Patents

Literature

70results about How to "No surface damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

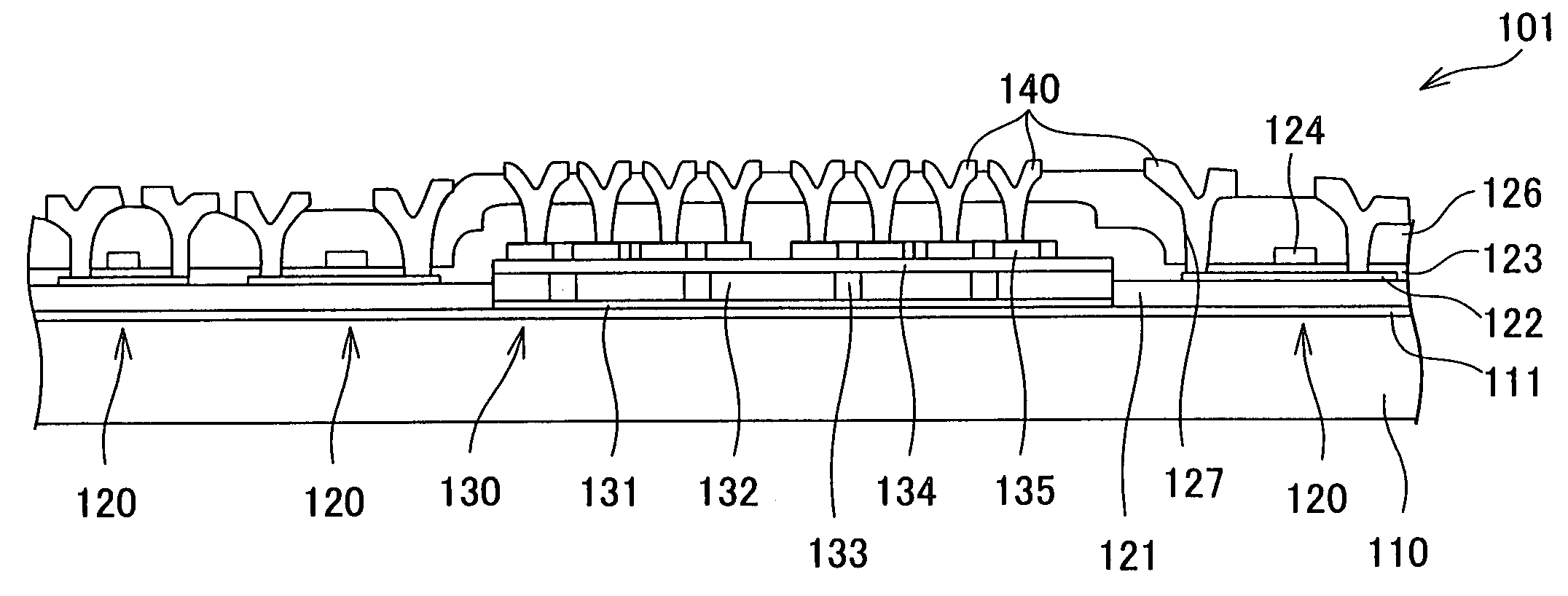

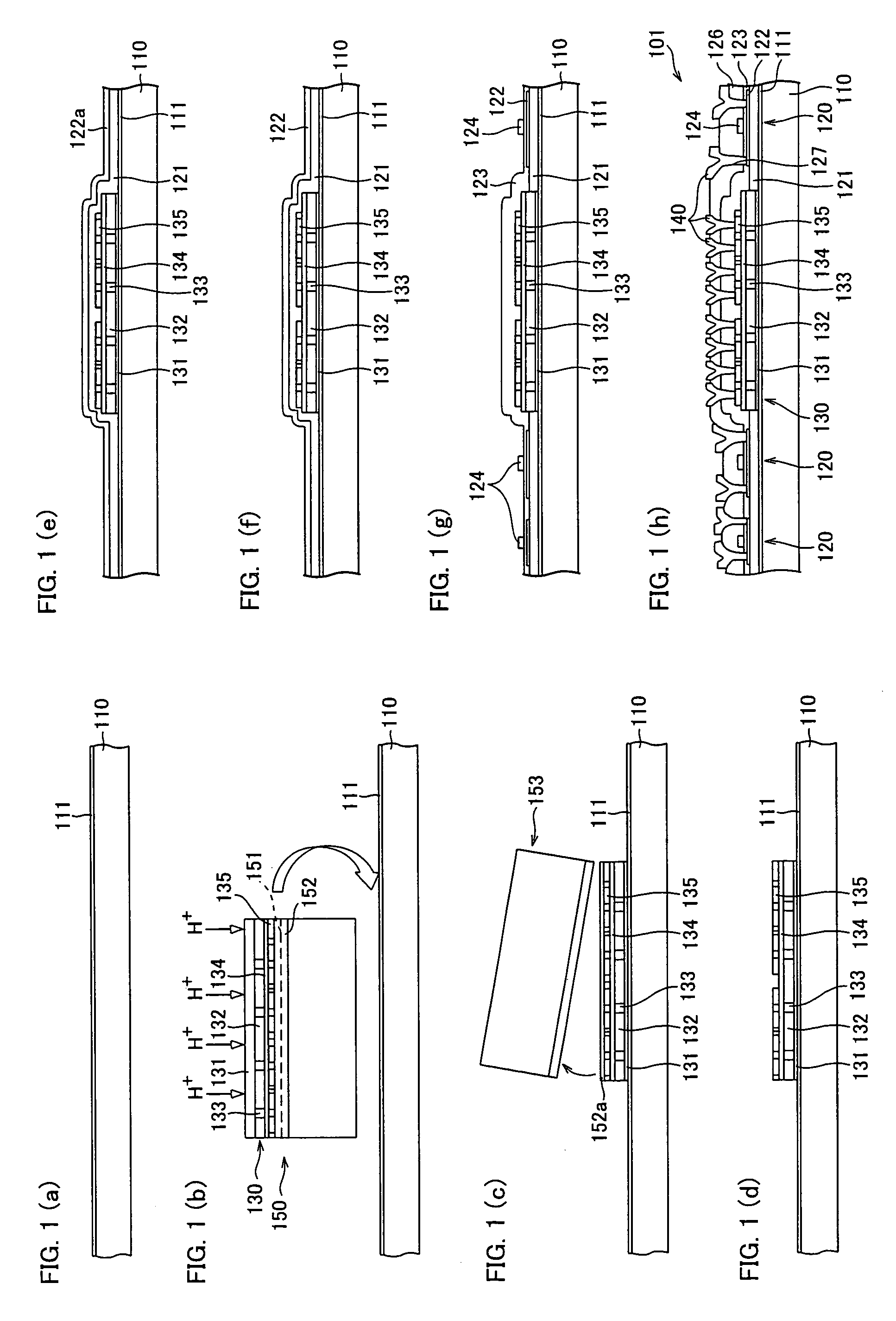

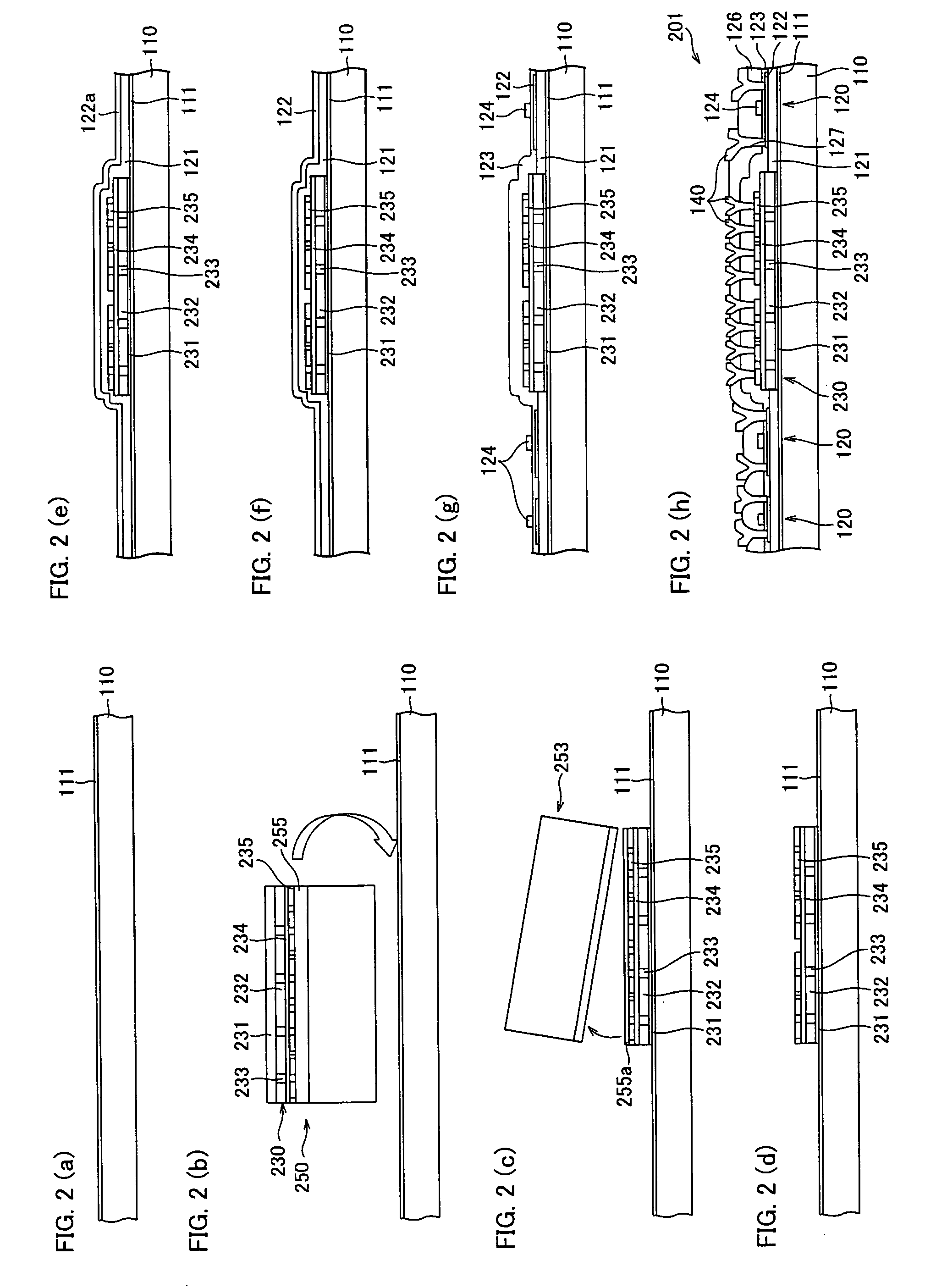

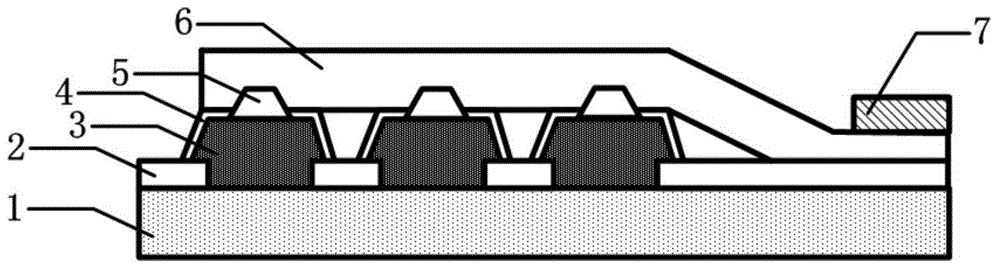

Semiconductor device

InactiveUS7244990B2Well formedUniform thicknessTransistorSolid-state devicesAdhesiveIon implantation

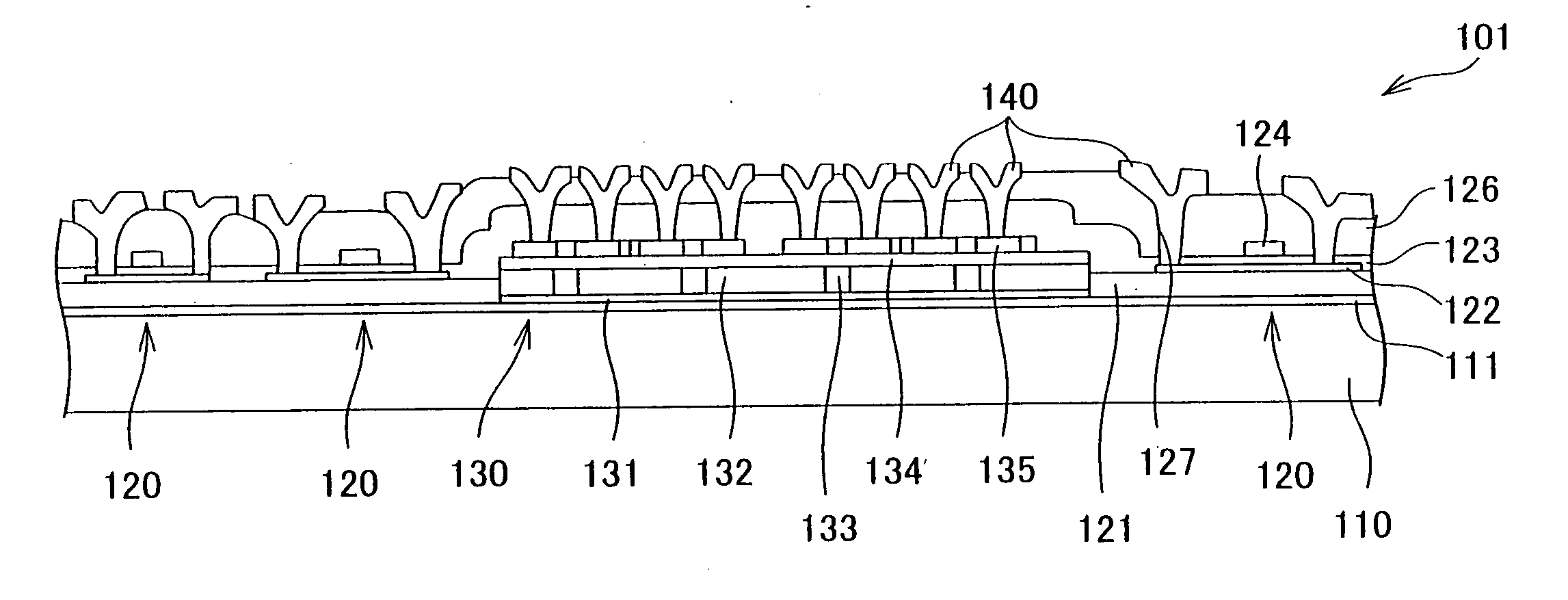

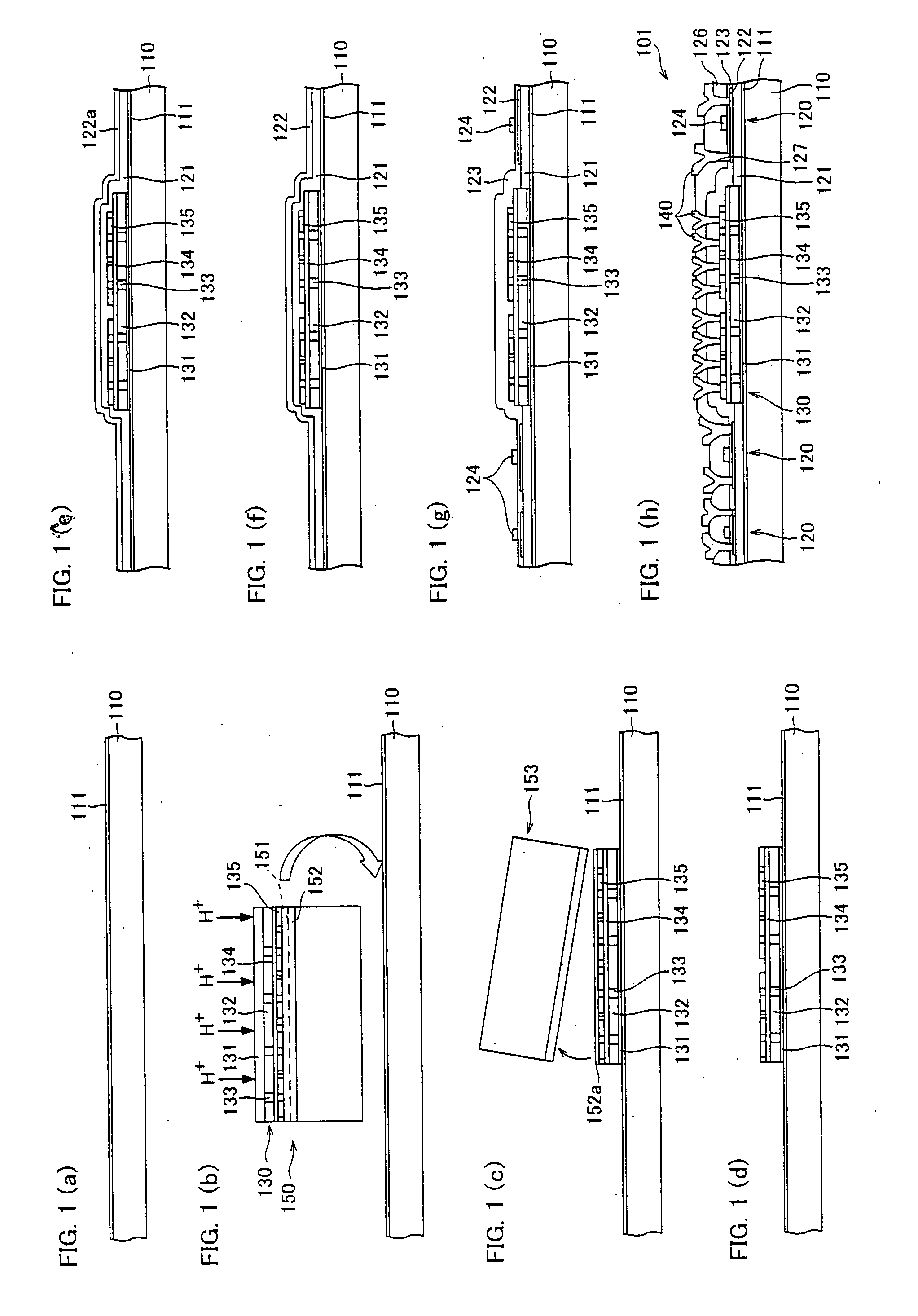

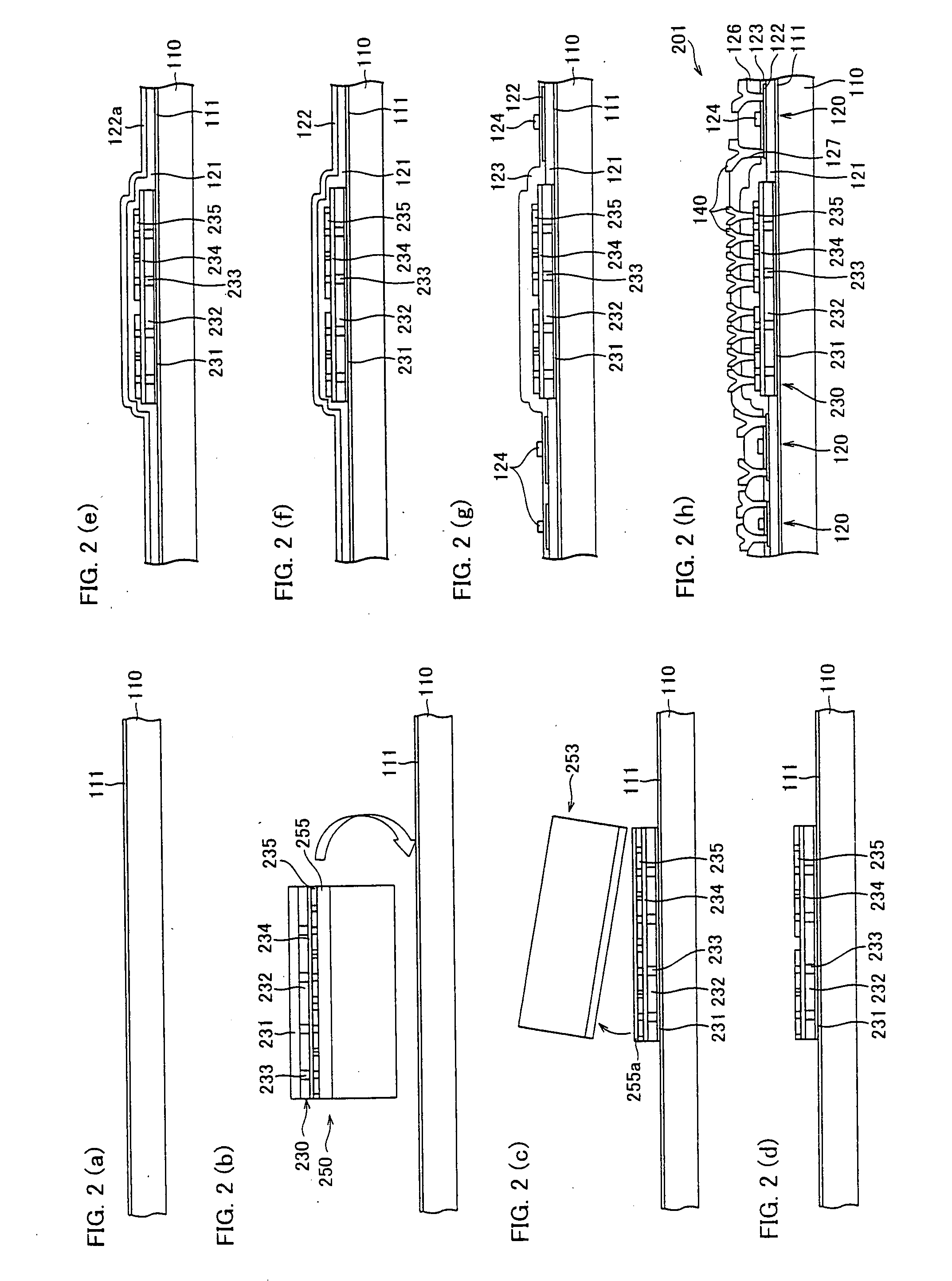

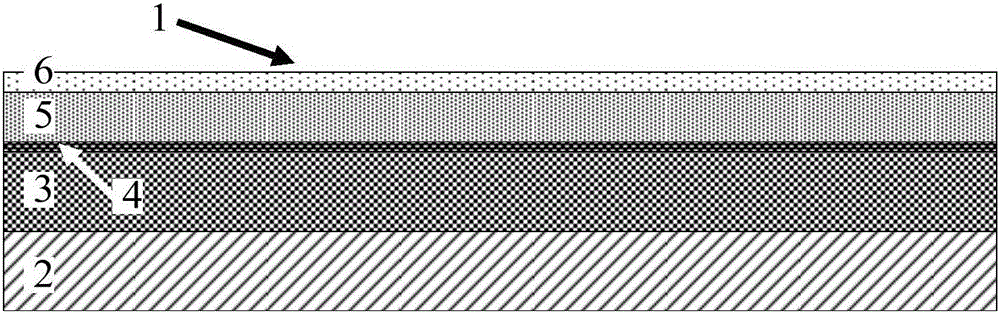

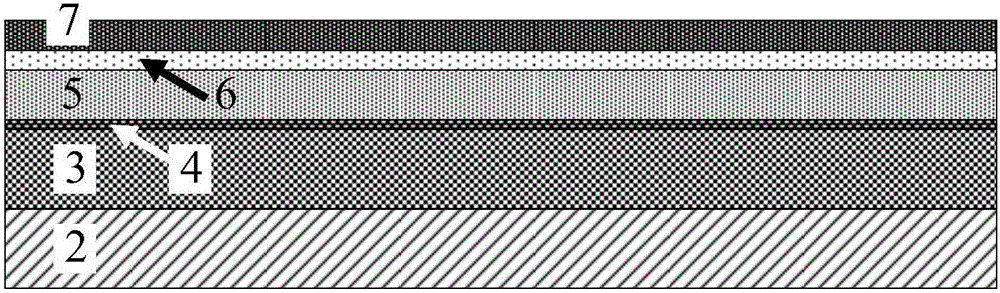

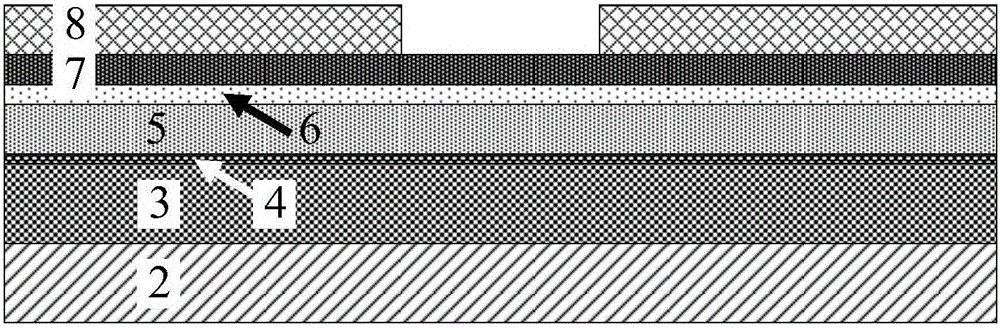

On an SOI substrate, a hydrogen ion implantation section in which distribution of hydrogen ions peaks in a BOX layer (buried oxide film layer), and a single-crystal silicon thin-film transistor are formed. Then this SOI substrate is bonded with an insulating substrate. Subsequently, the SOI substrate is cleaved at the hydrogen ion implantation section by carrying out heat treatment, so that an unnecessary part of the SOI substrate is removed, Furthermore, the BOX layer remaining on the single-crystal silicon thin-film transistor is removed by etching. With this, it is possible to from a single-crystal silicon thin-film device on an insulating substrate, without using an adhesive. Moreover, it is possible to provide a semiconductor device which has no surface damage and includes a single-crystal silicon thin film which is thin and uniform in thickness.

