Coating device and coating method

A coating method and coating technology, which are applied to devices and coatings for coating liquids on the surface, can solve problems such as scattering, and achieve the effects of improving utilization, improving coating efficiency, and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are described in detail below:

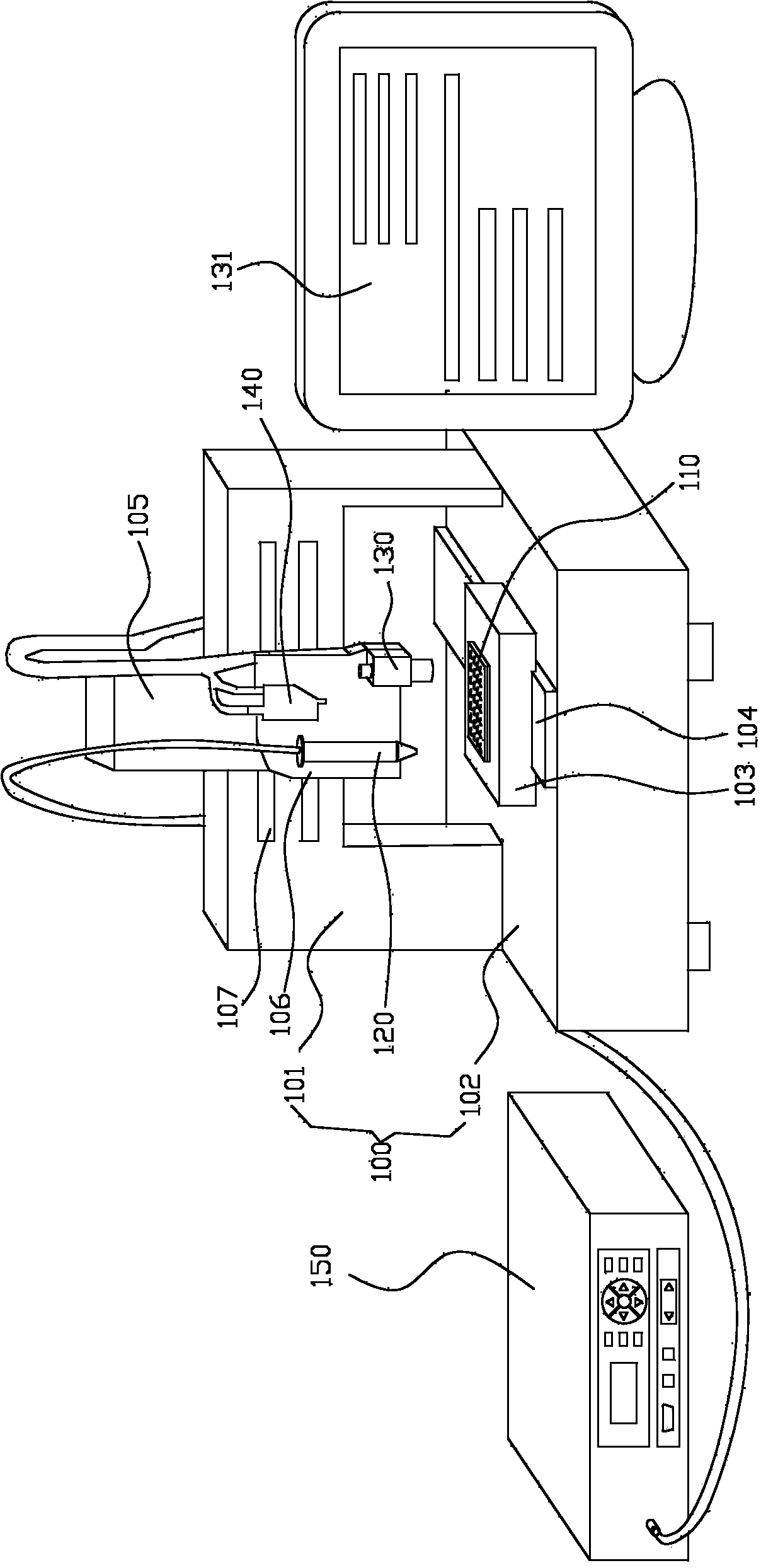

[0031] Such as figure 1 As shown, a coating device includes a bracket 100, a clamp 110 is slidably installed on the bracket 100, the needle 120 is slidably installed above the clamp 110, and above the clamp 110 is also provided with The laser emitting head 140 of the camera 130 and the laser height measuring device is connected with the needle head 120 to control the flow rate and the opening degree of the flow control device, and also includes a control device, the camera 130, the laser height measuring device and the The flow control devices are all connected to the control device; wherein, the needle head 120 can move vertically relative to the clamp 110, and by controlling the horizontal, vertical and vertical distances between the needle head 120 and the clamp 110, the needle head 120 can be arranged on the Paint is poured into the dot point of each product to be coated (plate, signboard) on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com