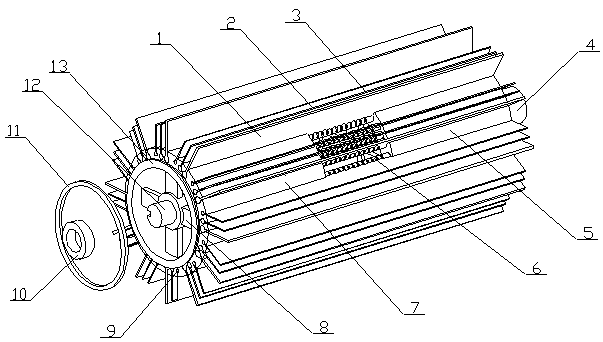

Grinding roller of polishing machine

A polishing machine and emery roller technology, which is applied in the field of wood processing, can solve the problems of large polishing limitations, waste, and affecting the surface finish of special-shaped parts, and achieve the effect of improving polishing uniformity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

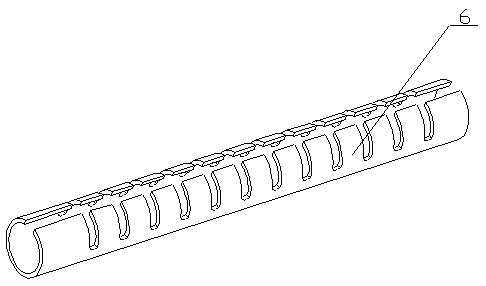

[0022] The sand roller of a polishing machine of the present invention is realized in this way. When in use, the transmission rod is connected with the drive motor shaft of the polishing machine through the transmission sleeve (4), so that the transmission rod and the drive motor shaft are coaxial, and the other end of the drive rod is fixed On the support table of the polishing machine, the drive motor shaft rotates to drive the transmission shaft (12) to rotate through the transmission sleeve (4), and the transmission shaft (12) is transmitted through the rectangular protrusion on the support plate (8) to drive the support plate ( 8) Rotate synchronously, so that the main sand roller (7) and the auxiliary sand roller (5) rotate, and when rotating, the corresponding emery cloth belt (1), the first brush (3) and the second brush (2) rotate , move the plate to fit the emery cloth belt (1) step by step, and perform polishing and grinding. When the arc surface needs to be polished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com