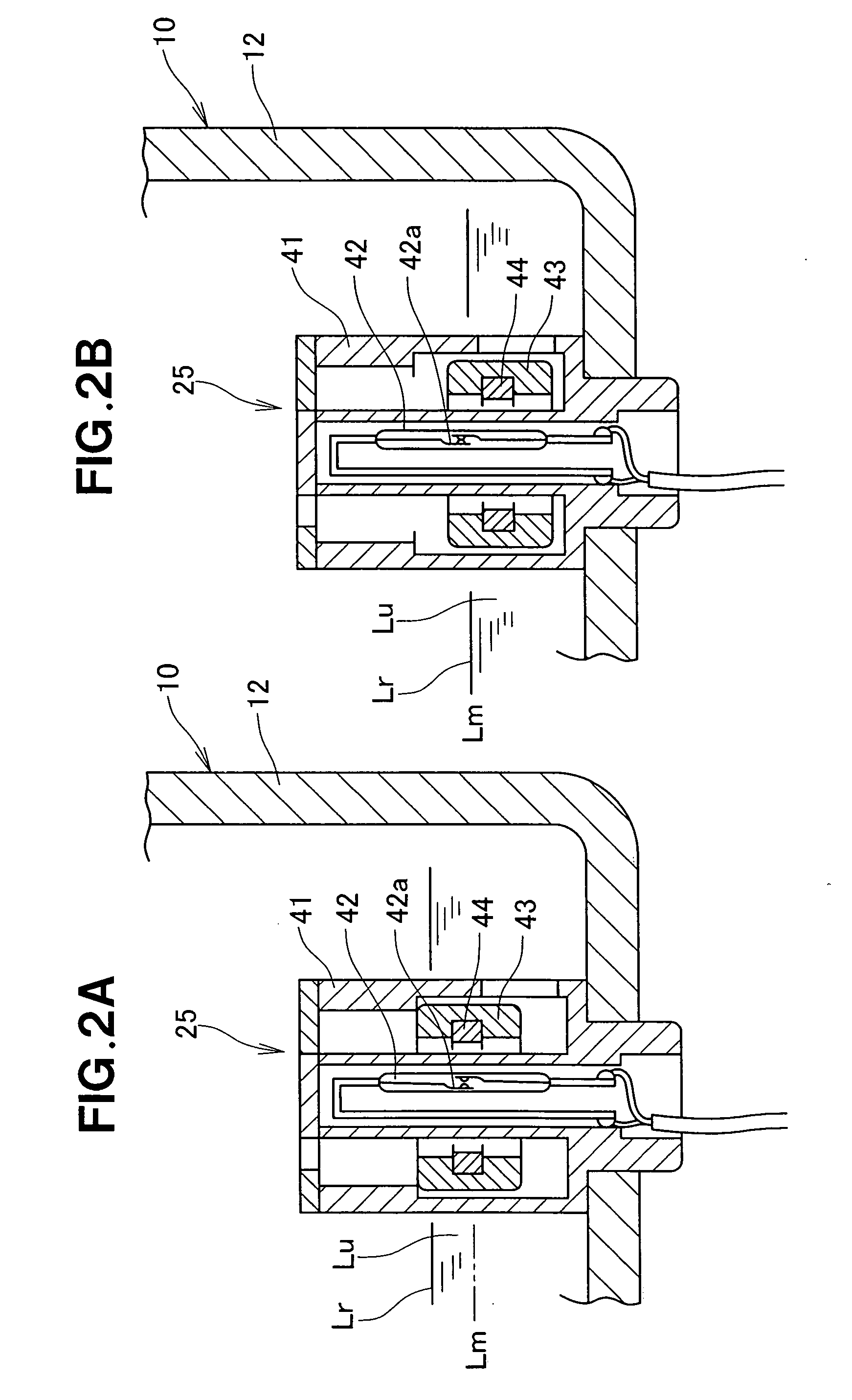

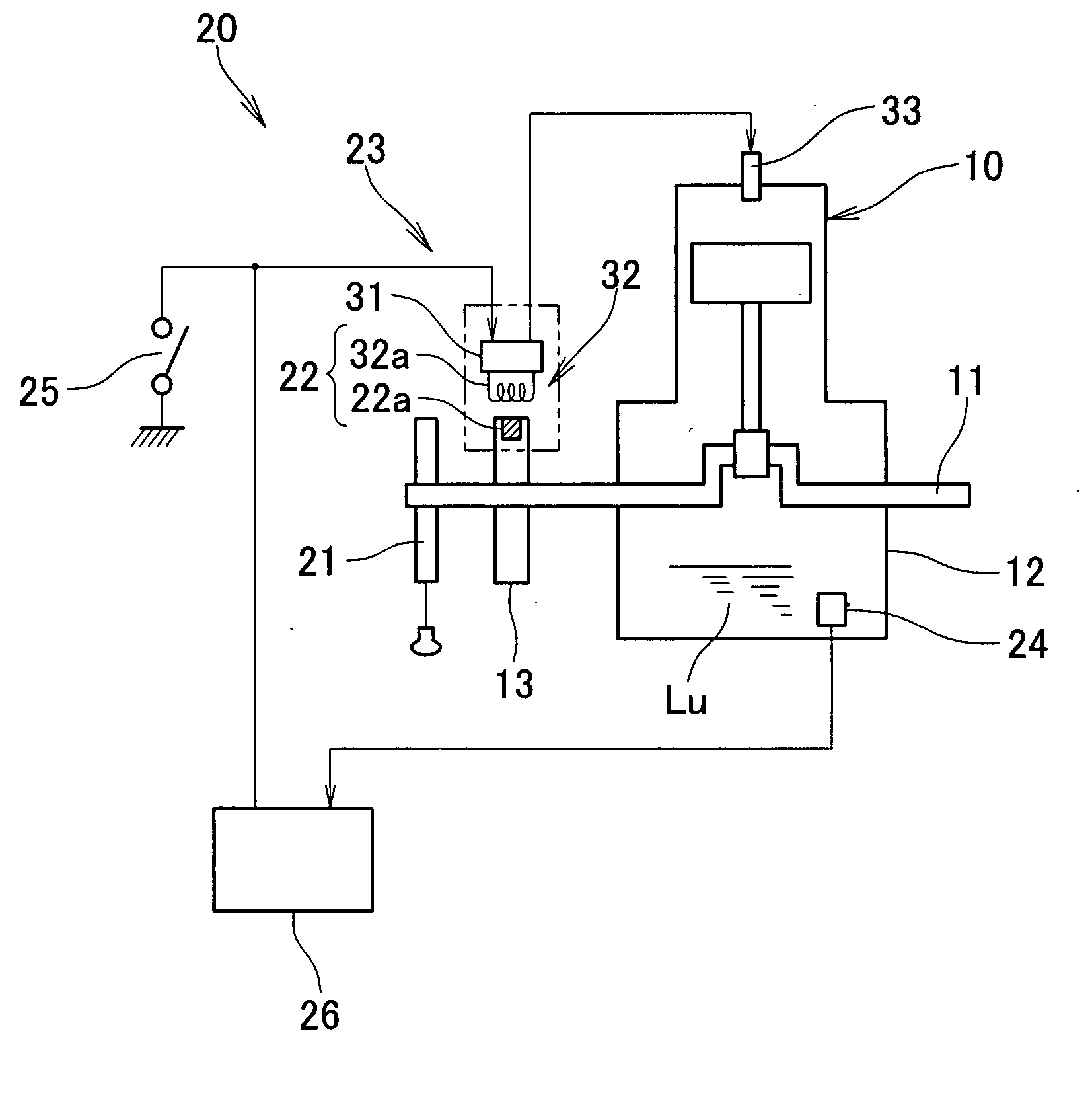

Engine start control apparatus

InactiveUS20070204833A1Inhibition of activationSufficient durability of engineMachines/enginesAdvancing/retarding ignitionThyratronEngineering

Oil level detection sensor detects an oil level in a crankcase. First charging circuit includes a serial connection of a first charging capacitor for charging a reverse voltage produced in a primary coil, the detection sensor, and a first diode. Thyristor is turned on, in response to voltage-charging of the first charging capacitor, to disable an ignition operation of an ignition circuit. Second charging circuit includes a serial connection of a second charging capacitor for charging a forward voltage, produced in the primary coil, and a second diode. Transistor is turned on, in response to voltage-charging of the second charging capacitor, to disable a turning-on operation of the thyristor.

Owner:HONDA MOTOR CO LTD +1

Roller tool for the linear deformation of sheet metal and sheet deformation facility having such a roller tool

ActiveUS20060162413A1Evenly lubricatedPromote formationShaft and bearingsRolling equipment maintainenceEngineeringPhysics

A roller tool is used within a sheet deformation facility for the linear deformation of sheet metal. The roller tool comprises a press roller having a shaft and a roller body rolling around the same as well as a counterbody. The press roller and the counterbody can be jointly moved in a linear manner relative to a sheet positioned between them that is to be processed for performing the sheet metal deformation. The roller body has a plurality of roller discs which are adjacent to each other, which together form the section of the roller body that can be placed onto the sheet to be processed and which can rotate around the shaft independently of each other. The sheet deformation facility is furthermore provided with a roller tool support and a drive for pivoting the roller tool support around an axis perpendicular to the sheet that is to be processed.

Owner:PASS STANZTECHN

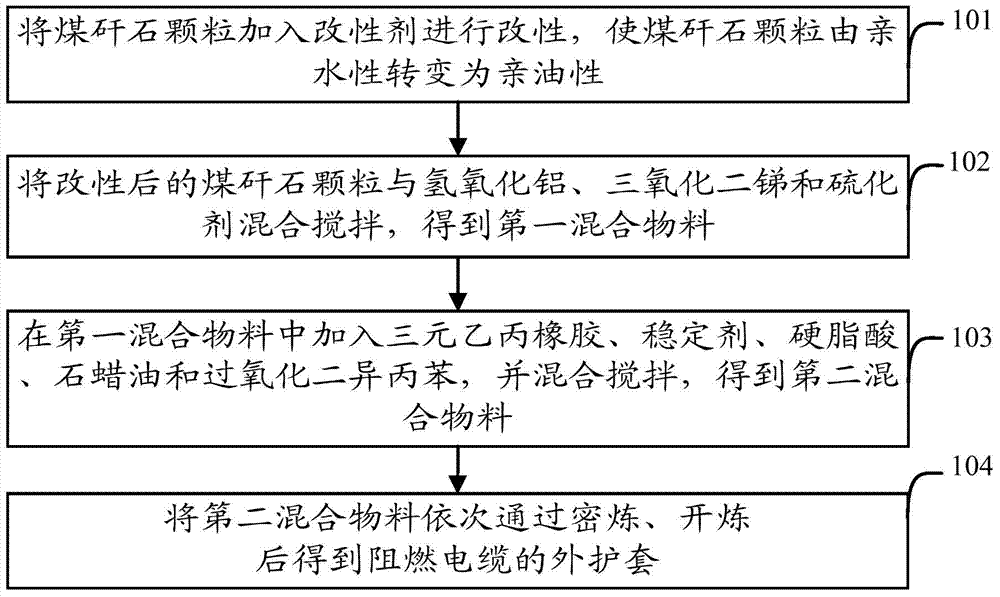

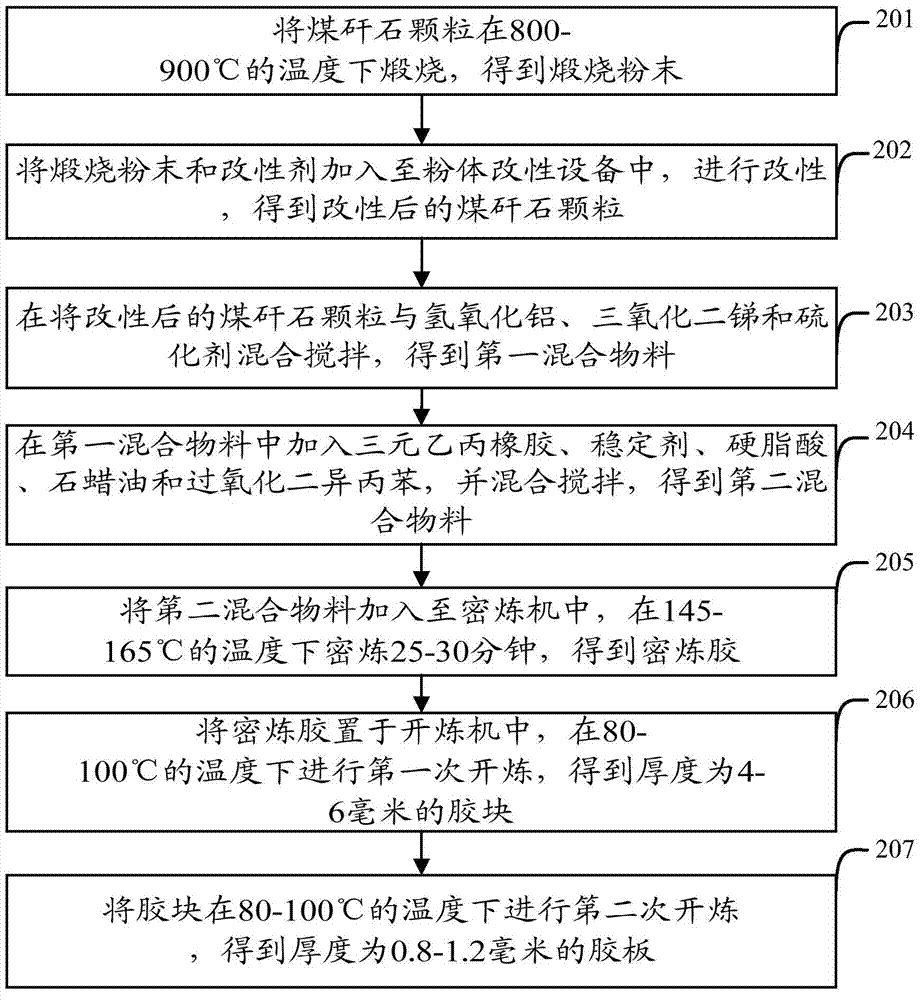

Outer sheath of fire-resistant cable, and production method thereof

InactiveCN103497431AHigh tensile strengthImprove anti-aging propertiesRubber insulatorsInsulated cablesToxic gasEthylene-propylene-diene-monomer

The invention relates to the field of cables, and particularly relates to an outer sheath of a fire-resistant cable, and a production method thereof. The outer sheath of the fire-resistant cable comprises the compositions in parts by weight: 43-47 parts of coal gangue particles, 7-9 parts of aluminum hydroxide, 5-7 parts of diantimony trioxide, 23-27 parts of ethylene propylene diene monomer (EPDM), 0.8-1.2 parts of modifier, 10-12 parts of vulcanizing agent, 3-5 parts of stabilizer, 0.4-0.8 part of stearic acid, 5-7 parts of paraffin oil, and 3-6 parts of dicumyl peroxide. According to the outer sheath of the fire-resistant cable, provided by the invention, the emission amount of hazardous and toxic gas in the burning process can be reduced, and the content of hazardous and toxic gas in a fire scene can be decreased so as to guarantee the life security of rescuers.

