Patents

Literature

49results about How to "Improve polishing uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

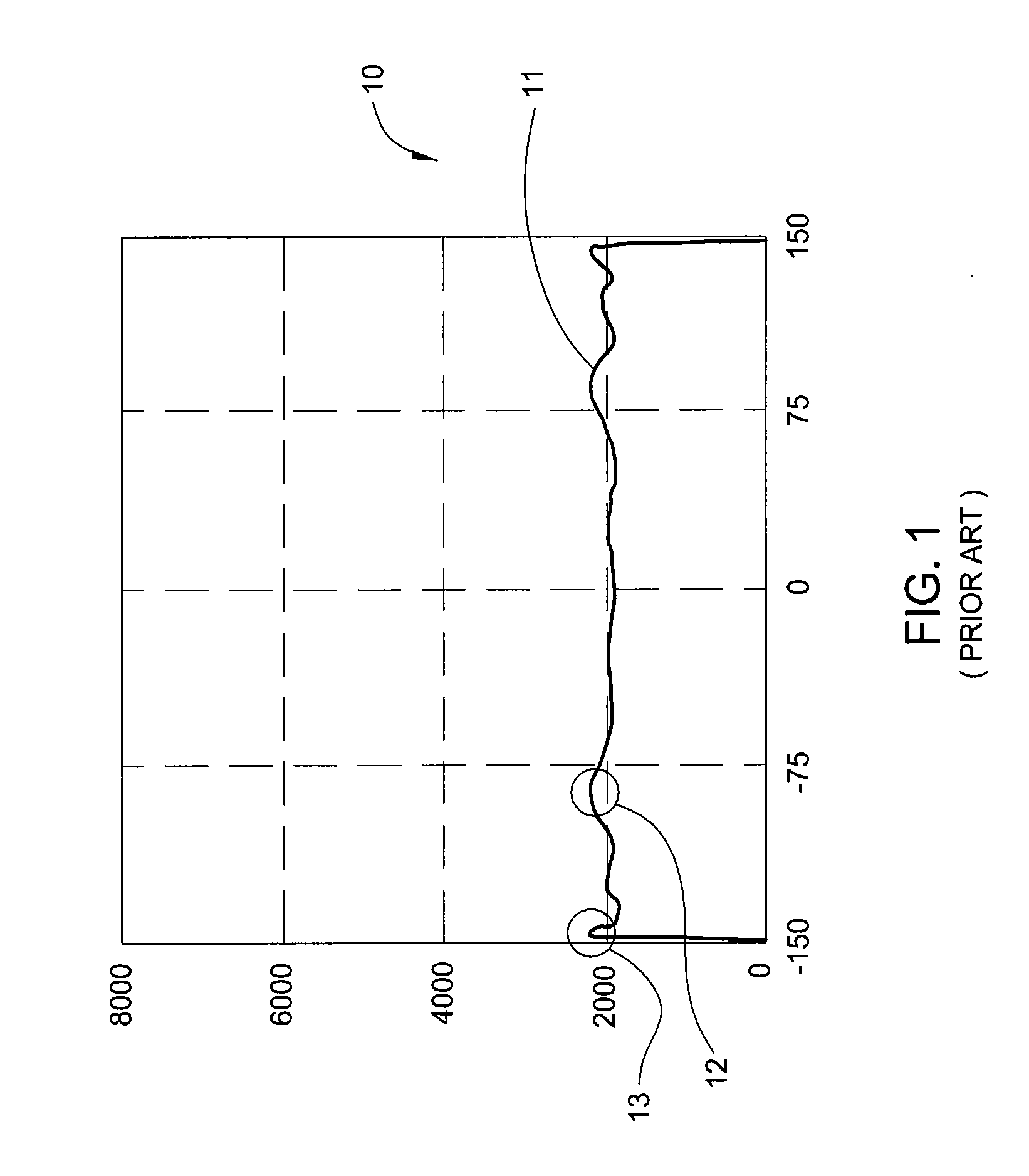

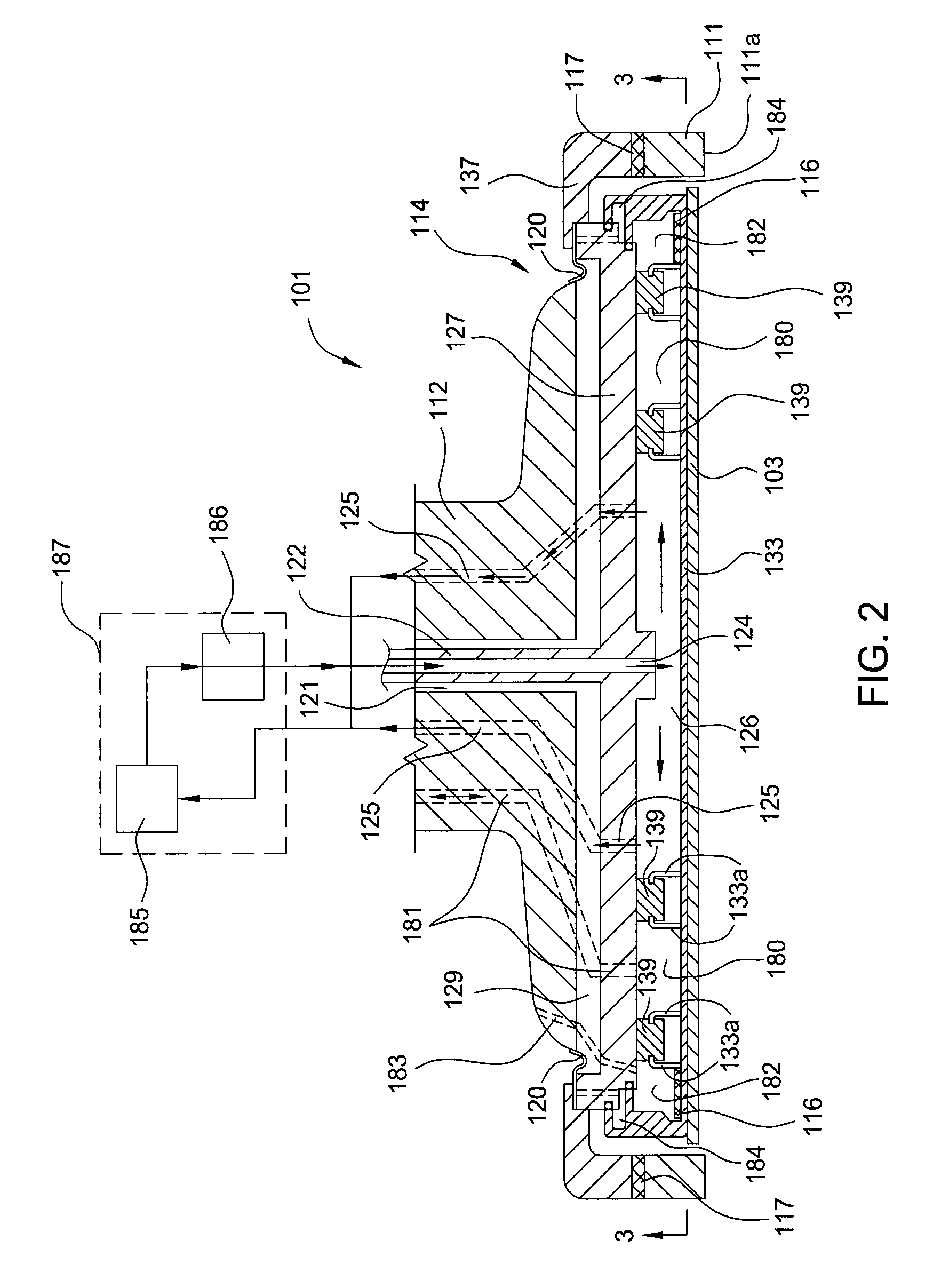

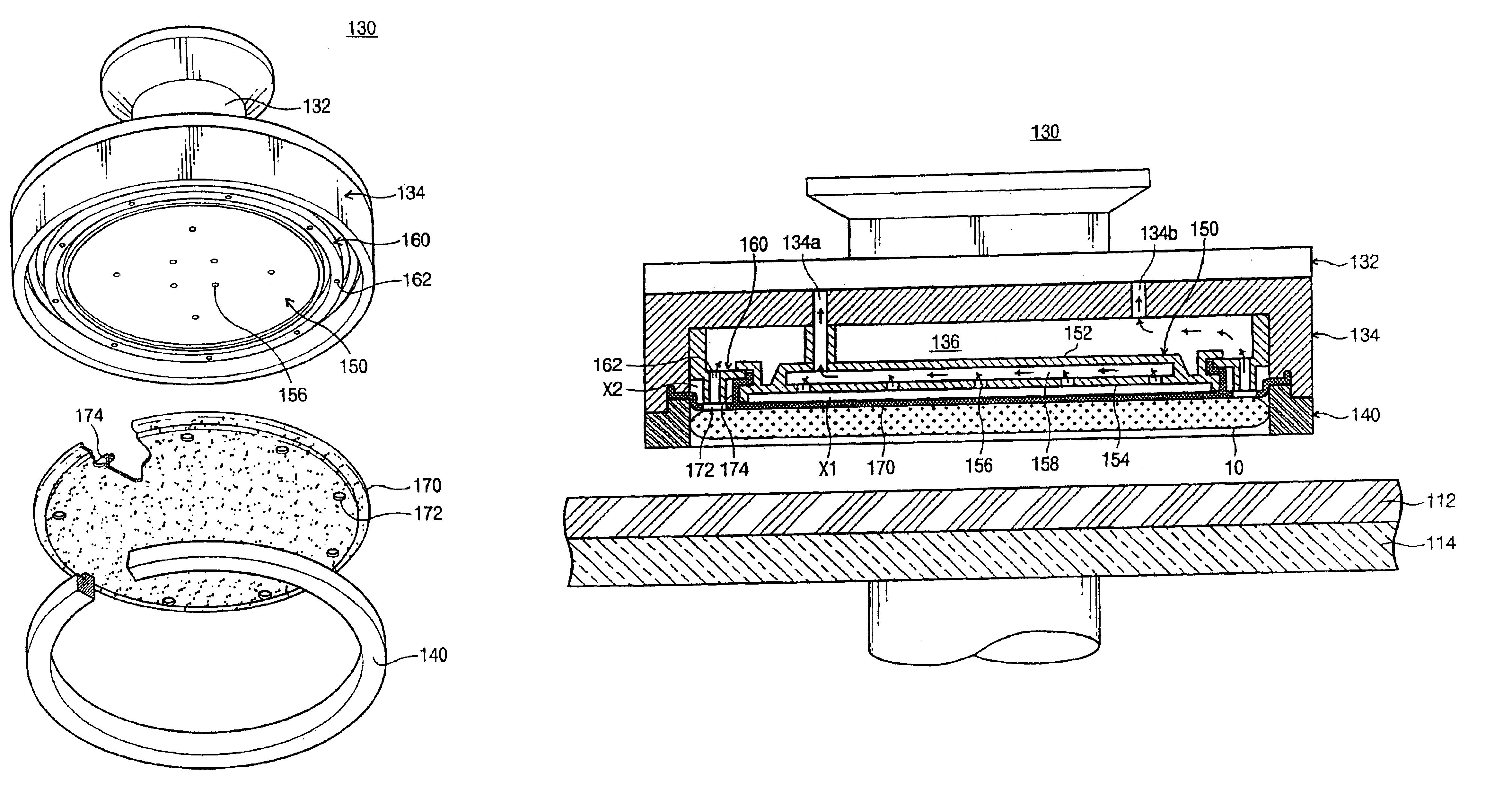

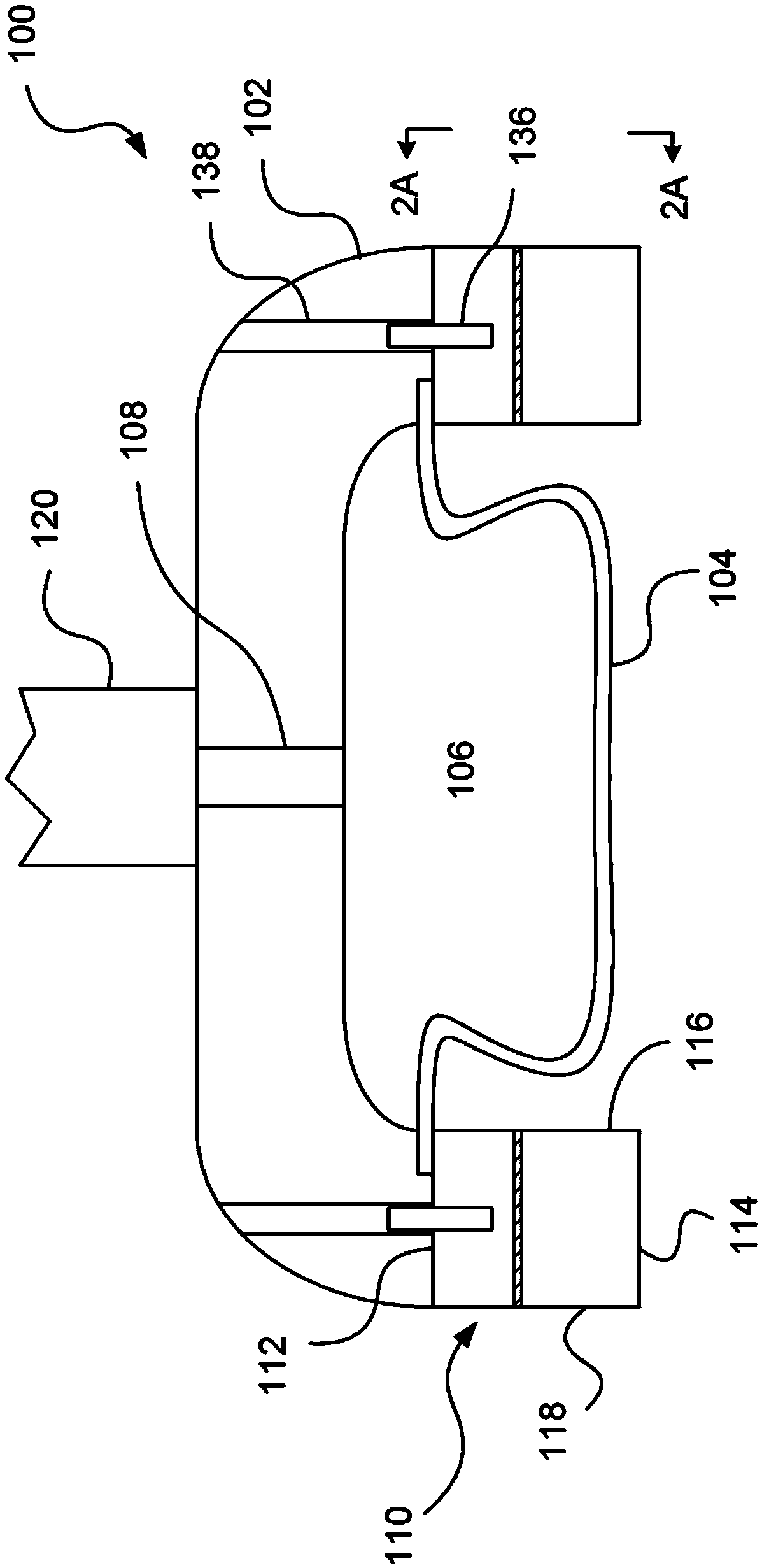

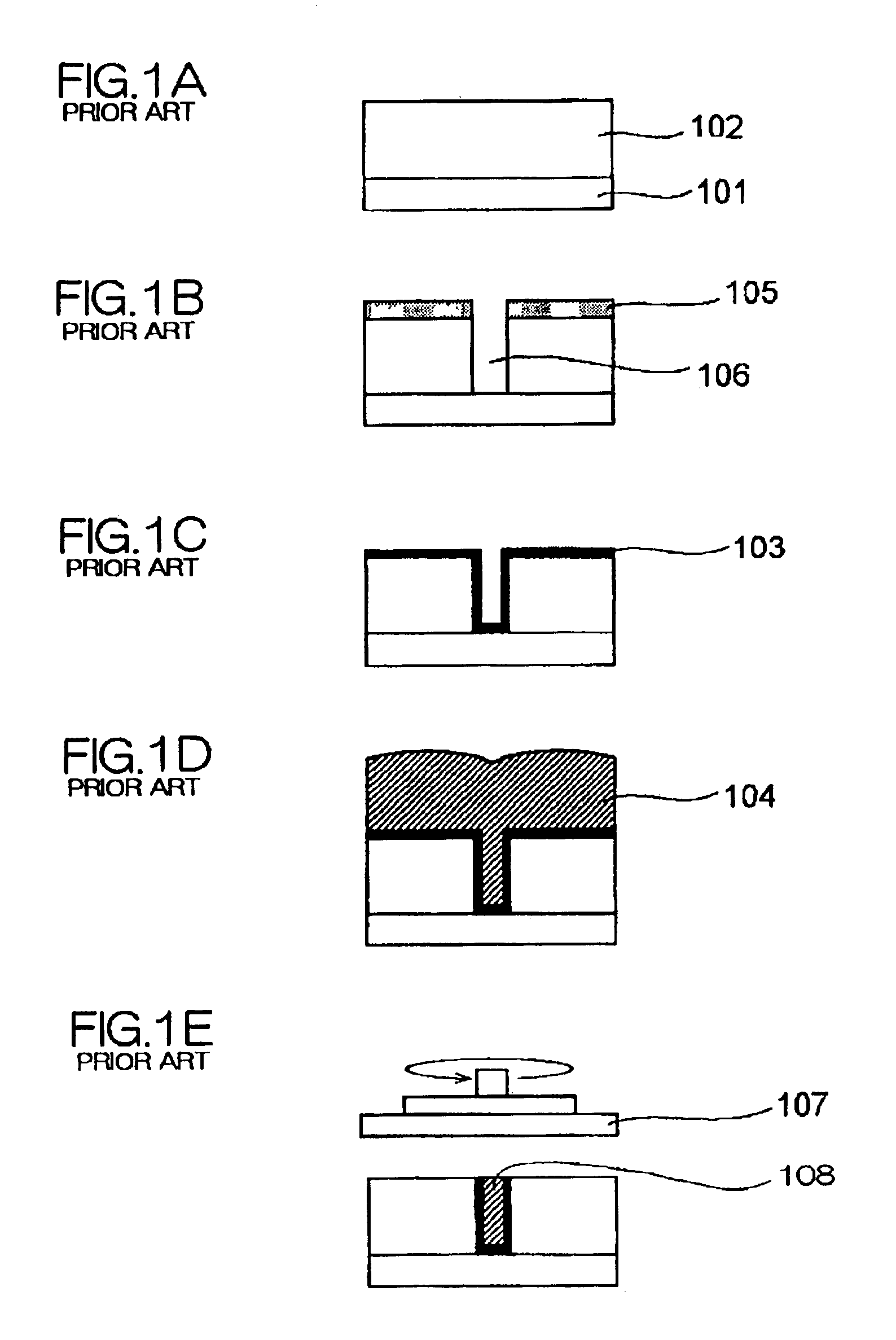

Apparatus and method for temperature control during polishing

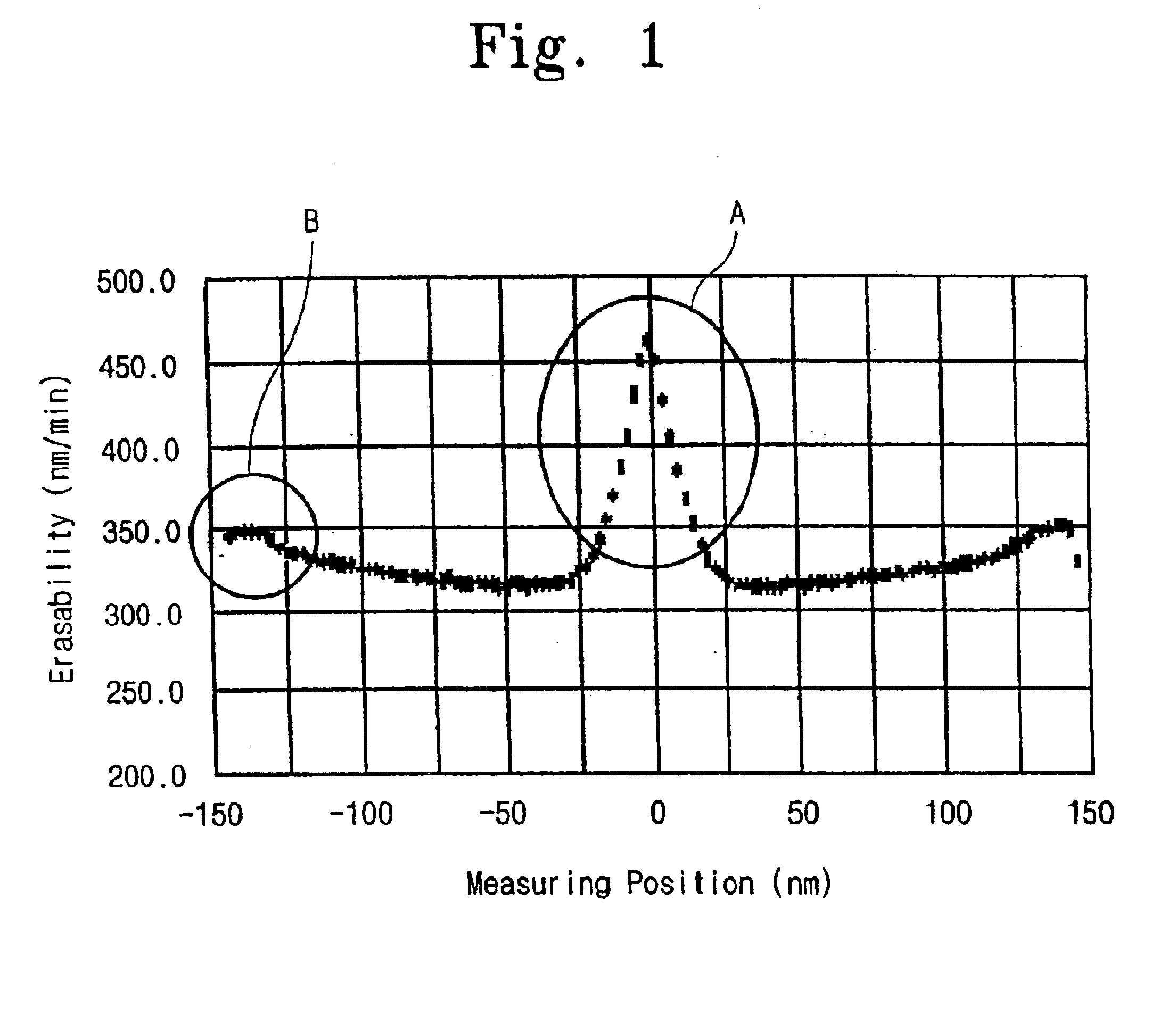

InactiveUS20120040592A1Improve polishing uniformityImprove uniformityPolishing machinesRevolution surface grinding machinesThermal energyTemperature control

Embodiments of the present invention relate to apparatus and method for improve uniformity of a polishing process. Embodiments of the present invention provide a heating mechanism configured to apply thermal energy to a perimeter of a substrate during polishing, or a cooling mechanism configured to cool a central region of the substrate during polishing, or a biased heating mechanism configured to create a temperature step differential on a given radius of a polishing pad.

