Novel electrochemical polishing device

A polishing device and electrochemical technology, applied in the field of new electrochemical polishing devices, can solve the problems of unsatisfactory wafer polishing uniformity, difficult to control the shape of liquid column stably, polishing result is not stable, etc., so as to improve polishing uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

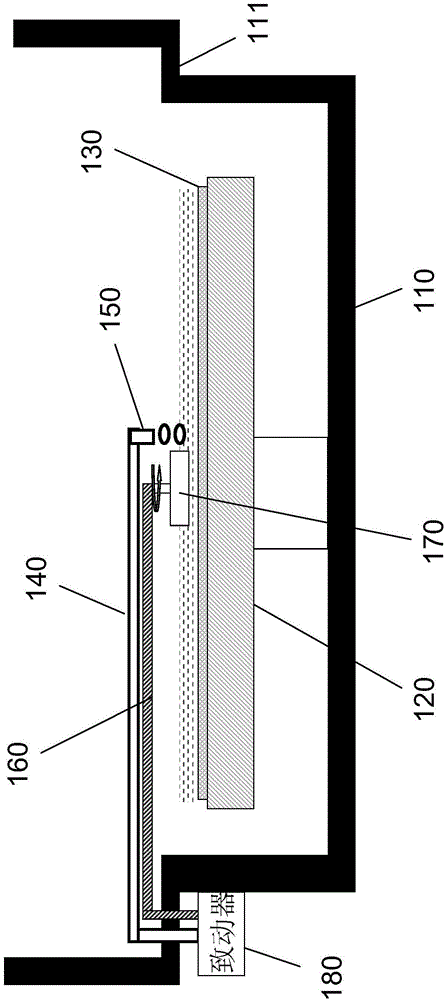

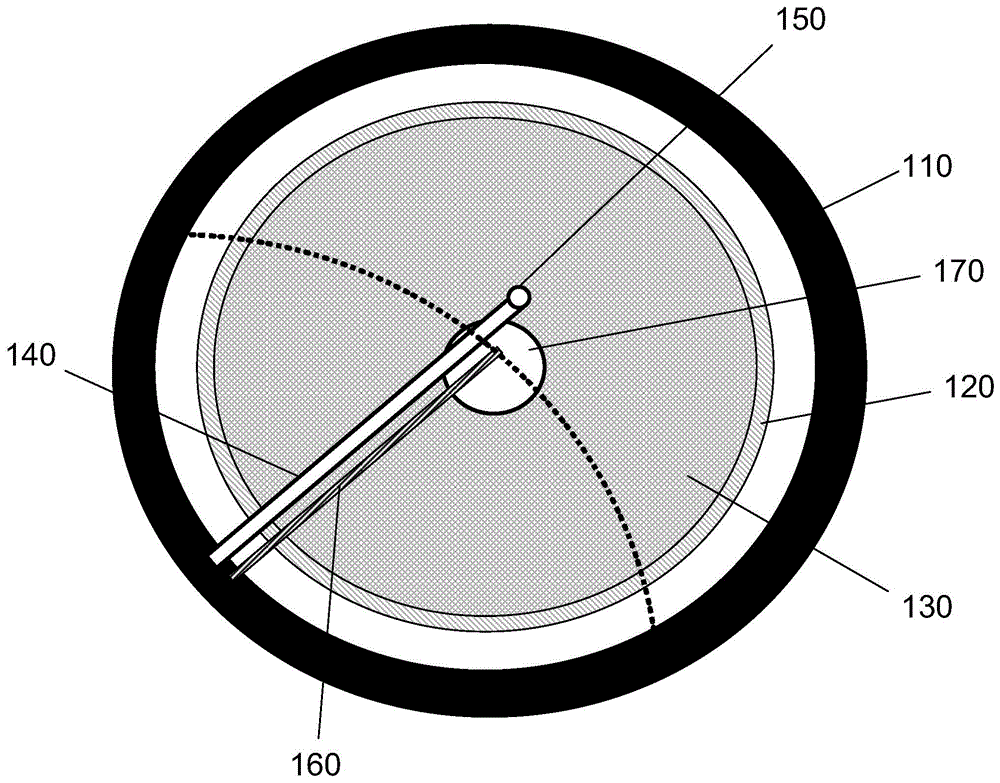

[0023] refer to figure 1 and figure 2 , The novel electrochemical polishing device according to the first embodiment of the present invention includes a polishing chamber 110, a wafer chuck 120, an electrolyte supply device, and a polishing power circuit forming device.

[0024] The polishing cavity 110 has a bottom wall and a side wall, and the side wall of the polishing cavity 110 extends outward to form a stepped portion 111 . The wafer chuck 120 is located in the polishing chamber 110 , and the wafer chuck 120 is arranged on the bottom wall of the polishing chamber 110 . The wafer chuck 120 holds the wafer 130 horizontally, and the surface of the wafer 130 to be polished is upward. The wafer chuck 120 can be a vacuum chuck. Driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com