Patents

Literature

57results about How to "Effectively break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thrombectomy and tissue removal method

InactiveUS6926726B2Increase speedReduce local pressureCannulasSurgical instrument detailsThrombusHigh pressure

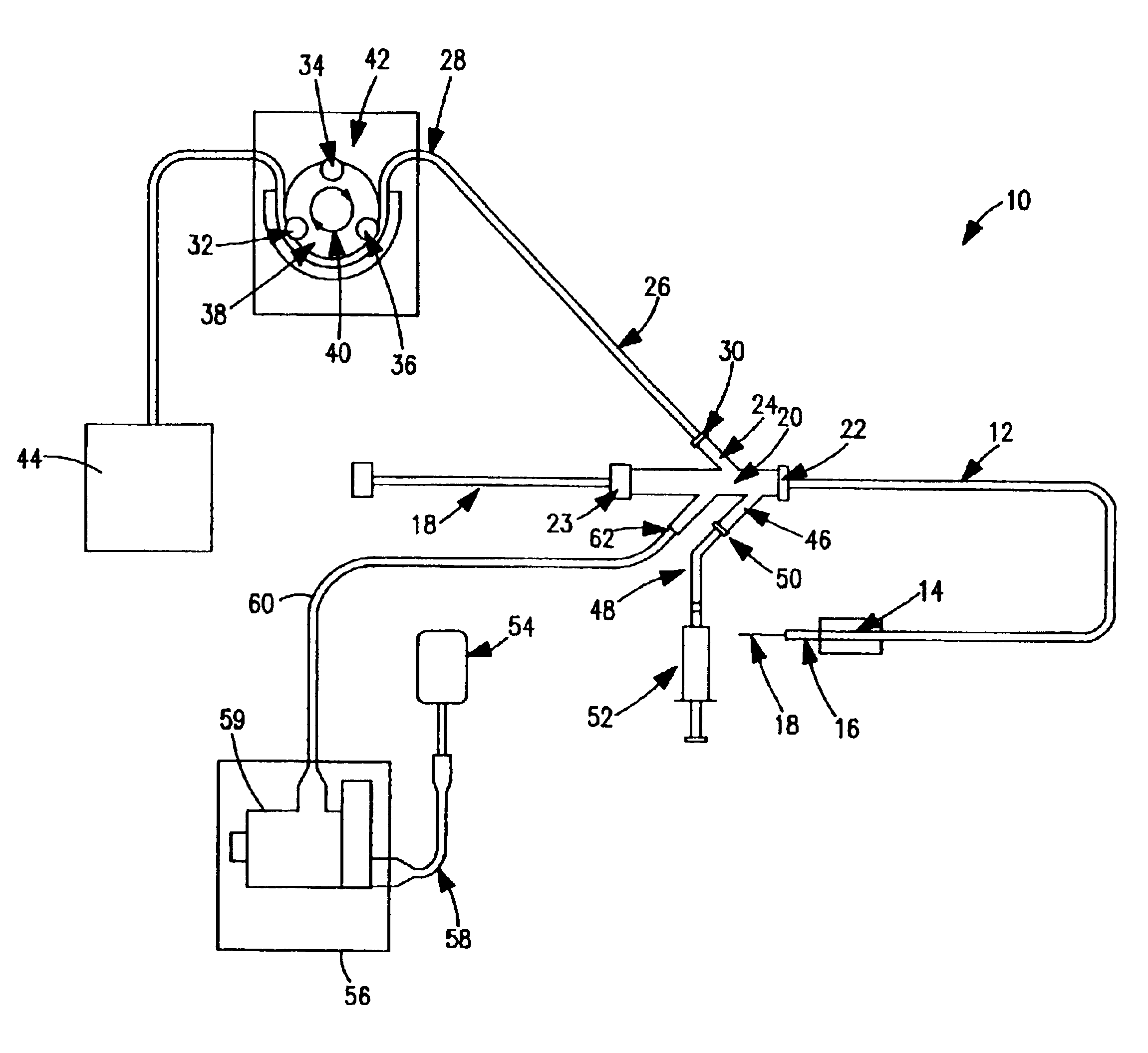

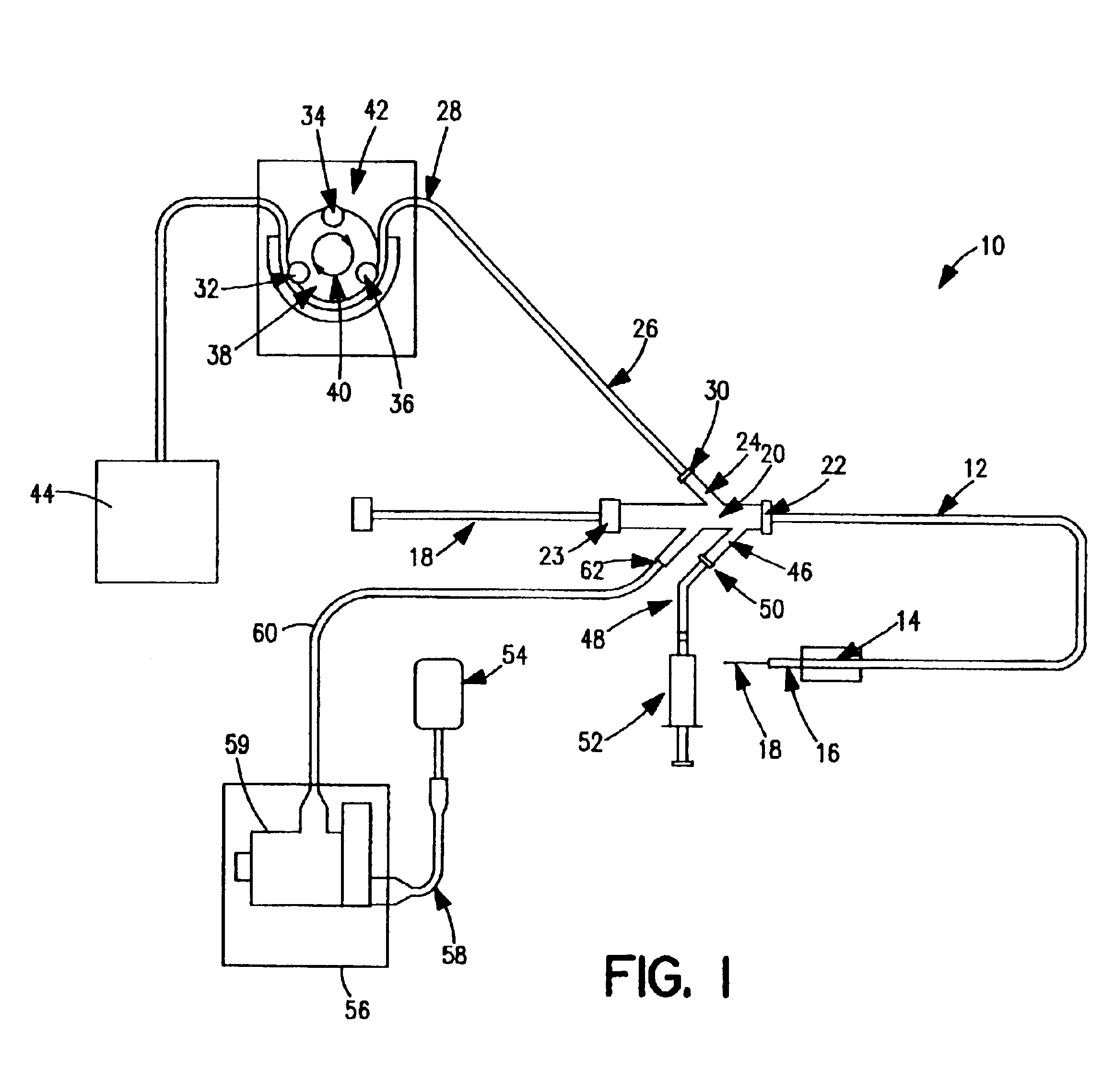

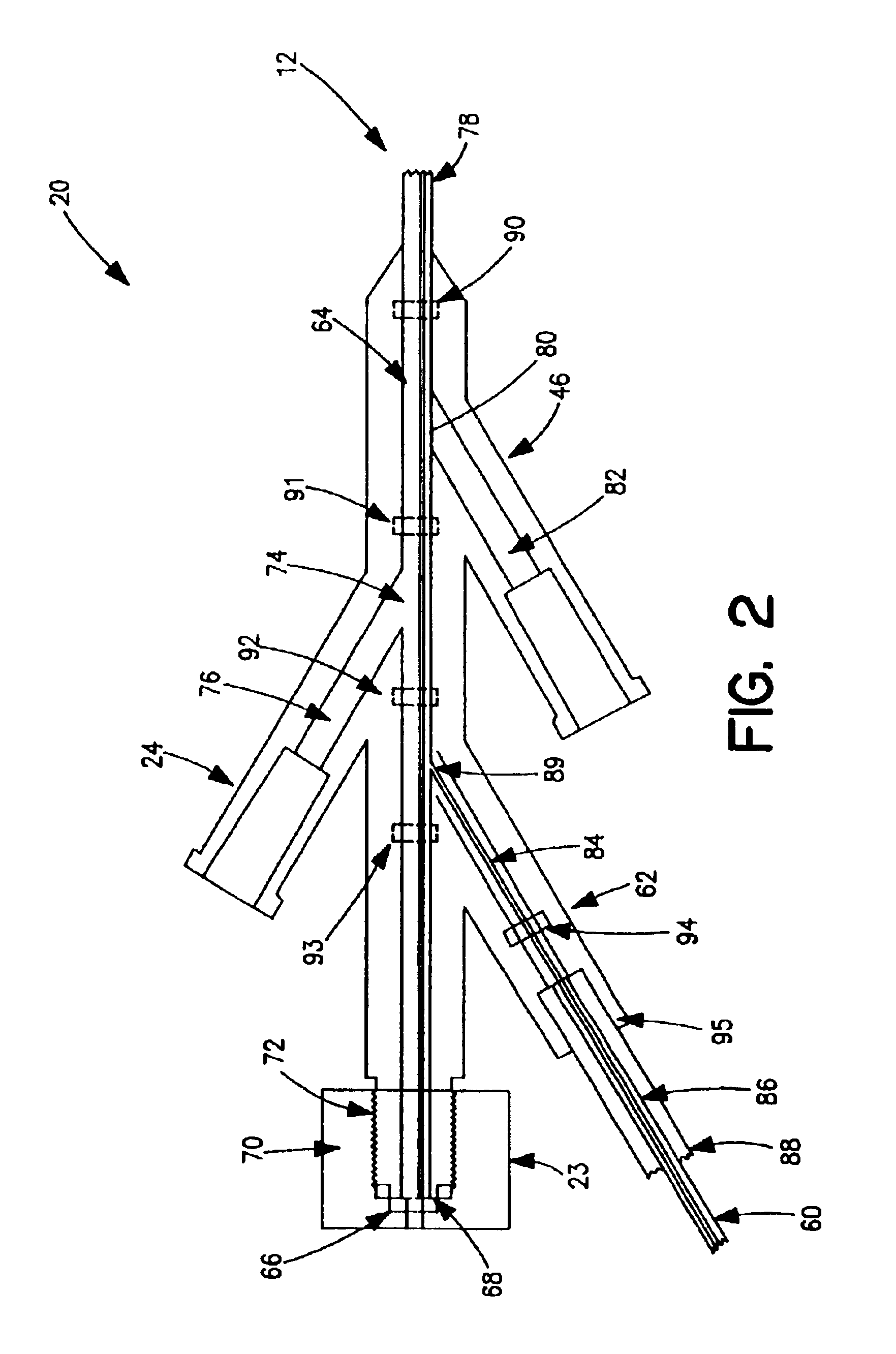

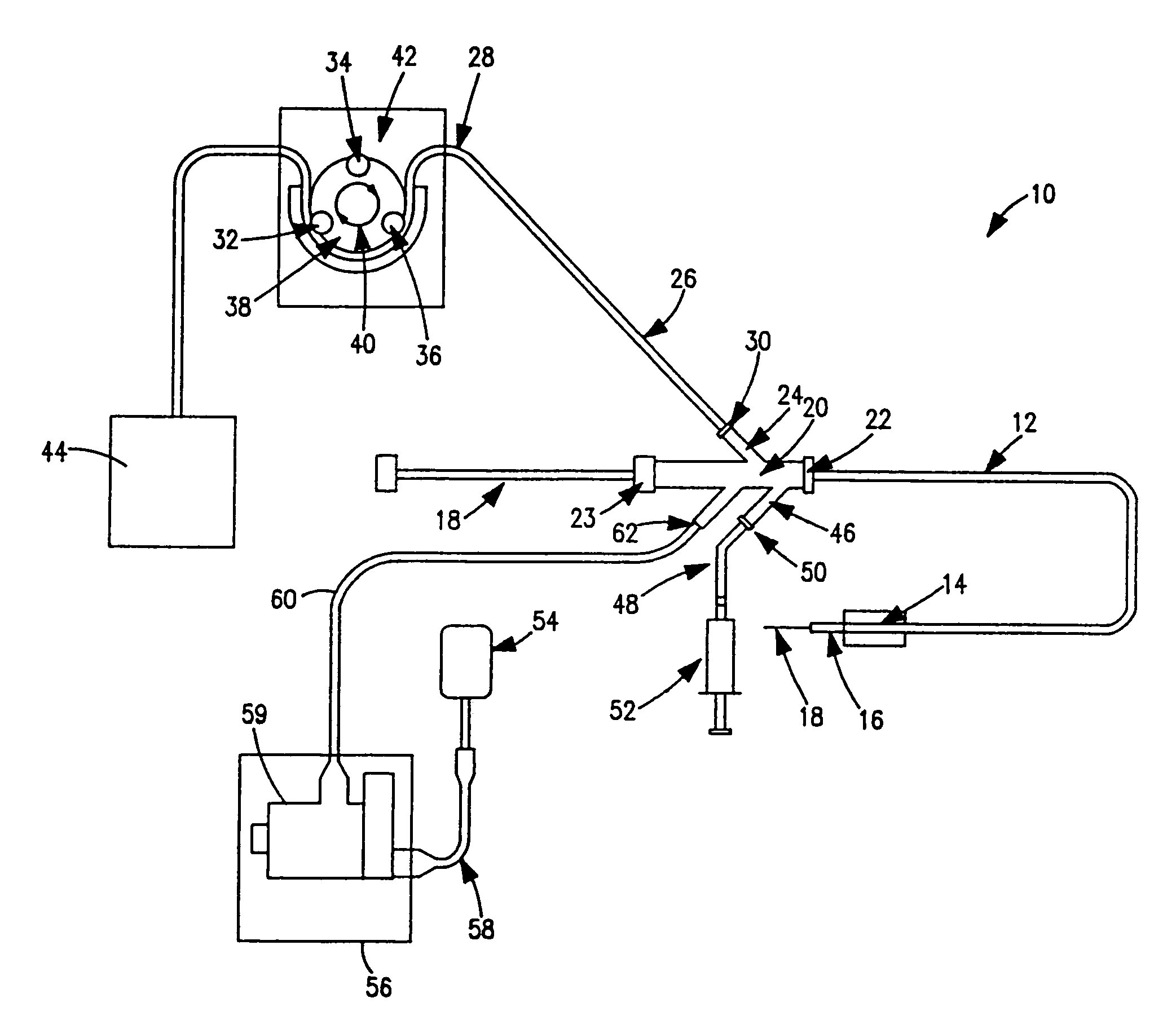

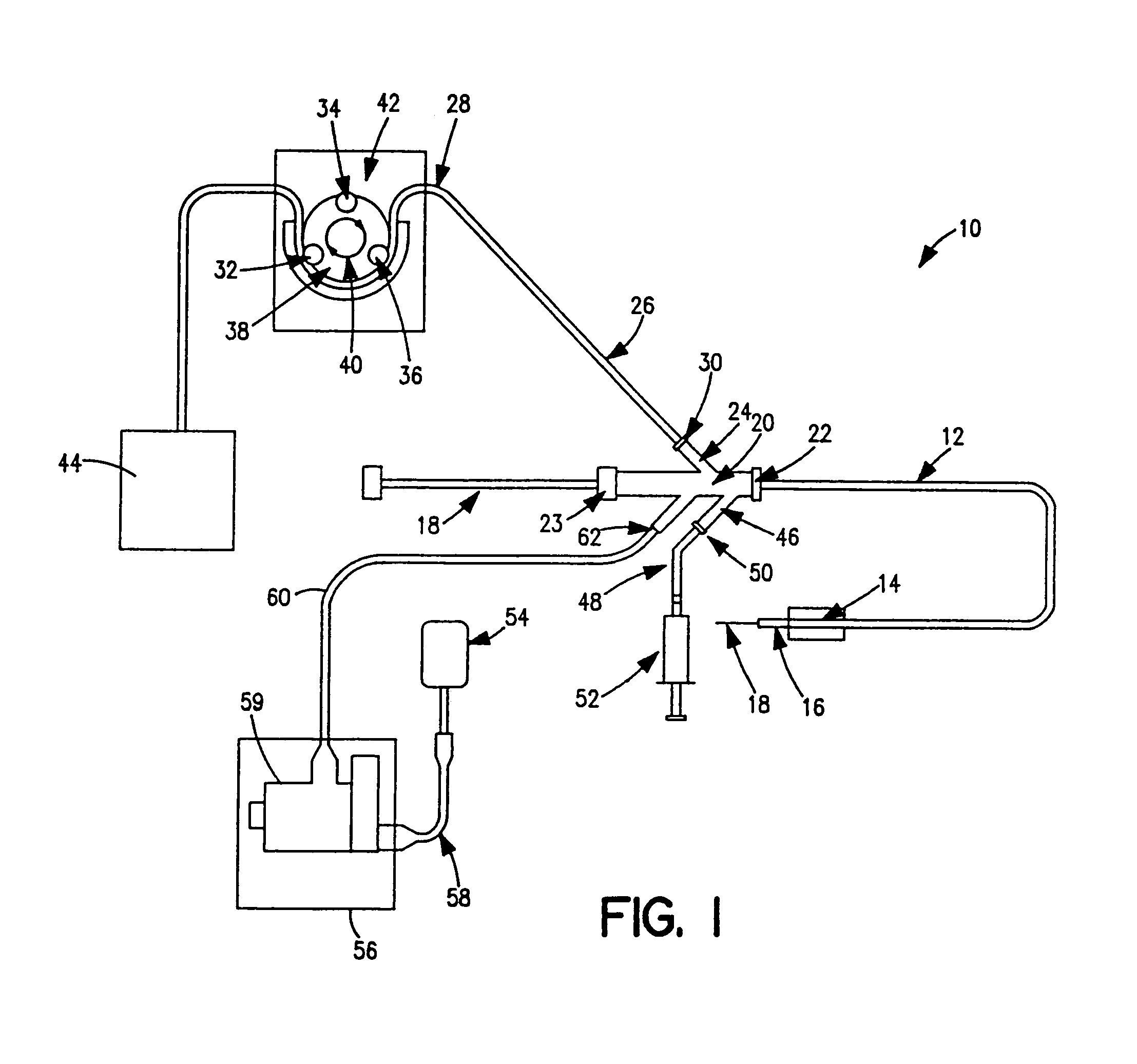

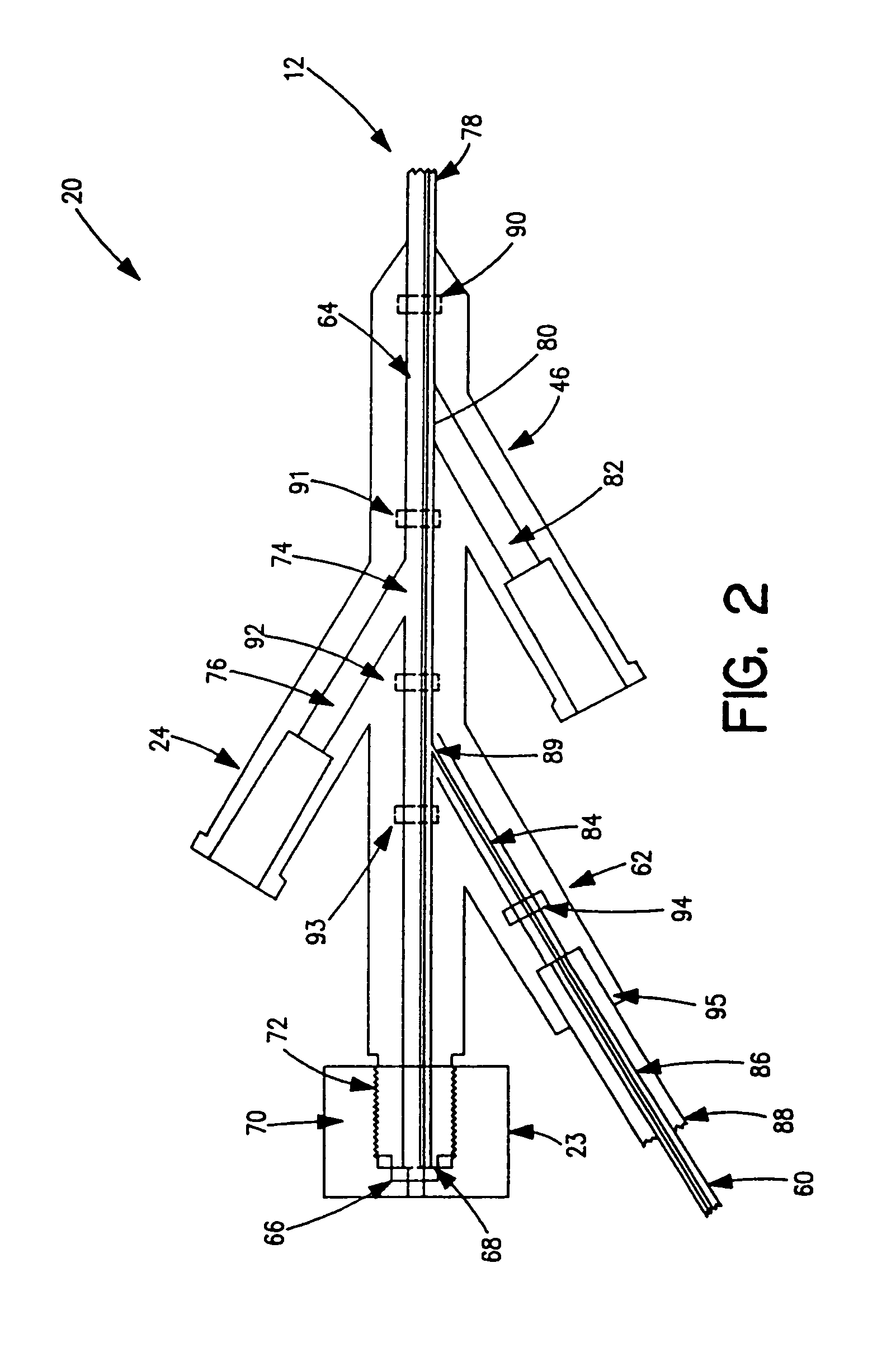

A method for removing thrombus or other material from a natural or synthetic body vessel or cavity without the need for direct surgical access. The method includes providing a device supplying high pressure fluid to at least one distal orifice, causing high pressure fluid to emanate from the orifice creating at least one fluid jet, and using the fluid jet to break up material in the vessel. The method further includes directing at least one fluid jet at the opening of an exhaust lumen or target incorporated into the device and using the jet to provide a localized negative pressure which entrains material into the jet for break-up. The method optionally includes using the jet to provide stagnation pressure which drives material along the exhaust lumen. The method optionally includes metering the exhaust to match the fluid input or to be greater or less than the input. A positive displacement pump operating at steady or pulsatile flow provides the high pressure saline to the distal end of the catheter.

Owner:MEDRAD INC.

Thrombectomy and tissue removal method

InactiveUS6984239B1Reduce local pressureIncrease speedMedical devicesFluid jet surgical cuttersThrombusHigh pressure

A device for removing a thrombus or other tissue deposit from the cardiovascular system, natural or synthetic tubule or cavity found in the human body of a patient without the need to surgically access the location of the thrombus or other tissue deposit via a cut-down or other surgical procedure. A flexible metal or high pressure plastic tube conveys an extremely high pressure stream of sterile saline or other physiologic solution to at least one jet at the distal end of the catheter. At least one jet is directed at the opening of a large exhaust lumen or other target. The jet(s) is responsible for providing a localized negative pressure which entrains tissue into the jet from break-up of the debris. This jet(s) can also provide stagnation pressure in the exhaust lumen which drives the tissue or thrombotic debris out of the exhaust lumen. Operation of the device with tip pressure greater than 500 psi provides this device with the entrainment and exhaust characteristics which contribute to its effectiveness. The rate of exhaust of tissue debris is metered to ensure minimal local impact on the vasculature at the site of the thrombus deposit. A fluid metering means, such as a roller pump, controls the rate of exhaust such that it is in balance with the saline input or can be adjusted to be greater or less than the input. A positive displacement pump operating at steady or pulsatile flow provides the high pressure saline to the tip of the catheter.

Owner:MEDRAD INC.

