Intelligent production line for high-speed aluminum bar saw cutting

A technology of intelligent processing and high-speed sawing, applied in metal sawing equipment, metal processing equipment, sawing machine devices, etc., can solve the problems of product similarity, surplus of ordinary products, and unreasonable industrial structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing:

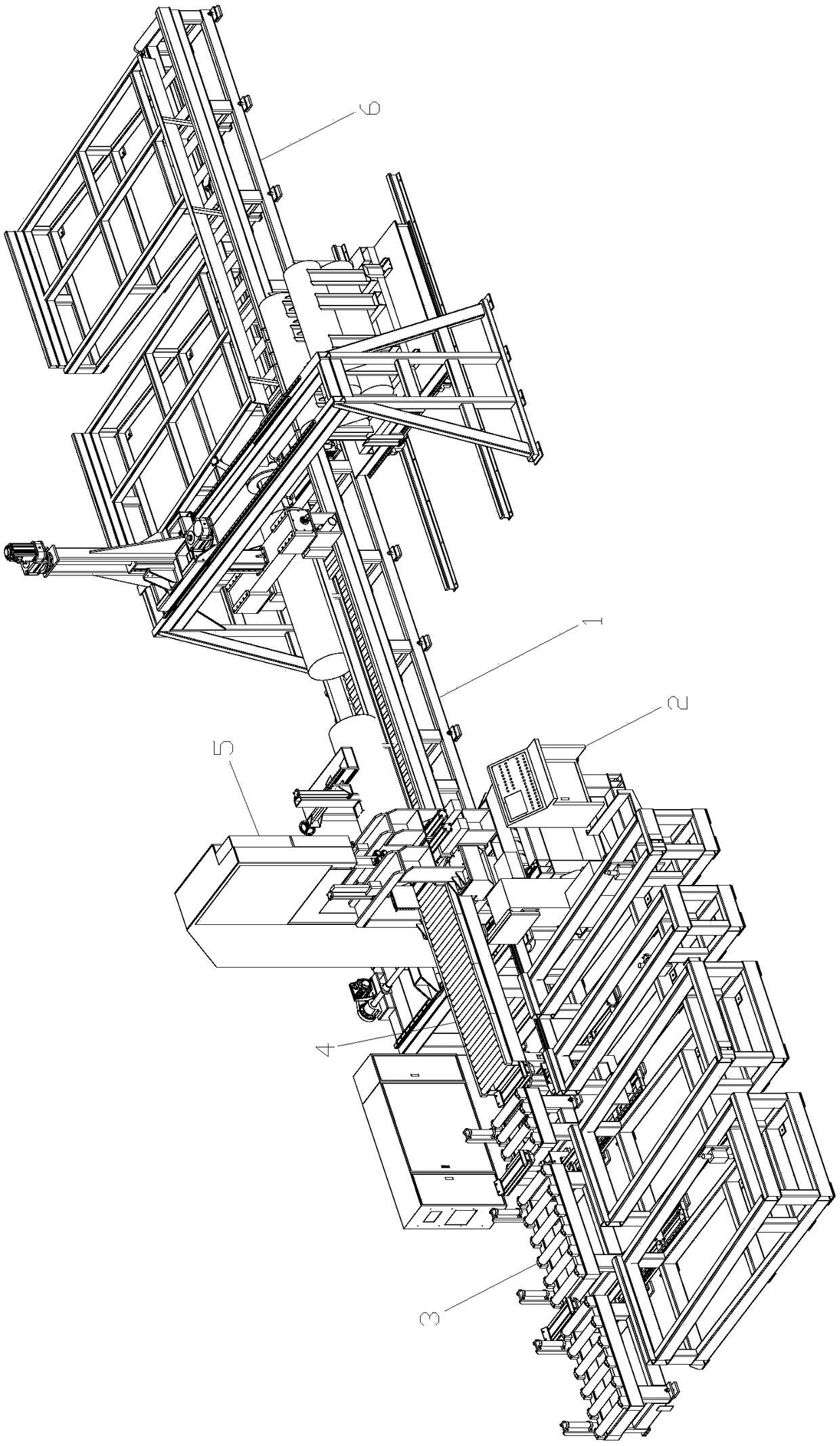

[0042] Referring to the accompanying drawings: this aluminum rod high-speed sawing intelligent processing line includes a body 1, an operation table 2 for controlling the operation of the body 1, and the body 1 includes a feeding device 3 for conveying aluminum rods, which cooperates with the feeding device 3 The feeding and sizing device 4 used, the host sawing device 5 used in conjunction with the feeding and sizing device 4, and the discharging device 6 for discharging after sawing;