Owner:SHARP KK

Method for cleaning sapphire substrate

InactiveCN102632055AImprove product yieldWon't catchCleaning processes and apparatusChemistryNitrogen

The invention relates to a method for cleaning a sapphire substrate. The surface of a sapphire epitaxial substrate has a larger quality difference of the substrate surface and has a difference in defects of an oxidation layer and a subsurface after being cleaned by organic impurities and inorganic metal impurities due to chemical-mechanical polishing (CMP). The sapphire substrate is generally classified according to the cleaning conditions of the substrate surface. And when an imaging (PSS (Poly(sodium-p-styrenesulfonate))) substrate is prepared or heteroepitaxy is directly carried out, the product uniformity is different so that the final yield of the product is decreased. The method provided by the invention is characterized in that the sapphire substrate is cleaned with the organic impurities and the inorganic metal impurities and then is cleaned with hydrogen-nitrogen plasmas. After the cleaning method provided by the invention is carried out, the surface of the sapphire substrate has no oxidation impurities, defection layers and no subsurface defection layers. The surface quality of the substrate is good in consistency. The cleaning method provided by the invention has high yield of the PSS substrate or high crystallization quality of a GaN layer subjected to the heteroepitaxy.

Owner:CHANGZHOU TONGTAI PHOTOELECTRIC

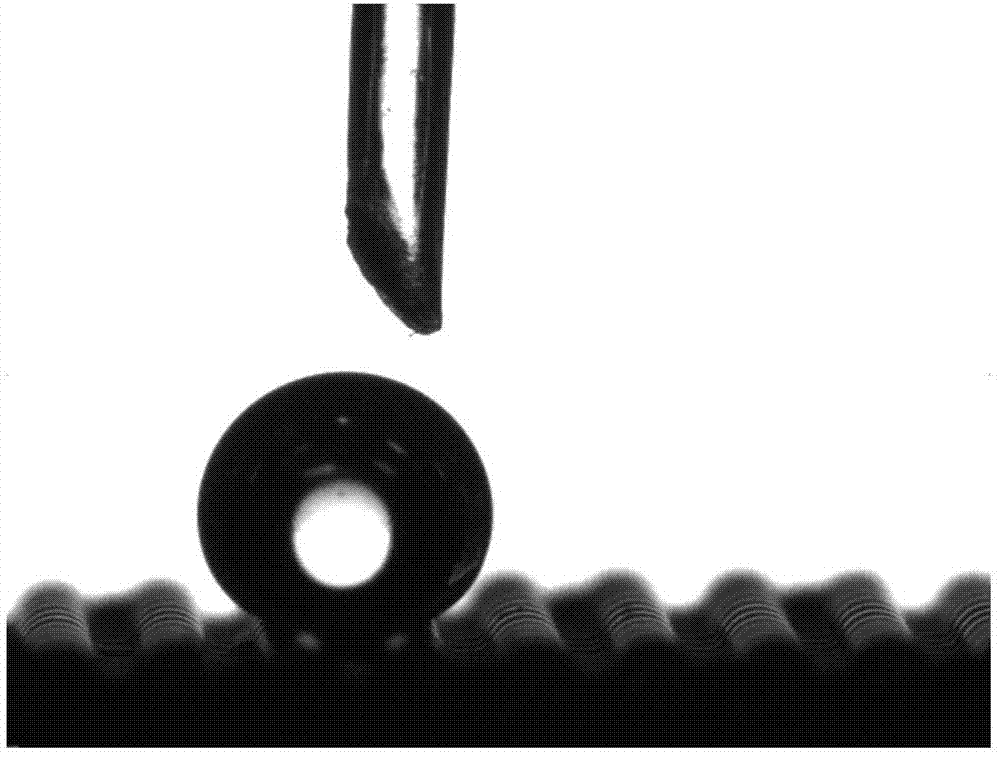

Method of preparing isotropic super-hydrophobic and superoleophobic regular porous silicone rubber with anisotropic structure

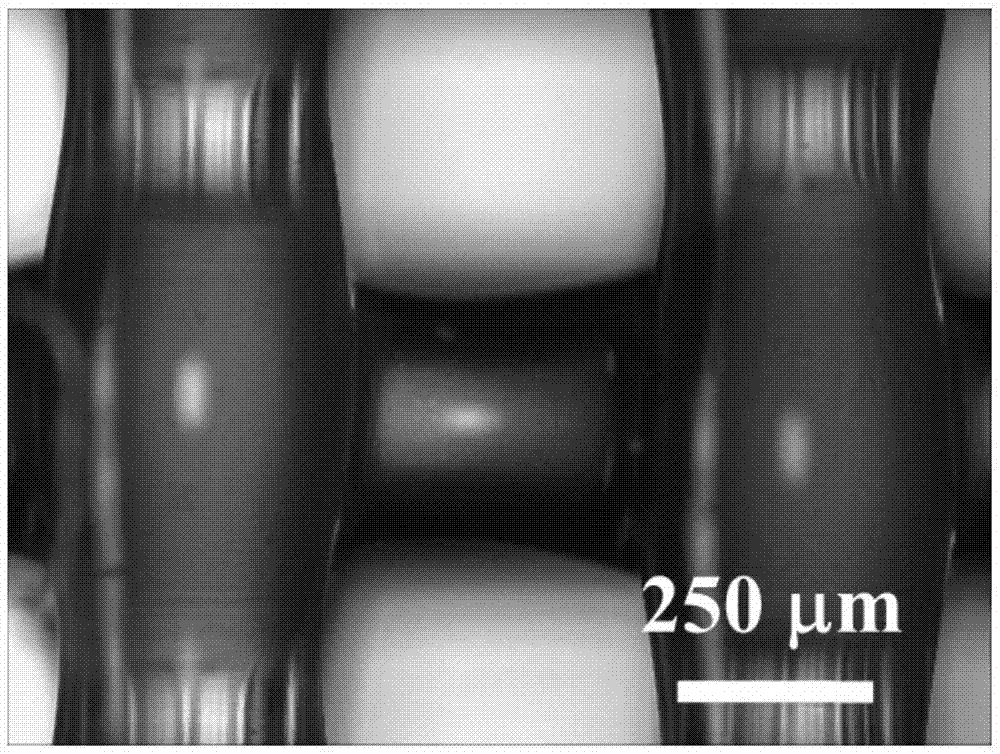

ActiveCN107974089ARegular porous structureFlexibleAdditive manufacturing apparatusAdditive manufacturing with liquidsPolymer sciencePtru catalyst

The invention discloses a method of preparing an isotropic super-hydrophobic and superoleophobic regular porous silicone rubber with an anisotropic structure. The method comprises the following stepsof (1) uniformly mixing silicone oil containing C=C double bond, inorganic nanometer filler, a catalyst and an inhibitor to obtain a first mixture; (2) adding hydrogen-containing silicone oil and a silicone rubber additive in the first mixture prepared in the step 1, performing uniform mixing to obtain a second mixture, and performing defoaming to obtain ink for printing; (3) charging the ink in a3D printer, and performing printing according to the anisotropic porous structural characteristics to prepare silicone rubber with a porous structure; and (4) performing pre-solidification treatment,then performing dip coating and drying on the treated silicone rubber in a treating agent solution, performing superthermal hydrogen treatment, taking out the treated silicone rubber for cleaning, and then performing drying again to obtain the isotropic super-hydrophobic and superoleophobic silicone rubber material. According to the method provided by the invention, by combining the silicone rubber with the inorganic nanometer filler, organic combination of a physical structure and the material characteristics is realized by utilizing 3D printing, and the isotropic super-hydrophobic and superoleophobic silicone rubber is prepared.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

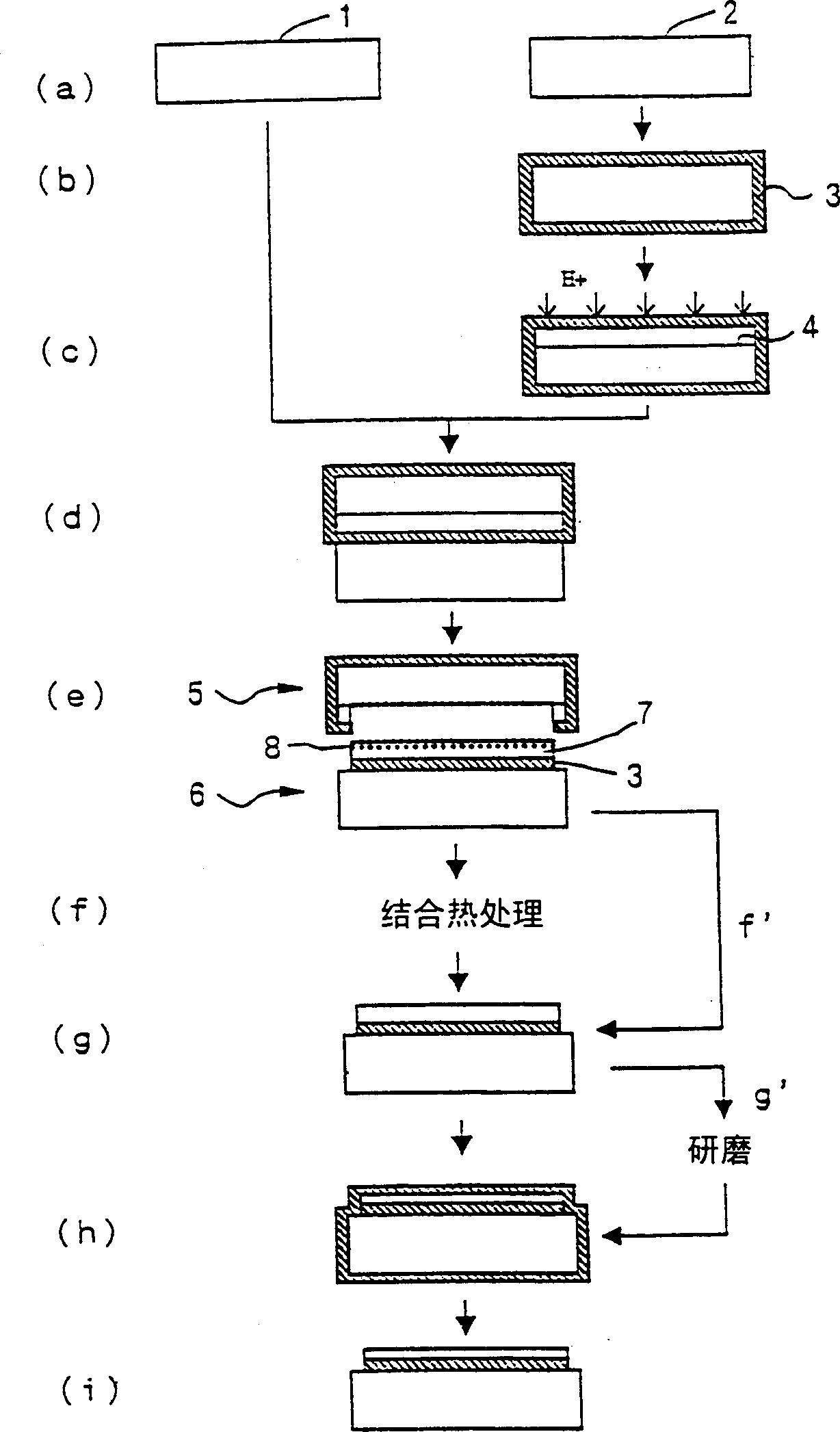

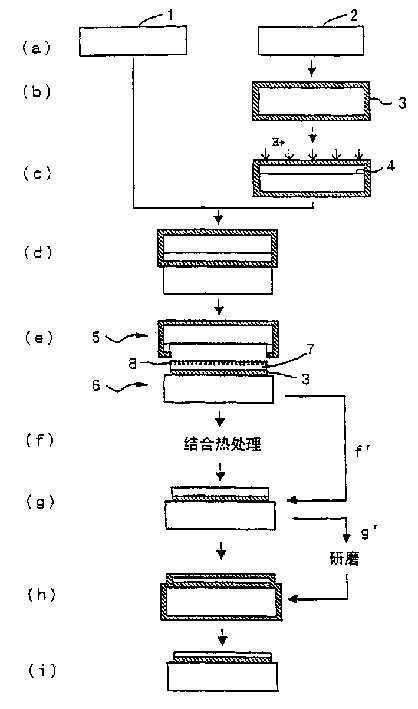

Semiconductor device and method of manufacturing the same

InactiveUS20070235734A1Well formedUniform thicknessTransistorSolid-state devicesAdhesiveDevice material

On an SOI substrate, a hydrogen ion implantation section in which distribution of hydrogen ions peaks in a BOX layer (buried oxide film layer), and a single-crystal silicon thin-film transistor are formed. Then this SOI substrate is bonded with an insulating substrate. Subsequently, the SOI substrate is cleaved at the hydrogen ion implantation section by carrying out heat treatment, so that an unnecessary part of the SOI substrate is removed, Furthermore, the BOX layer remaining on the single-crystal silicon thin-film transistor is removed by etching. With this, it is possible to from a single-crystal silicon thin-film device on an insulating substrate, without using an adhesive. Moreover, it is possible to provide a semiconductor device which has no surface damage and includes a single-crystal silicon thin film which is thin and uniform in thickness.

Owner:TAKAFUJI YUTAKA +1

Dendritic polyurethane coating

ActiveCN101678392ALow viscosityImprove scratch resistanceAntifouling/underwater paintsThixotropic paintsCross-linkPolyurethane coating

Owner:NIPSEA TECH PTE

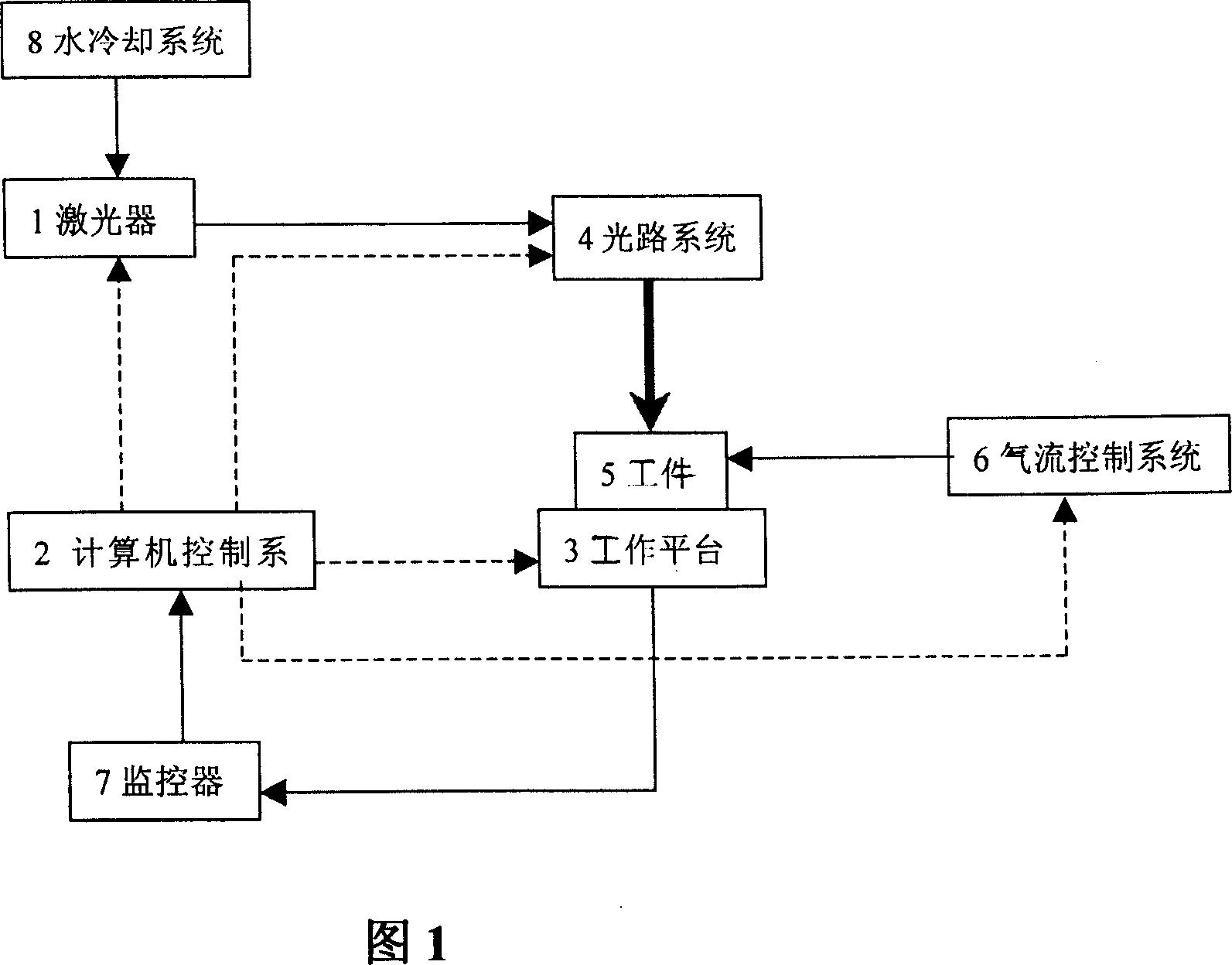

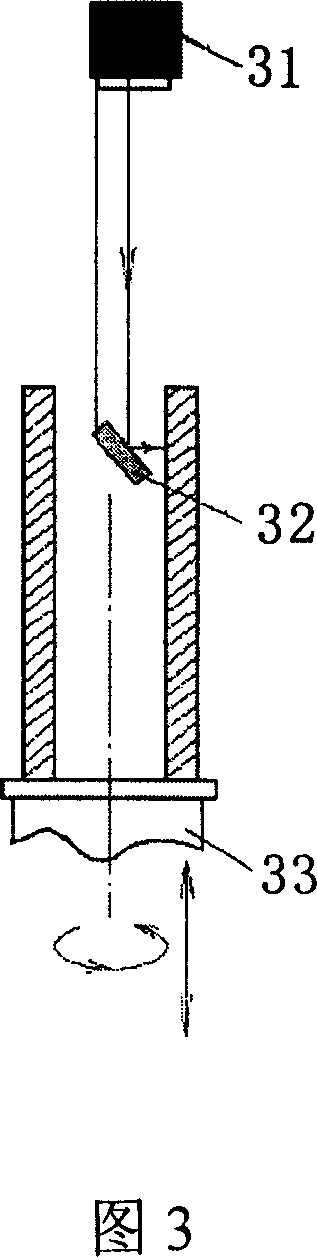

Method and device of laser three-dimensional processing of ceramic body

InactiveCN101032832ANo surface damageNo intelligenceCeramic extrusion diesLaser processingMetallurgy

The present invention provides 3D laser ceramic biscuit making process and apparatus. The process includes the following steps: preparing dried ceramic biscuit, located the ceramic biscuit precisely on a laser processing stage, compiling laser processing program, and ablating organic connecting matter in ceramic biscuit selectively, quickly and precisely while controlling the motion of both the workpiece and the laser beam and sucking generated ceramic powder with air flow to obtain ceramic biscuit with precise sizes. The present invention realizes no-mold formation, may be used widely in structure ceramic formation, and is especially suitable for producing ceramic product of small batch and high precision.

Owner:HEBEI YL BANGDA NEW MATERIALS LTD CO +1

Thermal edge finishing

InactiveCN101646524AImprove impact resistanceImprove fracture performanceLaser beam welding apparatusGlass productionThermal treatmentIn plane

A thermal edge finishing process includes preheating at least one cut edge of a glass sheet, laser finishing the edge to a single full continuous radius from a position orthogonal to the edge and in-plane with the glass sheet while continuing to heat the glass, and localized annealing of the edge to reduce residual stress from the laser / thermal treatment of the edge. By the present process, edgestress is reduced considerably, such as to less than 3000 psi, and more preferably to less than 2500 psi, and to as low as 1000 psi in the first 1 mm along the treated edge.