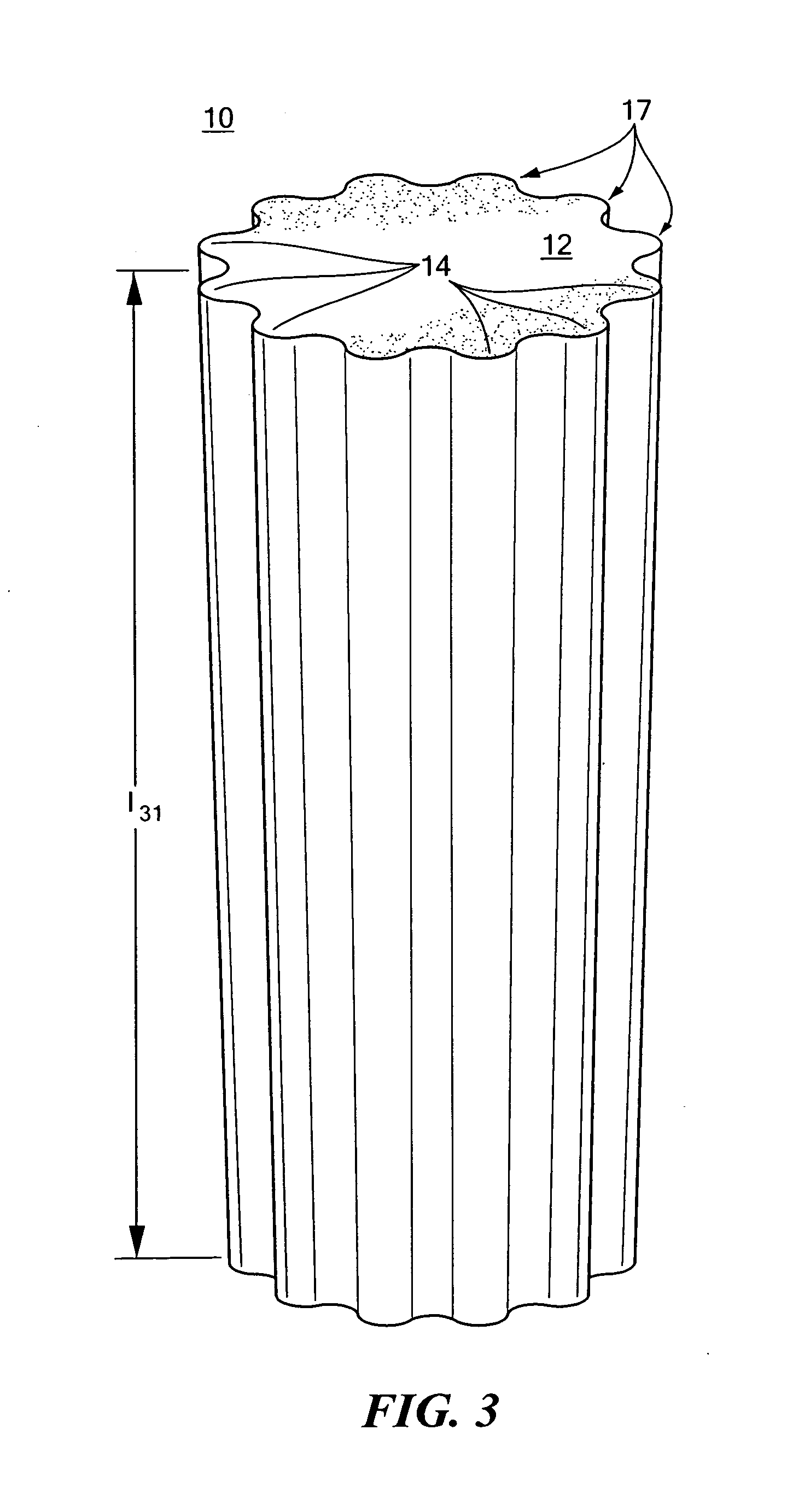

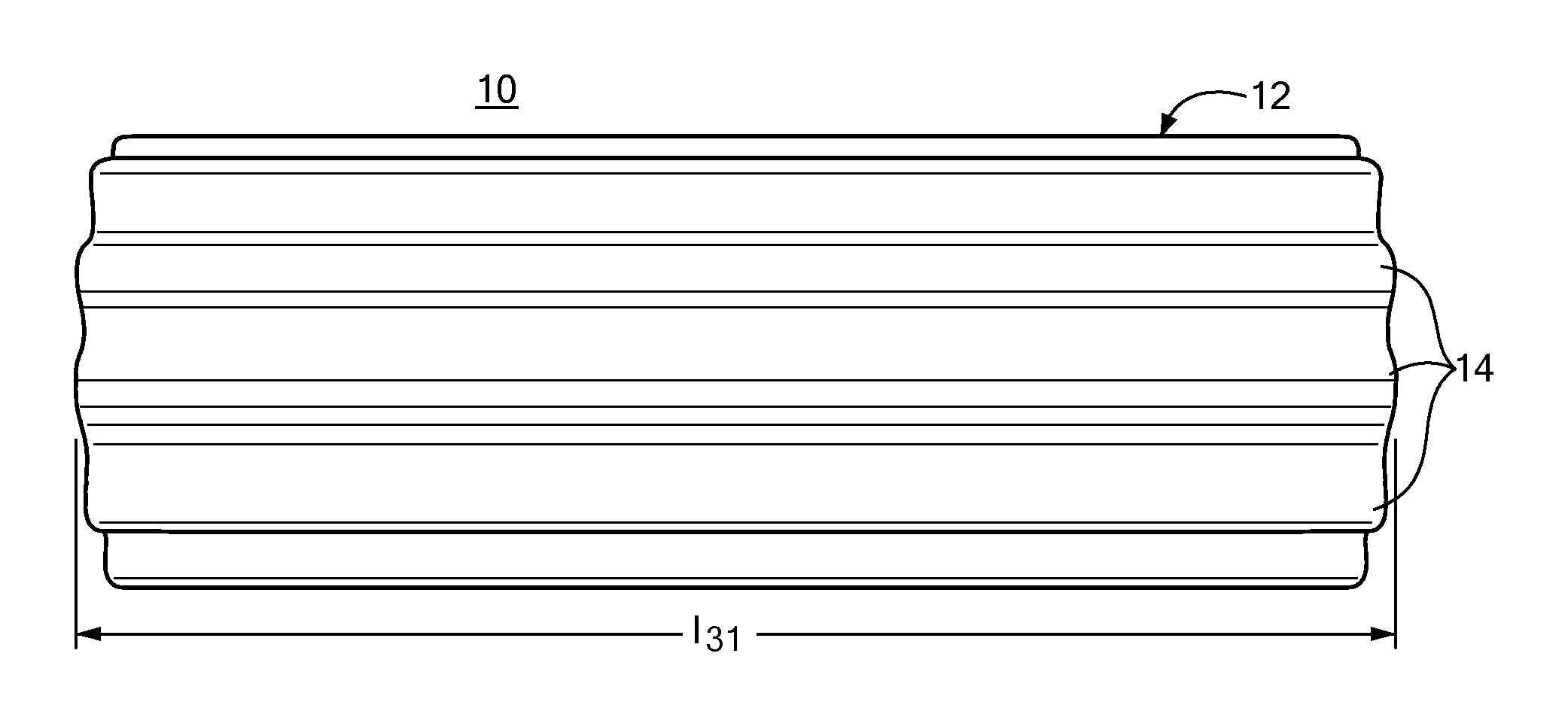

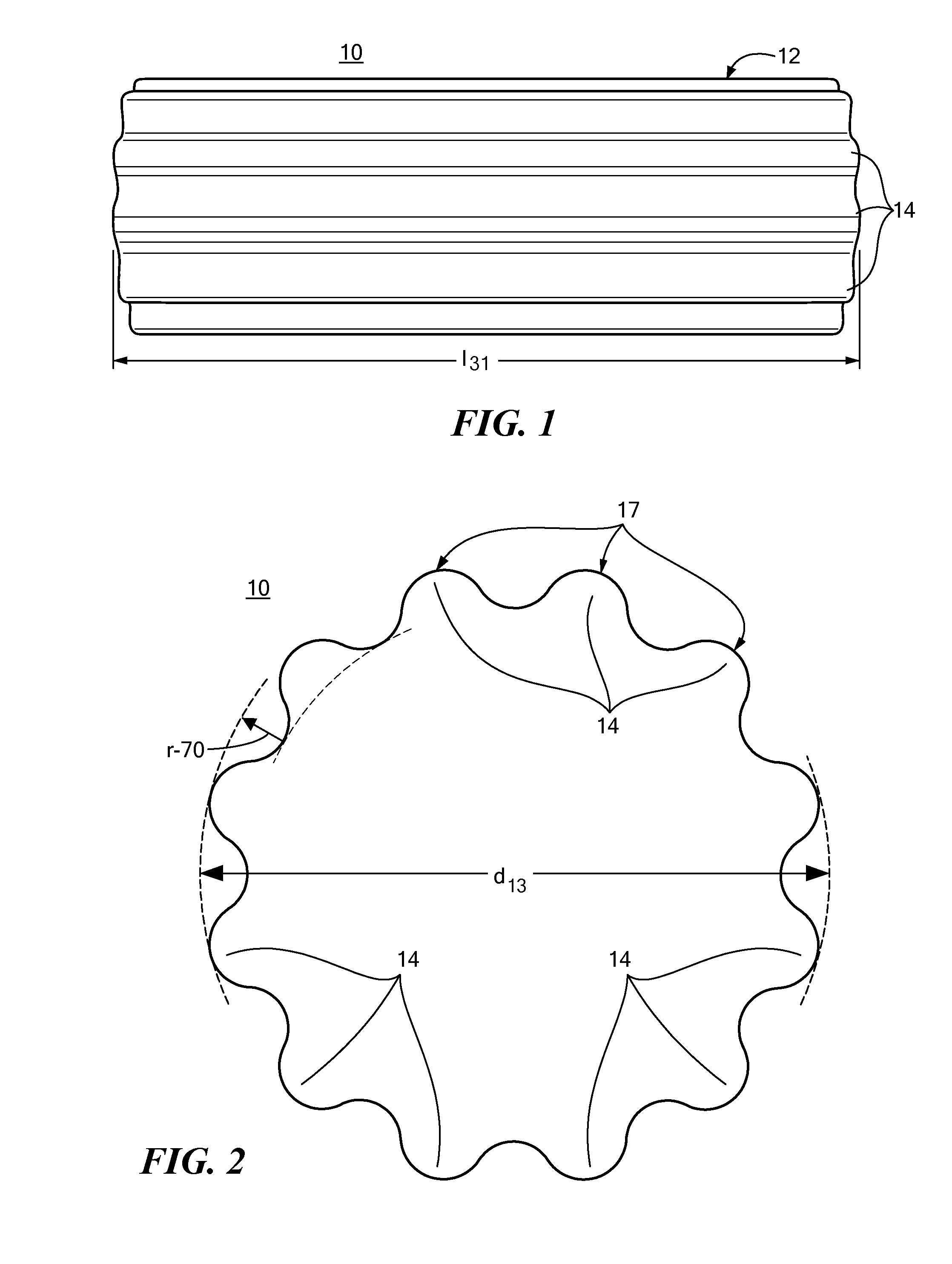

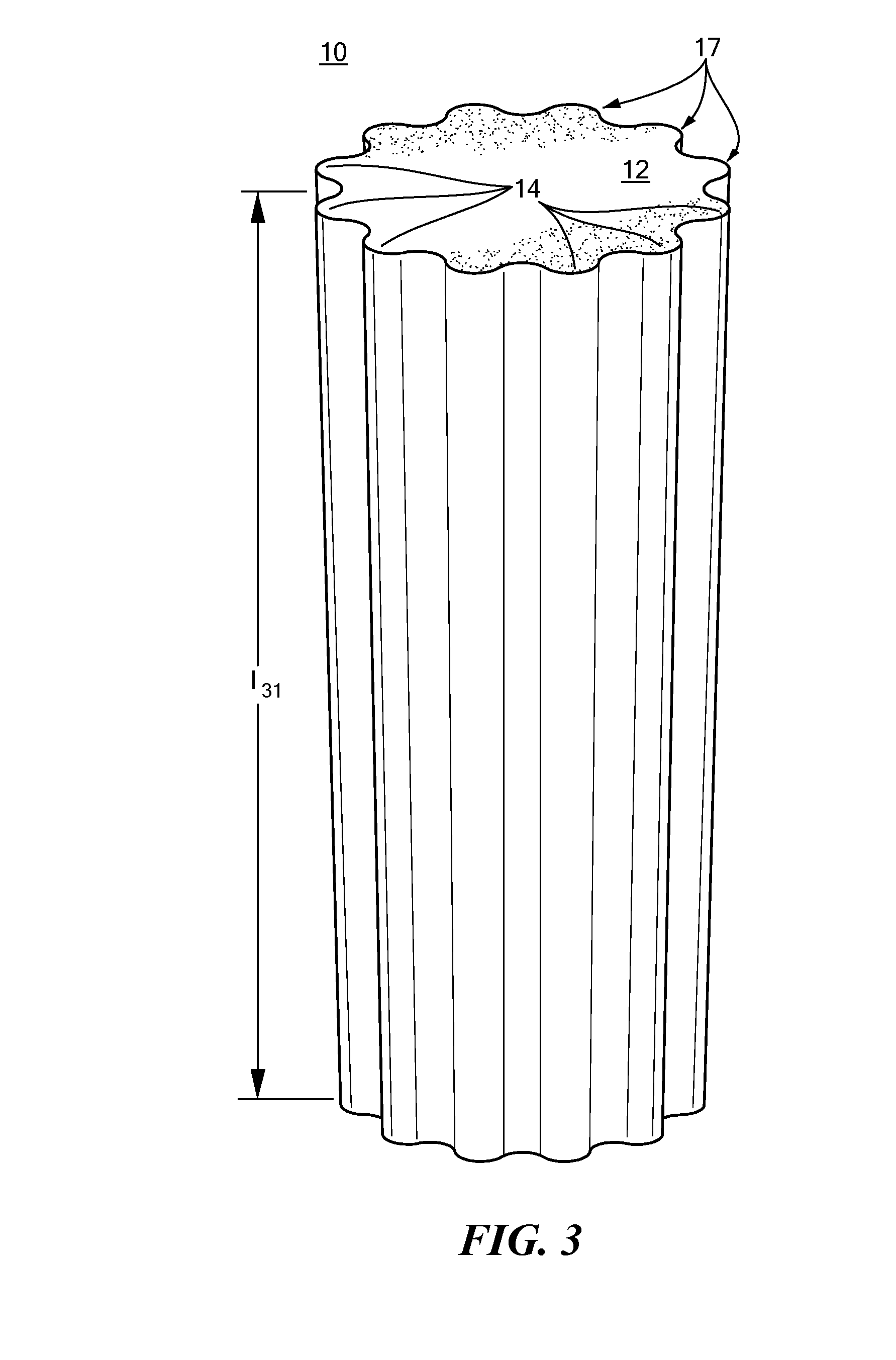

Therapeutic, fitness, and sports enhancement device

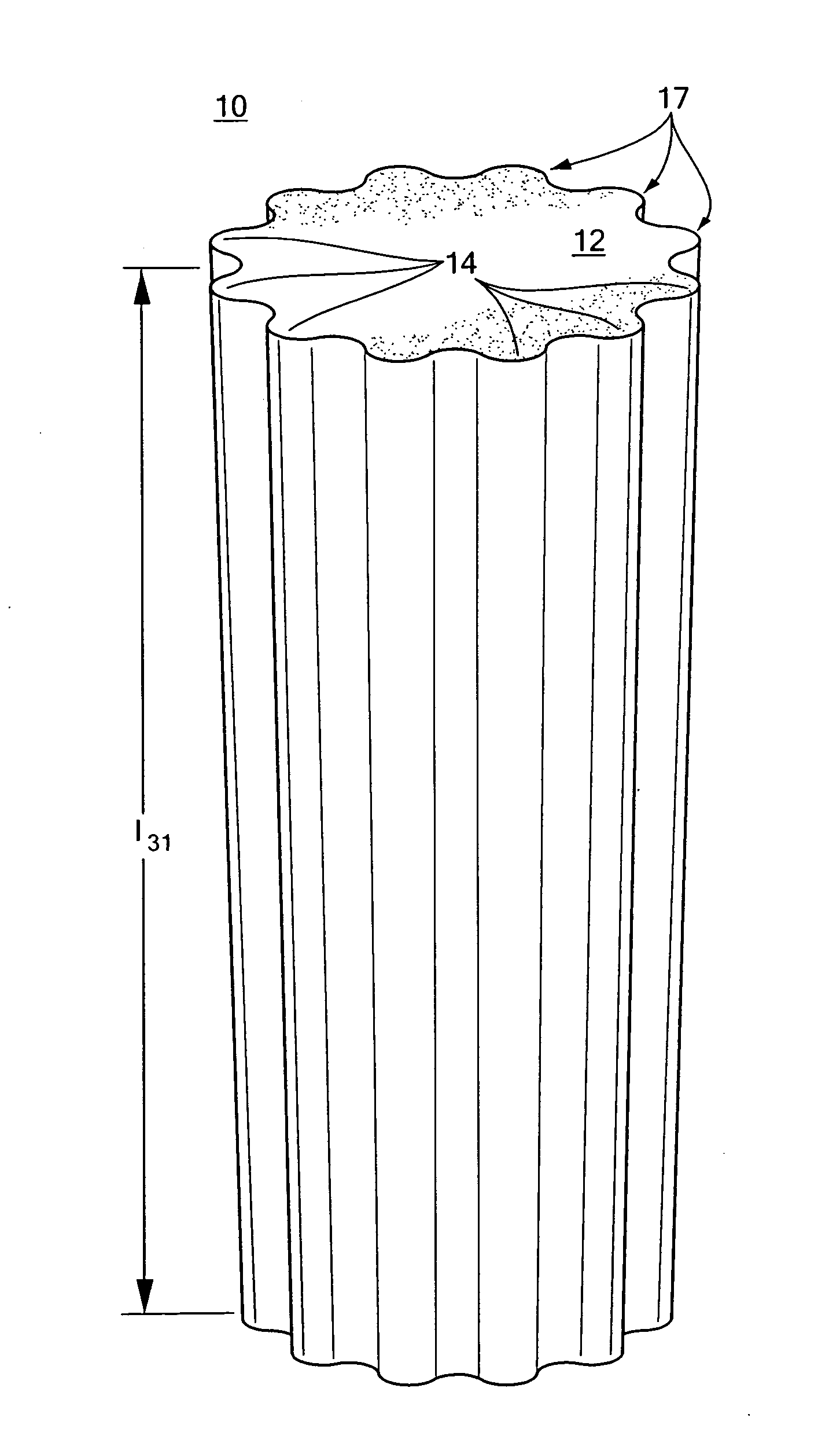

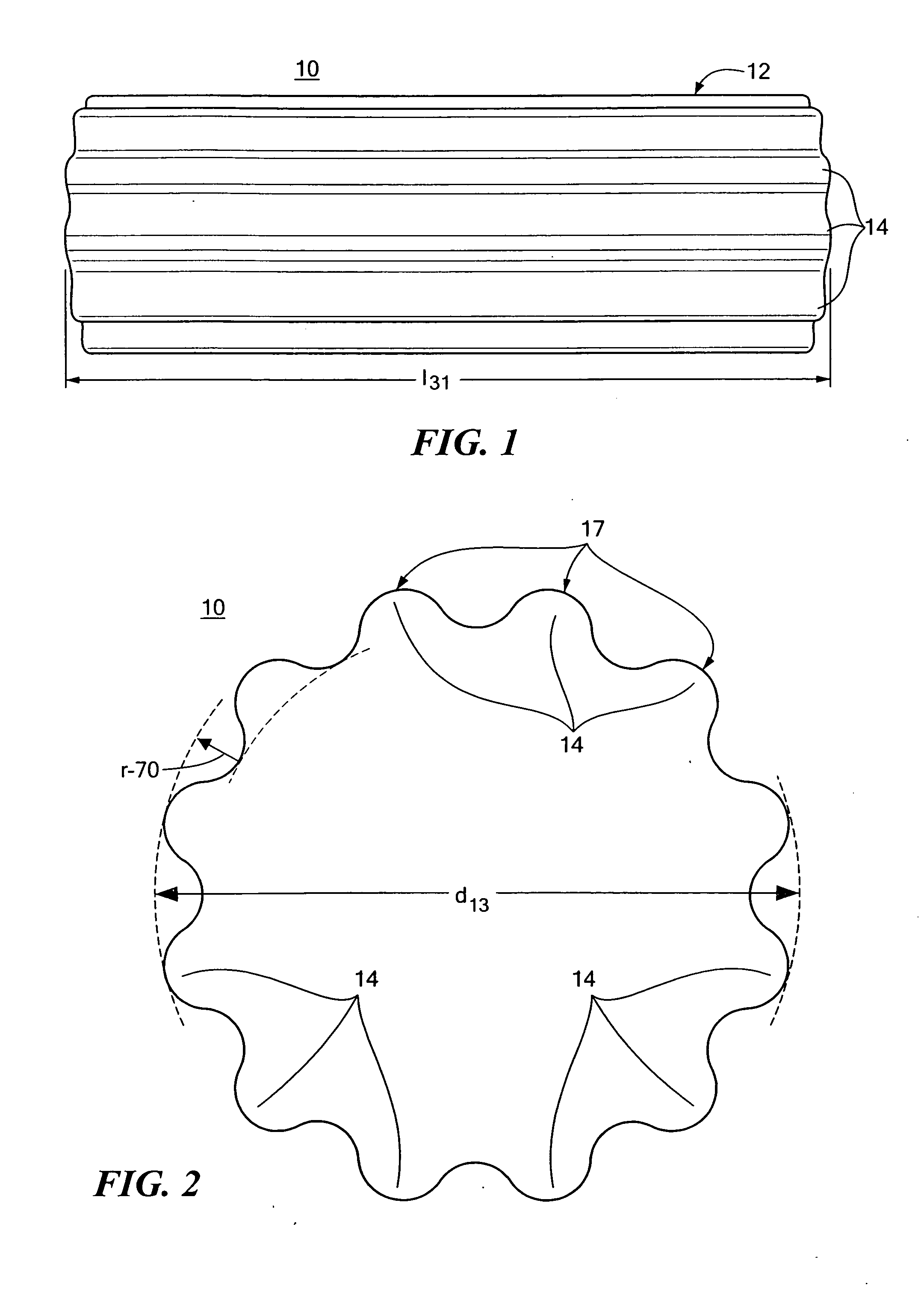

ActiveUS20120035029A1Optimize core strengthIncrease flexibilityRoller massageStiltsHuman bodyVolumetric Mass Density

A therapeutic, fitness, and sports enhancement device which includes a cylindrically shaped body having a predetermined density and predetermined diameter, the body including a plurality of projections of a predetermined shape. One or more of the predetermined density and the predetermined diameter in combination with the predetermined shape of the projections optimize mobilization of soft tissue structures of the human body.

Owner:PERFORMANCE SOLUTIONS

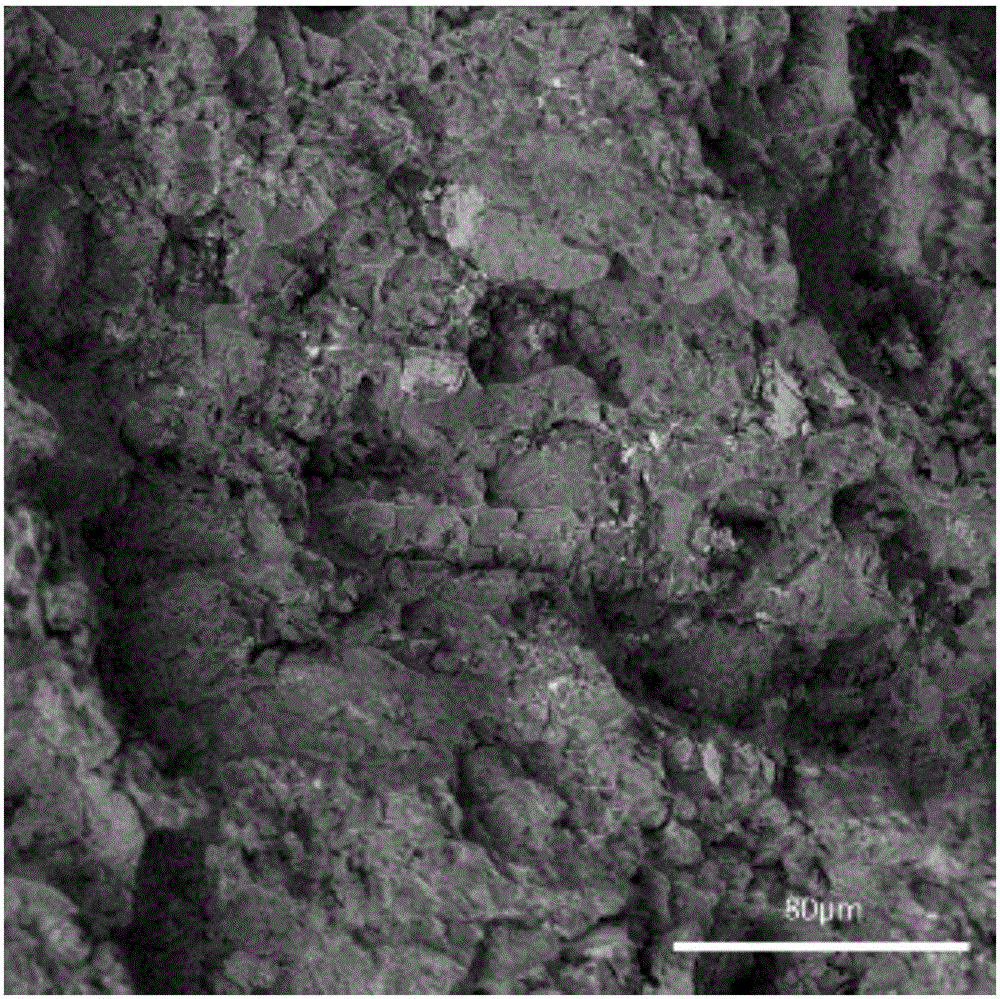

Process for extracting dendrobium polysaccharide and dendrobine from dendrobium officinale

The invention provides a process for extracting dendrobium polysaccharide and dendrobine from dendrobium officinale. The raw material used in the process comprises dendrobium officinale, cellulase (a biochemical reagent), glucose, phenol, acetone, petroleum ether and absolute ethyl alcohol. According to the process provided by the invention, the polysaccharide and dendrobine in the dendrobium officinale are extracted by using cellulase-catalyzed extraction in a combination manner; the dendrobine is obtained when the dendrobium polysaccharide is obtained; high efficiency for single extraction of the polysaccharide by an enzymic method is kept; the effects of effectively breaking cell walls are improved; dissolution of polysaccharide and the like are promoted; the process and condition are mild; the extraction rate is improved to a certain extent; and the economic benefits are relatively high.

