Polishing pad with grooves in surface

A polishing pad and groove technology, applied in the field of polishing pads, can solve the problems of low utilization of polishing liquid, affecting polishing quality, and over-polishing at the edge, so as to improve polishing uniformity, ensure polishing quality, and prevent over-polishing at the edge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

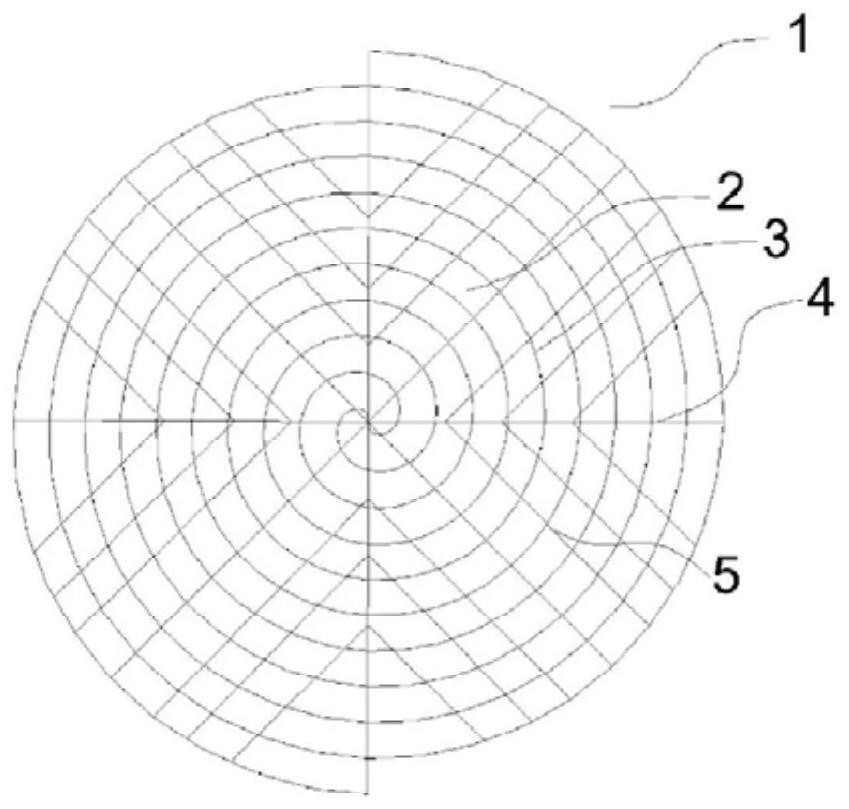

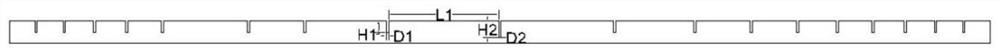

[0039] Such as figure 1 As shown, the polishing pad provided in this embodiment includes a substrate layer (not shown in the figure) and a polishing layer 1 , and the surface of the polishing layer 1 is provided with a first groove 3 , a second groove 4 and a third groove 5 . The first groove 3 is a double helix starting from the center of the circle. The width of the first groove 3 is D1, 1mm≤D1≤3mm, for example, it can be 1mm, 1.5mm, 1.7mm, 2.1mm, 2.4mm, 3mm, etc. The depth of the first groove 3 is H1, 0.5mm≤H1≤2mm, for example, it can be 0.5mm, 0.7mm, 1.2mm, 1.8mm, 2mm and so on. The radial spacing of the first groove 3 Wherein, a is a parameter, 1≤a≤15, θ is the angle between a straight line connecting any point of the first groove 3 to the center of the circle and the horizontal direction, 0≤θ≤nΠ, n is an integer. Wherein, the spacing of the first grooves 3 along the radial direction is the same.

[0040] read on figure 1 , the second groove 4 is distributed along th...

Embodiment 2

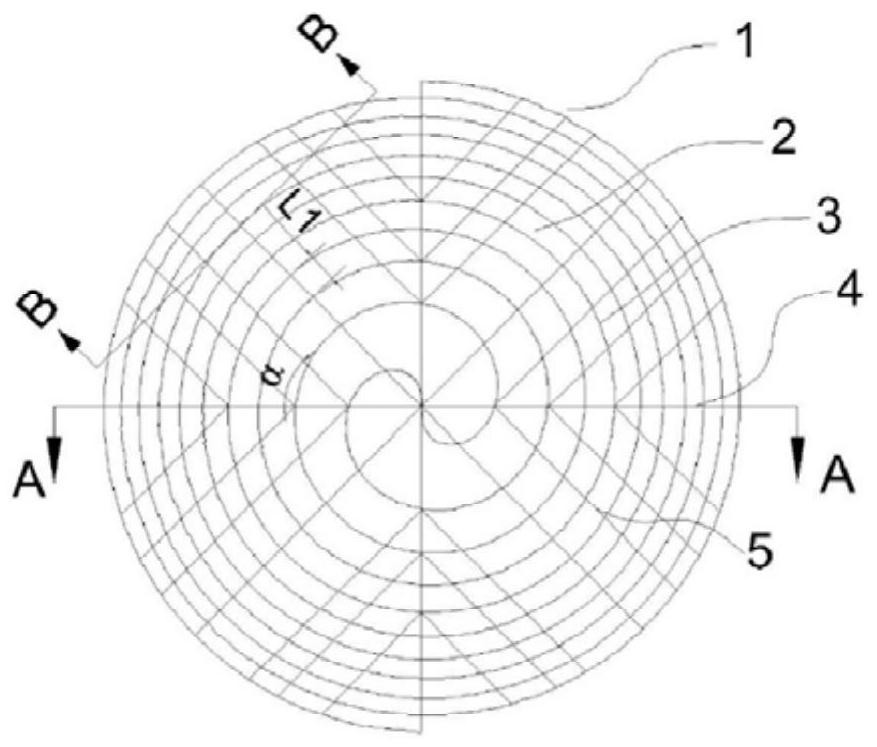

[0044] Such as Figure 2a - Figure 2c As shown, the difference between the polishing pad provided in this embodiment and the first embodiment is only that the distance between the first grooves 3 gradually decreases radially from the center of the polishing layer 1 .

[0045] Specifically, when the distances between the first grooves 3 are equal, the velocity of the polishing liquid will gradually increase when it moves toward the edge, and certain uneven polishing will occur. In this embodiment, after the distance between the first grooves 3 is reduced radially, the change in the tangential velocity of the polishing fluid flowing along the grooves is effectively delayed, the velocity distribution of the polishing fluid along the tangential direction is effectively improved, and the phenomenon of uneven polishing is reduced. .

[0046] Other parts of this embodiment are the same as those of Embodiment 1 and will not be repeated here.

Embodiment 3

[0048] Such as image 3 As shown, the difference between the polishing pad provided in this embodiment and the second embodiment is only that the shape of the middle region of the second groove 4 is a sinusoidal function.

[0049] Specifically, it can be set that the center area on the surface of the polishing layer 1 is the first grinding area 6, the edge area is the third grinding area 7, and the area between the first grinding area 6 and the third grinding area 7 It is the second grinding area 2 , and the middle area of the second groove 4 is basically located in the second grinding area 2 . The polishing liquid flows out in a straight line from the center of the circle in the first grinding area 6 along the second groove 4, which effectively improves the problem of uneven pressure distribution in the central area; the polishing liquid flows out in the second grinding area 2 along the sinusoidal trajectory of the second groove 4 , effectively increasing the contact time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com