Owner:APPLIED MATERIALS INC

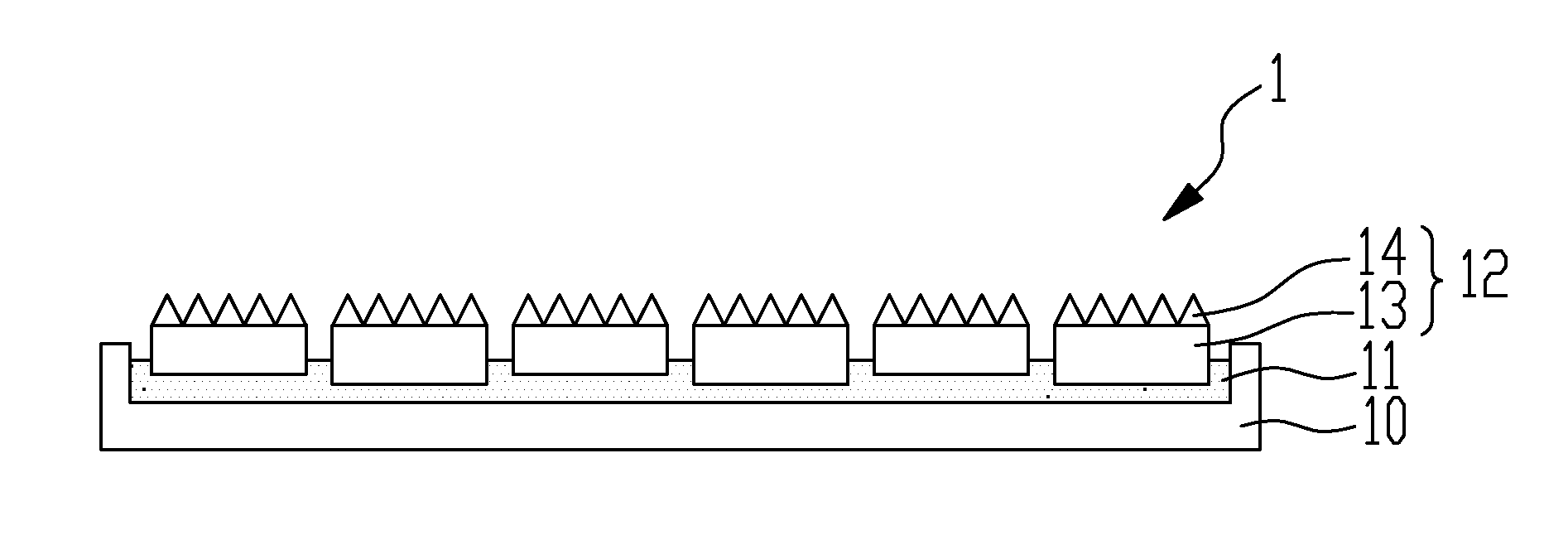

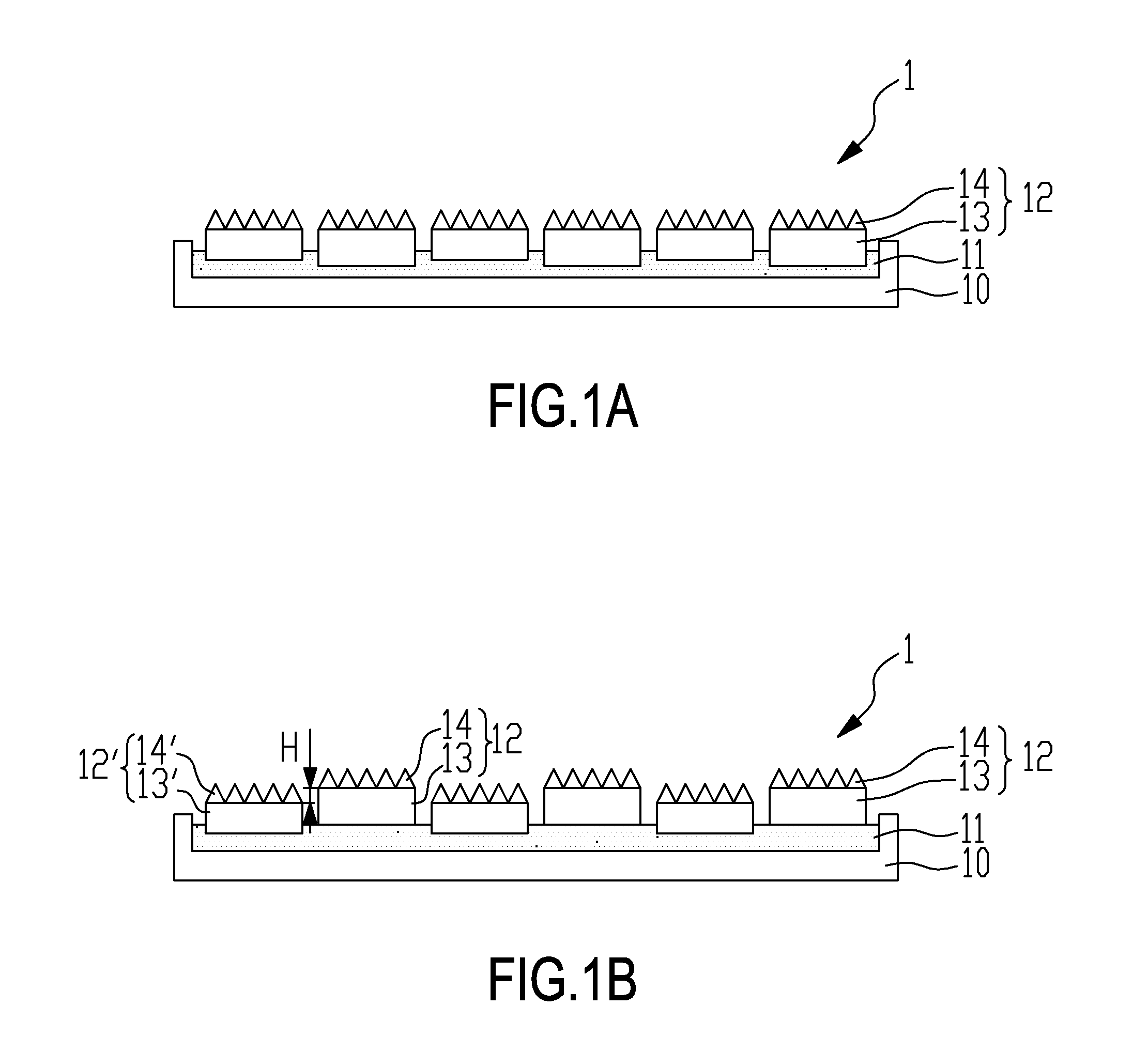

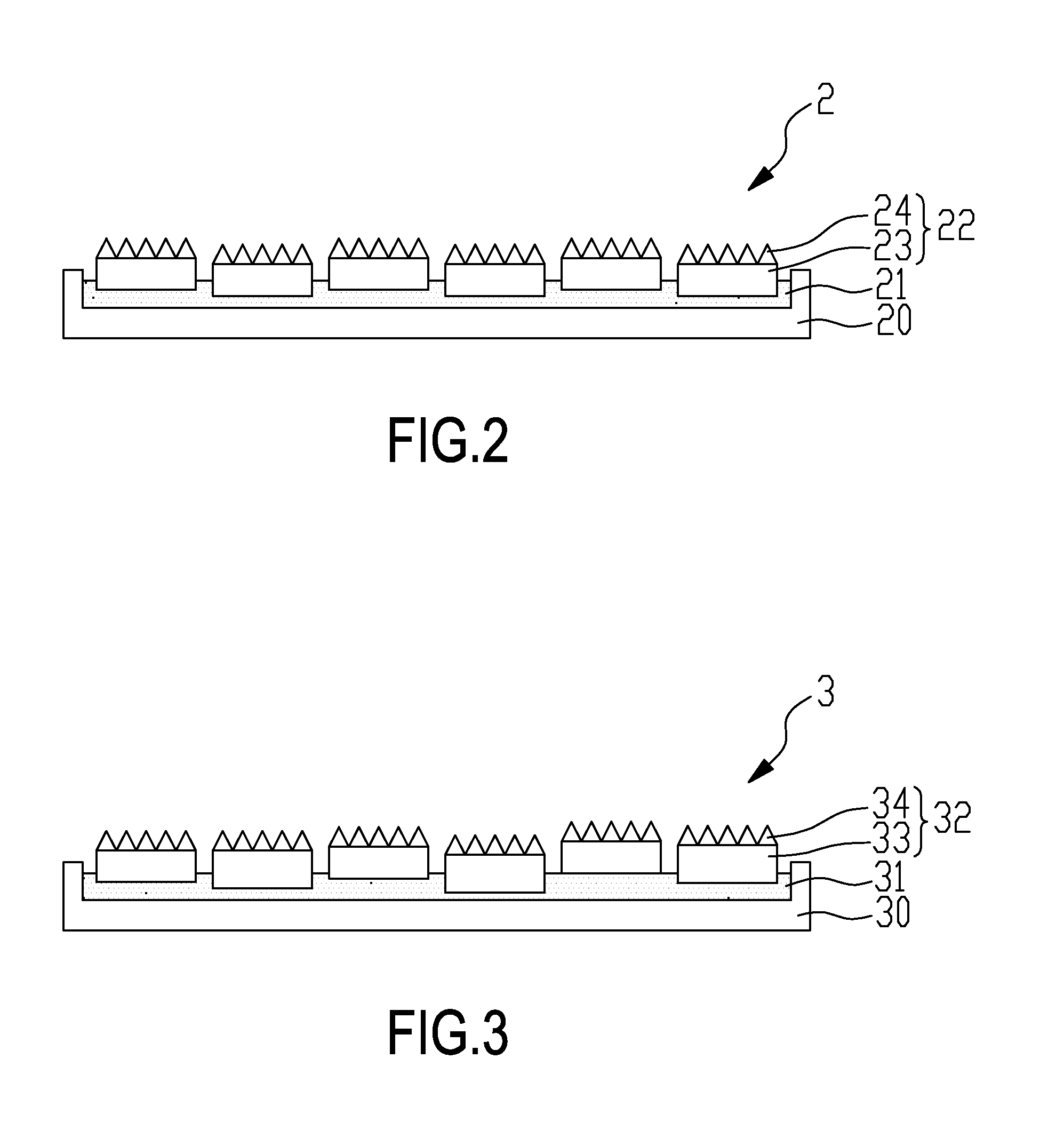

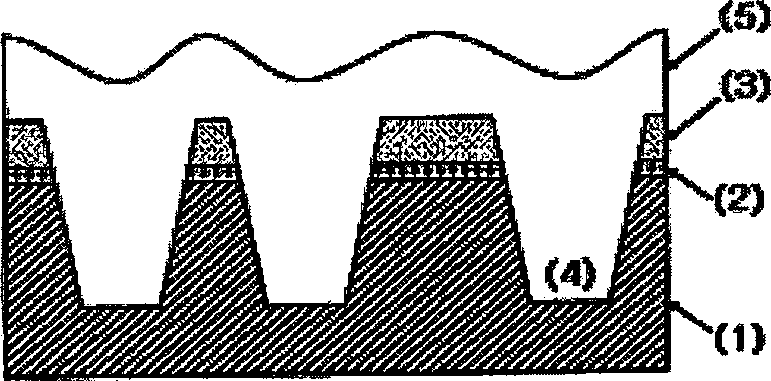

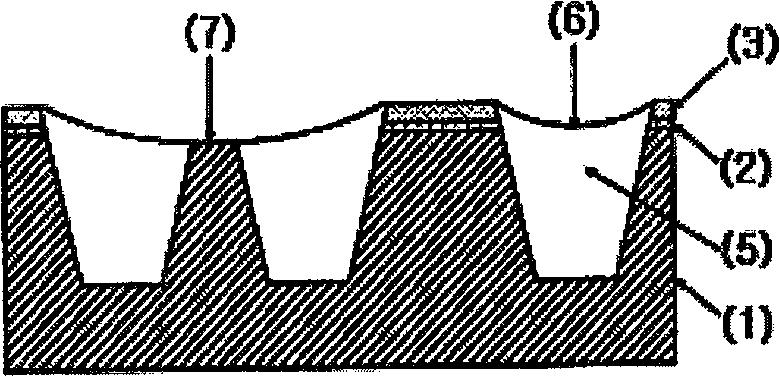

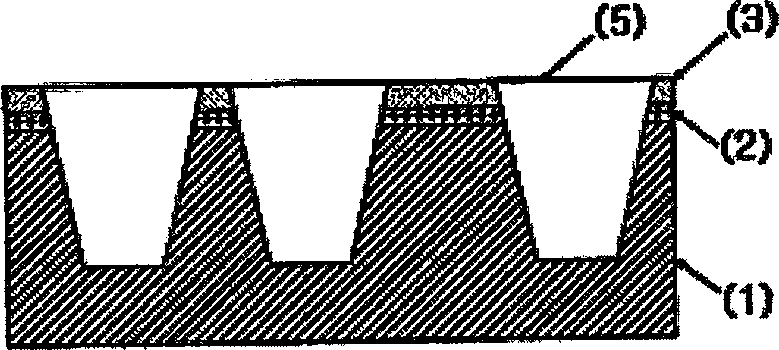

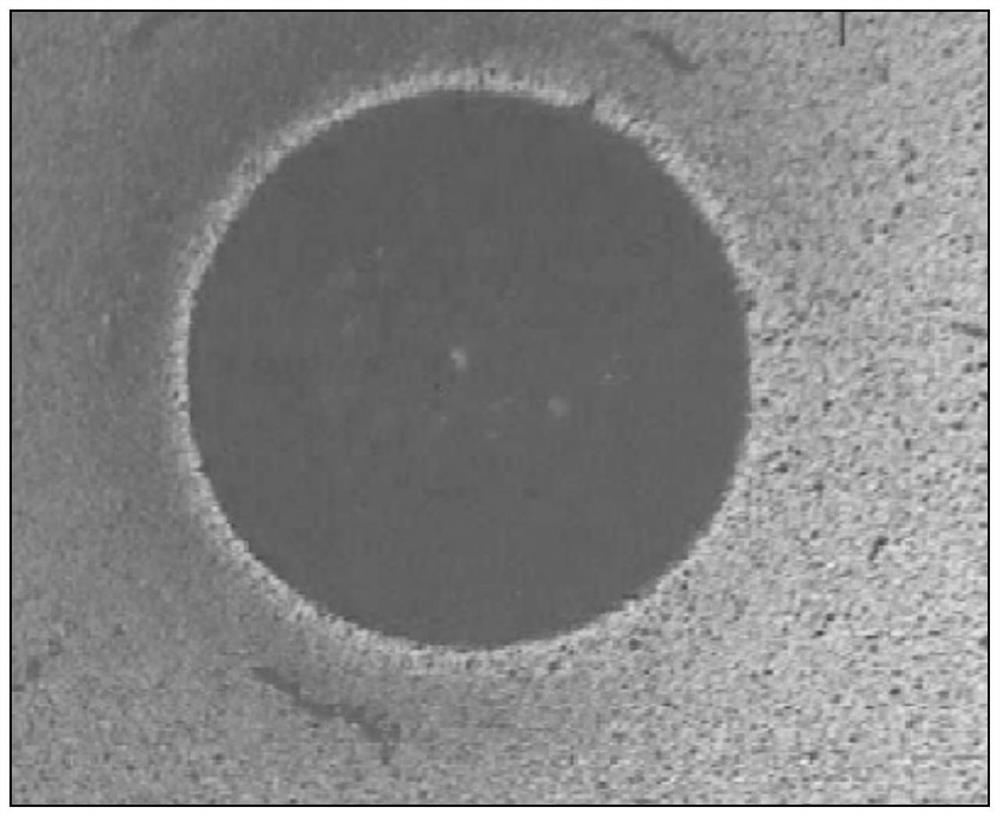

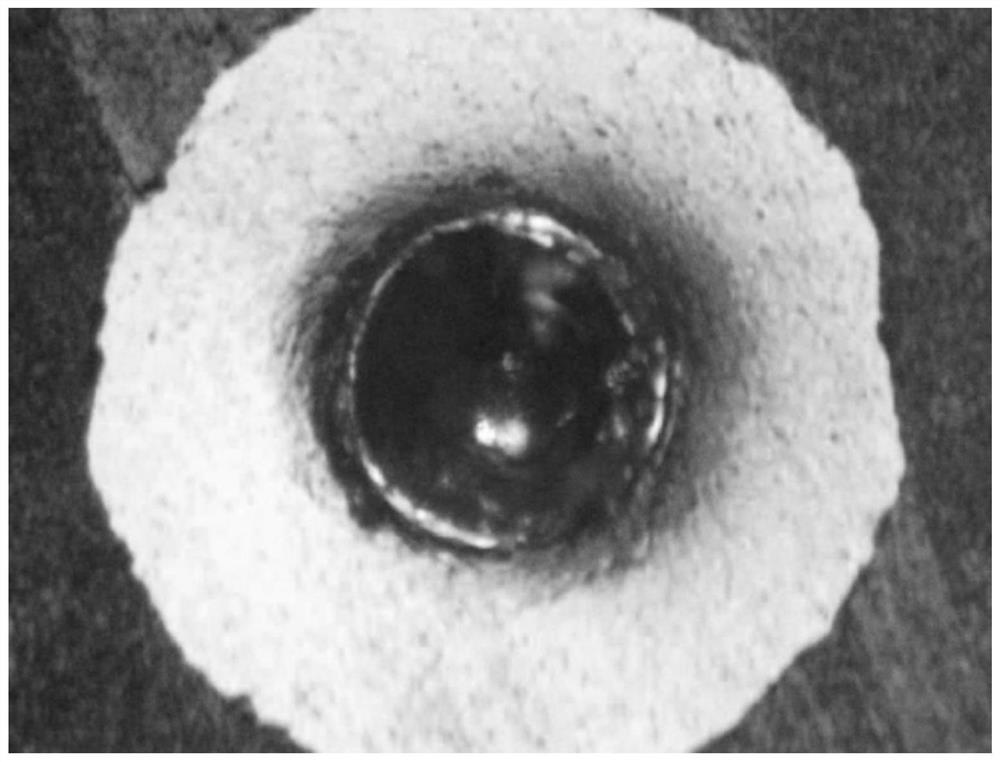

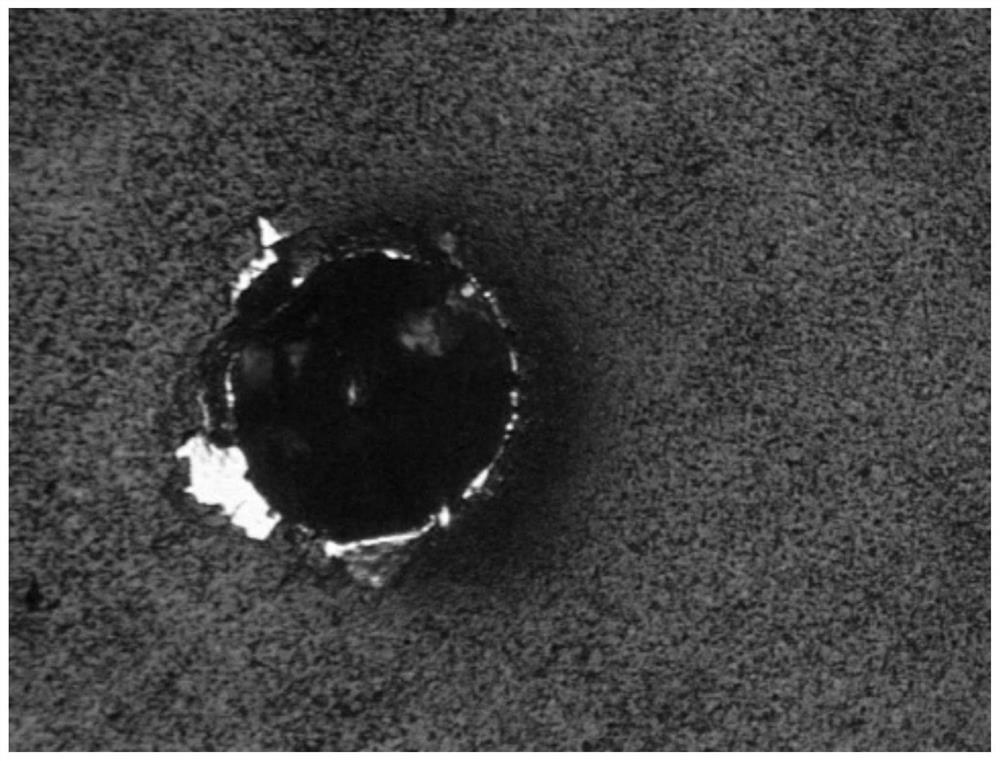

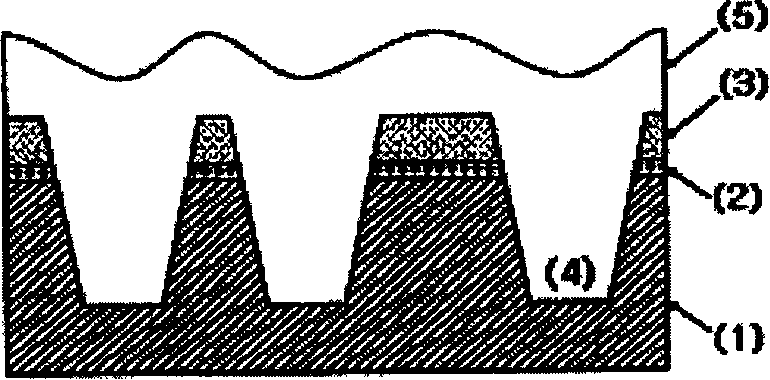

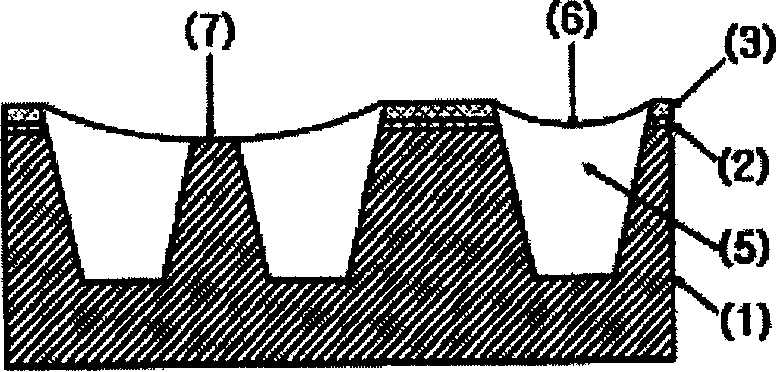

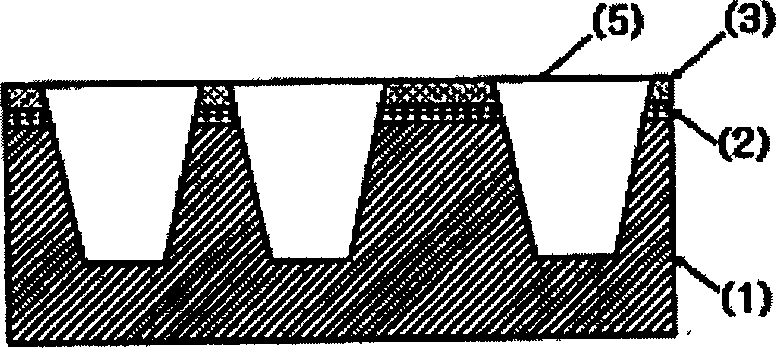

Chemical mechanical polishing conditioner having different heights

InactiveUS20150283672A1Improve polishing uniformityPrevent thermal deformationGrinding drivesBelt grinding machinesSurface roughnessSlurry

The present invention relates to a chemical mechanical polishing conditioner having different heights, comprising: a substrate; a binding layer disposed on the substrate; and multiple abrasive units placed on the binding layer. Each abrasive unit has an abrasive unit substrate and an abrasive layer which is a diamond film formed by chemical vapor deposition and has multiple abrasive tips. The abrasive units have a first tip height and a second tip height. The first tip height is different from the second tip height. The chemical mechanical polishing conditioner can adjust the surface roughness of the pad to be polished and improve the drainage of abrasive slurry.

Owner:KINIK

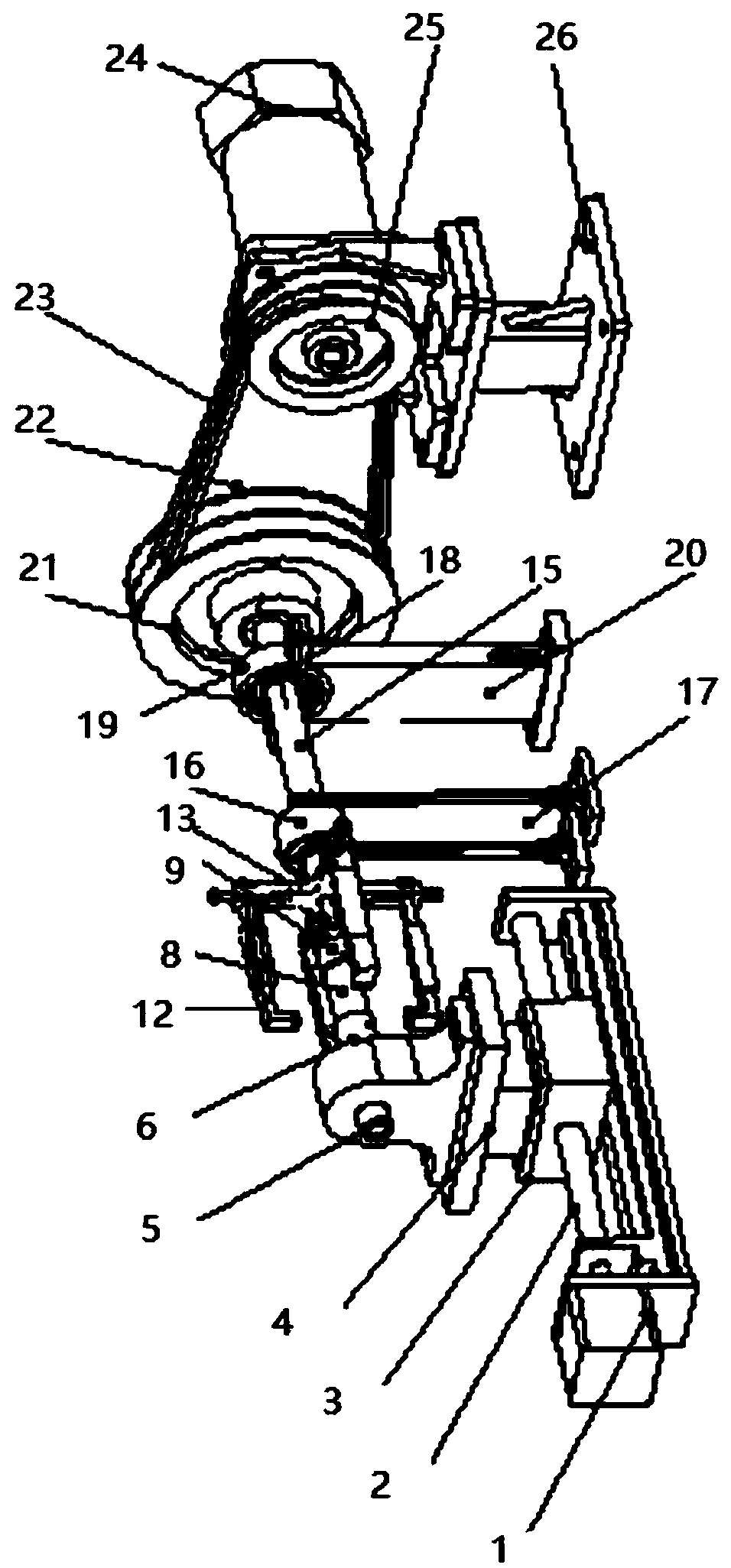

Rotary magnetic pole magnetorheology polishing device and method

InactiveCN108788937ASimple structurePolished evenlyGrinding drivesGrinding work supportsApparent viscosityReciprocating motion

The invention provides a rotary magnetic pole magnetorheology polishing device used for polishing the inner wall of a pipe-like workpiece. The rotary magnetic pole magnetorheology polishing device comprises a magnetorheology liquid feeding system, a workpiece supporting and driving mechanism and a magnetic pole rotating mechanism. Under the effect of a liquid pressure pump, magnetorheology liquidis pumped in an inner cavity of a pipe fitting from a liquid input pipe on a pipe fitting clamping device, by means of high pressure generated by the pressure pump, the magnetorheology liquid flows fast in the inner cavity of the pipe fitting, when flowing through a polishing area, the magnetorheology liquid generates the rheology effect due to the influence of the intensity of a magnetic field, shear yield stress and apparent viscosity are increased fast, under reciprocating motion of the workpiece and rotating motion of a rotating magnetic frame, compound motion between the workpiece and themagnetorheology liquid is achieved, and removal of materials on the inner surface of the workpiece is completed. The invention further provides a method adopting the device for carrying out polishing. The polishing device can polish the inner wall of a thin short non-magnetic pipe automatically, and has the advantages of being simple in structure, uniform in polishing, high in efficiency, high incontrollability of the polishing process, free of surface damage and the like.

