Rotary magnetic pole magnetorheology polishing device and method

A technology of magnetorheological polishing and magnetorheological fluid, which is used in grinding drive devices, grinding/polishing equipment, and parts of grinding machine tools. It can solve the problems of poor controllability and uneven polishing in the polishing process. Improve polishing efficiency and polishing uniformity, good polishing uniformity and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to better explain the present invention, the specific implementation manners of the present invention will be described in detail below with reference to the drawings.

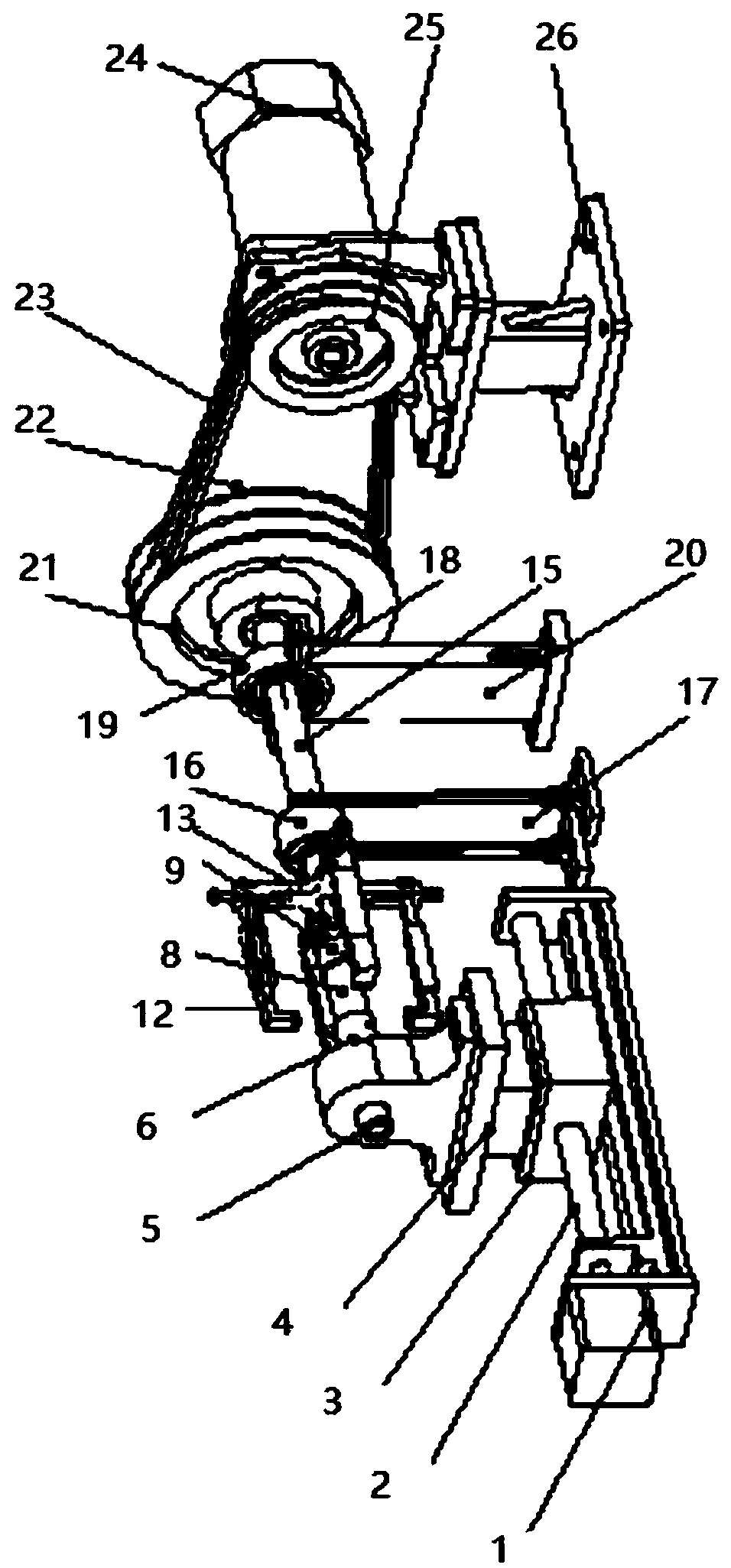

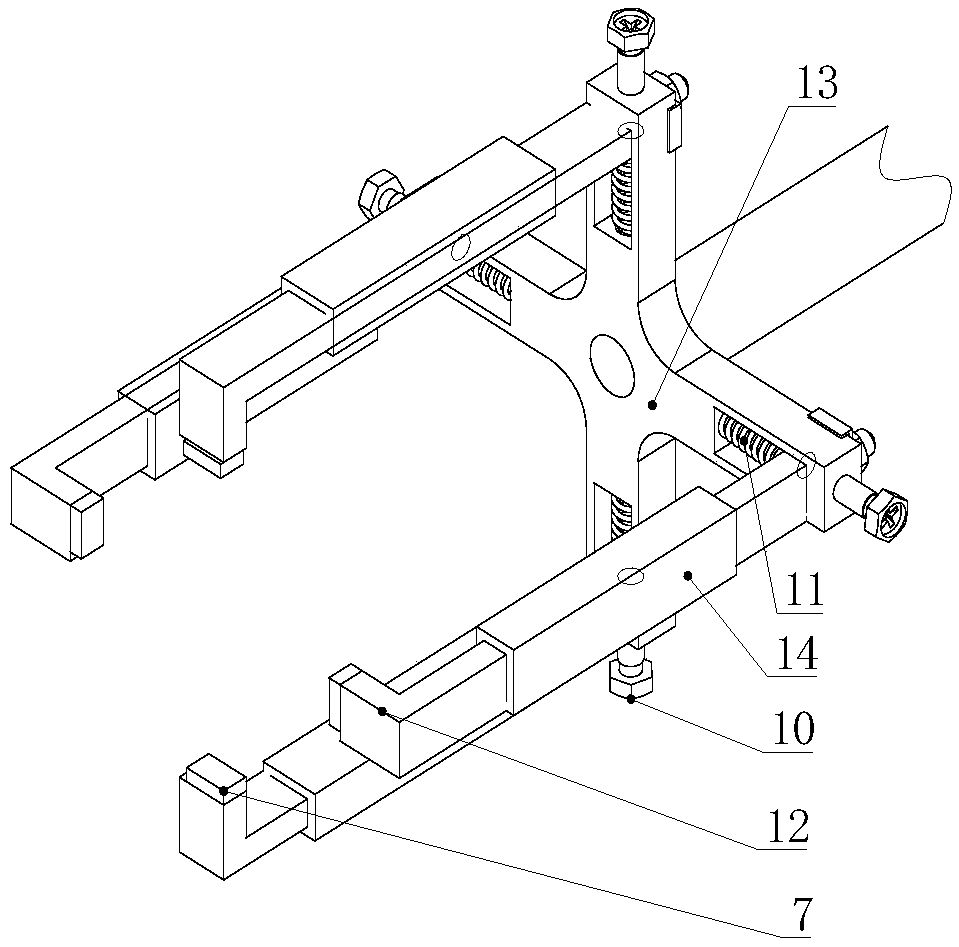

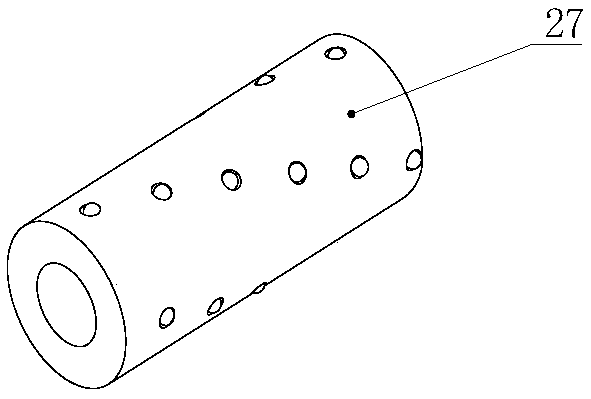

[0043] Such as figure 1 — Figure 4 As shown, the present invention provides a rotating magnetic pole magneto-rheological polishing device for polishing the inner wall of a tubular workpiece 8, which includes a magnetorheological fluid supply system, a workpiece support and drive mechanism, and a magnetic pole rotation mechanism.

[0044] The workpiece supporting and driving mechanism comprises a stepper motor 1 arranged on the base, a ball screw 2 and a worktable 4 driven by the stepper motor 1 to rotate, and the bottom of the workbench 4 is fixedly provided with a 2 Engaged lead screw slide 3 . The ball screw 2 runs through the screw slider 3 and one end is connected to the stepping motor 1. The ball screw 2 and the screw slider 3 slide and fit together. Driven by the stepping motor 1, the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com