HPLC (High Performance Liquid Chromatography) analysis method for sodium 3,3'-dithiodipropane sulfonate

A technology of sodium polydithiodipropane sulfonate and high performance liquid chromatography, which is applied in the field of analysis, can solve the problems of inability to accurately measure the concentration of compounds, large errors in measurement results, and inaccurate content determination, etc., and achieve short measurement cycles , Easy to operate, strong repeatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) High performance liquid chromatography conditions:

[0038] Chromatographic column: KromasilC18, 5μm, 250mm×4.6mm;

[0039] Mobile phase composition volume ratio: methanol: buffer solution = 10:90;

[0040] Buffer solution: 0.17mol / L acetic acid + 0.142mol / L triethylamine + ultrapure water;

[0041] Flow rate: 0.8mL / min;

[0042] Column temperature: 25°C;

[0043] Detector: UV detector;

[0044] Detection wavelength: 230nm;

[0045] 2) Preparation of mobile phase: Accurately pipette 5ml of glacial acetic acid and 10ml of triethylamine into a 1L volumetric flask. Prepare the mobile phase with a buffer solution volume ratio of 10:90, mix well, degas with an ultrasonic cleaner for half an hour, and cool to room temperature;

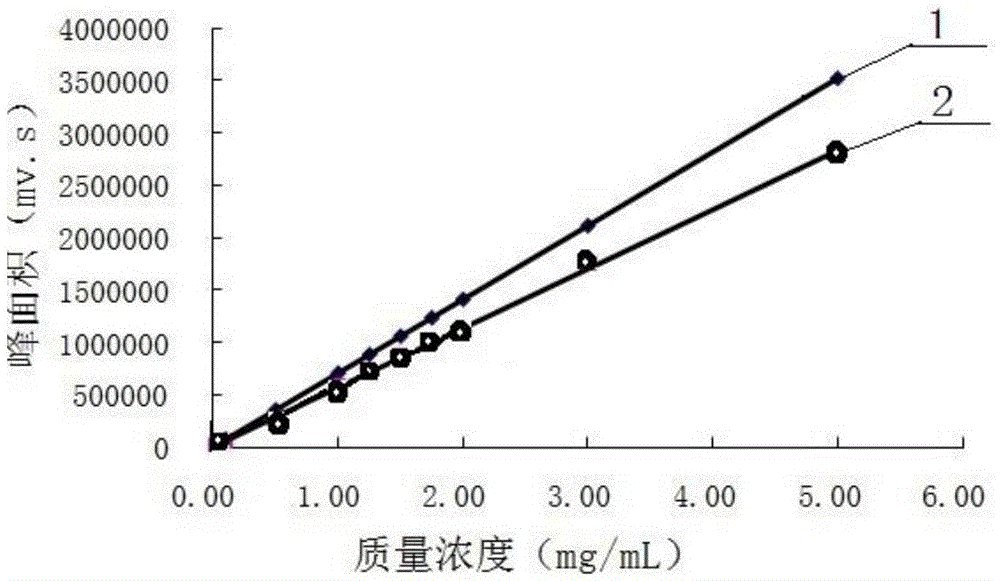

[0046] 3) Prepare standard solutions of sodium polydithiodipropanesulfonate with different concentrations: Accurately weigh 500.0 mg of imported sodium polydisulfidedipropanesulfonate in a 50ml volumetric flask, dissolve and constant volume w...

Embodiment 2

[0058] 1) High performance liquid chromatography conditions:

[0059] Chromatographic column: KromasilC18, 5μm, 250mm×4.6mm;

[0060] Mobile phase composition volume ratio: methanol: buffer solution = 20:80;

[0061] Buffer solution: 0.17mol / L acetic acid + 0.142mol / L triethylamine + ultrapure water;

[0062] Flow rate: 0.8mL / min;

[0063] Column temperature: 25°C;

[0064] Detector: UV detector;

[0065] Detection wavelength: 230nm;

[0066] 2) Preparation of mobile phase: Accurately pipette 5ml of glacial acetic acid and 10ml of triethylamine into a 1L volumetric flask. Prepare the mobile phase with a volume ratio of 20:80 to the buffer solution, mix well, degas with an ultrasonic cleaner for half an hour, and cool to room temperature;

[0067] 3) Prepare standard solutions of sodium polydithiodipropanesulfonate with different concentrations: Accurately weigh 500.0 mg of imported sodium polydisulfidedipropanesulfonate in a 50ml volumetric flask, dissolve and constant v...

Embodiment 3

[0074] 1) High performance liquid chromatography conditions:

[0075] Chromatographic column: KromasilC18, 5μm, 250mm×4.6mm;

[0076] Mobile phase composition volume ratio: methanol: buffer solution = 40:60;

[0077] Buffer solution: 0.17mol / L acetic acid + 0.142mol / L triethylamine + ultrapure water;

[0078] Flow rate: 0.8mL / min;

[0079] Column temperature: 25°C;

[0080] Detector: UV detector;

[0081] Detection wavelength: 230nm;

[0082] 2) Preparation of mobile phase: Accurately pipette 5ml of glacial acetic acid and 10ml of triethylamine into a 1L volumetric flask. Prepare the mobile phase with a buffer solution volume ratio of 10:90, mix well, degas with an ultrasonic cleaner for half an hour, and cool to room temperature;

[0083] 3) Prepare standard solutions of sodium polydithiodipropanesulfonate with different concentrations: Accurately weigh 500.0 mg of imported sodium polydisulfidedipropanesulfonate in a 50ml volumetric flask, dissolve and constant volume w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com