Owner:NORTHEASTERN UNIV

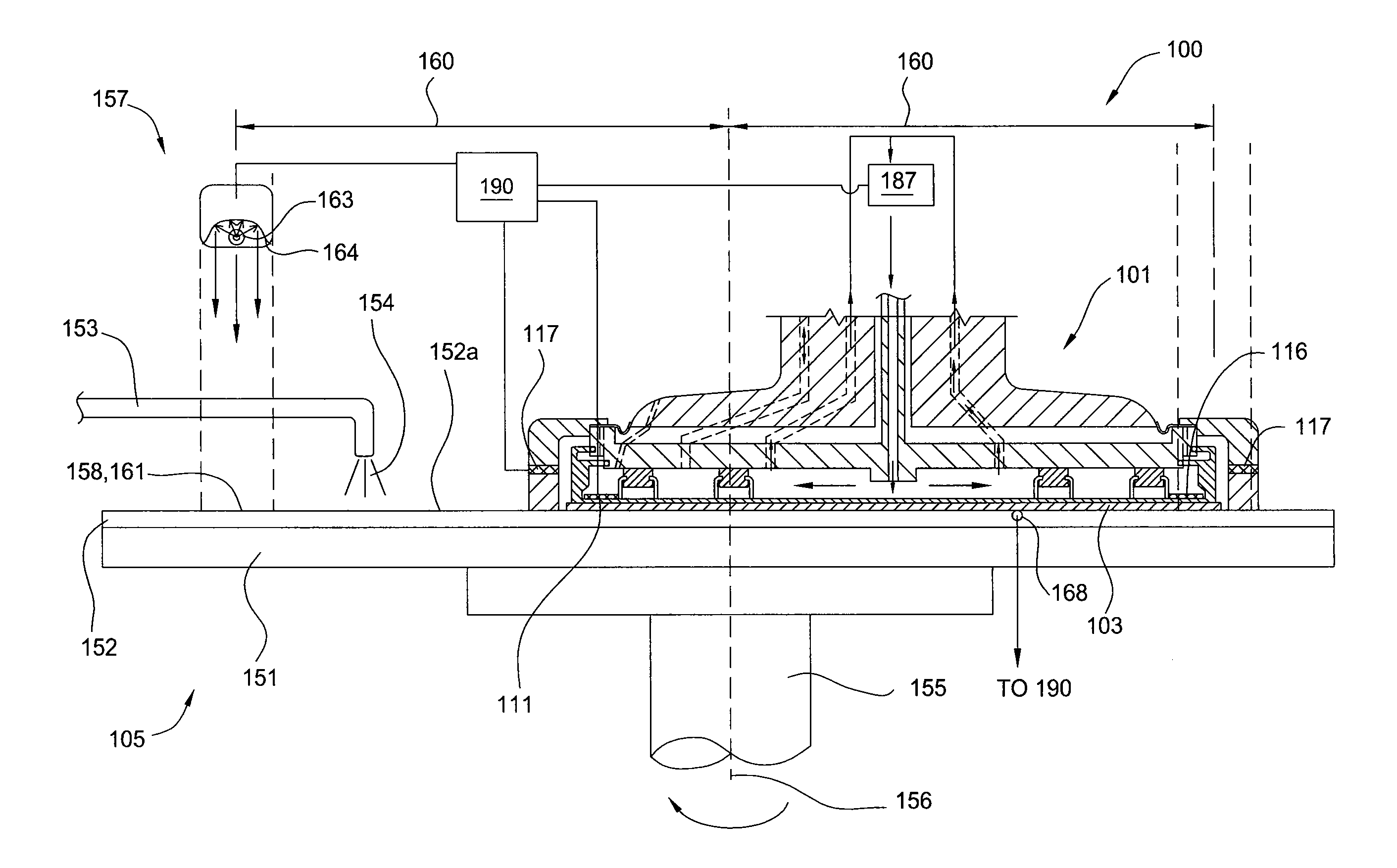

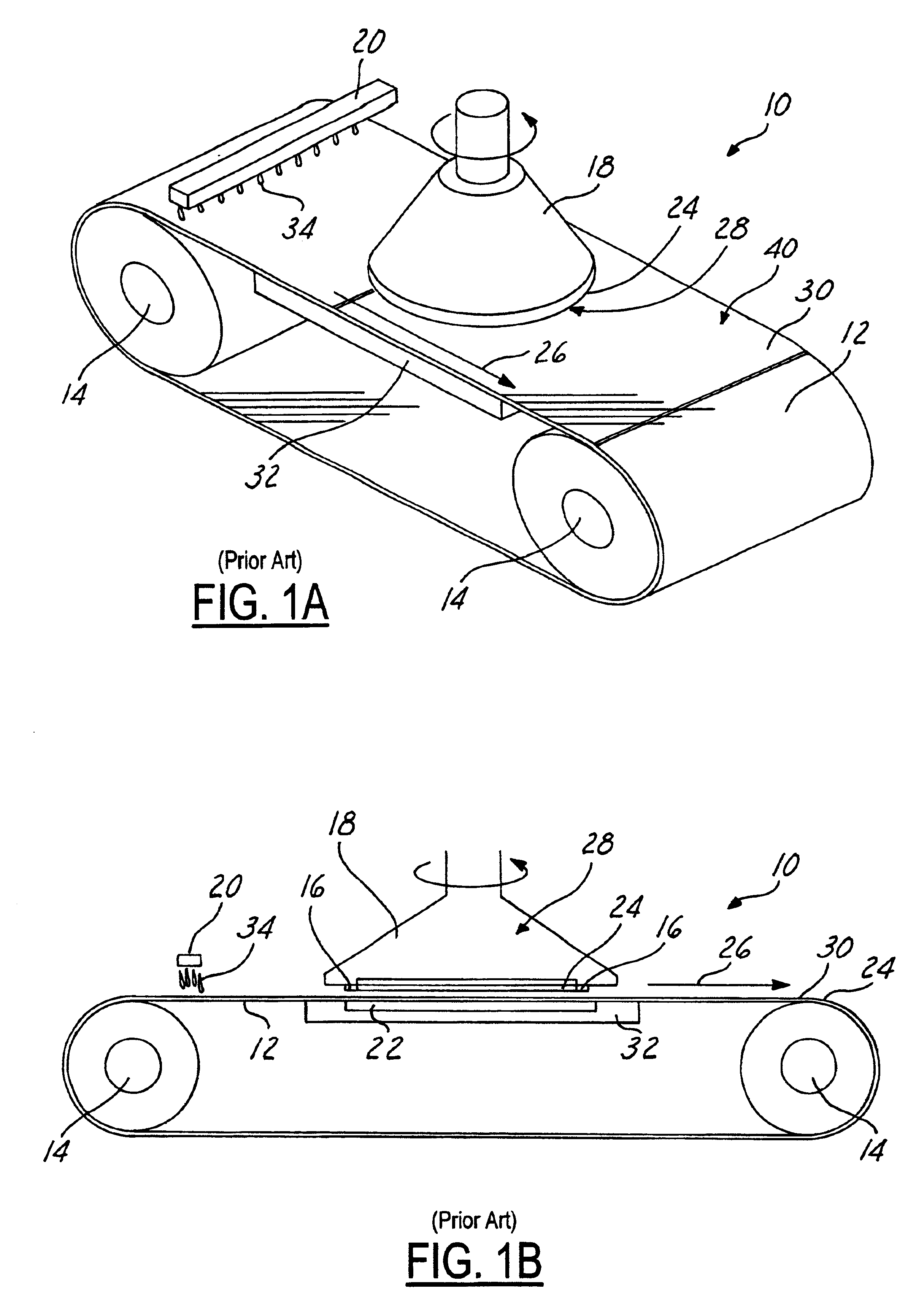

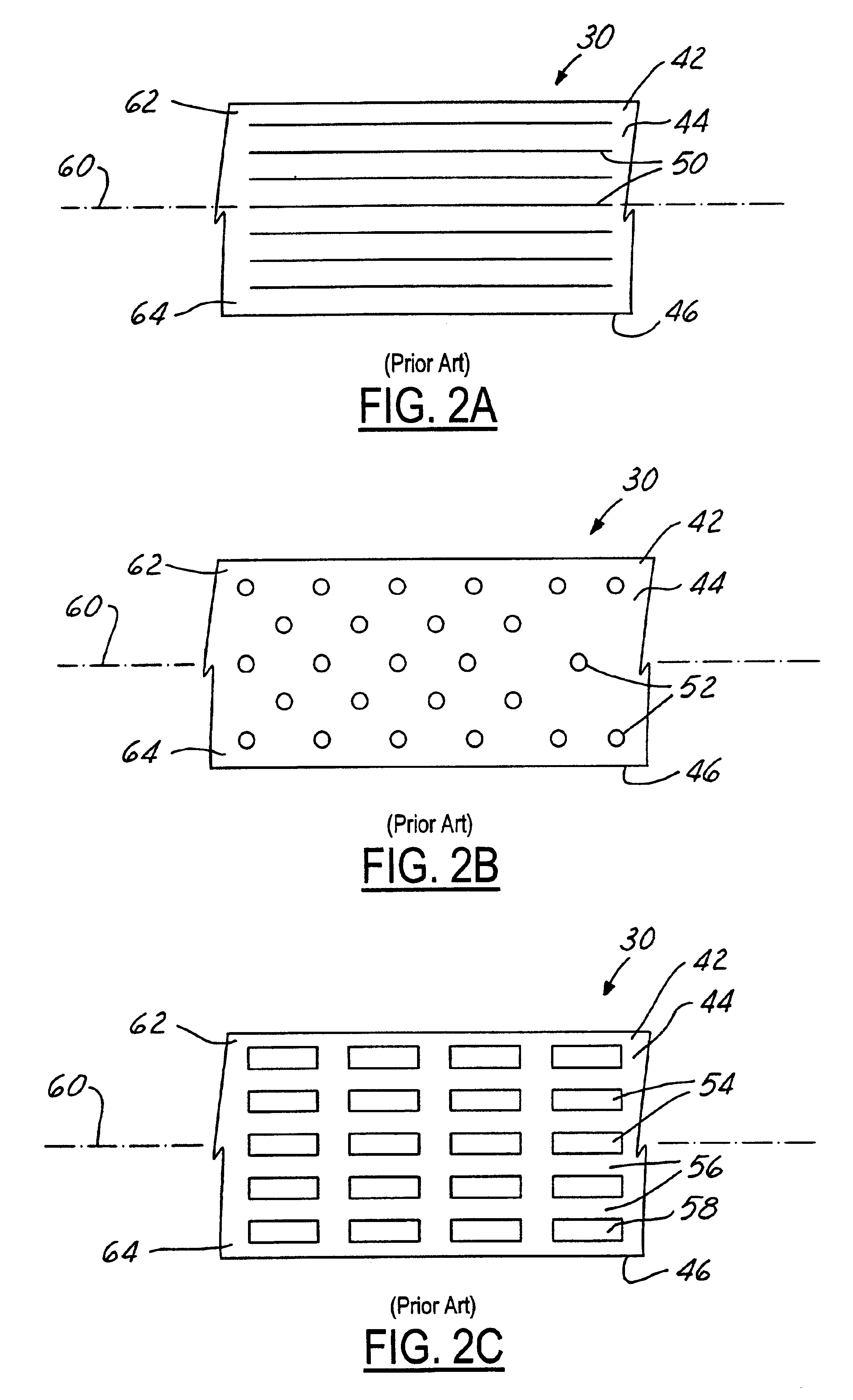

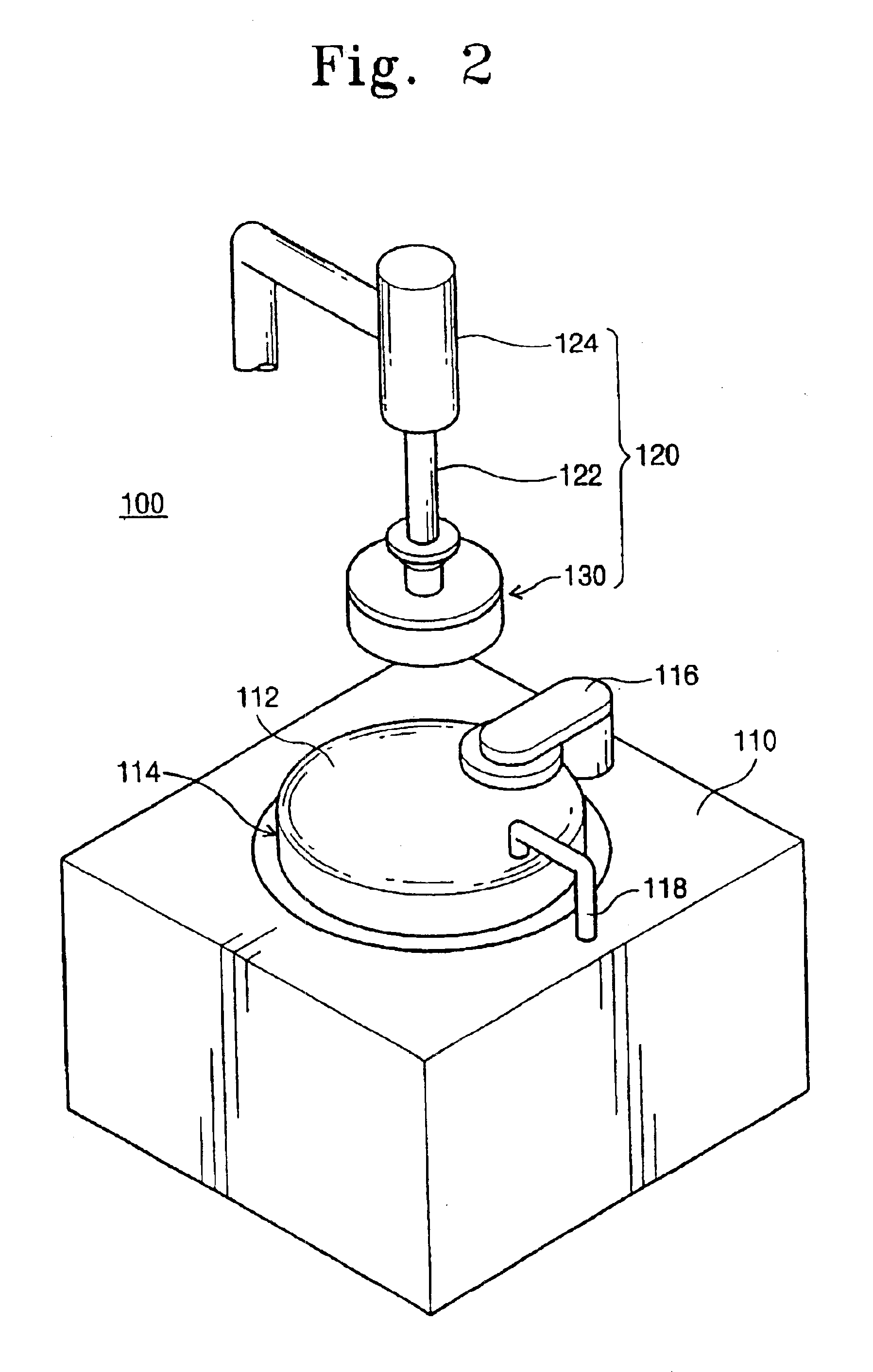

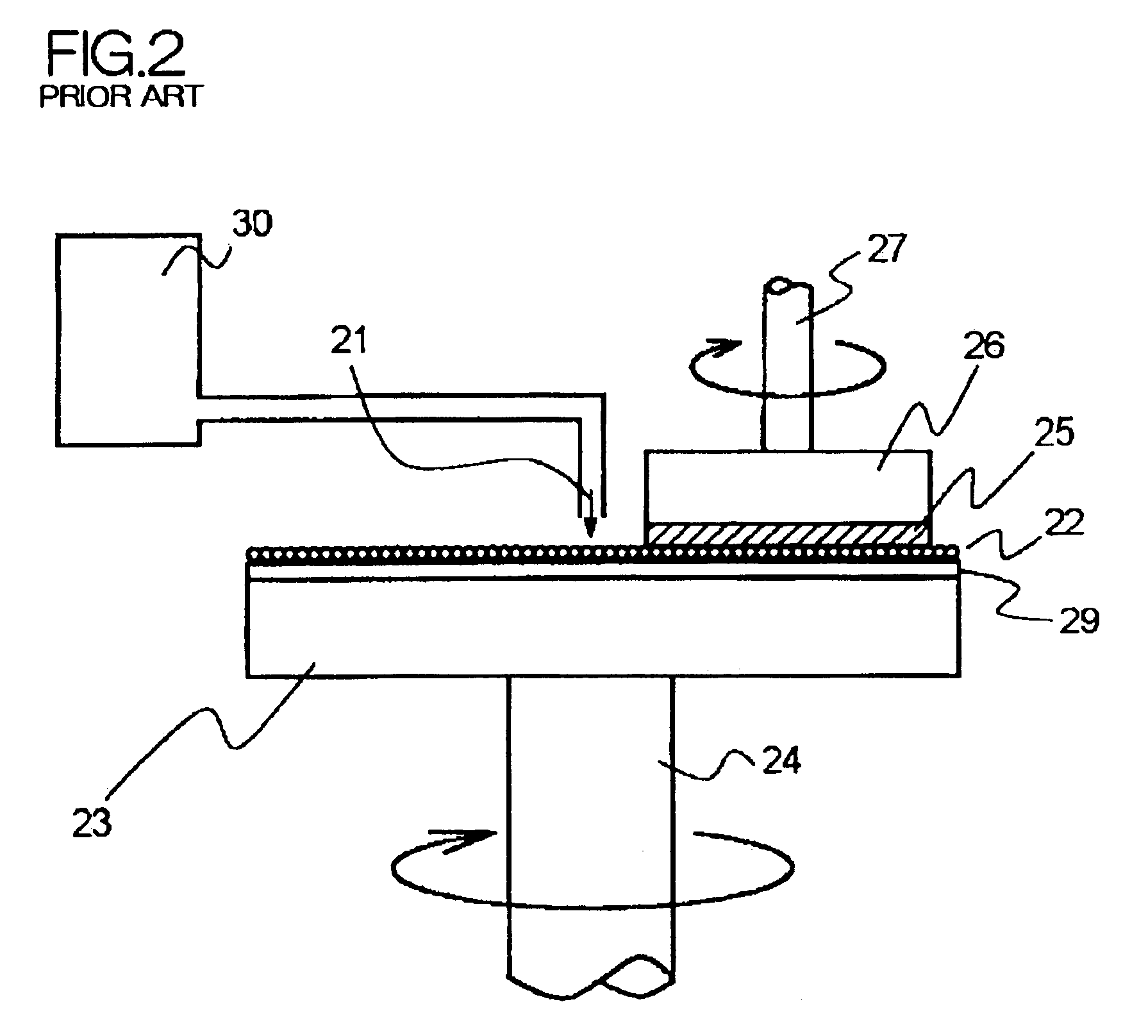

Linear chemical mechanical polishing apparatus equipped with programmable pneumatic support platen and method of using

InactiveUS6837774B2Improve polishing uniformityPolishing machinesRevolution surface grinding machinesMechanical engineering

A linear chemical mechanical polishing apparatus that is equipped with a programmable pneumatic support platen and a method for controlling the polishing profile on a wafer surface during a linear CMP process are disclosed. The programmable pneumatic support platen is positioned juxtaposed to a bottom surface of a continuous belt for the linear CMP apparatus and positioned corresponding to a position of the wafer carrier so as to force the polishing pad against the wafer surface to be polished. The support platen has a predetermined thickness, a plurality of apertures through the thickness and a plurality of openings in a top surface in fluid communication with a gas source through the plurality of apertures.

Owner:TAIWAN SEMICON MFG CO LTD

Ceria serosity combination with reinforced polishing uniformity

InactiveCN1872900AReduce saggingReduce erosionOther chemical processesSemiconductor/solid-state device manufacturingSlot insulationAlcohol

The invention discloses a chemical mechanical polishing slurry compound. It comprises: ceric oxide grinding agent; polycarboxylic acids or polycarboxylate with weight average molecular weight being 50,000-500,000; alcohol compound and water. The optimum proportion by weight of components in relative to total slurry compound are: ceric oxide grinding agent 0.1-20%, polycarboxylic acids or polycarboxylate 0.01-20%, alcohol compound 0.001-10%, and the pH of said slurry is 5-10. The CMP slurry compound is processed with STI (shallow slot insulation) method to form multiplayer construction and increase polishing uniformity and inhibit dent and corrosion of chip.

Owner:DONGJIN SEMICHEM CO LTD

Polishing head of chemical mechanical polishing apparatus and polishing method using the same

InactiveUS6881135B2Improve polishing uniformityHigh polishing uniformityPolishing machinesRevolution surface grinding machinesCompound (substance)Membrane configuration

A chemical mechanical polishing (CMP) apparatus includes a polishing head that is composed of a carrier and a membrane, and is positioned on a polishing pad of a supporting part. The polishing head has a supporter installed at an internal center of the carrier, a chucking ring positioned between the carrier and the supporter, and means for moving the chucking ring up and down in a vertical direction. The supporter forms a sealed space together with the membrane, and the chucking ring chucks the wafer in vacuum.

Owner:SAMSUNG ELECTRONICS CO LTD

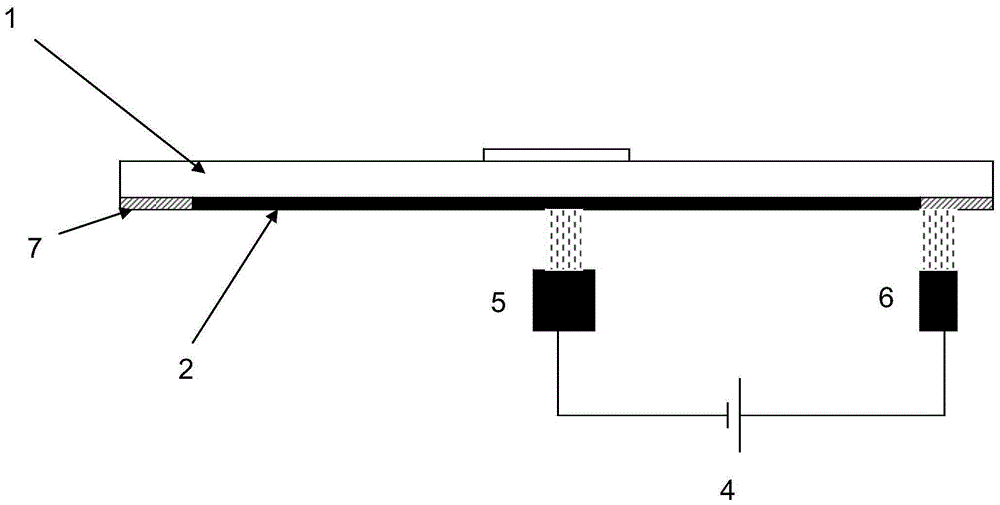

Novel electrochemical polishing device

InactiveCN104894634AImprove polishing uniformityElectric field stabilizationConductive materialsElectrochemistry

The invention discloses a novel electrochemical polishing device, which comprises: a wafer chuck, an electrolyte solution supply apparatus and a polishing power circuit formation apparatus. The wafer chuck clamps a wafer, and a metal layer is distributed on the wafer surface. The electrolyte solution supply apparatus includes a nozzle, which sprays the electrolyte solution to a metal layer on the wafer surface. The polishing power circuit formation apparatus consists of a polishing disk and a power supply. The polishing disk is made of a conductive material, the bottom surface of the polishing disk and the wafer surface are in parallel arrangement, the polishing disk and the nozzle are in synchronous movement, the anode of the power supply and the wafer chuck are in electric connection, and the cathode of the power supply and the polishing disk are in electric connection. According to the invention, the polishing disk is set and the polishing disk and the power supply are in electric connection so as to ensure that in any region of the wafer surface, a stable electric field can be formed between the polishing disk and wafer, and a current circuit is formed between the polishing disk and wafer through the electrolyte solution, thus improving the wafer surface polishing uniformity.

