Grease filled bearing

A grease seal and bearing technology, applied in the direction of bearings, roller bearings, shafts and bearings, etc., can solve the problems of difficult to completely suppress poor lubrication, damage to the raceway ring, rust, etc., achieve excellent durability, and inhibit bearing damage. , the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~24、 comparative example 1~2

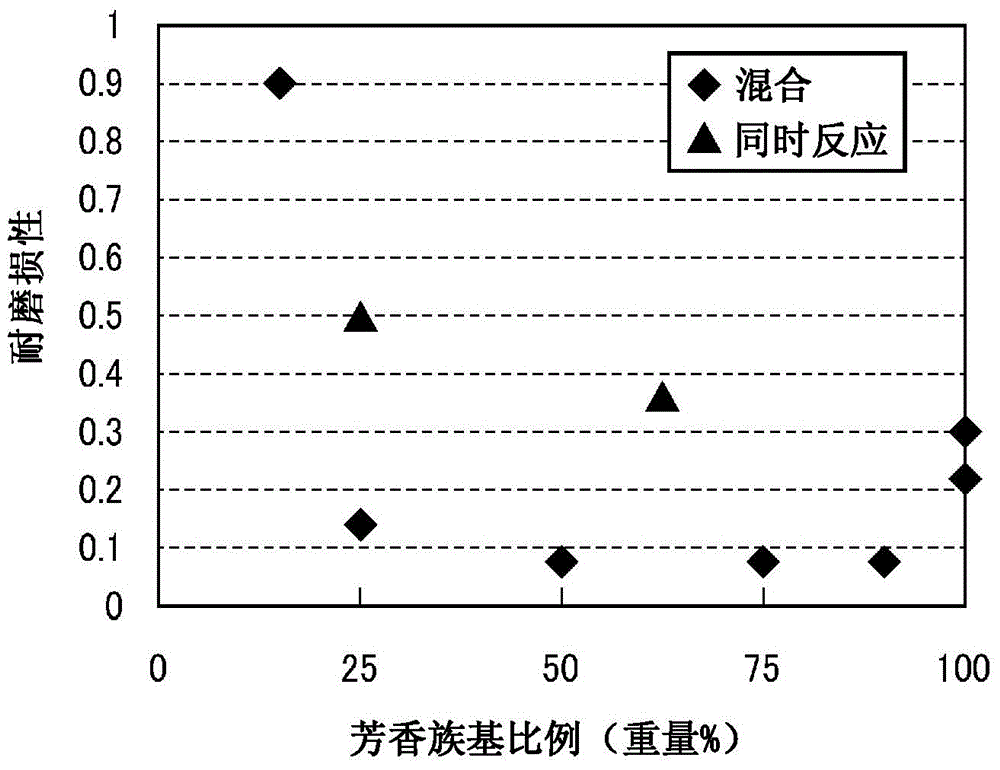

[0071] Test greases having the compositions shown in Table 1 were prepared. At this time, in Examples 1 to 7 and 17 to 20, grease compositions using an aromatic diurea compound (tA) as a thickener and grease compositions using an aliphatic diurea compound (tB) as a thickener were prepared, respectively. Grease composition, and mix the two grease compositions to prepare test grease. In addition, the mixing ratio of the aromatic diurea compound (tA) and the aliphatic diurea compound (tB) is shown in Table 1. In the thickener tA, TDI was used as the isocyanate, p-toluidine was used as the monoamine, and in the thickener tB, MDI was used as the isocyanate, and octylamine was used as the monoamine.

[0072] In addition, in Examples 10-16, 21-24, the aromatic amine compound and the aliphatic amine compound were simultaneously reacted in the base oil, and the test grease which used the reaction product (tC) as a thickener was prepared. In addition, in Examples 11 to 16, 40% by mass o...