Owner:HUOSHAN COUNTY TIANXIA ZEYU BIOLOGICAL TECHDEV

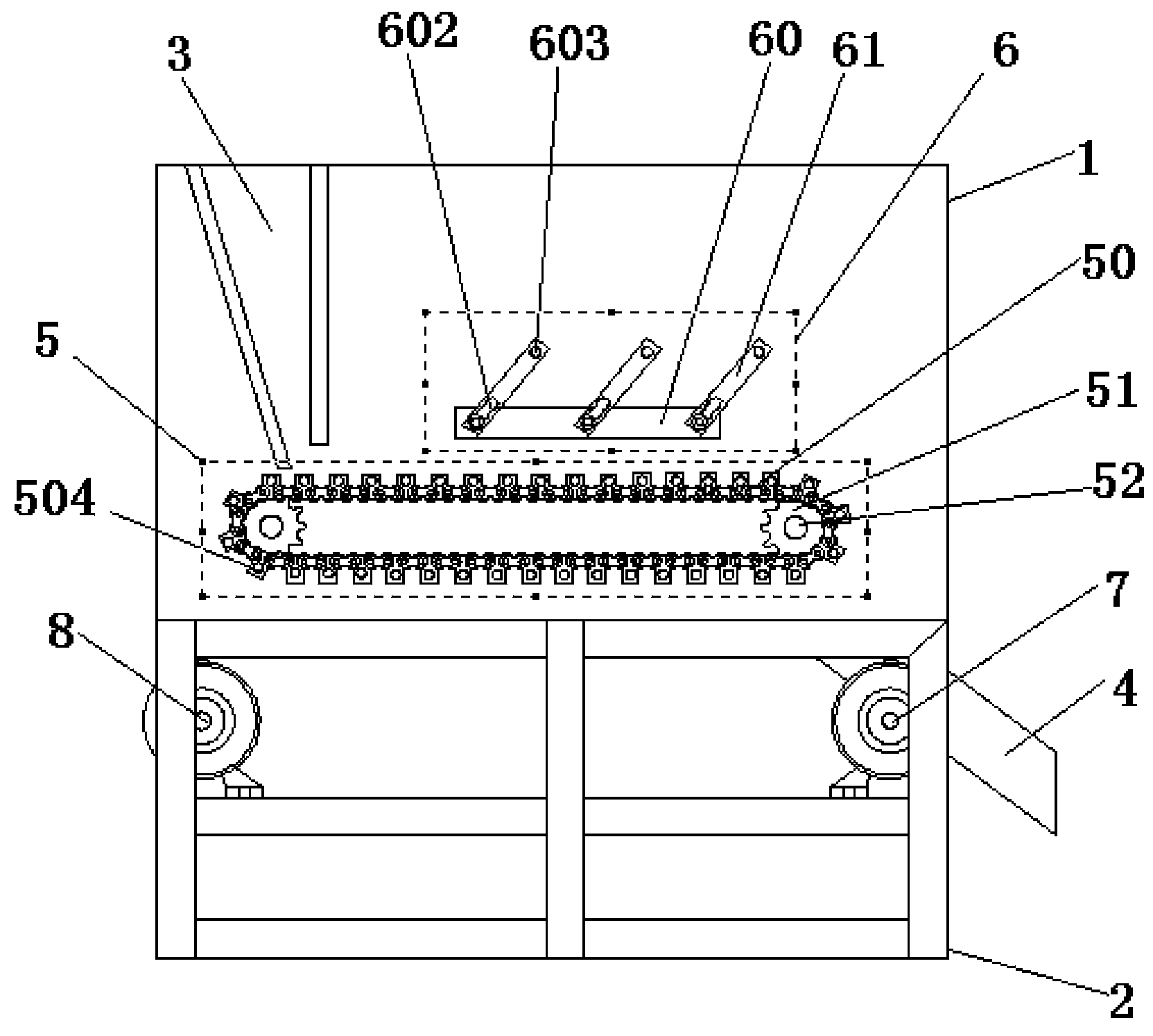

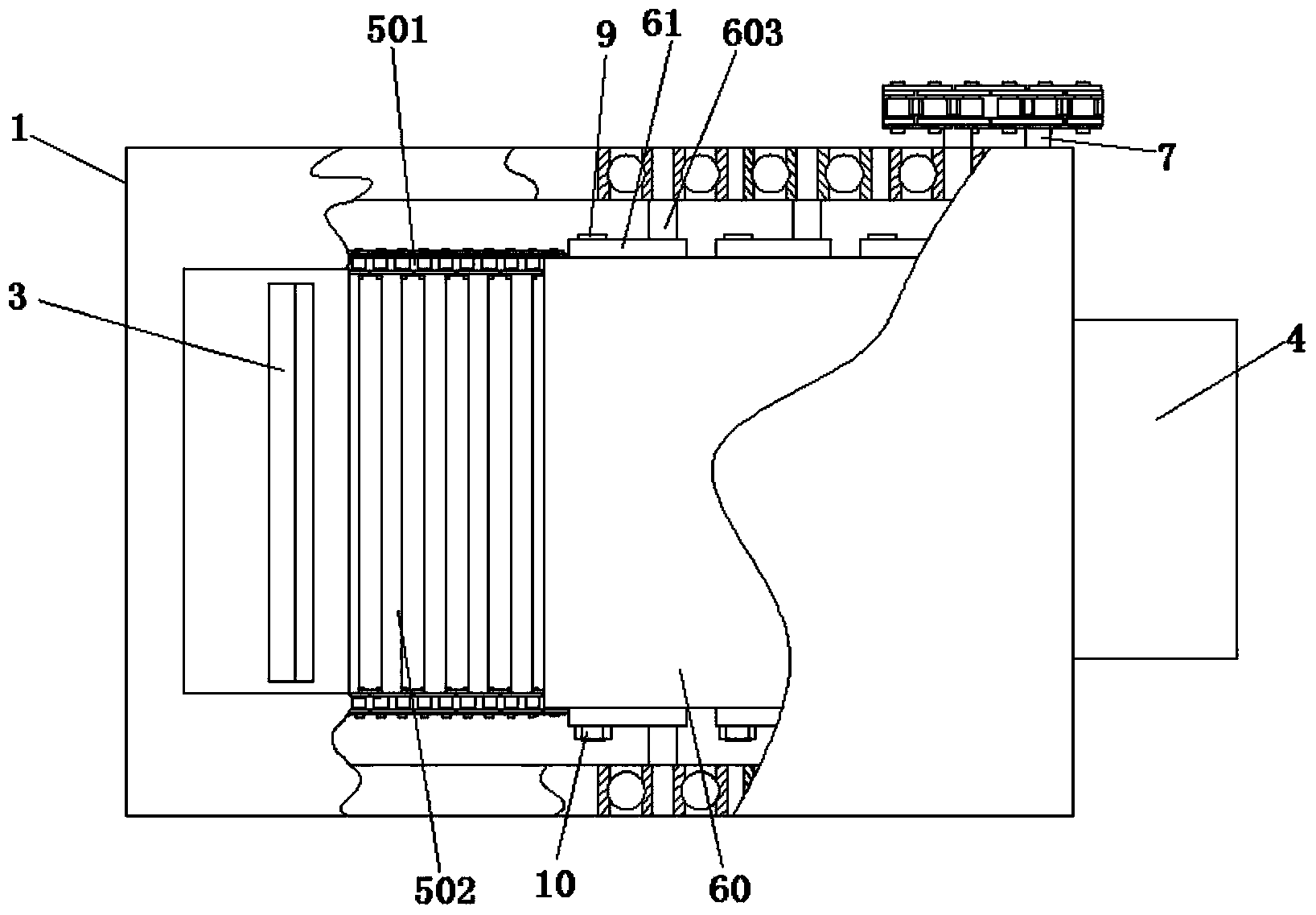

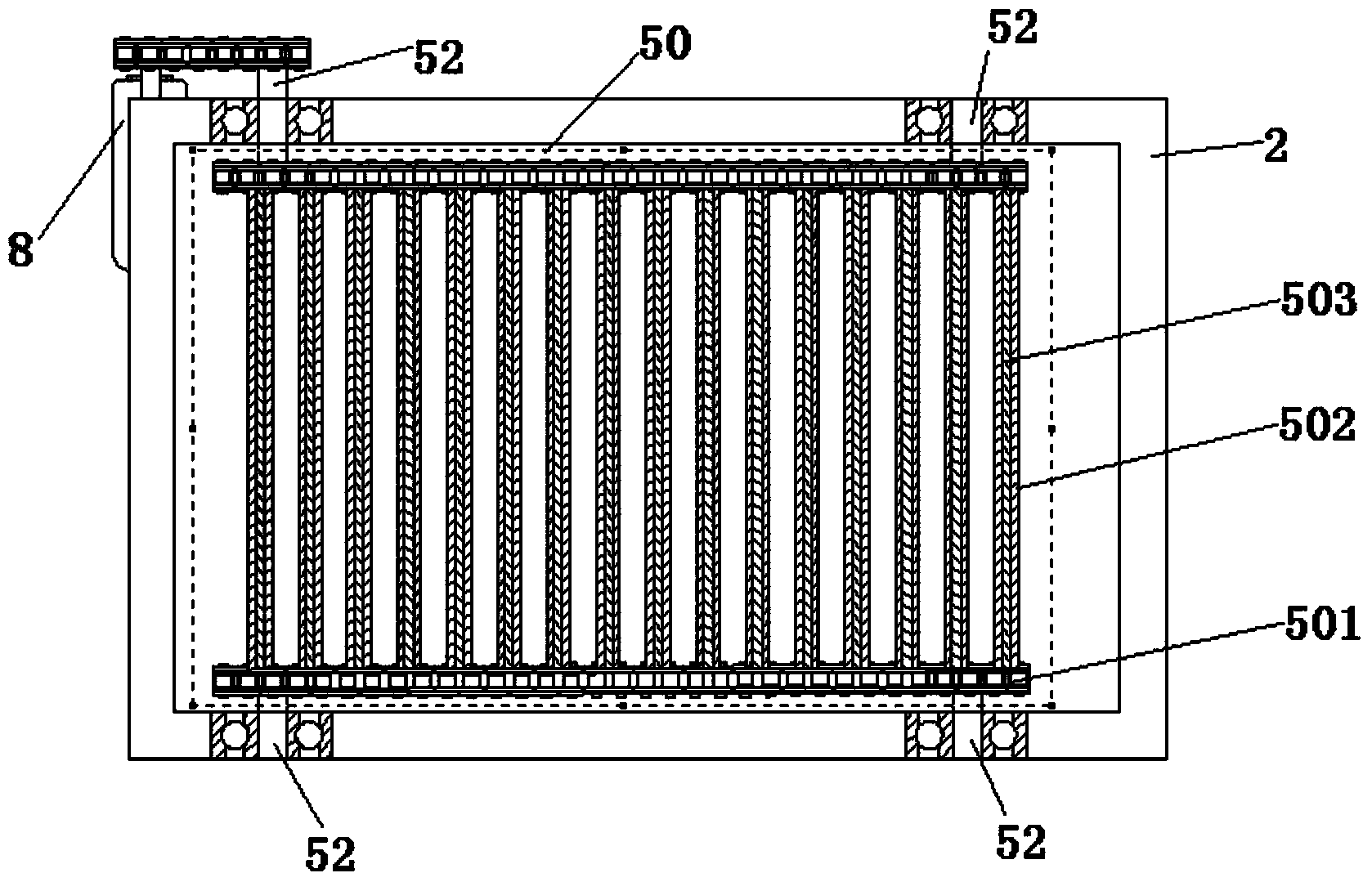

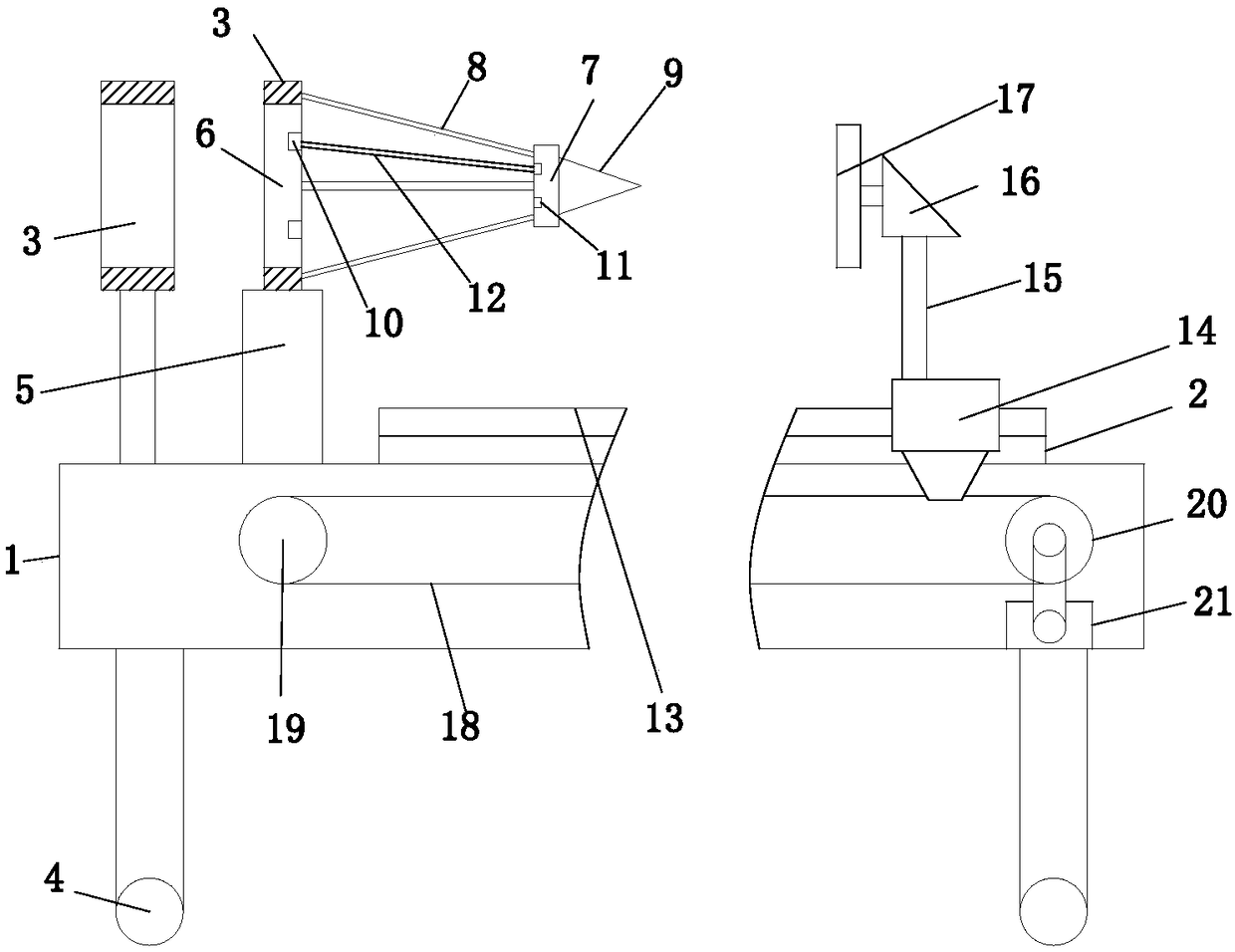

Extruding and rubbing type walnut shell breaking device

The invention provides an extruding and rubbing type walnut shell breaking device which comprises a box body and a rack. The box body is arranged on the rack. A feeding port is arranged on the top surface of one side of the box body. A discharging port is arranged on the bottom surface of the other side of the box body. A conveyer and a shell breaker are arranged inside the box body. The conveyer is located at a horizontal position between the feeding port and the discharging port and used for conveying walnuts which fall into the conveyer from the feeding port to the discharging port. The shell breaker is located above the conveyer and used for breaking shells of the walnuts conveyed by the conveyer. When the extruding and rubbing type walnut shell breaking device is used, the walnuts are placed into the feeding port, fall onto a conveying chain due to gravity, and rotate along with the conveying chain; the walnuts are extruded by a pressing plate and rubbed by rollers, so that it is guaranteed that the shells of the walnuts are completely broken. According to the extruding and rubbing type walnut shell breaking device, the distance between the pressing plate and the conveying chain can be adjusted according to the sizes of the walnuts, the walnuts are rubbed in the extrusion process so that the shells of the walnuts are completely broken, and therefore the extruding and rubbing type walnut shell breaking device has the advantages of being high in work efficiency, shell breaking rate and perfect kernel rate, low in cost and convenient to use.

Owner:SHAANXI UNIV OF SCI & TECH

Therapeutic, fitness, and sports enhancement device

InactiveUS20130267396A1Increase flexibilityImprove acceleration performanceRoller massageStiltsHuman bodyVolumetric Mass Density