Owner:HYDRAULIC MACHINERY PLANT SHANXI PROV

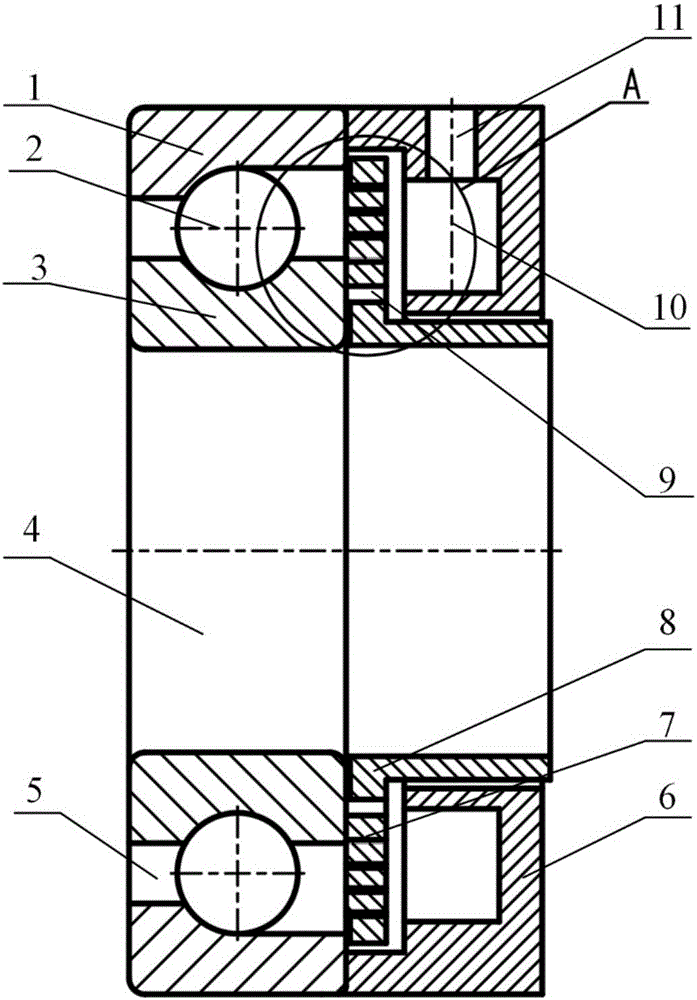

Porous array lubricating device for high-speed rolling bearing

InactiveCN106402163AReduce temperature riseExtended service lifeRolling contact bearingsShaftsRolling-element bearingOil distribution

The invention belongs to the technical field of fluid lubrication, and particularly relates to a bearing lubricating device. According to the technical scheme adopted by the invention, a porous array lubricating device for a high-speed rolling bearing lubricating device is characterized in that an oil inlet sleeve is equipped with a ring-shaped oil storage cavity and an oil inlet path which communicates with the oil storage cavity; an oil distribution sleeve is equipped with circumferential inner ring radiating oil storage holes and oil spray holes which are arranged in the form of array; the oil distribution sleeve is connected on a main shaft in a sleeving mode; and the oil inlet sleeve is assembled with the oil distribution sleeve, and fits to one side of the rolling bearing. According to the porous array lubricating device, lubricating oil which enters the lubricating device can achieve the effects of spraying oil to lubricate, and also can keep certain lubricating oil amount of an inner ring of the rolling bearing; and the oil storage cavity in one side of the inner ring of the rolling bearing also can achieve the effects of cooling bearings. According to the lubricating device, oil spraying small holes are designed, so that lubricating oil lubricates the bearings in the form of mist, and therefore, lubricating oil amount can be reduced, lubricating is more uniform, and the temperature rise of the inner ring of the rolling bearing is lower.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

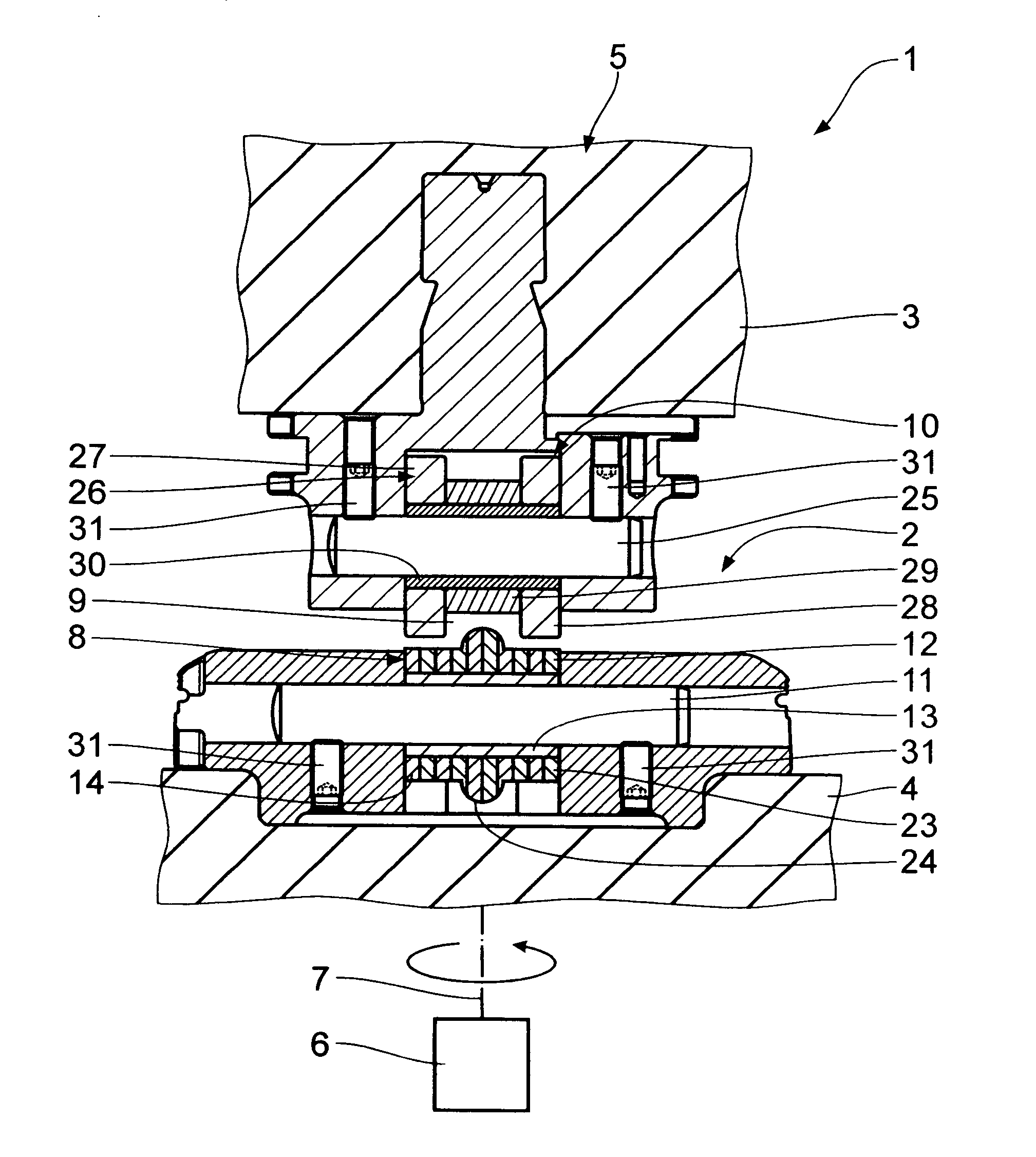

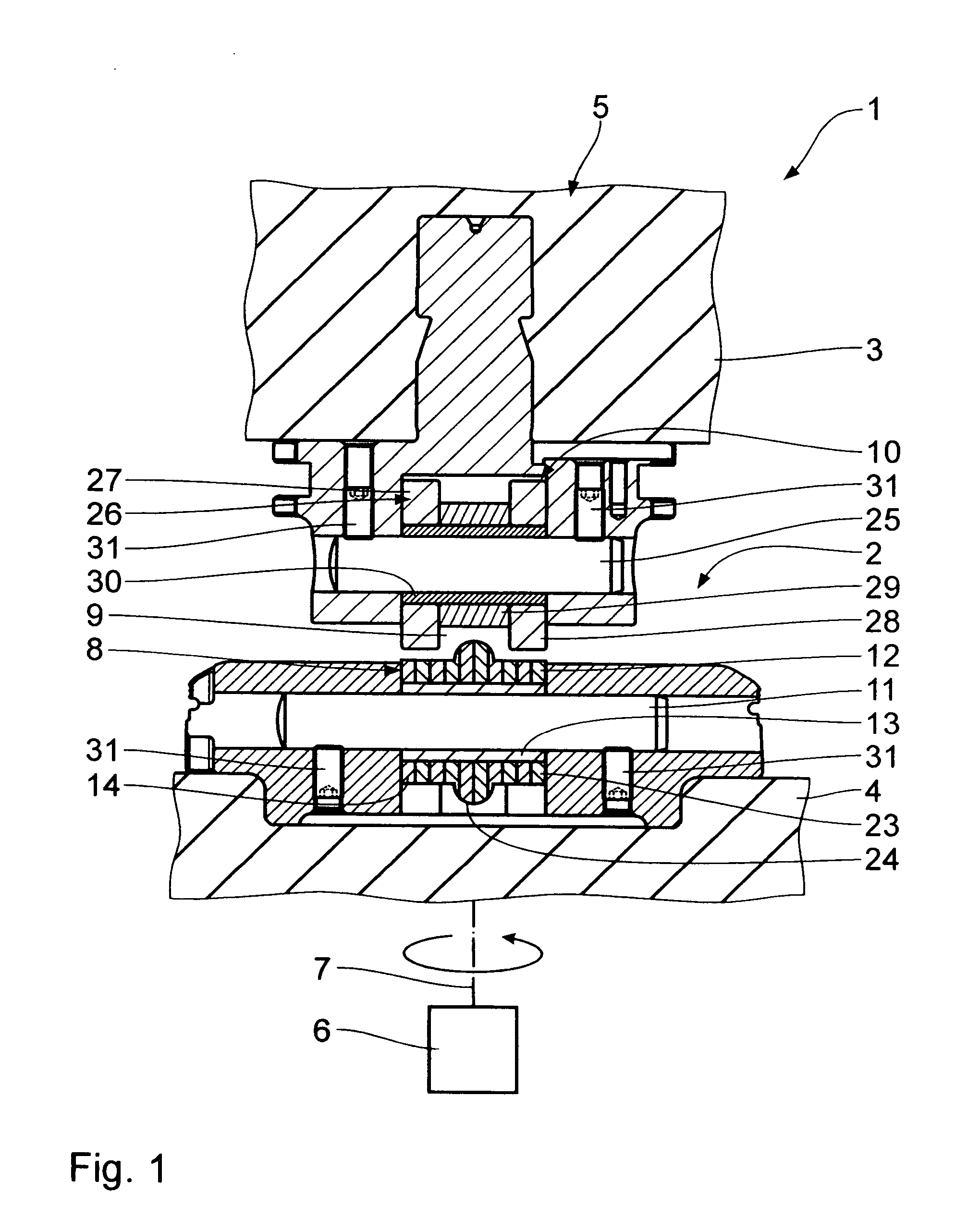

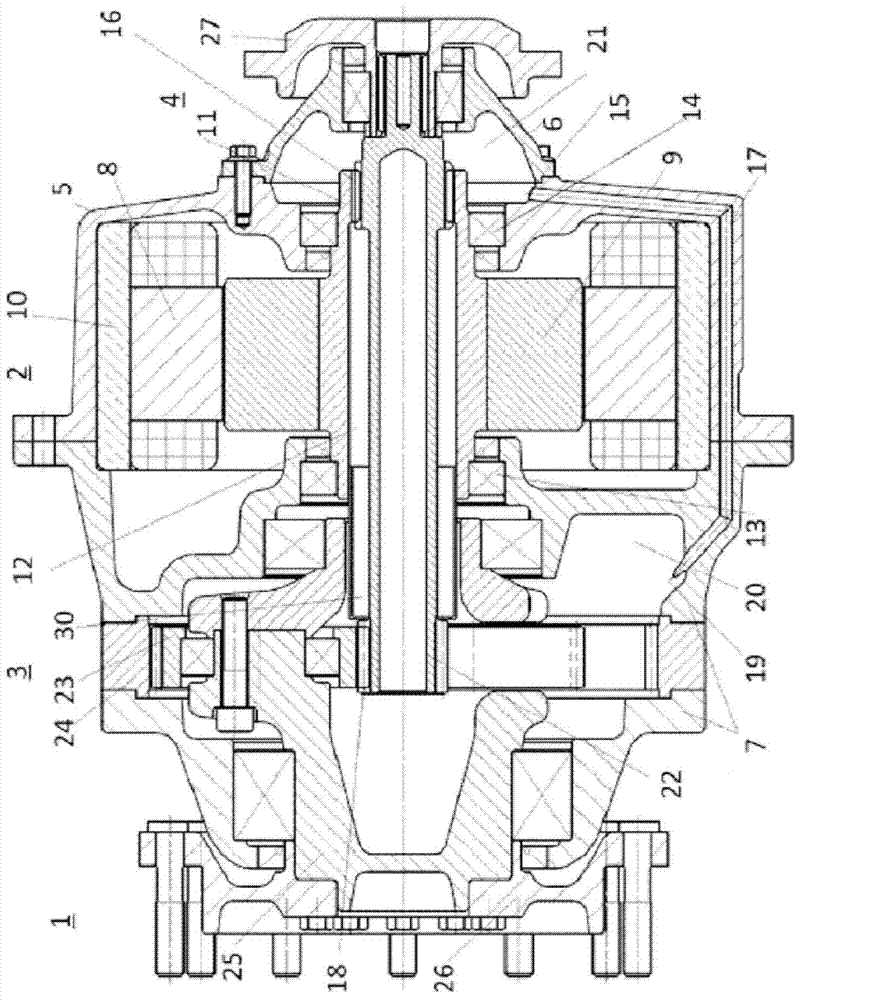

Drive unit with oil exchange

ActiveCN104246309ASmooth feedingEvenly lubricatedMagnetic circuit rotating partsGear lubrication/coolingLubricantElectrical and Electronics engineering

The invention relates to a drive unit with oil exchange for vehicles, which drive unit has a gearbox (3), a brake (4) and an electric machine (2), arranged between the latter, in an at least two-part housing (5, 6, 7), wherein the electric machine (2) has a cooling jacket (10), and the further components (3, 4) are lubricated via a separate lubricant circuit. According to the invention there is provision that the separate lubricant circuit in the at least two-part housing (5, 6, 7) for the gearbox (3) and brake (4) is maintained by using existing components (23, 22, 11).