Embodiment 3

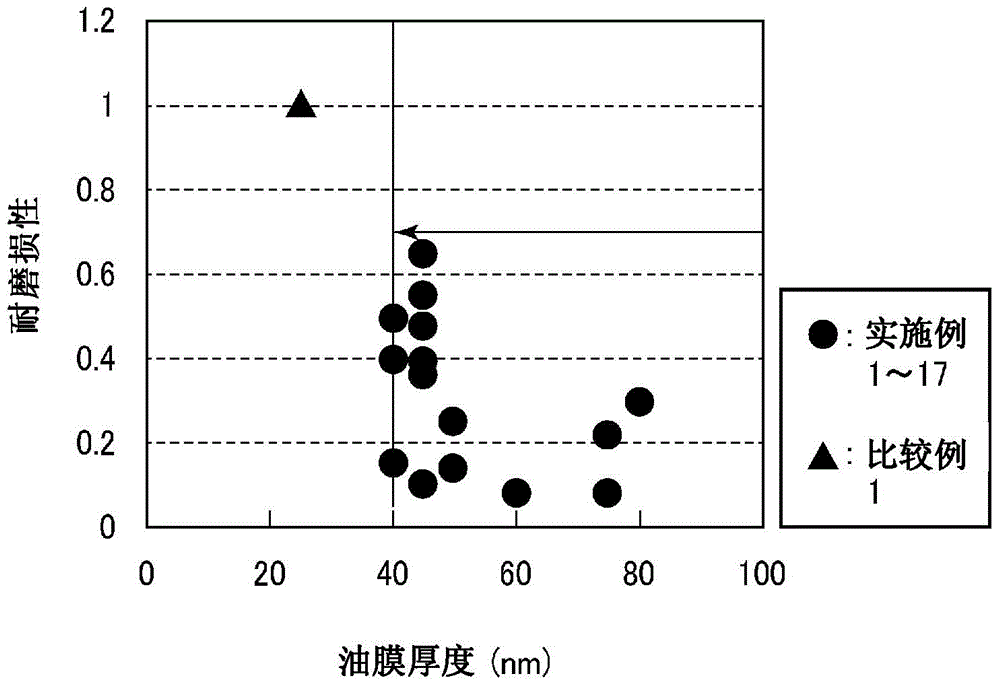

[0096] The types of thickeners in Examples 3, 4, 22, and 23 are the same, but due to differences in preparation methods, the composition and structure of thickener fibers are different. For Example 3 and Example 4, which were mixed after synthesizing aliphatic diurea and aromatic diurea respectively, compared with Example 22 and Example 23, which synthesized and mixed three kinds of diurea at the same time, the oil film was thicker, Excellent performance, good wear resistance.

[0097] From Examples 1-9 and Examples 12-17, it turns out that wear resistance improves by containing an aromatic diurea compound at 40 mass % or more.

[0098] From Examples 1 to 5, it can be seen that the weight ratio of the aromatic diurea compound to the aliphatic diurea compound is 40:60 to 95:5, and the apparent viscosity is below 0.6 Pa·s, thereby further improving the wear resistance .

[0099] From Examples 3 to 5, it can be seen that the weight ratio of the aromatic diurea compound to the a...

Embodiment 25 to 27

[0102] The test grease of Example 4 was used, and the rust preventive agent and antioxidant shown in the rust preventive treatment A or rust preventive treatment B shown below were added. Then, the following (5) rust resistance test was performed to evaluate the rust resistance. The results are shown in Table 2. In addition, the addition amount is the ratio to the total amount of test grease.

[0103] Antirust treatment A: 1.0% by mass of sorbitan trioleate (HLB=1.8), 1.0% by mass of succinic anhydride, 1.0% by mass of calcium dinonyl naphthalenesulfonate, 1.0% by mass of alkenyl succinic imide

[0104] Antirust treatment B: 1.0% by mass of sorbitan trioleate (HLB=1.8), 1.0% by mass of calcium dinonylnaphthalenesulfonate

[0105] ・Antioxidant: 1.0% by mass of alkylated diphenylamine

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com