Owner:PERFORMANCE SOLUTIONS

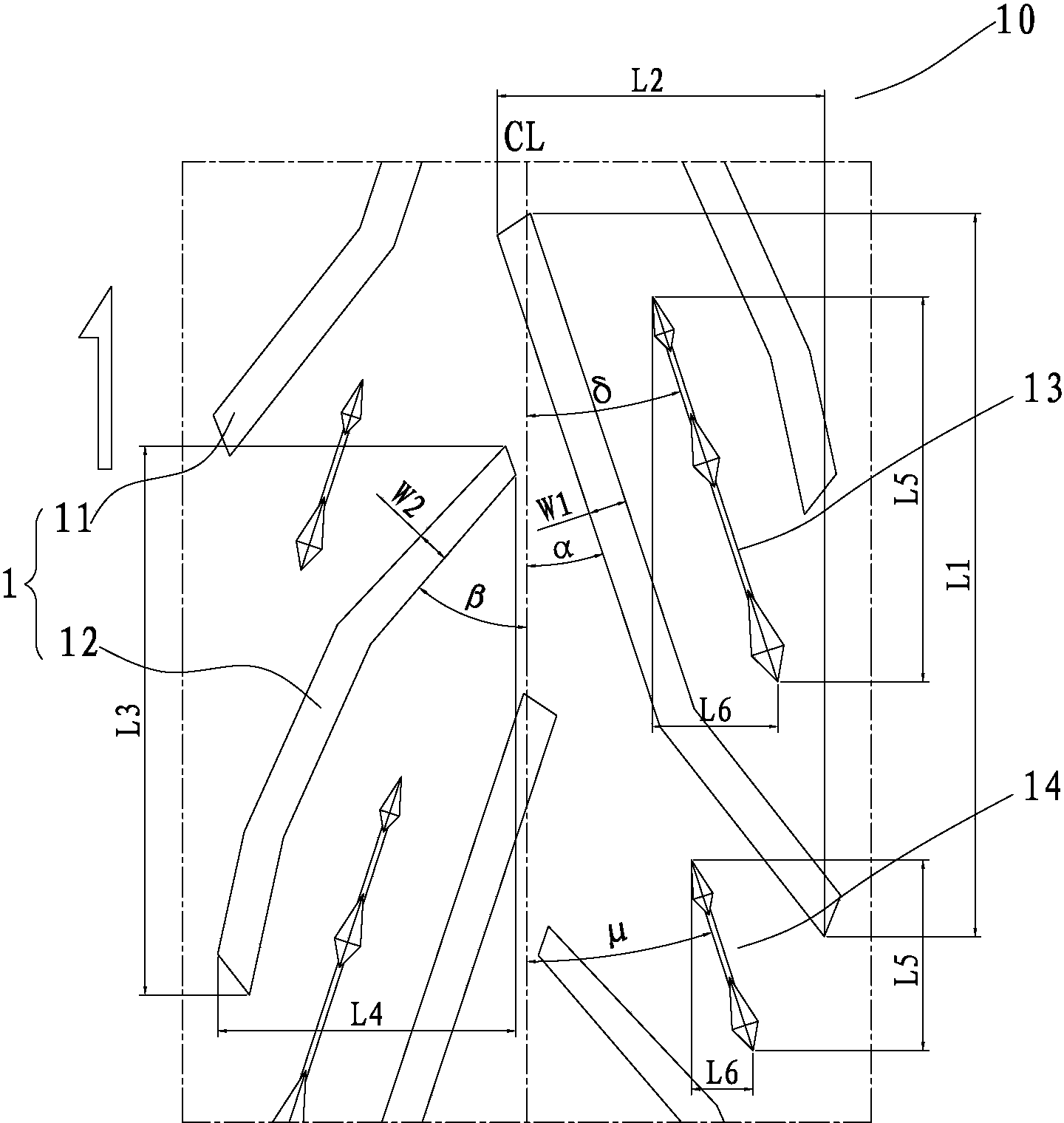

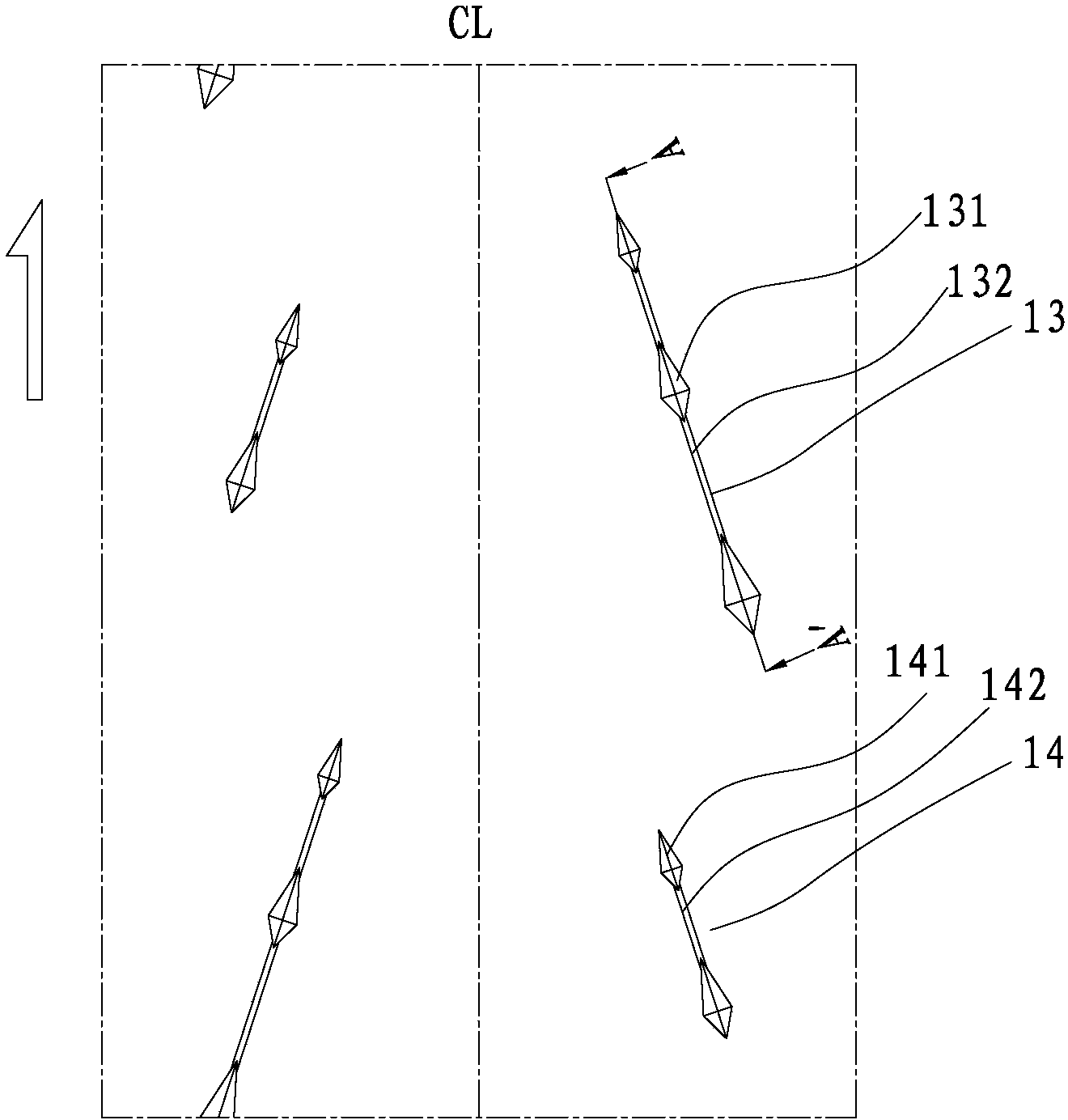

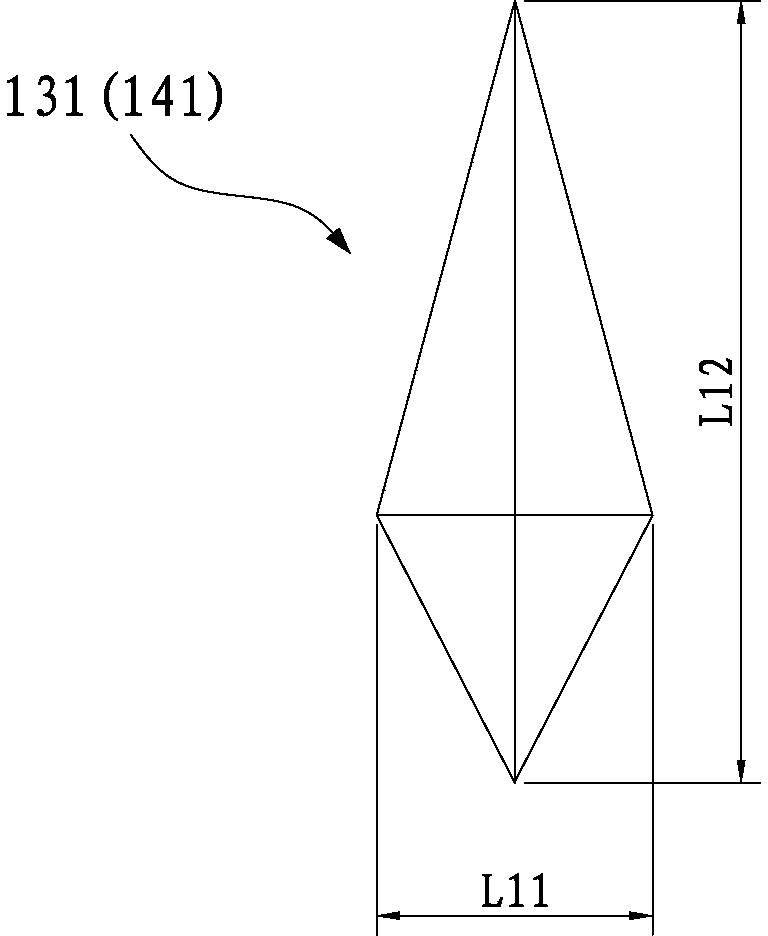

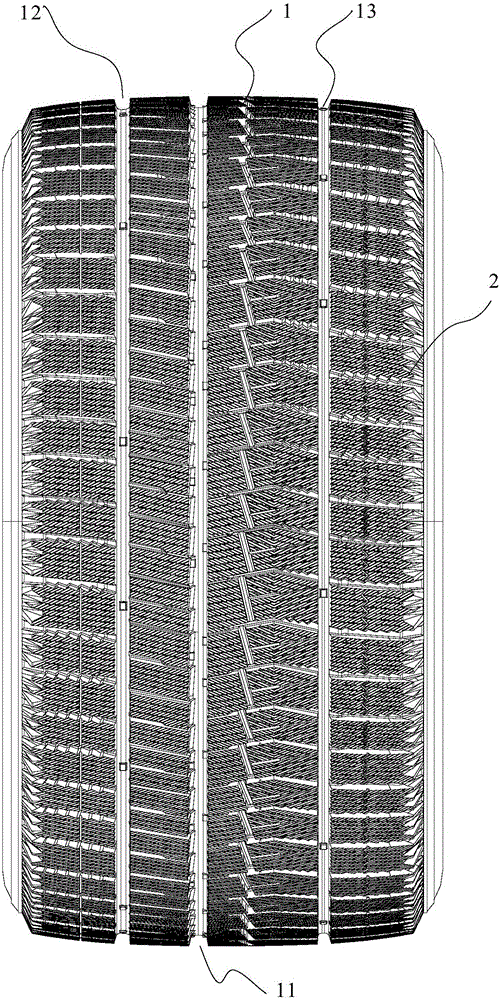

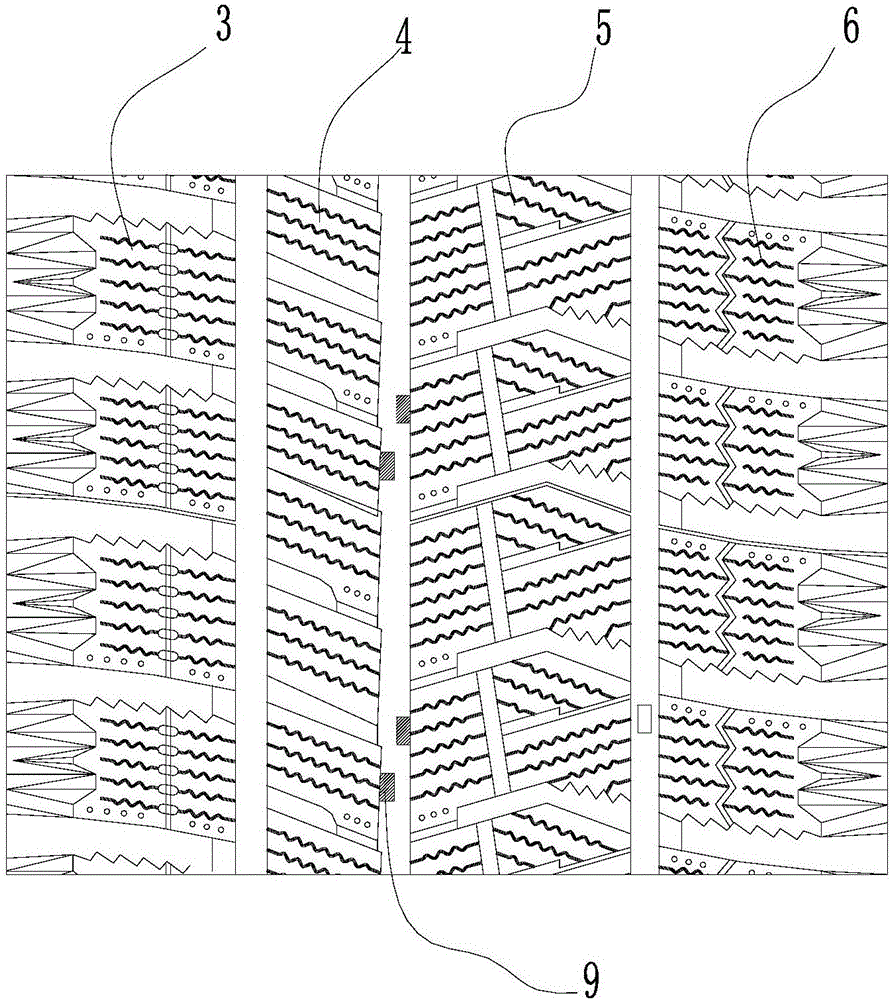

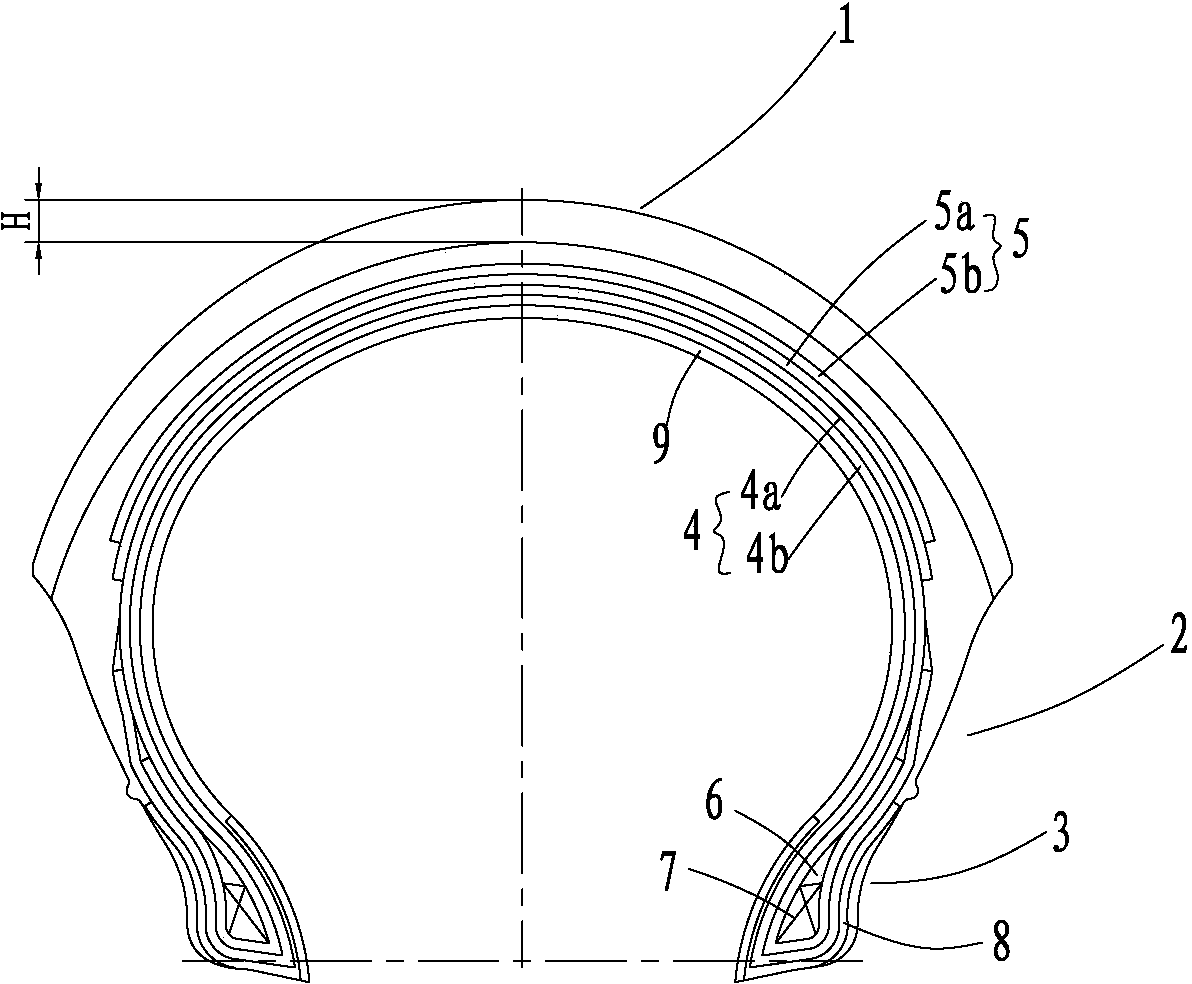

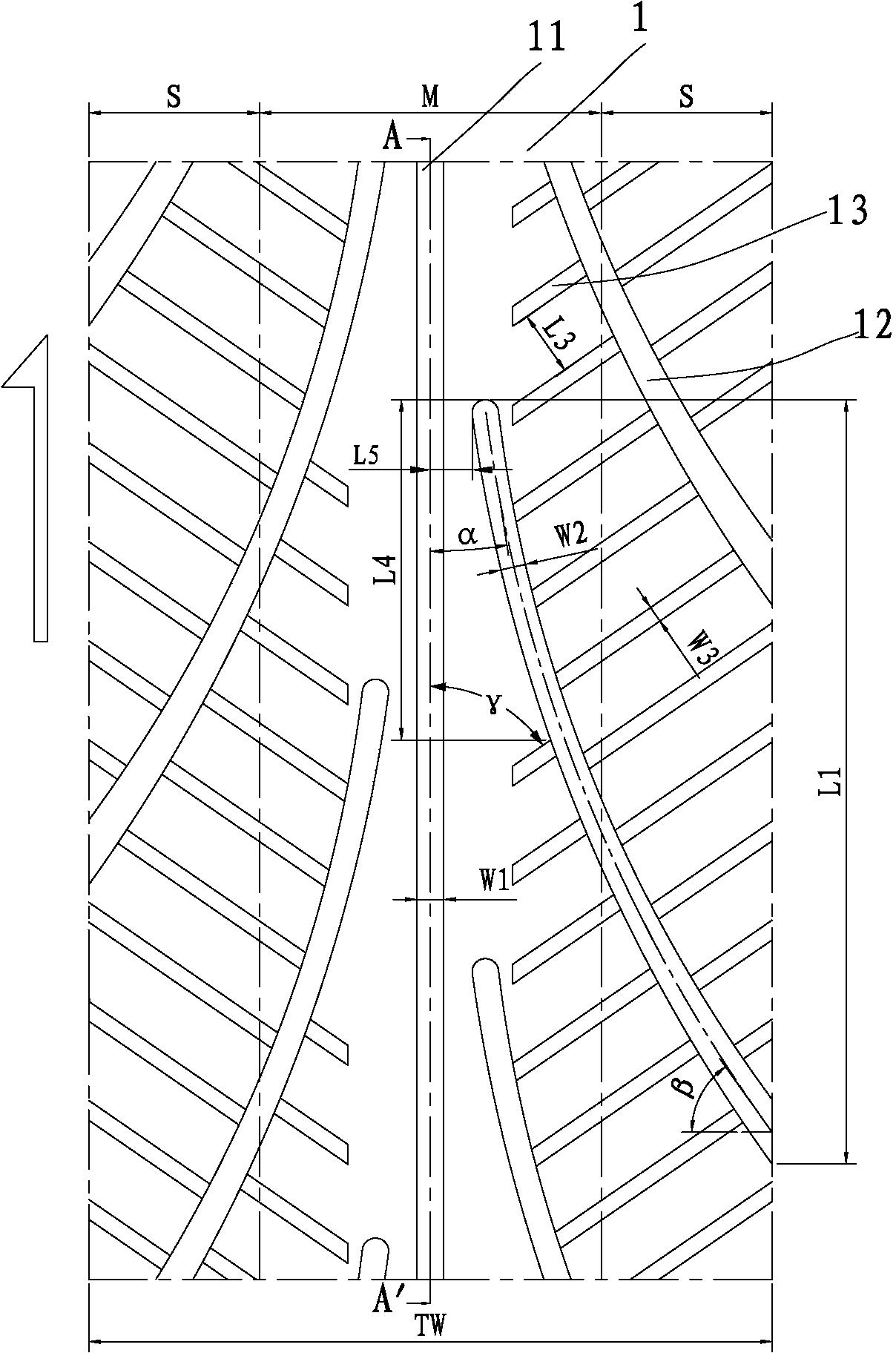

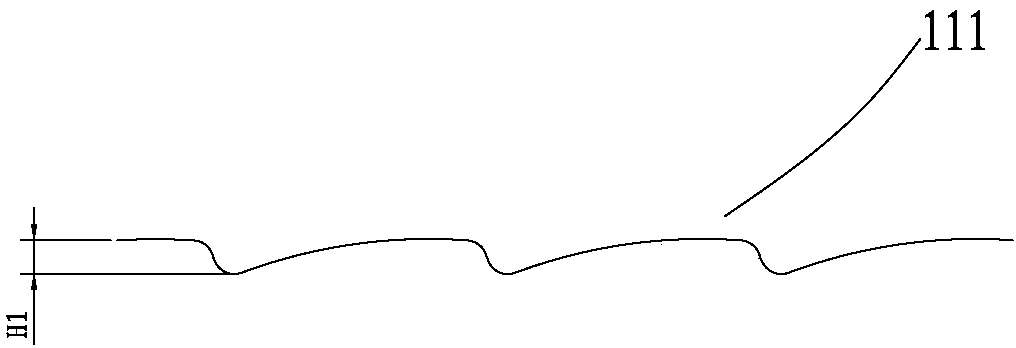

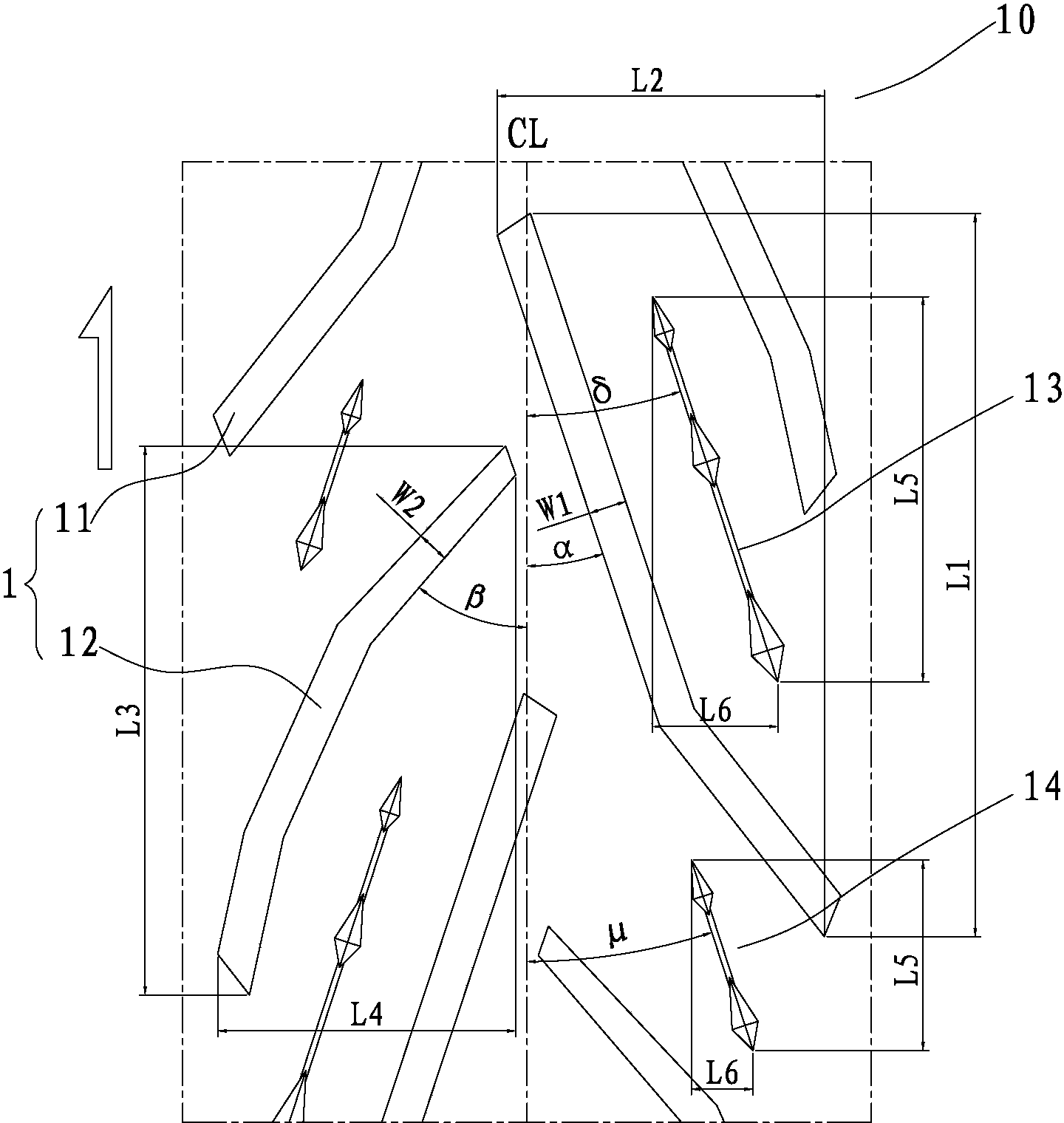

Tread structure of pneumatic tire for motorcycle

ActiveCN104029567AImprove tire drainage performanceImproves tire grip in wet conditionsTyre tread bands/patternsEngineeringTread

The invention discloses a tread structure of a pneumatic tire for a motorcycle. A tread comprises a plurality of main pattern groove groups which are formed in a staggered manner by using the center of the tread as a symmetry center, wherein first auxiliary fine diamond pattern grooves are formed among the main pattern groove groups, and each first auxiliary fine diamond pattern groove comprises a fine diamond part which is provided with a plurality of tangent planes and a fine groove which is connected with the fine diamond part. The fine diamond parts and the fine grooves of the auxiliary fine diamond pattern grooves are designed to be in mutual connection, so that water films can be effectively broken, the water drainage performance of the tire is effectively improved, and the wet land gripping performance of the tire is improved.