Owner:BOMBARDIER TRANSPORTATION GMBH

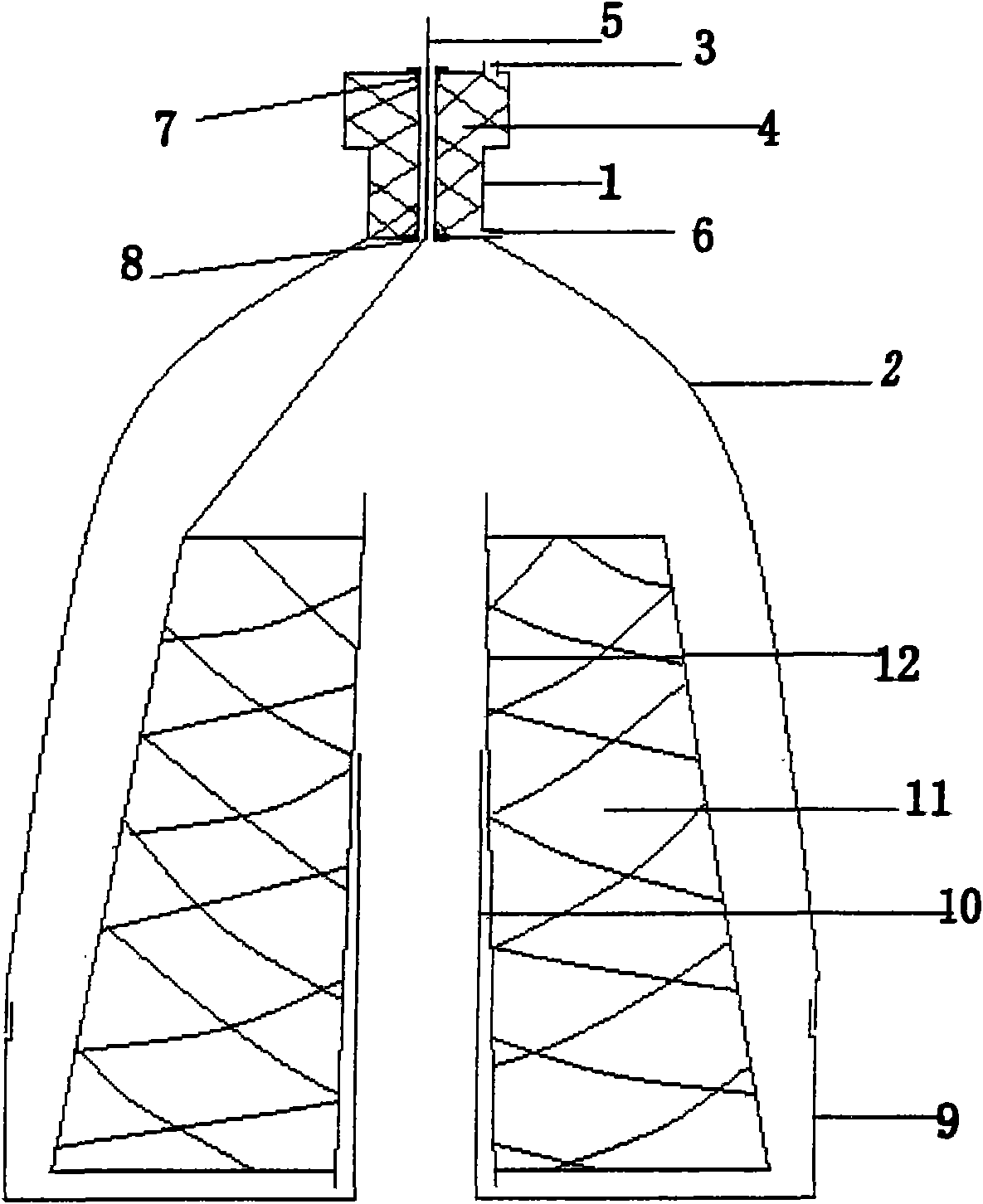

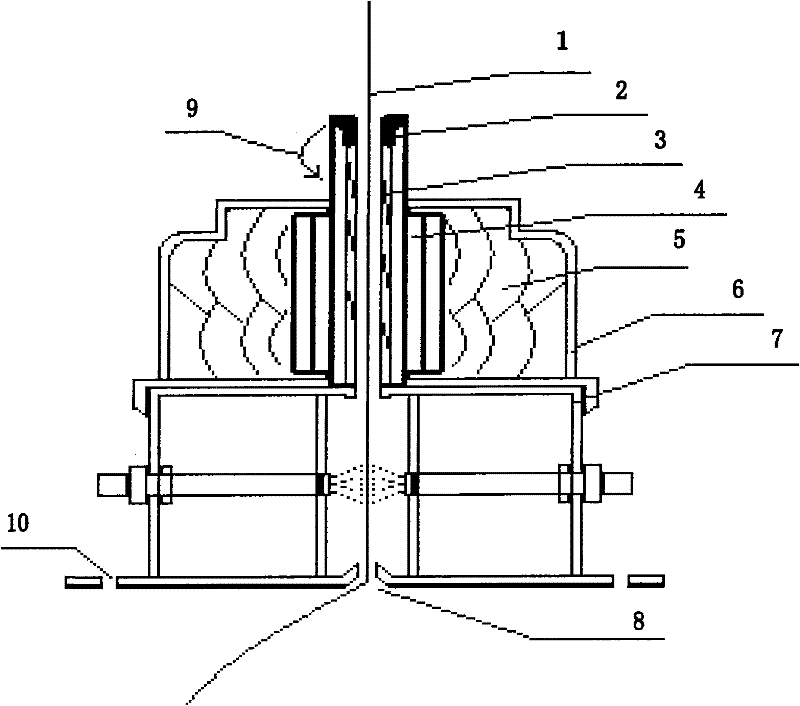

360-degree yarn automatic lubricating device

InactiveCN101775720AReasonable structureEasy to useLiquid/gas/vapor yarns/filaments treatmentOil supplyTextile industry

The invention relates to the field of textile, in particular to a yarn automatic lubricating device which is used for reducing the frication between yarn and machinery in the textile industry. The 360-degree yarn automatic lubricating device has a structure that a lubricating oil box (1) is connected with a thread storage box (2), the thread storage box (2) is spliced with a bottom box (9), a paper tube (12) is inserted in a central tube (10), and a reel of thread (11) is fixed in a dust cover. The lubricating oil box (1) is internally filled with a special nano oil absorbing substance (4); an oil filling port (3) is connected with a micro-metering pump (15) to oil the oil box; and surplus oil is recycled through an oil return tube (6). Yarn (5) is led upwards through a central hole of a magnetic hole (8) at the bottom of the oil box and is led out through a magnetic hole (7) at the top of the oil box. A main oil box is oiled through an oil filling port (13), and lubricating oil supplies oil as required through the micro-metering pump (15). The invention is mainly used for the textile industry, can be widely installed on a flat knitting machine, stranding equipment, weaving equipment, warp knitting equipment, warping equipment, resultant yarn weaving equipment, and the like. The yarn automatic lubricating device has the structural and technical characteristic of realizing that the yarn screws for 360 degrees to straighten out hairiness and synchronously and uniformly lubricate, which is defined as screwing 360 degrees for straightening out hairiness and synchronously and uniformly lubricating.

