Chemical mechanical polishing conditioner having different heights

a technology of mechanical polishing conditioner and height, which is applied in the direction of grinding drive, abrasive surface conditioning device, manufacturing tool, etc., can solve the problems of reducing the polishing effect and efficiency, scratching, local over-polishing, etc., to improve the drainage of abrasive slurry, improve the uniformity of polishing, and prevent thermal deformation of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

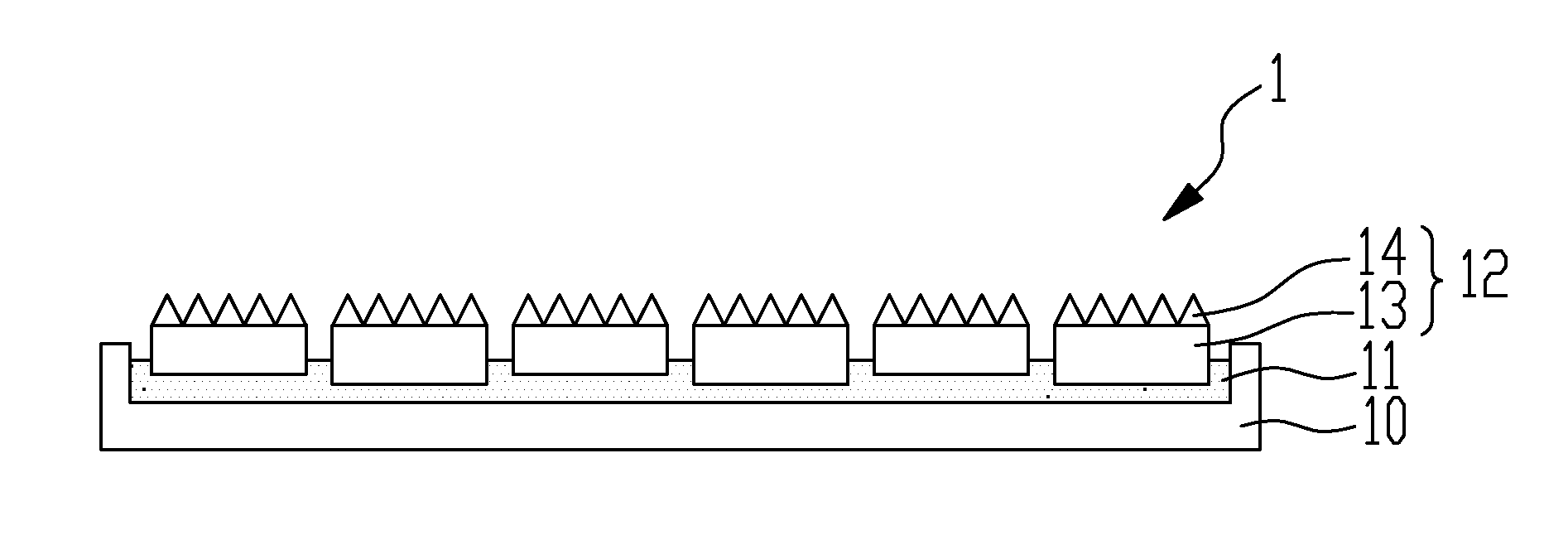

[0036]With reference to FIG. 1A, the present invention provides a chemical mechanical polishing conditioner having different heights 1. The chemical mechanical polishing conditioner having different heights 1 comprises a substrate 10 made of stainless steel, a binding layer 11, and multiple abrasive units 12. The substrate 10 is a flat substrate and has a thickness of 80 mm. The binding layer 11 is disposed on the substrate 10. Each abrasive unit 12 has an abrasive unit substrate 13 and an abrasive layer 14. The abrasive unit substrate 13 is a ceramic substrate made of silicon carbide. The abrasive unit substrates 13 have two different thicknesses, 20 mm and 30 mm. A surface of the abrasive unit substrate 13 is a flat surface and the abrasive layer 14 is successively formed on the surface tips by chemical vapor deposition to obtain multiple abrasive tips. The abrasive tips are in the shape of pyramids. Specifically, with reference to FIG. 5A, the abrasive tips are continuously arran...