Owner:CHENG SHIN RUBBER XIAMEN IND

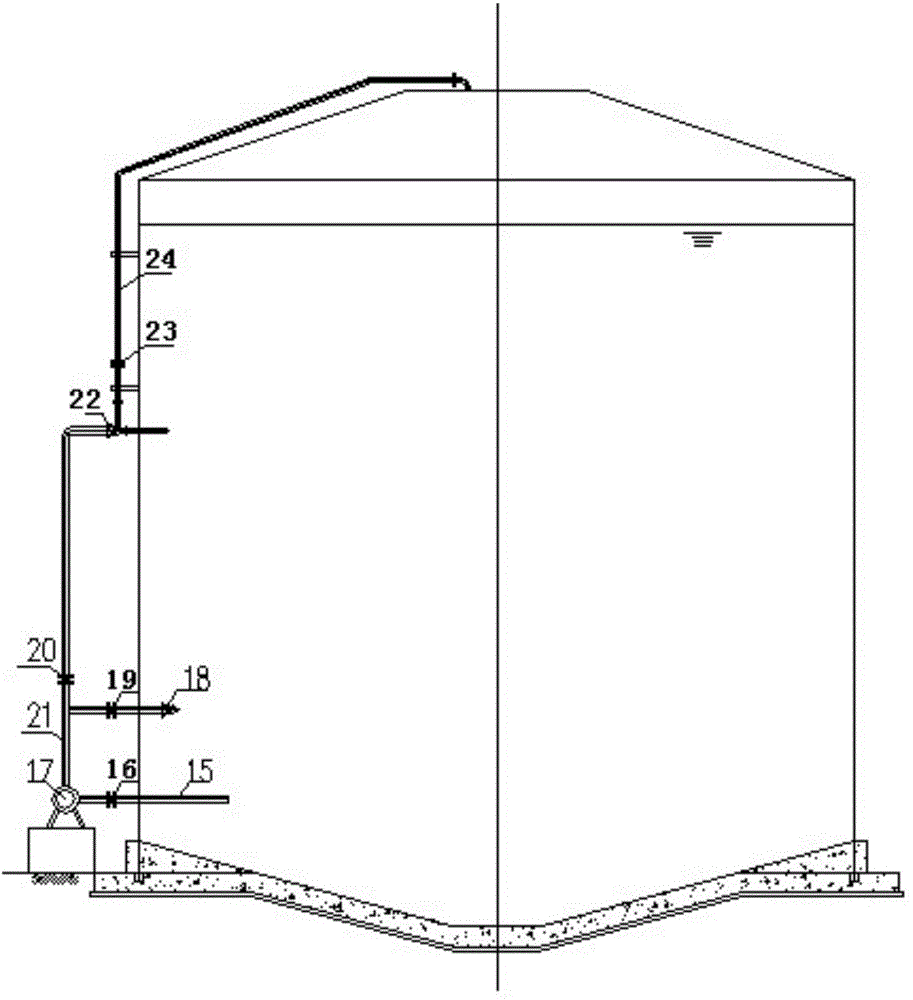

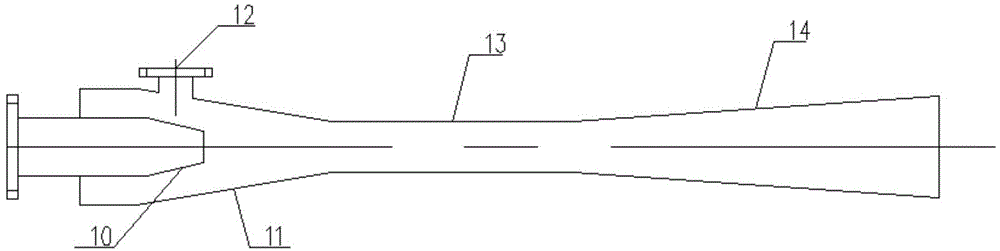

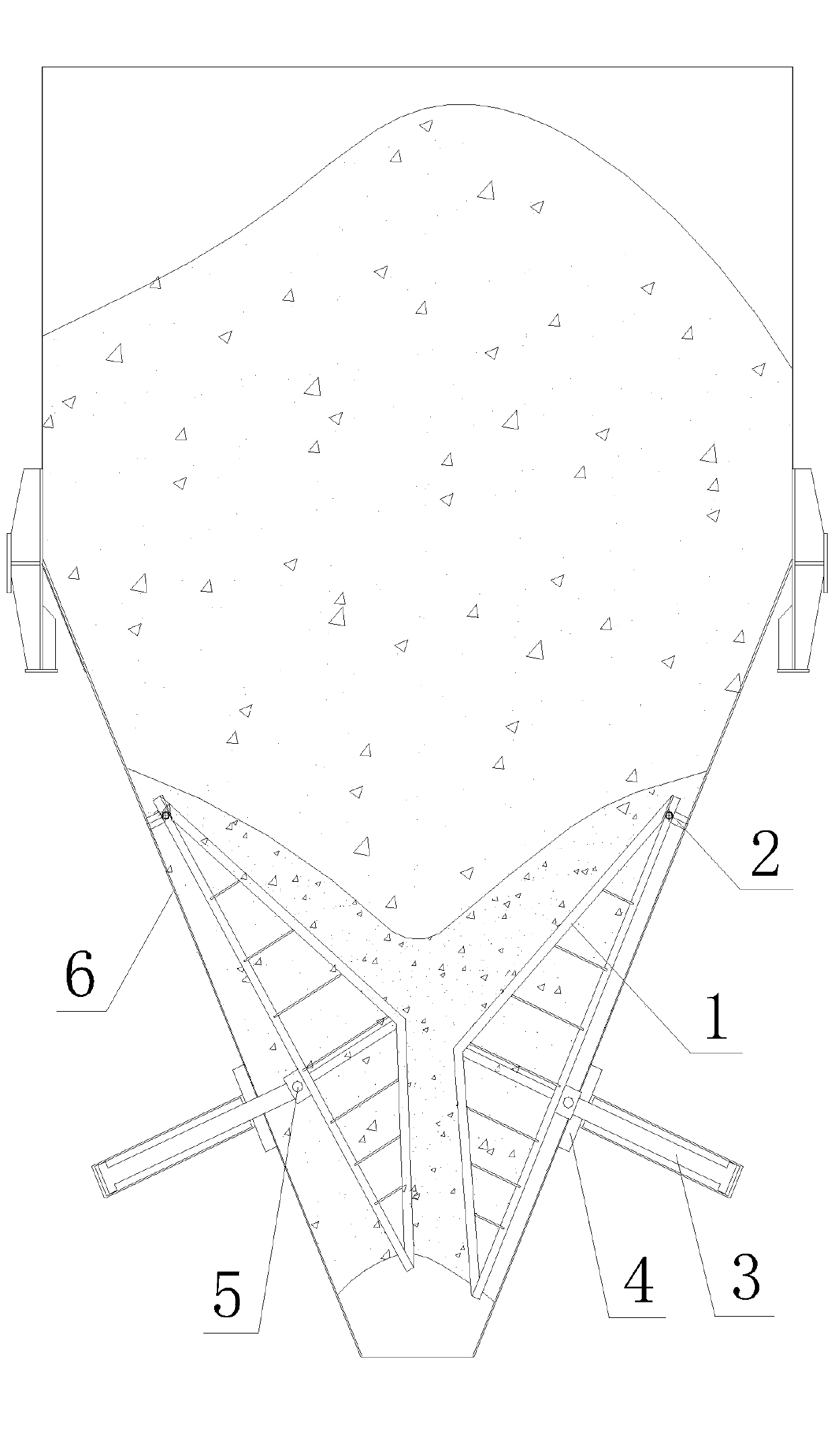

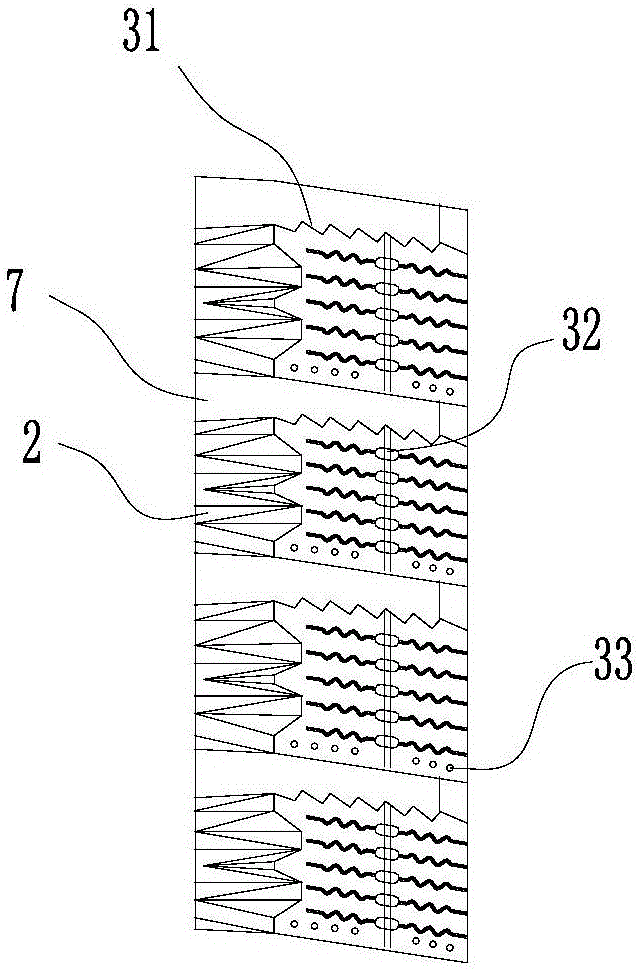

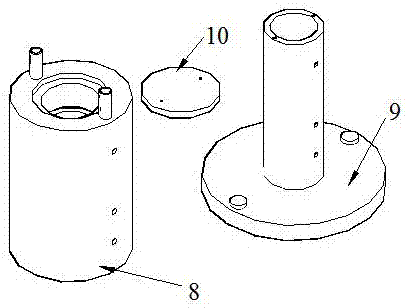

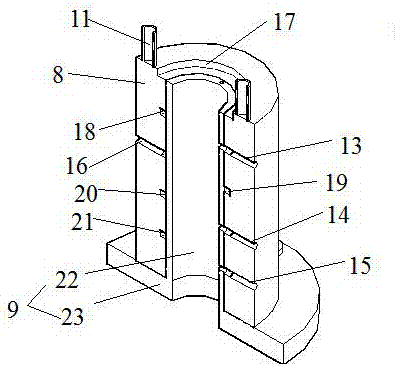

High-solid anaerobic fermentation tank and jet stirring device for same

ActiveCN104893964ALight structureEasy to installBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid jetFermentation

The invention discloses a high-solid anaerobic fermentation tank and a jet stirring device for the same. The jet stirring device comprises a circulating crushing pump, a liquid-liquid jet stirrer and a gas-liquid jet stirrer. A feed inlet of the circulating crushing pump is connected with a suction pipe, a discharge outlet of the circulating crushing pump is connected with a supply pipe, a suction gate valve is arranged on the suction pipe, and the front end of the suction pipe is mounted on the inner lower portion of the anaerobic fermentation tank; the rear end of a liquid-liquid jet pipeline of the liquid-liquid jet stirrer is connected with the supply pipe of the circulating crushing pump, and a liquid-liquid jet device at the front end of the liquid-liquid jet pipeline is mounted on the inner lower portion of the anaerobic fermentation tank; a gas-liquid jet device at the front end of a gas-liquid jet pipeline of the gas-liquid jet stirrer is mounted on the inner upper portion of the anaerobic fermentation tank, the front end of a biogas pipeline connected to the upper end of the gas-liquid jet device is connected to the top of the anaerobic fermentation tank, and the biogas pipeline is communicated with the inside of the anaerobic fermentation tank. The high-solid anaerobic fermentation tank and the jet stirring device have the advantages that anaerobic fermentation mixing stirring effects can be realized by the jet stirring device, the jet stirring device has a scum crushing function, and accordingly the gas yield can be greatly increased by the jet stirring device; drainage pressures can be greatly lowered, accordingly, energy consumption can be saved, and the jet stirring device is suitable for the high-solid anaerobic fermentation tank.

Owner:北京中持绿色能源环境技术有限公司

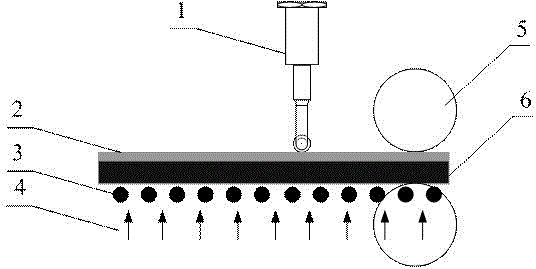

Double-physical-field-assisted single-face laminated metal composite plate manufacturing method

InactiveCN104438323AEffectively breakReduce pollutionMetal rolling arrangementsSide effectPhysical field

The invention provides a double-physical-field-assisted single-face laminated metal composite plate manufacturing method. The method includes the following steps that the surface of a base metal plate is cleaned through an acid pickling method, grease, stains and oxidation films are removed, and drying is conducted; the base metal plate is preheated under the atmospheric conditions or nitrogen or argon protection condition, the preheating temperature ranges from 150 DEG C to 1700 DEG C; rolling is conducted on the base metal plate or a base metal plate of preset low-melting-point filling materials through an inner-cooling type water cooling roller, meanwhile, ultrasonic waves and magnetic fields are applied continuously till a single-face laminated metal composite plate is manufactured. The double-physical-field-assisted single-face laminated metal composite plate manufacturing method has the advantages that the ultrasonic waves and the magnetic fields are applied, control over the interface reaction and intensifying of mass transfer process are facilitated, a composite welding seam for intensifying intermetallic compound particles is obtained, welding seam grain is refined, residual stress is lowered, the oxidation films are broken effectively, consumption of brazing flux is lowered or avoided, the toxic and side effect on staff and adverse effects on combined interfaces are reduced, energy saving is facilitated, and the environmental pollution is lowered.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

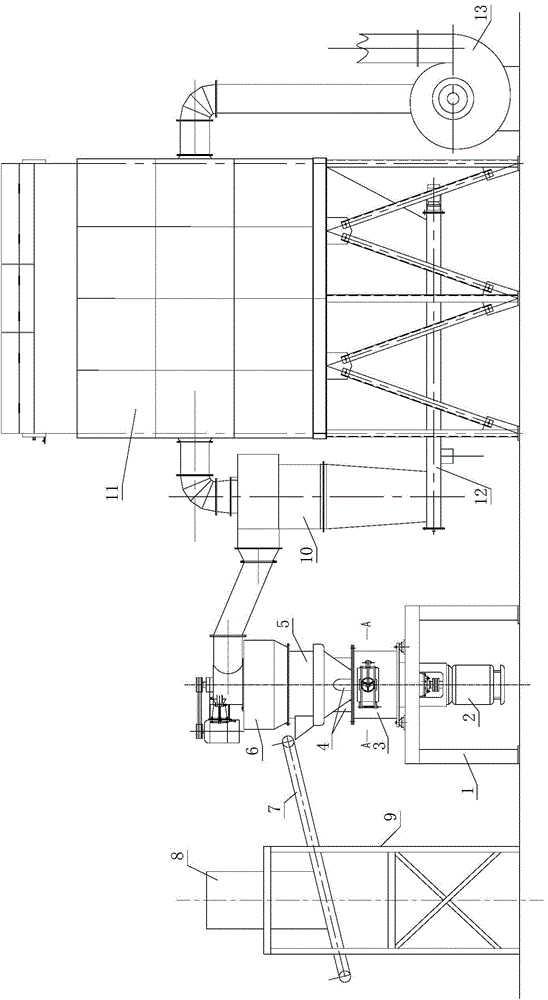

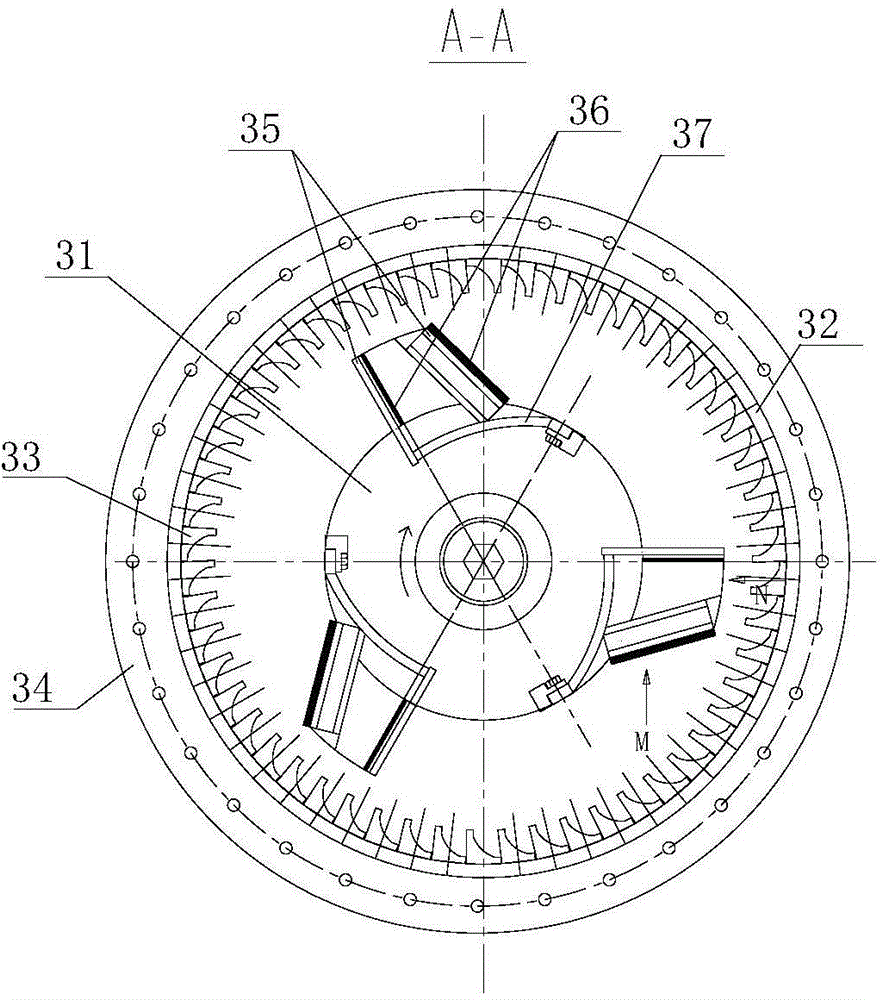

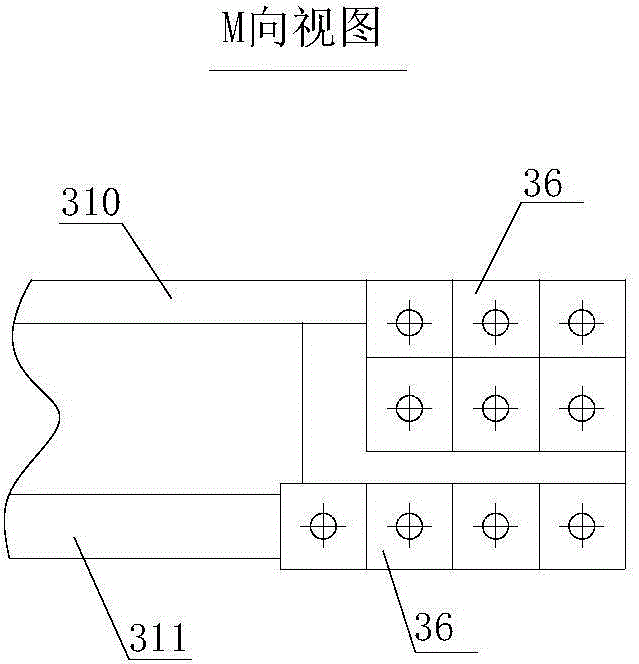

Solid material grinding method and solid material grinding machine

The invention relates to a solid material grinding method and a grinding machine. Solid materials enter a grinding body of a grinding room after being subjected to primary air classification, and are thrown onto a lining plate along the radial direction to be broken due to collision under the centrifugal effect of the grinding body in high-speed rotation; after rebounding from the lining plate, the broken materials oppositely collide newly-added materials to be broken; large-particle materials drop under the gravity effect and upwards enter a working cabin through a guide pipe after being subjected to high-speed hammering; the working bin has the functions of feeding and wind mixing elutriation; the materials subjected to wind mixing elutriation enter a classifier to be classified; finished material products achieving the granularity requirements are collected by a spiral collector and a bag-type dust remover and then are discharged from a finished product discharging device; and materials not achieving the granularity requirements are returned to the grinding room to be reground. The grinding machine has the beneficial effects that the grinding granularity is small, the grinding efficiency is high, the fine powder collecting effect is good, the equipment is compact in structure, the maintenance cost is low, powder bodies with the granularity in a range of 80-1,500 meshes can be produced, and the grinding machine has the advantages of high yield ad stable quality particularly when producing ultrafine powder with the granularity being greater than 800 meshes and materials with higher rigidity.

Owner:蔡昌荣

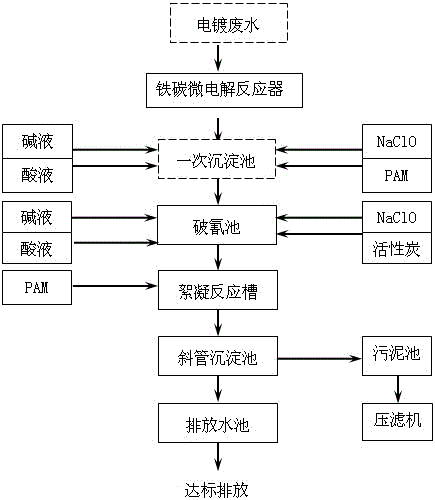

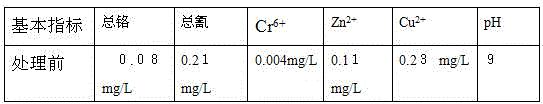

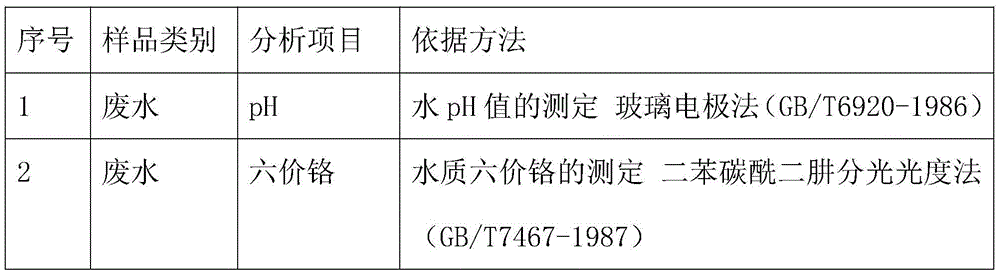

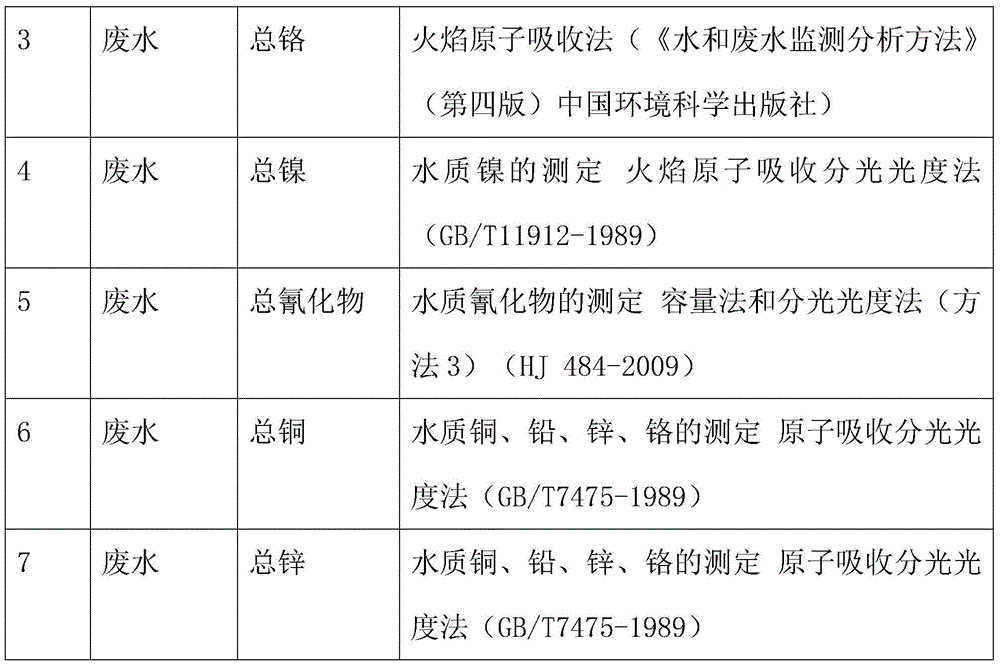

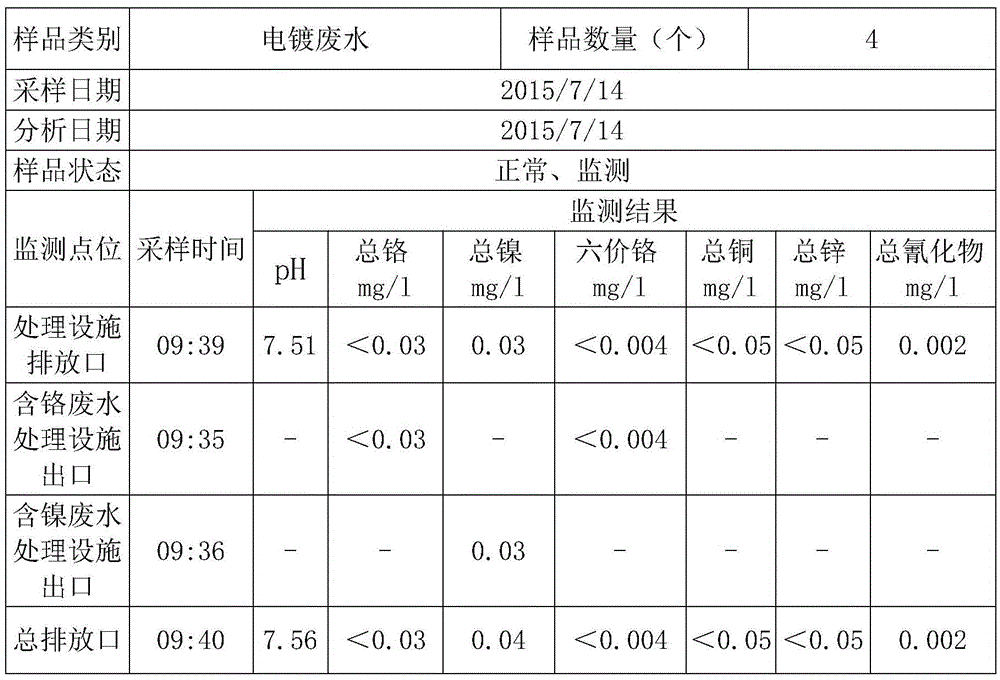

Treatment process of electroplating wastewater containing cyanogen and chromium

ActiveCN105948336AReduce secondary pollutionImprove purification efficiencyWaste water treatment from metallurgical processMultistage water/sewage treatmentFlocculationElectrolysis

The invention relates to a treatment process of electroplating wastewater containing cyanogen and chromium. The treatment process is characterized by comprising the following steps: (1) enabling the electroplating wastewater containing cyanogen and chromium to flow through an iron-carbon micro-electrolysis reactor; (2) adjusting pH to be 9-11, then adding sodium hypochlorite, reacting for 10-60 minutes, controlling the pH value to be 4-6, reacting for 10-60 minutes, then adding a flocculant for carrying out flocculation treatment, and then carrying out precipitation treatment; (3) adjusting the pH value to be 10-12, then adding sodium hypochlorite, enabling oxidation-reduction potential of the treated wastewater to be 350mV or above, reacting for 30-60 minutes, and then adding active carbon and reacting for 10-60 minutes; and (4) adding the flocculant and then precipitating. The treatment process is capable of removing harmful materials in the wastewater, particularly removing iron-cyanogen complex which is difficultly removed by conventional methods, adsorbing heavy metals and ensuring that various indexes of the treated electroplating wastewater containing cyanogen and chromium reach the standards.