Owner:崔建明

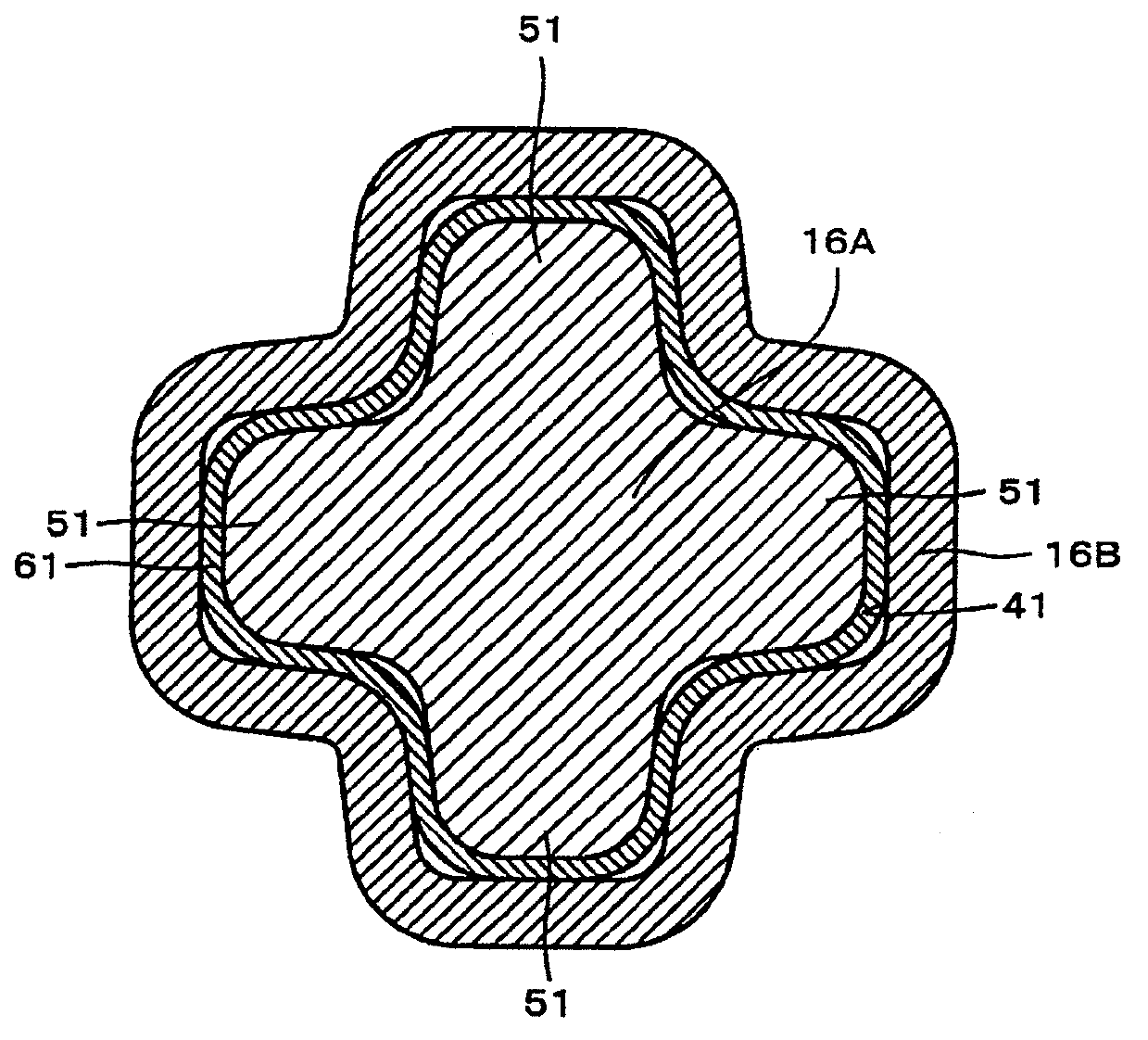

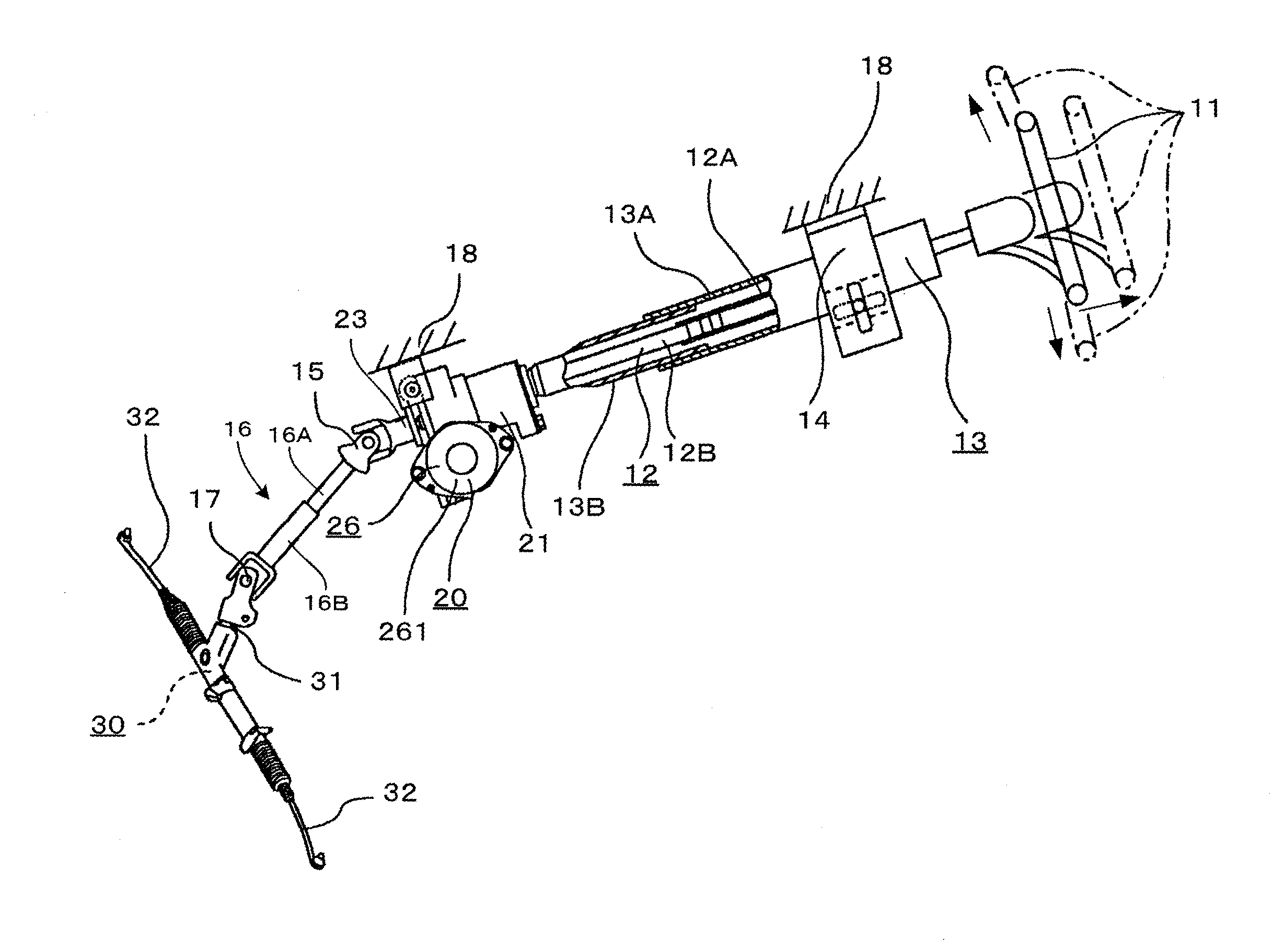

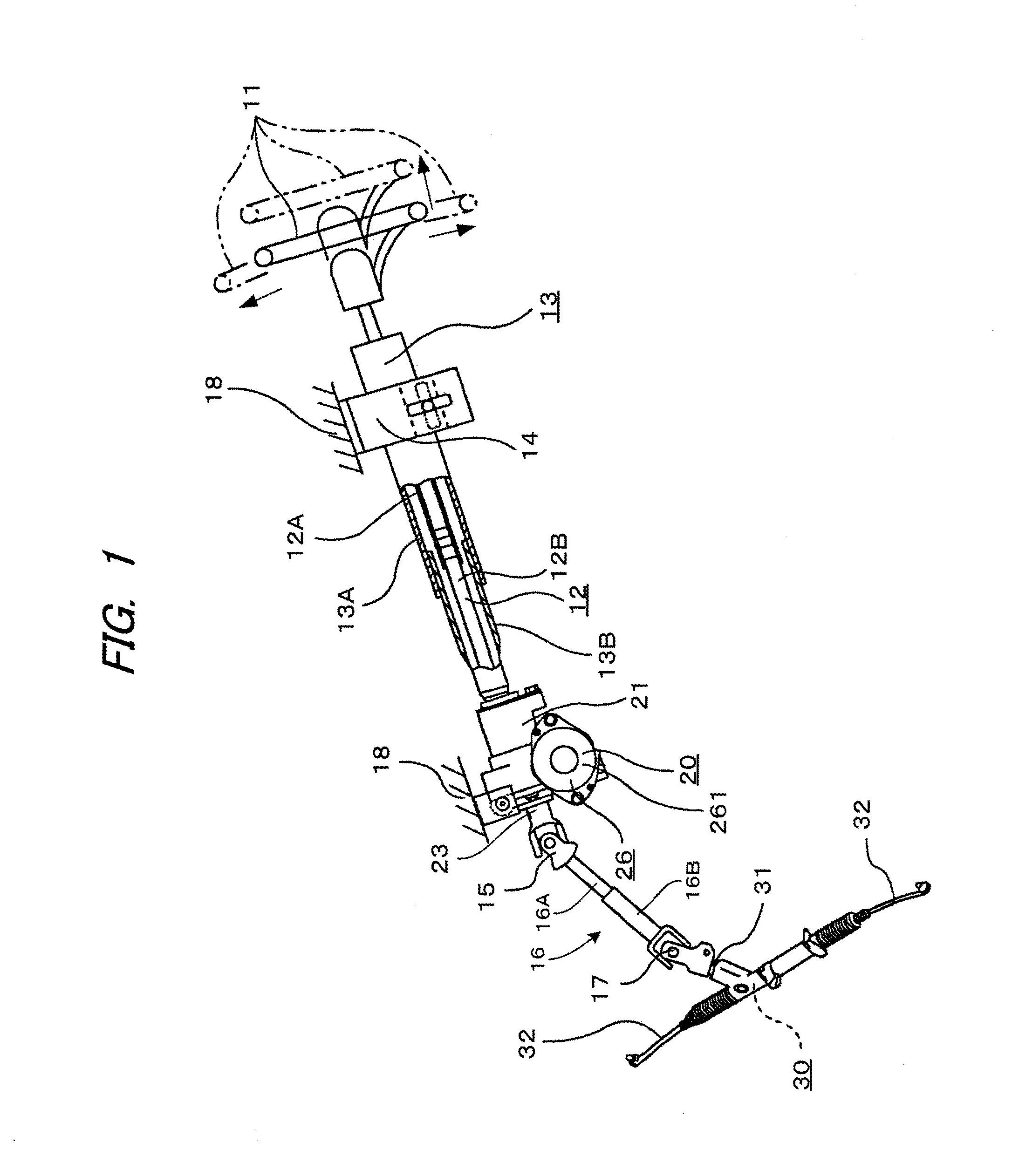

Telescopic shaft

A telescopic shaft includes a male shaft having an outer circumference on which a plurality of protruding teeth are formed, and a female shaft having an inner circumference on which a plurality of tooth grooves are formed. The tooth grooves of the female shaft are fitted onto the protruding teeth of the male shaft such that the male shaft and the female shaft are relatively slidable in an axial direction and such that a rotational torque is transmittable between the male shaft and the female shaft. One of a curvature radius of a tooth surface of the protruding teeth and a curvature radius of a tooth surface of the tooth grooves is smaller than the other of the curvature radius of the tooth surface of the protruding teeth and the curvature radius of the tooth surface of the tooth grooves.

Owner:NSK LTD

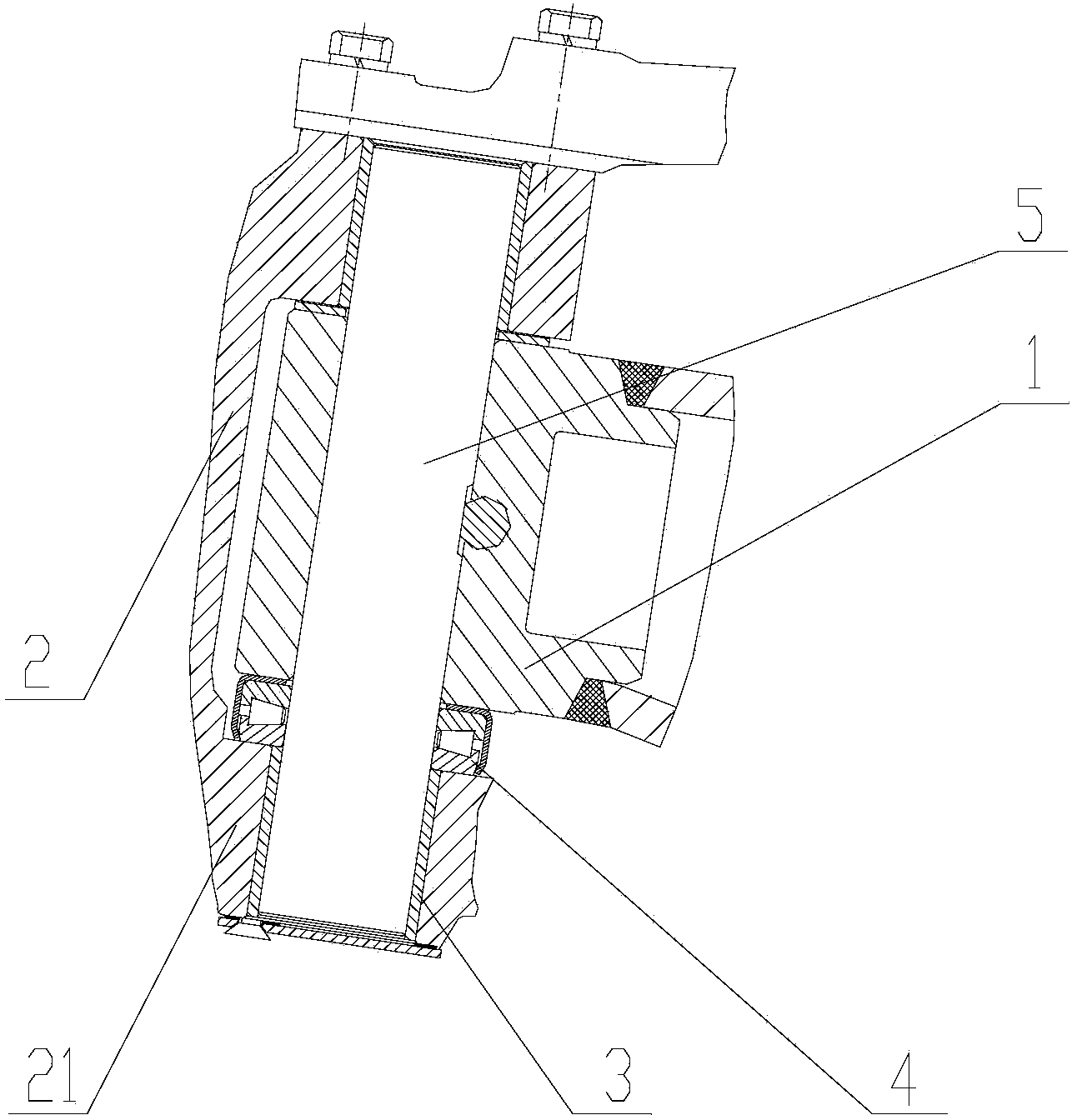

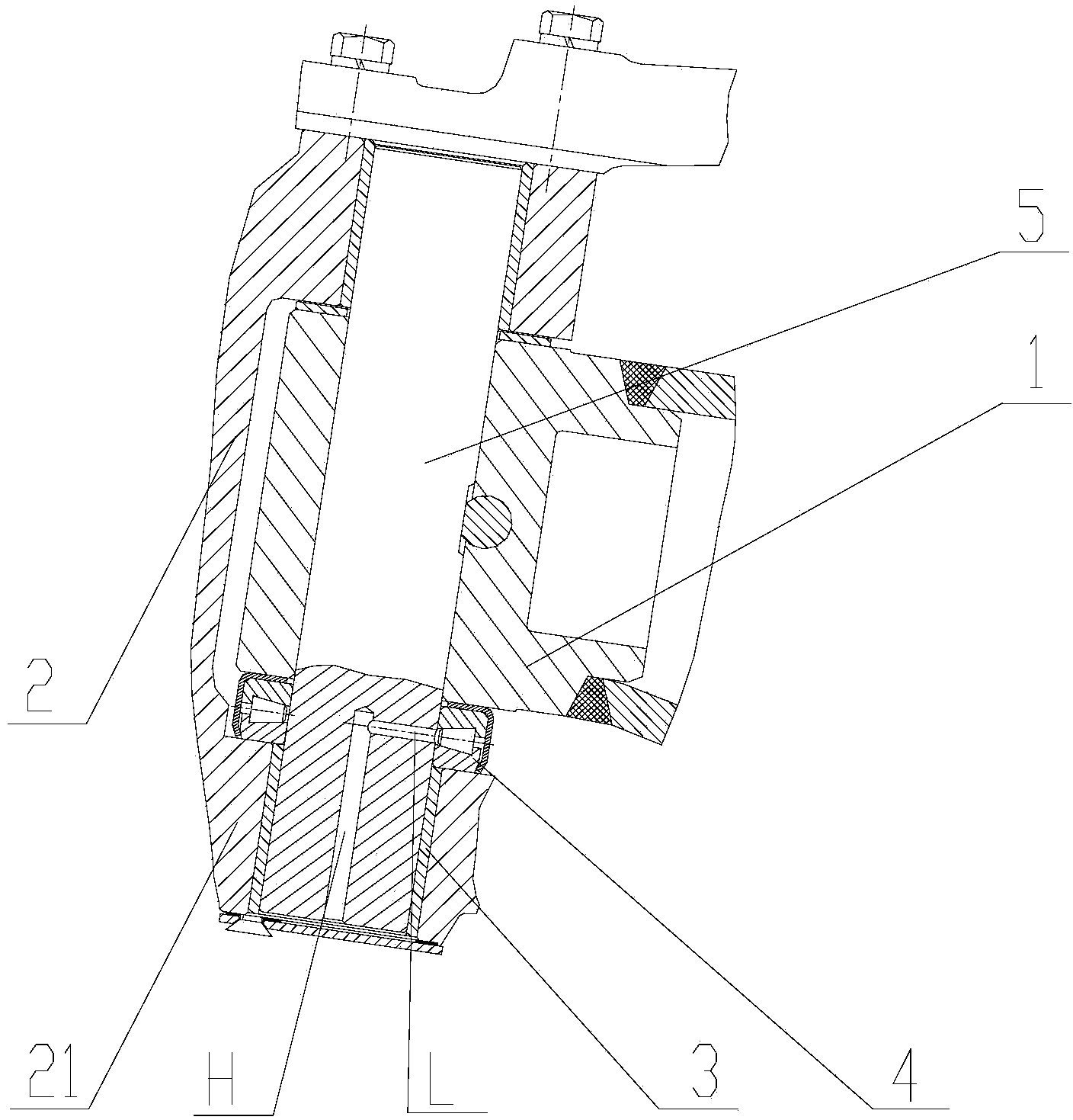

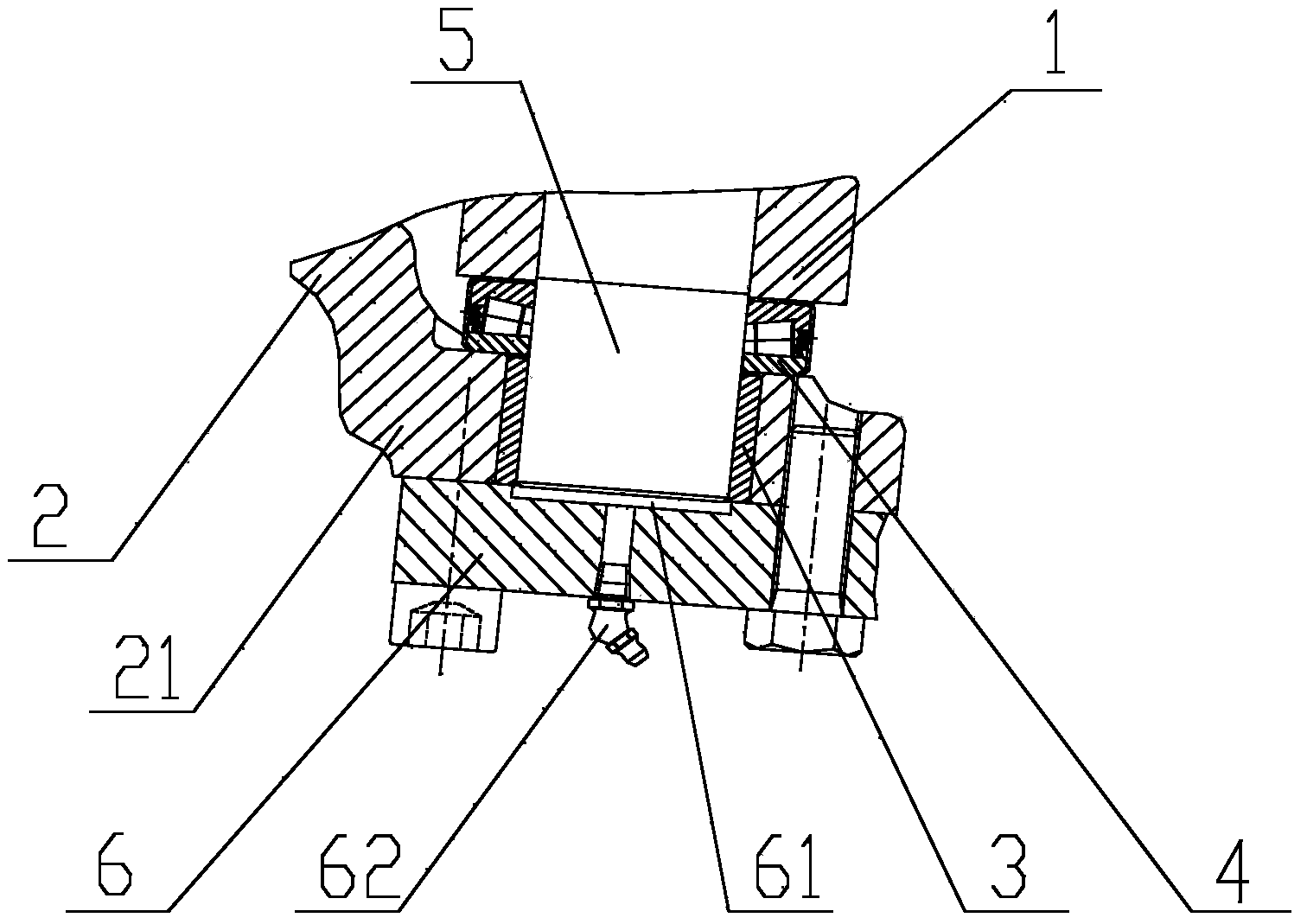

Bearing component, steering bridge and vehicle

ActiveCN103410867AEvenly lubricatedSteering linkagesBearing componentsEngineeringMechanical engineering

The invention discloses a bearing component. The bearing component comprises a bearing (4) and a bearing outer cover (41) which is connected to the exterior of the bearing (4) in adjacency, wherein a through hole (42) which can enable the interior of the bearing (4) to be communicated with the outside is formed in the bearing outer cover (41). Because the through hole which can enable the interior of the bearing to be communicated with the outside is formed in the bearing outer cover, the air exhaust effect of the through hole can enable workpieces of pins, shafts and the like which are matched with the bearing to lubricate oil grease more smoothly.

Owner:湖南中联重科车桥有限公司 +1

Engine start control apparatus

InactiveUS7395810B2Increased durabilityEasy constructionElectric motor startersMachines/enginesThyratronEngineering

Oil level detection sensor detects an oil level in a crankcase. First charging circuit includes a serial connection of a first charging capacitor for charging a reverse voltage produced in a primary coil, the detection sensor, and a first diode. Thyristor is turned on, in response to voltage-charging of the first charging capacitor, to disable an ignition operation of an ignition circuit. Second charging circuit includes a serial connection of a second charging capacitor for charging a forward voltage, produced in the primary coil, and a second diode. Transistor is turned on, in response to voltage-charging of the second charging capacitor, to disable a turning-on operation of the thyristor.

