Polishing head and chemical mechanical polishing device and method

A chemical machinery and polishing head technology, applied in grinding devices, grinding/polishing equipment, grinding machine tools, etc., can solve the problems of difficult to control the thickness at the extreme edge of the wafer, the thickness cannot meet the polishing requirements, etc., to improve the polishing uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In order to solve the problems in the prior art, the invention provides a polishing head, comprising:

[0032] The main body is used to clamp the wafer and make the surface of the wafer to be polished face down for chemical mechanical polishing; wherein,

[0033] An edge liquid supply circuit is provided on the main body, and the edge liquid supply circuit is used to provide liquid to the edge of the wafer during chemical mechanical polishing to change the concentration of the polishing liquid at the edge of the wafer .

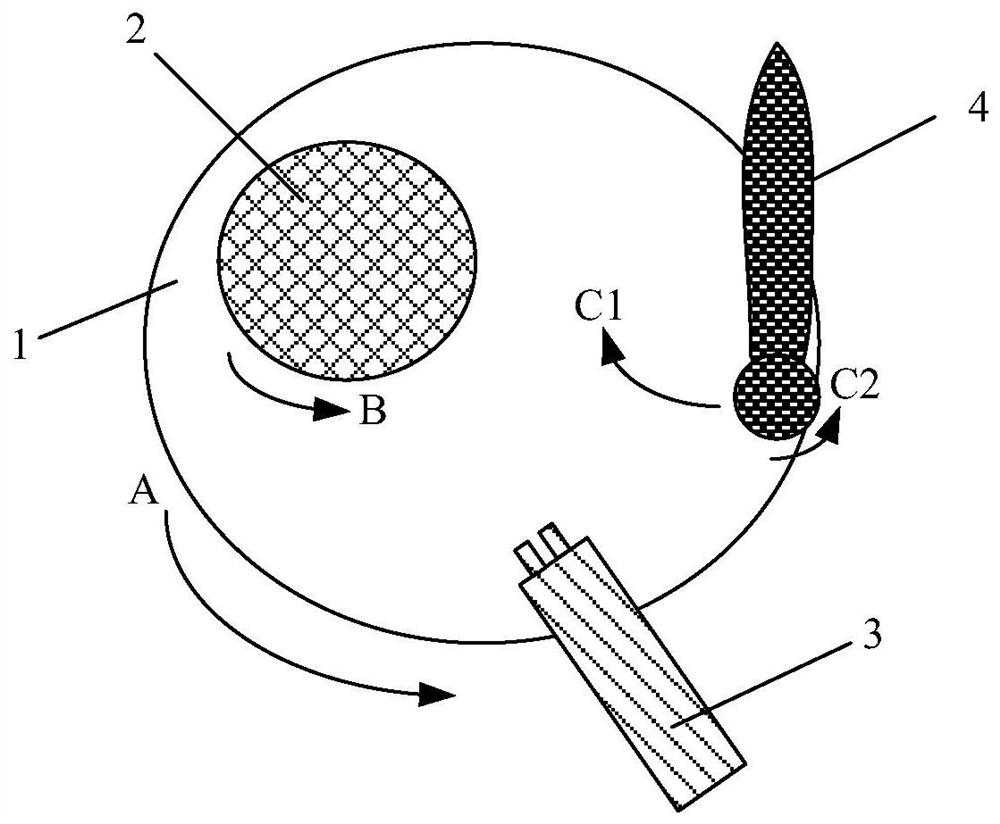

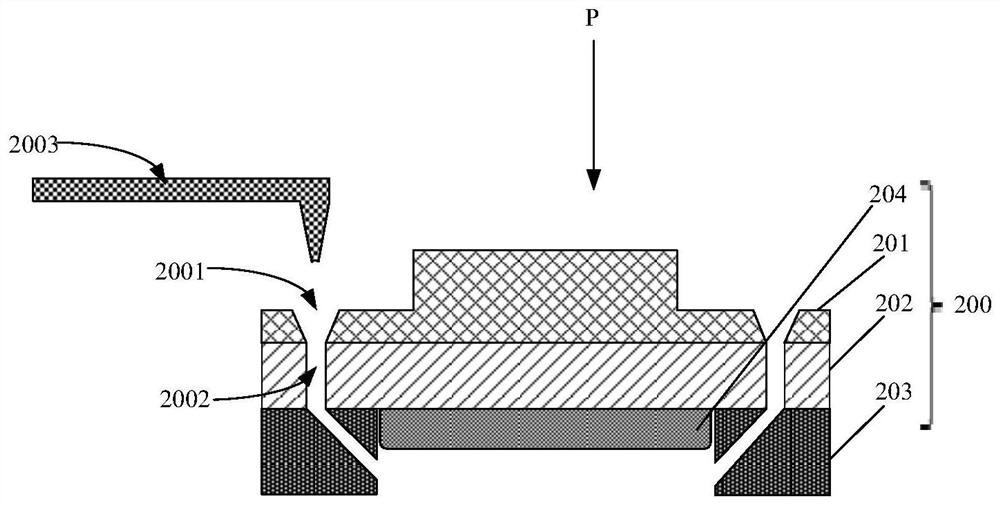

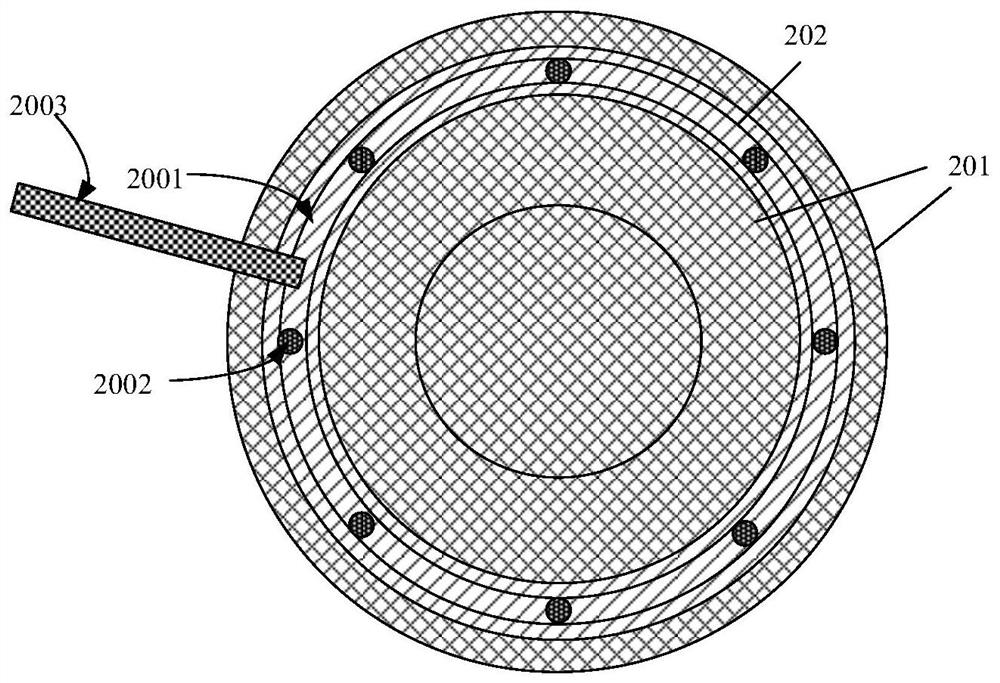

[0034] see below figure 1 , Figure 2A-Figure 2B and image 3 A polishing head according to the present invention is exemplified. in, figure 1 It is a schematic plan layout diagram of a chemical mechanical polishing device according to an embodiment; Figure 2A It is a structural schematic diagram of a polishing head according to an embodiment of the present invention; Figure 2B for from Figure 2A Schematic diagram of the structure of the pol...

Embodiment 2

[0059] The present invention also provides a chemical mechanical polishing device, which includes the polishing head as described in the first embodiment.

[0060] According to the chemical polishing device of the present invention, in the chemical mechanical polishing process, the polishing head provides liquid to the edge of the wafer to change the concentration of the polishing liquid on the edge of the wafer, thereby changing the polishing rate of the edge of the wafer, thereby controlling the chemical polishing of the edge of the wafer. The mechanical polishing rate improves the polishing uniformity of the wafer in the chemical mechanical polishing process.

Embodiment 3

[0062] The present invention also provides a chemical mechanical polishing method, which specifically includes: during the process of performing a chemical mechanical polishing process to perform chemical mechanical polishing on a wafer, providing a liquid to the edge of the wafer to change the The concentration of the polishing solution.

[0063] The liquid includes deionized water and / or grinding liquid, wherein the concentration of the grinding liquid is adjustable.

[0064] The liquid that provides liquid to the edge of the wafer includes deionized water or polishing fluid, wherein deionized water is provided to the edge of the wafer to dilute the polishing fluid on the edge of the wafer, thereby reducing the polishing rate of the edge of the wafer; Provide polishing fluid, the concentration of which can be adjusted according to the polishing rate of the wafer edge. For example, when the polishing rate at the edge of the wafer is low, the edge of the wafer is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com