Owner:CORNING INC

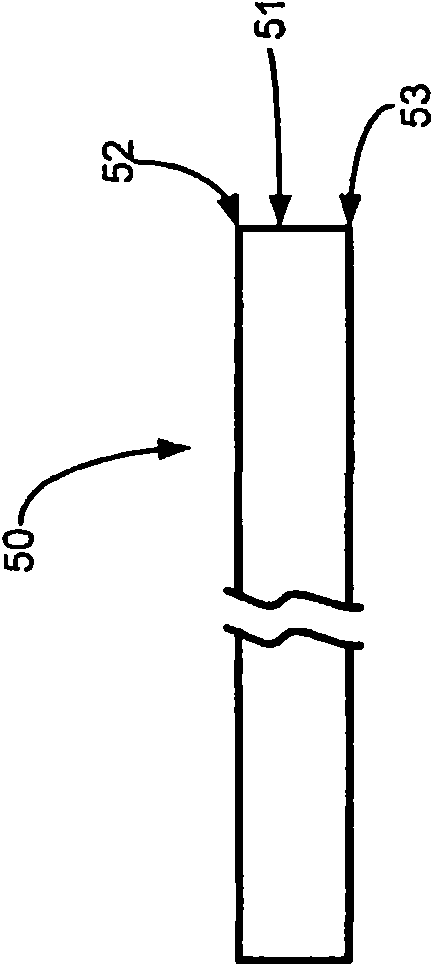

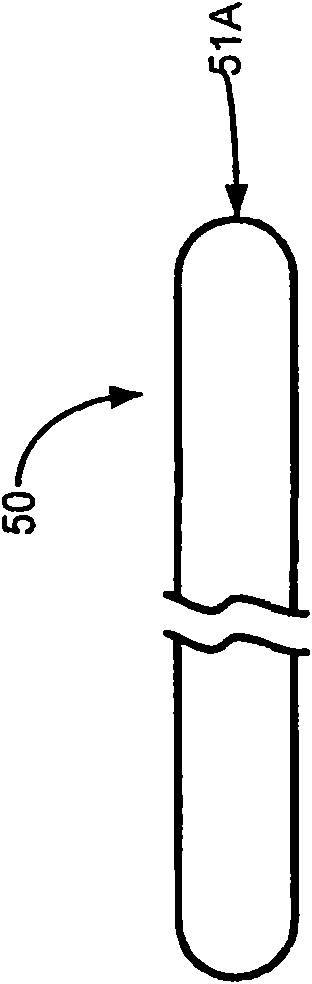

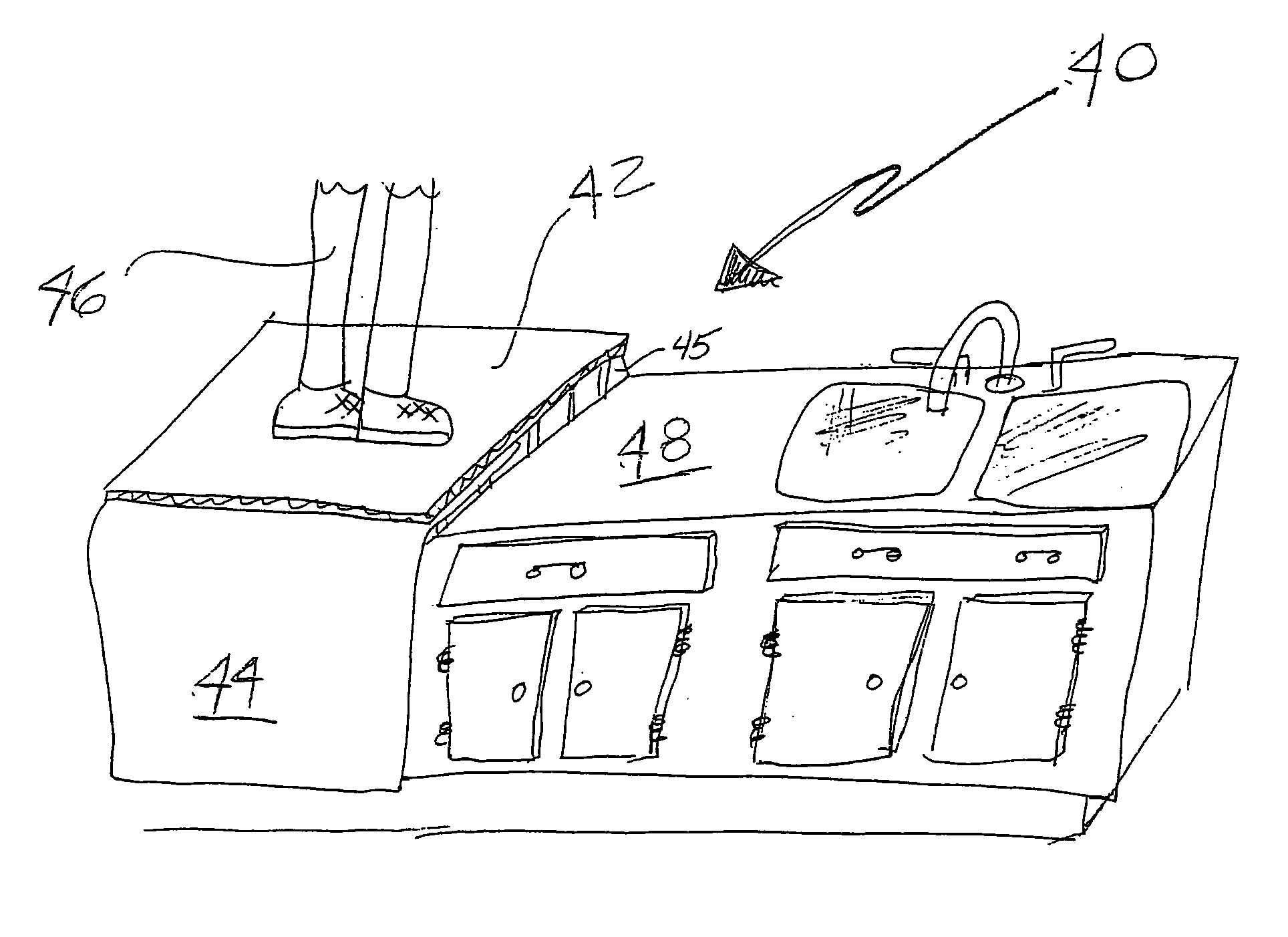

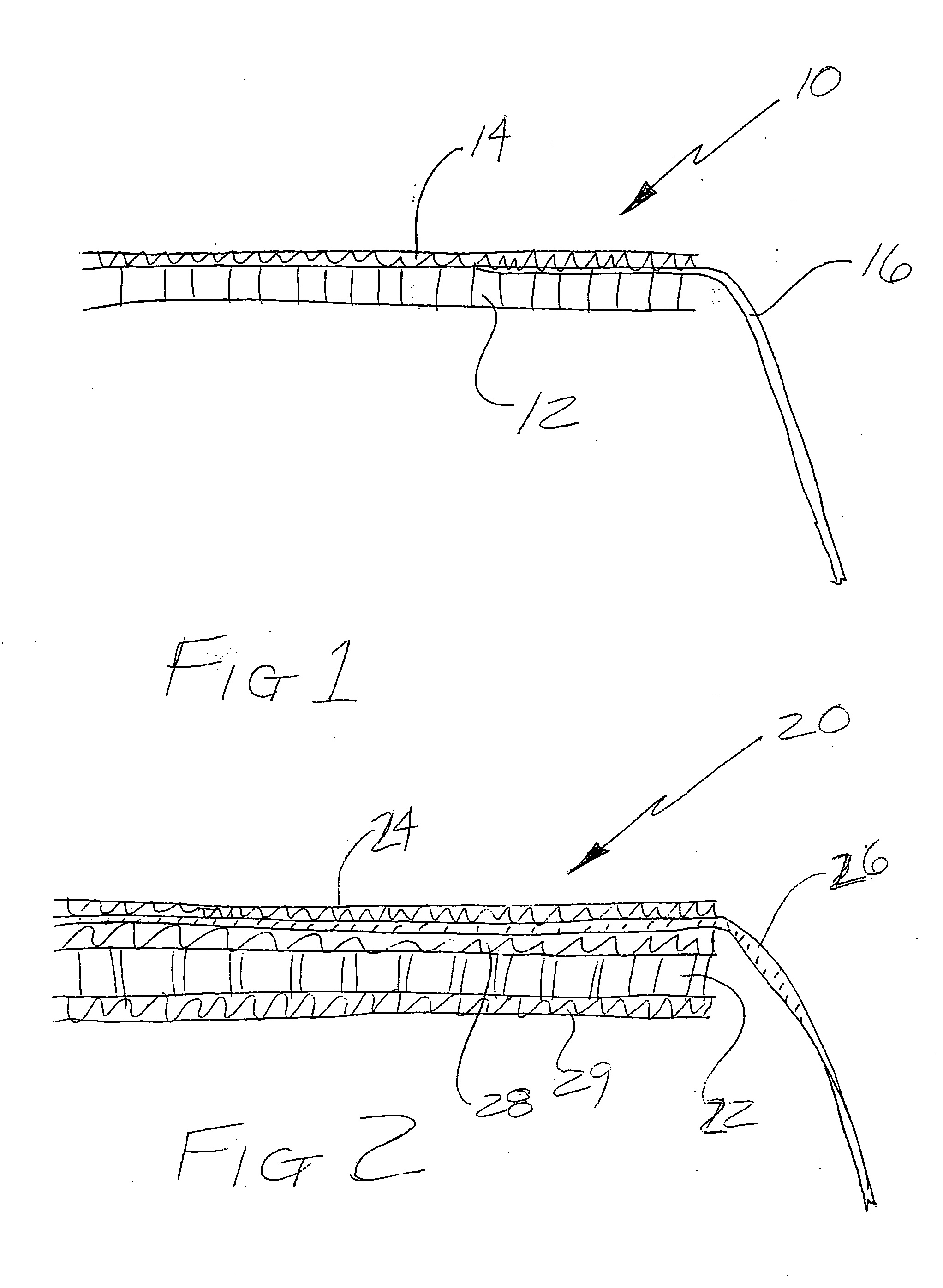

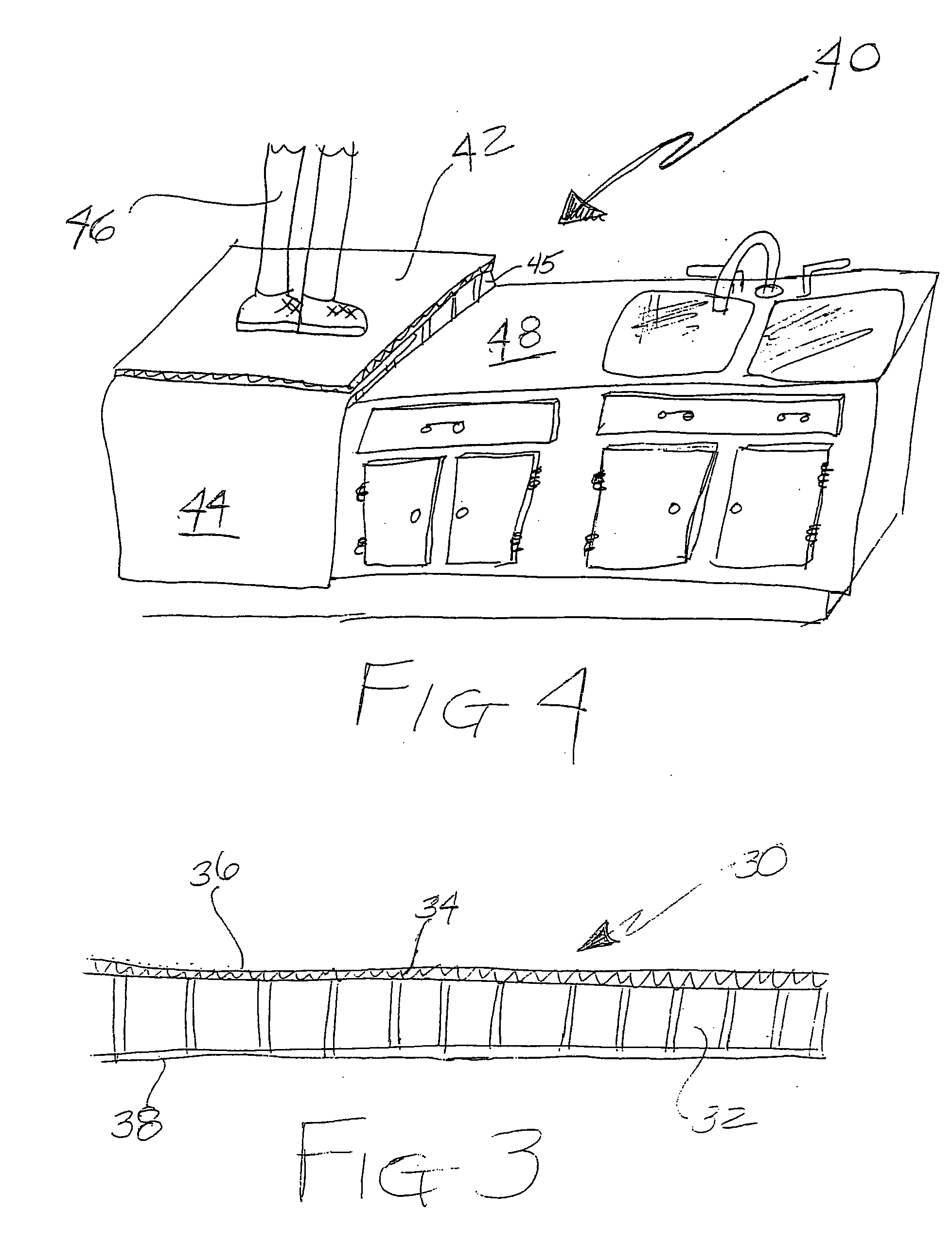

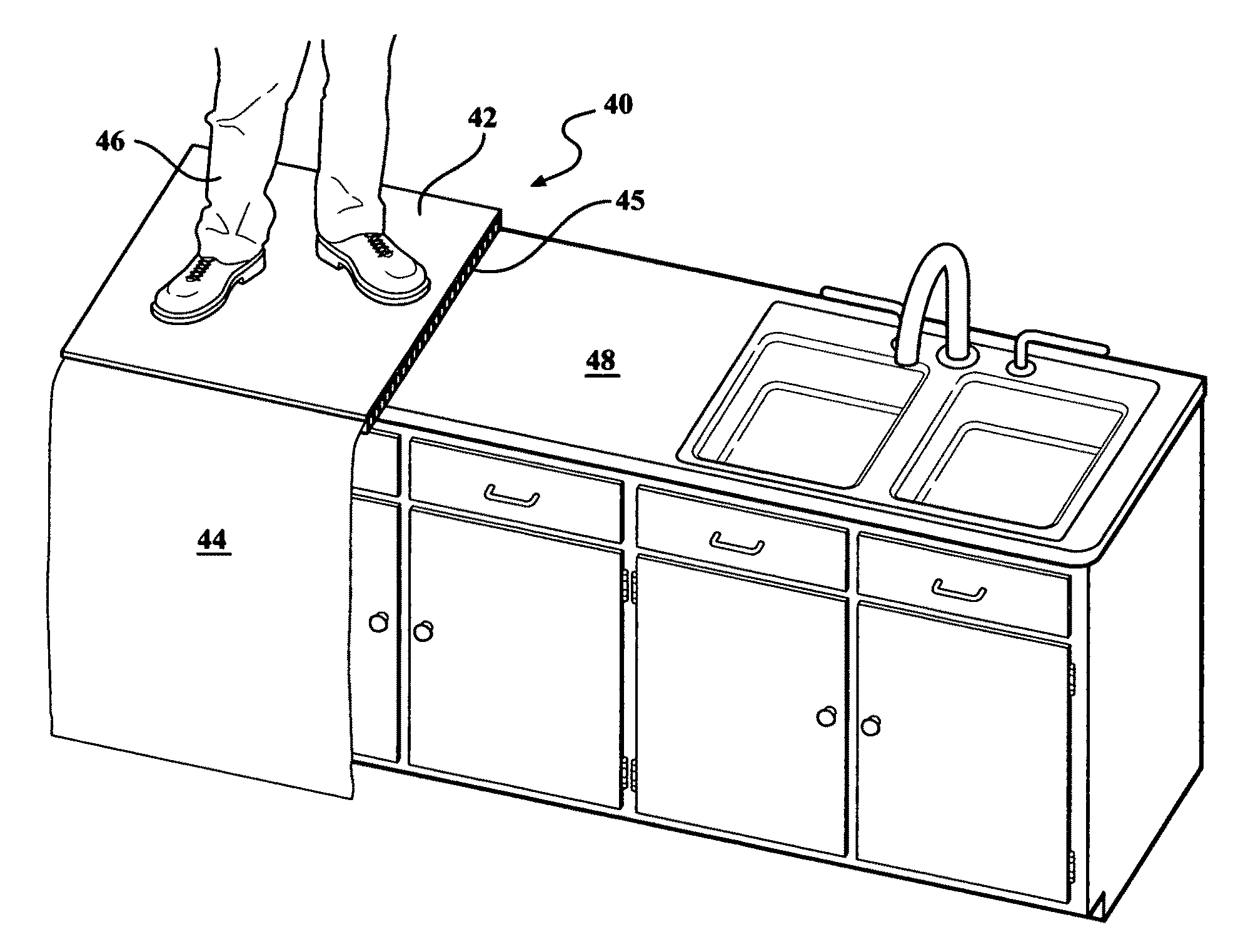

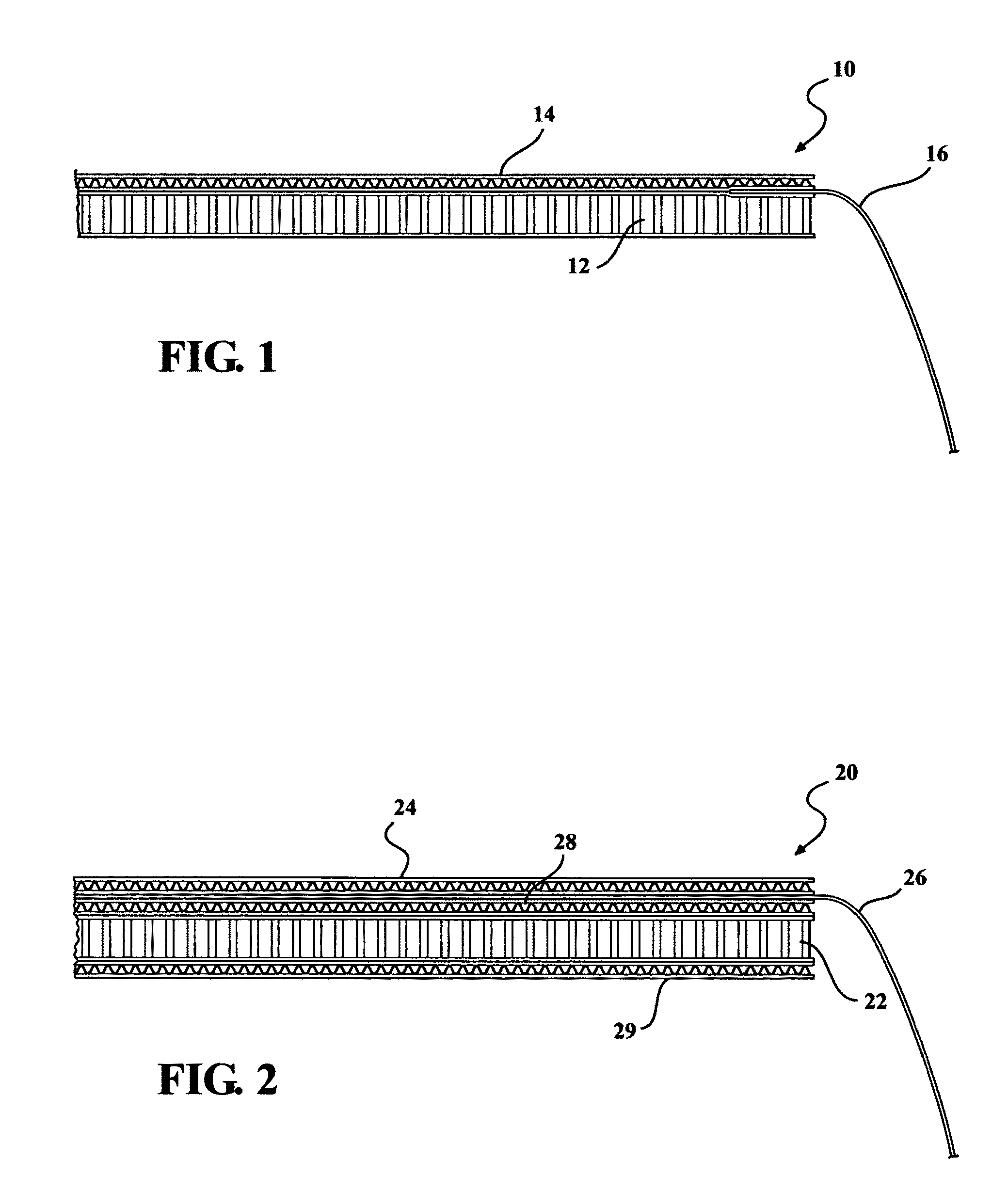

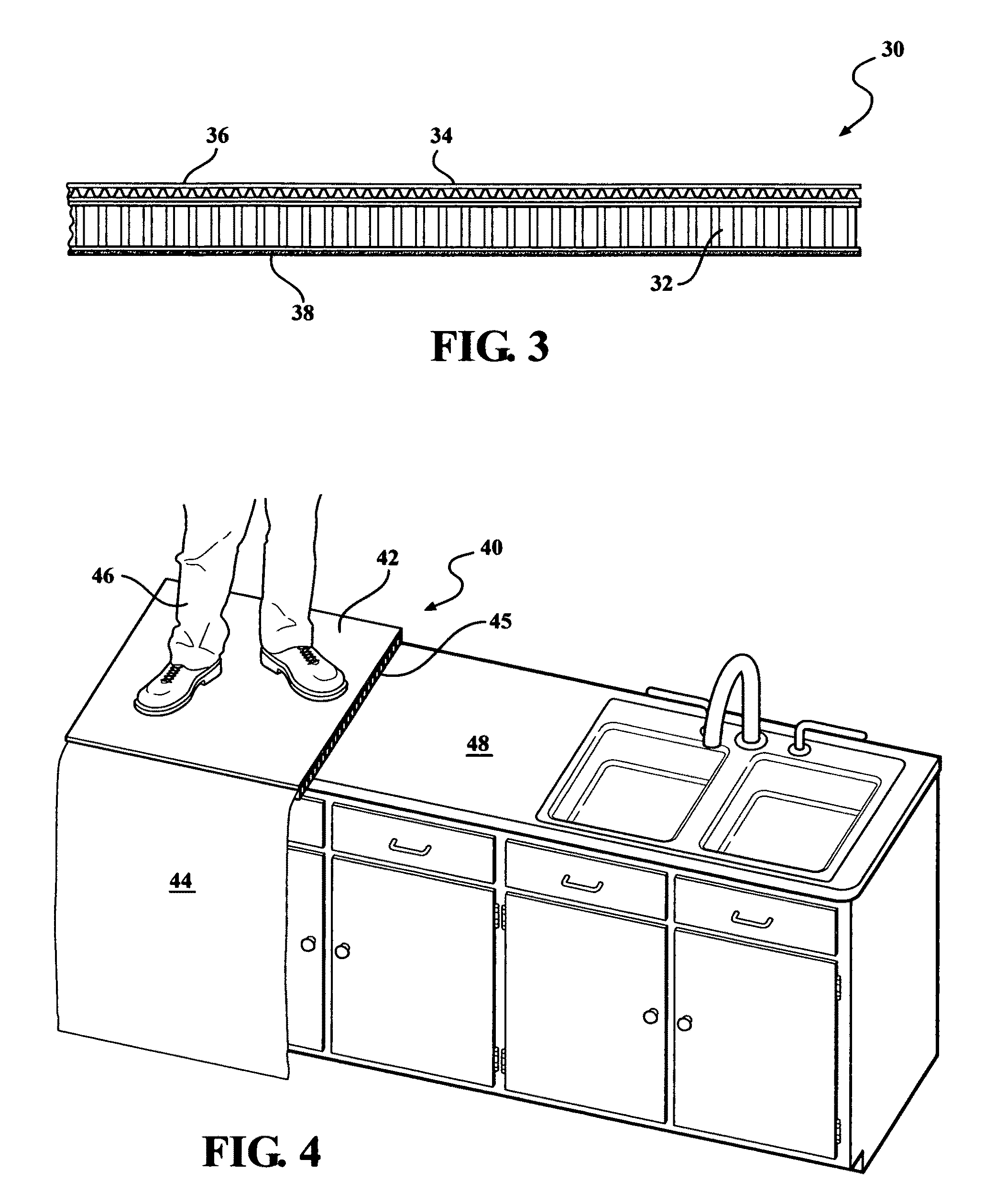

Protective coverings

InactiveUS20050223650A1Protecting delicate finishesNo surface damageBathsDouchesEngineeringElectrical equipment

Protective covering for cabinets, appliances, and residential construction components of multi-layer sheeted materials capable of being die-cut into shapes and configurations suitable for protecting kitchen and bath countertops and appliances, home construction components, and desirable multi-layer configurations for various embodiments of the invention. Corrugated materials including paper and plastic are provided in sheets and may be combined with other layers of complementary materials, including plastic sheets, for extending downwardly to protect kitchen and bath cabinets and countertops from paint splashes and for covering air duct openings.