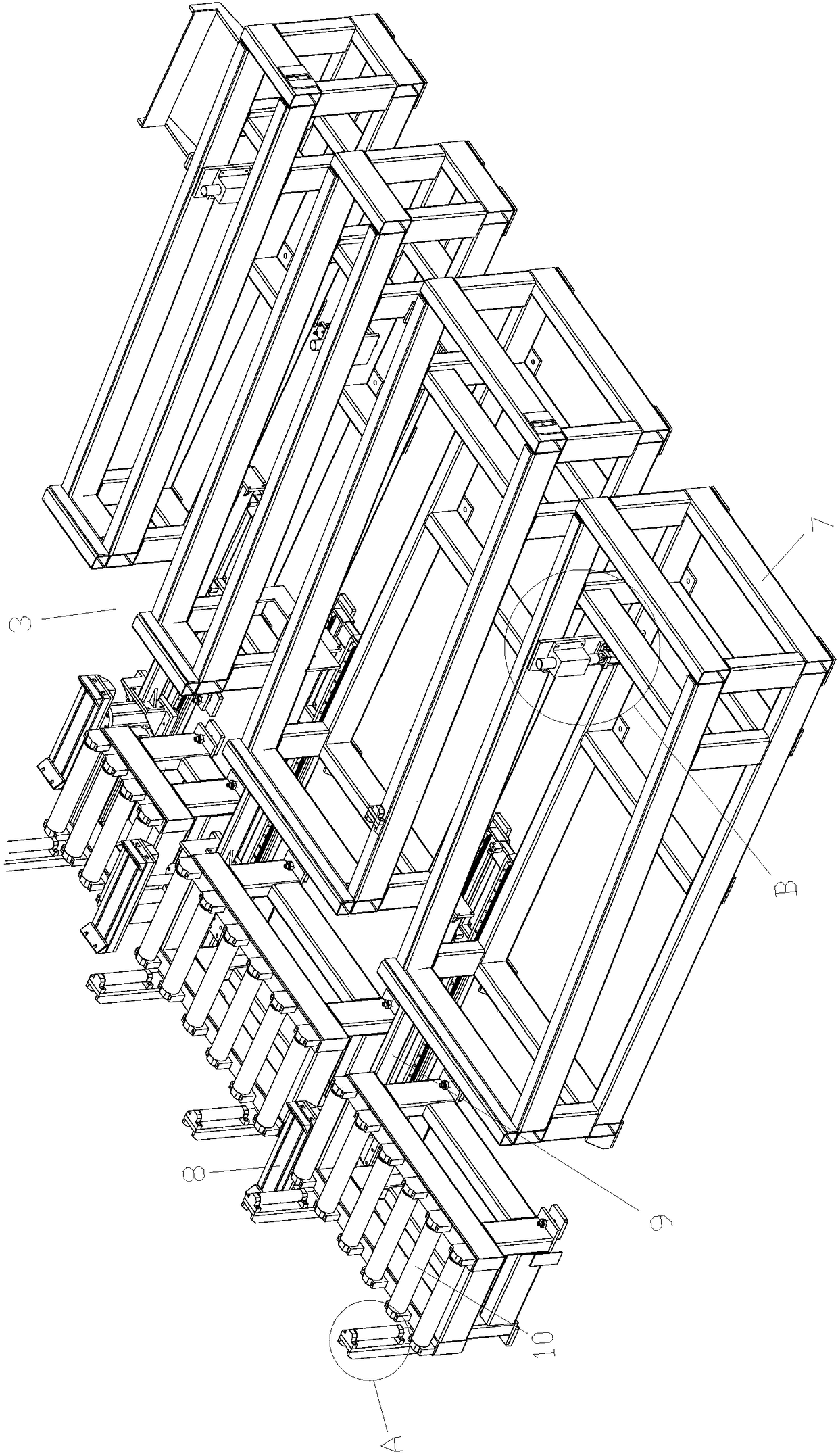

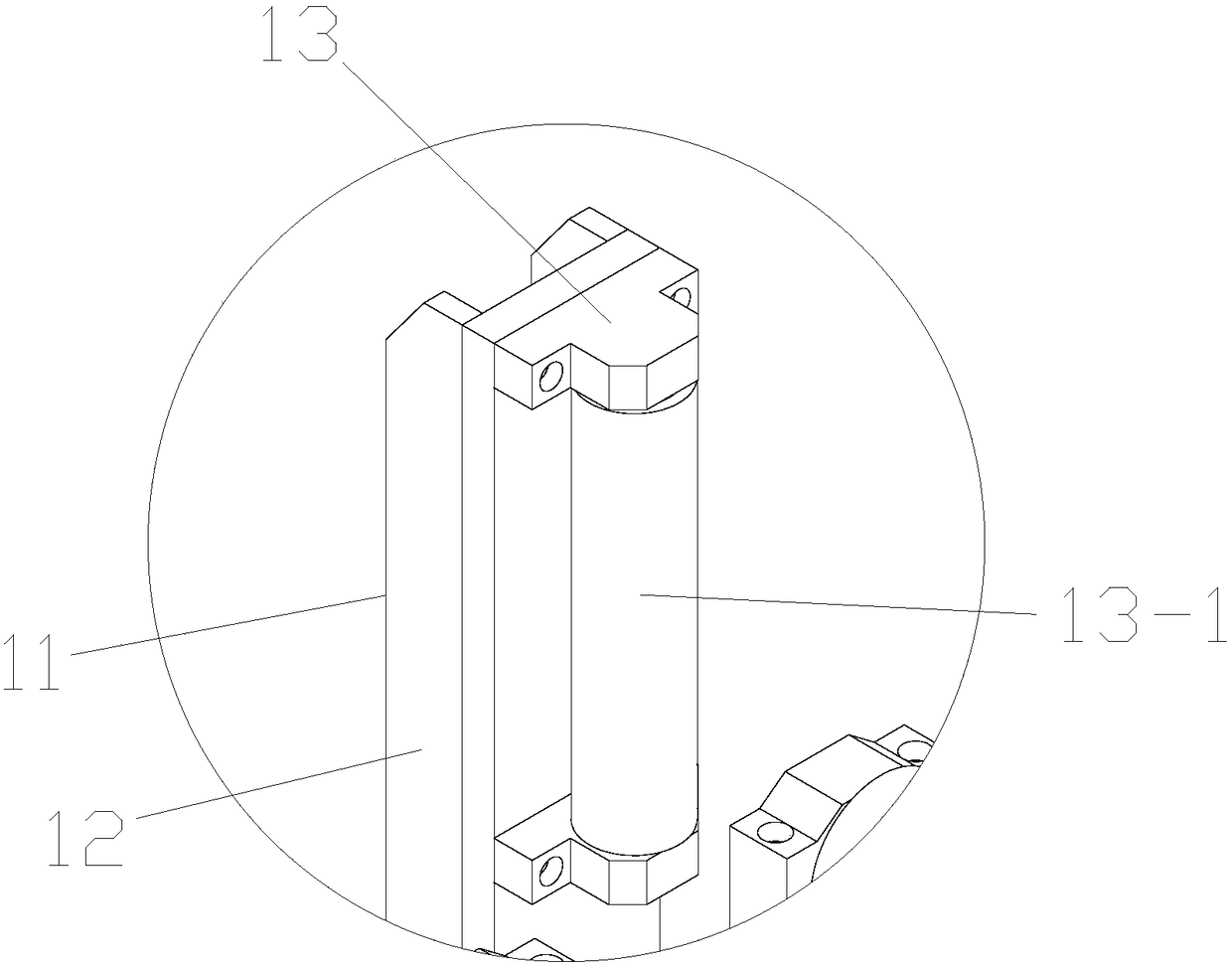

[0043] The feeding device 3 includes a row of feeding material holders 7 distributed at intervals and placed horizontally. A feeding trolley unit 8 is arranged between adjacent feeding material holders 7. Frame 9, the side portion of feeding material bearing frame 7 is provided with the feeding roller conveying frame 10 that placement position is consistent with feeding material bearing fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com