Owner:HONDA MOTOR CO LTD +1

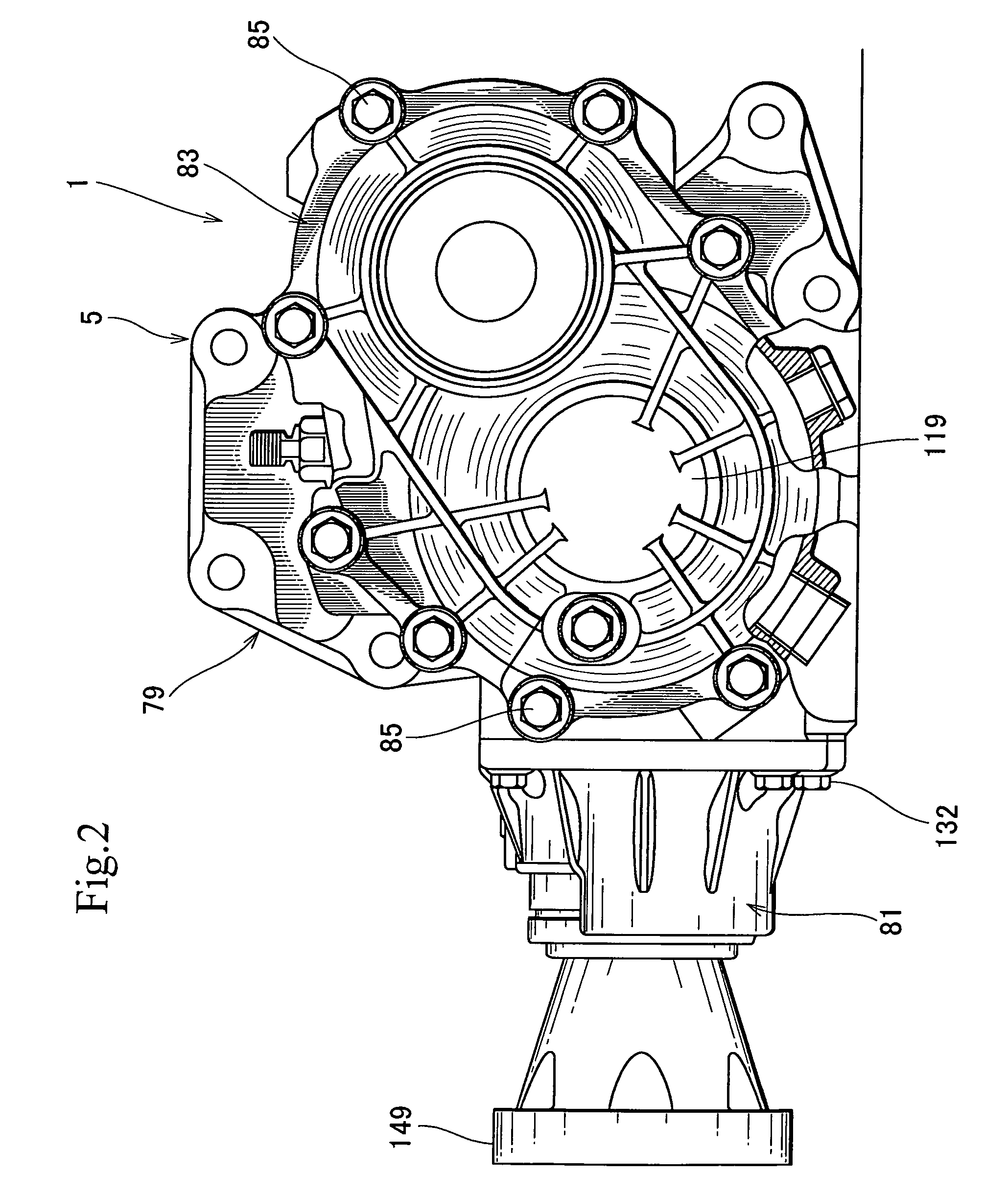

Power transmission apparatus

InactiveUS20090186737A1Accurate supplyEvenly lubricatedGear lubrication/coolingEngine lubricationTransfer caseBall bearing

A power transmission apparatus is capable of easily passing lubricant toward a seal arranged between a higher shat and an opening of a case of the apparatus. The apparatus includes the higher shaft, i.e., a hollow connecting shaft that faces the outside of the transfer case through the opening of the transfer case. The oil seal is arranged between the hollow shaft and the opening of the transfer case. The hollow shaft meshes, through helical spur gears, with an intermediate transferring shaft that is positioned lower than the hollow shaft. A lubricant guide is arranged to receive lubricant splashed up by the ring gear and helical spur gear of the intermediate shaft and guide the received lubricant toward the oil seal and a ball bearin

Owner:GKN DRIVELINE TORQUE TECHNOLOGY KK

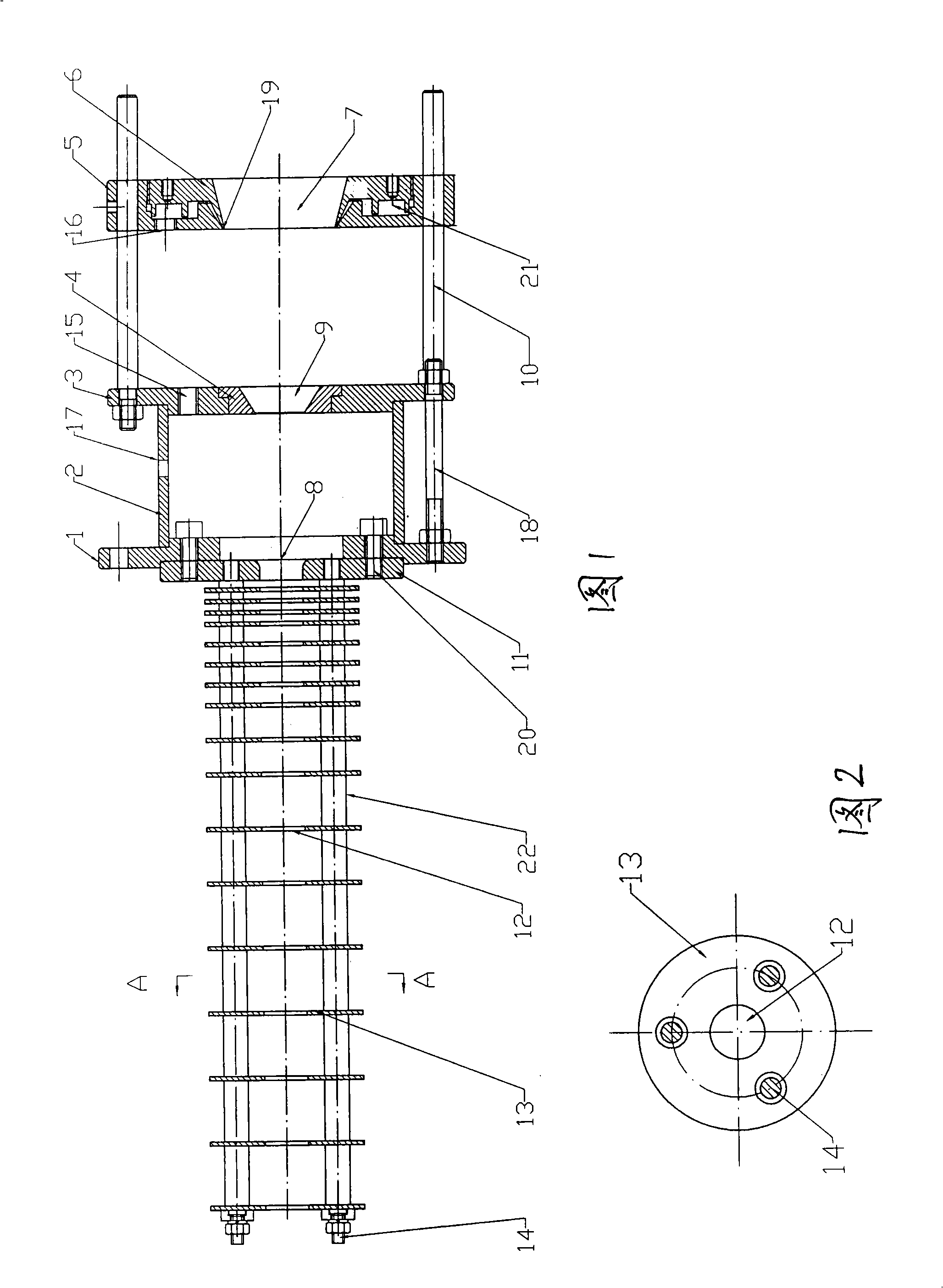

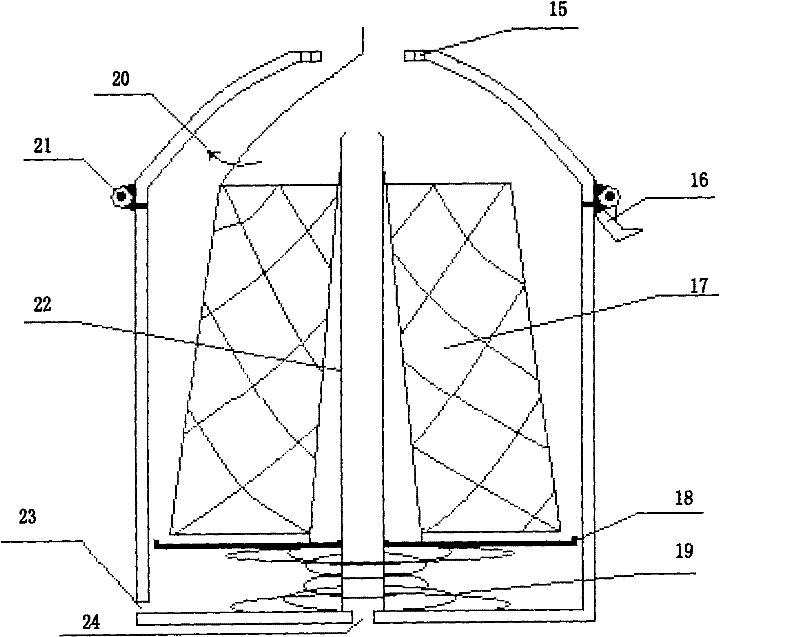

Immersion type plastic pipe sizing device

The invention discloses a sizing device of a submerged plastic tubular product. A lamination base is arranged at one side of a hollow fixing disk; the central part of the lamination base is provided with an inlet of the plastic tubular product; the other side of the hollow fixing disk is connected with a connection disk by a water bath hood; the middle position of the connection disk is provided with a guide sleeve; a supporting rod extending to the outside is arranged on the connection disk; a cooling water ring far from the connection disk is arranged on the supporting rod; the middle position of the cooling water ring is provided with an adjustable water disk; an adjustable water gap is formed between the cooling water ring and the adjustable water disk; the central position of the adjustable water disk is provided with a plastic tubular product feed opening corresponding to an extruding head of the extruder of the plastic tubular product; a supporting rod is parallel arranged on the lamination base; the supporting rod is sheathed and provided with a plurality of alternatively arranged laminations; the central position of the lamination is provided with a tubular product sizing opening corresponding to the aperture of the inlet of the plastic tubular product. The sizing device of the tubular product has fast cooling speed and the manufacture efficiency is improved by more than 2 times than that of the devices of the same category.

Owner:潍坊凯德塑料机械有限公司

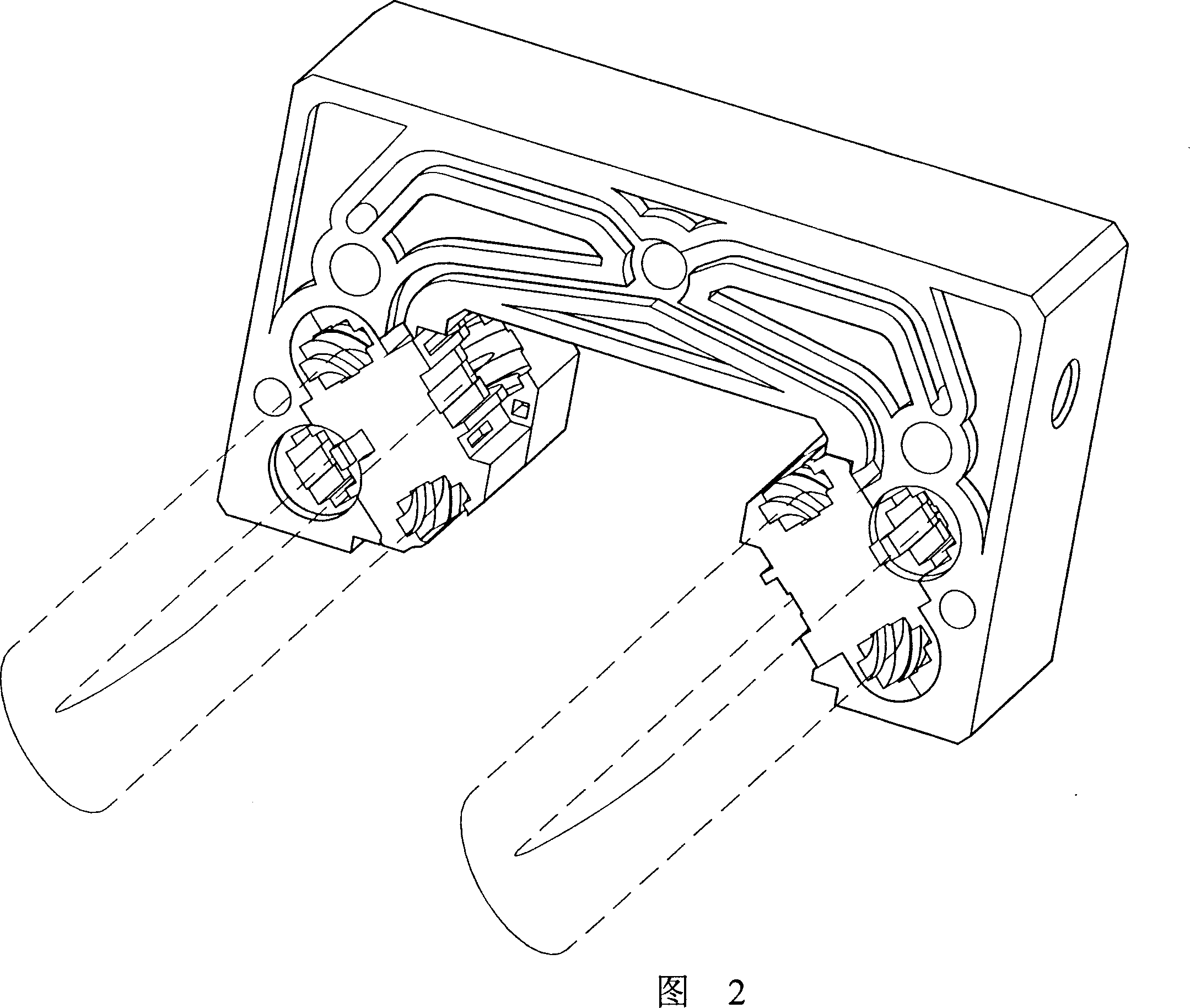

Return flow system of linear slide rail

The invention relates to a linear sliding rail return flow system, formed with upper and lower return circuit space between sliding rails, slide blocks jacketed on the sliding rails, and the two sides of each one in two groups of sliding block end covers, respectively, for multiple rolling bodies to make limitless rolling circulation, where one side of the end cover is equipped with upper turning channel and lower turning channel and the other side is equipped with inclined turning channel and U-shaped turning channel, which forms a return flow system integrating cross return flow turning path with split return flow turning path. Thus, the rolling bodies arranged in the return flow spaces only need two installation operations, able to raise production assembly efficiency. Besides, when the rolling bodies in the upper and lower rows make return flow movement, it can make them perform exchange circulation and smoothly turn and make their received force and oil path lubrication uniform, and can increase number of circulating rolling bodies and effectively improve linear sliding rail reliability.