Owner:SY HLDG

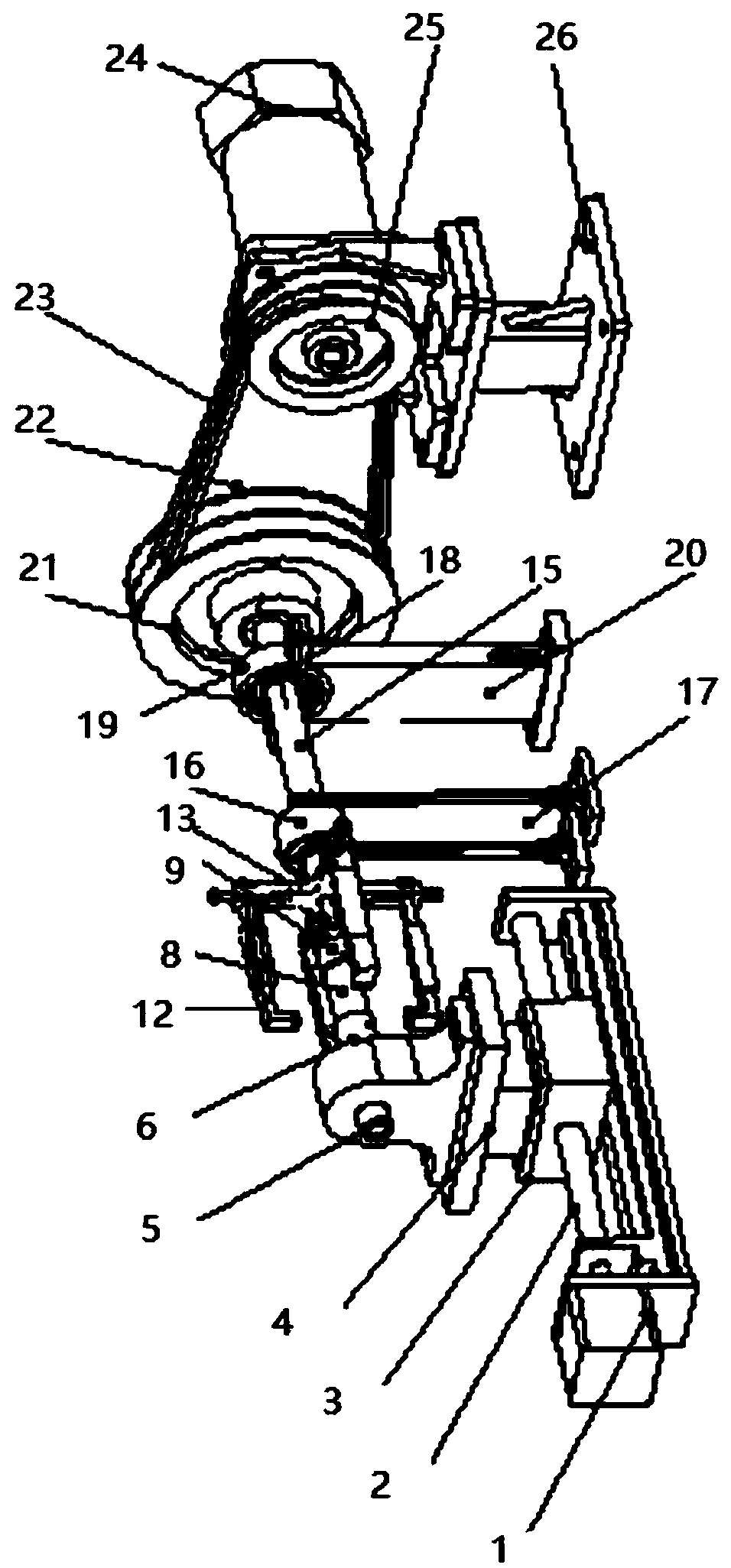

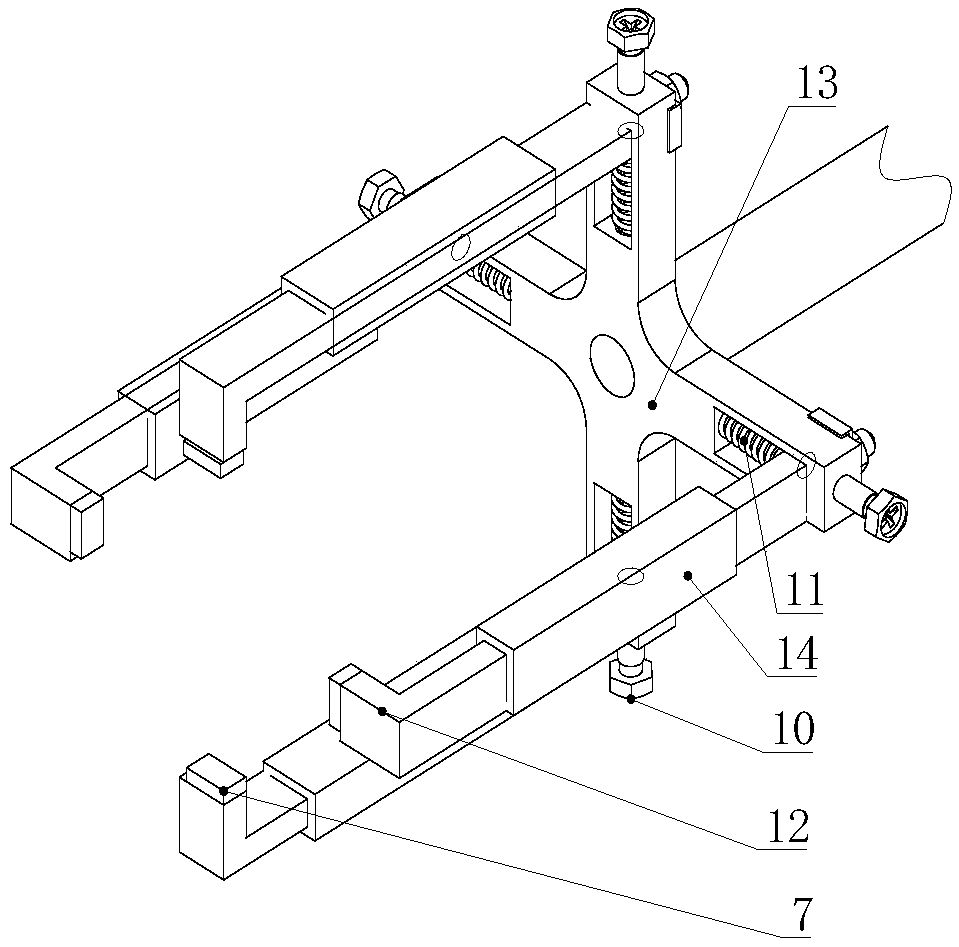

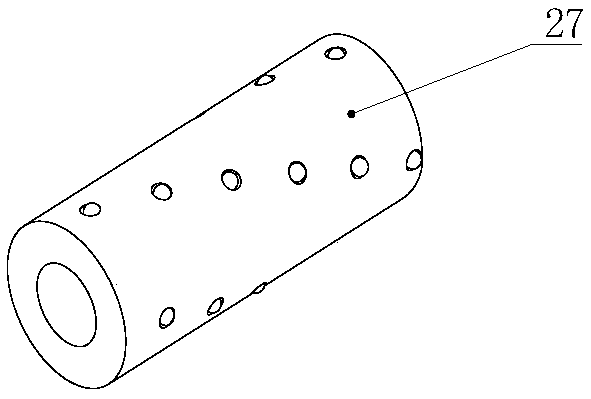

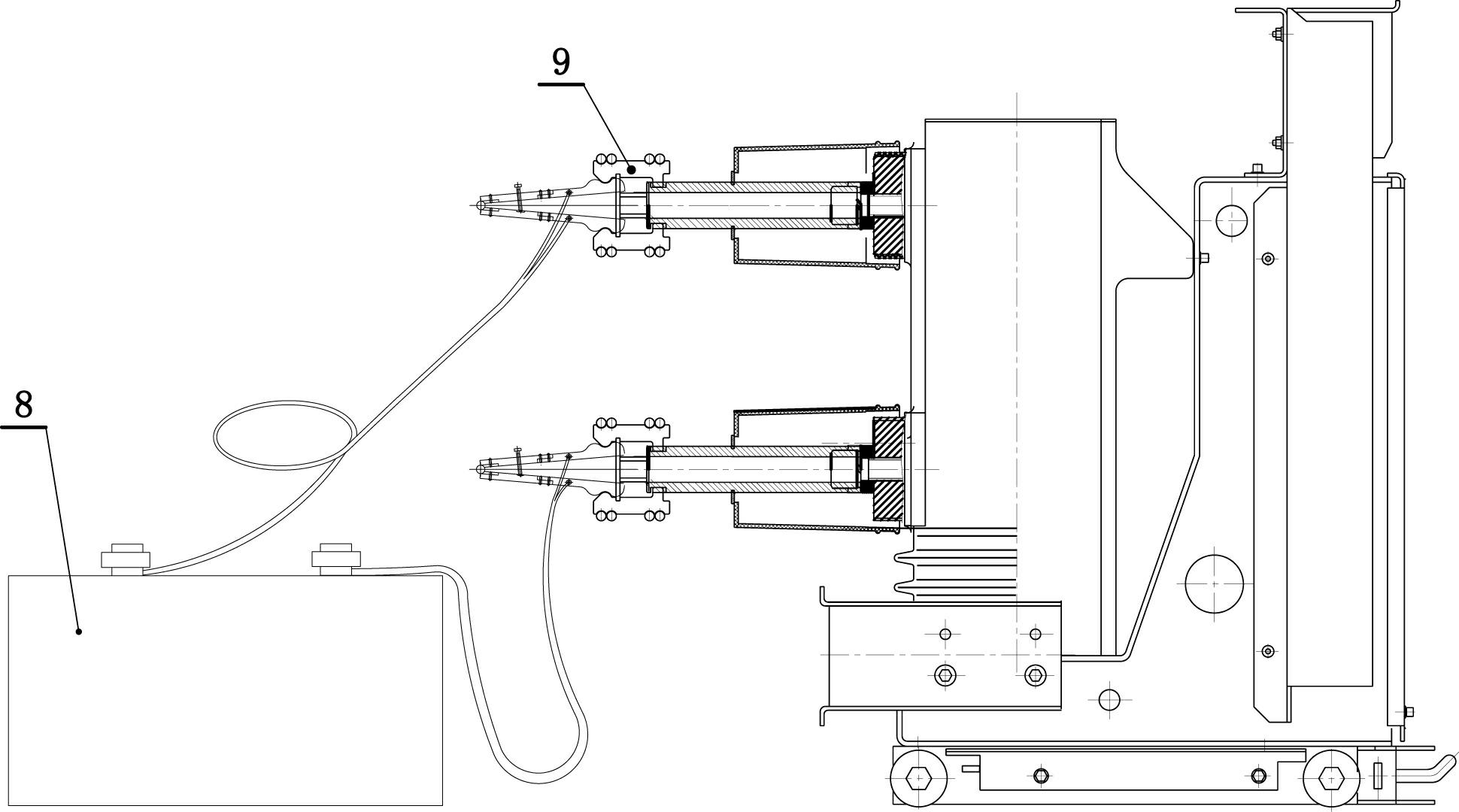

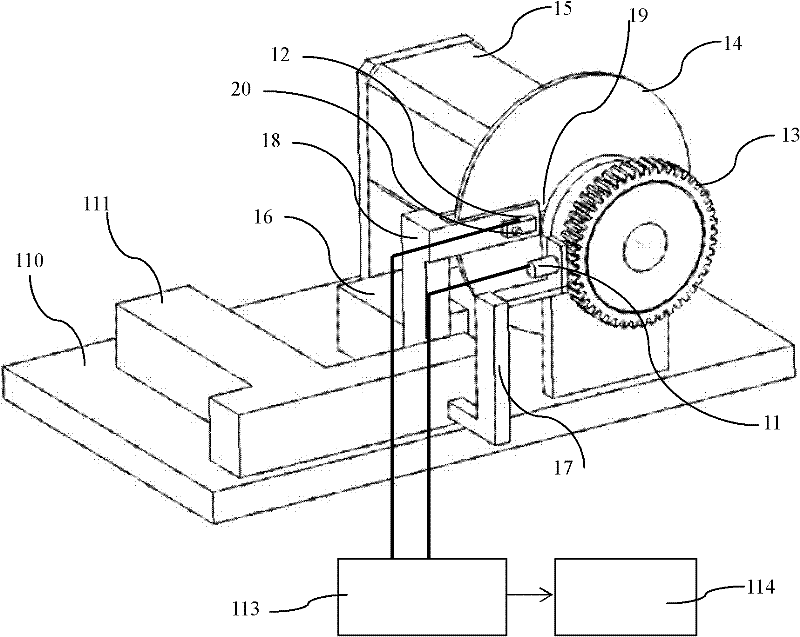

Rotary magnetic pole magnetorheology polishing device and method

InactiveCN108788937ASimple structurePolished evenlyGrinding drivesGrinding work supportsApparent viscosityReciprocating motion

The invention provides a rotary magnetic pole magnetorheology polishing device used for polishing the inner wall of a pipe-like workpiece. The rotary magnetic pole magnetorheology polishing device comprises a magnetorheology liquid feeding system, a workpiece supporting and driving mechanism and a magnetic pole rotating mechanism. Under the effect of a liquid pressure pump, magnetorheology liquidis pumped in an inner cavity of a pipe fitting from a liquid input pipe on a pipe fitting clamping device, by means of high pressure generated by the pressure pump, the magnetorheology liquid flows fast in the inner cavity of the pipe fitting, when flowing through a polishing area, the magnetorheology liquid generates the rheology effect due to the influence of the intensity of a magnetic field, shear yield stress and apparent viscosity are increased fast, under reciprocating motion of the workpiece and rotating motion of a rotating magnetic frame, compound motion between the workpiece and themagnetorheology liquid is achieved, and removal of materials on the inner surface of the workpiece is completed. The invention further provides a method adopting the device for carrying out polishing. The polishing device can polish the inner wall of a thin short non-magnetic pipe automatically, and has the advantages of being simple in structure, uniform in polishing, high in efficiency, high incontrollability of the polishing process, free of surface damage and the like.

Owner:NORTHEASTERN UNIV

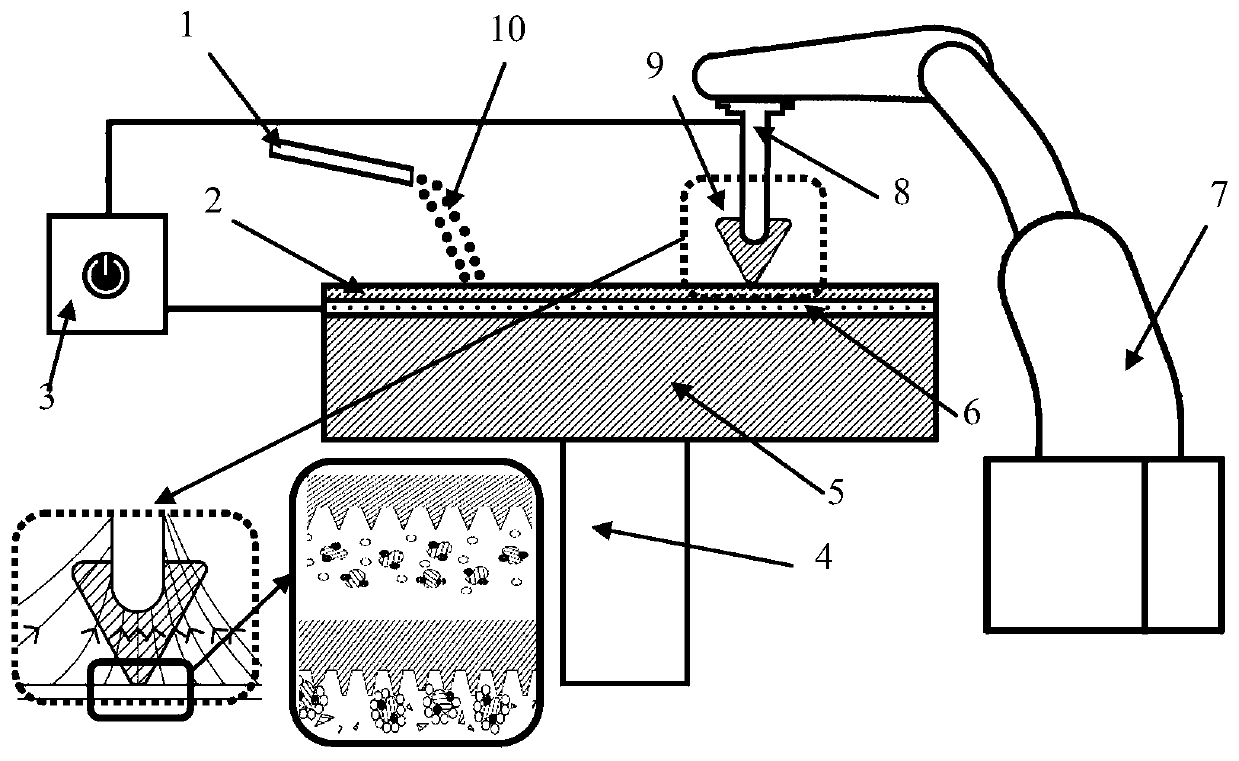

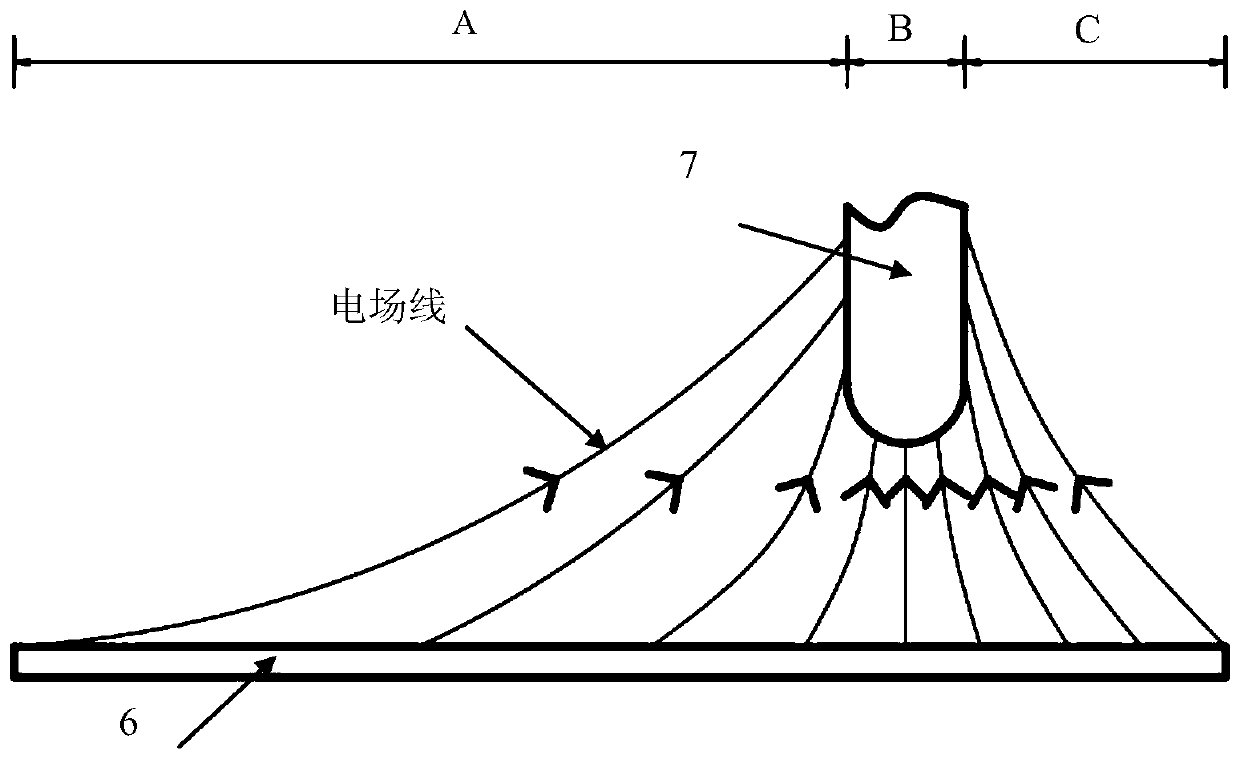

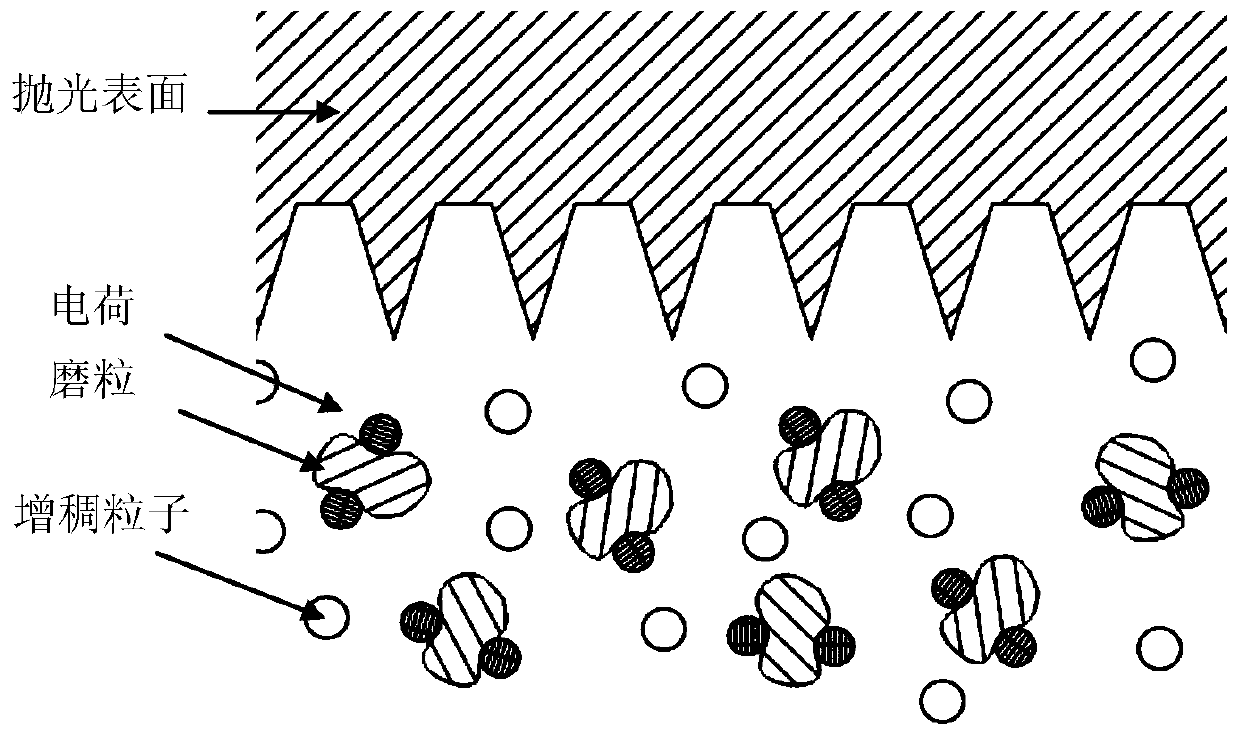

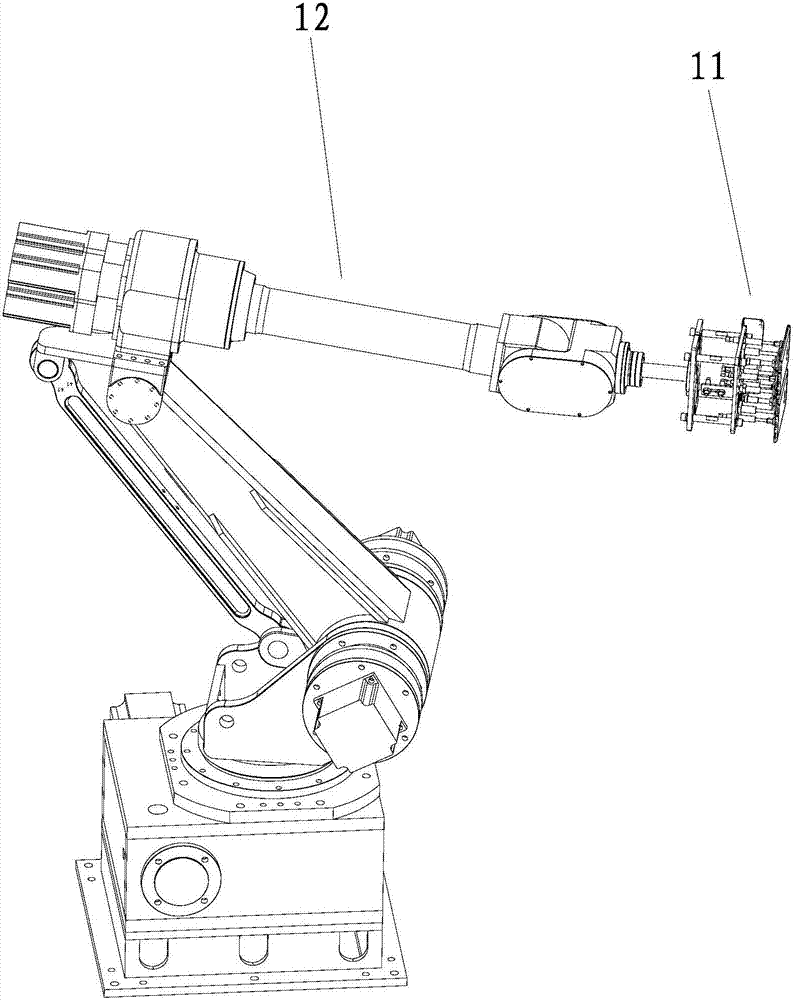

Shear thickening-electrophoresis composite polishing method

PendingCN110026828AImprove polishing efficiencyReduce surface damageGrinding work supportsElectrophoresisMaterial removal

The invention discloses a shear thickening-electrophoresis composite polishing method. The shear thickening-electrophoresis composite polishing method comprises the following steps of 1) selecting a workpiece clamp, and installing the workpiece clamp on a mechanical arm; 2) clamping the workpiece on a workpiece clamp; 3) polishing solution with the shear thickening-electrophoresis composite effect, and the polishing solution is placed in an infusion tube; 4) polishing solution is input to the polishing disk, and the main spindle is started to drive the polishing disk; and 5) starting the shearthickening effect the mechanical arm for controlling, the direct-current power supply for controlling the electrophoresis effect, polishing solution with the shear thickening-electrophoresis composite effect on surface of workpiece under the action of mechanical arm, and is used for providing a load; actively controlling the micro-rotation of the workpiece, meanwhile, electrophoretic effect of abrasive particles generated at two ends of power supply electrode, so that the height matching and material removal of the polishing solution and the surface of the workpiece are formed, and the shearthickening-electrophoresis composite polishing are realized. The invention provides a high-efficiency, and surface-damage-low / free or sub-surface damage shear thickening and the electrophoresis composite ultra-precision polishing method.