Owner:NORTHERN ENG DESIGN & RES INST CO LTD

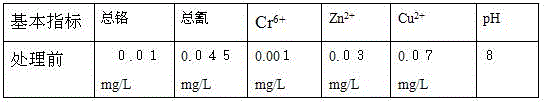

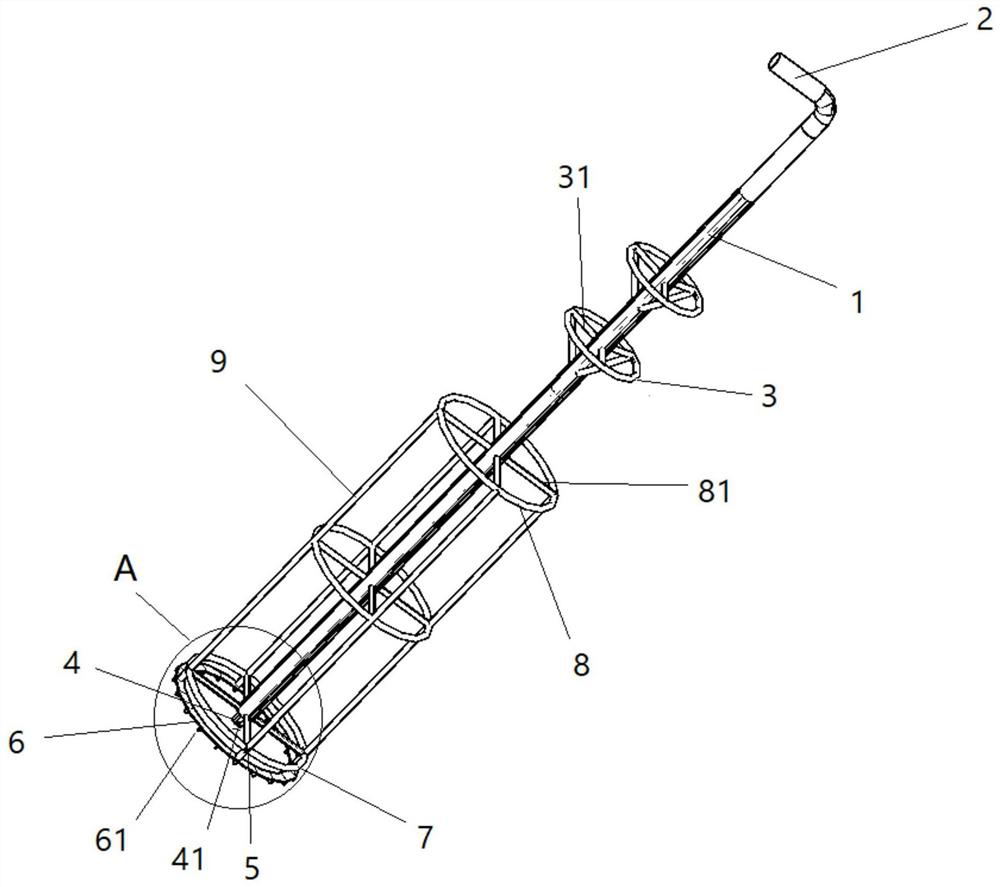

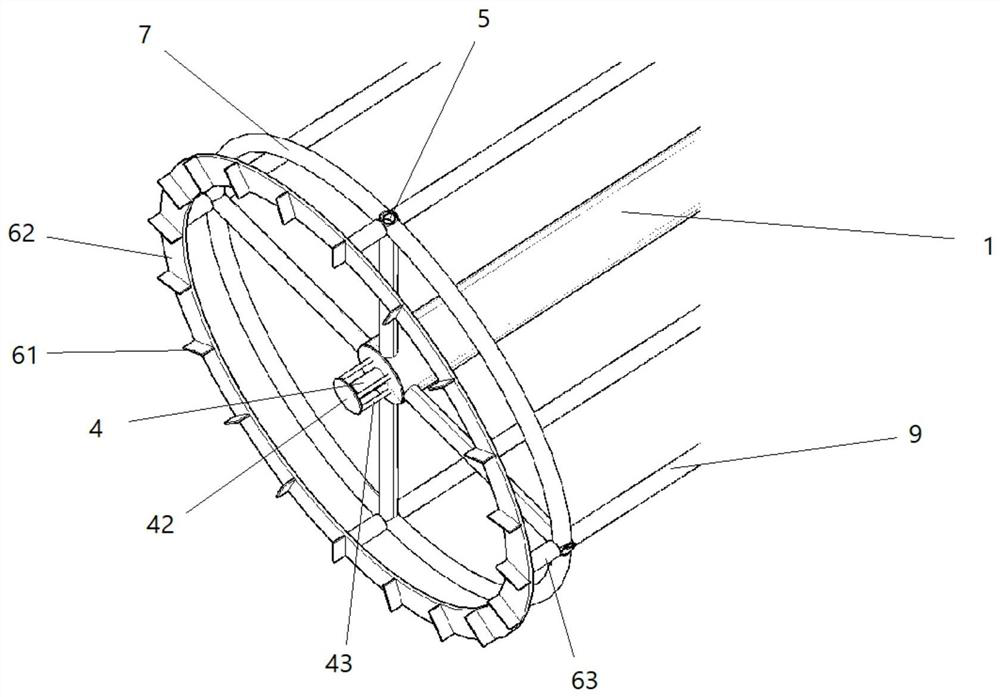

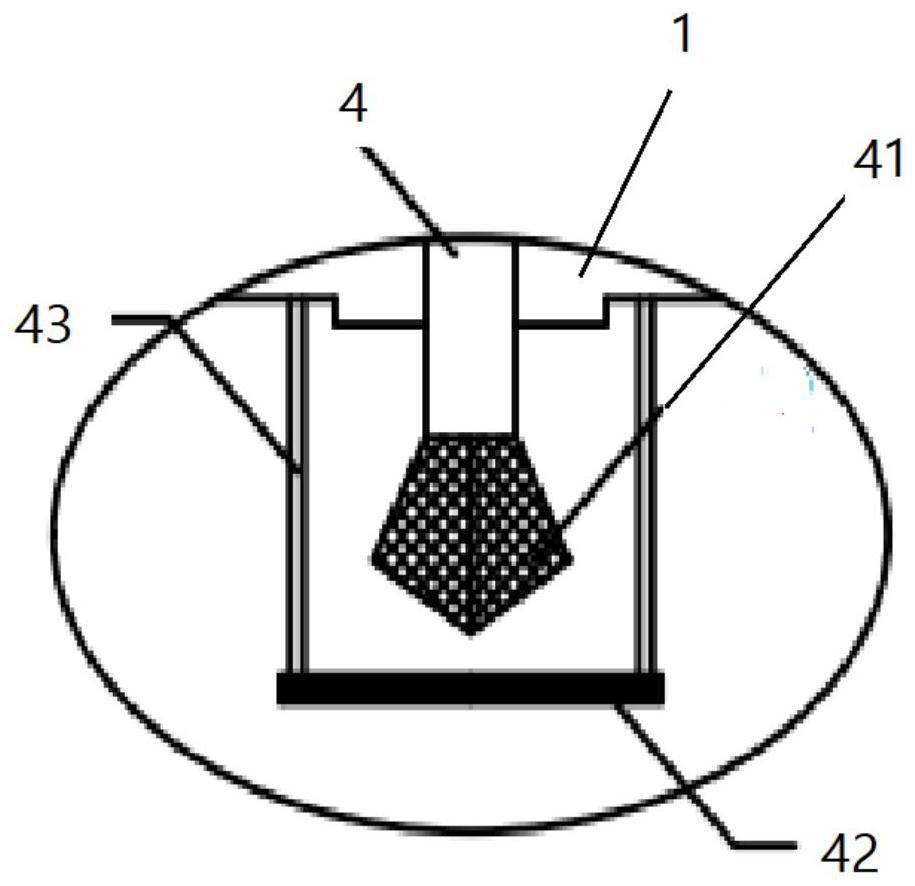

Breaking and dismantling device for rescue

A breaking and dismantling device for rescue comprises a barrier breaking puncher pin. The barrier breaking puncher pin is mounted at one end tip of an impacting rod 2, and the other end of the impacting rod penetrates through a guide bush and is connected with an eccentric steel ball. The guide bush is fixed at one end of a sleeve, and the eccentric steel ball is connected with a check ring through an impacting needle and a return spring which is arranged on the impacting needle in a sleeved mode. The check ring is mounted on one side of an impacting block, and the other side of the impacting block is connected with the bottom of a spring route adjusting rear cover through a force application spring. The spring route adjusting rear cover is connected with one end of the sleeve. The eccentric steel ball, the return spring, the impacting needle, the check ring, the impacting block and the force application spring are located in the sleeve. The spring route adjusting rear cover is mounted on a handle which is connected with a gun stock. When the breaking and dismantling device for the rescue is used, the handle on the spring route adjusting rear cover is held, the barrier breaking puncher pin abuts against a masonry barrier to be broken and is pushed forward to compress the springs, and after being compressed to certain distances, the springs are released abruptly to generate large enough impact force which can break through the masonry barrier. The breaking and dismantling device for the rescue has the advantages of being capable of being operated manually, convenient to carry and use, high in efficiency and capable of being used in all directions.

Owner:XIAN SIYUAN UNIV

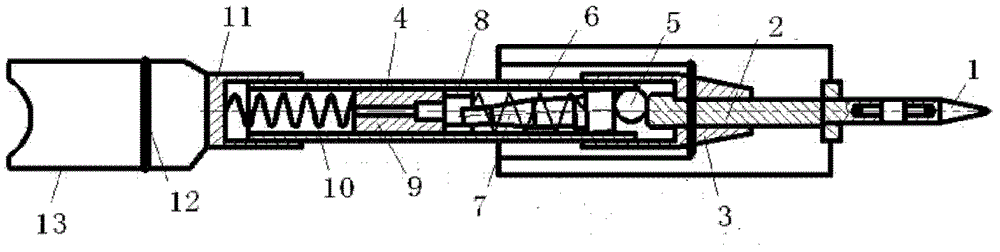

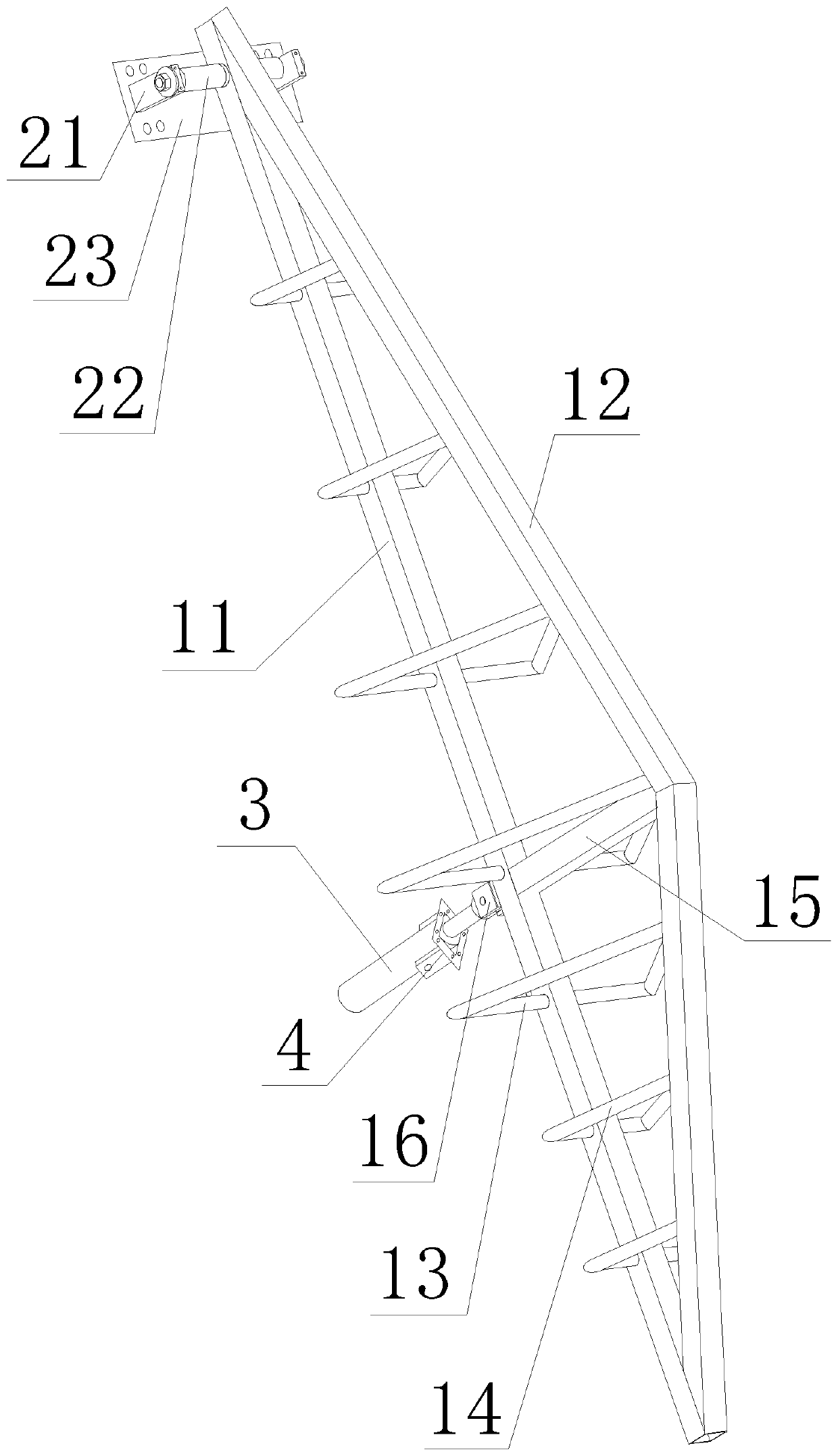

Stock bin arch breaking device

The invention relates to the technical field of stock bin arch breaking equipment, in particular to a stock bin arch breaking device. The device comprises an impact support matched with the shape of astock bin, the upper part of the impact support is hinged to the stock bin through a connecting support which is fixedly assembled on the inner side wall of the stock bin, the middle lower part of the impact support is provided with a power driving device for driving the impact support to swing by taking the connecting support as a base point for arch breaking, and the power driving device is assembled on the side wall of the stock bin. The impact support is driven to swing back and forth by the power driving device to extrude and impact arch materials, so that the arch materials are effectively broken; and moreover, the device is simple in structure, convenient to manufacture, wide in application range and particularly applicable to breaking the blockage at the opening part of stock bin.

Owner:刘怀收

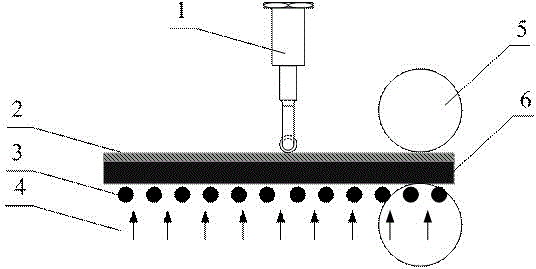

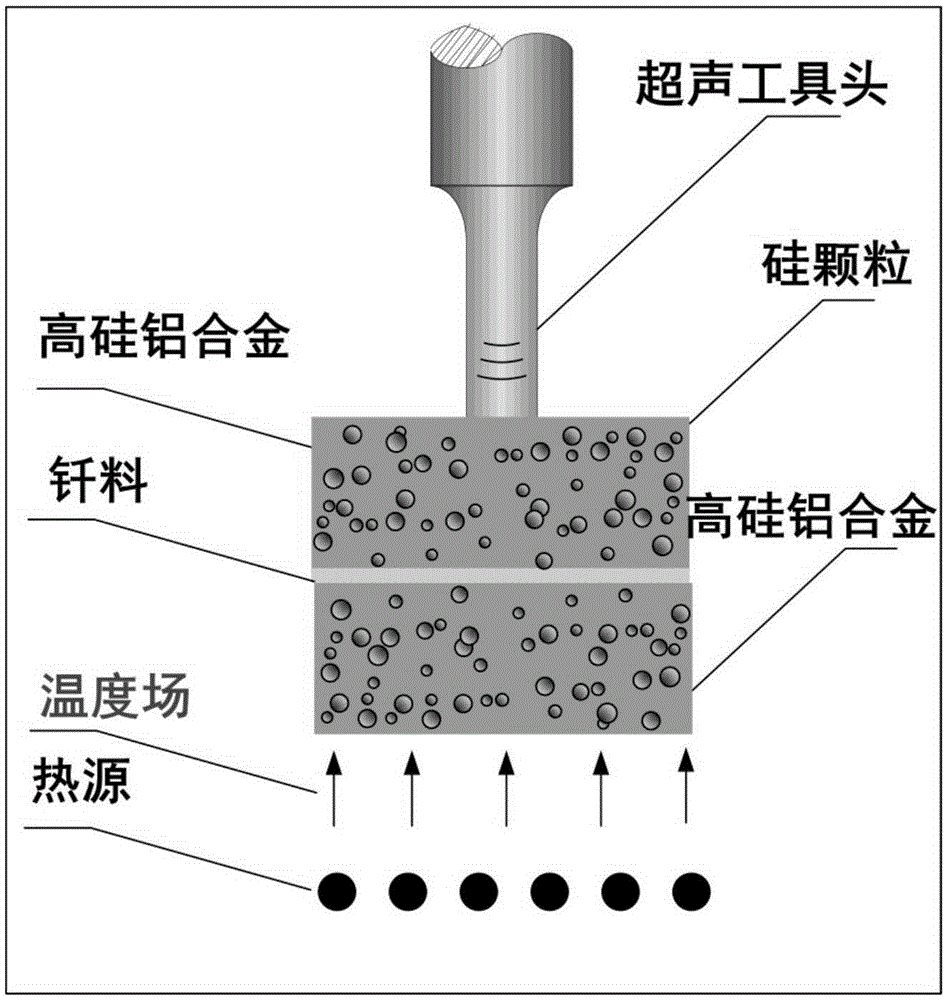

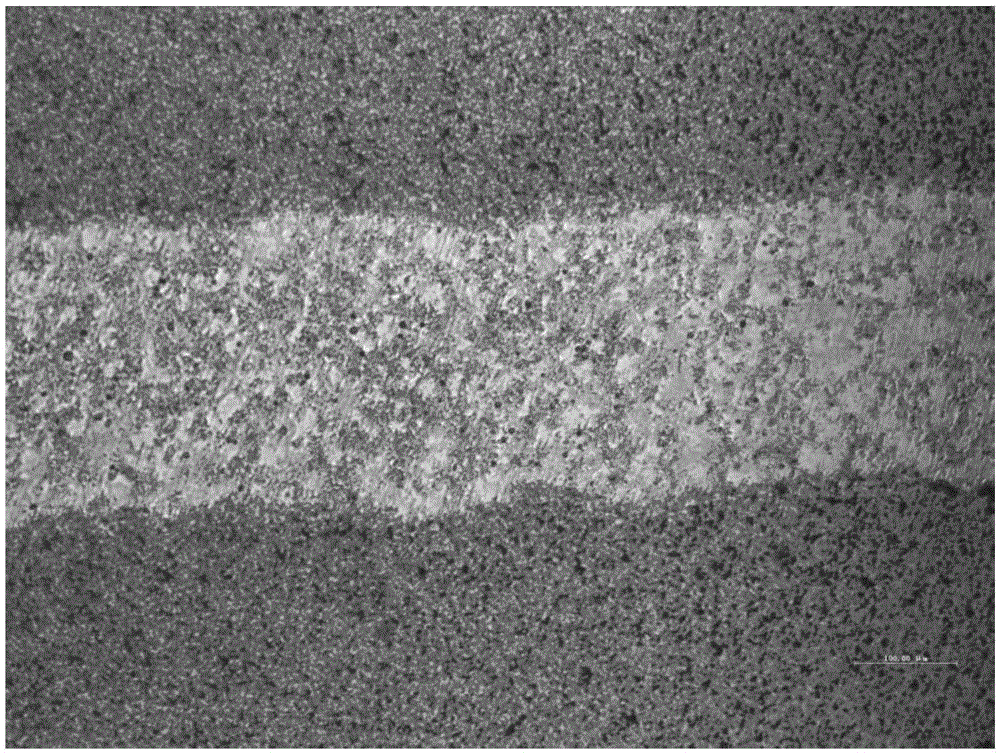

High-silicon aluminum alloy welding method for forming particle-reinforced weld joints through thermo-acoustic coupling

InactiveCN105269105AEffectively breakHelp wettingSoldering apparatusWelding/soldering/cutting articlesMultiphysics couplingCoupling

The invention belongs to the technical field of material welding and connection, and particularly relates to a high-silicon aluminum alloy welding method for forming particle-reinforced weld joints through thermo-acoustic coupling. The method mainly solves the problems that in the high-silicon aluminum alloy welding process, because the affinity of aluminum and oxygen is high, generated refractory substance oxidation films have adverse effects on weld joint fusion and silicon cracks and agglomeration growth are caused when a large amount of silicon is contained in high-silicon aluminum alloy. The method includes the steps of conducting medium and low temperature welding on high-silicon aluminum alloy through brazing filler metal under the atmosphere condition under the effects of an external heating source and ultrasounds, the reinforcing phase Si in high-silicon aluminum alloy is made to enter weld joints to form particle-reinforced composite weld joint structures through thermo-acoustic coupling, and therefore high-strength and reliable connection of high-silicon aluminum alloy difficult to weld is achieved.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Activated sintering method of aluminum or aluminum alloy

ActiveCN106623915AImprove sintering performanceEvenly meltedTransportation and packagingMetal-working apparatusMechanical propertyPhysical property

The invention relates to an activated sintering method of aluminum or aluminum alloy. Mixed salt capable of generating an activating reaction with oxidation films on the surface of aluminum powder or aluminum alloy powder is prepared in advance before aluminum or aluminum alloy part forming and fully mixed with the aluminum powder or the aluminum alloy powder; when sintering is conducted, a uniform mixture of LiCl, KCl and K2ZrF6 is melted to react with oxides on the surfaces of aluminum powder or aluminum alloy powder particles at the temperature of 560 DEG C to 620 DEG C, so that the oxidation films are expanded, crinkled, broken, integrally loosened and stripped by being influenced by liquid phase flowing, then the oxidation films are effectively removed, and substrates of the aluminum particles are exposed outside; substance transmission can be enhanced through the exposed oxidation-free surfaces, metallurgical bonding can be achieved among the powder particles, the sinterability of the aluminum or aluminum alloy is greatly improved, and the physical property and the mechanical property of a sintered part are improved. According to the sintering method, the processes are simple, ordinary powder metallurgy equipment is needed, the universality is achieved, and large-scale production and popularization are promoted.

Owner:NBTM NEW MATERIALS GRP

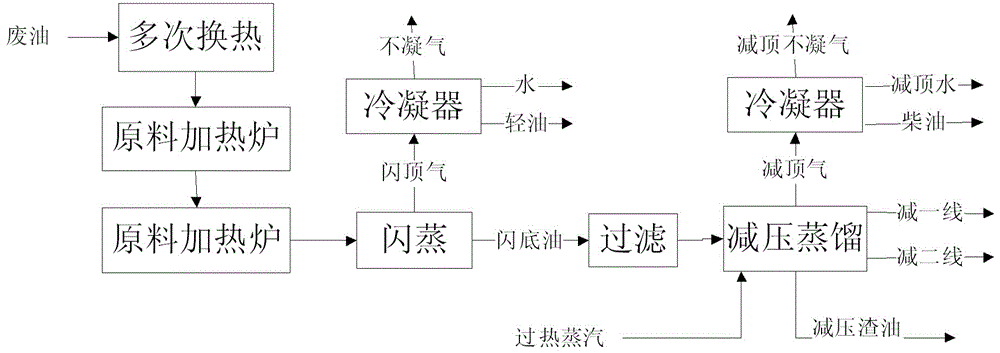

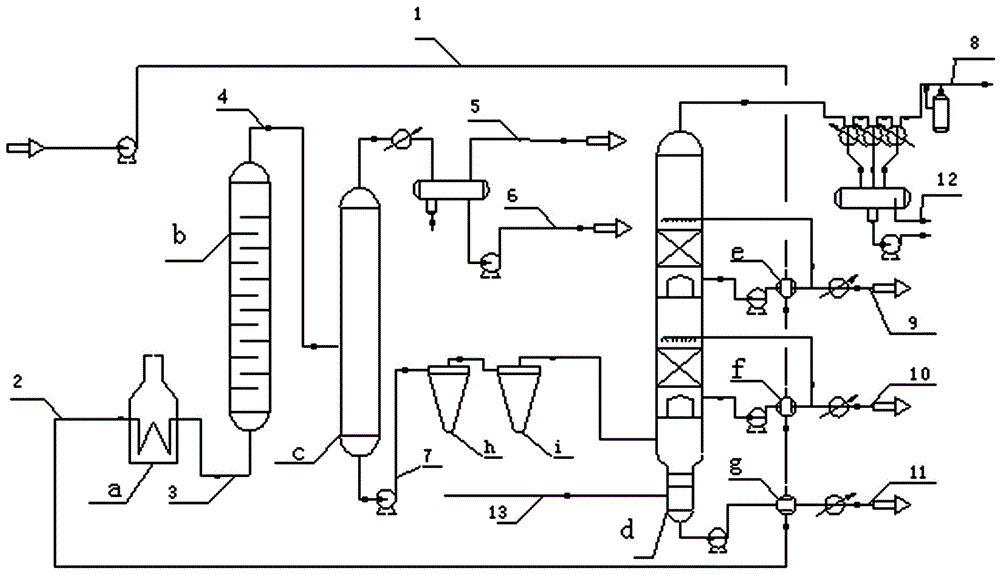

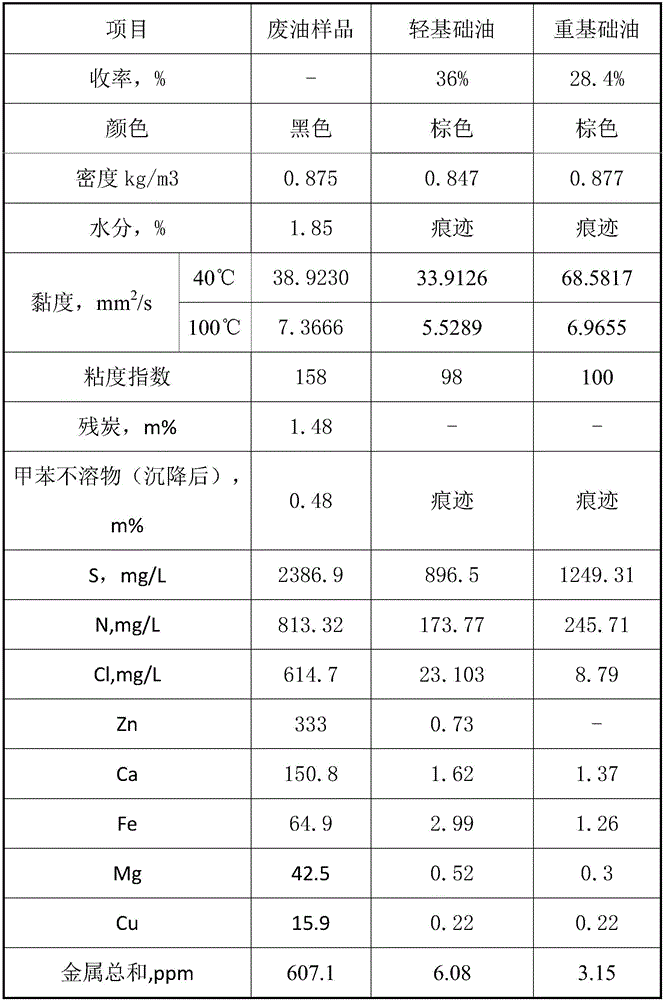

A continuous distillation process for regeneration of waste lubricating oil

InactiveCN104099171BEffectively breakEffectively break the clean dispersion in waste oilLubricant compositionOrganic acidDecomposition

The invention discloses a continuous distillation process for regeneration of waste lubricating oil. The process includes a heat exchange process between waste oil and distilled cut fractions, a visbreaking heat treatment unit and a flash evaporation-vacuum distillation unit. The detergency and dispersion additives in waste oil can be effectively removed through visbreaking heat treatment, so that suspended impurities such as metals in waste oil can be deposited more easily, and at the same time, some metal salt additives and corrosive organic acids can be decomposed or deteriorated. Light components and base oil fractions can be effectively extracted by using flash-vacuum distillation. In addition, the optimized heat exchange system effectively reduces the energy consumption of continuous distillation, the overall extraction rate of waste oil through the process of the invention is higher than 85%, the technical economy is good, the impurity content is low (especially low metal content), Distilled products can be directly used as high-quality raw materials for subsequent hydrofining.