Owner:HIWIN TECH

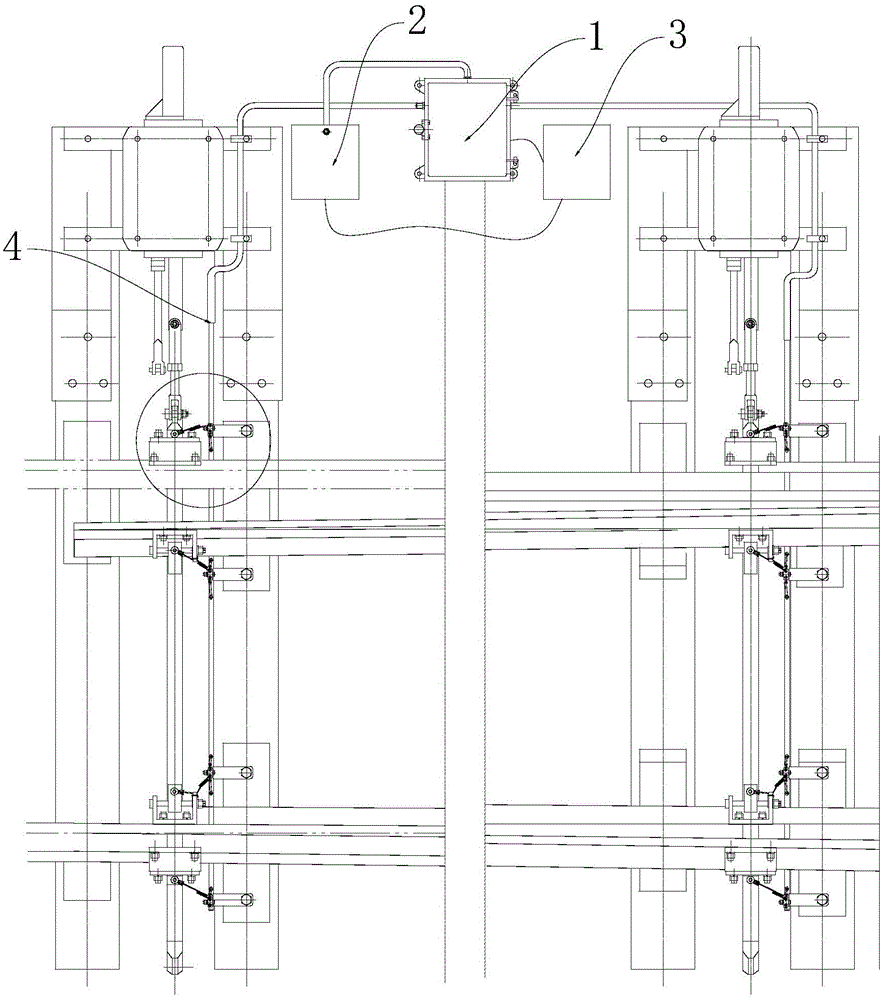

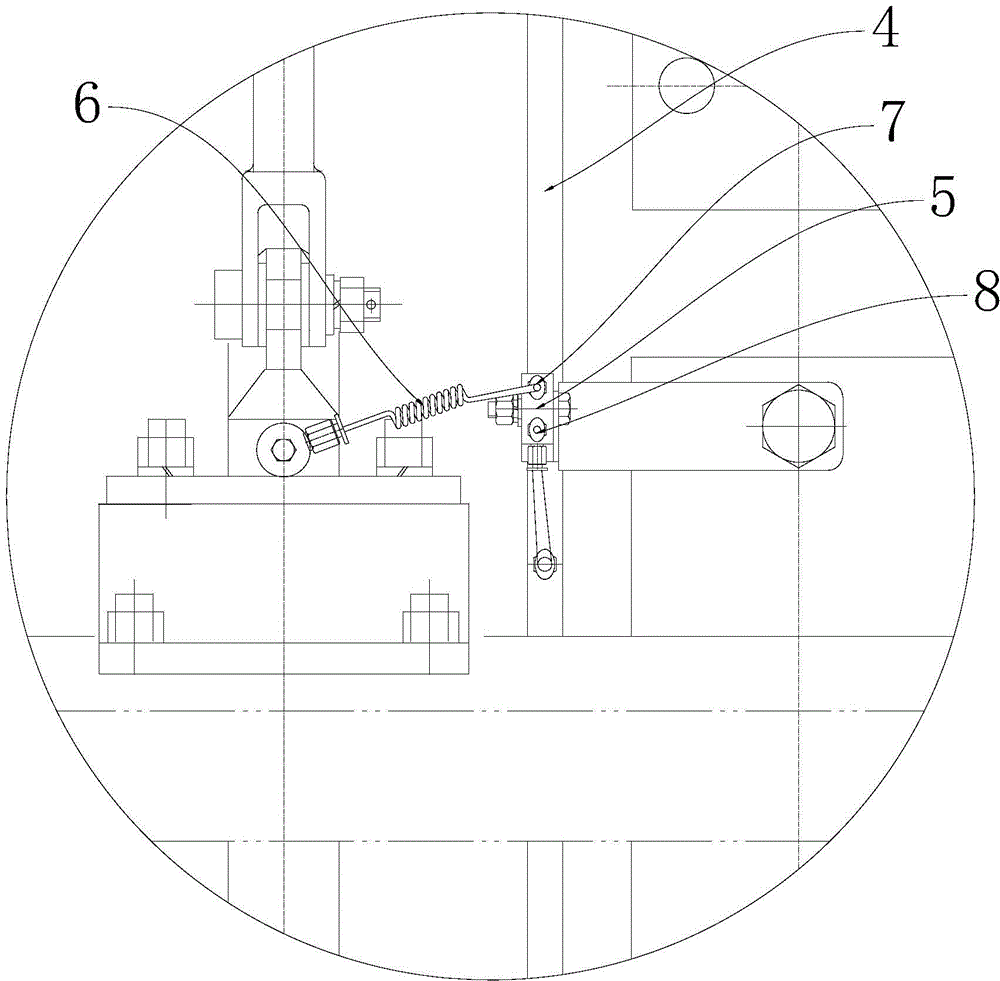

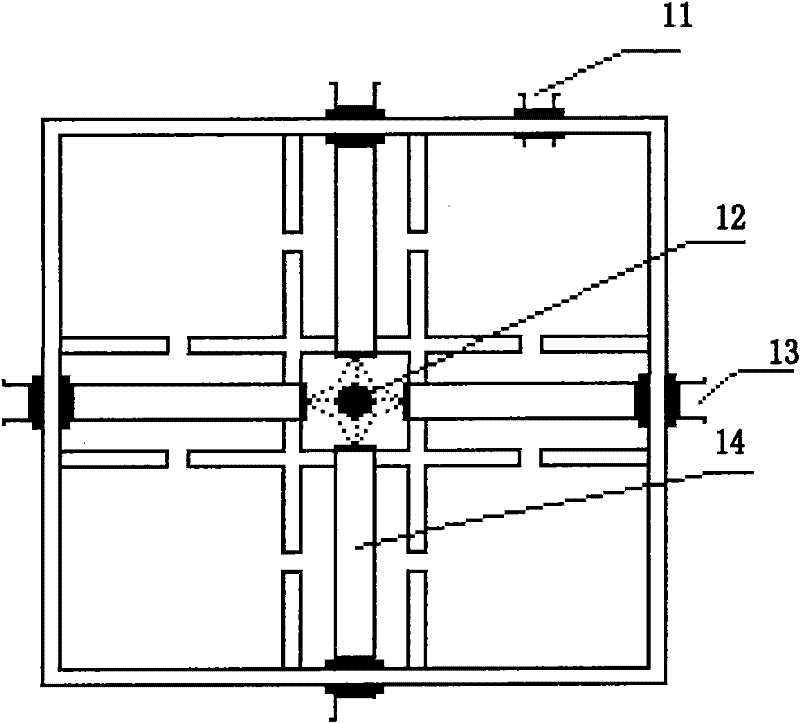

Automatic oiling system of turnout

The invention relates to the field of maintenance devices of railway turnout switching devices, in particular to an automatic oiling system of a turnout. The automatic oiling system of the turnout can carry out oiling lubrication on all the movable points of a locking device outside the turnout regularly. The automatic oiling system of the turnout comprises an oiling machine, a controller and a power supply mechanism, wherein the power supply mechanism is connected with the oiling machine, the oiling machine is connected with the controller, an oil supply pipe is connected to the oiling machine, the oil supply pipe is connected to a first towing point, a second towing point and a third towing point of the turnout, oil distributors are arranged on the two sides of the first towing point, the two sides of the second towing point and the two sides of the third towing point, the oil distributors are communicated with the oil supply pipe, and the oil distributors are connected with a lock hook, locking iron and a locking rod of the turnout through oil conveying pipes. According to the automatic oiling system of the turnout, lubricating oil is supplied through the oiling machine, oiling is carried out on components such as the lock hook, the locking iron and the looking rod through the oil supply pipe, the oil distributors and the oil conveying pipes, lubrication of the turnout is better, motion frictional force of the turnout is reduced, lubrication is even, and safety performance is improved.