Owner:HUNAN UNIV OF SCI & TECH

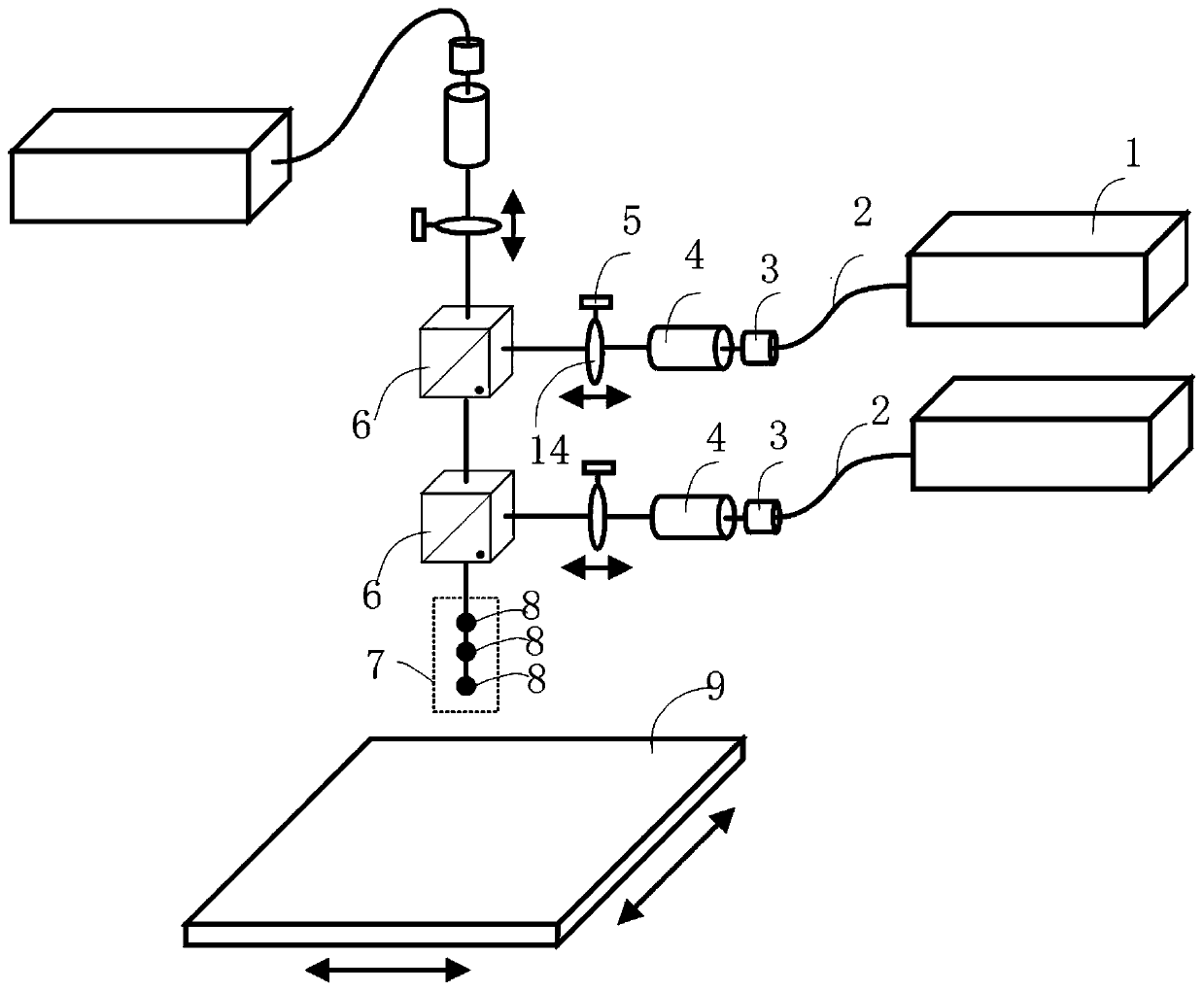

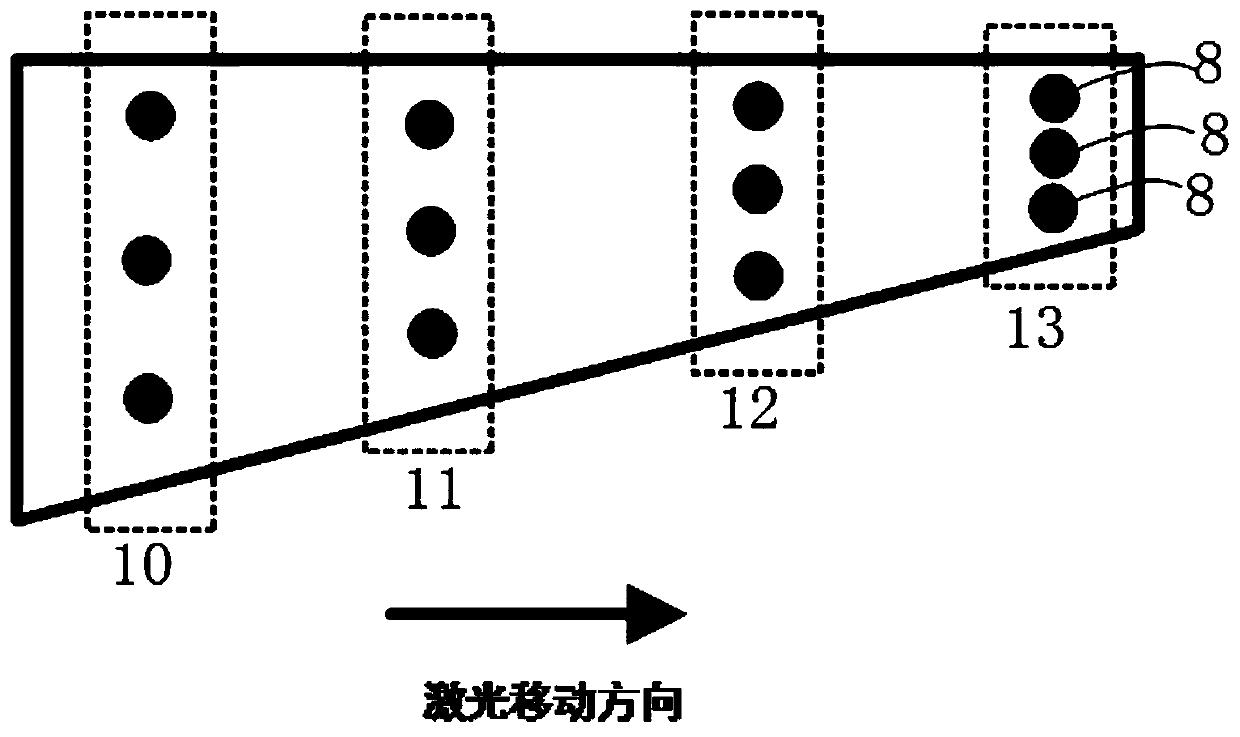

Device and method used for cutting brittle materials by multiple laser focuses and capable of producing dynamically adjustable optical field

InactiveCN110303243ARealize dynamic regulationSolve the problem of only being able to cut planar structural glass materialsLaser beam welding apparatusBeam expanderBeam splitter

The invention discloses a device and a method used for cutting brittle materials by multiple laser focuses and capable of producing a dynamically adjustable optical field, and relates to the technicalfield of brittle material cutting. The device comprises multiple laser branch circuits, each laser branch circuit comprises a laser, each laser is connected with an optical fiber coupler through an optical fiber, a beam expander is arranged behind each optical fiber coupler, and a focusing mirror is arranged behind each beam expander. The device further comprises beam splitter prisms, and the beam splitter prisms are used reversely for combining the focused laser beams in a plurality of the laser branch circuits so as to generate the multiple laser focuses on the same optical axis to cut materials to be cut and separated. Through precise control of the number, the positions and the power density of the laser focuses, the dynamic laser field matched with the structure of the cut and separated materials is always generated within the materials, and thus laser separation of the brittle materials with the complex structure is completed.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Loop resistance measuring pliers for trolley type switch

InactiveCN102590742AImprove measurement accuracyEquipment well protectedResistance/reactance/impedenceCircuit interrupters testingEngineeringElectrical and Electronics engineering

Owner:ZAOZHUANG POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

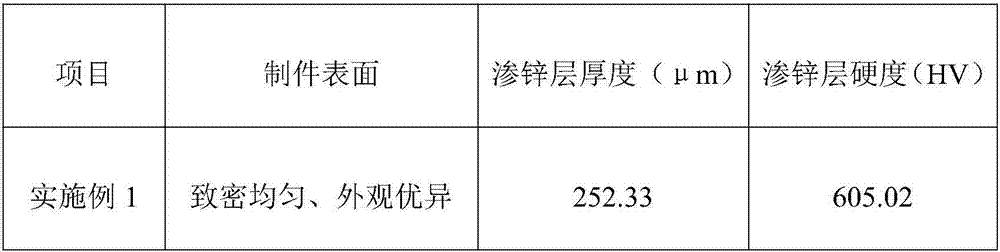

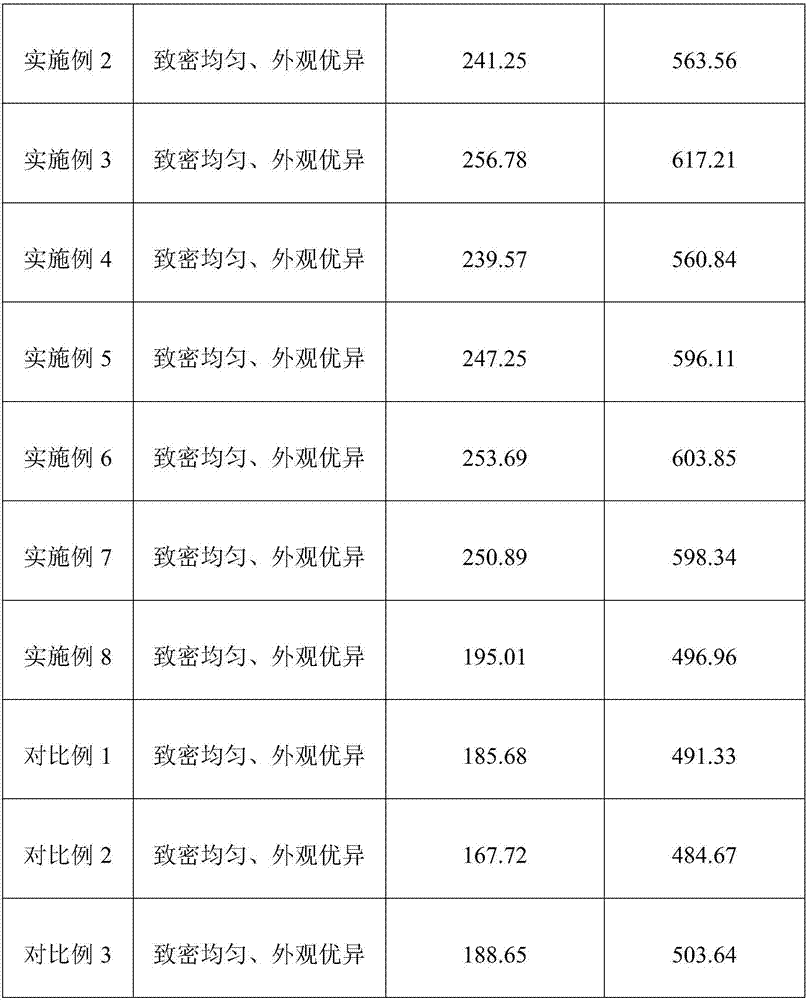

Zinc powder sherardizing method enabling thickness of zinc coat to be considerable and uniform

InactiveCN107267913AHigh activityFast penetrationSolid state diffusion coatingCalcium silicateAccelerant

The invention discloses a zinc powder sherardizing method enabling the thickness of a zinc coat to be considerable and uniform. The method comprises the steps of sand blasting, encasing, powder blending, zinc sherardizing, centrifugal zinc shredding, cooling, selecting and packaging. A zinc powder sherardizing agent used during zinc sherardizing comprises the following raw materials of zinc powder, zeolite powder, aluminum chloride powder, aluminum oxide powder, aluminum sulfate powder, cobaltous oxide powder, lead powder, magnesium stearate powder, sodium borate powder, calcium silicate powder, graphene powder, a surfactant, a dispersing agent, a modifier, an activating agent, a diffusant, an intensifier, a chelating agent, an sherardizing accelerant and a stabilizer. The zinc coat of a zinc powder sherardizing product prepared through the method is considerable and uniform in thickness and free of hydrogen embrittlement or surface damage, the zinc sherardizing technology process is free of environment pollution, the zinc utilization rate is high, and the raw materials can be effectively saved.

Owner:广西高企科技有限公司

Method for producing bonding wafer

InactiveCN1465104AImprove qualityImprove film thickness uniformitySolid-state devicesSemiconductor/solid-state device manufacturingHydrogenEngineering

A method for producing a bonded wafer by the ion implantation delamination method includes at least a step of bonding a bond wafer having a micro bubble layer formed by gaseous ion implantation and a base wafer serving as a support substrate and a step of delaminating the bond wafer at the micro bubble layer as a border to form a thin film on the base wafer. After the delamination of the bond wafer, the bonded wafer is subjected to a heat treatment in an atmosphere of an inert gas, hydrogen or a mixed gas thereof, then the bonded wafer is subjected to thermal oxidation to form a thermal oxide film on the surface of the thin film, and then the thermal oxide film is removed to reduce thickness of the thin film.

Owner:SHIN-ETSU HANDOTAI CO LTD

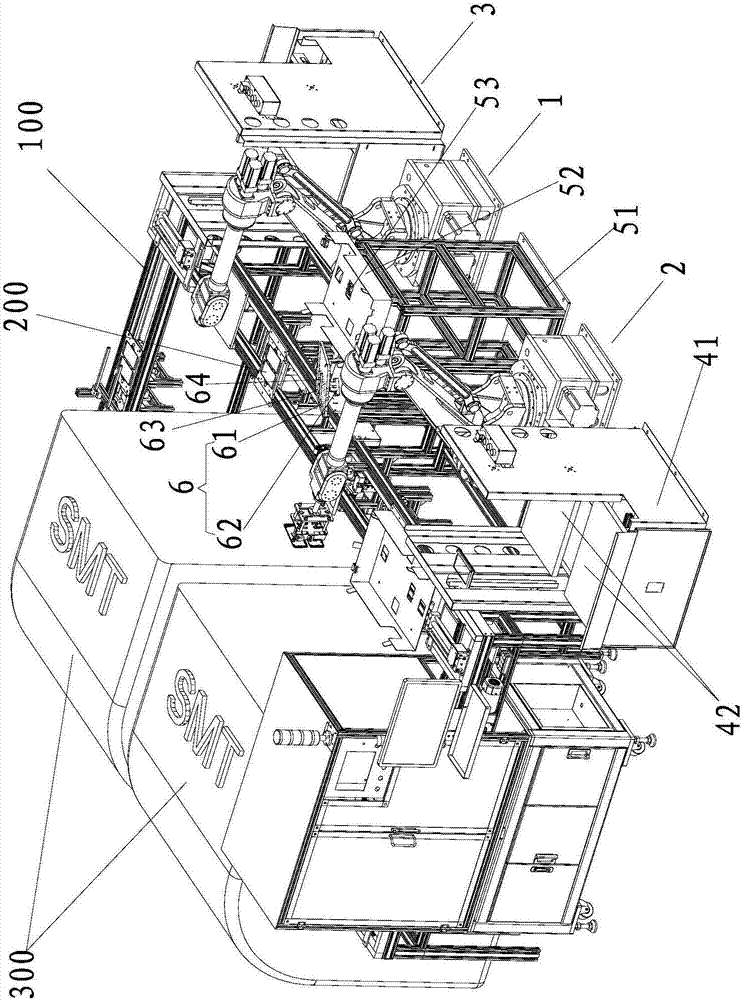

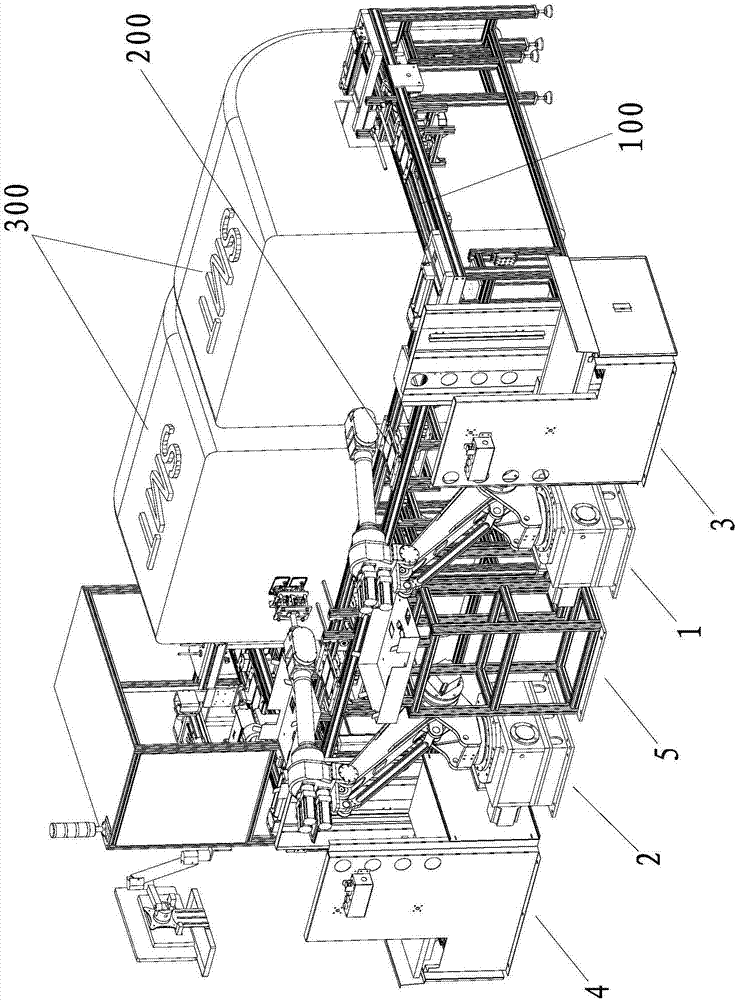

Automatic loading and unloading system of copper coil placement equipment

ActiveCN107416522APlay a protective effectWon't crushConveyor partsStructural engineeringCopper coil

The invention provides an automatic loading and unloading system of copper coil placement equipment. The automatic loading and unloading system comprises a conveying device, a workpiece tray, a loading mechanism, an unloading mechanism, a loading placement device, an unloading placement device, a foam board transfer device and an alignment device, wherein the loading mechanism and the unloading mechanism are used for absorbing and releasing a rear cover of a mobile phone and a foam board; the loading placement device and the unloading placement device are used for placing a stack of foam boards; the foam board transfer device is used for placing one foam board; the alignment device is used for placing the rear cover of the mobile phone, straightening, aligning and correcting the rear cover of the mobile phone; the unloading placement device, the unloading mechanism, the foam board transfer device, the loading mechanism and the loading placement device are positioned in the conveying direction of the loading and unloading station side along the conveying device and are arranged at intervals side by side in sequence; the alignment device and the foam board transfer device are arranged side by side; and the alignment device is positioned between the conveying device and the foam board transfer device. Compared with the prior art, the automatic loading and unloading system has the beneficial effects that the rear cover of the mobile phone is loaded and unloaded in a mechanical automation manner with no need for manual operation; and the automatic loading and unloading system has the advantages of fast loading and unloading speed, low labor intensity of workers, good loading effect and ensuring the placement quality of a copper foil of the rear cover of the mobile phone.

Owner:FUJIAN SHISHI TONGDA ELECTRICAL APPLIANCE

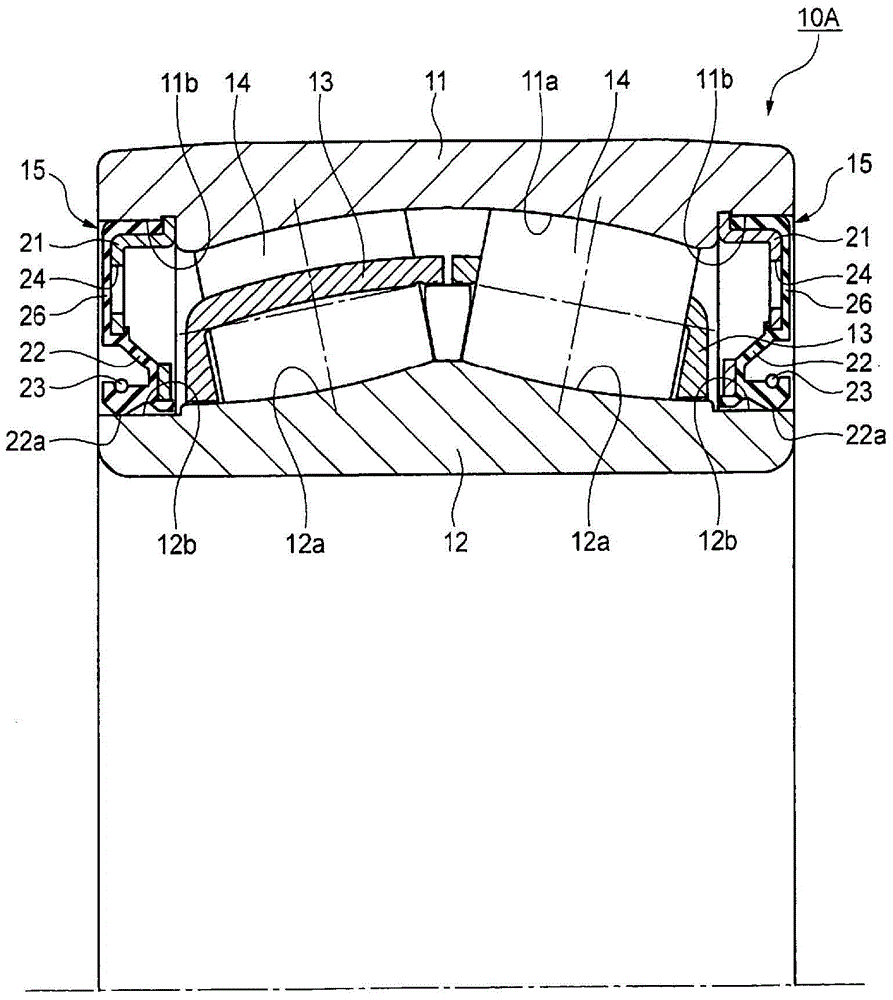

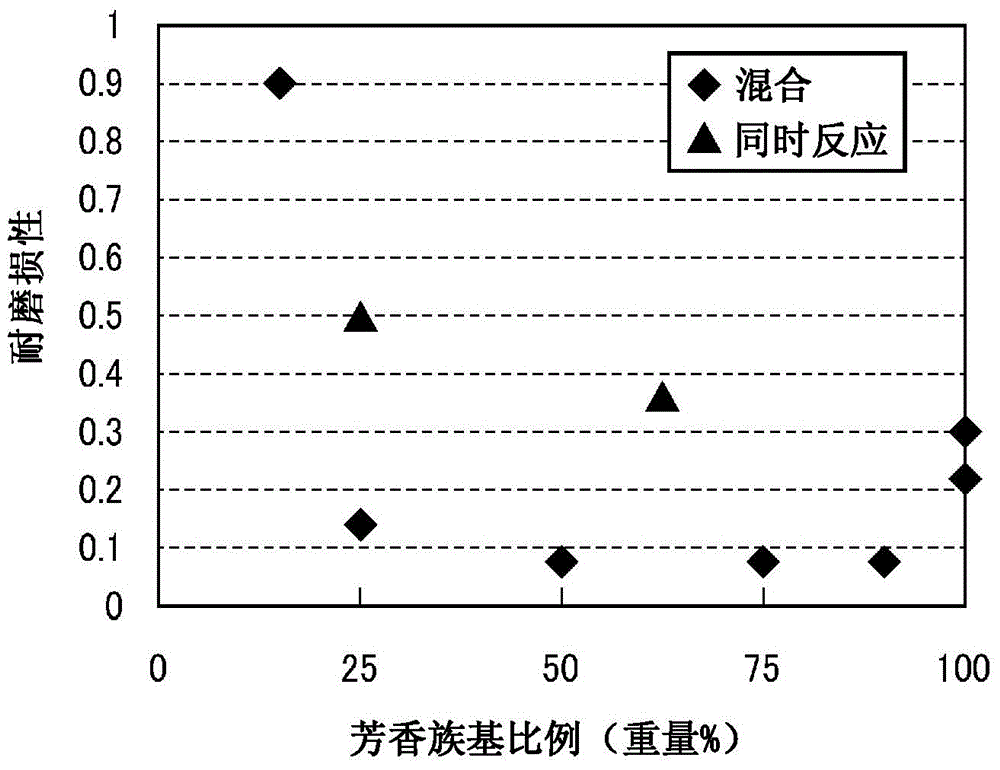

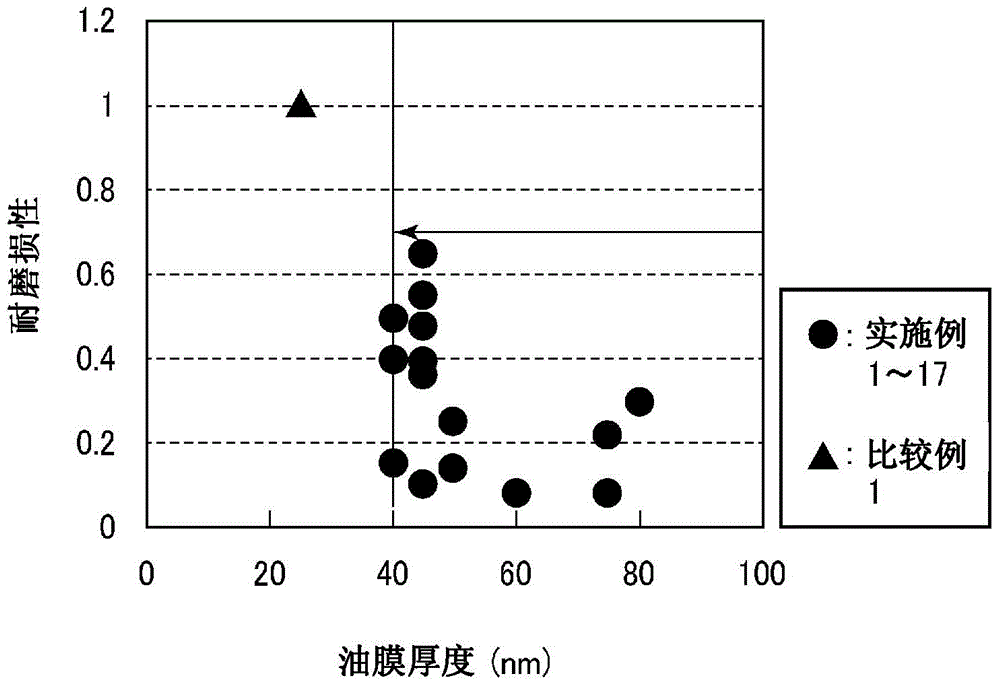

Grease filled bearing

InactiveCN105008738AAvoid damageReduce consumptionRoller bearingsBearing componentsDiphenyl etherAliphatic hydrocarbon