Owner:ACM RES SHANGHAI

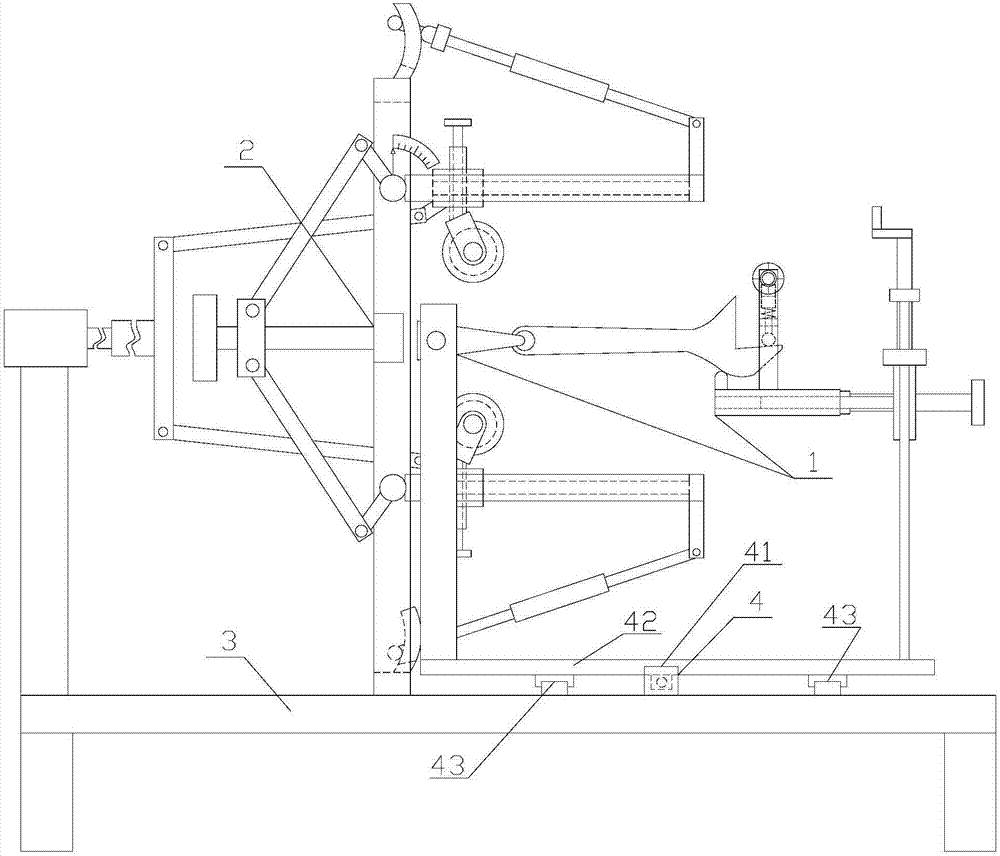

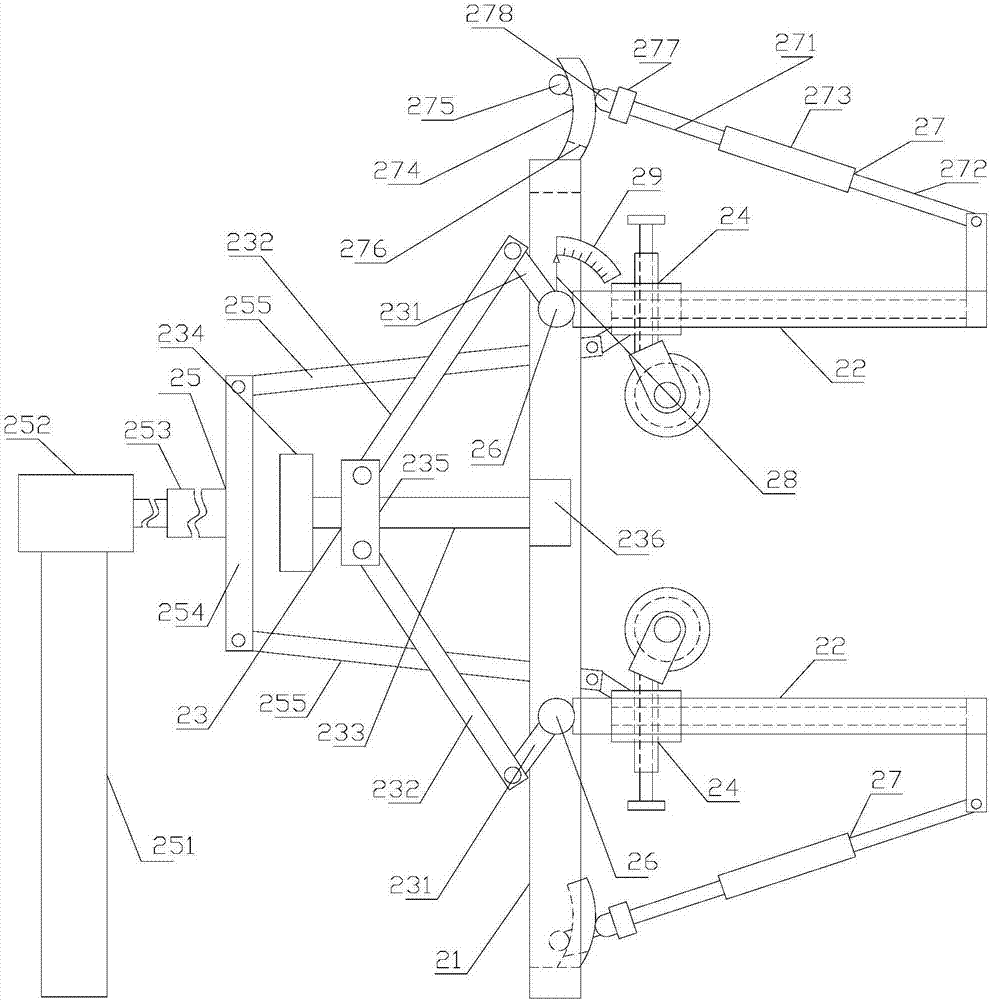

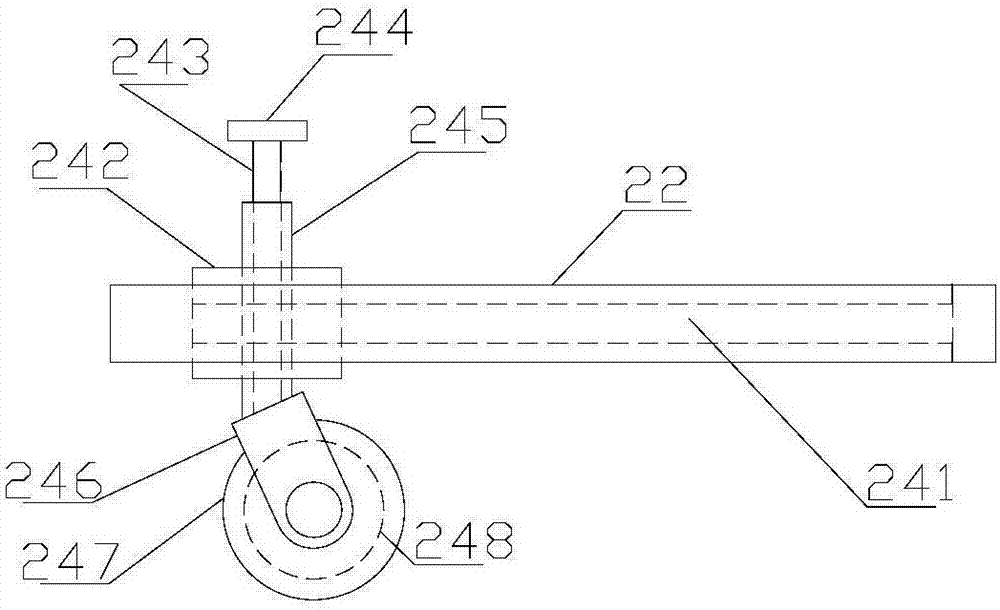

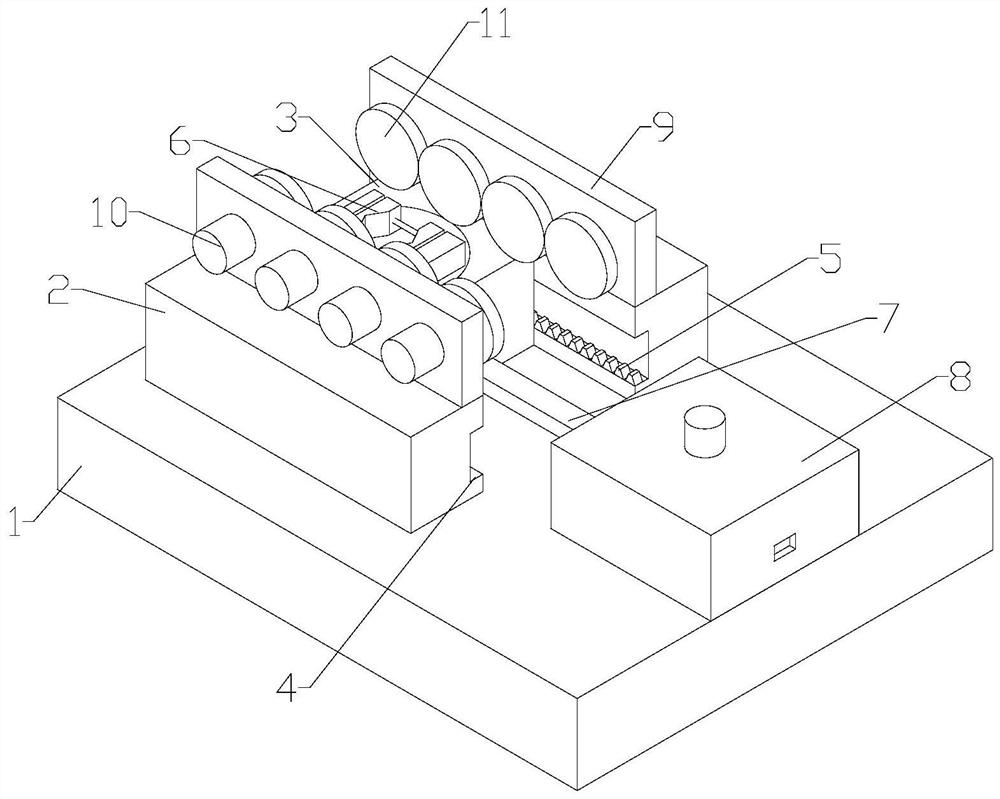

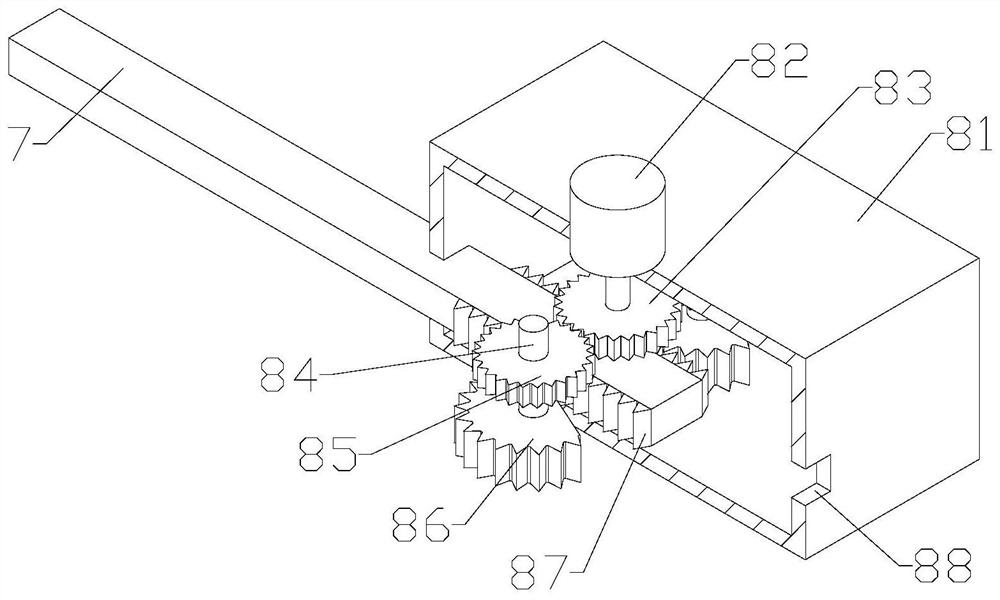

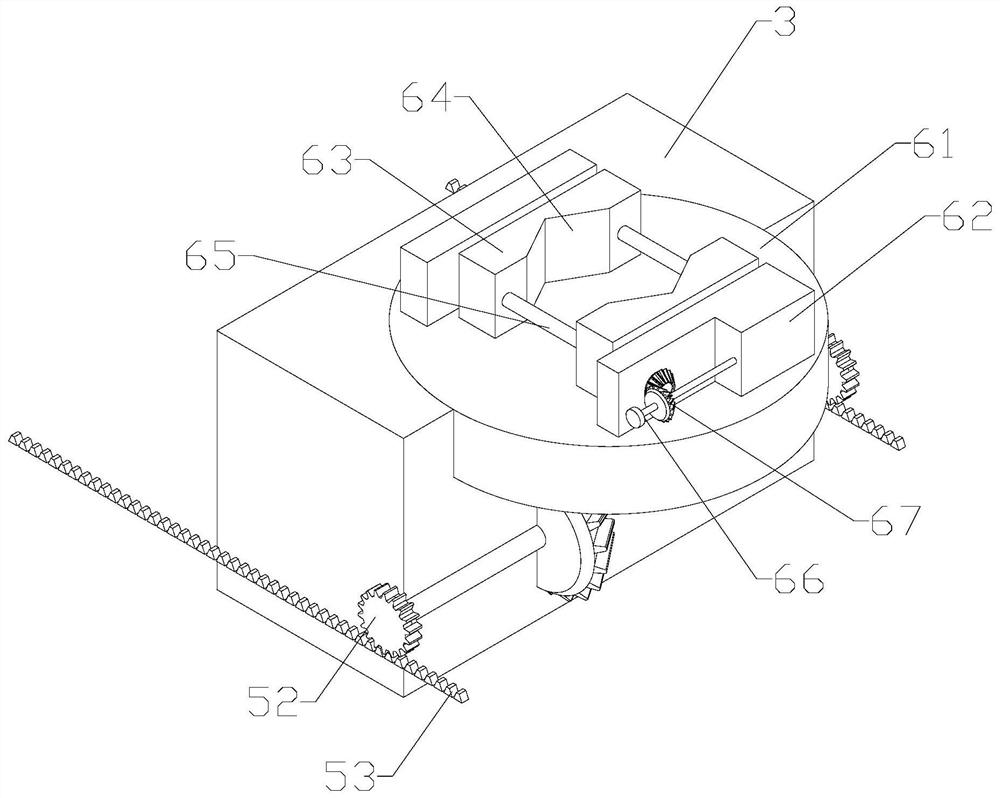

Improved spanner polishing machine

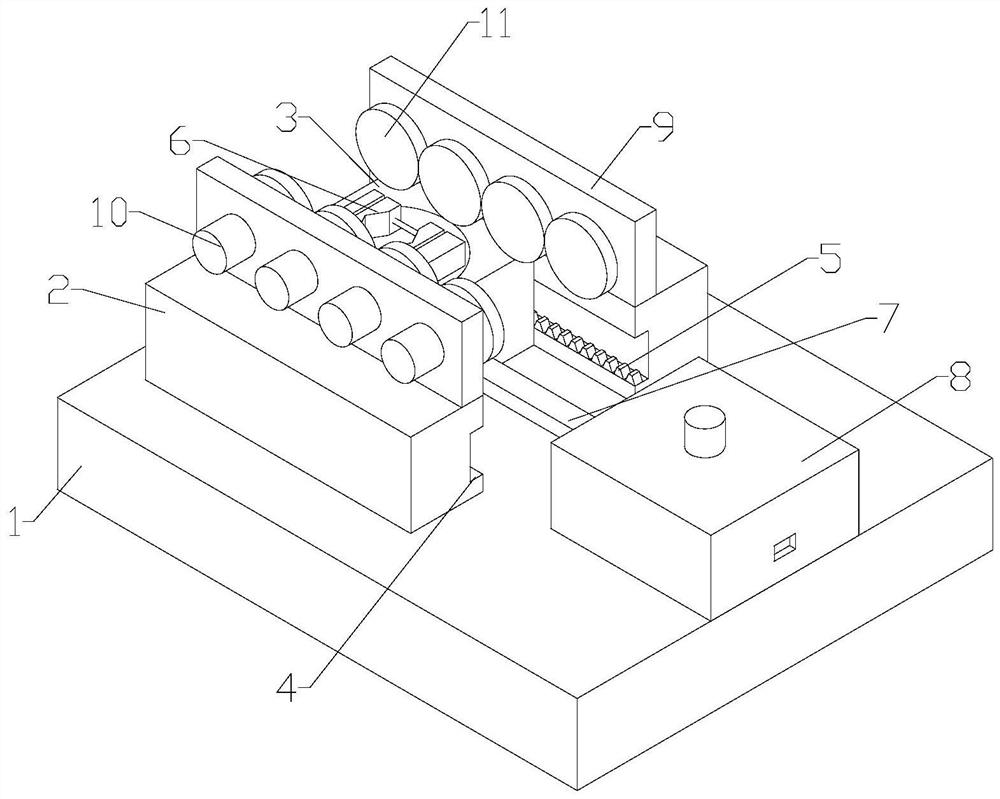

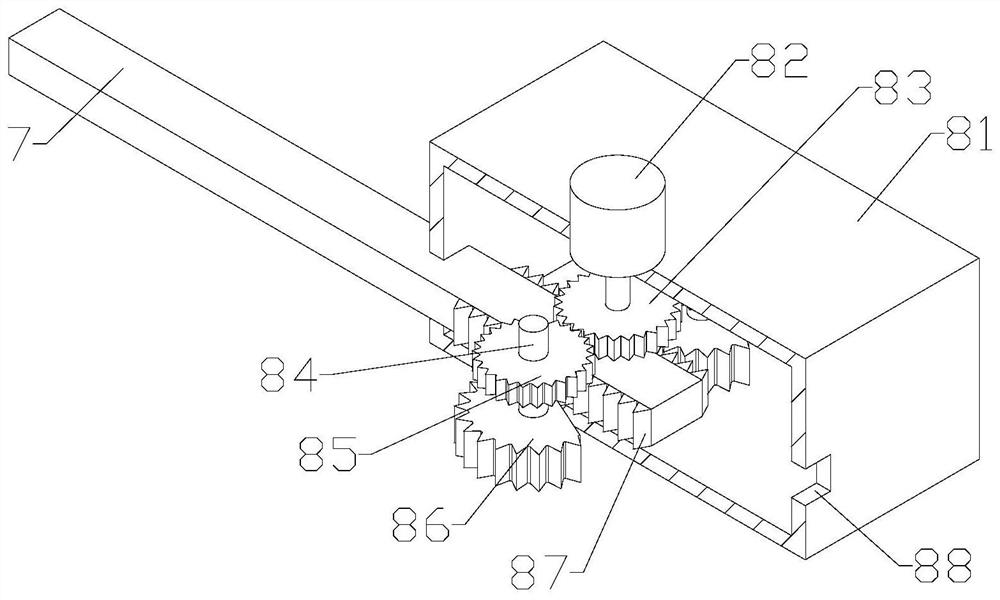

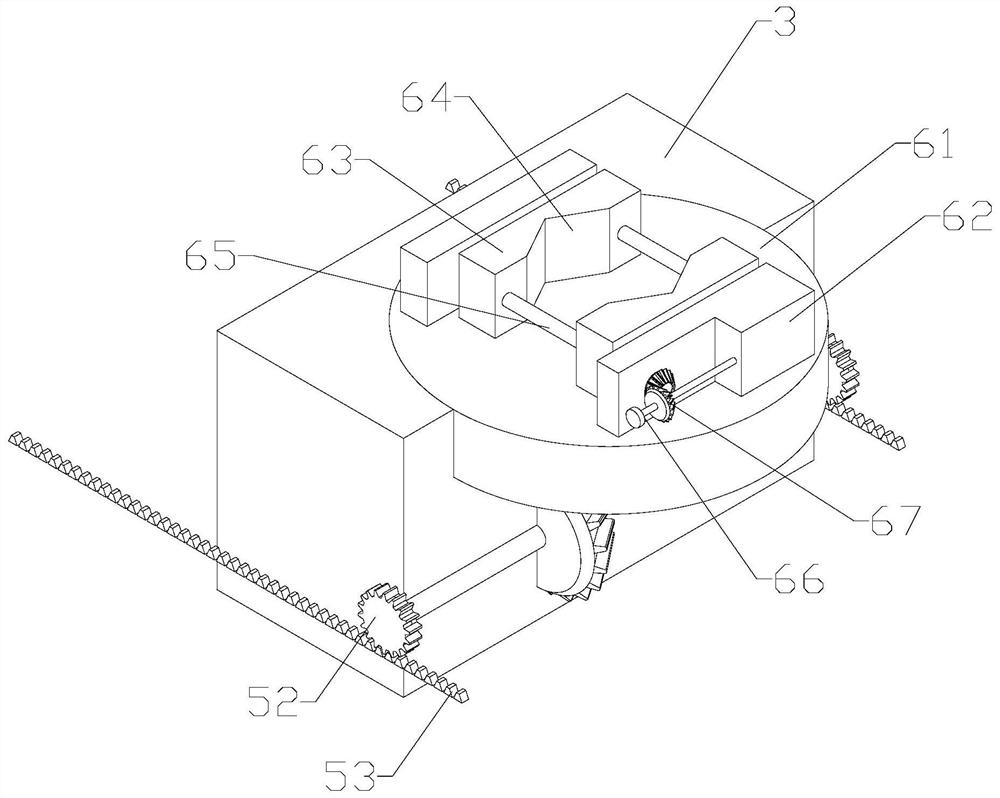

PendingCN107378736AConstant distanceGuaranteed level statusGrinding carriagesPolishing machinesEngineeringWrench

The invention discloses an improved spanner polishing machine which comprises a spanner fixing device, a polishing device, a frame and a movable seat mechanism, the movable seat mechanism and the polishing device positioned in front of the movable seat mechanism are arranged on the frame, a spanner fixing device is arranged on the movable seat mechanism and comprises a lifting mechanism, an adjustable fixing mechanism and a fixing device, the adjustable fixing mechanism is used for fixing spanner head, the fixing device for fixing a free end of a spanner handle, the lifting mechanism and the fixing device are arranged on the movable seat mechanism, and the adjustable fixing mechanism is arranged on the lifting mechanism and comprises a placing seat, two sliding rods, an adjusting screw, an adjusting disk, two supports, a connector, two sliders, a compressing body, two springs, two block bodies, a screw body, two supporting bodies, a mounting seat and a rotating disk. Compared with the prior art, the polishing machine is applicable to spanners with various sizes, and working efficiency and polishing uniformity are improved.

Owner:HAIYAN XINGCHEN HANDTOOLS

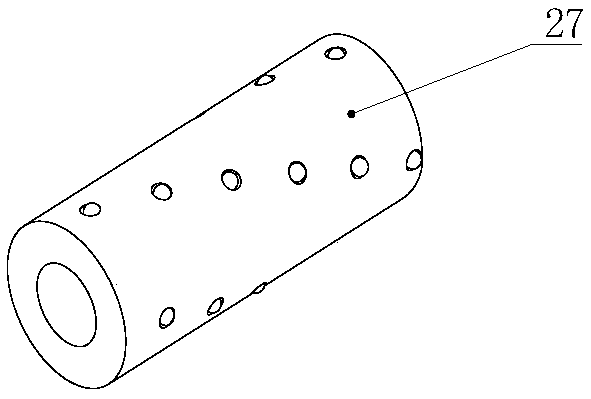

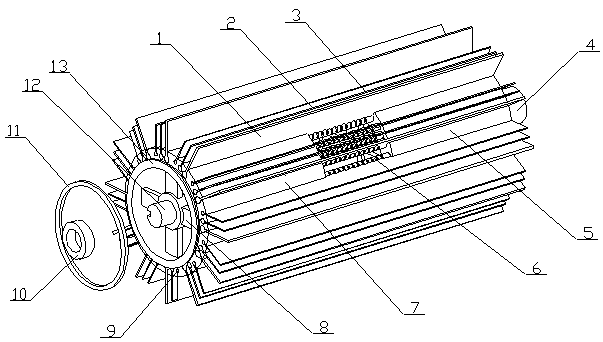

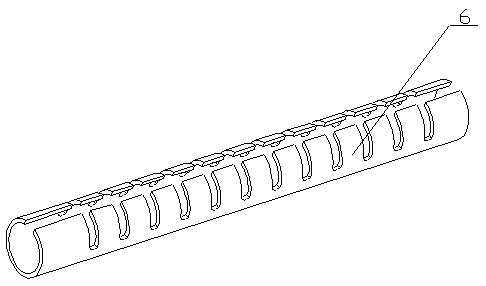

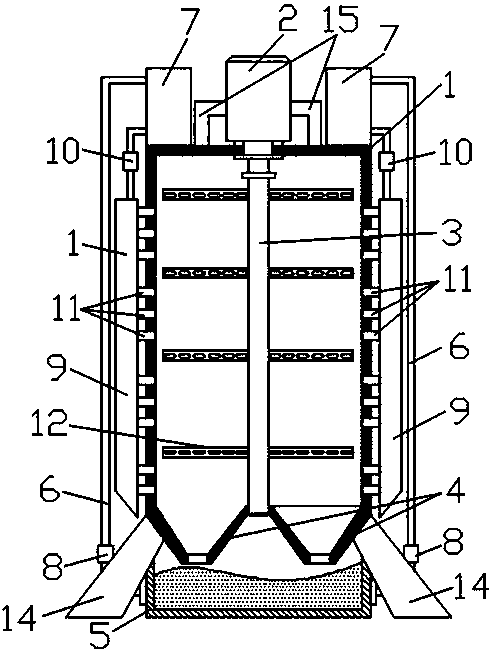

Grinding roller of polishing machine

ActiveCN109015255ASimple structureImprove polishing uniformityBelt grinding machinesDrive shaftEngineering

The invention discloses a grinding roller of a polishing machine. According to the grinding roller, two separated grinding roller bodies are connected through a connection rod, and are rotated synchronously through a drive shaft, the connection rod is bent by adjusting the distance between the two separated grinding roller bodies, an arc groove is formed between the two grinding roller bodies, andthus plates can be polished and ground. The grinding roller of the polishing machine is characterized in that two supporting plates are arranged in the main grinding roller body and located at the two ends of the main grinding roller body separately; each supporting plate is formed by combining a center circular ring and four supporting arms arranged on the outer side wall of the center circularring at equal angles; the center circular rings and the main grinding roller body are coaxial; a rectangular protrusion is arranged on the inner side wall of each center circular ring, and the rectangular protrusions on the two supporting plates are located on the same straight line; a plurality of mounting grooves are formed in the outer side walls of the main grinding roller body and distributedalong the circumference and extend in the axial direction of the main grinding roller body; every three mounting grooves fall into one group, and the widths of the three mounting grooves of each group are gradually decreased; a chuck is disposed at the end face of one end of the main grinding roller body.

Owner:安徽省汇金木业股份有限公司

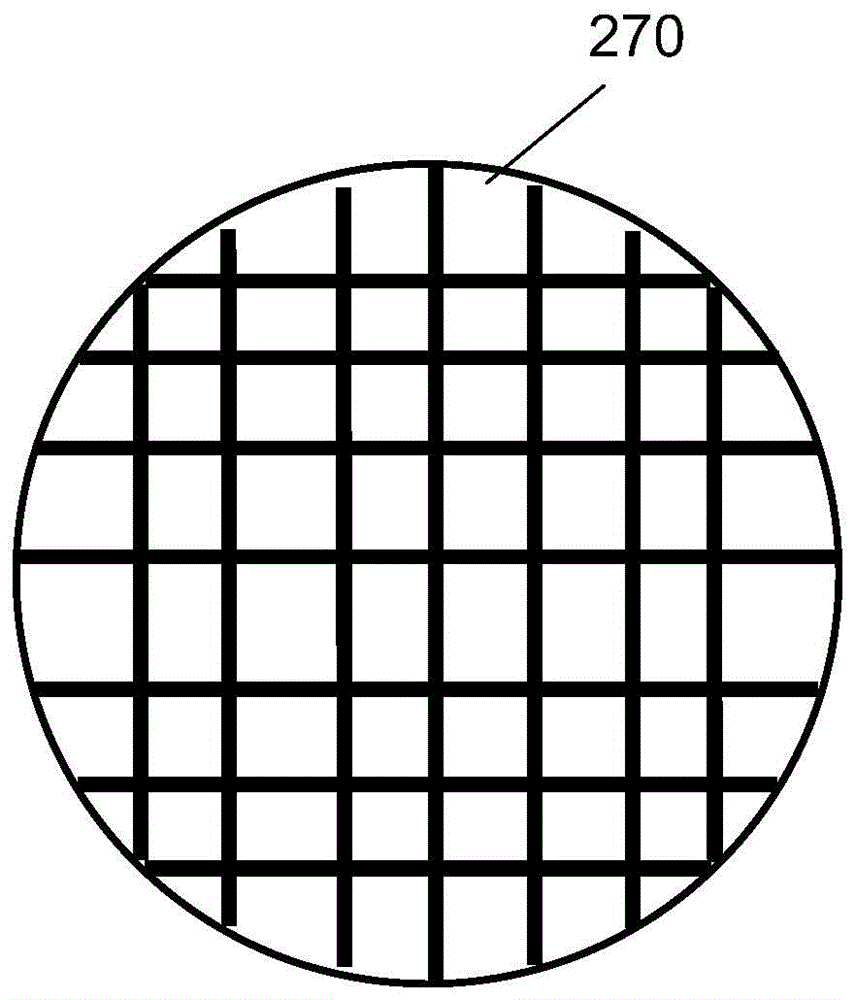

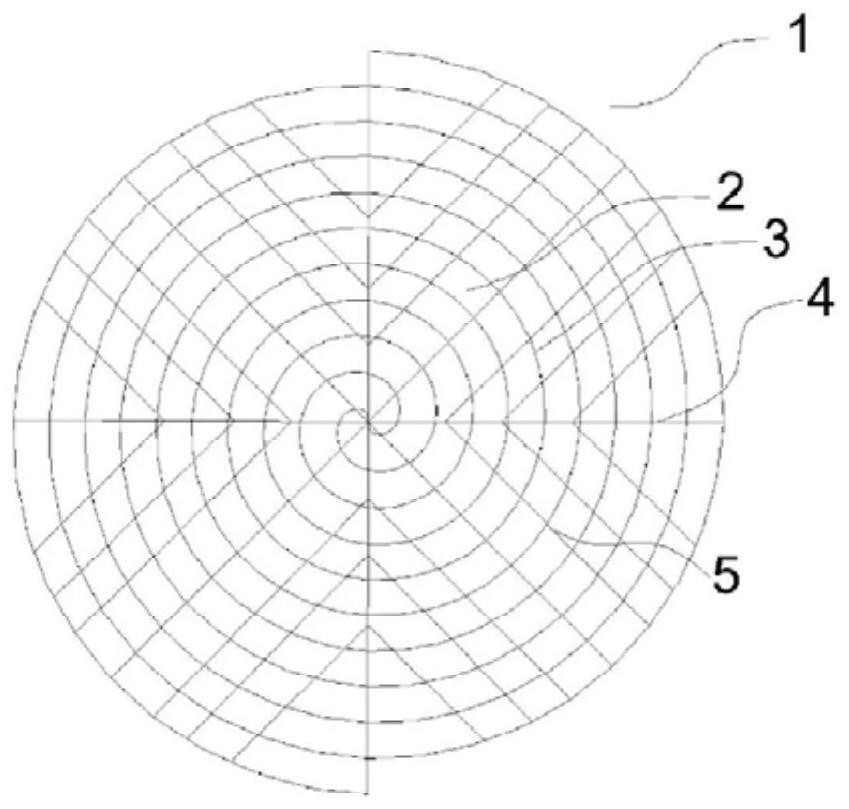

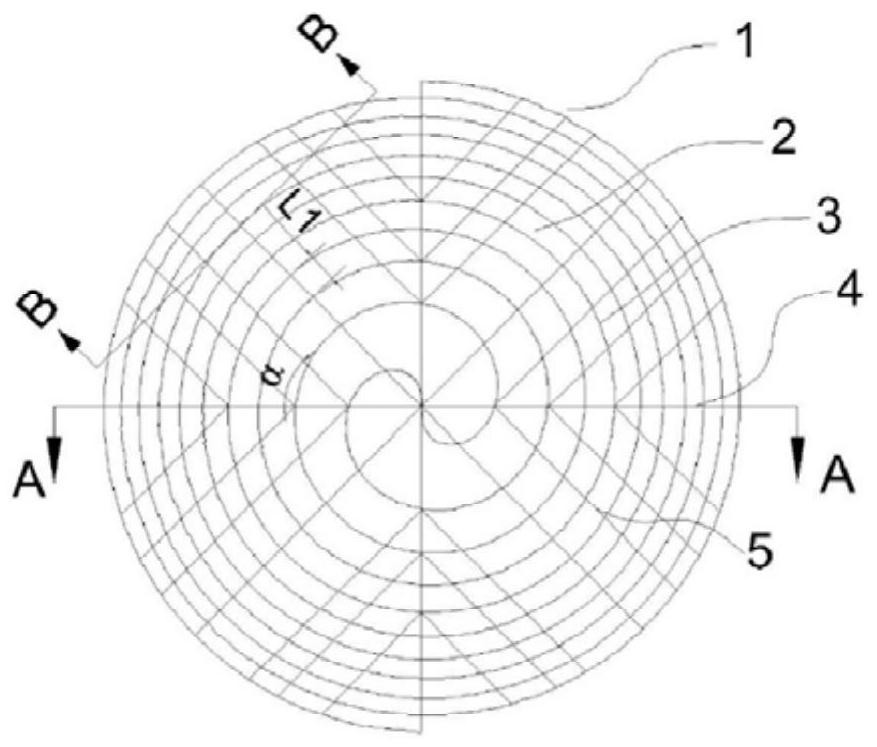

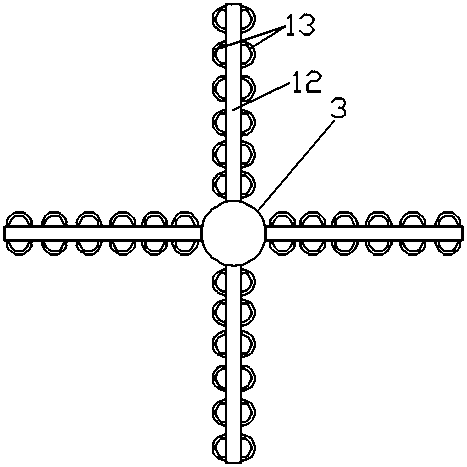

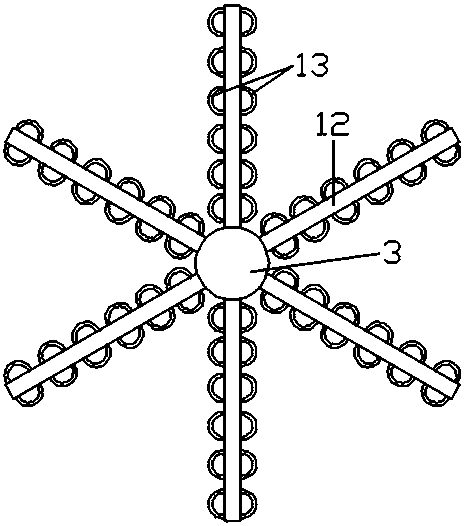

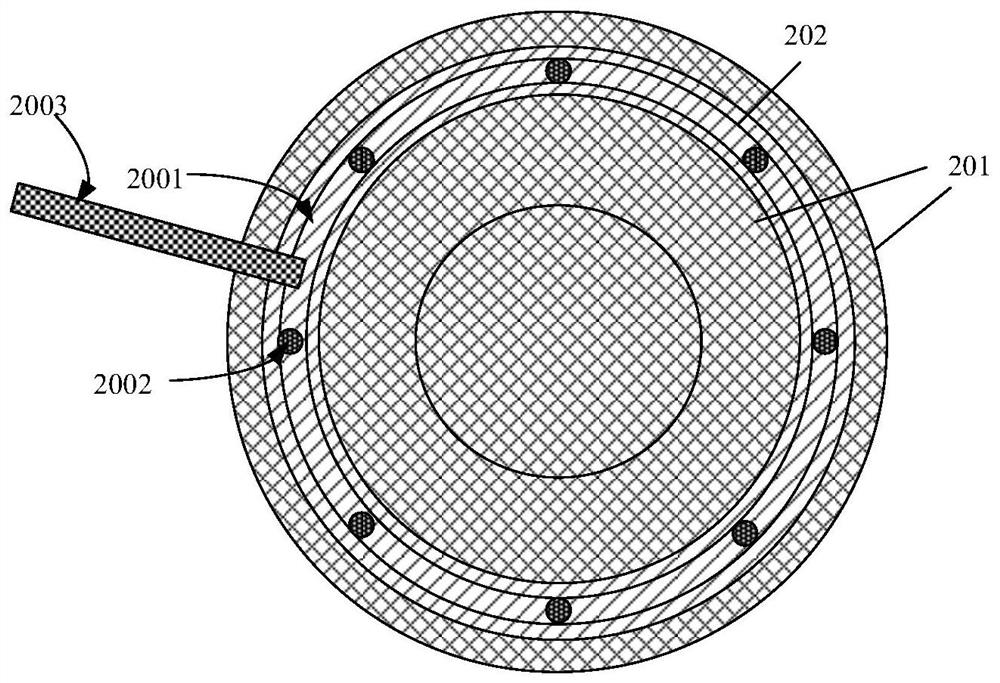

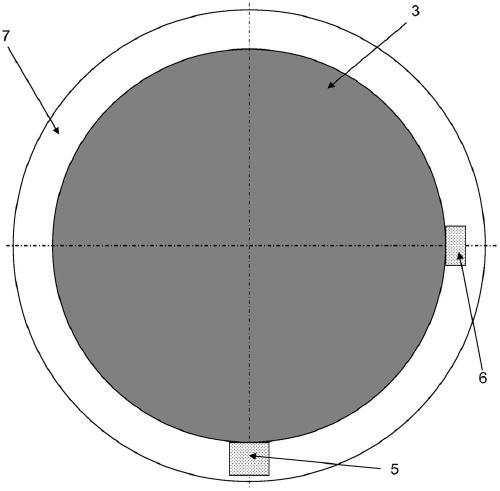

Polishing pad with grooves in surface

PendingCN113752160AControl Tangential AccelerationIncrease storage capacityLapping toolsPolishingRetention time

The invention relates to the technical field of chemical-mechanical polishing, and discloses a polishing pad with grooves in the surface. The polishing pad comprises a circular polishing layer, and the polishing layer is provided with first grooves, second grooves and third grooves; the first grooves are located in the surface of the polishing layer and spirally extend to the edge of the polishing layer with the circle center of the polishing layer as the starting point; the second grooves are located in the surface of the polishing layer and extend to the edge of the polishing layer in the radial direction with the circle center of the polishing layer as the starting point; and the third grooves are located in the surface of the polishing layer and extend to the edge of the polishing layer with certain points on the second grooves as the starting point. According to the polishing pad, the tangential acceleration of a polishing solution can be regulated and controlled through the spirally-extending first grooves, the polishing solution is uniformly distributed, the removal rate is improved, the radial acceleration of the polishing solution can be regulated through the radially-extending second grooves and the third grooves forming Y shapes with the second grooves, the speed change of the polishing solution is delayed, and the retention time of the polishing solution is prolonged.