Owner:海宁由拳铁路器材有限公司

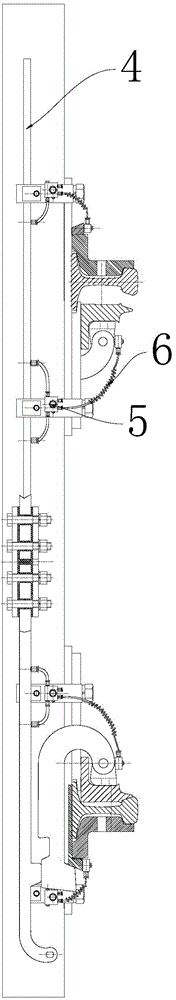

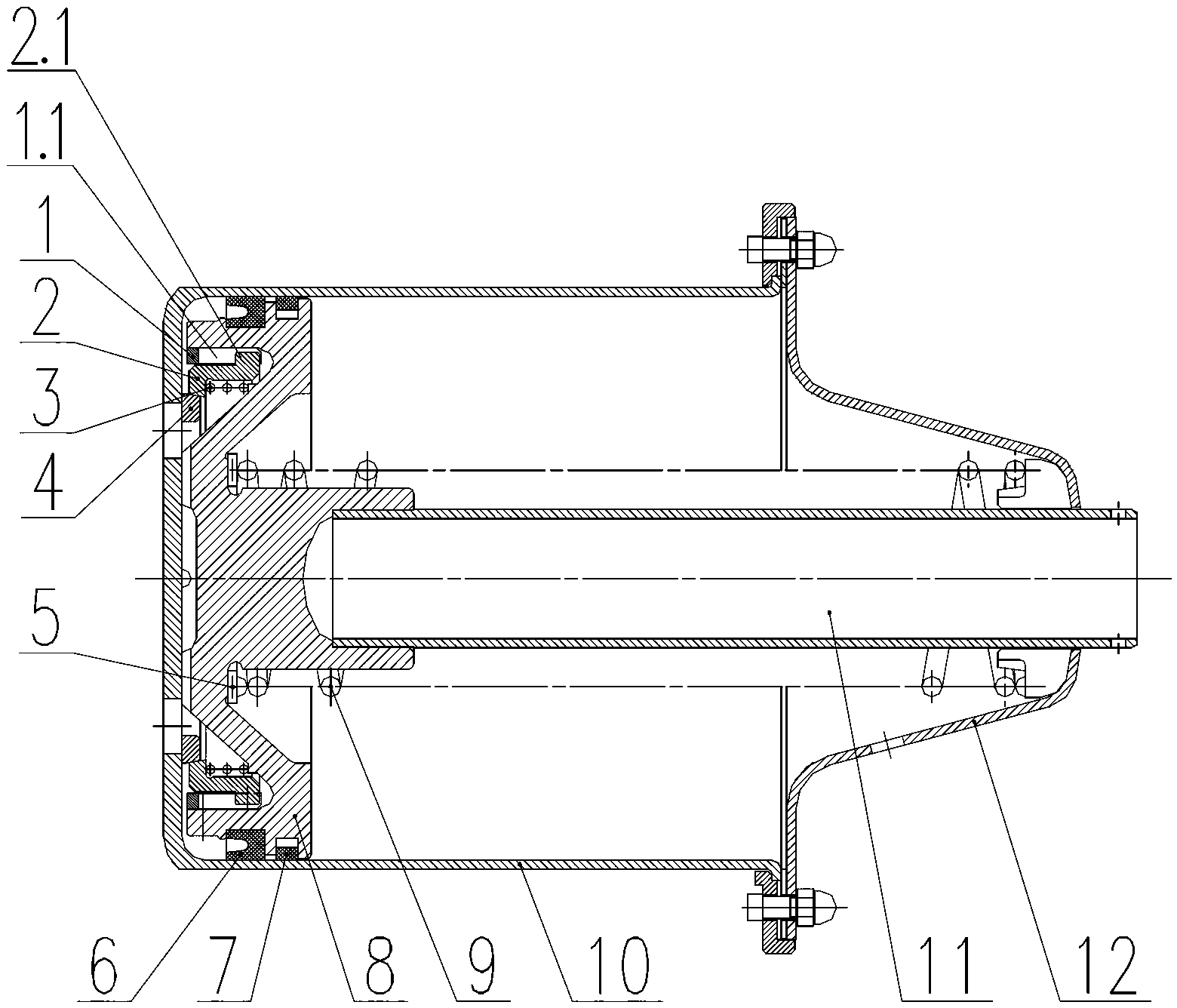

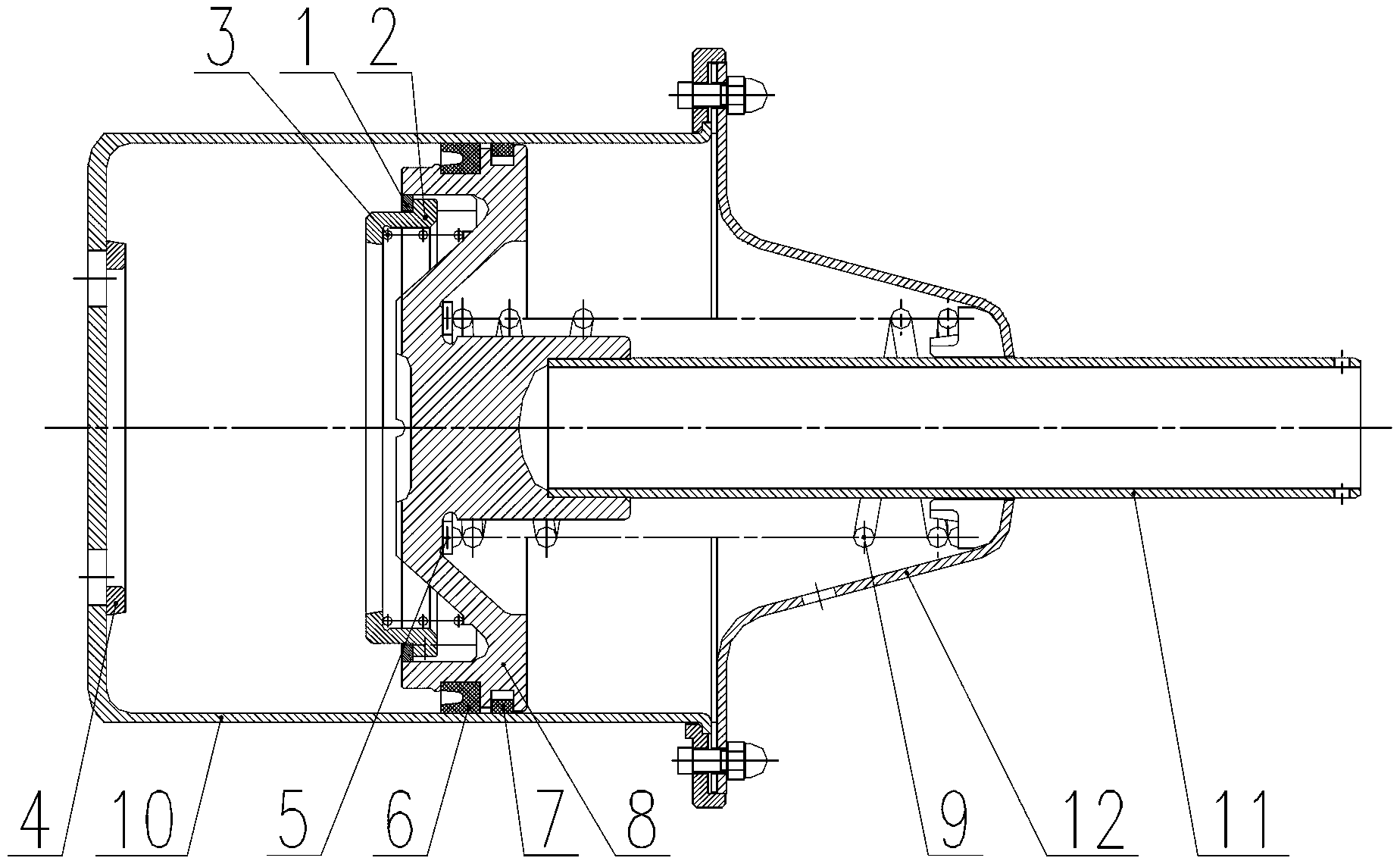

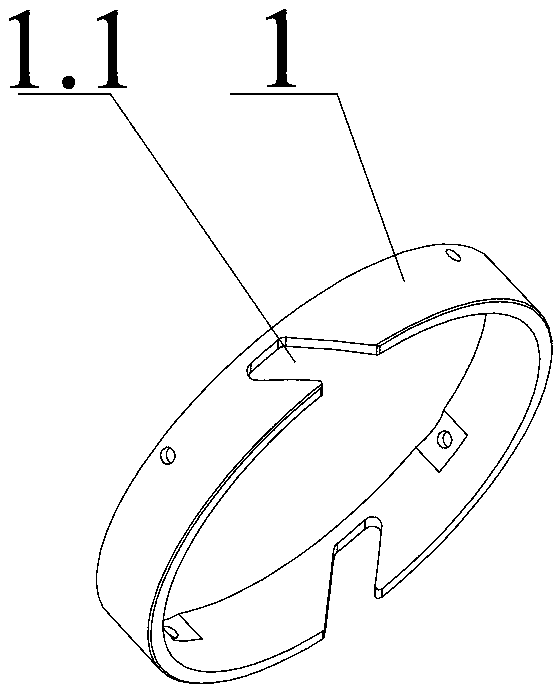

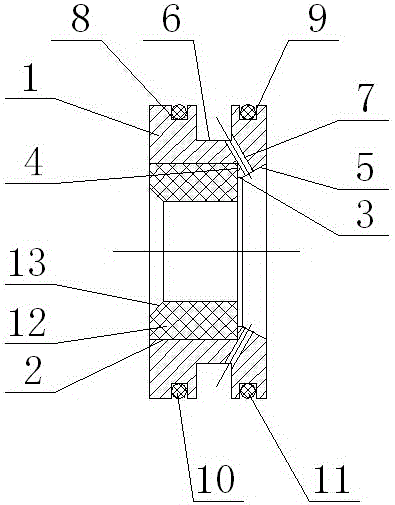

Rotationally lubricating type sealing brake cylinder for railway vehicles

ActiveCN103307151AEvenly lubricatedDoes not affect basic performanceBrake actuating mechanismsActuatorsClutch controlCylinder block

The invention provides a rotationally lubricating type sealing brake cylinder for railway vehicles, which comprises a cylinder body and a front cover assembly, wherein a piston and a piston rod are arranged inside the cylinder body, a sealing ring and a lubricating sleeve are arranged on the outer wall of the piston, a release spring is arranged between the bottom of the piston and the front cover assembly, the piston rod sticks out of the front cover assembly, a guiding ring is fixed on the inner wall of the ring slot in the top of the piston, a guiding sleeve is arranged on the inner side of the guiding ring, a reset spring is arranged between the guiding sleeve and the ring slot of the top of the piston, and a guiding base is fixed at the bottom of the cylinder body; and the guiding ring and the guiding sleeve form a screw rotation mechanism, the guiding sleeve and the guiding base form a clutch mechanism, the reset spring and the release spring form a clutch control mechanism, so as to enable the piston to rotate in only one direction under the action of the three mechanisms, the lubricating grease deposited at the bottom of the cylinder body is brought to mid-upper part of the cylinder body, the grease is pasted on the inner wall of the cylinder body uniformly, uniform lubricating of the piston sealing ring is guaranteed, and harmful or leaking faults are avoided. The rotationally lubricating type sealing brake cylinder provided by the invention has a simple structure, is small in revamping workload, and does not affect the basic performance of the conventional braking device of the vehicle.

Owner:CRRC YANGTZE CO LTD

Numerical control slurry spraying yarn repair lubricator and method thereof

InactiveCN102220666ACleanlinessReduce occupational diseasesTextile treatment by spraying/projectingLubricationPositive direction

The invention relates to a numerical control slurry spraying yarn repair lubricator and a method thereof. The numerical control slurry spraying yarn repair lubricator mainly comprises a micro speed-regulating hollow shaft motor, an atomization slurry spraying chamber, a yarn clew dust cover and a numerical control metering pump which are connected in sequence. The lubricator is characterized in that the micro speed-regulating hollow shaft motor is connected with the atomization slurry spraying chamber, and the lower end of the atomization slurry spraying chamber is connected with yarn clew dust cover which is provided with a dust exhaust port and is internally embedded with a gravity pressure spring; and nozzles on two sides of the atomization slurry spraying chamber are formed by connecting a slurry supply pipeline and a high-pressure metering pump. When yarns are reeled off from cheese, a rotary balloon naturally spirally lifted in positive direction is produced, the yarns pass through the high-pressure atomization slurry spraying chamber in time, and input slurry is automatically and preciously controlled by the high-pressure metering pump according to a computer instruction; the high-pressure slurry spraying chamber is provided with two or a plurality of nozzles for balanced multidimensional stereoscopic slurry spraying with multiple surfaces, multiple points and multiple angles; the yarn sprout ratio reaches a critical point of saturation and unsaturation; after being repaired and film-formed, the yarns are flexible internally and smooth externally and are rich in elasticity; and the method is an unsaturated slashing method. The working procedures of slashing and lubrication are merged and finished in one time, and a wrapped lubricant slurry film (30) is arranged outside the yarns. The method is grain-saving, water-saving, electricity-saving, time-saving, waste water zero-discharged, energy-saving and environmentally-friendly.

Owner:崔建明

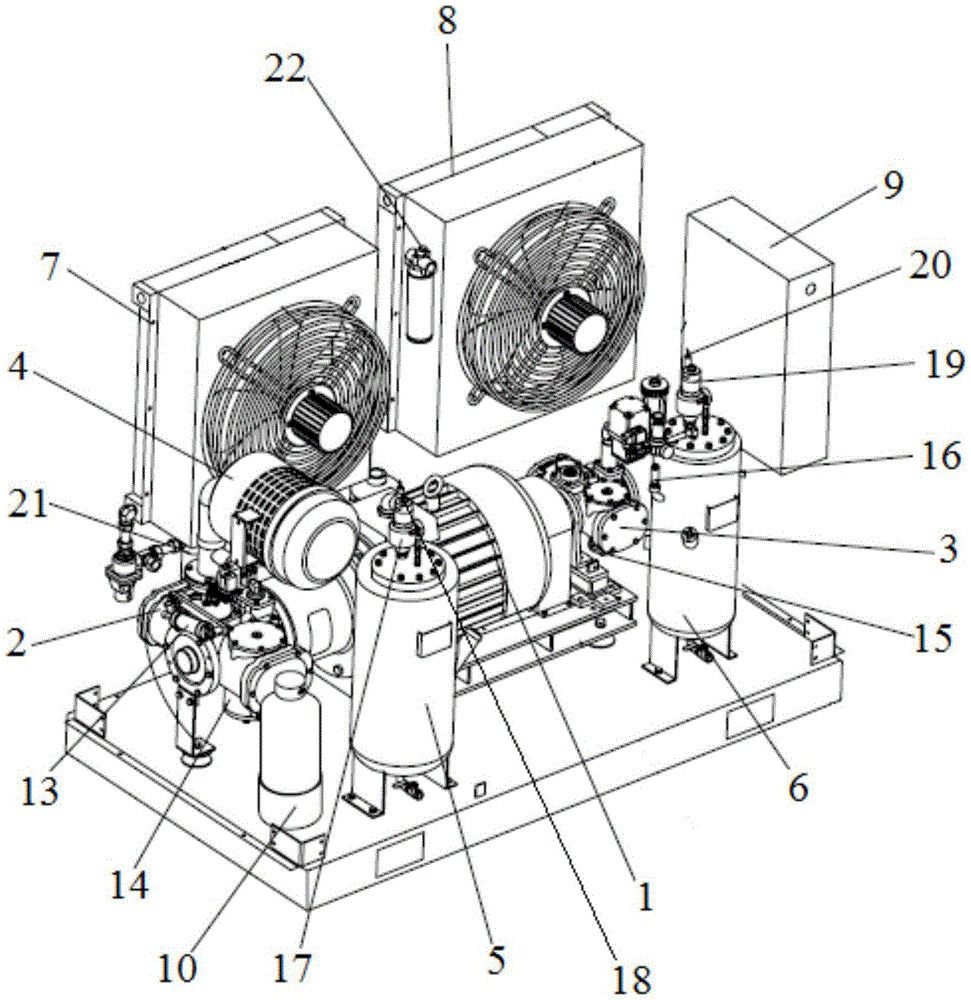

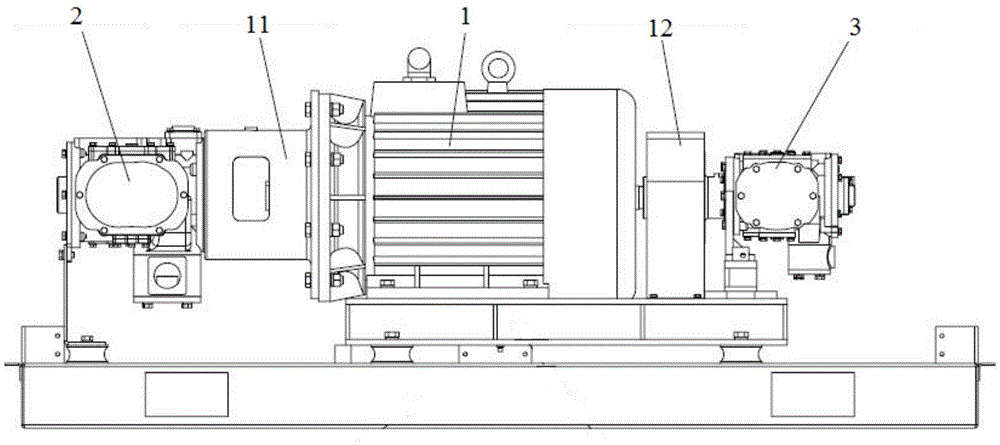

Water-lubrication oil-free medium pressure two-stage-compression single-screw-rod air compressor

InactiveCN105626530AEasy to cleanEnsure safetyRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsAir filterGas cooler

The invention relates to a water-lubrication oil-free medium pressure two-stage-compression single-screw-rod air compressor. The air compressor comprises an electric motor, a first-stage single-screw-rod compression main machine, a second-stage single-screw-rod compression main machine, an air filter, a first-stage water and gas separator, a second-stage water and gas separator, a first-stage gas cooler, a second-stage gas cooler and an electrical control box; the first-stage single-screw-rod compression main machine and the second-stage single-screw-rod compression main machine are in transmission connection with the electric motor, and the air filter is connected with a gas inlet of the first-stage single-screw-rod compression main body; and the first-stage gas cooler is connected with the first-stage water and gas separator, the second-stage gas cooler is connected with the second-stage water and gas separator, and the electrical control box is electrically connected with the electric motor. Compared with the prior art, the water-lubrication oil-free medium pressure two-stage-compression single-screw-rod air compressor has the beneficial effects that the whole structure is simple and compact, complex pipelines and valves do not need to be additionally arranged, water lubrication is adopted, resistance losses are small, running reliability is good, volume efficiency is high, oil is avoided, zero emissions are achieved, no environmental pollution exists, running is carried out at the normal temperature, and the air compressor is environment-friendly, energy-saving and low in maintaining cost and has the very good application prospect.

Owner:SHANGHAI GAIRS MACHINERY CO LTD

Roller tool for the linear deformation of sheet metal and sheet deformation facility having such a roller tool

ActiveUS7343767B2Promote formationImprove the lubrication effectShaft and bearingsRolling equipment maintainenceBody rollEngineering

A roller tool is used within a sheet deformation facility for the linear deformation of sheet metal. The roller tool comprises a press roller having a shaft and a roller body rolling around the same as well as a counterbody. The press roller and the counterbody can be jointly moved in a linear manner relative to a sheet positioned between them that is to be processed for performing the sheet metal deformation. The roller body has a plurality of roller discs which are adjacent to each other, which together form the section of the roller body that can be placed onto the sheet to be processed and which can rotate around the shaft independently of each other. The sheet deformation facility is furthermore provided with a roller tool support and a drive for pivoting the roller tool support around an axis perpendicular to the sheet that is to be processed.