embodiment 2

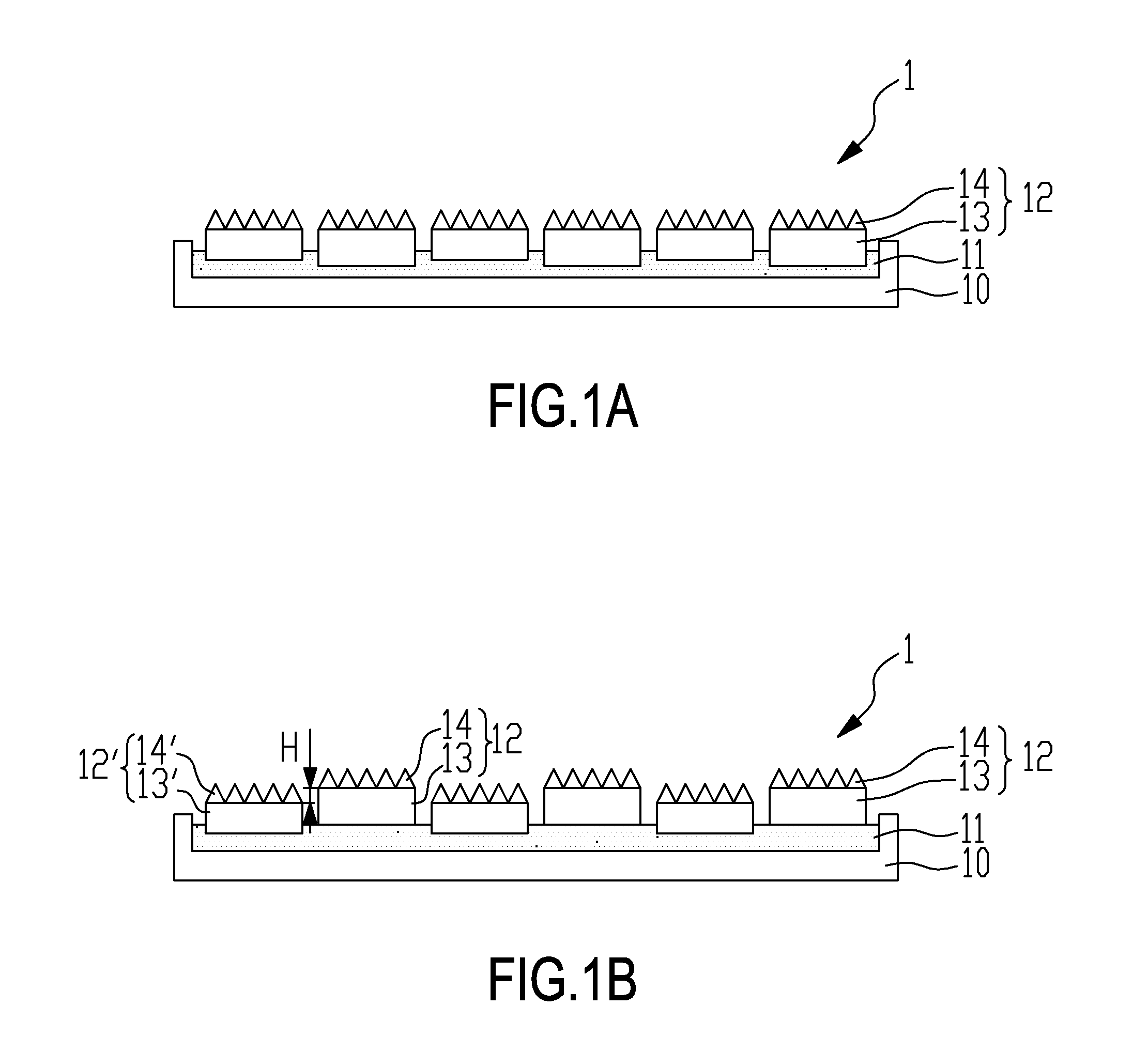

[0037]With reference to FIG. 2, the CMP conditioner having different heights 2 in Embodiment 2 is similar with the CMP conditioner having different heights in Embodiment 1. The difference between the two embodiments is that the thicknesses of the abrasive units of the CMP conditioner having different heights in Embodiment 1 are different and the thickness of the binding layer of the CMP conditioner having different heights in Embodiment 1 is fixed. However, the thicknesses of the abrasive units of the CMP conditioner having different heights in Embodiment 2 are equal and thickness of the binding layer of the CMP conditioner having different heights in Embodiment 2 is varied. The CMP conditioner having different heights 2 of the present embodiment comprises the substrate 20 made of stainless steel, the binding layer 21, and the abrasive units 22. The substrate 20 is a flat substrate and has a thickness of 80 mm. The binding layer 21 is disposed on the substrate 20. Each abrasive unit...