Owner:广东粤港澳大湾区黄埔材料研究院

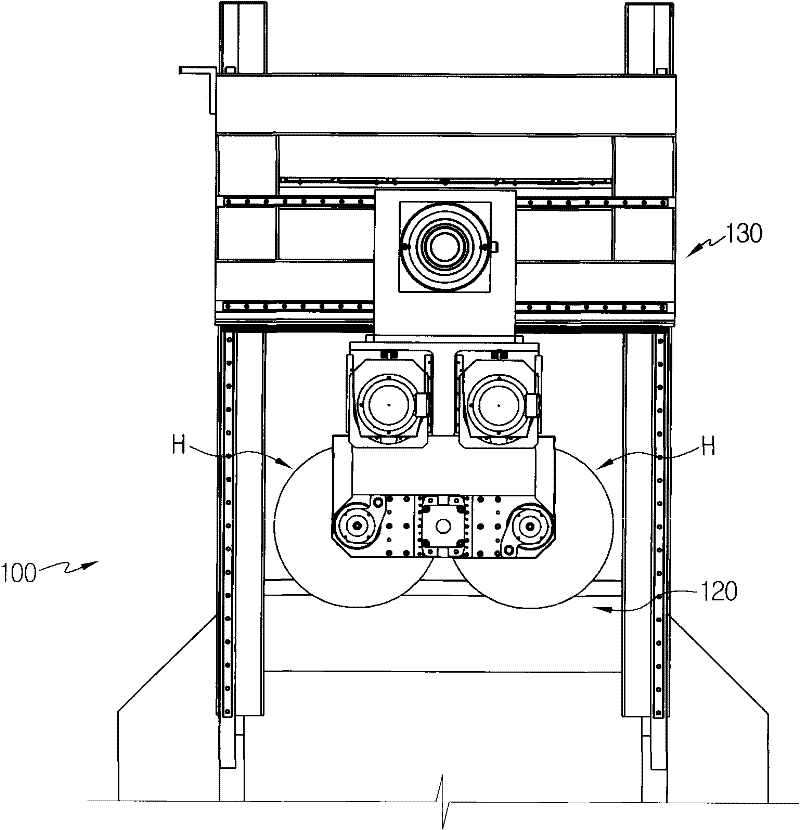

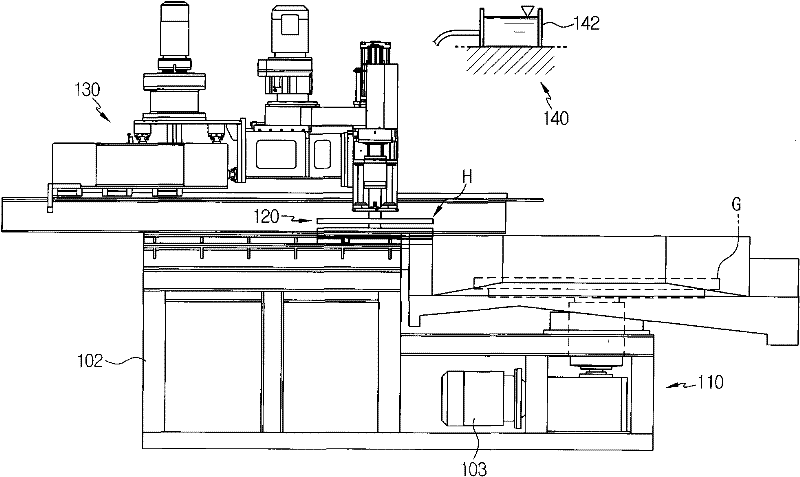

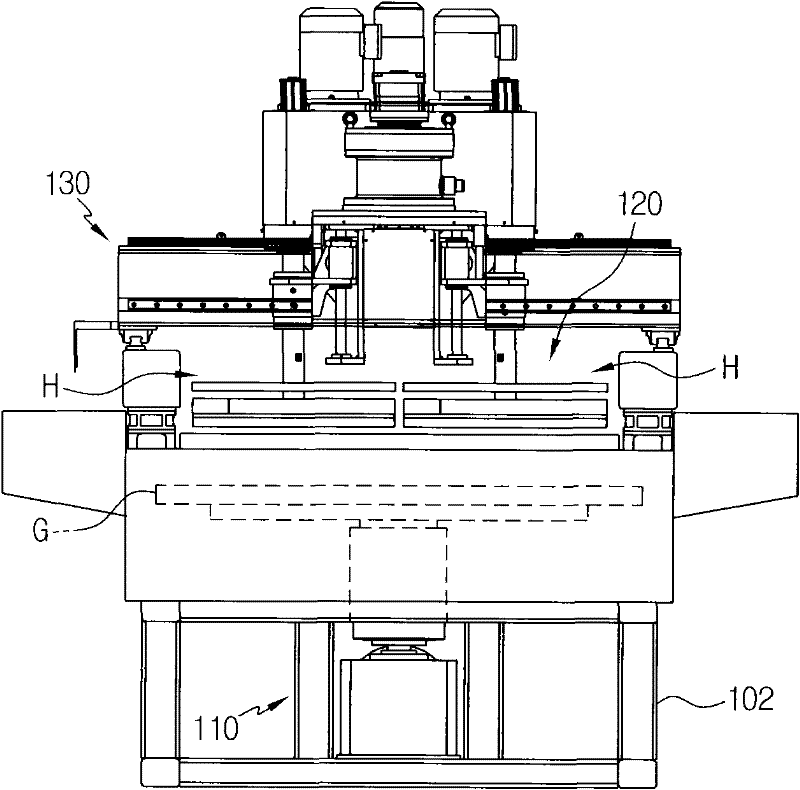

Method and system for polishing glass

ActiveCN102049712ASmall polish differenceImprove polishing uniformityOptical surface grinding machinesLapping machinesLiquid-crystal displayEngineering

Owner:LG CHEM LTD

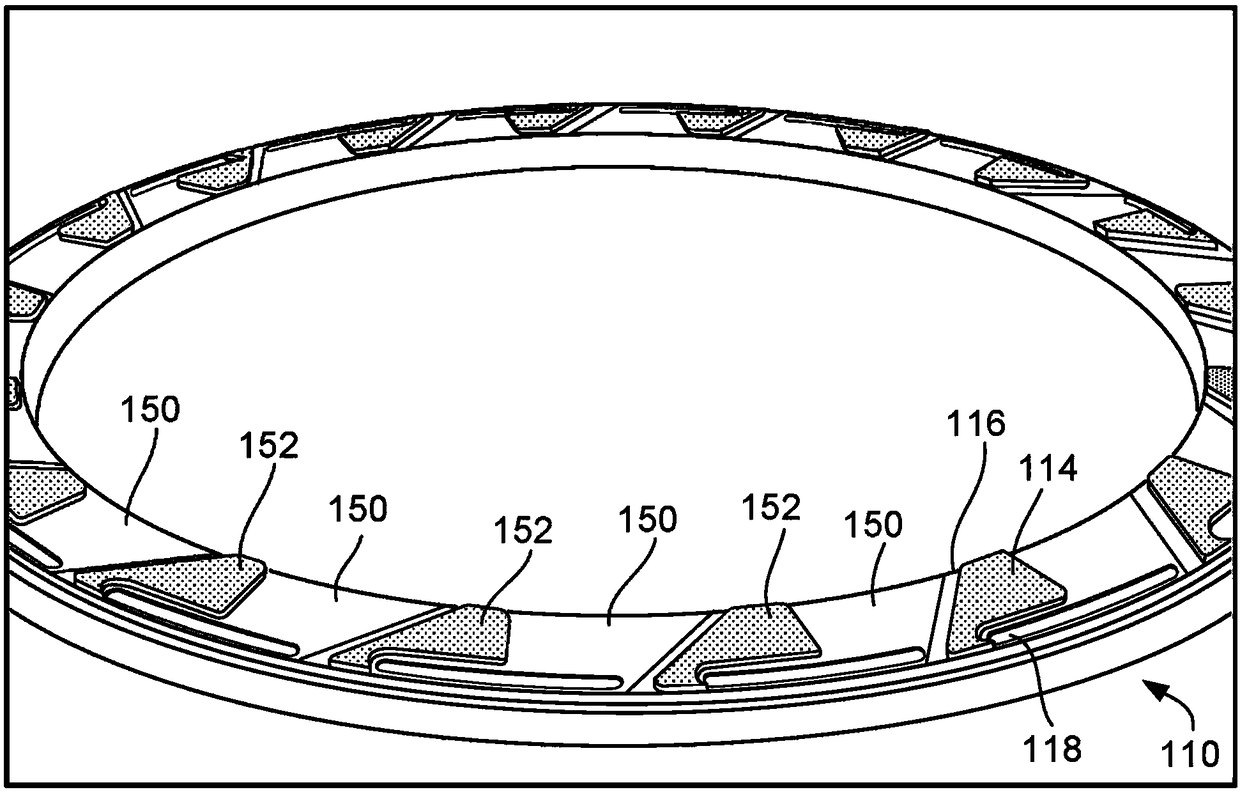

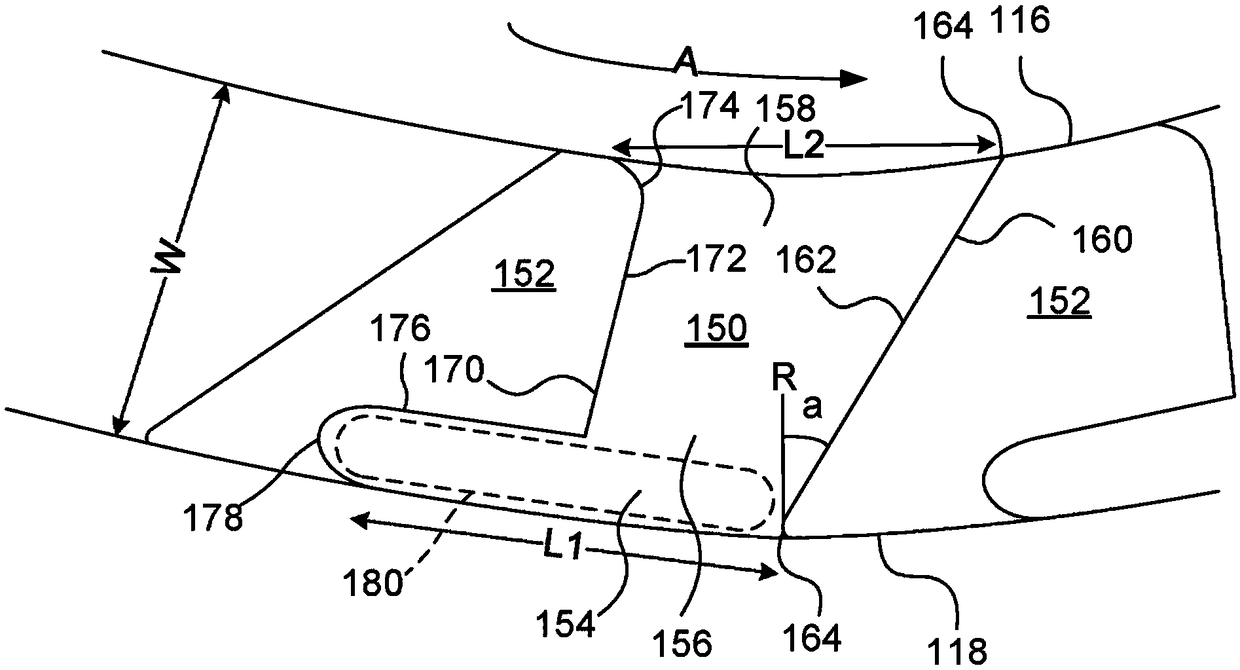

Retaining ring for cmp

ActiveCN109475997AReduce the rebound effectPolishing Rate ControlSemiconductor/solid-state device manufacturingLapping machinesEngineering physicsRetaining ring

A retaining ring includes a generally annular body having an inner surface to constrain a substrate and a bottom surface, the bottom surface having a plurality of channels extending from an outer surface to the inner surface, and a plurality of islands separated by the channels and providing a contact area to contact a polishing pad, wherein the contact area is about 15-40% of a plan area of the bottom surface.