A grease-filled bearing filled with a grease composition containing a thickener which is a diurea compound represented by R 1 -NHCONH-R 2 -NHCONH-R 3 or a mixture thereof and a base oil containing alkyl diphenyl ether oil and containing poly ±-olefin oil as an optional component at a mass ratio of 40:60 to 100:0 (alkyl diphenyl ether oil:poly ±-olefin oil). In general formula (1), at least one of R 1 and R 3 is a C 6-12 aromatic hydrocarbon group and the other is a C 6-12 aromatic hydrocarbon group or a C 6-20 aliphatic hydrocarbon group. R 2 is a C 6-15 aromatic hydrocarbon group.

Owner:NSK LTD +1

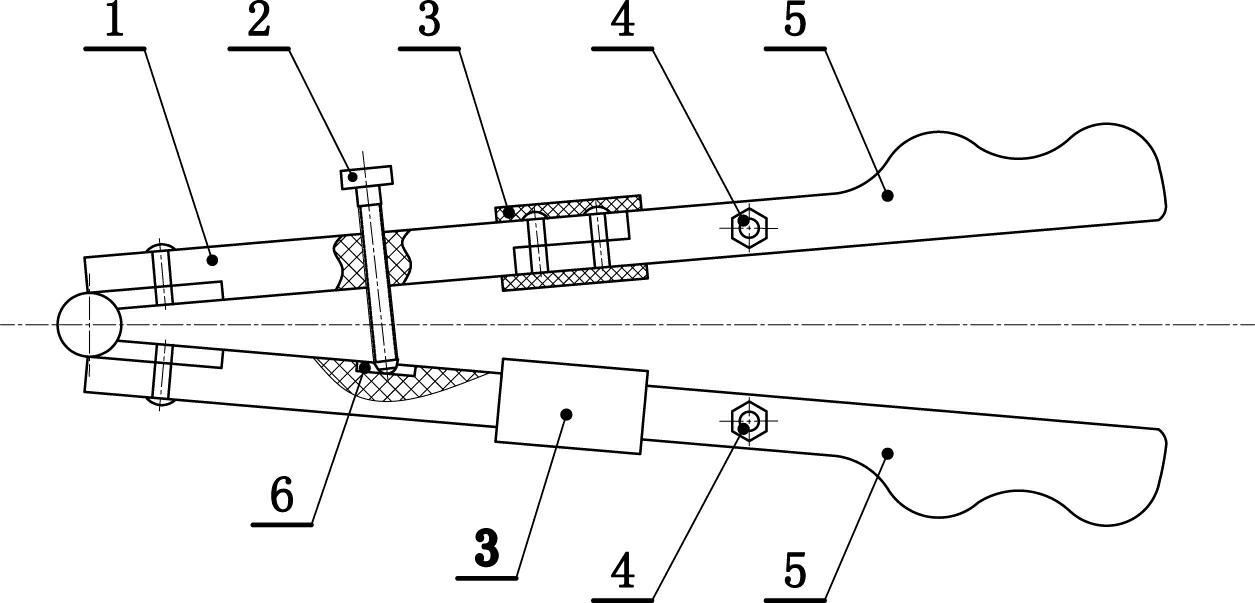

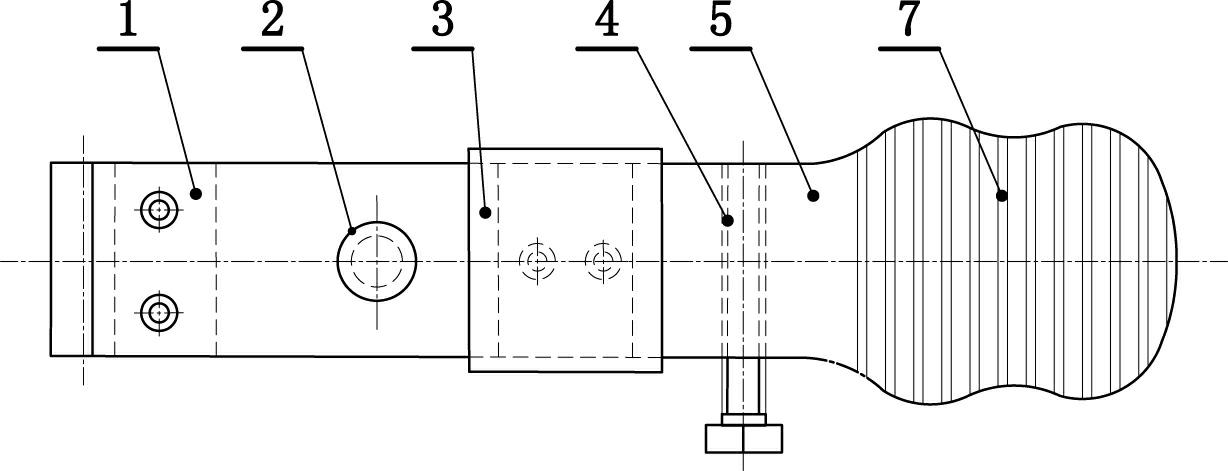

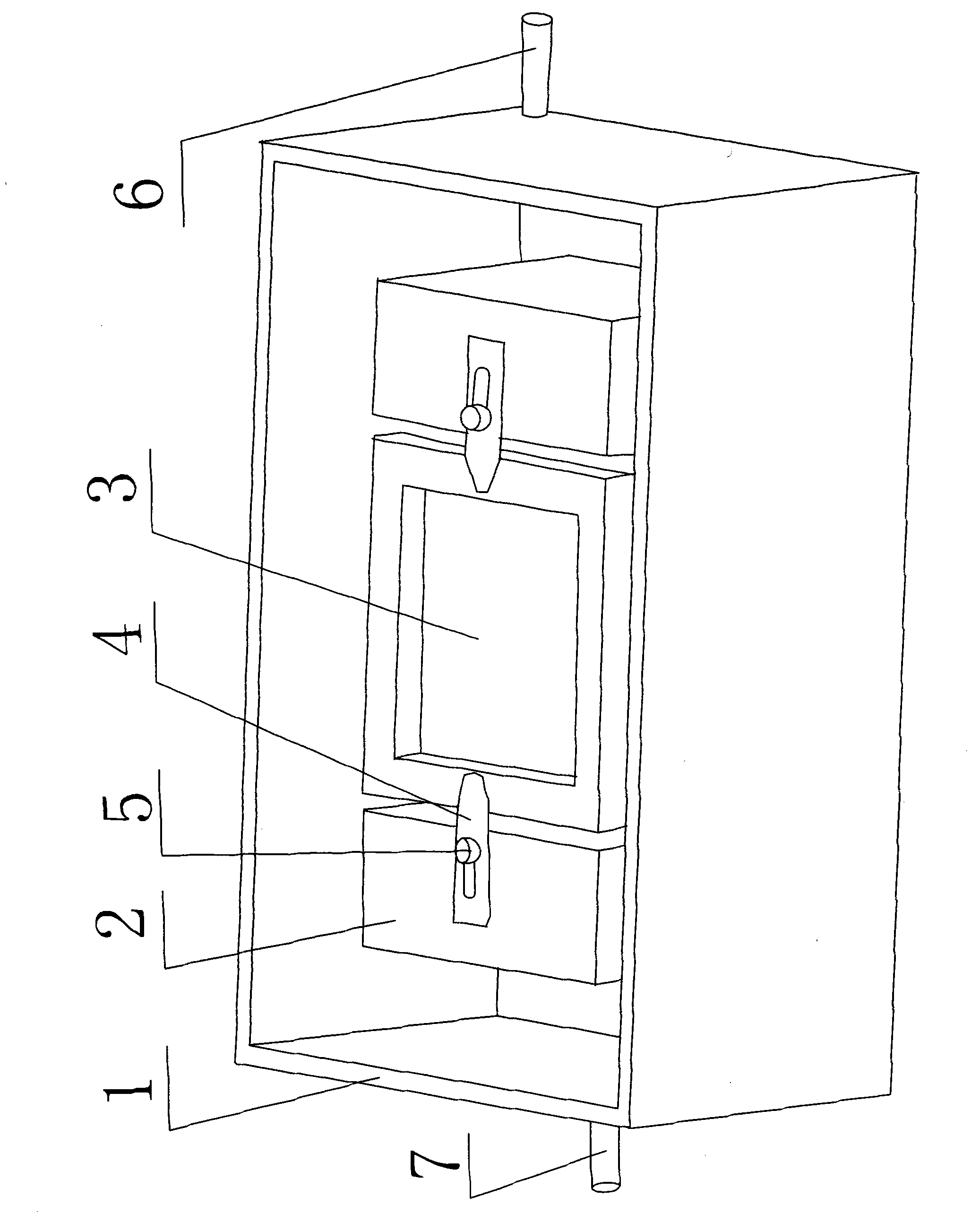

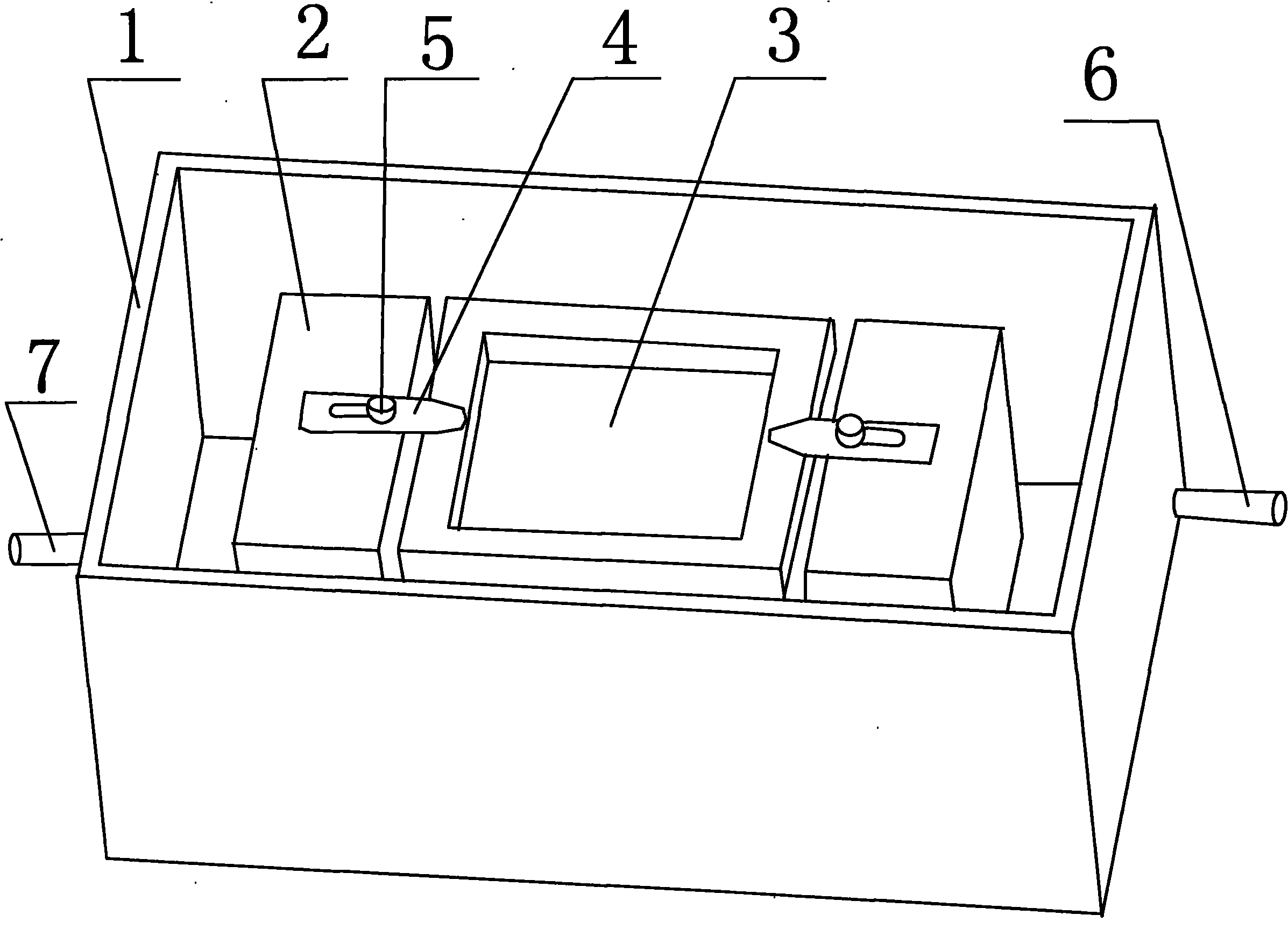

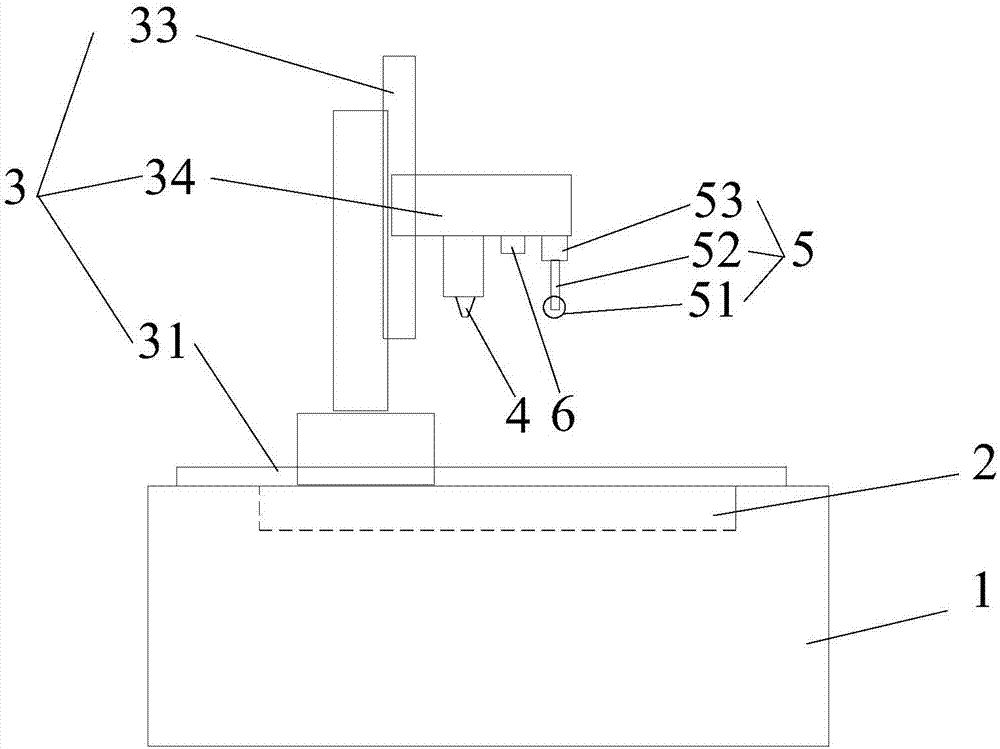

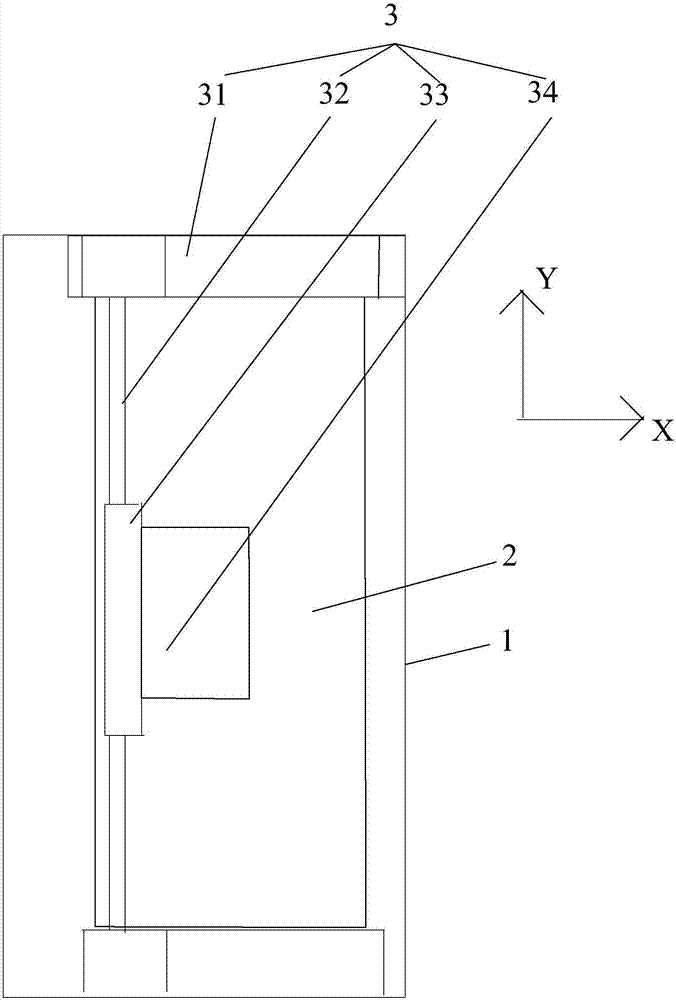

Mechanical processing device and method of ceramic-based complex curved surface parts with wave transmissivity

The invention relates to a mechanical processing device and a method of ceramic-based complex curved surface parts with wave transmissivity. Most of parts of an aircraft are products with complex curved surfaces, the design and production cycle is long, and the processing workload accounts for more than 65% of that of the whole system; and a wave-transmitting radome has the characteristics of small dimension, compact structure and the like as a key part of a fairing of the aircraft, thereby affecting the flight performance of the aircraft. The device comprises a water storage tank (1), wherein a padding block (2) is arranged in the water storage tank, a workpiece (3) is mounted in the middle of the padding block, a fire poker (4) with a long circular hole is arranged on the padding block (2), the fire poker is fixed on the padding block by using a bolt (5) when pressing the processed workpiece, a water outlet (6) is formed below one side outside the water storage tank, and a water inlet (7) is formed above one side outside the water storage tank. The device is used for SiO2 fiber- toughened SiO2 ceramic-based composite materials, in particular to mechanical processing of the ceramic-based complex curved surface parts with the wave transmissivity.

Owner:航天科工哈尔滨风华有限公司

Protective coverings

Protective covering for cabinets, appliances, and residential construction components of multi-layer sheeted materials capable of being die-cut into shapes and configurations suitable for protecting kitchen and bath countertops and appliances, home construction components, and desirable multi-layer configurations for various embodiments of the invention. Corrugated materials including paper and plastic are provided in sheets and may be combined with other layers of complementary materials, including plastic sheets, for extending downwardly to protect kitchen and bath cabinets and countertops from paint splashes and for covering air duct openings.

