Breaking and dismantling device for rescue

A technology of demolition and barrier-breaking, which is applied in the field of rescue and demolition devices, which can solve problems such as inability to meet on-site rescue, poor work reliability, and inconvenient portability, and achieve the effect of light weight, small operating space, and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

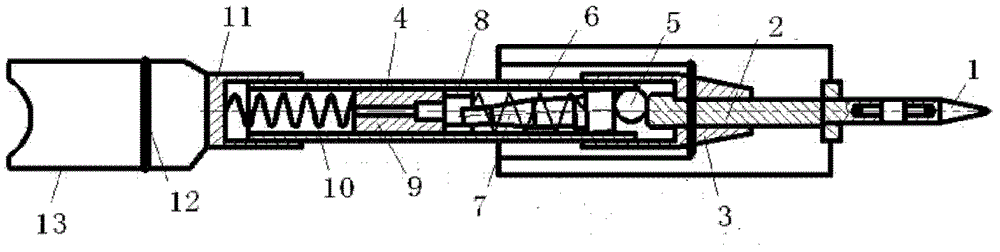

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

[0009] Referring to the accompanying drawings, a rescue and demolition device includes a barrier-breaking punch 1, which is installed at one end of the striking rod 2, and the other end of the striking rod 2 passes through the guide sleeve 3 and the eccentric steel ball 5 in phase with each other. Then, the guide sleeve 3 is fixed on one end of the sleeve 4, the eccentric steel ball 5 is connected with the retaining ring 8 through the striker 7 and the return spring 6 set on the striker 7, the retaining ring 8 is installed on the side of the collision block 9, and the collision block 9 The other side of the other side is connected with the bottom of the spring stroke adjustment back cover 11 through the force spring 10, the spring stroke adjustment back cover 11 is connected with one end of the sleeve 4, the eccentric steel ball 5, the return spring 6, the striker 7, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com