Owner:APPLIED MATERIALS INC

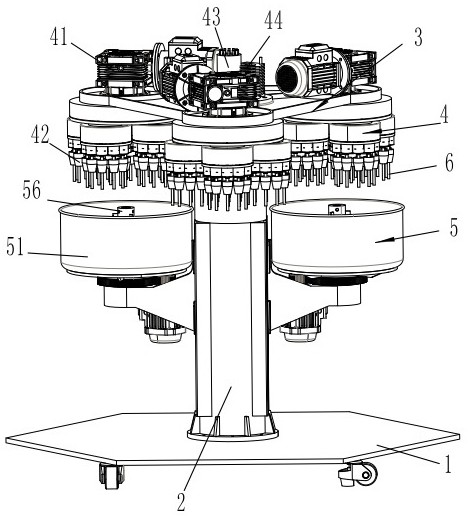

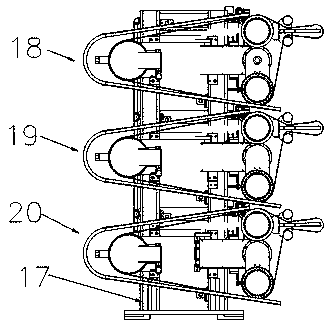

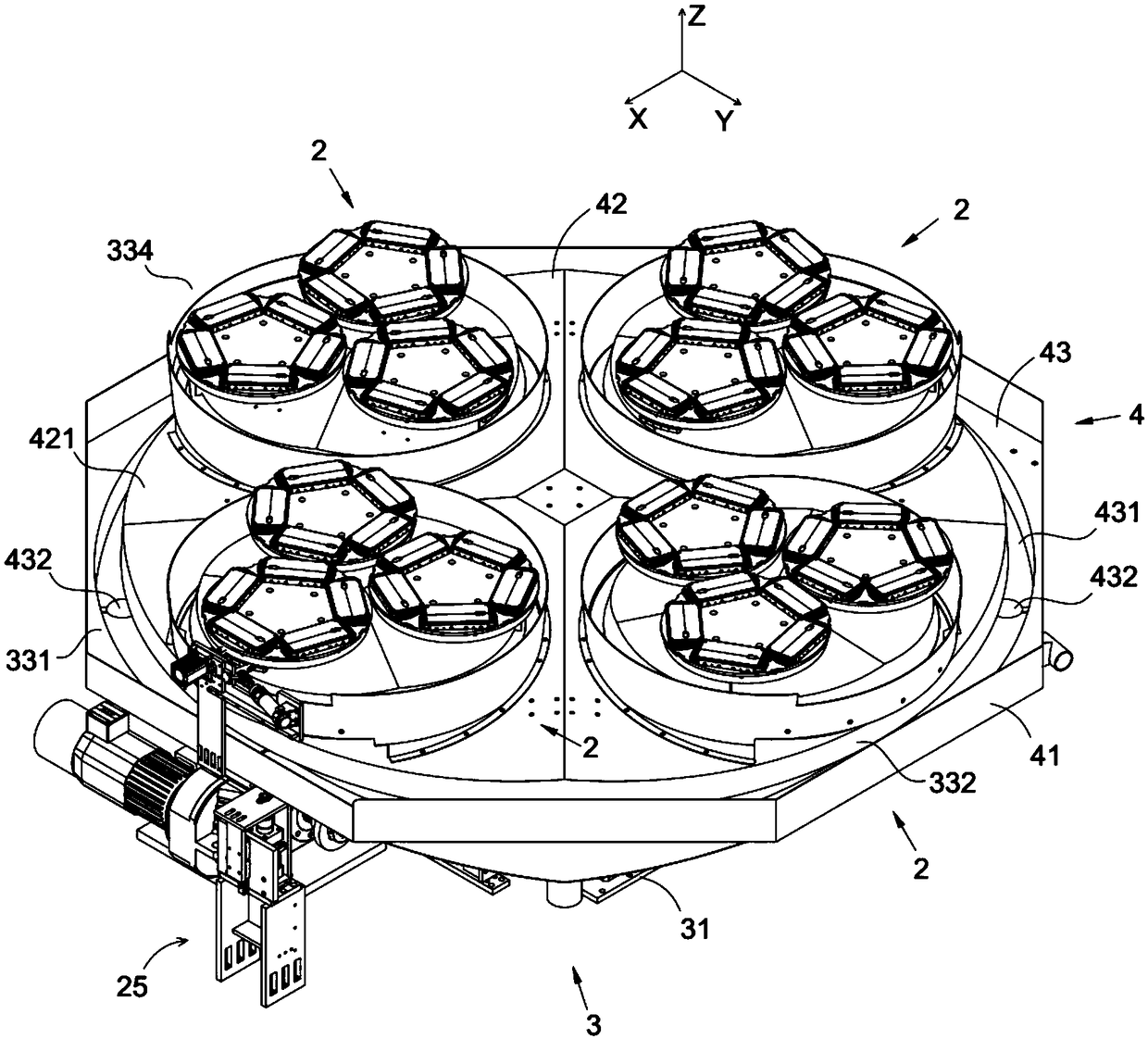

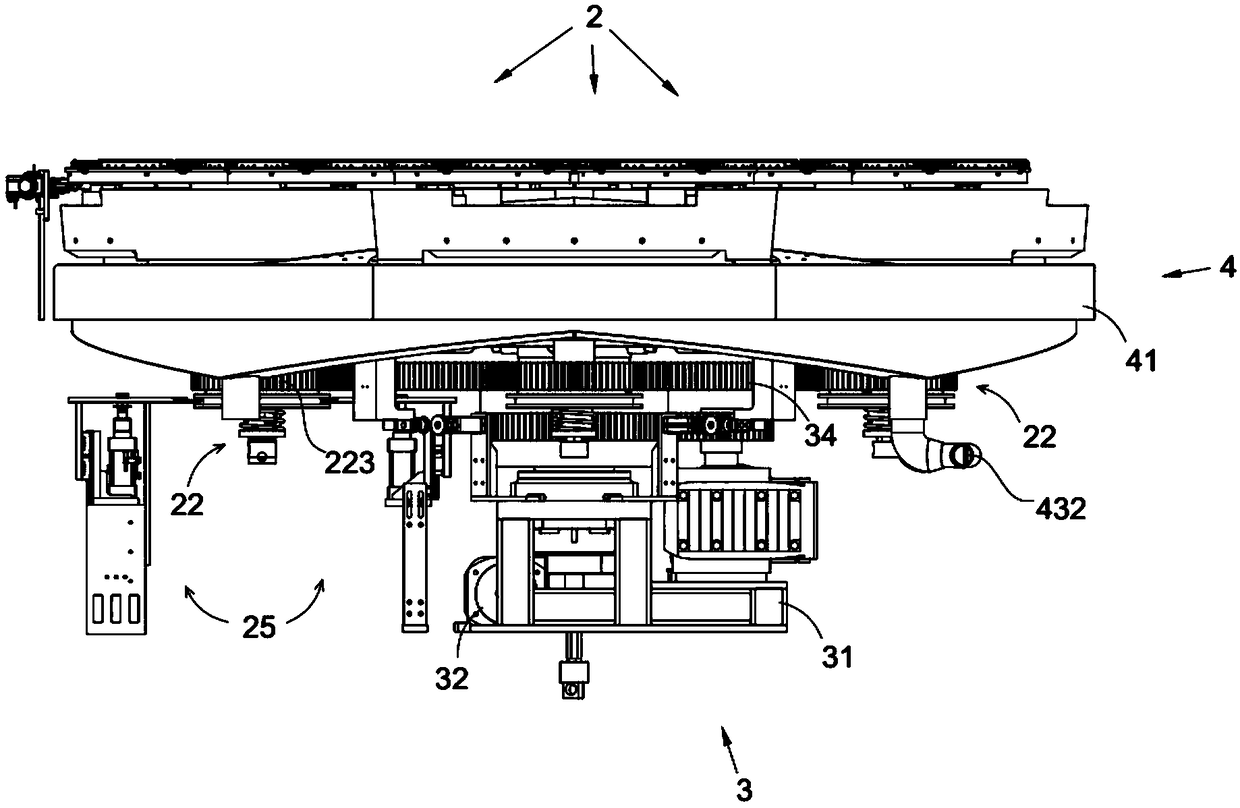

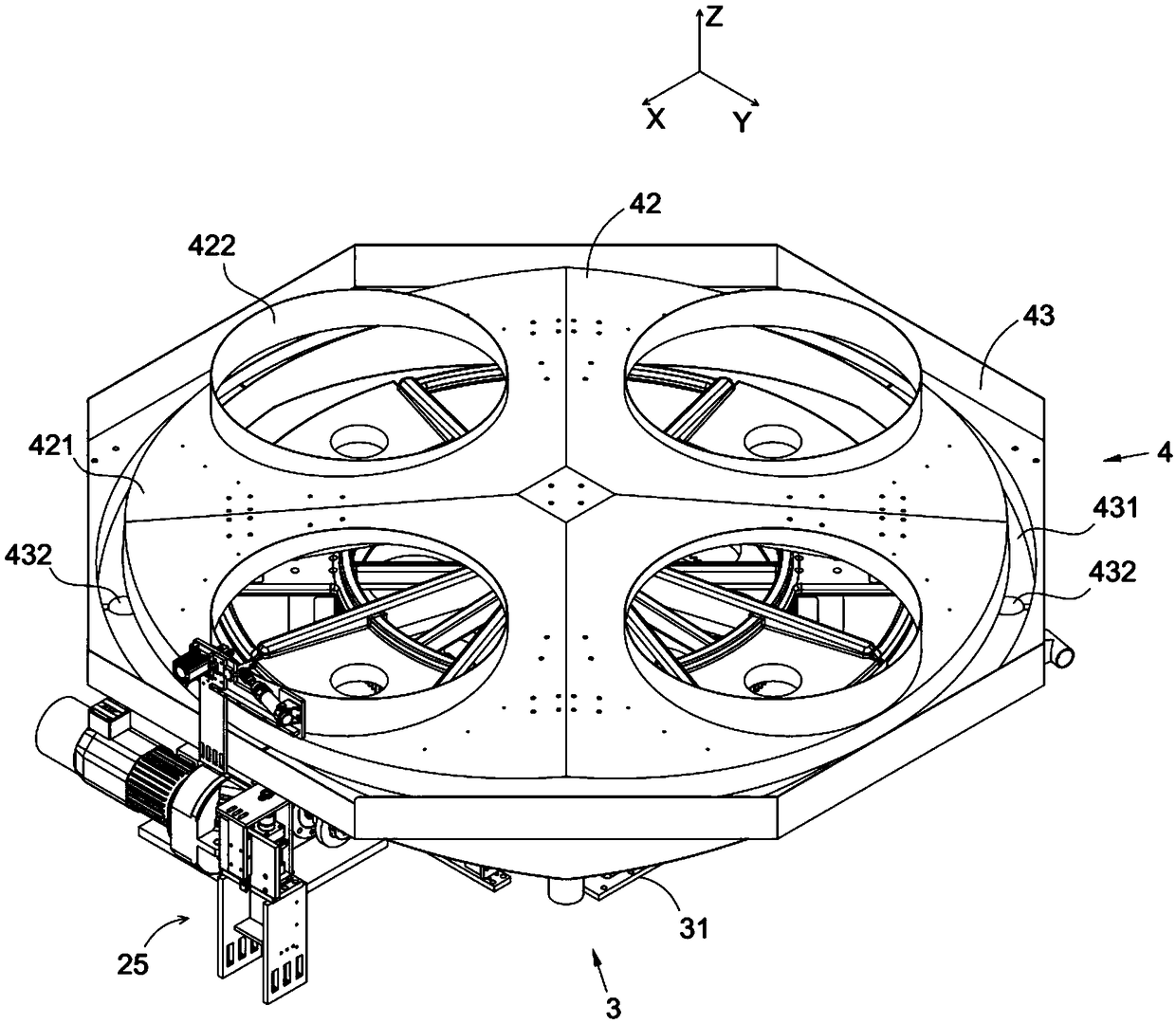

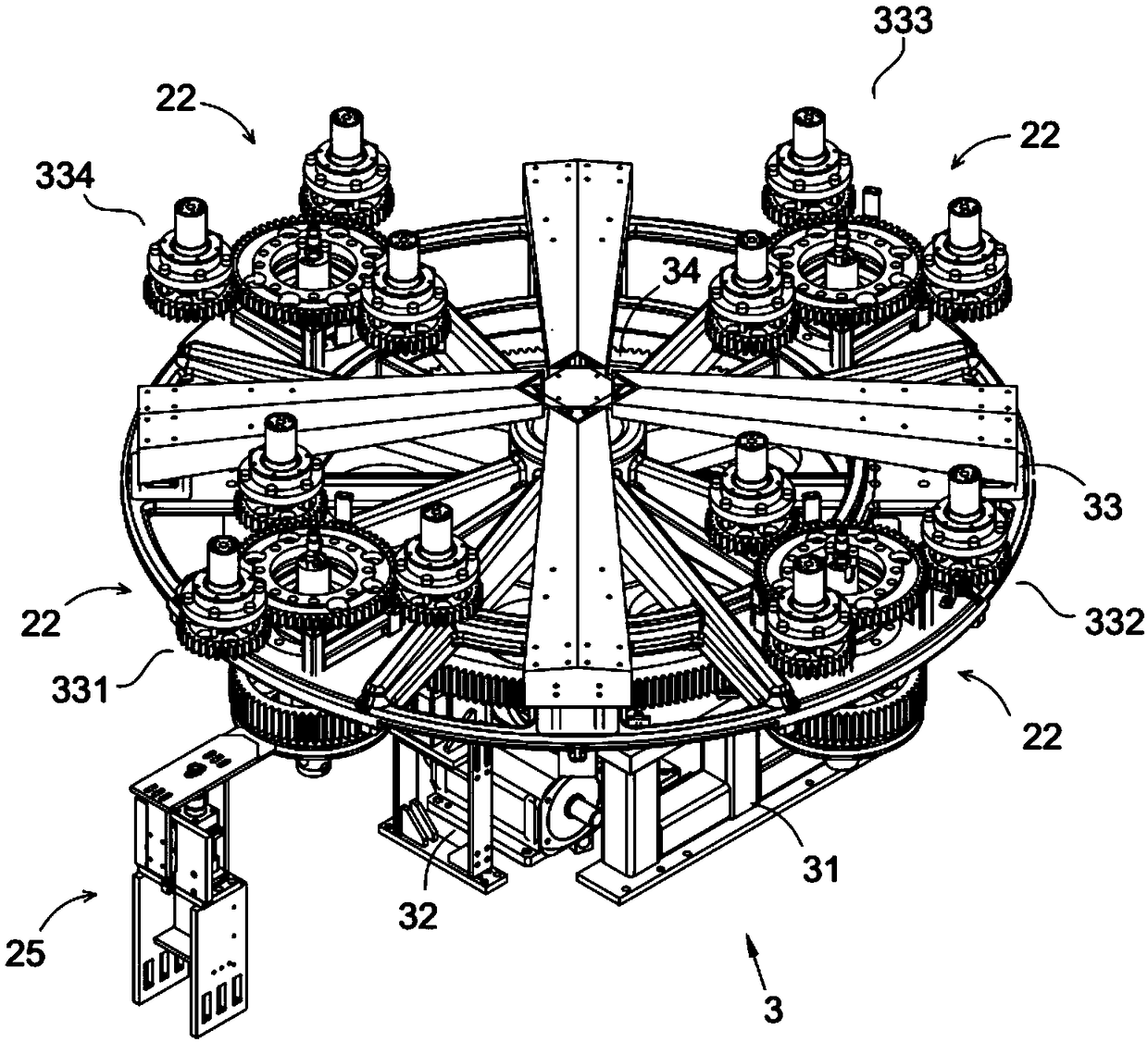

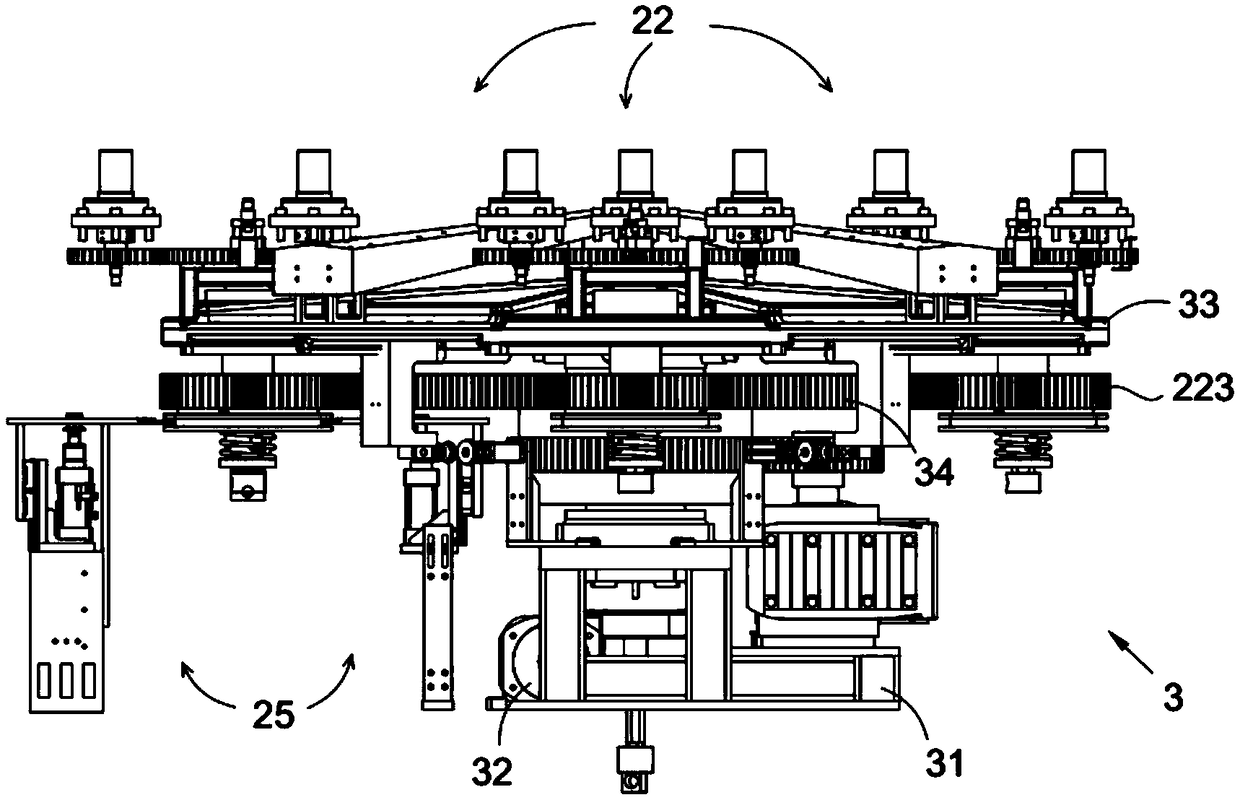

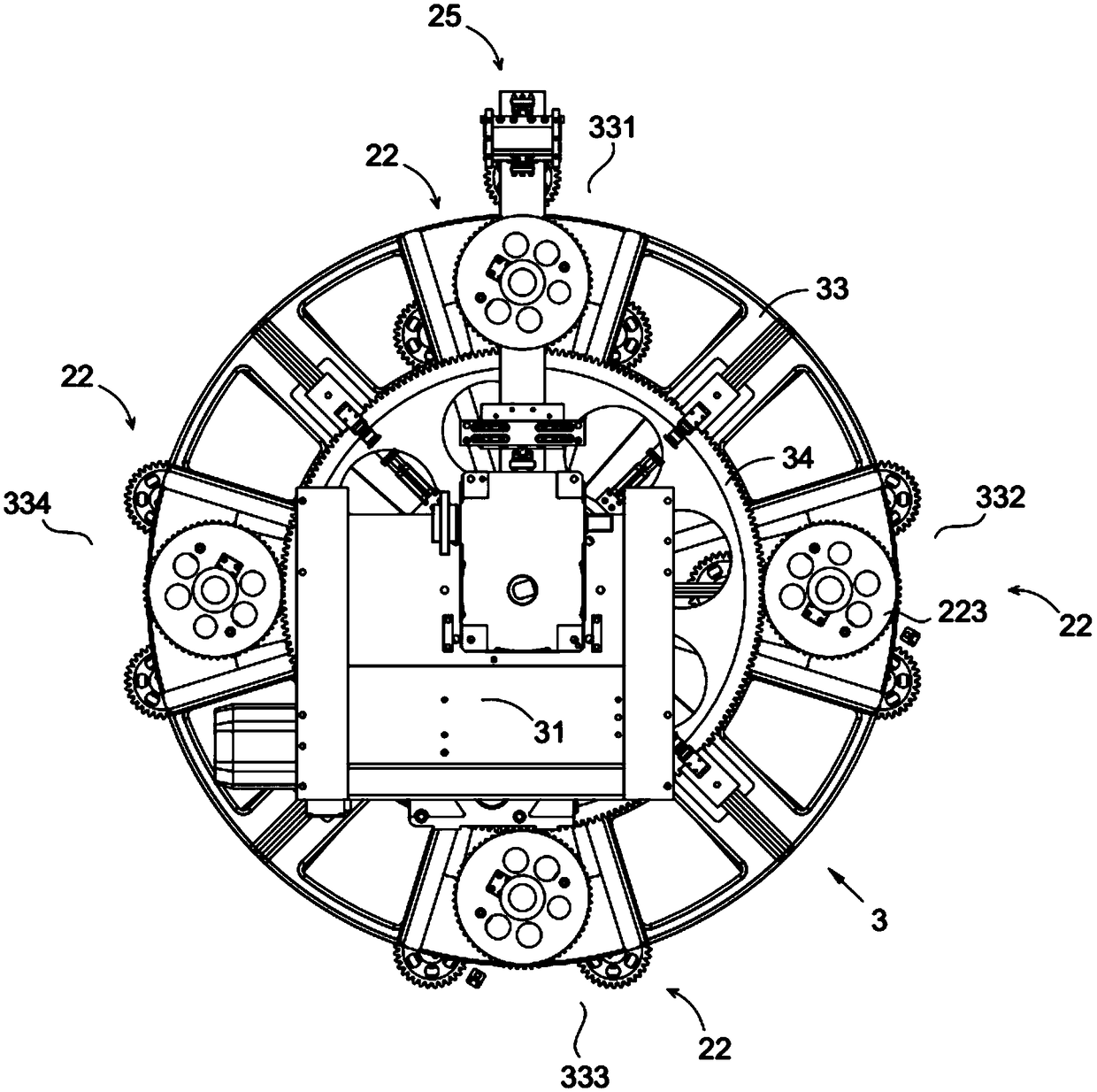

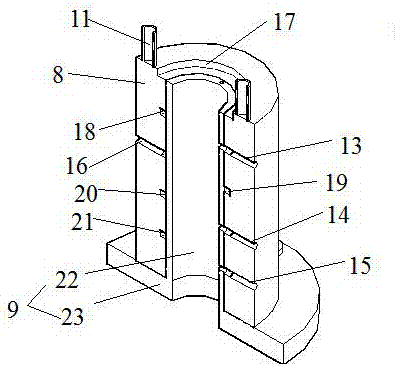

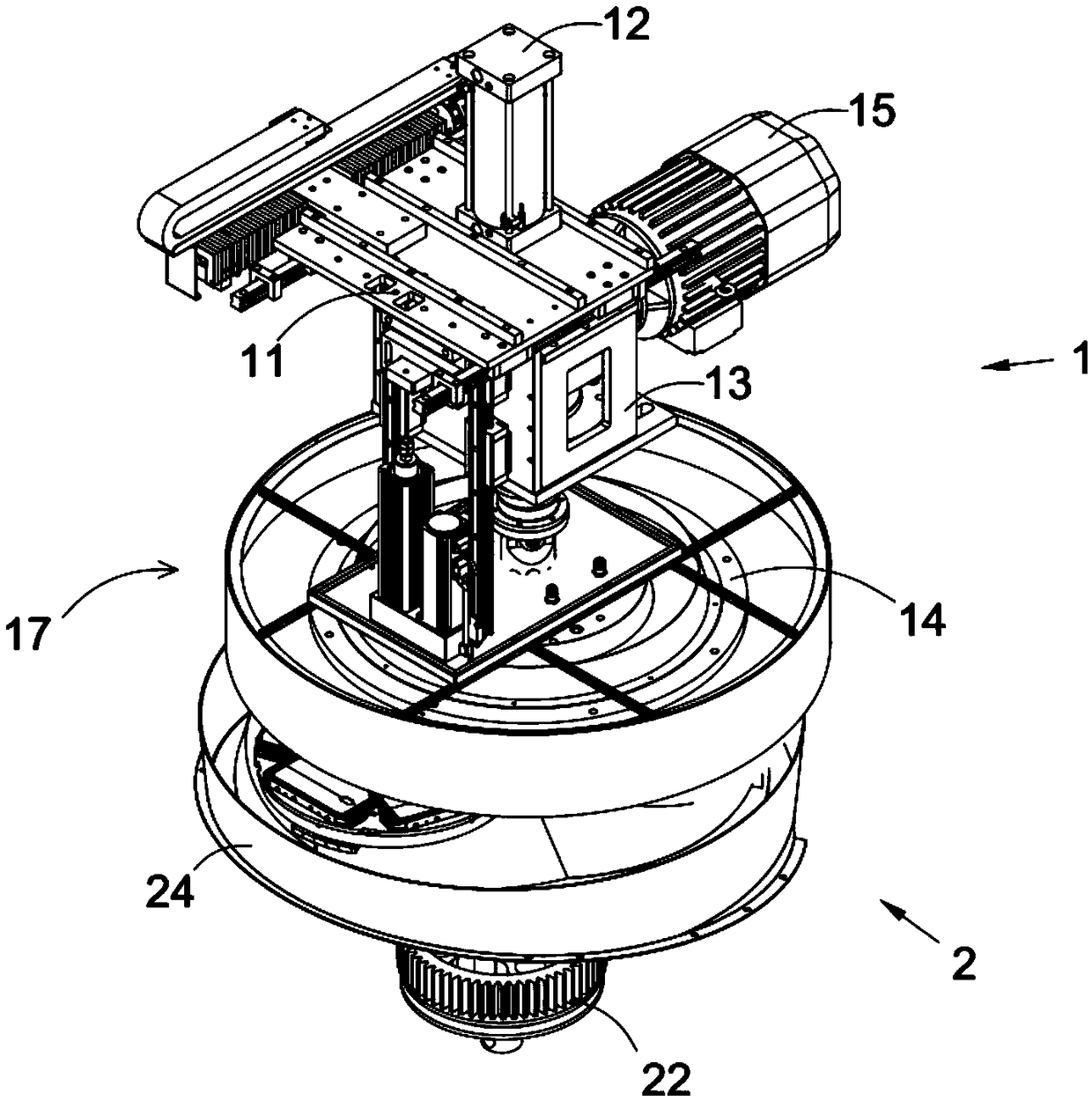

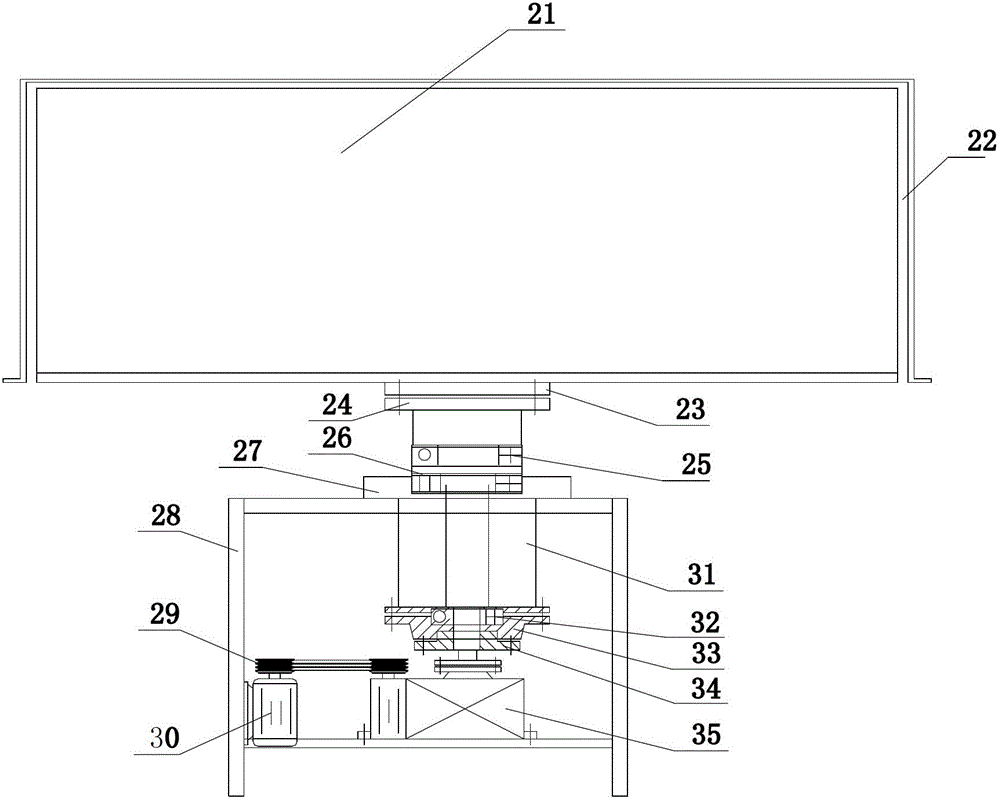

Multi-station vertical rotary abrasive flow polishing device and working method thereof

ActiveCN112497043ARealize the whole process of polishingSolve the problem of uneven polishing qualityEdge grinding machinesGrinding carriagesPolishingElectric machine

The invention discloses a multi-station vertical rotary abrasive flow polishing device and a working method thereof, and belongs to the technical field of machining. According to the multi-station vertical rotary abrasive flow polishing device, a plurality of planetary rotary discs are evenly distributed on a rotary disc assembly in the annular direction to correspond to stations of loading, unloading, rough polishing, fine polishing and the like, and a polishing motor drives a workpiece installed below the planetary rotary discs and a polishing medium evenly mixed in a charging basket to rotate relatively to achieve polishing of the workpiece, after certain procedure is finished, the rotary disc assembly drives the workpiece to enter the polishing of the next procedure, so that the whole-process polishing of the workpiece is circularly realized. A planetary rotary disc mechanism is matched with a charging basket assembly internally provided with a fixed flow guide mechanism, so that rotation and revolution of the workpiece are achieved, and the speed required by polishing is achieved; and the polishing medium rotates and overturns up and down along with the charging basket, is uniformly mixed and is prevented from settling and layering. The multi-station vertical rotary abrasive flow polishing device is provided with a plurality of stations, one-time clamping of the workpieceis achieved, multi-station and multi-procedure polishing is conducted at the same time, the polishing process is greatly simplified, and then the overall polishing efficiency is improved.

Owner:DALIAN UNIV OF TECH +1

High-adhesion nano cutter coating and preparation method thereof

PendingCN113652632AImprove structural strengthGood adhesionVacuum evaporation coatingSputtering coatingInterface layerHigh adhesion

The invention relates to the field of hard coatings, and particularly discloses a high-adhesion nano cutter coating and a preparation method thereof. The high-adhesion nano cutter coating comprises a CrN interface layer, an AlTiN intermediate layer, an AlTiN / TiSiN connecting layer and a TiSiN coating layer which are sequentially coated on the cutter surface subjected to matrix modification from inside to outside, and the CrN interface layer, the AlTiN intermediate layer, the AlTiN / TiSiN connecting layer and the TiSiN coating layer are prepared by adopting a deposition coating scheme. The preparation method comprises the following steps: S1, taking a matrix modified cutter, and activating; and S2, after activation of the cutter is completed, performing deposition in sequence, and preparing the high-adhesion nanom cutter coating. In addition, the surface structure of the cutter material is optimized, and the adhesion performance and anti-falling performance of the hard coating on the cutter surface are improved.

Owner:科汇纳米技术(常州)有限公司

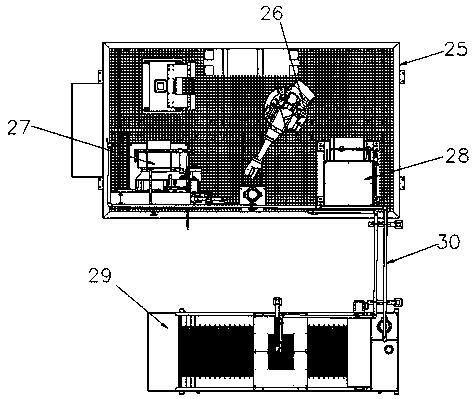

High-efficiency workpiece polishing and polishing device

PendingCN110039416ANovel structural designHigh degree of automationPolishing machinesBelt grinding machinesManipulatorSurface finishing

The invention discloses a high-efficiency workpiece polishing and polishing device. The high-efficiency workpiece polishing and polishing device comprises a base station main body; a grabbing manipulator, an abrasive belt mechanism and a polishing mechanism are arranged on the base station main body; and a cutting fluid circulation filtering system is arranged on one side of the base station mainbody, and the cutting fluid circulation filtering system communicates with the abrasive belt mechanism and the polishing mechanism through pipelines. The high-efficiency workpiece polishing and polishing device is novel in structural design, high in automation degree, and capable of rapidly grinding and polishing workpieces, good workpiece surface treatment uniformity is achieved, and the workpiece quality is improved.

Owner:JIANGSU ZUNSION AUTOMOBILE TECH CO LTD

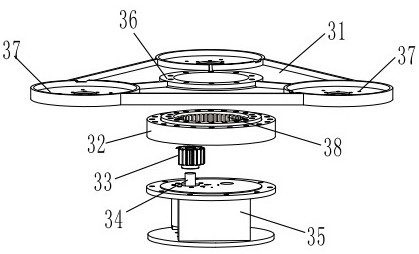

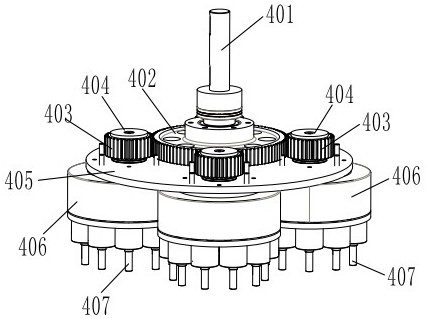

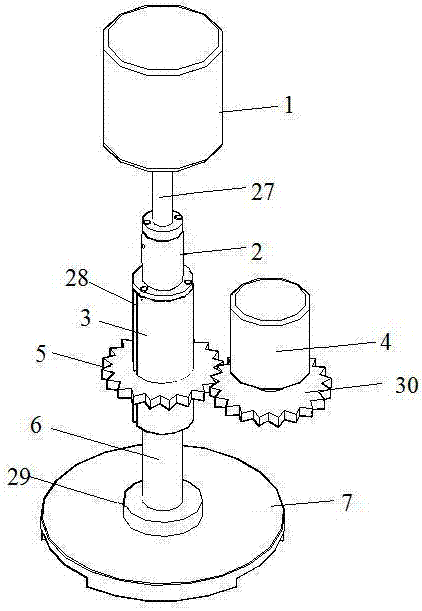

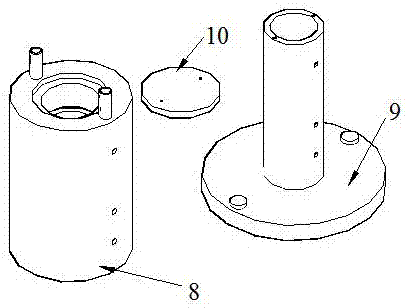

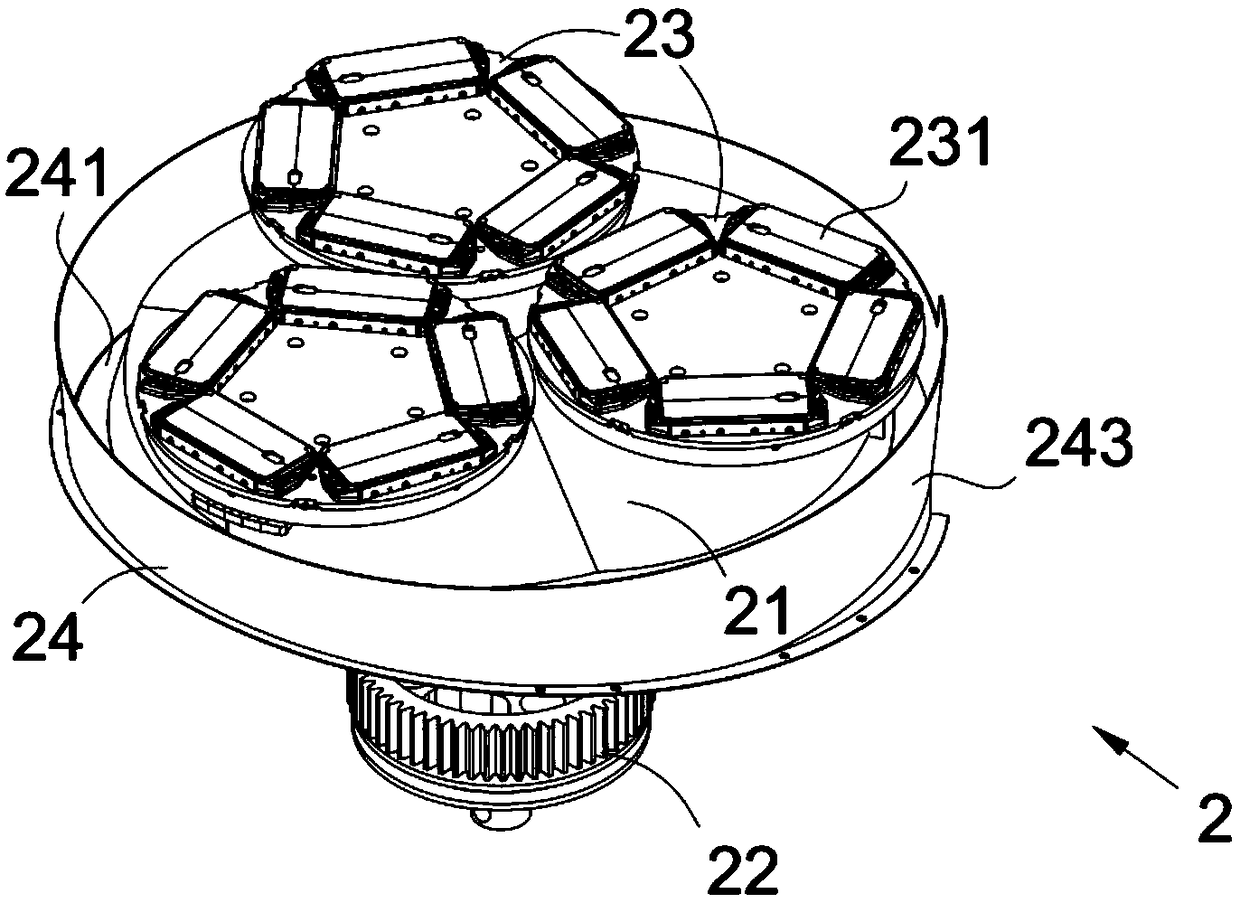

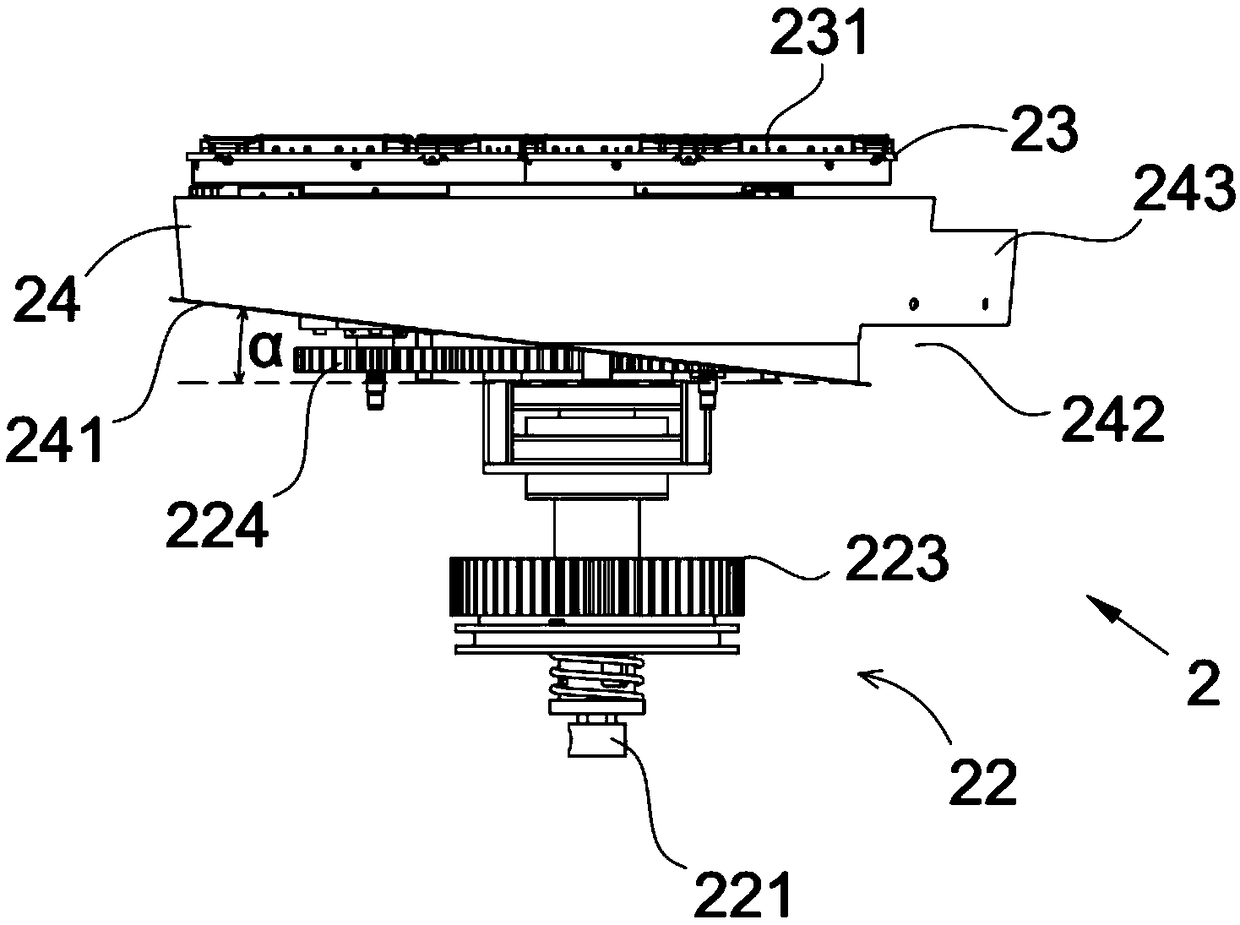

Two-stage planet gear type polishing carrier for 3D bent glass

The invention discloses a two-stage planet gear type polishing carrier for 3D bent glass. The two-stage planet gear type polishing carrier comprises a sun wheel assembly and at least two sets of planet epicyclic type carriers meshing with the periphery of a sun wheel; the sun wheel assembly comprises a sun wheel supporting frame and the sun wheel arranged on the sun wheel supporting frame; a polishing solution collecting plate and a planet carrier are sequentially arranged right above the sun wheel from up to down and the polishing solution collecting plate and the planet carrier rotate synchronously with the sun wheel; the planet carrier is sequentially provided with feeding and discharging stations and at least one polishing station in the circumferential direction; the planet epicyclictype carriers are installed above the planet carrier, and the number of the planet epicyclic type carriers is equal to the sum of the number of the feeding and discharging stations and the number of the polishing stations. According to the two-stage planet gear type polishing carrier for the 3D bent glass, the polishing uniformity is improved, the 3D bent glass can be changed between each stationrepeatedly at the same time, the degree of automation and the polishing efficiency are improved, polishing chips generated in the process of polishing can be discharged in time, polishing solutions are recycled further, the production cost is lowered, and the requirement of environment protection is met at the same time.