Owner:四川省中明环境治理有限公司 +1

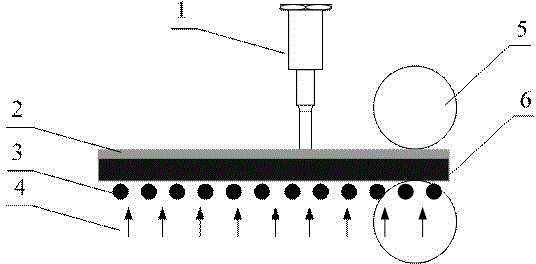

Method for preparing thin-film aluminum steel composite plate by ultrasonic-assisted liquid-solid rolling

ActiveCN102489529AEffectively breakReduce usageWork treatment devicesAuxillary arrangementsBond interfaceSide effect

The invention relates to a method for preparing a thin-film aluminum steel composite plate by ultrasonic-assisted liquid-solid rolling, which solves the problems that: when an aluminum steel layered metal composite plate is prepared by the traditional liquid-solid rolling method, a large number of flux is needed and the obtained composite plate has low interface bonding strength. The method comprises the following steps: firstly, treating a steel surface, and preheating under the protection of nitrogen; secondly, melting all pure aluminum materials under the protection of nitrogen, and allowing liquid aluminum to form a crest; thirdly, plating aluminum by aids of ultrasound; and finally, adopting an internally-cooled water-cooled roller to carry out cooling rolling so as to obtain the thin-film aluminum steel composite plate. The method has the advantages that: firstly, the use of flux is avoided, the toxic side effects on the staff and the adverse effects on the bonding interface of the aluminum steel are reduced, and the preparation cost is reduced; and finally, the bonding strength is improved. The invention is mainly used for preparing the thin-film aluminum steel composite plate.

Owner:HARBIN INST OF TECH

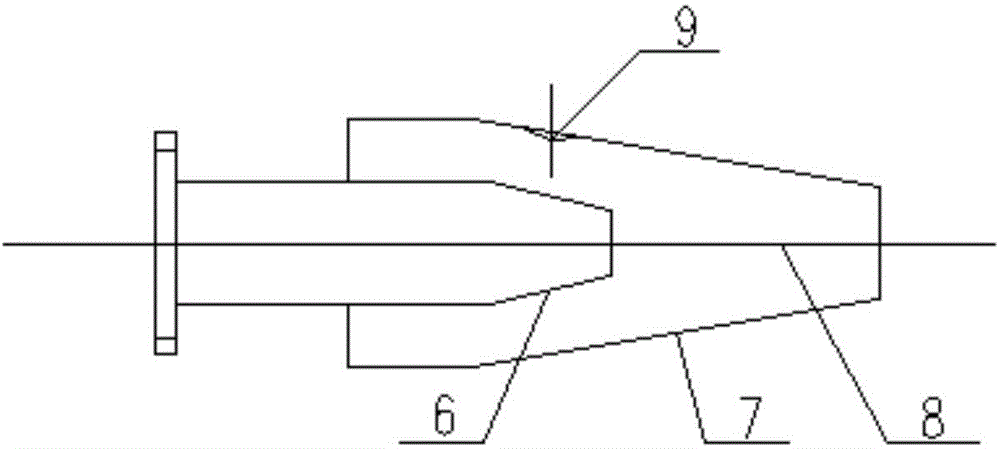

Efficient bamboo slicer

InactiveCN108356937AImprove opening efficiencyEasy dischargeCane mechanical workingKnife bladesEngineering

The invention discloses an efficient bamboo slicer. The efficient bamboo slicer comprises a rack (1), and the rack (1) is sequentially provided with a bamboo moving mechanism (2), a slicing mechanism(22) and a bamboo guiding base (3), and movable wheels (4) are arranged below the rack (1). The slicing mechanism (22) comprises a fixing support (5) arranged on the rack (1), the fixing support (5) is provided with an annular frame (6), and a set of fixing blades (8) distributed in a conical structure manner are arranged on the side face of the annular frame (6). A fixing disc (7) is arranged atthe end portions of the fixing blades (8). The fixing disc (7) is further provided with a wall breaking cutter (9) corresponding to the bamboo moving mechanism (2) in position. The efficient bamboo slicer has the beneficial effect that the slicing efficiency can be improved.

Owner:ANJI HENGSHENG BAMBOO WOOD

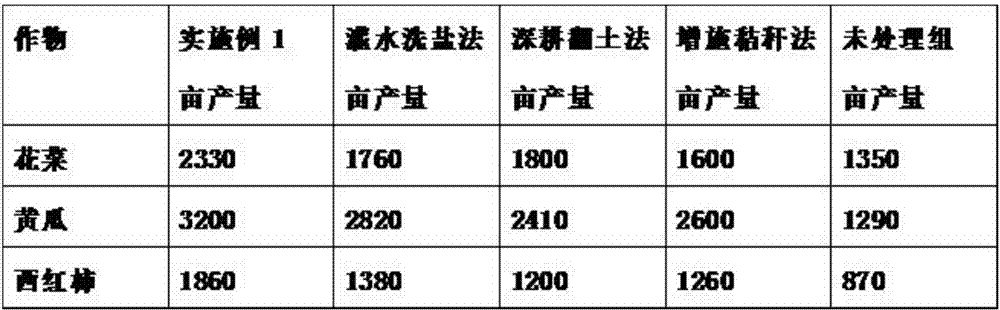

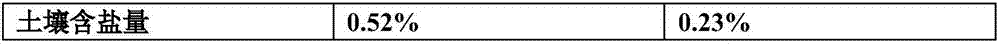

Method of repairing and improving secondary salinized soil in facility agriculture

The invention discloses a method of repairing and improving secondary salinized soil in facility agriculture. The method comprises the following steps of: (1) scattering a pH adjustor in a corresponding quantity into soil according to a detection result of pH value of soil; (2) performing rotary tillage on the soil; (3) thoroughly watering the soil and airing the soil; (4) scattering a first fertilizer into the soil; (5) scattering a loosening agent into the soil and performing rotary tillage again on the soil; (6) uniformly mixing leguminous plant seeds and nodule bacteria to form mixed plant seeds; (7) sowing the mixed plant seeds into the soil and watering the seeds; (8) when the leguminous plants grown from the mixed plant seeds grow to 15-25cm, performing total crop return on the leguminous plants; (9) scattering a second fertilizer into the soil; and (10) planting salt-absorbing crops in the soil and harvesting the crops. By means of the steps, the method disclosed by the invention can effectively adjust the pH value of the soil, reduce soil hardening, reduce the residual salt content in the soil and improve the utilization ratio of the soil, so that the crops grow more favorably.

Owner:KANG SHUNDA SUZHOU AGRI SCI & TECH CO LTD

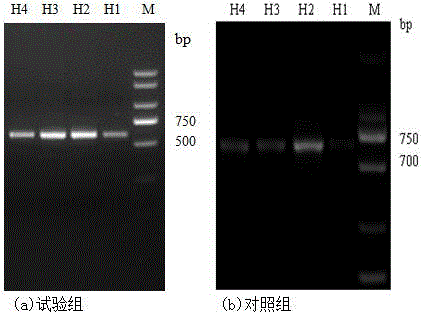

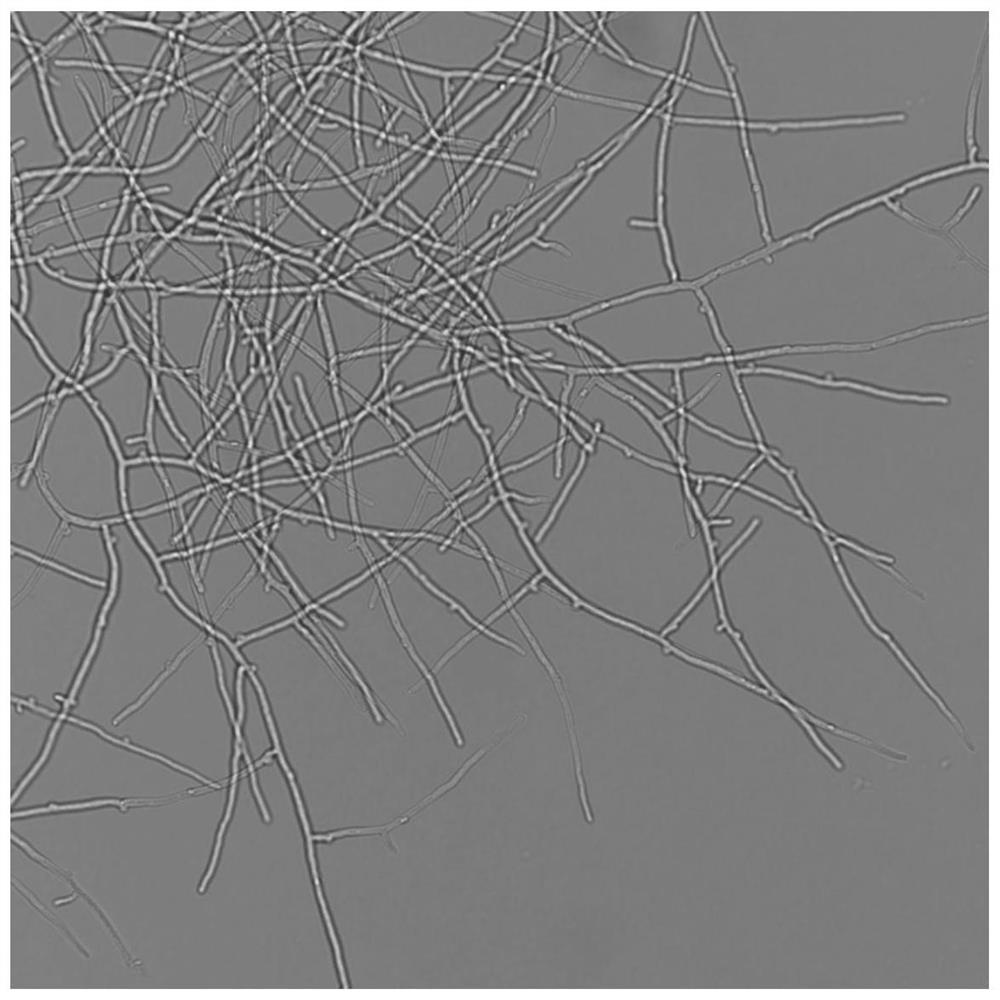

Extraction method of metagenome of microbes in seawater

ActiveCN106047869AImprovement of impurity interferenceIncrease experiment rateDNA preparationIonSeawater

The invention provides an extraction method of metagenome of microbes in seawater. According to the invention, the special sample, seawater, undergoes saline ions removal treatment, double-membrane filtration and recovery processing. The invention aims to provide an efficient and rapid method for extracting metagenome of microbes in seawater. The method comprises the following specific steps: removal of impurities in seawater, cracking of microbes in seawater, dissociation and adsorption of DNA and DNA elution. Interference of many saline ions in seawater can be effectively eliminated; and microbial cells in seawater are fully cracked to fully release DNA. According to the DNA extracted by the method, A260 / 280 ratio of the DNA is maintained between 1.8 and 2.0. The obtained DNA has good quality and high purity, can meet requirements of gene library construction and qPCR and high-throughput sequencing, and provides good foundation for the research on heritable variation diversity of microbial genomes.

Owner:厦门基源医疗科技有限公司

Tire

InactiveCN106671706AImprove gripGood drainage and snow removalTyre tread bands/patternsEngineeringWater storage

The invention provides a tire. The tire comprises a tread making contact with the ground during traveling and tire shoulders arranged on two sides of the tread, wherein the annular surface in the middle of the tread along the circumference of the tire is an equatorial plane; a plurality of grooves are formed in the tread and parallel to the equatorial plane; a plurality of cross grooves are formed in the tread in the axial direction of the tire and intersect with the plurality of grooves to form a plurality of tread blocks; water bags capable of storing rain water and snow water are arranged on the tread blocks adjacent to the tire shoulders; each water bag comprises a columnar groove extending to the center of the tire in the direction perpendicular to the corresponding tread block, an inwards concave water storage cavity is formed in the bottom of the columnar groove, and the rain water and the snow water formed on the tread converge to the water storage cavity for storage under guidance of the columnar groove. The tire can store the rain water and the snow water effectively.

Owner:QINGDAO DOUBLESTAR TIRE IND CO LTD

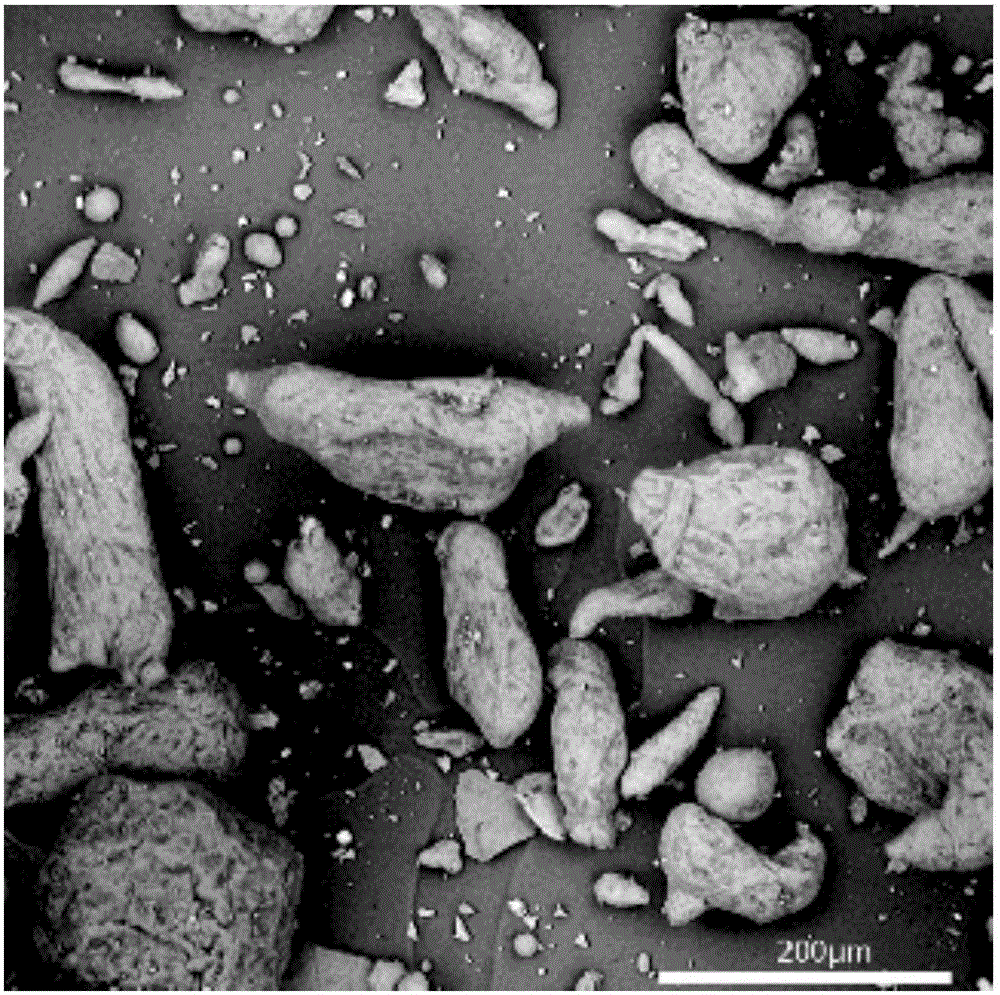

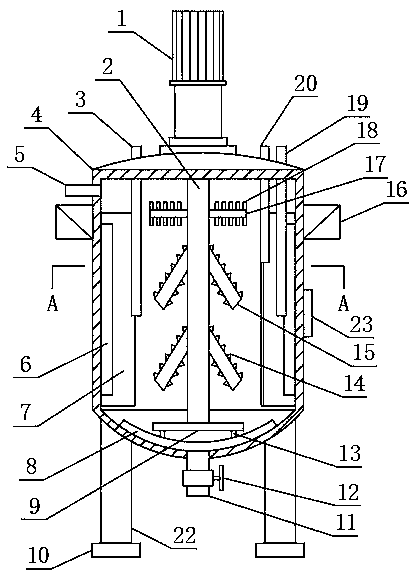

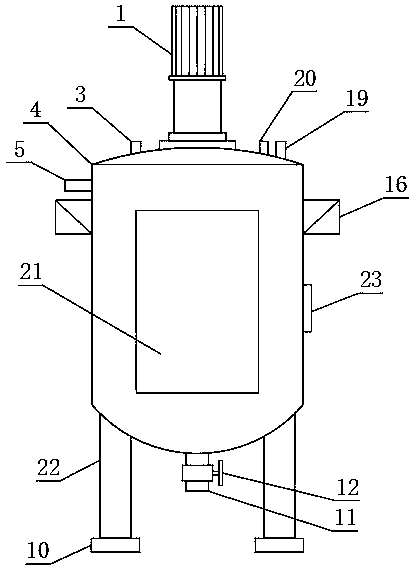

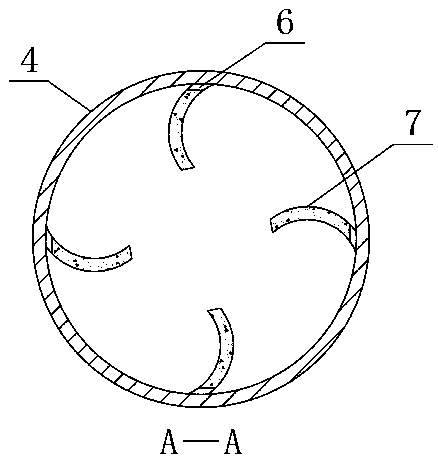

Equipment for producing nickel-cobalt-manganese ternary precursor

InactiveCN109399731AAchieve clearingEffectively breakCell electrodesSecondary cellsMotor driveAmmonium hydroxide

The invention discloses equipment for producing a nickel-cobalt-manganese ternary precursor. The equipment comprises a reaction kettle body, wherein the outer side of the upper surface of the reactionkettle body is provided with an alkali liquor inlet pipe, an ammonium hydroxide inlet pipe and a metal salt inlet pipe respectively, the middle of the upper surface of the reaction kettle body is provided with a motor, an output shaft of the motor penetrates through the reaction kettle body and is provided with a stirring shaft, the upper portion of the outer side of the stirring shaft is symmetrically provided with fixing rods, the outer side of each fixing rod is provided with a plurality of scraping rods, the middle of the outer side of the stirring shaft is uniformly provided with four stirring blades, and the outer side of each stirring blade is provided with a plurality of protruding thorns. The equipment for producing the nickel-cobalt-manganese ternary precursor has the advantagesthat the rotation of the motor drives the stirring shaft to rotate, so that the effect is achieved that the scraping rods remove foam on the surface of a reaction liquid, reaction medium foam generated by stirring is effectively broken, crystals do not aggregate easily, all-around overturn is performed so that each crystal nucleus grows separately, and therefore compact spherical crystals withcontrollable sizes can be generated.

Owner:LIUZHOU SHENTONG AUTOMOBILE TECH CO LTD

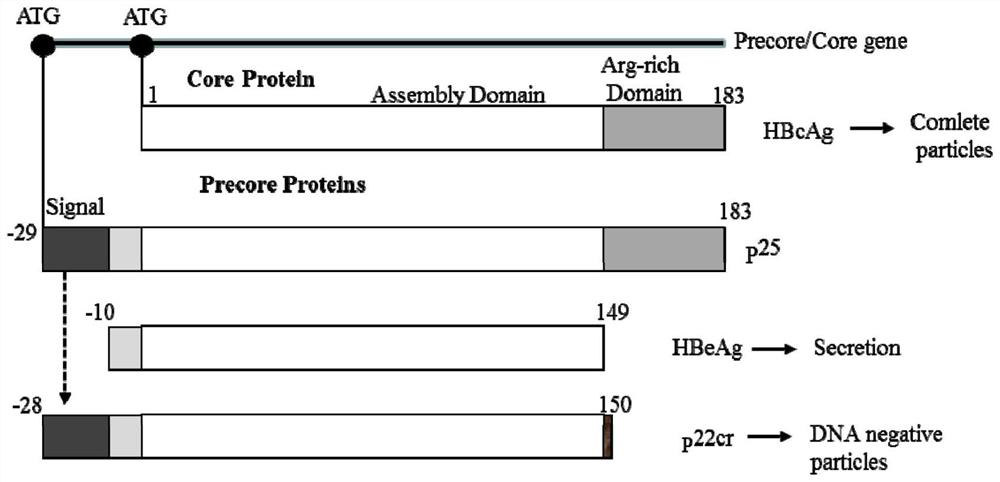

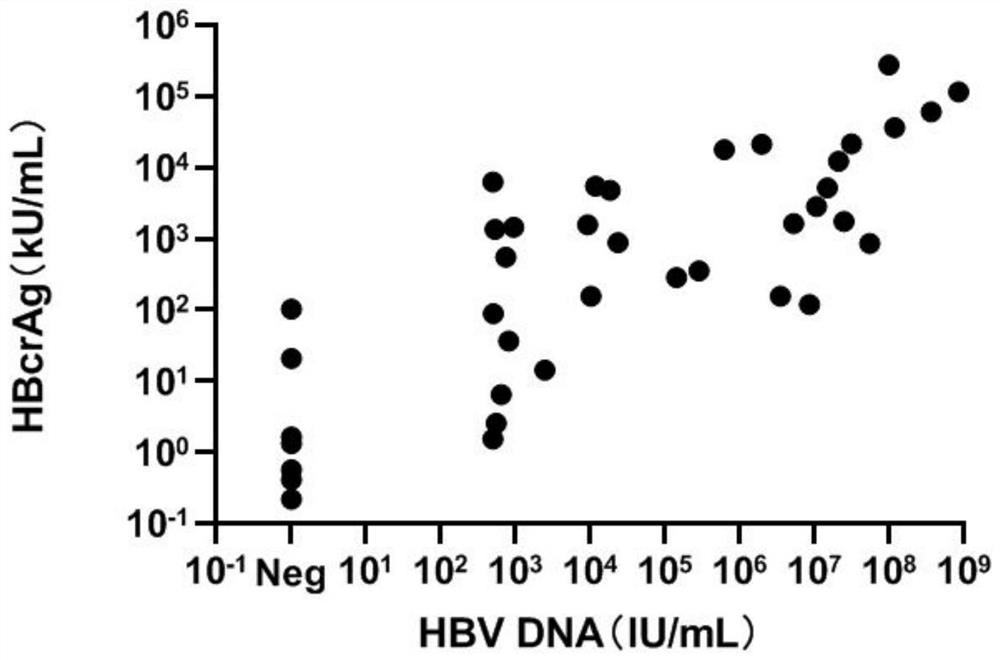

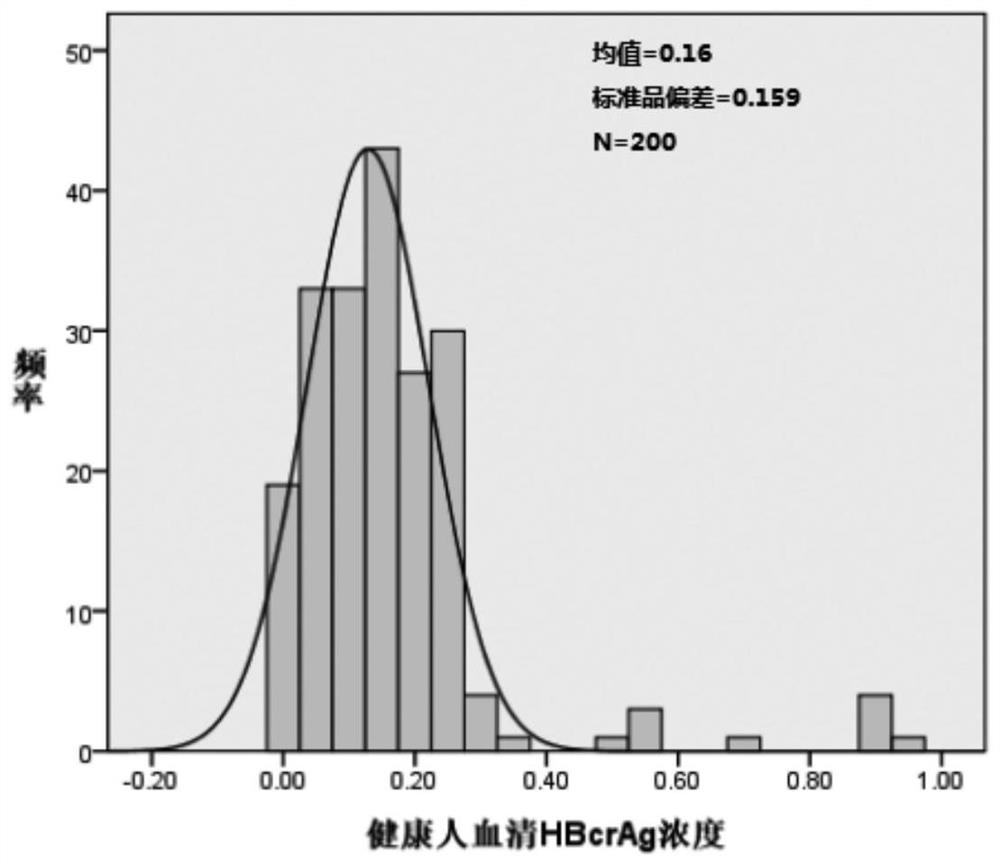

Sample pretreatment solution and kit for combined detection of hepatitis B virus core-related antigens

ActiveCN112526136AEffectively breakHigh detection sensitivityMaterial analysisAgainst vector-borne diseasesAntigenActive agent

The invention relates to a sample pretreatment solution and a kit for combined detection of hepatitis B virus core related antigens. The sample pretreatment solution is a buffer solution containing achelating agent, high-concentration salt ions, a protein denaturing agent, a reducing agent and a surfactant. The sample pretreatment solution is utilized to construct the kit for combined detection of the hepatitis B virus core related antigens. The kit can effectively break virus shells to release three related antigens, greatly improves the detection sensitivity of samples, has extremely high clinical application value, and can be widely applied to inspection of various types of samples.

