Polishing device for metal part

A polishing device and a technology for metal parts, which are applied in the direction of used abrasive processing devices, metal processing equipment, abrasives, etc., can solve the problems of low polishing efficiency of metal parts, inability to meet high-efficiency production, and long polishing time, so as to improve the overall The effect of polishing uniformity, improving the overall polishing efficiency, and improving the stability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

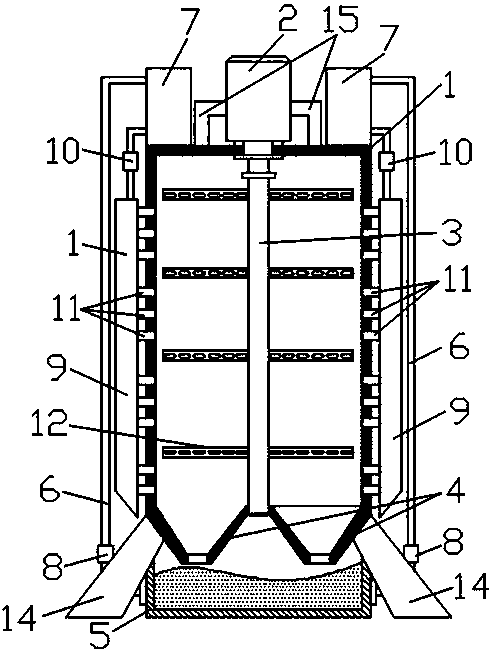

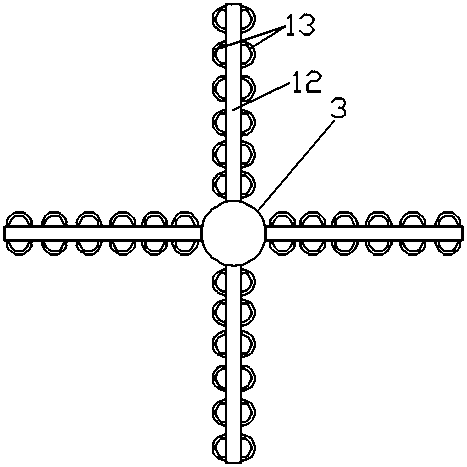

[0022] Embodiment 1: There are four hanging rods 12 in the hanging rod group.

Embodiment 2

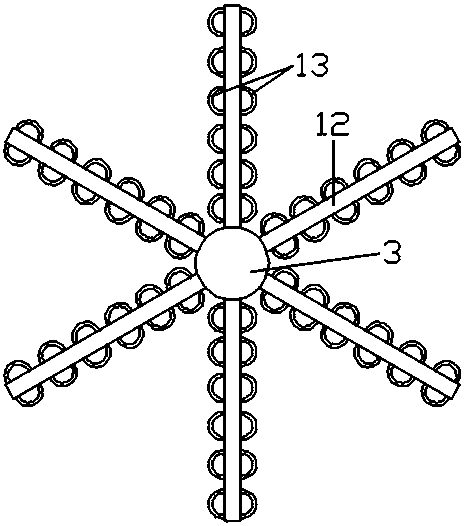

[0023] Embodiment 2: There are six hanging rods 12 in the hanging rod group.

[0024] The principle of operation of the polishing device for metal parts is as follows:

[0025] First of all, the operator can hang the metal parts on the hanging rod 12 through the hook, and then during the sandblasting process, the electric drive reduction motor 2 runs, so that the rotating shaft 3 can rotate to drive the hanging rod group to rotate, and the hanging rod group The hanging metal parts can be rotated by themselves, so that they can be polished at 360 degrees without dead angles, which can greatly improve the uniformity of polishing, shorten the overall polishing time, and improve polishing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com