Owner:SY HLDG

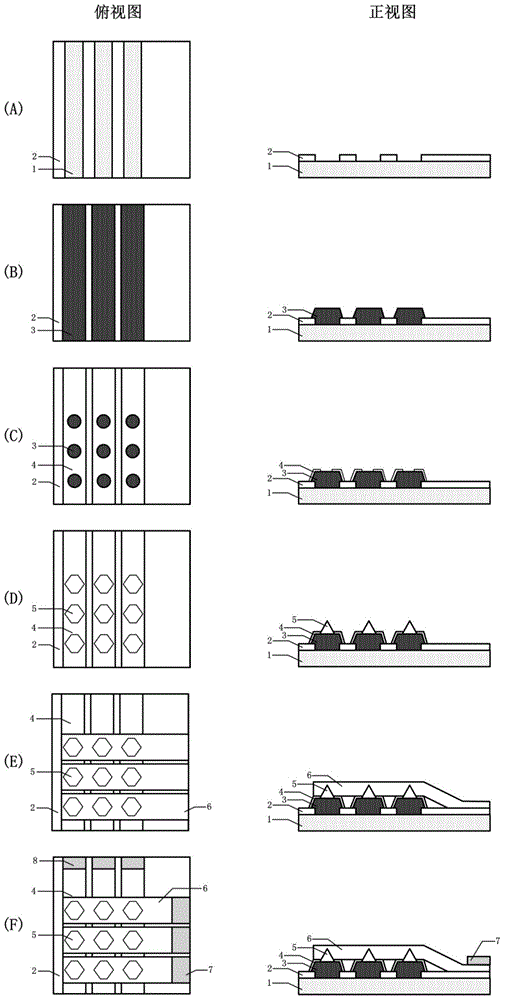

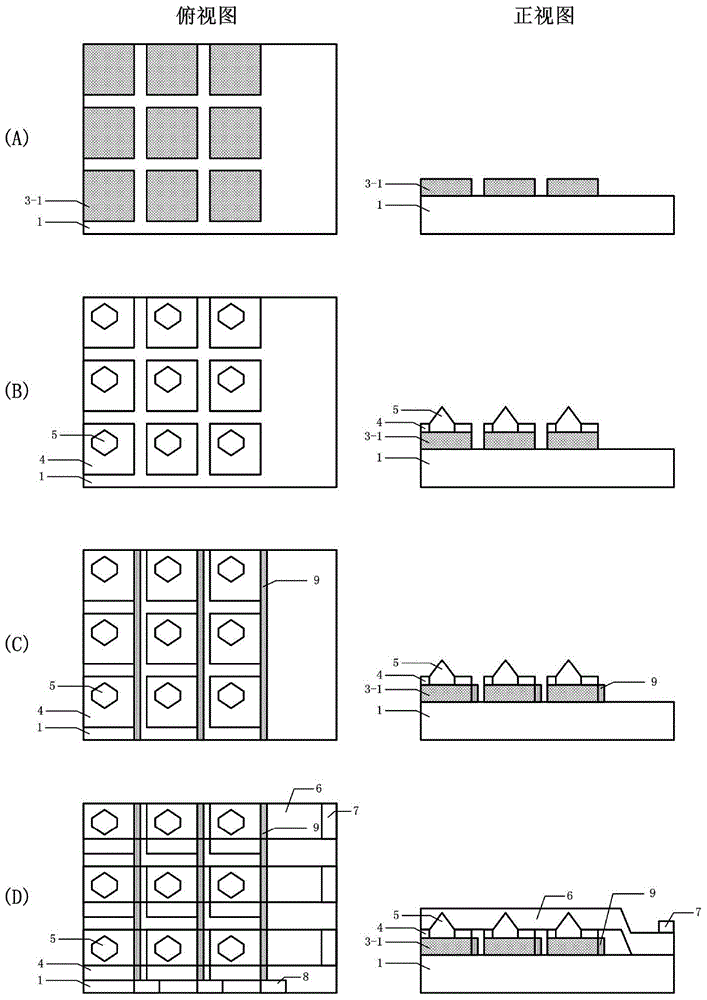

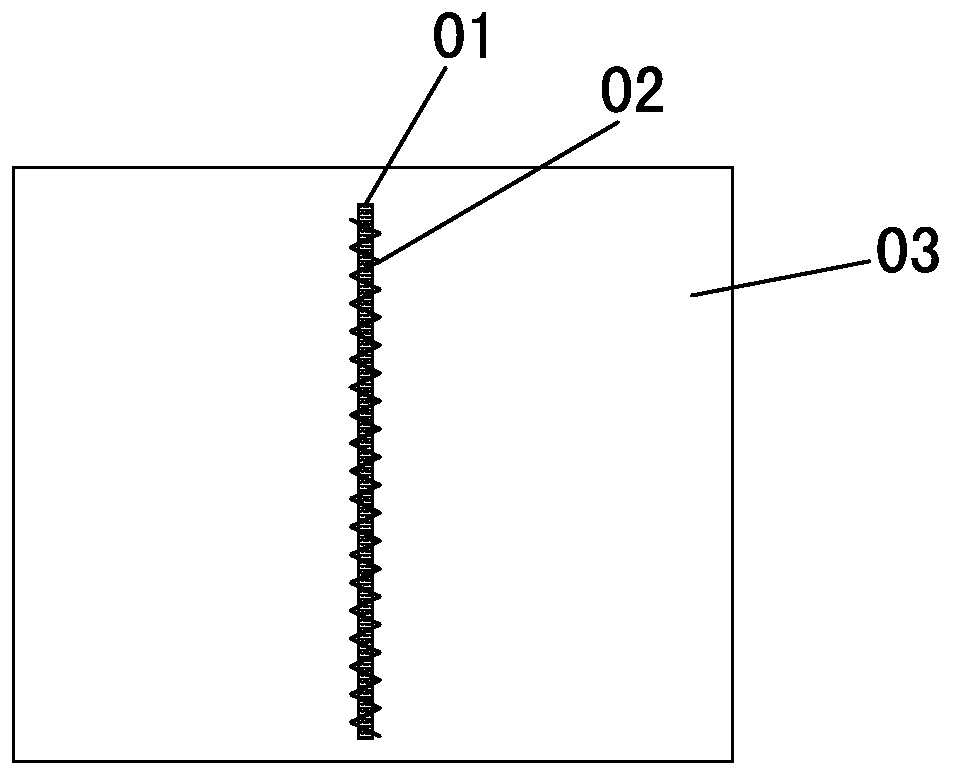

GaN-based light emitting diode (LED) array micro display device and fabrication method thereof

ActiveCN105140352AReduce leakage currentUltra low power consumptionSolid-state devicesSemiconductor devicesPolymer light emitting diodesDisplay device

The invention discloses a GaN-based light emitting diode (LED) array micro display device and a fabrication method thereof based on a selective region epitaxial growth technique. The fabrication method of the device comprises the following steps of: (A) fabricating mask membranes arranged in a strip shape on a substrate, and growing a strip-structurized n-type GaN array through the selective region epitaxial growth technique; (B) fabricating a mask membrane provided with periodically-distributed opening holes on the strip-structurized n-type GaN array, and growing a three-dimensional structurized miniature LED array through the selective region epitaxial growth technique; (C) fabricating a strip-shaped transparent conductive layer on the surface of the three-dimensional structurized miniature LED array; and (D) respectively fabricating a negative electrode and a positive electrode on the strip-structurized n-type GaN array and the strip-shaped transparent conductive layer. According to the method, the selective region epitaxial growth technique is used for growing a GaN-based miniature LED, the problem of current leakage caused by a dry etching method for fabrication the miniature LED is solved, and a miniature display device having matrix addressing, low power consumption and high brightness is provided.

Owner:SUN YAT SEN UNIV

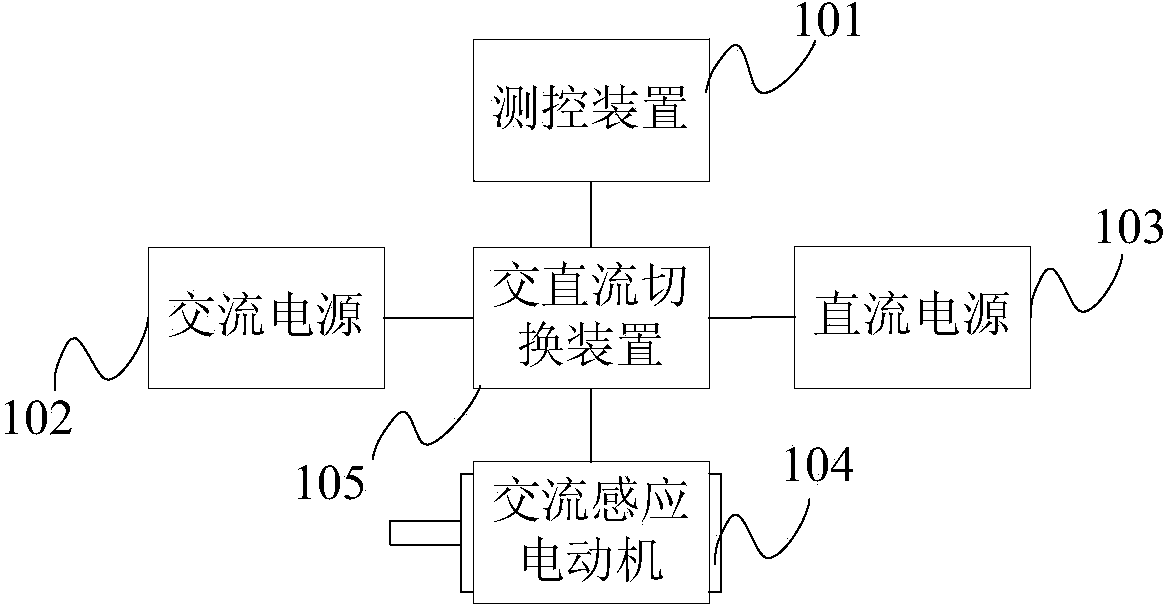

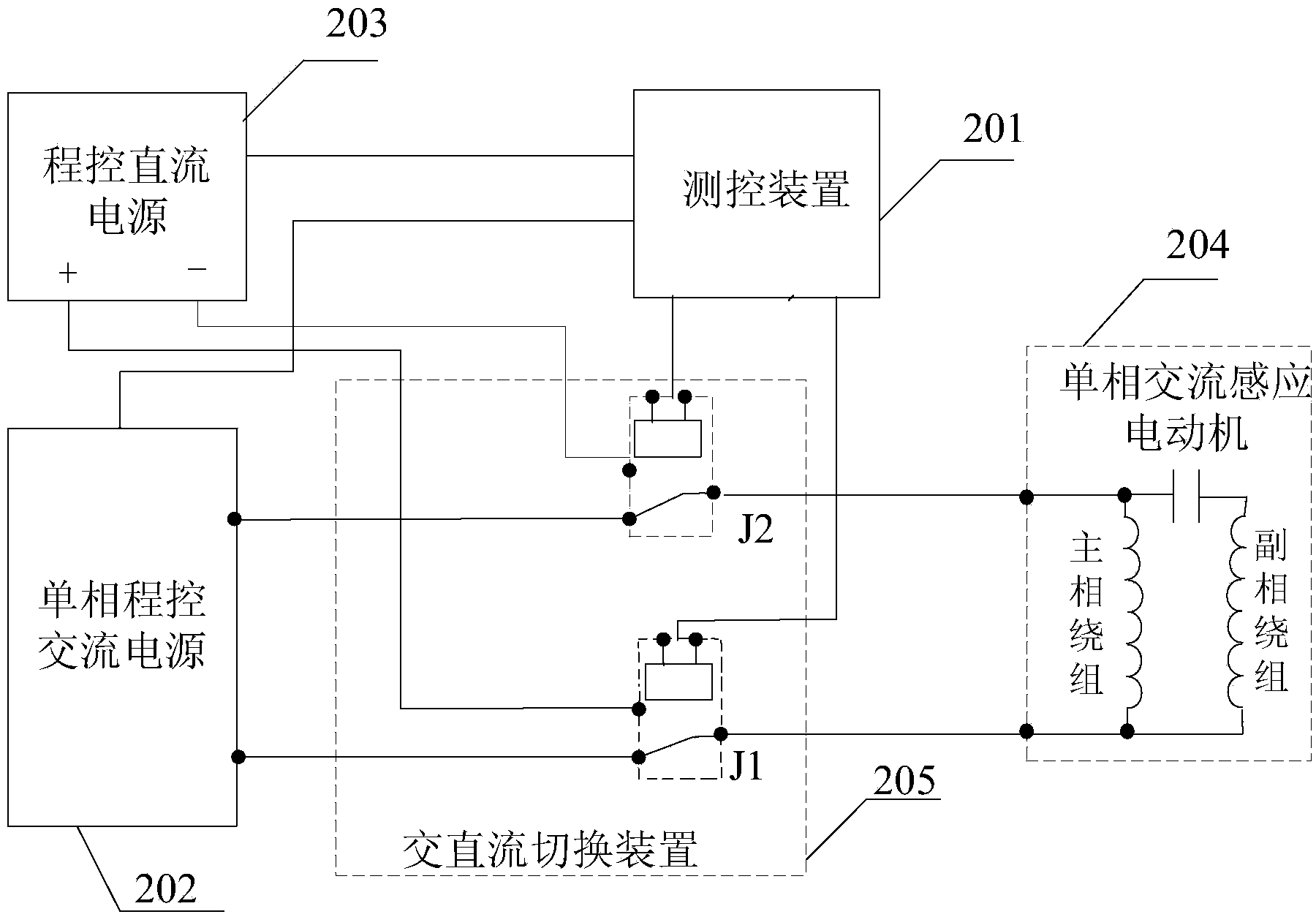

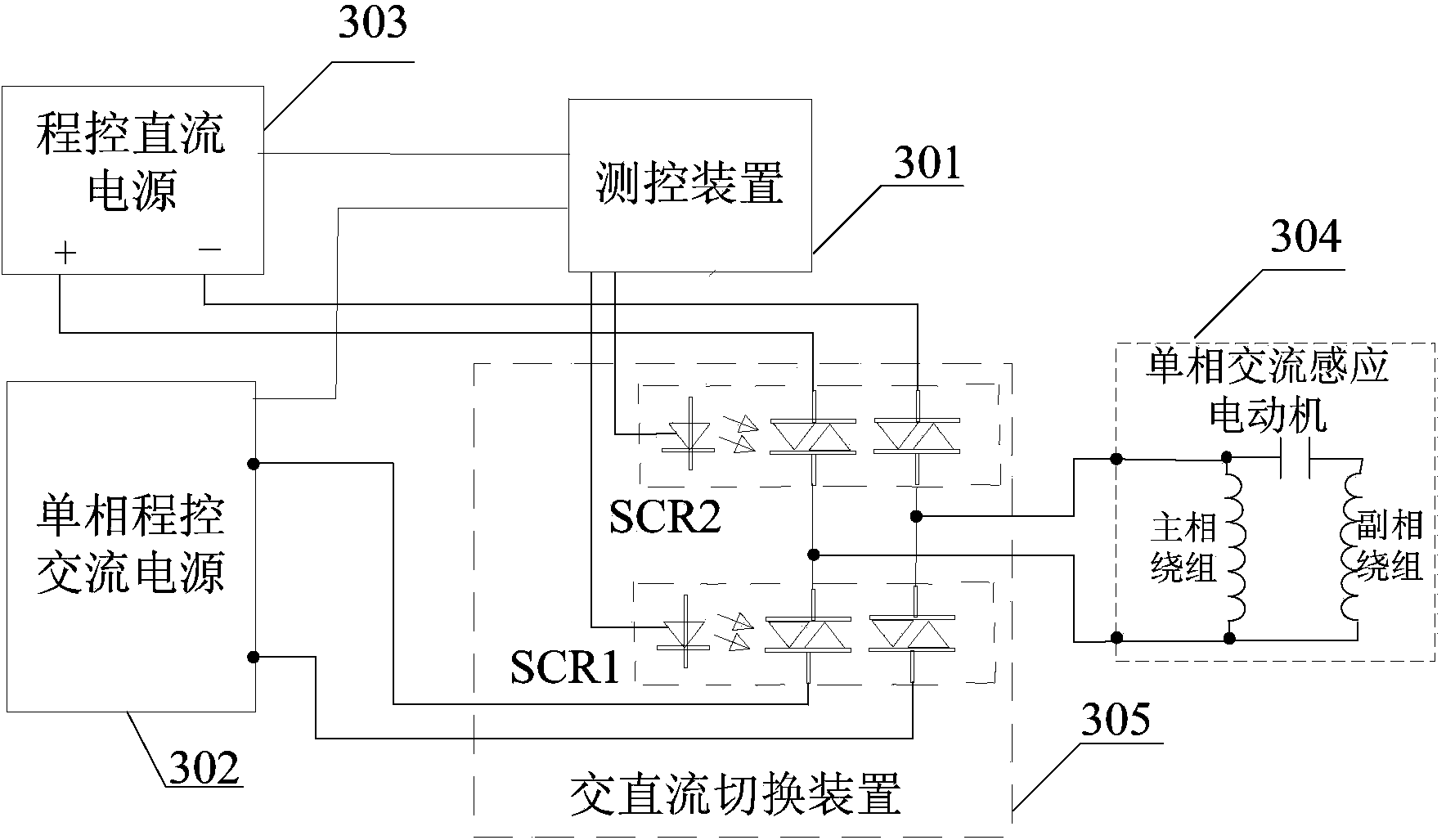

Alternating current induction motor detection brake device and detection system

InactiveCN104111421AShorten detection timeNo surface damageDynamo-electric machine testingBrake torqueSingle phase

The invention provides an alternating current induction motor detection brake device and a detection system. When detection of some gear is completed, an alternating current power supply stops providing power for an alternating current induction motor; when the detected alternating current induction motor performs decelerated motion, a measuring and control device connects a direct current power supply with the alternating current induction motor by controlling an alternating current and direction current switching device, the direct current power supply provides the alternating current induction motor with a direct excitation signal lasting for a certain time so as to enable a stator of the alternating current induction motor to produce a constant magnetic field, and the magnetic field enables a rotor of the alternating current induction motor to produce a brake torque to control the rotator to rapidly stop rotating, so that detection time of any gear of the alternating current induction motor is greatly shortened, and detection efficiency is improved. Besides, since an additional mechanical clamping shaft device is not needed, mechanical abrasion does not exist, and surface damages to a shaft of the single-phase alternating current induction motor are avoided.

Owner:SHANGHAI AOBOOR ELECTRONICS

Fabric softening agent

InactiveCN107780219ANo surface damageBouncyGrip property fibresAbrasion resistant fibresPentaerythritolSodium stearate

The invention discloses a fabric softener, which is characterized in that it comprises the following raw materials in parts by mass: 2-6 parts of sodium stearate, 10-15 parts of ester group quaternary ammonium salt, 3-8 parts of acrylamide, pentaerythritol fat 5-12 parts of acid ester, 10-15 parts of sorbitan fatty acid ester, 10-18 parts of ethanol, 10-20 parts of polyoxyethylene ether, 2-5 parts of ethylene oxide, and 80-100 parts of water. Compared with the prior art, the invention has good application effect, simple preparation process, no damage to the fabric surface, and can make the fabric soft, smooth, elastic and wear-resistant.

Owner:南通亚点毛巾染织有限公司

Ultrathin single crystal germanium wafer processing method

ActiveCN103862354AUniform thicknessImprove flatnessPolishing machinesLapping machinesSingle crystalCorundum

The invention discloses an ultrathin single crystal germanium wafer processing method. The ultrathin single crystal germanium wafer processing method is characterized by comprising the following steps: first, using wire-electrode cutting equipment to cut a single crystal germanium rod to obtain single crystal germanium wafers with the thickness being less than 0.5mm; second, clamping the single crystal germanium wafers on a low-temperature polishing machine; third, firstly using a hard abrasive material with the Mohs hardness being greater than 9, such as diamond, corundum, silicon carbide, boron carbide with the granularity of 10-28[mu]m to froze and solidify an abrasive material polishing disk to serve as a polishing head for rough machining, and taking an anhydrous organic solvent as polishing liquid; using an abrasive material with the Mohs hardness being smaller than 9, such as CeO2 and silica with the granularity of 0.06-2[mu]m to froze and solidify the abrasive material polishing disk to serve as a polishing head for fine machining, and carrying out secondary processing, wherein the polishing temperature is controlled to be within minus 30DEG C to minus 10DEG C, the polishing pressure is controlled to be within 100-500g / cm<2>, the polishing solution is the anhydrous organic solvent, the flow rate is 50-500ml / min, the polishing rotation speed is 10-300r / min, and finally the ultrathin germanium wafers with the thickness being less than 0.15mm are obtained. The ultrathin single crystal germanium wafer processing method is simple and the yield is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Compound semiconductor corrosion method

InactiveCN106257624AControllable corrosion rateImprove accuracySemiconductor/solid-state device manufacturingHigh densityOhmic contact

The invention provides a compound semiconductor corrosion method. The compound semiconductor corrosion method includes the following steps that 1, a compound semiconductor is covered with a patterned mask layer, wherein the compound semiconductor is a binary and / or multivariant group-III-V compound semiconductor; 2, a high-density plasma produced by a high-density plasma source to conduct oxidation treatment on the exposed compound semiconductor to obtain an oxidation layer, wherein the mask layer does not react with the high-density plasma; 3, the oxidation layer is removed; 4, the patterned mask layer is removed to obtain a corroded compound semiconductor. The method can rapidly and accurately control the etching rate and etching depth of the binary and / or multivariant group-III-V compound semiconductor, surface damages are few, no residue is produced, the etched surface is high in uniformity, and the compound semiconductor corrosion method can be used for formation of transistor recessed gates, ohmic contact structures and the like.

Owner:BEIJING DEFT ELECTRONICS TECH CO LTD

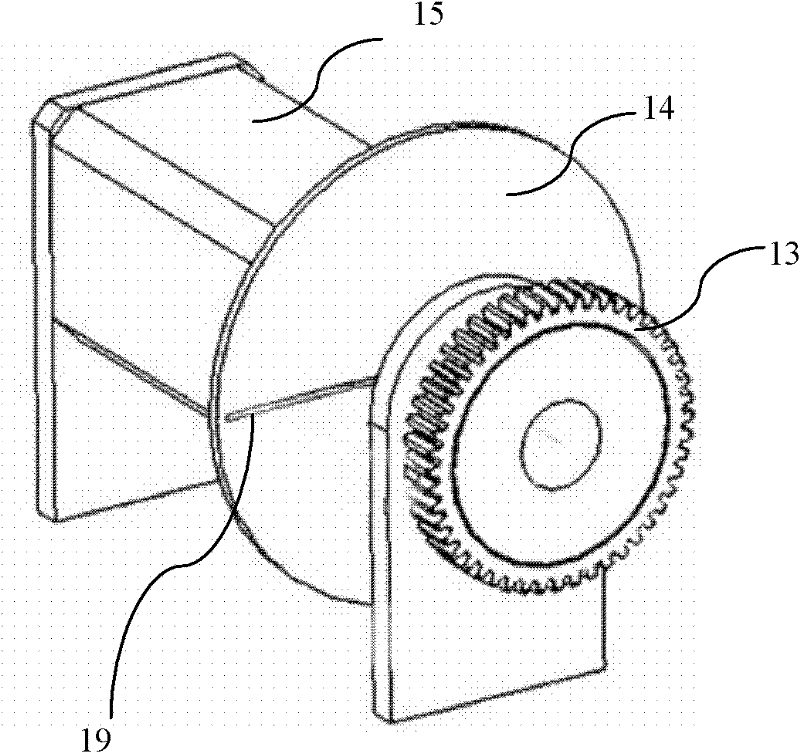

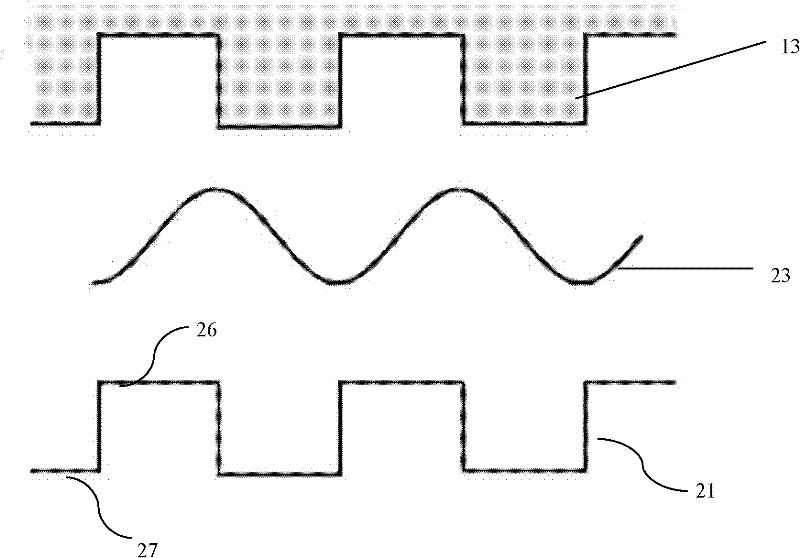

Device for detecting pitch error of acrylonitrile butadiene styrene (ABS) gear ring by magnetic induction

ActiveCN102410806AAvoid False Test ResultsIncrease credibilityUsing electrical meansContact testTest flow

The invention discloses a device for detecting a pitch error of an acrylonitrile butadiene styrene (ABS) gear ring by magnetic induction. The device is characterized by comprising a rotating mechanism, a switch mode magnetic induction sensor positioned on one side of the rotating mechanism, a data acquisition and storage device and a signal analysis device. In the device for detecting the pitch error of the ABS gear ring by the magnetic induction, a non-contact test is adopted, so the surface of the ABS gear ring to be tested cannot be damaged; a test flow is performed automatically, so an additional error caused by different selections on test points and subjective factors during manual measurement is avoided; and evaluation of the pitch error of the gear ring and outoftolerance tooth positioning are performed at the same time, so analysis basis is supplied to an ABS gear ring manufacturer for improving a corresponding production method and a corresponding process under the conditionthat products are unqualified or the quality of the products is unstable.

Owner:上海龙感汽车电子有限公司

Corrugated cardboard cutting and pressing integrated machine

PendingCN106863902AReduce frictional resistanceHigh sensitivityBox making operationsPaper-makingCardboardEngineering

The invention discloses a corrugated cardboard cutting and pressing integrated machine comprising a rack, a workbench arranged on the rack and used for placing a corrugated cardboard, a three-dimensional displacement structure arranged on the rack, a laser cutting system used for emitting laser, an indentation wheel structure for indenting the corrugated cardboard and a control device; the laser cutting system, the indentation wheel structure and an image acquisition system are arranged above the workbench and are connected with the three-dimensional displacement structure; and the control device is connected with the three-dimensional displacement structure and is also connected with the laser cutting system and the indentation wheel structure, and the laser cutting system and the indentation wheel structure are driven by the three-dimensional displacement structure to displace. Due to the adoption of the structure, the corrugated cardboard cutting and pressing integrated machine is low in processing cost, short in period, high in cutting precision, precise in location, convenient to mount and debug, high in flexibility, free of jittering during starting and free of creeping phenomena during operating at low speed, so that the micro-feeding can be precisely controlled, and the corrugated cardboard cutting and pressing integrated machine has the advantages of motion stability, high driving efficiency, high precision and good synchronism.