Owner:PASS STANZTECHN

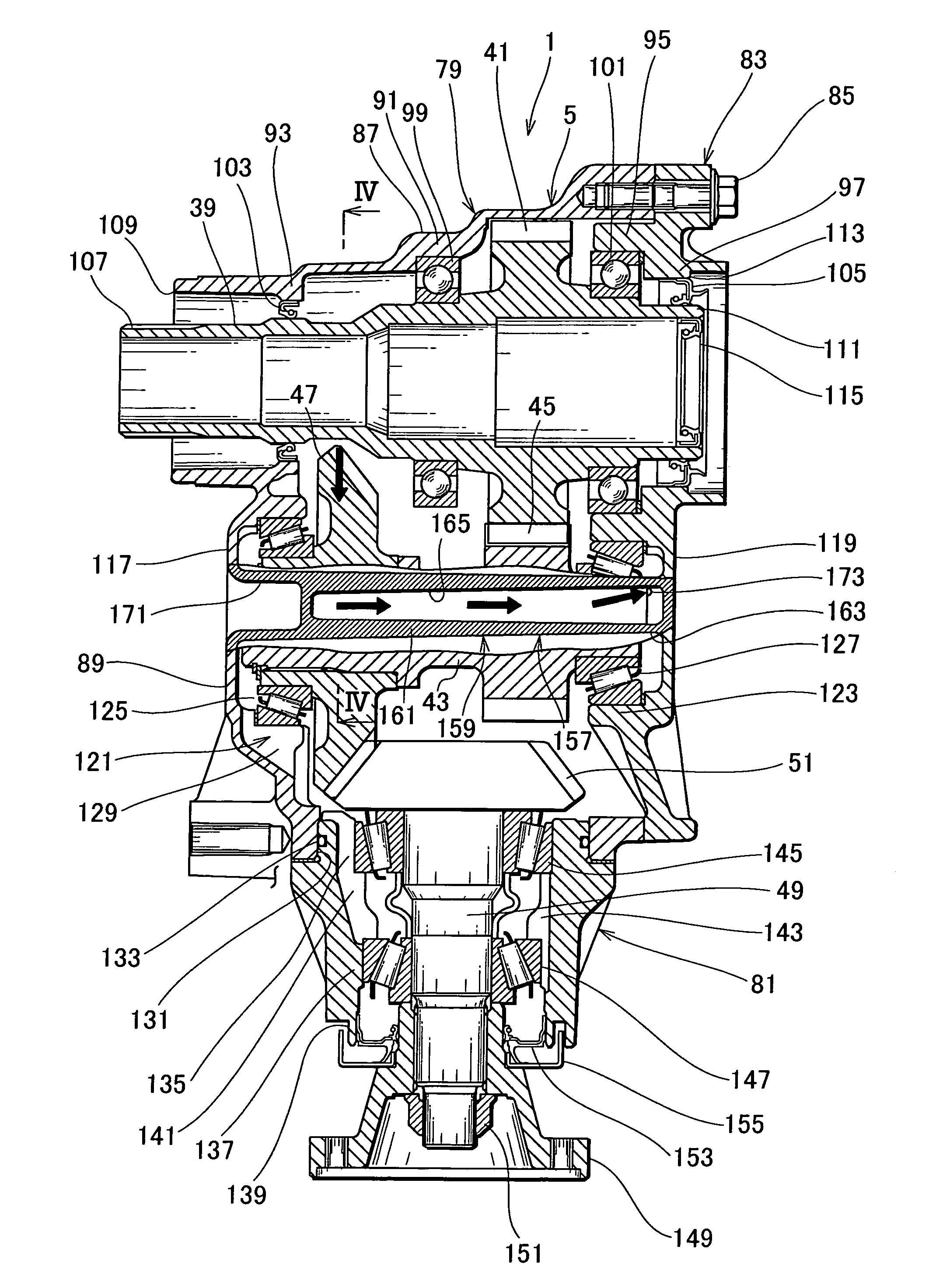

Drive unit

ActiveCN103363078ASimple sealing structureEvenly lubricatedElectric devicesGear lubrication/coolingCountermeasureReducer

The present invention is concerned with a drive unit including an integrated motor and reducer, in which a sealing structure for the motor can be simplified. Oil flows through a motor-shaft oil passage (89) as shown by the arrow (3). Accordingly, the oil dose not leak into a motor case (49), so that the inside of the motor case (49) is "dry". Wires (123) extending from a stator (71) penetrate the motor case (49) and extend to the outside, but a simple seal (such as a dust seal) can be used. Thus, in the drive unit, the sealing structure for the motor can be simplified.

Owner:HONDA MOTOR CO LTD

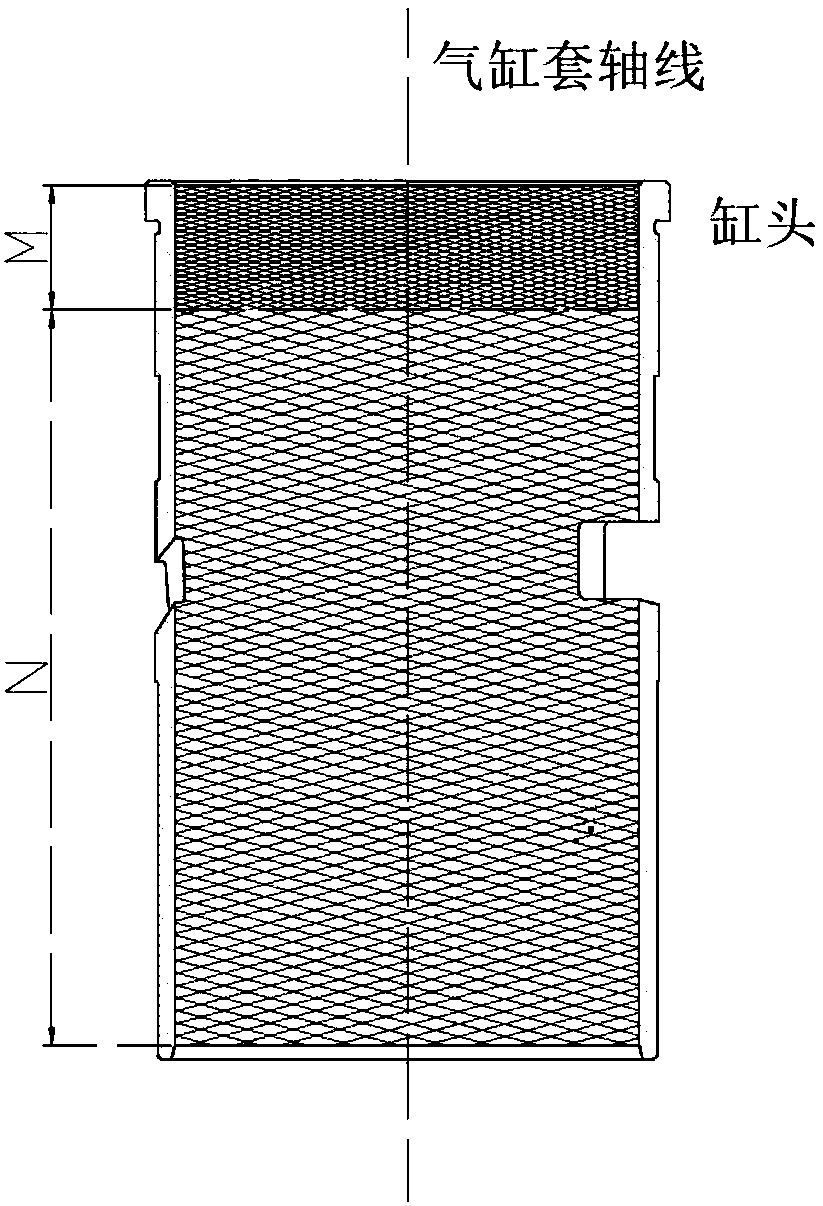

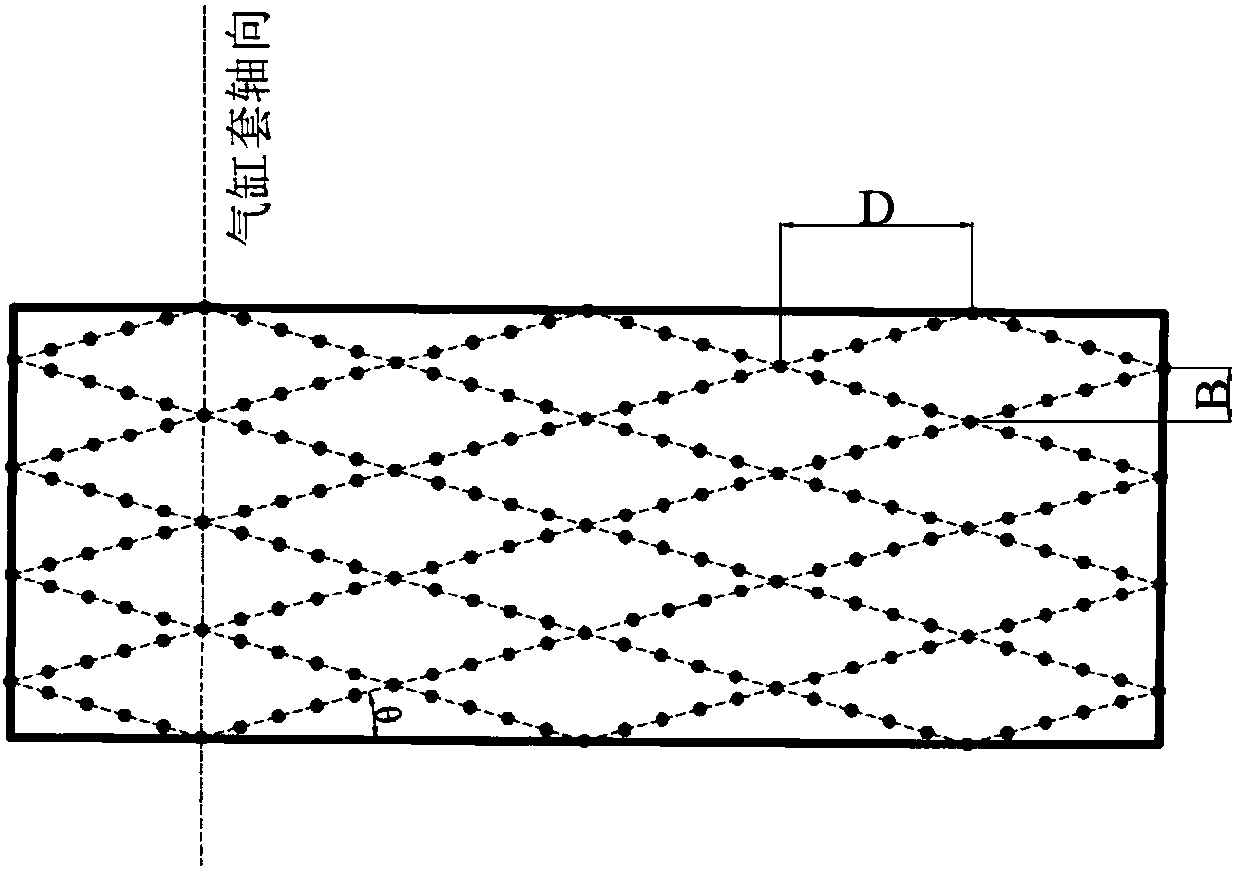

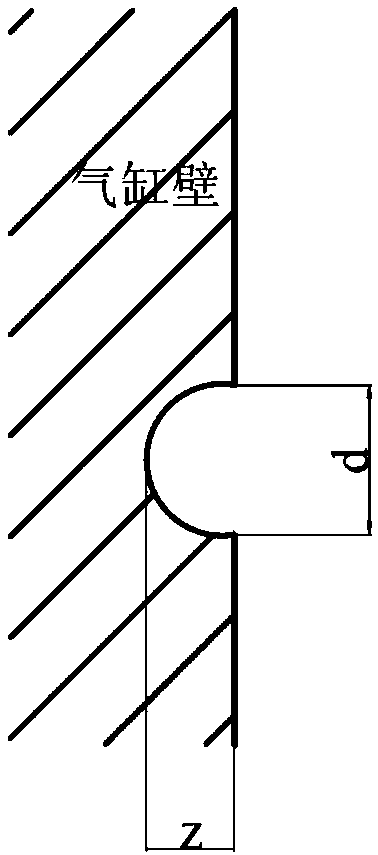

Two-cycle aviation heavy oil piston engine cylinder sleeve inner wall laser micro-texturing structure

ActiveCN107687375AReduce consumptionImprove emission characteristicsPiston ringsCylinder headsBoundary lubricationFuel oil

The invention discloses a two-cycle aviation piston engine drive lubrication cylinder sleeve inner wall laser micro-texturing structure design method. The method comprises the steps that firstly, through analysis modeling on boundary lubrication of the two friction pairs including a piston ring-a cylinder sleeve and a piston skirt-the cylinder sleeve which are abraded most severely, micro texturesfollowing the optimal arranging rules are arranged on the surface of the cylinder sleeve in a targeted mode, pits of the micro textures are filled with various abrasive particles in the up-down strokes of a piston and the piston ring, the cylinder sleeve is prevented from being damaged during pulling, and accordingly, the service lives of the cylinder sleeve and an engine comprising the cylindersleeve are prolonged; and secondly, the micro textures following the optimal arranging rules are utilized for organizing motion of lubricating oil film, the oil film is prevented from being broken, the velocity of motion of the lubricating oil film in the axial direction of an air cylinder is decreased, the component velocity in the circumferential direction of the piston ring is increased, thus,the amount of lubricating oil entering a combusting chamber is decreased, and consumption of the lubricating oil is reduced. Meanwhile, the flow rate of the oil film in the circumferential direction of the piston ring is increased, lubrication is improved, the airtightness of a piston ring set is improved simultaneously, and consumption of the lubricating oil is reduced.

Owner:北京领动国创科技有限公司

Oil injection ring for drawing copper pipe

The invention discloses an oil injection ring for drawing a copper pipe. The oil injection ring comprises a ring body, and a channel is formed in the center of the ring body; a boss is formed at an opening in the front end of the inner wall of the ring body, the inner side surface of the boss is a vertical plane perpendicular to the central axis of the ring body, and the outer side surface of the boss is an inclined plane; an annular oil groove is formed in the outer side of the ring body, oil injection holes are formed in the ring body, one ends of the oil injection holes are opened in the bottom of the oil groove, and the other ends of the oil injection holes are opened in the inclined plane; a first sealing groove and a second sealing groove are formed in the outer side of the ring body, and O type sealing rings are installed in the first sealing groove and the second sealing groove respectively; and a nylon ring is installed in the channel, the rear end of the nylon ring is flush with an opening in the rear end of the inner wall of the ring body, the front end of the nylon ring abuts against the vertical plane of the boss, the nylon ring is in interference fit with the inner wall of the ring body, and the inner diameter of the nylon ring is smaller than the diameter of the channel. According to the oil injection ring, the copper pipe can be comprehensively lubricated, the temperature of a drawing die can be lowered, the outer wall of the copper pipe can be effectively protected, and the product accuracy can be improved.

Owner:CHONGQING LONGYU PRECISION COPPER TUBE CO LTD +1

Grease filled bearing

InactiveCN105008738AAvoid damageReduce consumptionRoller bearingsBearing componentsDiphenyl etherAliphatic hydrocarbon

A grease-filled bearing filled with a grease composition containing a thickener which is a diurea compound represented by R 1 -NHCONH-R 2 -NHCONH-R 3 or a mixture thereof and a base oil containing alkyl diphenyl ether oil and containing poly ±-olefin oil as an optional component at a mass ratio of 40:60 to 100:0 (alkyl diphenyl ether oil:poly ±-olefin oil). In general formula (1), at least one of R 1 and R 3 is a C 6-12 aromatic hydrocarbon group and the other is a C 6-12 aromatic hydrocarbon group or a C 6-20 aliphatic hydrocarbon group. R 2 is a C 6-15 aromatic hydrocarbon group.

Owner:NSK LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com