embodiment 3

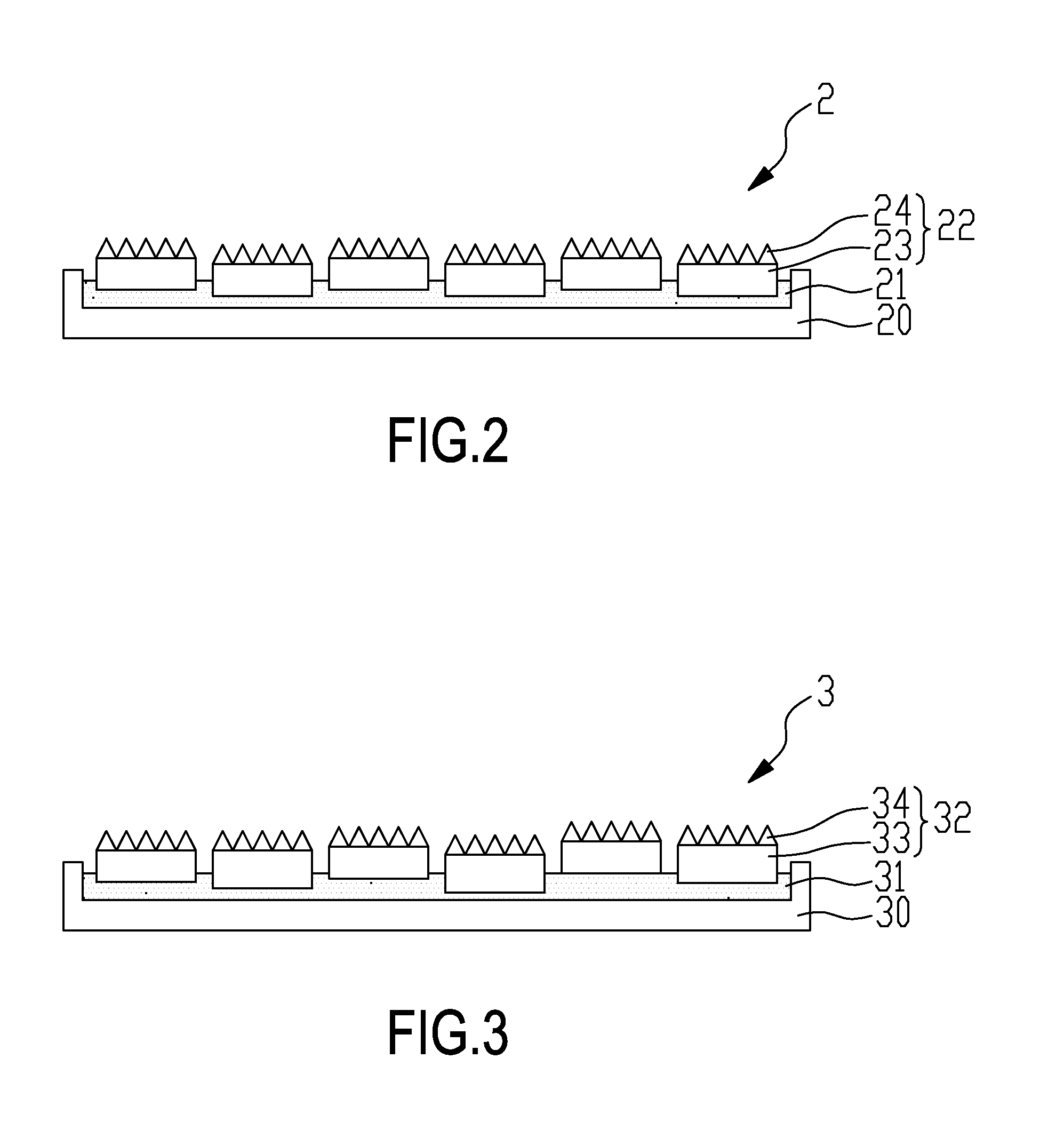

[0038]With reference to FIG. 3, the CMP conditioner having different heights 3 in Embodiment 3 is similar with the CMP conditioner having different heights in Embodiment 1. The difference between the two embodiments is that thicknesses of the abrasive units of the CMP conditioner having different heights in Embodiment 1 are different and thickness of the binding layer of the CMP conditioner having different heights in Embodiment 1 is fixed. However, the thicknesses of the abrasive units of the CMP conditioner having different heights in Embodiment 3 are different and the thickness of the binding layer of the CMP conditioner having different heights in Embodiment 3 is varied. The CMP conditioner having different heights 3 of the present embodiment comprises the substrate 30 made of stainless steel, the binding layer 31, and the abrasive units 32. The substrate 30 is a flat substrate and has a thickness of 80 mm. The binding layer 31 is disposed on the substrate 30. Each abrasive unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com