Owner:GUANGZHOU DARUI BIOTECH

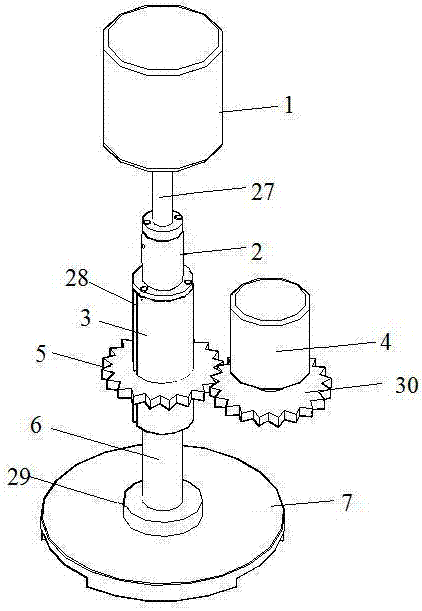

Rotating adjusting type upper shaft mechanism for single-side polishing of large-size wafers

ActiveCN106881660AImprove sealingEffectively breakPolishing machinesGrinding drivesWater leakageLarge size

The invention provides a rotating adjusting type upper shaft mechanism for single-side polishing of large-size wafers. The rotating adjusting type upper shaft mechanism comprises a cylinder, a rotating connector, a rotating shaft, a rotating motor, a rotating gear, a connecting shaft rod and an upper disc face, wherein the cylinder controls the upper disc face to rise and fall, the rotating motor controls the rotating gear, the rotating shaft, a rotating block, the connecting shaft rod and the upper disc face to rotate, an air tube inlet port is connected with a pneumatic electronic valve, and a water tube inlet port and a water tube outlet port are connected with a water tank. The rotating adjusting type upper shaft mechanism for single-side polishing of the large-size wafers is simple in structure and reasonable in design, a rubber sealing piece and a water leakage detection port are arranged, the sealing performance of the rotating connector is effectively improved, and monitoring is provided for monitoring water leakage situation of the rotating connector; meanwhile, in the polishing operation process, the upper disc face can be effectively cooled, the situation that due to the fact that temperature of the upper disc face rises, flatness of a ceramic disc and the surface of the upper disc face is changed, and the stability is destroyed is avoided, and then polishing uniformity is improved, and the flatness of the surfaces of the polished wafers is improved; and a vacuum layer between the ceramic disc and the bottom of the upper disc face is easy to remove, and wafers can be taken out more rapidly.

Owner:TUNGHSU GRP

Breaking process for electroplating wastewater complex

InactiveCN105585186AEasy to meet emission standardsEffectively breakWater aerationWaste water treatment from metallurgical processStrong acidsEmission standard

The invention discloses a breaking process for an electroplating wastewater complex. The breaking process comprises the following steps: step 1, electroplating wastewater is collected; step 2, a strong acid solution is added to the electroplating wastewater, and the pH value of the electroplating wastewater is regulated to be lower than 2.5; step 3, a strong oxidizing agent is added to the electroplating wastewater for coagulating sedimentation; step 4, the coagulating sedimentation is subjected to continuous aeration for 4 hours; step 5, an alkaline solution and a coagulant aid PAM (polyacrylamide) are added to the electroplating wastewater, the pH value of the electroplating wastewater is regulated to 11, a hydroxide precipitate is formed in the electroplating wastewater and is removed, and the electroplating wastewater can meet the emission standard. The breaking process has the advantages that the metal complex can be broken effectively, metal is released from the complex, the breaking efficiency is increased, the treatment cost is reduced, and the electroplating wastewater can meet the emission standard more easily.

Owner:XIAMEN TONGLIYUAN ELECTRIC EQUIP

Special tire tread pattern structure of motorcycle for race in rainy day

InactiveCN104015569AMake sure the tread is rigidImprove traction performanceTyre tread bands/patternsAutomotive engineeringSpecial design

The invention relates to a special tire tread pattern structure of a motorcycle for race in rainy day, which is characterized in that the tire surface comprises a central groove through a circumferentially continuous bar-shaped straight groove design, inclined main grooves and inclined auxiliary grooves arranged by taking the tire surface as a center in a symmetrical and interlace mode; the bottom of the central groove is arranged along a circumferential direction with an equant mode to form wave tooth; the inclined main groove extends from the center of the tire surface to tire shoulder in an extension manner, the groove width is gradually increased from the tire surface center to the tire shoulder; multi-strip inclination auxiliary grooves are arranged between adjacent inclined main grooves at same side, the inclination direction of each inclined auxiliary groove and the inclined main groove is arranged in an opposite way, and each inclined auxiliary groove is communicated to at least one of the inclined main groove. Through a special design of the central groove bottom and the inclined auxiliary groove, the traction performance and gripping performance on wetland can be increased when the motorcycle drives on pavement at high speed in rainy day.

Owner:CHENG SHIN RUBBER XIAMEN IND

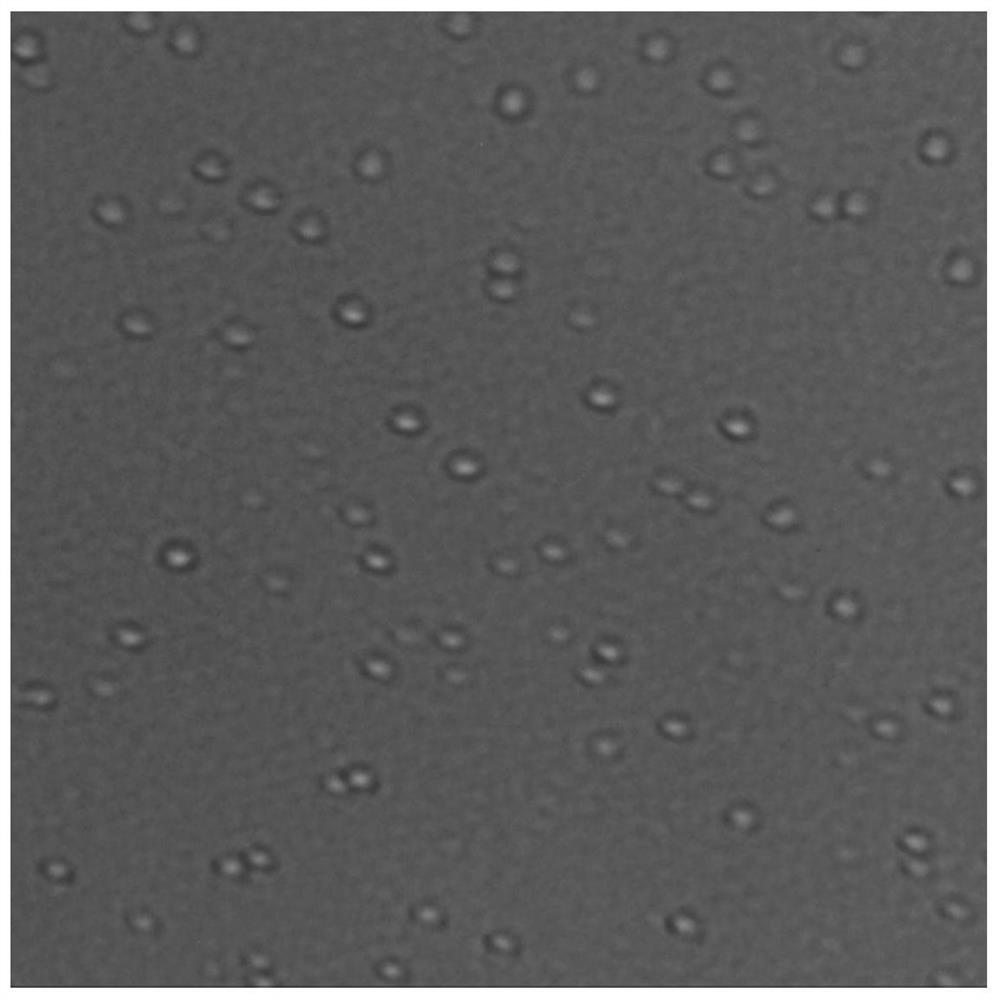

Pleurotus tuber-regium protoplast preparation method

ActiveCN113005042AEffectively breakSimple processFungiMicroorganism based processesBiotechnologyMicroorganism

The invention relates to a Pleurotus tuber-regium protoplast preparation method, and belongs to the technical field of bioengineering. According to the invention, cellulase is selected for enzymolysis according to the composition of glycosidic bonds of Pleurotus tuber-regium cell wall polysaccharides, Pleurotus tuber-regium protoplasts are effectively obtained, the number can reach 5 * 10 < 6 > / mL, and the regeneration rate reaches 11%. The method provided by the invention has the advantages of simple process and strong operability, and has potential application prospects in the fields of edible and medicinal fungus resource development, genetic breeding, molecular biology, microbiology and the like.

Owner:JIANGNAN UNIV

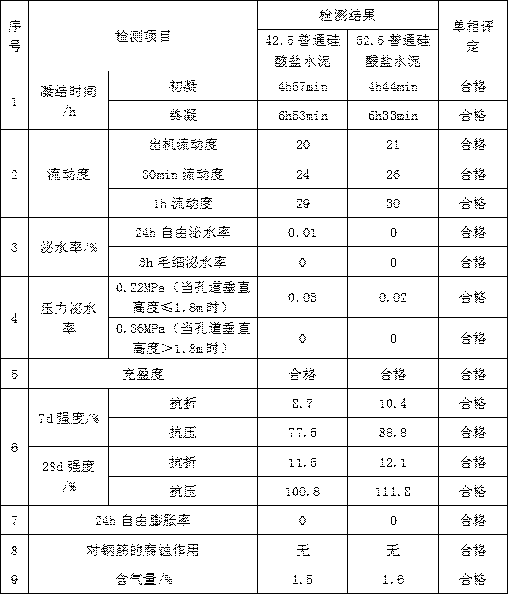

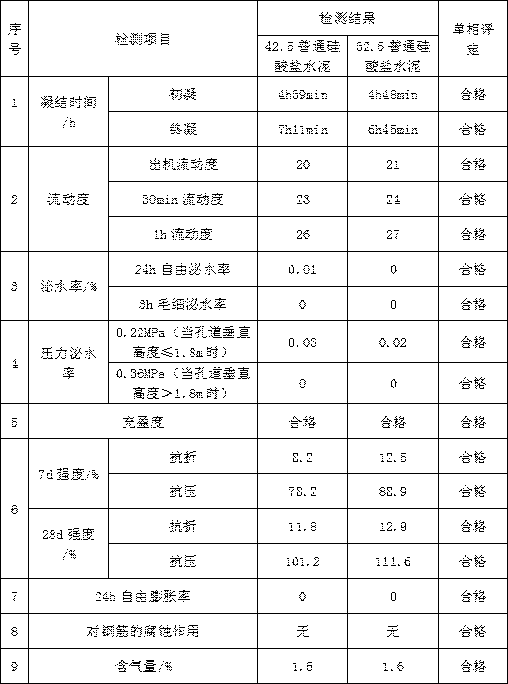

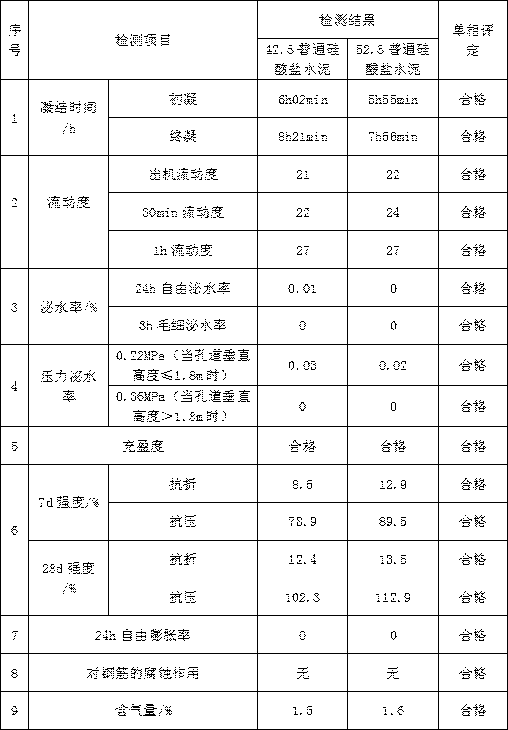

Grouting agent and preparation method thereof

The invention provides a grouting agent and a preparation method thereof, and relates to a concrete additive and a preparation method thereof. The grouting agent prepared according to the method is applicable to the fields of grouting of equipment foundation, and anchoring grouting of ground anchor systems. The grouting agent comprises 7-12 parts of silica fume, 2-4 parts of fly ash, 3-5 parts ofpolycarboxylic acid, 1-1.5 parts of magnesium oxide, 0-0.05 part of sodium thiosulfate, 0.3 part of sodium sulfate, 0.1-0.2 part of beta-naphthalene sulfonated formaldehyde condensates, 0.01 part of organic silicon, 0.1 part of rosin saponated substance, 0.2-0.3 part of sodium carbonate, and 550-650 parts of cement. According to the grouting gent prepared according to the method, the dose of the added components can be adjusted and controlled based on different types of the used cement and different use temperatures, so that the grouting agent prepared according to the method can work normallyin various environments and is not influenced by different types of cement.

Owner:云南森博混凝土外加剂有限公司

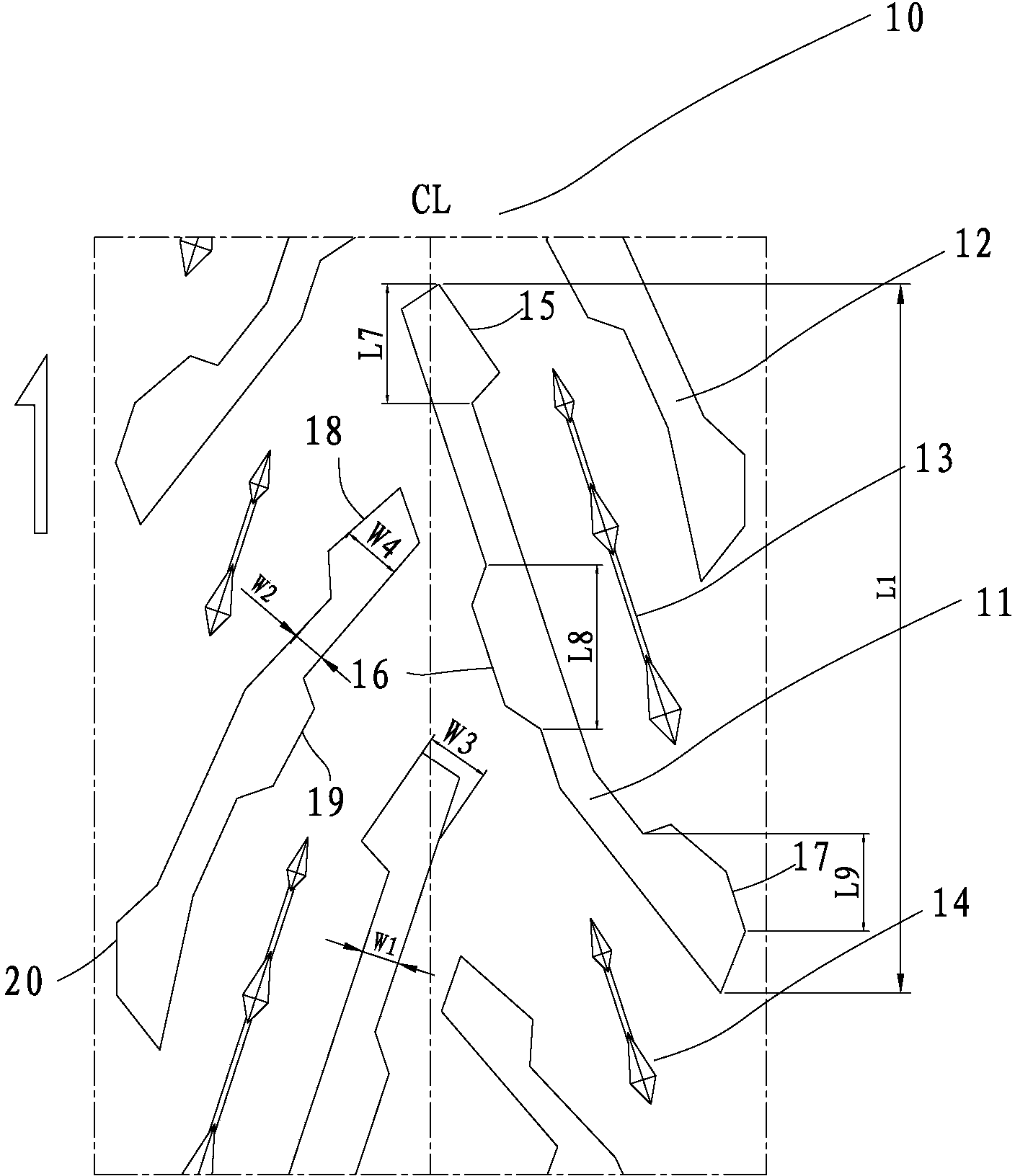

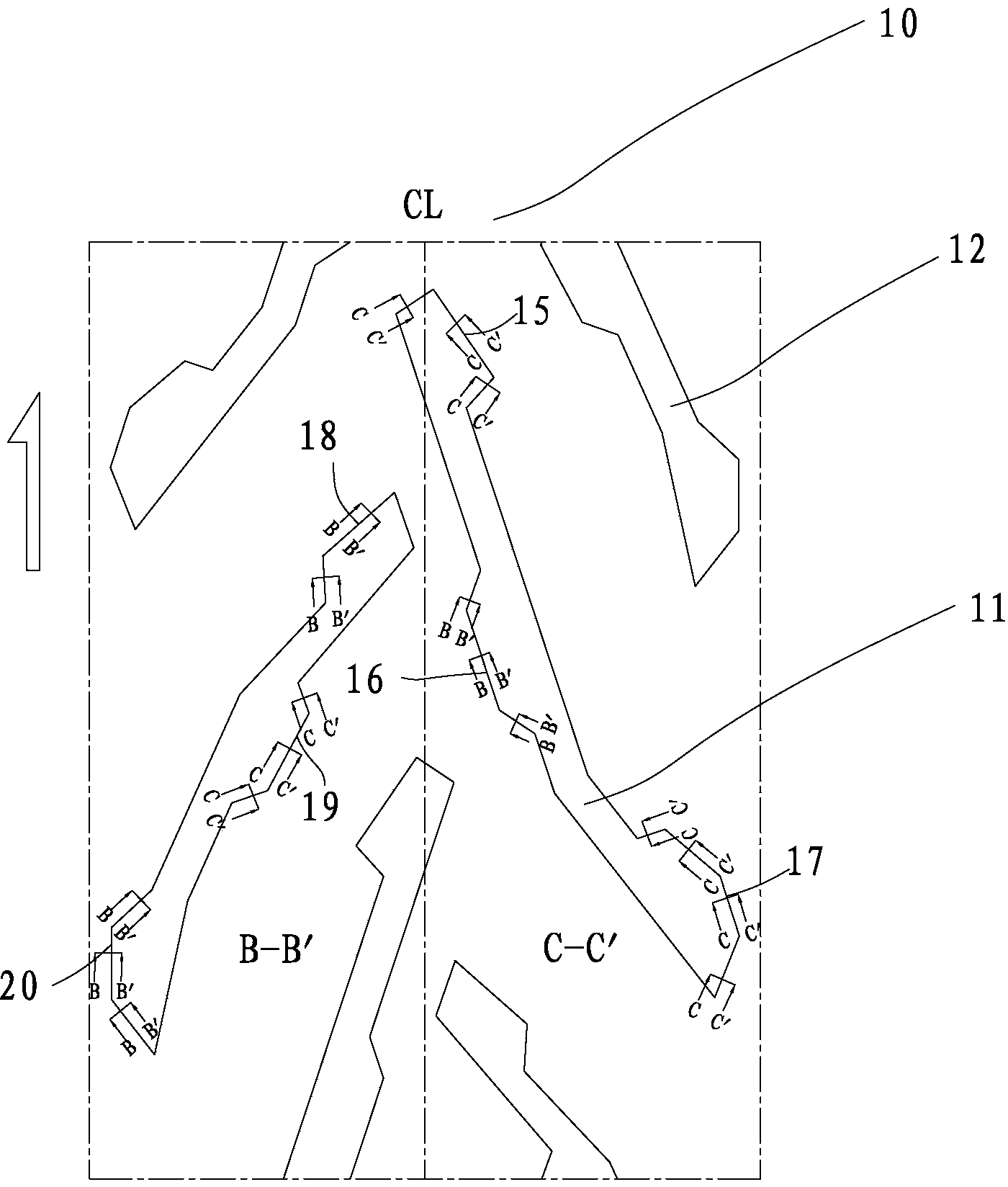

Tire tread structure of pneumatic tire of motorcycle

InactiveCN104029568AMake sure the tread is rigidHelps to expel stonesMotorcycle tyresTyre tread bands/patternsEngineeringAdditive ingredient

The invention discloses a tire tread structure of a pneumatic tire of a motorcycle. A tire tread comprises a plurality of main pattern groove groups which are formed in a staggered manner by using the center of the tread as a symmetry center, and each main pattern groove group comprises a first main pattern groove and a second main pattern groove which are formed in a tilt manner from the inner side of the tire tread to the outer side, wherein stone removing openings with irregularly polygonal edges are respectively formed in the front ends, the middle parts and the tail ends of the first main pattern groove and the second main pattern groove. The left sides and the right sides of the longitudinal main pattern grooves formed in the tire tread are arranged alternately, so that the guide performance and the water drainage performance of the tire are ensured. In order to improve the situation that the tire has better traction performance and stone removing functions on non-paved roads, the stone removing openings are formed in the front ends, the middle parts and the tail ends of the patterned main grooves, so that the rigidity of the tire tread can be ensured, and the stone removing is facilitated; at the same time, the stone removing openings are provided with the irregularly polygonal edges, the ingredients of the edges are high, so that the tire has better traction performance when the motorcycle is driven on the non-paved roads.

Owner:CHENG SHIN RUBBER XIAMEN IND

Device and method for breaking pile head of foundation pile

ActiveCN111794231AShorten the construction periodReduce construction costsBulkheads/pilesArchitectural engineeringWater flow

The invention relates to a device and method for breaking a pile head of a foundation pile, and belongs to the technical field of concrete filling piles. The method for breaking the pile head of the foundation pile comprises the following steps: 1, erecting the breaking device, and arranging the breaking device on a super-pouring part of the cast-in-place pile before concrete is preliminarily solidified; 2, cutting the pile head of the cast-in-place pile, enabling the cut material to form high-speed water flow in the breaking device through a high-pressure device to be used for cutting the pile head of the cast-in-place pile; and 3, cleaning the pile head, removing the breaking device and discharging waste liquid in a template after the breaking device finishes cutting, removing the template after the concrete is preliminarily solidified, and washing to expose steel bars. According to the method, the pile head of the foundation pile can be effectively broken, and the damage to a main reinforcement can be reduced in the breaking process.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com