Owner:SUZHOU RS TECH

Two-stage planetary gear transmission mechanism for three-dimensional (3D) curved glass polishing machine

PendingCN109505928AStop in timeGuaranteed rotation angleGrinding drivesToothed gearingsEngineeringGear transmission

The invention discloses a two-stage planetary gear transmission mechanism for a three-dimensional (3D)curved glass polishing machine. The two-stage planetary gear transmission mechanism comprises a sun wheel assembly and at least two groups of planetary gear assemblies; the sun wheel assembly comprises a sun wheel bracket and a sun wheel arranged on the sun wheel bracket; the planetary gear assemblies are engaged with the periphery of the sun wheel, wherein a planet framesynchronously rotated with the sun wheel is arranged over the sun wheel, a feeding and discharging station and one or more polishing stations are successively arranged on the planet frame in the circumferential direction of the planet frame, and the planetary gear assemblies are installed on the planet frame. According tothe two-stage planetary gear transmission mechanism for the 3D curved glass polishing machine, at least two groups of planetary gear assemblies are arranged on the two-stage planetary gear transmission mechanism, agreat deal of 3D curved glass can be synchronously polished, it can be ensured that the rotating angle and amplitude of each 3D curved glass are uniform, and polishing uniformity is improved; meanwhile, a clutch assembly is responsive, and the phenomenon of braking feedback delay is greatly reduced; and meanwhile, the planetary gear assemblies can further be braked in time, and the polishing error is further decreased.

Owner:SUZHOU RS TECH

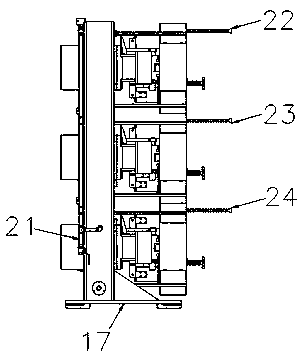

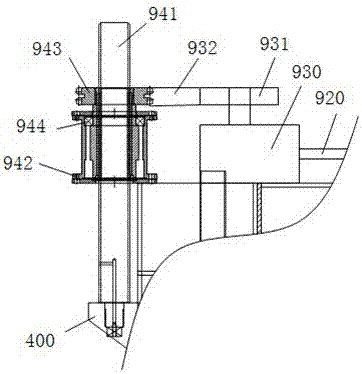

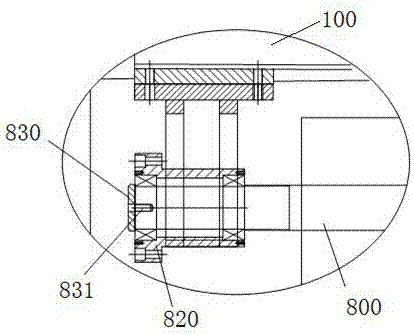

Rotating adjusting type upper shaft mechanism for single-side polishing of large-size wafers

ActiveCN106881660AImprove sealingEffectively breakPolishing machinesGrinding drivesWater leakageLarge size

The invention provides a rotating adjusting type upper shaft mechanism for single-side polishing of large-size wafers. The rotating adjusting type upper shaft mechanism comprises a cylinder, a rotating connector, a rotating shaft, a rotating motor, a rotating gear, a connecting shaft rod and an upper disc face, wherein the cylinder controls the upper disc face to rise and fall, the rotating motor controls the rotating gear, the rotating shaft, a rotating block, the connecting shaft rod and the upper disc face to rotate, an air tube inlet port is connected with a pneumatic electronic valve, and a water tube inlet port and a water tube outlet port are connected with a water tank. The rotating adjusting type upper shaft mechanism for single-side polishing of the large-size wafers is simple in structure and reasonable in design, a rubber sealing piece and a water leakage detection port are arranged, the sealing performance of the rotating connector is effectively improved, and monitoring is provided for monitoring water leakage situation of the rotating connector; meanwhile, in the polishing operation process, the upper disc face can be effectively cooled, the situation that due to the fact that temperature of the upper disc face rises, flatness of a ceramic disc and the surface of the upper disc face is changed, and the stability is destroyed is avoided, and then polishing uniformity is improved, and the flatness of the surfaces of the polished wafers is improved; and a vacuum layer between the ceramic disc and the bottom of the upper disc face is easy to remove, and wafers can be taken out more rapidly.

Owner:TUNGHSU GRP

Polishing device for metal part

InactiveCN108262693AImprove the stability of useImprove polishing uniformityAbrasive machine appurtenancesAbrasive blasting machinesAbrasive blastingPulp and paper industry

The invention relates to a polishing device for a metal part. The polishing device comprises a polishing chamber, a reducing motor is perpendicularly arranged at the top end of the polishing chamber,the output end of the reducing motor is connected with a rotating shaft, the rotating shaft is perpendicularly provided with a plurality of hanging rod groups along the length direction, tapered sanddischarge openings are arranged at the lower end of the polishing chamber and positioned at two sides of the rotating shaft, a sand box is arranged at the lower end of the polishing chamber and positioned at the lower parts of the tapered sand discharging openings, two sides of the sand box are connected with transfer boxes through pipelines, the transfer boxes are fixedly arranged at two sides ofthe reducing motor at the upper end of the polishing chamber, the pipelines are fixedly provided with sand pumps, one sides of the transfer boxes are connected with sandblasting pipelines through pipelines, every transfer box and sandblasting pipeline connecting pipeline is provided with a pressure pump, the sandblasting pipelines are perpendicularly arranged at two sides of the polishing chamber, a plurality of sandblasting openings are perpendicularly arranged at one sides, facing the sidewall of the polishing chamber, of every sandblasting pipeline, and the plurality of sandblasting openings go through the sidewall of the polishing chamber, and extend into the polishing chamber. The polishing device for the metal part improves the overall polishing uniformity, shortens the polishing time and improves the overall polishing efficiency.

Owner:合肥盛强数控设备股份有限公司

Planetary turnover type 3D curved glass polishing machine

PendingCN109483388AUnified rotation angleUniform rotationPolishing machinesGrinding drivesPulp and paper industryScrap

The invention discloses a planetary turnover type 3D curved glass polishing machine. The machine comprises a polishing mechanism and a planetary turnover type polishing carrier arranged right above the polishing mechanism; the planetary turnover type polishing carrier comprises a carrying plate containing chamber, a carrying plate, at least two sub-planetary carrying plates, and a transmission assembly, wherein the top of the carrying plate containing chamber is opened, the carrying plate is arranged in the carrying plate containing chamber, the at least two sub-planetary carrying plates are arranged on the carrying plate, and the transmission assembly is arranged right below the carrying plate contaning chamber. According to the machine, the machine is provided with the planetary turnovertype polishing carrier, it is ensured that the rotating angle and amplitude of every 3D curved glass is uniform, and thus the polishing uniformity is improved; polishing scraps can also be timely discharged; and the pressure applied to the 3D curved glass by a polishing disk is controlled in real time, so that the problem of insufficient polishing or excessive polishing is solved, and in this way, the surface quality of the 3D curved glass is improved.

Owner:SUZHOU RS TECH

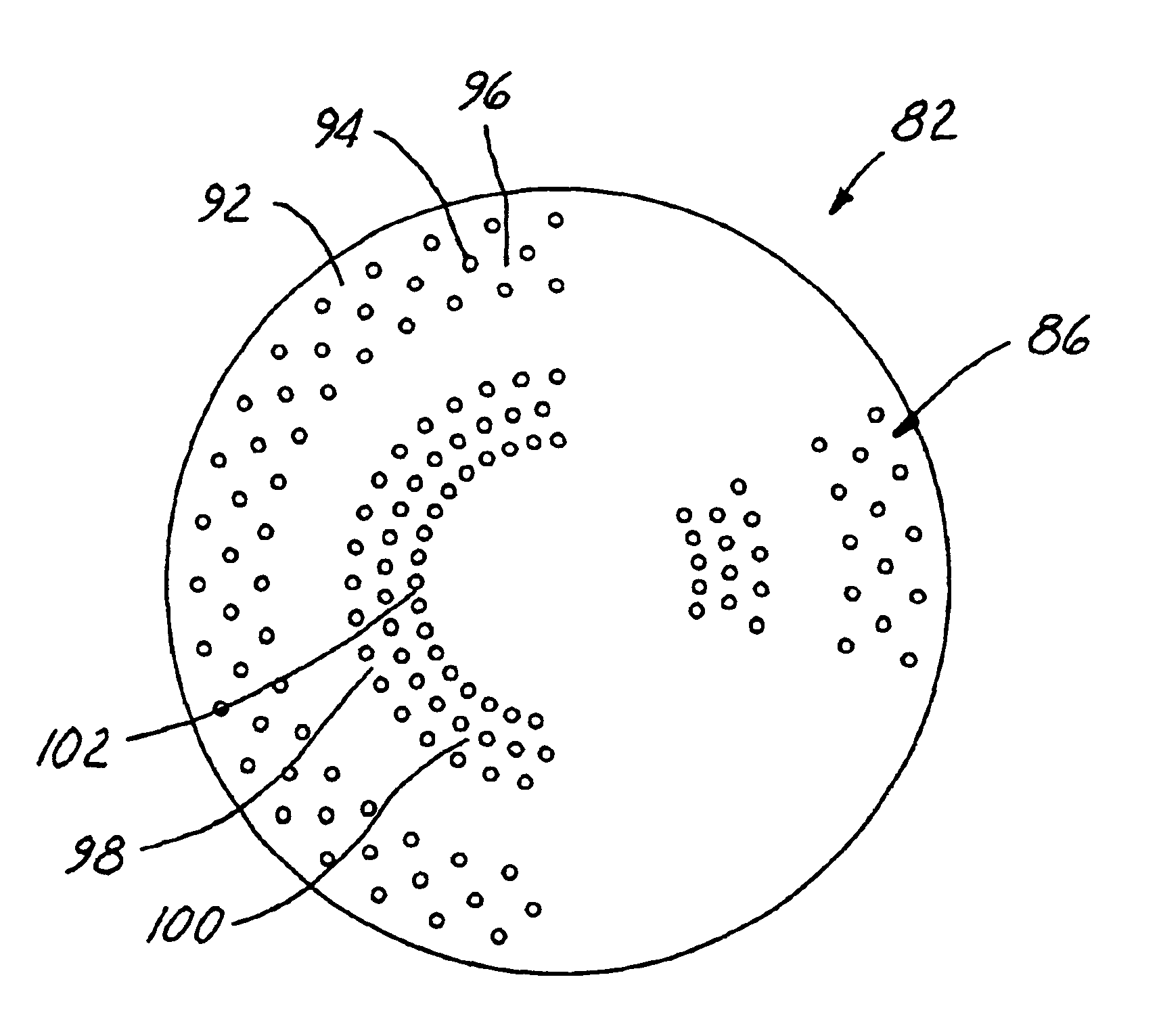

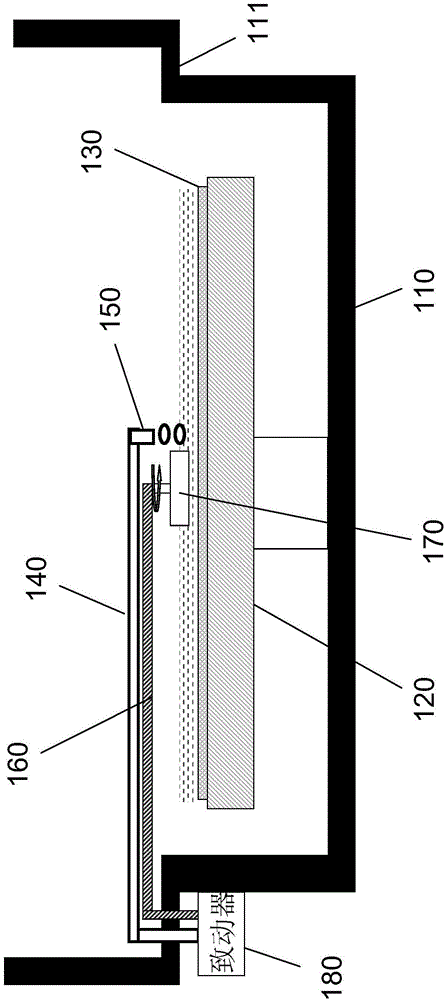

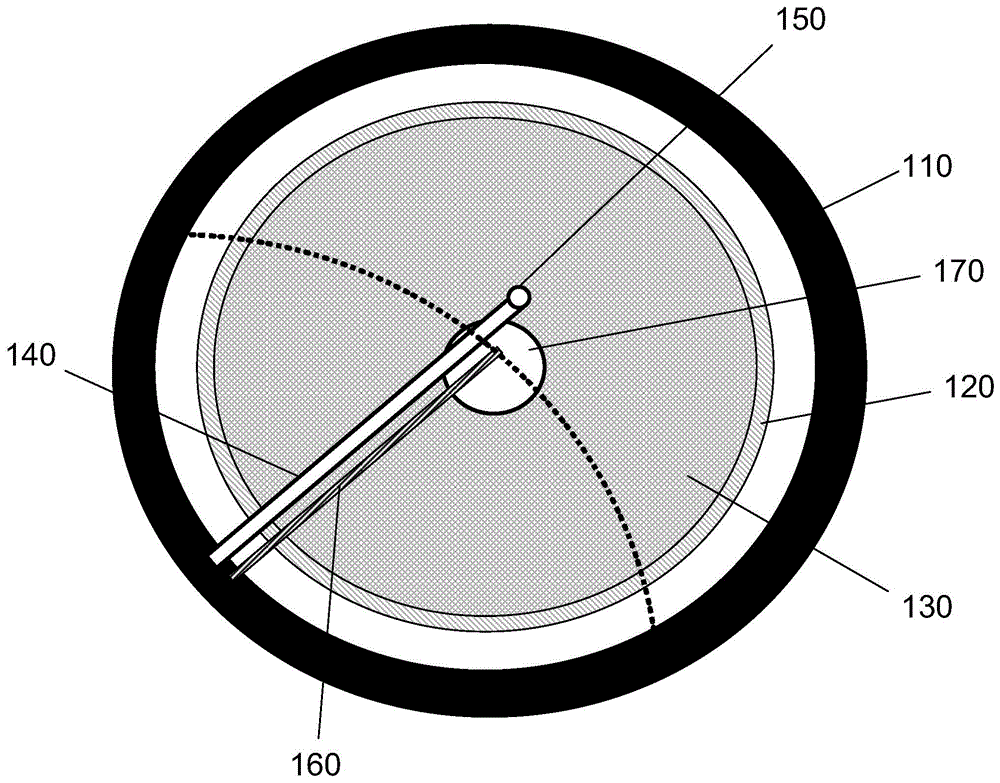

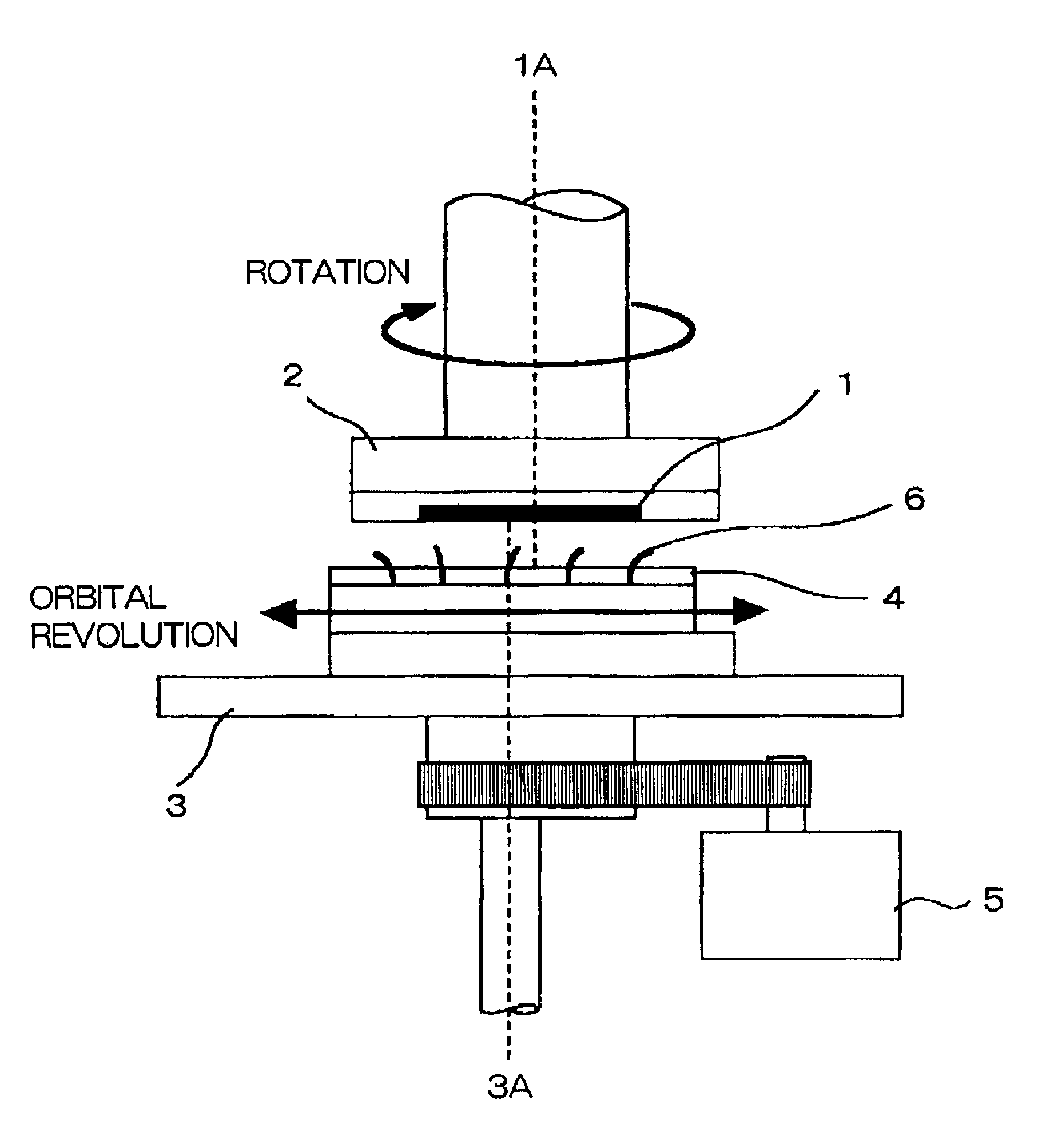

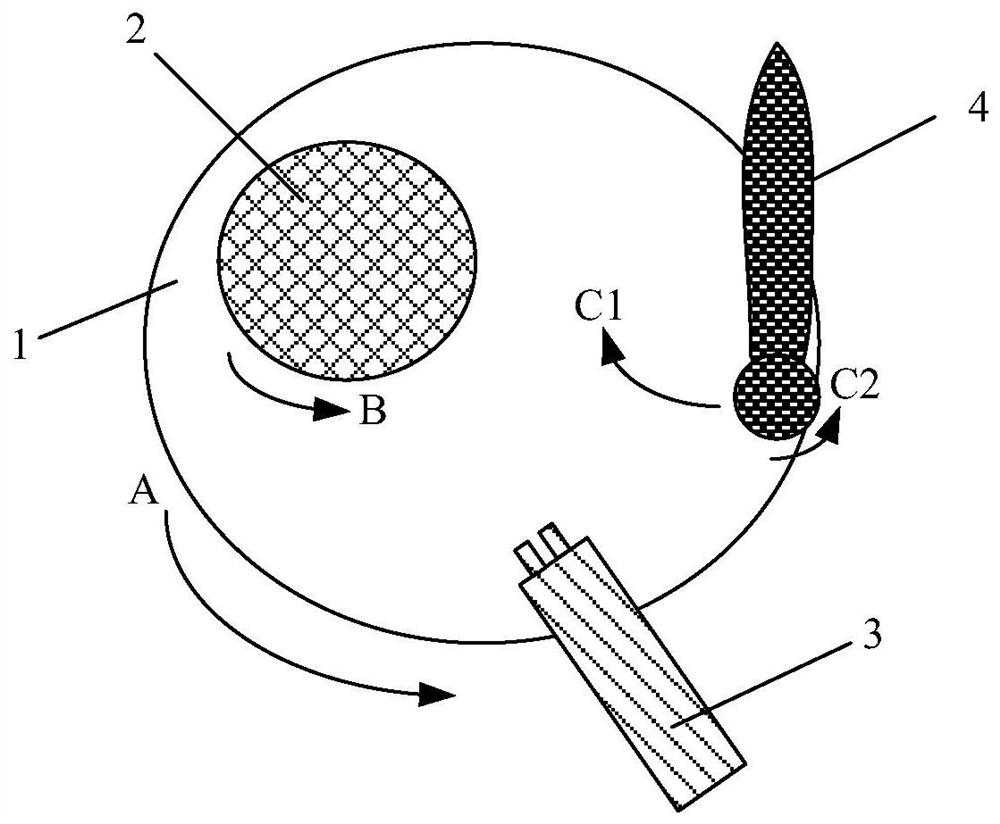

Chemical mechanical polishing apparatus and method of chemical mechanical polishing

InactiveUS6951512B2Enhance uniformityImprove polishing uniformityPolishing machinesRevolution surface grinding machinesChemical-mechanical planarizationEngineering

There is provided an apparatus for polishing a substrate, including (a) a polishing pad formed with a plurality of through-holes through which polishing material is supplied to a surface of the polishing pad, (b) a level block on which the polishing pad is mounted, and (c) a rotatable carrier for supporting a substrate thereon, the carrier being positioned in facing relation with the level block, the level block being rotatable around a rotation axis thereof with the rotation axis being moved along an arcuate path, and causing the polishing pad to make contact with the substrate for polishing the substrate, the polishing pad having a first ring-shaped region concentric thereto where no through-holes are formed. For instance, the first ring-shaped region has a width greater than 10%, but smaller than 95% of a radius of the polishing pad. The apparatus enhances uniformity in polishing a substrate.

Owner:RENESAS ELECTRONICS CORP

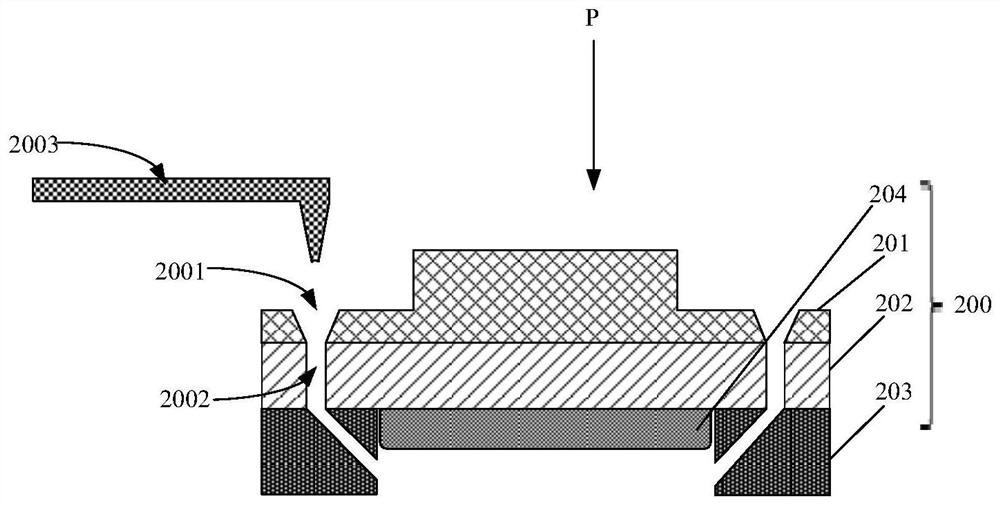

Polishing head and chemical mechanical polishing device and method

ActiveCN112677033AImprove polishing uniformityChange the concentration of the polishing solutionLapping machinesWork carriersMetallurgyWafer

The invention discloses a polishing head and a chemical mechanical polishing device and method. The polishing head comprises a main body part which is used for clamping a wafer and enabling a to-be-polished surface of the wafer to face downwards so as to carry out chemical mechanical polishing, wherein the main body part is provided with an edge liquid supply loop, and the edge liquid supply loop is used for supplying liquid to the edge of the wafer in the chemical mechanical polishing process so as to change the concentration of a polishing solution at the edge of the wafer. According to the polishing head and the chemical mechanical polishing method, the concentration of the polishing solution on the edge of the wafer is changed by introducing the liquid from the edge of the wafer in the polishing process, so that the chemical mechanical polishing rate of the edge of the wafer is controlled, and the polishing uniformity of the wafer in the chemical mechanical polishing process is improved.