Owner:昆明精研科技有限公司

Lotus root planting method

InactiveCN104855092AKind of lotus rootNo surface damageFertilising methodsHorticultureFertilizerLotus root

The invention discloses a lotus root planting method which comprises the specific steps that a good variety is chosen; a fertile clay loam field block is chosen; rational close planting is carried out; base fertilizers are applied; additional fertilization is implemented for the first time; the additional fertilization is implemented for the second time; lotus root shoots are rotated frequently; and the lotus roots are harvested. The lotus root planting method provided by the invention has the advantages such as high lotus root output and good quality.

Owner:霍邱县禾丰浅水藕种植专业合作社

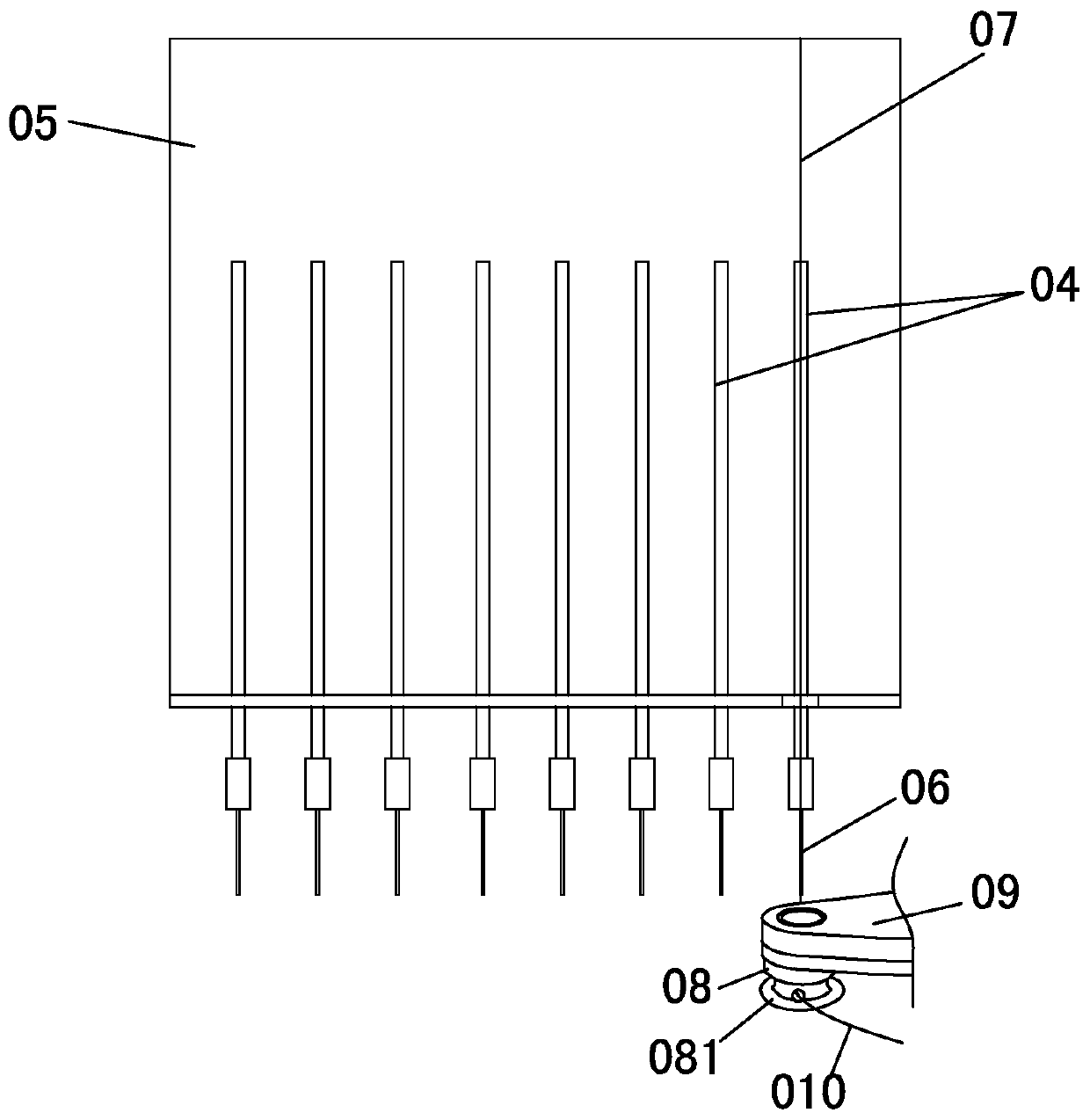

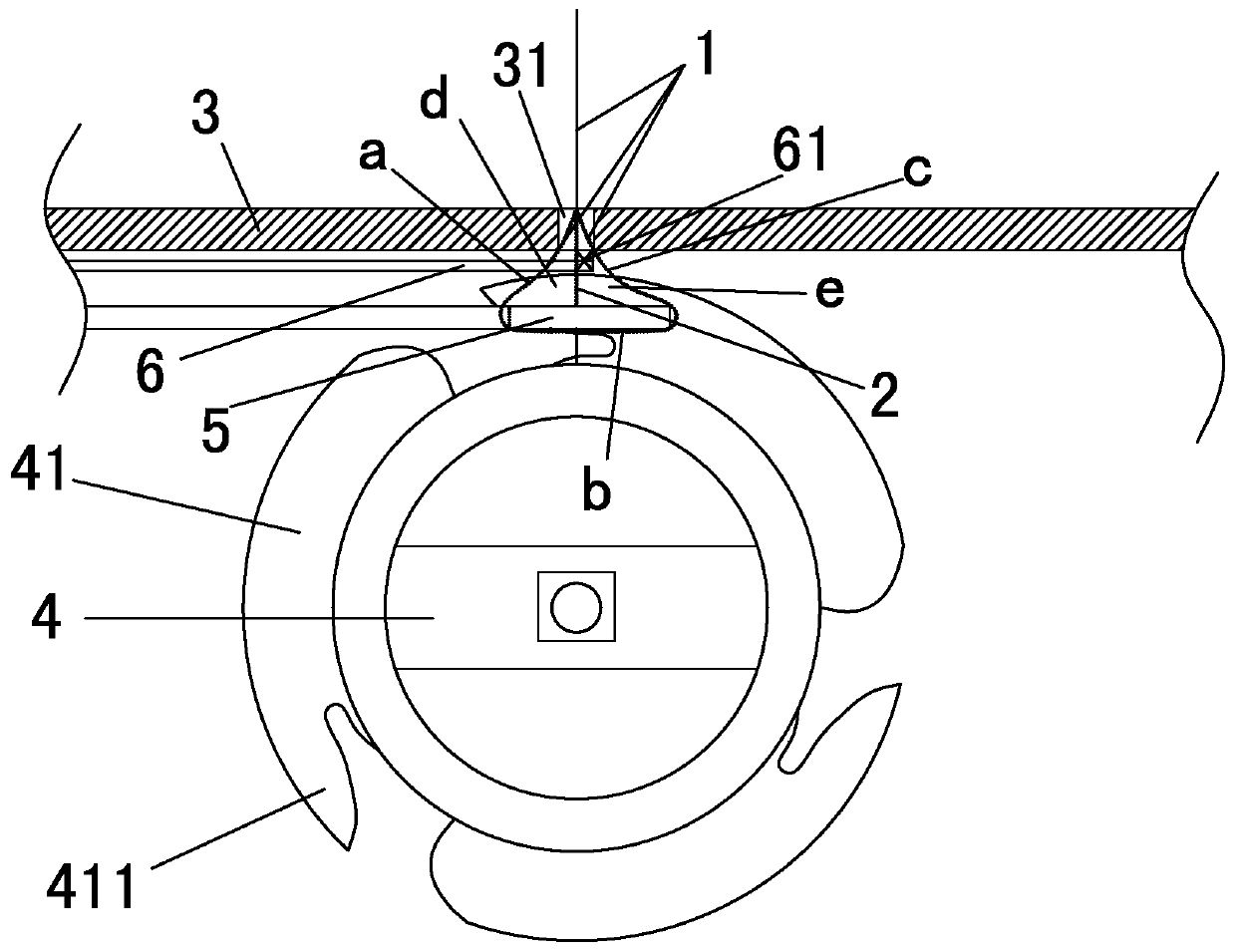

Disk embroidery assembly mechanism of protection type high-precision computer disk embroidery machine

ActiveCN110499597ASolve the problem that the presser foot cannot be setAvoid problems that cannot be applied to coil embroidery machinesAutomatic machinesAuxillary devicesEngineeringMechanical engineering

The invention relates to the field of computer embroidery machines, in particular to a disk embroidery assembly mechanism of a protection type high-precision computer disk embroidery machine. The diskembroidery assembly mechanism comprises an embroidery frame moving mechanism, a needle bar presser foot device arranged above the embroidery frame moving mechanism, and a bottom thread cutting mechanism arranged on the lower portion of an embroidery frame of the embroidery frame moving mechanism. Abrasion of a rail part in the using process can be reduced by means of a movable rail of the embroidery frame moving mechanism, the structure precision is improved, and the precision, embroidery effect and working efficiency of the computer embroidery machine in embroidery work are improved. The needle bar presser foot device is provided with a lifting mechanism, the structural arrangement is ingenious and reasonable so that the damage of disk ropes can be effectively avoided, and disk embroideries are stabilized. The bottom thread cutting mechanism is an upper cutter and lower cutter thread cutting mechanism on the computer embroidery machine which is provided with a double-knife structurecapable of effectively cutting off surface threads and bottom threads, reduces the mistaken cutting rate and prolongs the service life.

Owner:SHISHI SENKE INTELLIGENT TECH CO LTD

Damage-free high-planarity monocrystalline silicon carbide planar optical element and preparation method thereof

InactiveCN110919465AHigh thermal conductivitySmall coefficient of thermal expansionOptical surface grinding machinesCarbide siliconSingle crystal

The invention discloses a damage-free high-planarity monocrystalline silicon carbide planar optical element and a preparation method thereof. The preparation method comprises the following steps: (1)selecting a whole single crystal silicon carbide crystal ingot with a zero micro-pipeline; (2) cutting the single crystal silicon carbide crystal ingot to obtain a rough blank; (3) carrying out double-sided grinding on the rough blank to obtain two parallel rough grinding surfaces; (4) polishing the two parallel rough grinding surfaces to obtain an optical mirror surface; and (5) carrying out chemical mechanical polishing on the optical mirror surface, removing a damaged layer of the mirror surface, and carrying out local finishing to obtain the damage-free high-planarity monocrystalline silicon carbide planar optical element.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Electrolyte plasma polishing method for pure titanium denture support

The invention relates to the technical field of metal material surface treatment, in particular to an electrolyte plasma polishing method for a pure titanium denture support. In order to obtain the efficient, environment-friendly and simple polishing pure titanium denture support, the method comprises the following steps of (1) carrying out mechanical grinding; (2) carrying out ultrasonic cleaning; (3) drying; (4) carrying out electrolyte plasma polishing, wherein a polishing solution is a mixed aqueous solution of ammonium fluoride and potassium fluoride; the concentration of the ammonium fluoride aqueous solution is 3 to 18 g / L, and the concentration of the potassium fluoride dihydrate aqueous solution is 25 to 100 g / L; (5) carrying out ultrasonic cleaning; and (6) drying and carrying out vacuum sealing preservation to obtain a finished denture support with a bright mirror surface.

Owner:TAIYUAN UNIV OF TECH

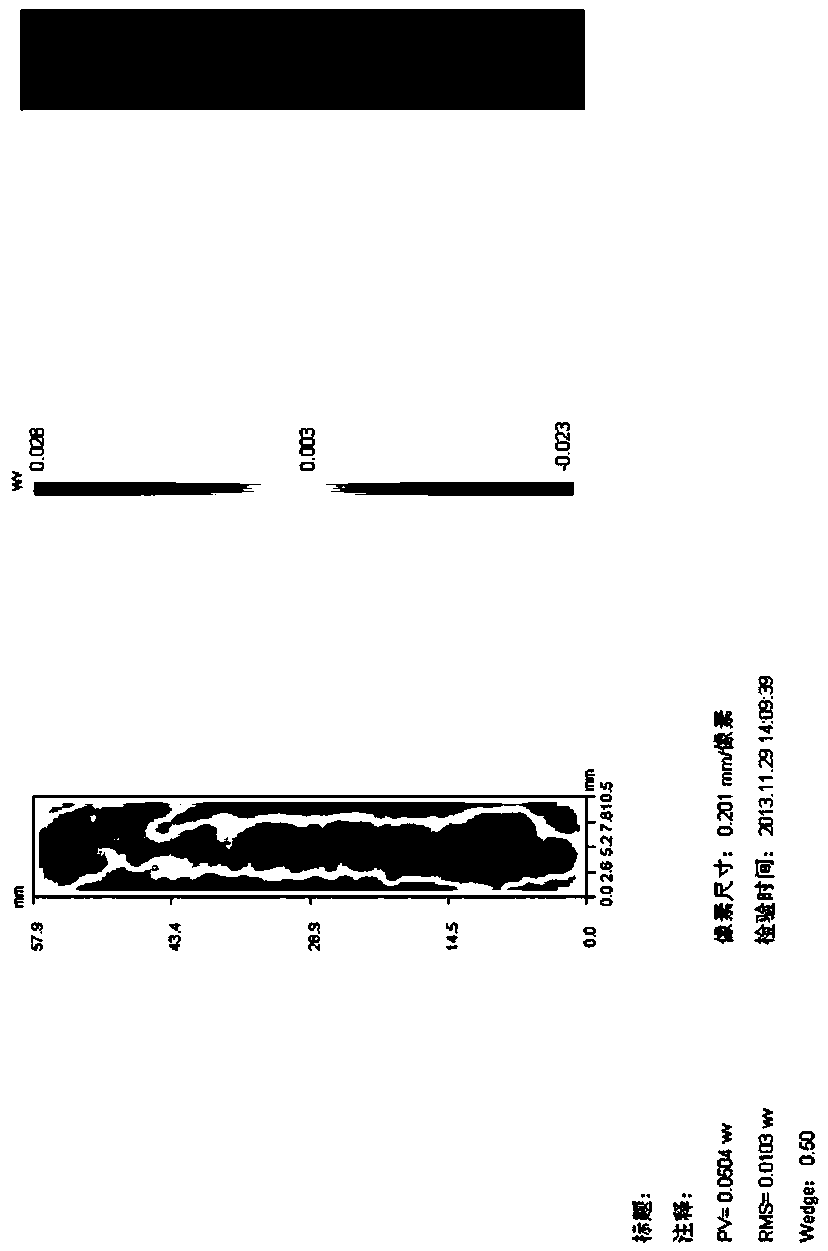

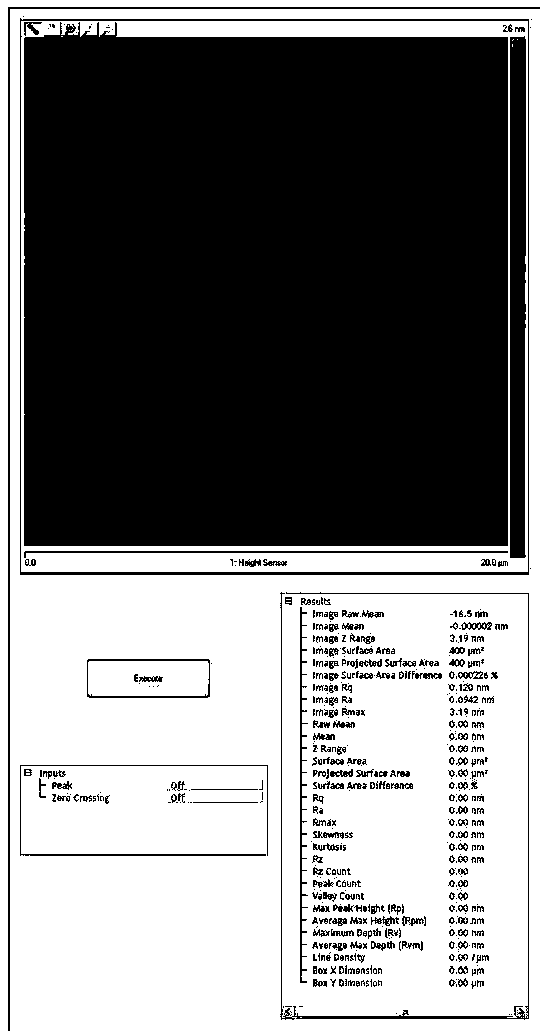

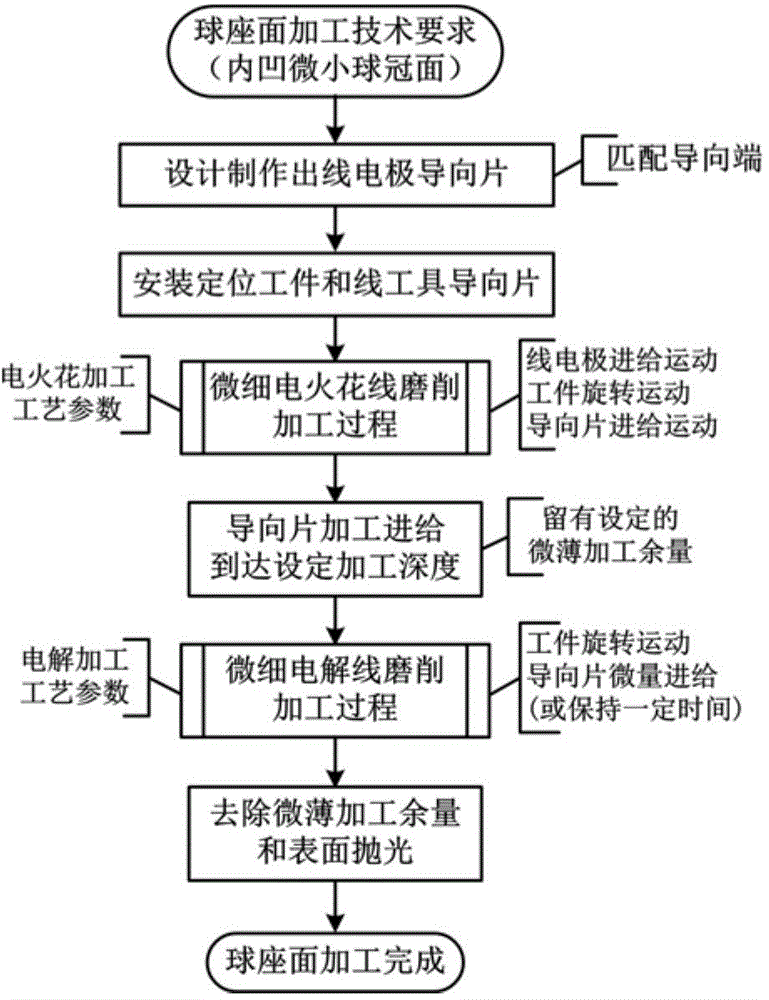

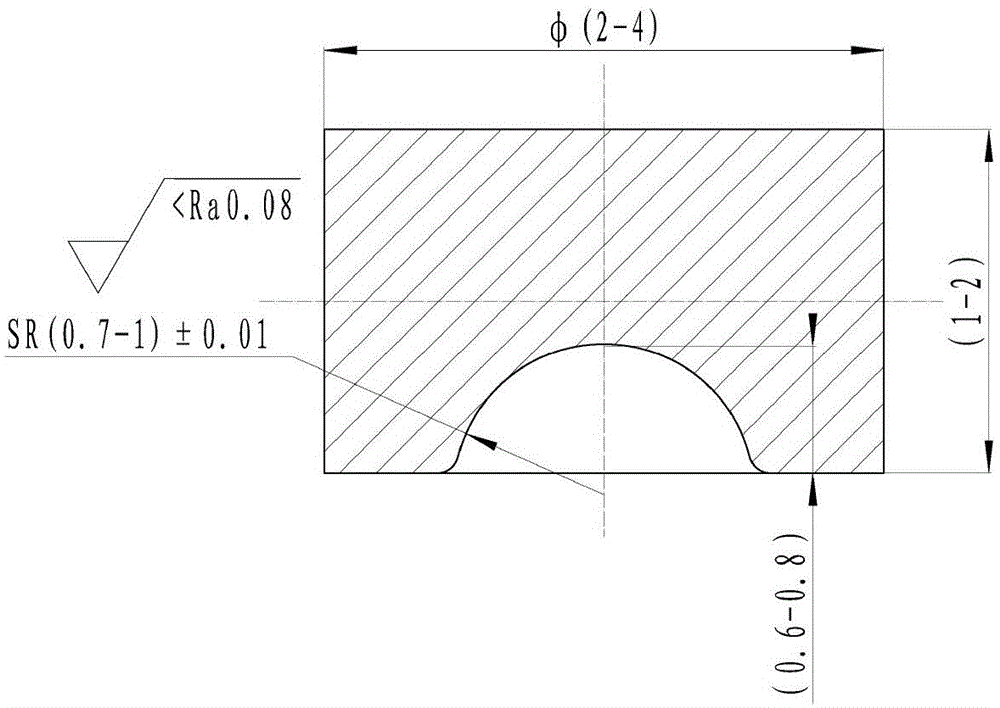

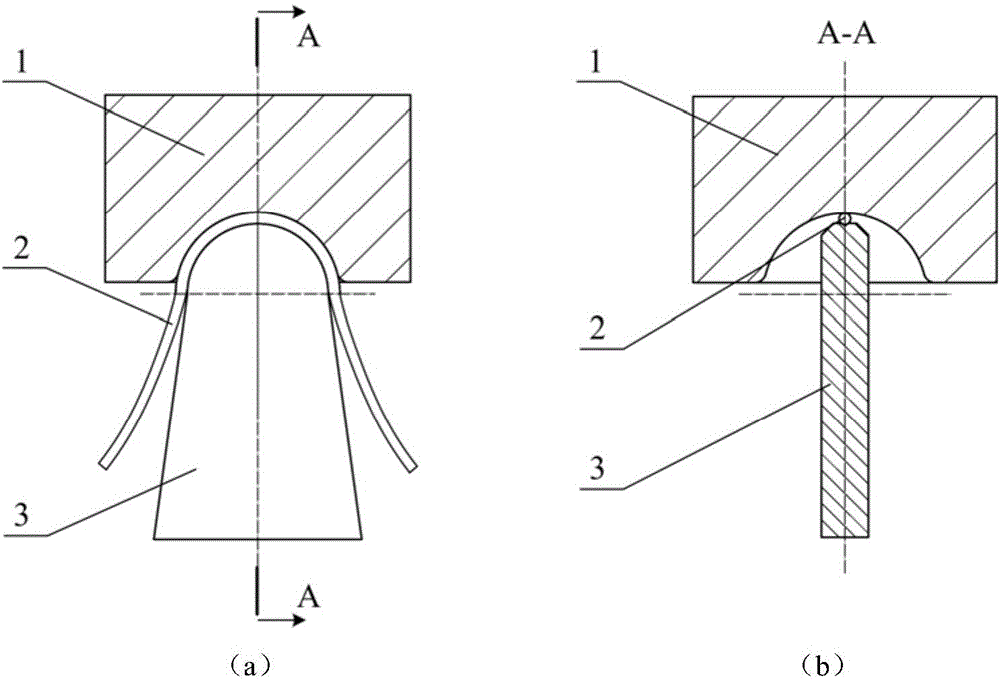

Precision electric grinding process for fuel injector tiny ball seat surface of high-pressure common-rail diesel engine

The invention relates to a precision electric grinding process for a fuel injector tiny ball seat surface of a high-pressure common-rail diesel engine and belongs to the technical field of micro non-traditional machining. The precision electric grinding process comprises steps of according to the size of the ball seat surface, designing and manufacturing a wire electrode guide plate with guide end semi-circular or arc; installing and positioning a ball seat surface workpiece and the wire electrode guide plate, and ensuring coaxial precision of symmetric axis of the guide plate and rotary symmetric axis of the ball seat surface workpiece; grinding a micro electric discharging wire to the set machining depth; grinding a micro electrolytic line to remove working allowance and polish the surface to reach machining technical requirements of the ball seat surface. According to the process, the same tool line electrode is utilized to perform online integration of micro electric discharging grinding and micro electrolytic grinding, the final shape and surface precision of the ball seat surface are achieved, and machining technical requirements of the tiny ball seat surface are achieved. The precision electric grinding process is suitable for machining the ball seat surface on a fuel injector control valve in a high-pressure common-rail diesel engine system and further suitable for machining high-precision axisymmetric concave surfaces on other conductive materials.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com