Water-lubrication oil-free medium pressure two-stage-compression single-screw-rod air compressor

An air compressor and two-stage compression technology, applied in the field of machinery, can solve the problems of many wearing parts, high vibration intensity, and intricate pipelines, etc., to ensure safety and reliability, increase lubrication area, reduce Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

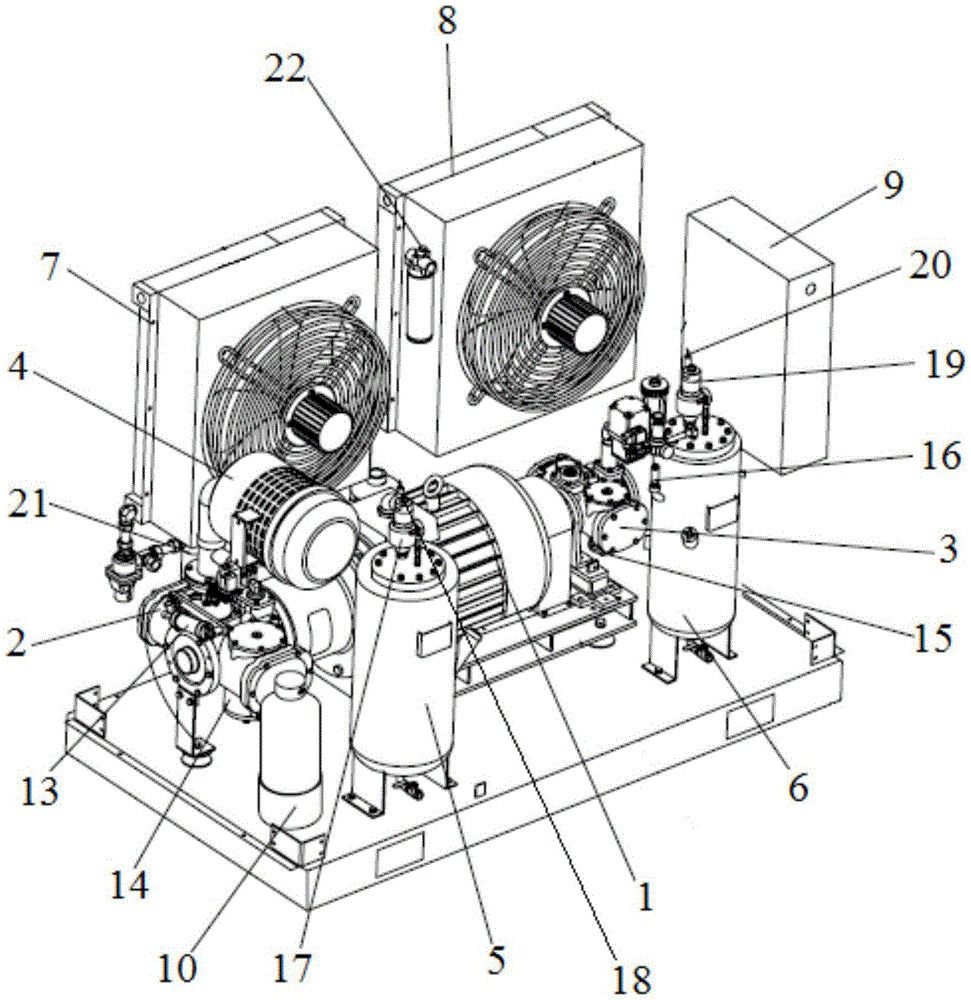

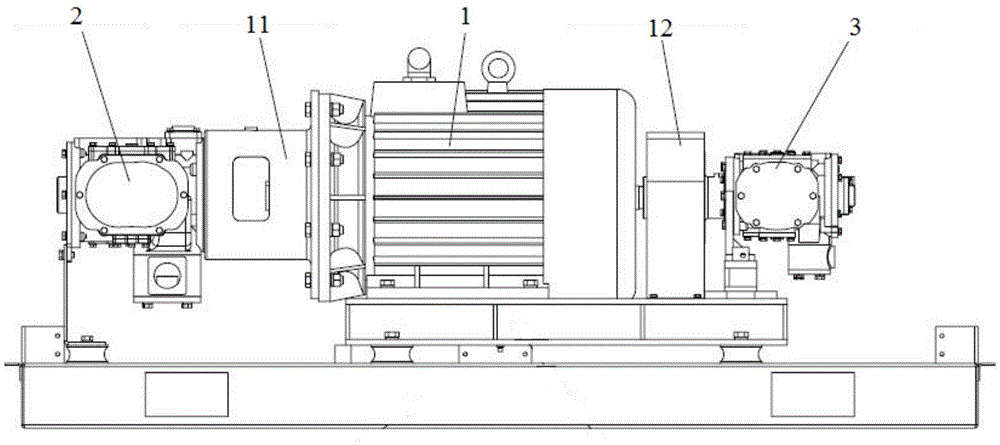

[0044] Such as Figure 1-2 As shown, a water-lubricated oil-free medium-pressure two-stage compression single-screw air compressor includes a motor 1, a first-stage single-screw compressor host 2 and a second-stage single-screw compressor host 3 connected to the motor 1, and a first-stage single-screw compressor. The air filter connected to the air inlet of the single-screw compressor host 2, the first-stage water-air separator 5, the second-stage water-air separator 6, and the first-stage air cooler 7 connected to the first-stage water-air separator 5 , the secondary air cooler 8 connected with the secondary water-gas separator 6 and the electric control box 9 electrically connected with the motor 1; The water outlet of the first-stage water-gas separator 5 is connected with the liquid injection port of the first-stage single-screw compressor host 2 through the first-stage water filter 21, and the air outlet of the first-stage water-gas separator 5 is connected with the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com