Owner:ZING SEMICON CORP

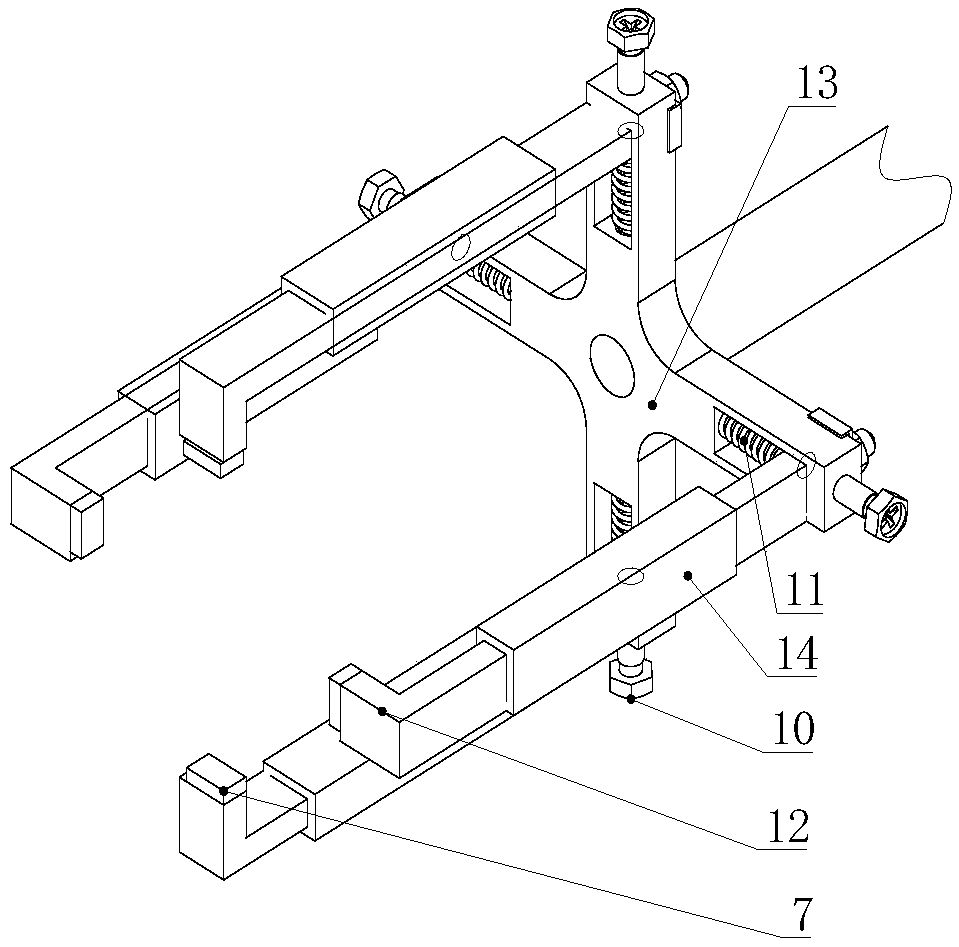

Push-type polishing mechanism based on medical sliding block

ActiveCN112720232AThe same amount of sandingImprove polishing uniformityGrinding carriagesPolishing machinesPolishingElectric machinery

The invention discloses a push-type polishing mechanism based on a medical sliding block. The push-type polishing mechanism comprises a base, guide plates are fixedly mounted at one end of the base, the sliding block is clamped between the guide plates, a guide groove formed in one side of each guide plate, a rotating mechanism is mounted between the sliding block and the guide grooves, a positioning mechanism is mounted on the sliding block, the rotating mechanism is connected with the positioning mechanisms, and a push rod is connected to one side of the sliding block, a driving mechanism is installed at the top of the base, the push rod is connected with the driving mechanism, vertical plates are installed at the tops of the guide plates, polishing motors are fixedly installed on the outer wall of one vertical plate, and output shafts of the polishing motors rotationally penetrate through the vertical plates and are fixedly provided with polishing discs. Parts are positioned and clamped on the sliding block through the positioning mechanism, the driving mechanism drives the push rod to reciprocate at a constant speed, the push rod pushes the sliding block to slide between the guide plates, the sliding block drives the parts to rotate through the rotating mechanism during sliding, and when the polishing motors drive the polishing discs to polish the outer walls of the parts, the parts are kept in a reciprocating rotating state, and polishing is more uniform, and the surface cylindricity of polished cylindrical parts is kept unchanged.

Owner:XUZHOU SHENFENG PRECISION MASCH CO LTD

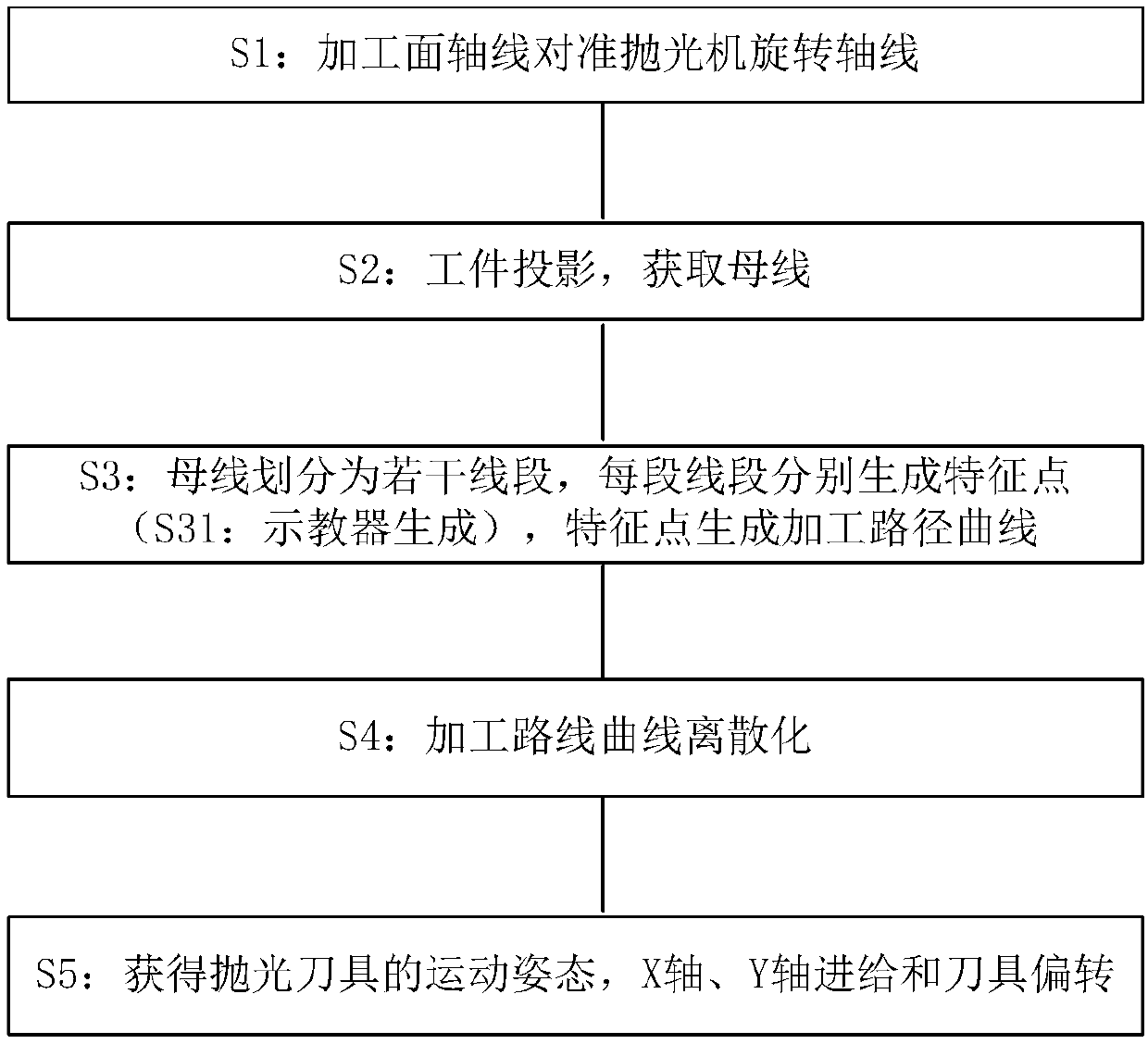

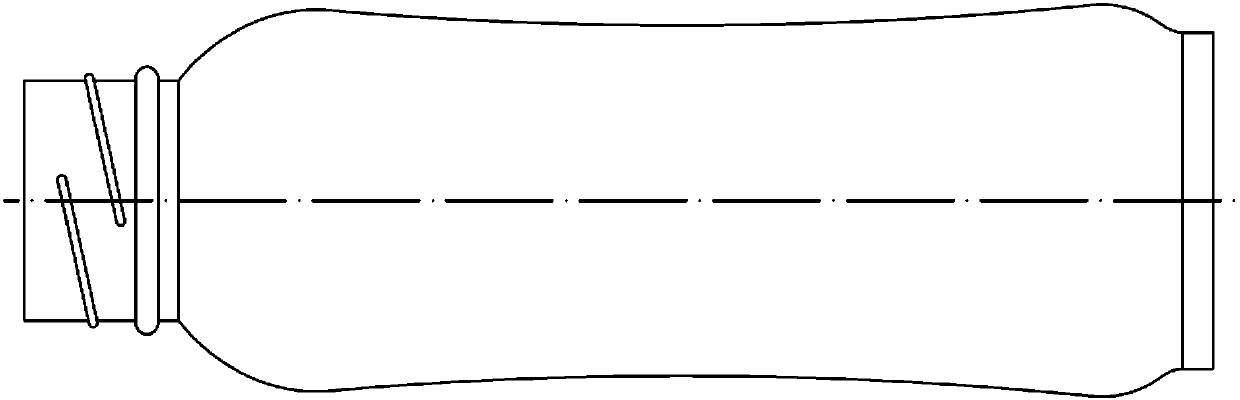

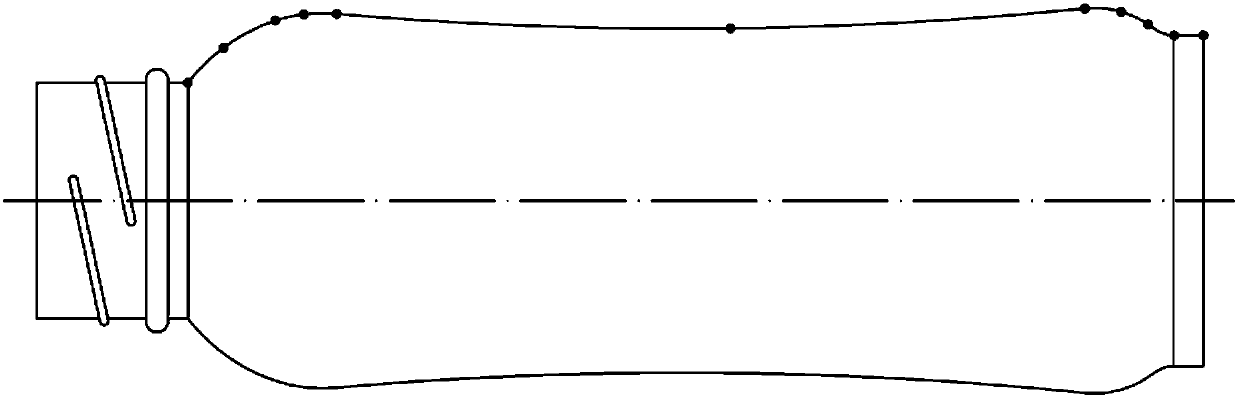

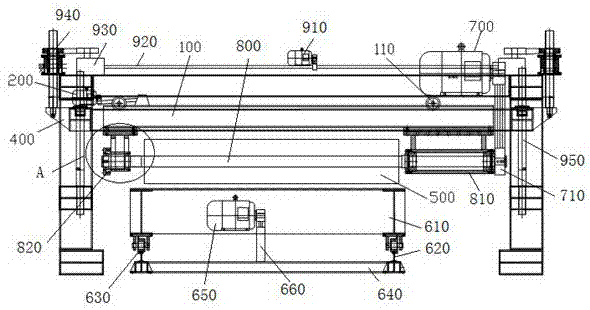

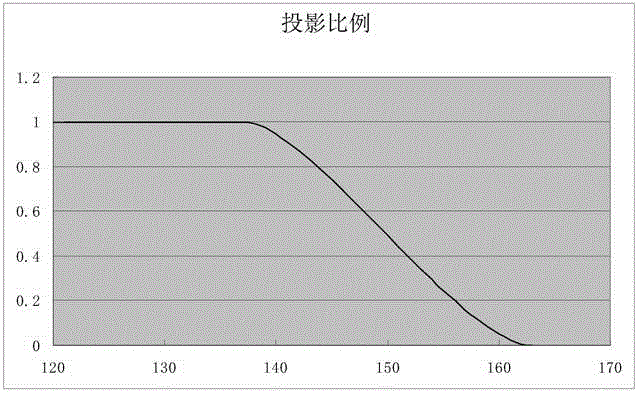

Implementation method of polishing machine machining path for vacuum cup

The invention discloses an implementation method of a polishing machine machining path for a vacuum cup. The method mainly comprises the following steps of making an axis of a machined surface of a workpiece coincide with a spindle of a polishing machine; obtaining one bus of the machined surface; dividing the bus into N characteristic line segments in sequence, generating one characteristic pointby each characteristic line segment, collecting the characteristic points by using a teach pendant and then restoring the characteristic points into a continuous machining path in sequence; discretizing the continuous machining path to generate polishing cutting points; adaptively generating X-axis feed and Y-axis feed of polishing tools according to the polishing cutting points and generating deflection of the polishing tools or deflection of the workpiece, wherein the workpiece rotates around the spindle of the polishing machine and the polishing tools also rotate; and achieving polishing of the workpiece according to the speed difference between the workpiece and the polishing tools. As a result, the automation degree of polishing work of the vacuum cup is improved, the polishing machine is suitable for polishing of the vacuum cup with various buses, the flexibility of the polishing machine is improved and the method is simple in programming and short in elapsed time.

Owner:上海捷至翔智能设备有限公司

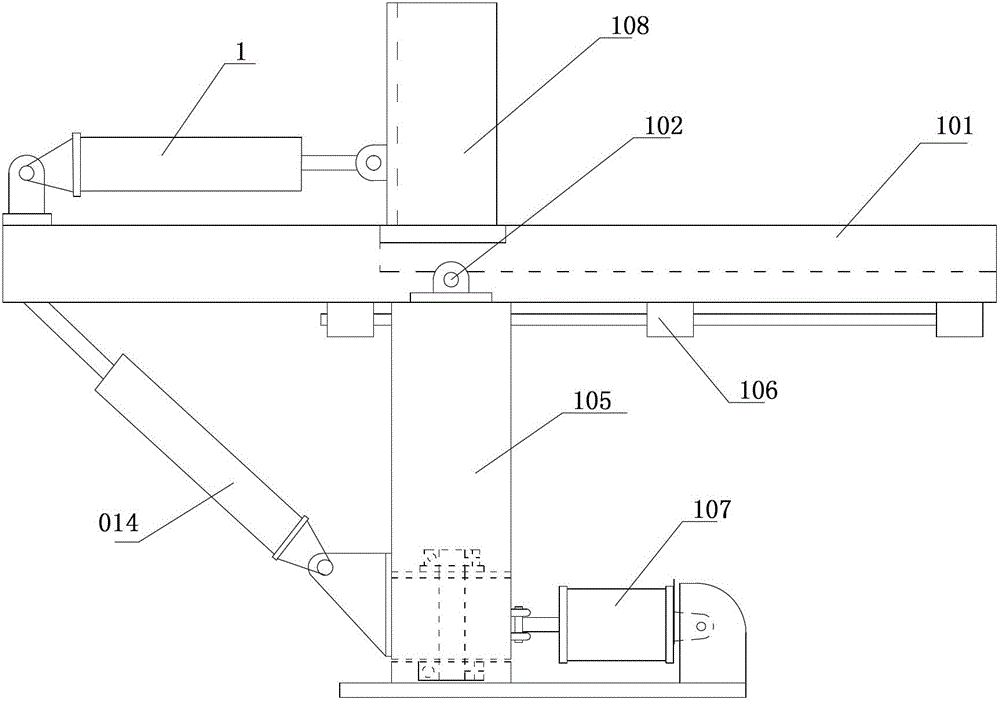

An aluminum plate polishing machine

ActiveCN104985517BSolve problems that require multiple polishingImprove polishing uniformityPolishing machinesResonanceMechanical engineering

Disclosed in the invention is an aluminium plate polishing machine comprising a polishing mechanism for carrying out polishing work by a polishing wheel, a lifting mechanism for controlling lifting of the polishing wheel, an oscillating mechanism for controlling the polishing wheel to make horizontal oscillation, and an automatic motion platform for controlling an aluminium plate to move. After the lifting mechanism controls the polishing wheel to touch the aluminium plate, the polishing wheel rotates under the control of the polishing mechanism and makes horizontal oscillator under the control of the oscillating mechanism; and the automatic motion platform carries the aluminium plate to move and thus the polishing wheel to polish the whole aluminium plate surface gradually to complete the polishing work. According to the invention, one-time polishing on a large panel can be realized and multi-times polishing is not required; and a problem that the existing polishing machine needs to carry out multi-times polishing can be solved. Meanwhile, the polishing uniformity of the polishing machine is high and the polishing effect is good. Moreover, a problem of springing of the polishing wheel main shaft due to resonance can be solved; and the equipment can be operated with high stability.

Owner:东莞市东铝铝业有限公司

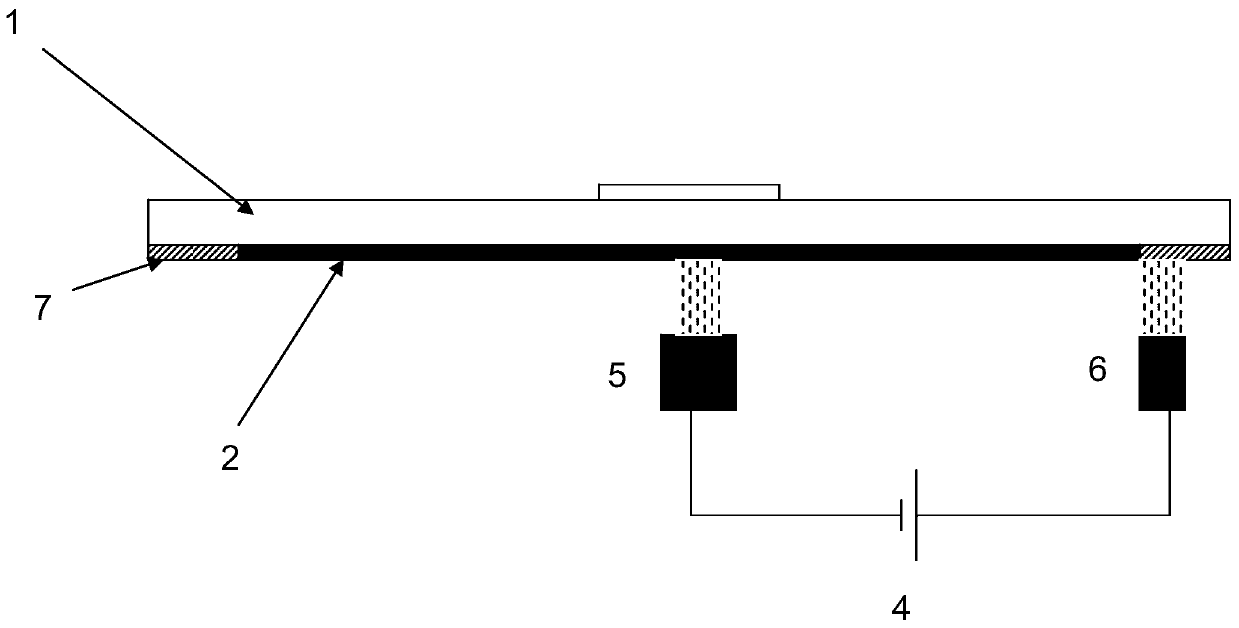

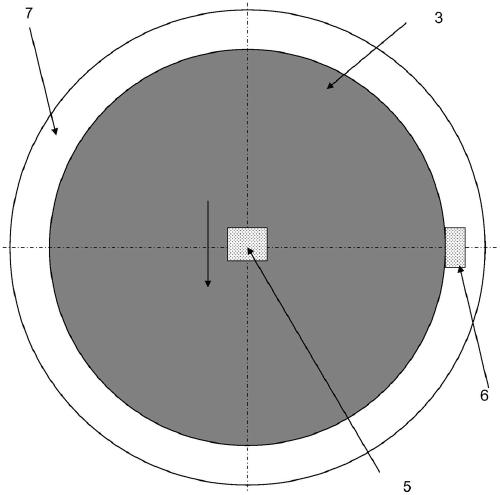

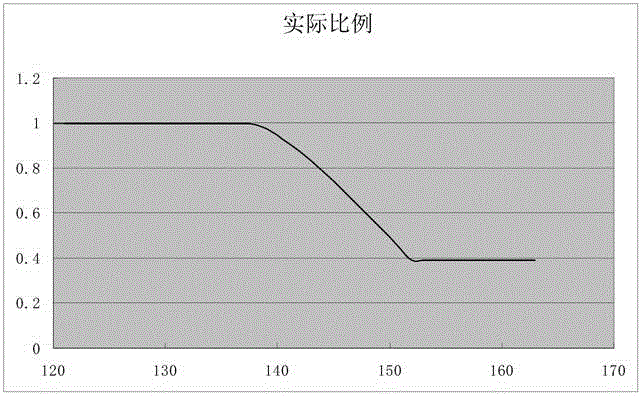

Wafer Spin Chuck Optimized Based on Cathode Shower Head Position Variation

ActiveCN106346354BConstant densityImprove polishing uniformitySemiconductor/solid-state device manufacturingWork carriersWaferEngineering

The invention discloses a wafer rotating chuck optimized on the basis of cathode spray head position change. A polishing current is regulated on the basis of position change in the cathode spray head moving process, and then the purpose of uniform polishing is achieved. According to the technical scheme, the radius of the chuck is larger than that of a wafer, a circular ring is arranged on the portion, exceeding the wafer, of the chuck, a wafer slot is formed in the middle of the chuck and used for adsorbing the wafer, and a power supply, a cathode spray head and an anode spray head are arranged below the chuck; the position of the anode spray head is constant relative to the wafer, the cathode spray head moves to the circular ring outside the wafer from the center of the wafer along the radius of the wafer, when the cathode spray head moves to the edge of the wafer, the intersection area of the cathode spray head and the wafer is decreased along with movement, and the polishing current on the cathode spray head is correspondingly decreased.

Owner:ACM RES SHANGHAI

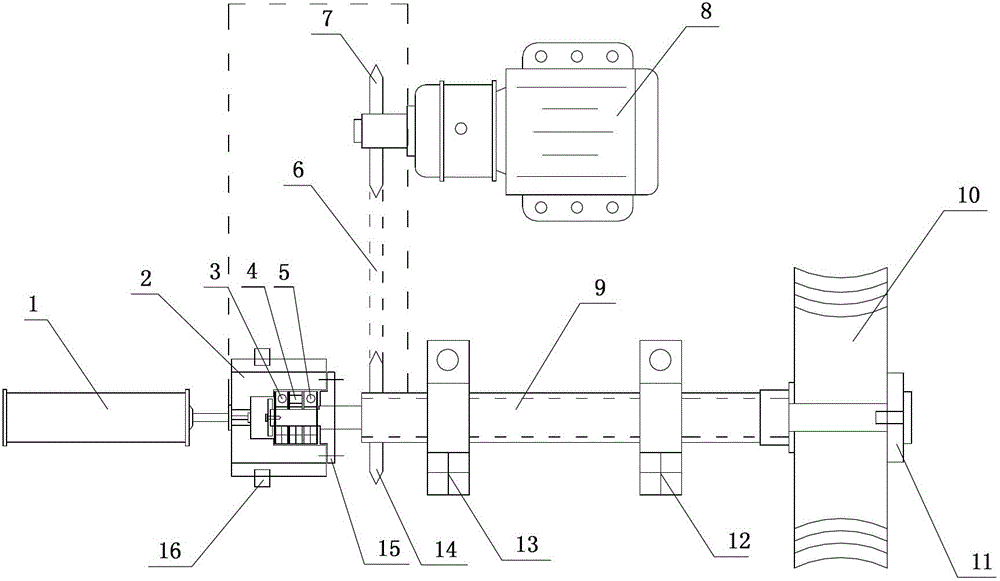

Automobile hub polishing method and device

ActiveCN103084966BImprove polishing uniformitySurface Topography RefinementEdge grinding machinesGrinding machine componentsEngineeringAbrasive

The invention discloses an automobile hub polishing method which comprises the following steps: 1, white steel jade balls serving as grinding materials are filled in a rotating barrel, wherein phi of each white steel jade ball is from 1mm to 2mm, and a rotating shaft of the rotating barrel is perpendicular to the ground; 2, an automobile hub is clamped on a main shaft, the main shaft and the rotating shaft of the rotating barrel are arranged in an intersecting mode; 3, the rotating barrel and the main shaft are rotated simultaneously, and polishing process is conducted; 4, the white steel jade ball grinding materials in the rotating barrel are changed to white alumina porcelain ball grinding materials, the rotating barrel and the main shaft are rotated continuously, and the polishing process is conducted; and 5, the automobile hub is dismounted and placed in a designated place to be cleaned. The automobile hub polishing method and the device can greatly improve polishing efficiency and polishing quality of the automobile hub.

Owner:湖州中云机械制造股份有限公司

A push-type polishing mechanism based on medical slider

ActiveCN112720232BThe same amount of sandingImprove polishing uniformityGrinding carriagesPolishing machinesPolishingElectric machinery

The invention discloses a push-type polishing mechanism based on a medical slider, which comprises a base, one end of the base is fixedly installed with a guide plate, a slider is clamped between the guide plates, a guide groove is opened on one side of the guide plate, and the slider and the guide groove are installed between the guide plates. Rotating mechanism, the positioning mechanism is installed on the slider, the rotating mechanism is connected to the positioning mechanism, one side of the slider is connected to the push rod, the driving mechanism is installed on the top of the base, the push rod is connected to the driving mechanism, the top of the guide plate is installed with a vertical plate, and the outer wall of the vertical plate is fixed Install the polishing motor, and the output shaft of the polishing motor rotates through the vertical plate and fixedly installs the grinding disc. The parts are positioned and clamped on the slider by the positioning mechanism, and the drive mechanism drives the push rod to reciprocate at a constant speed, then the push rod pushes the slider to slide between the guide plates. When the slider slides, the rotating mechanism drives the part to rotate, and the polishing motor drives the grinding disc. When grinding the outer wall of the part, the part maintains the reciprocating rotation state, and the grinding is more uniform, so that the surface cylindricity of the cylindrical part remains unchanged after polishing.

Owner:XUZHOU SHENFENG PRECISION MASCH CO LTD

Wafer rotating chuck optimized on basis of cathode spray head position change

ActiveCN106346354AConstant densityImprove polishing uniformitySemiconductor/solid-state device manufacturingWork carriersEngineeringRADIUS

The invention discloses a wafer rotating chuck optimized on the basis of cathode spray head position change. A polishing current is regulated on the basis of position change in the cathode spray head moving process, and then the purpose of uniform polishing is achieved. According to the technical scheme, the radius of the chuck is larger than that of a wafer, a circular ring is arranged on the portion, exceeding the wafer, of the chuck, a wafer slot is formed in the middle of the chuck and used for adsorbing the wafer, and a power supply, a cathode spray head and an anode spray head are arranged below the chuck; the position of the anode spray head is constant relative to the wafer, the cathode spray head moves to the circular ring outside the wafer from the center of the wafer along the radius of the wafer, when the cathode spray head moves to the edge of the wafer, the intersection area of the cathode spray head and the wafer is decreased along with movement, and the polishing current on the cathode spray head is correspondingly decreased.

Owner:ACM RES SHANGHAI

Ceria serosity combination with reinforced polishing uniformity

InactiveCN1872900BReduce saggingReduce erosionOther chemical processesSemiconductor/solid-state device manufacturingSlot insulationAlcohol

The invention discloses a chemical mechanical polishing slurry compound. It comprises: ceric oxide grinding agent; polycarboxylic acids or polycarboxylate with weight average molecular weight being 50,000-500,000; alcohol compound and water. The optimum proportion by weight of components in relative to total slurry compound are: ceric oxide grinding agent 0.1-20%, polycarboxylic acids or polycarboxylate 0.01-20%, alcohol compound 0.001-10%, and the pH of said slurry is 5-10. The CMP slurry compound is processed with STI (shallow slot insulation) method to form multiplayer construction and increase polishing uniformity and inhibit dent and corrosion of chip.

Owner:DONGJIN SEMICHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com