Improved spanner polishing machine

A polishing machine, an improved technology, applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding racks, etc., can solve the problems of low production efficiency, small size range of wrenches, different force, etc., and achieve improvement Work efficiency, improve the effect of polishing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

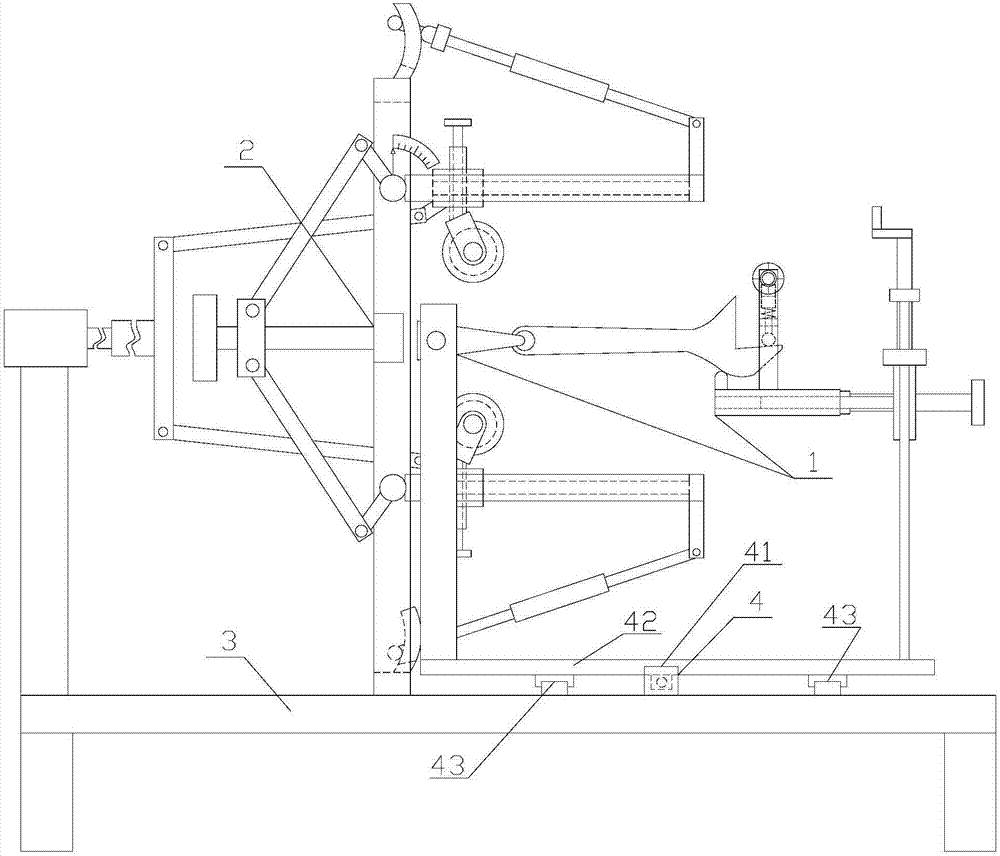

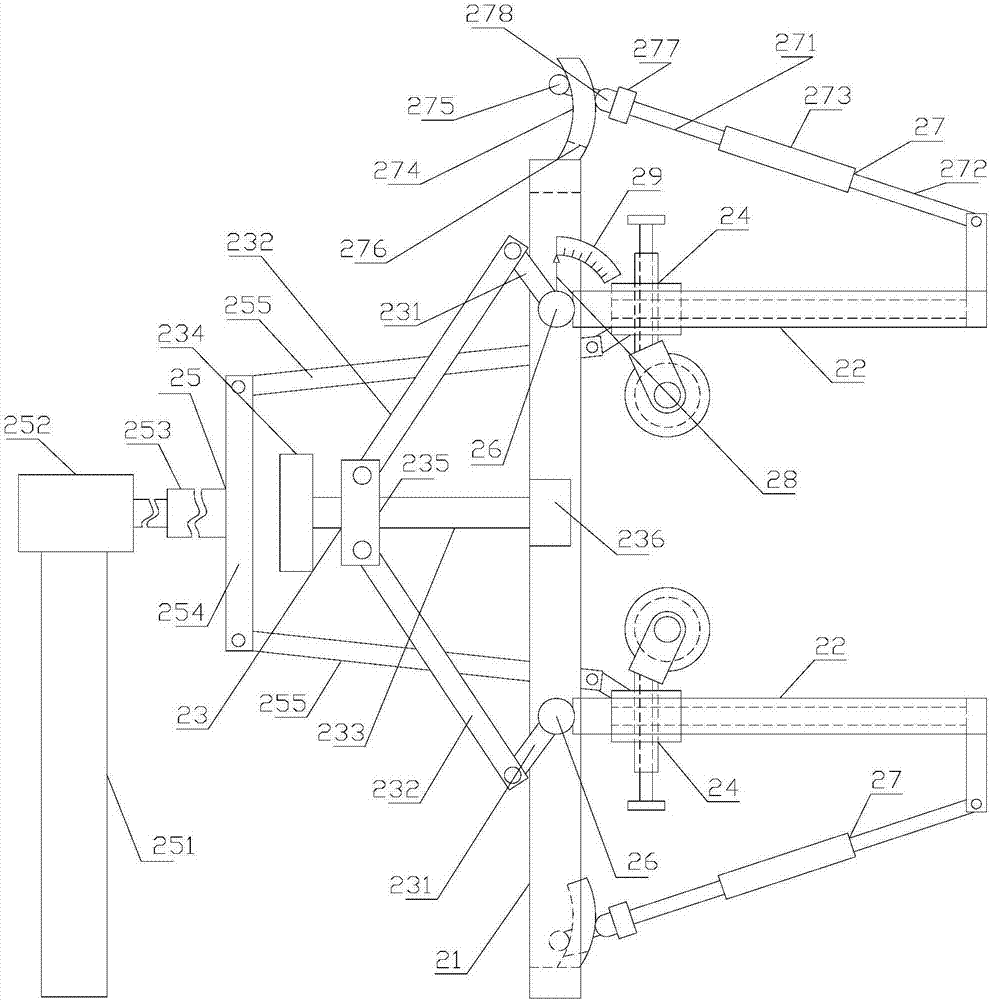

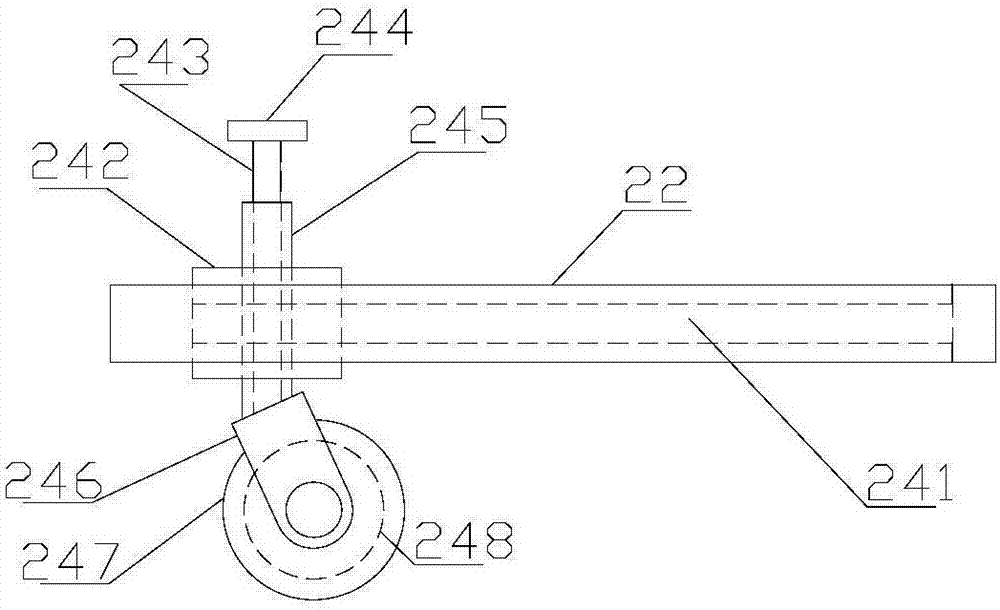

[0024] refer tofigure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , an improved wrench polishing machine of the present invention, comprising a wrench fixing device 1, a polishing device 2, a frame body 3 and a moving seat mechanism 4, the frame body 3 is provided with a moving seat mechanism 4 and a Polishing device 2, described mobile seat mechanism 4 is provided with wrench fixing device 1, and described wrench fixing device 1 comprises elevating mechanism 11, the adjustable fixing mechanism 12 of fixing wrench head and the fixing device 13 of the free end of fixing wrench handle, so The moving seat mechanism 4 is provided with a lifting mechanism 11 and a fixing device 13, and the lifting mechanism 11 is provided with an adjustable fixing mechanism 12, and the adjustable fixing mechanism 12 includes a shelving seat 121, two slide bars 122, an adjusting screw 123, adjusting disc 124, two pillars 125, connecting body 126, two sliding bodies 127, pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com