Patents

Literature

269results about How to "Increase impact force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

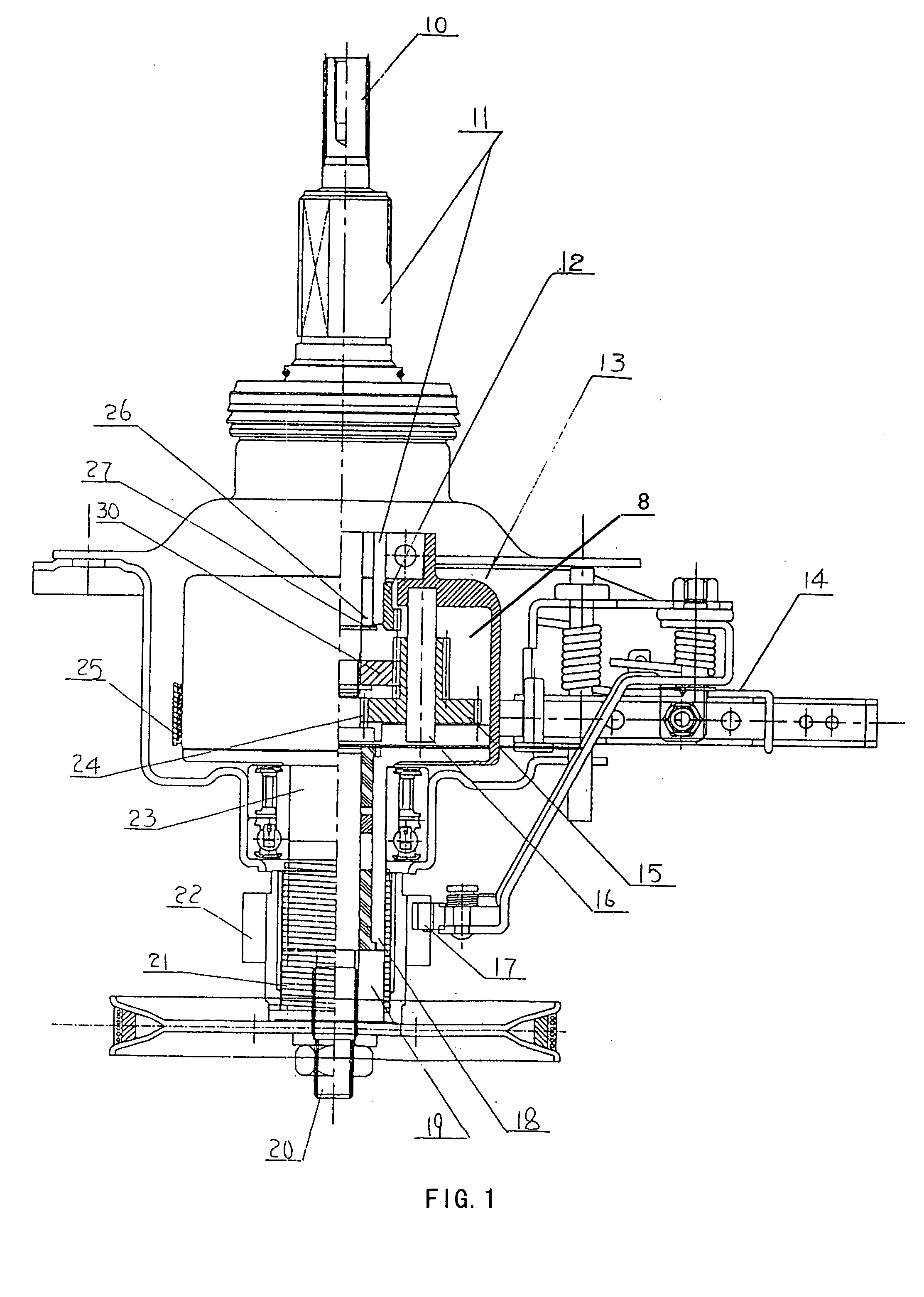

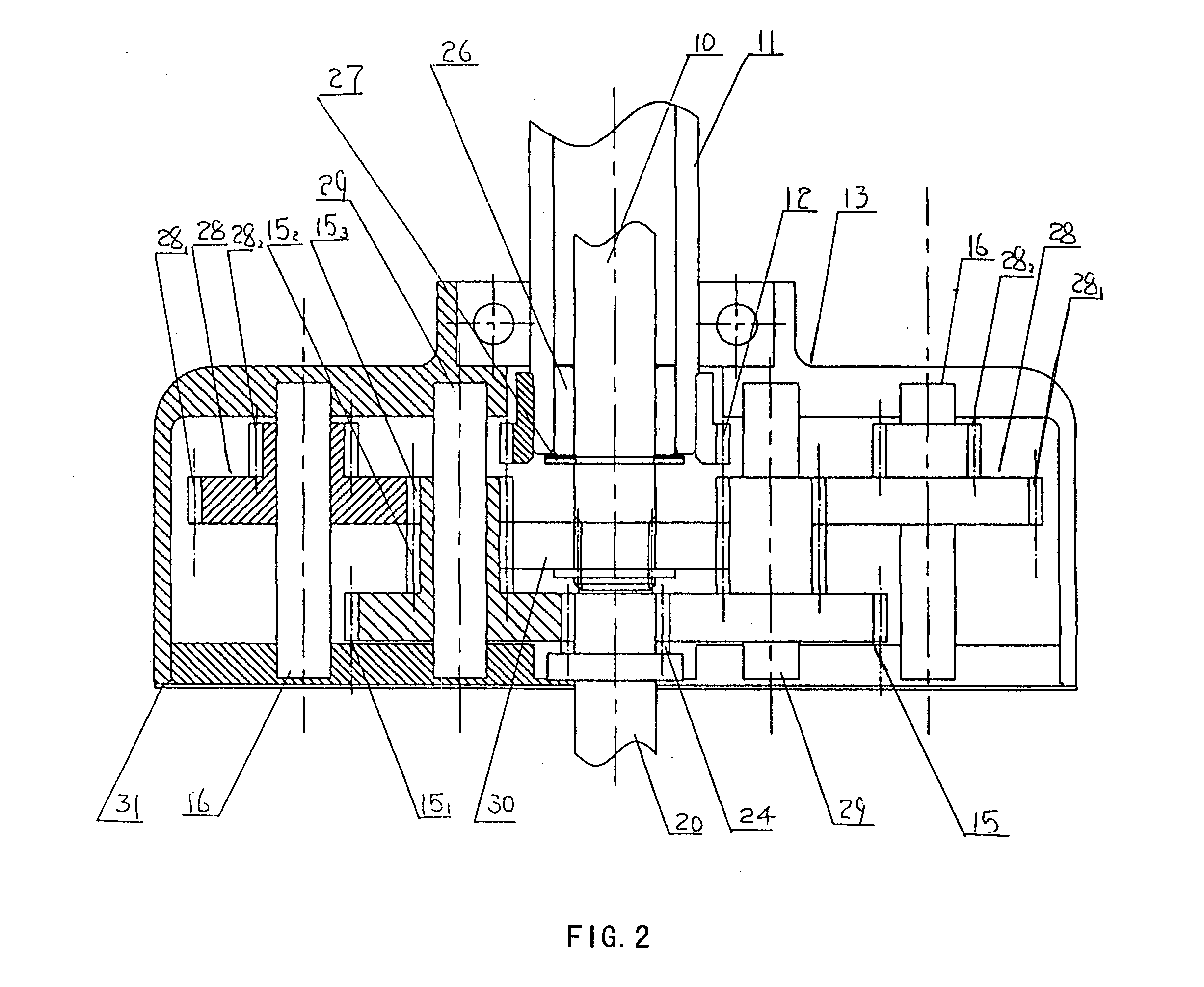

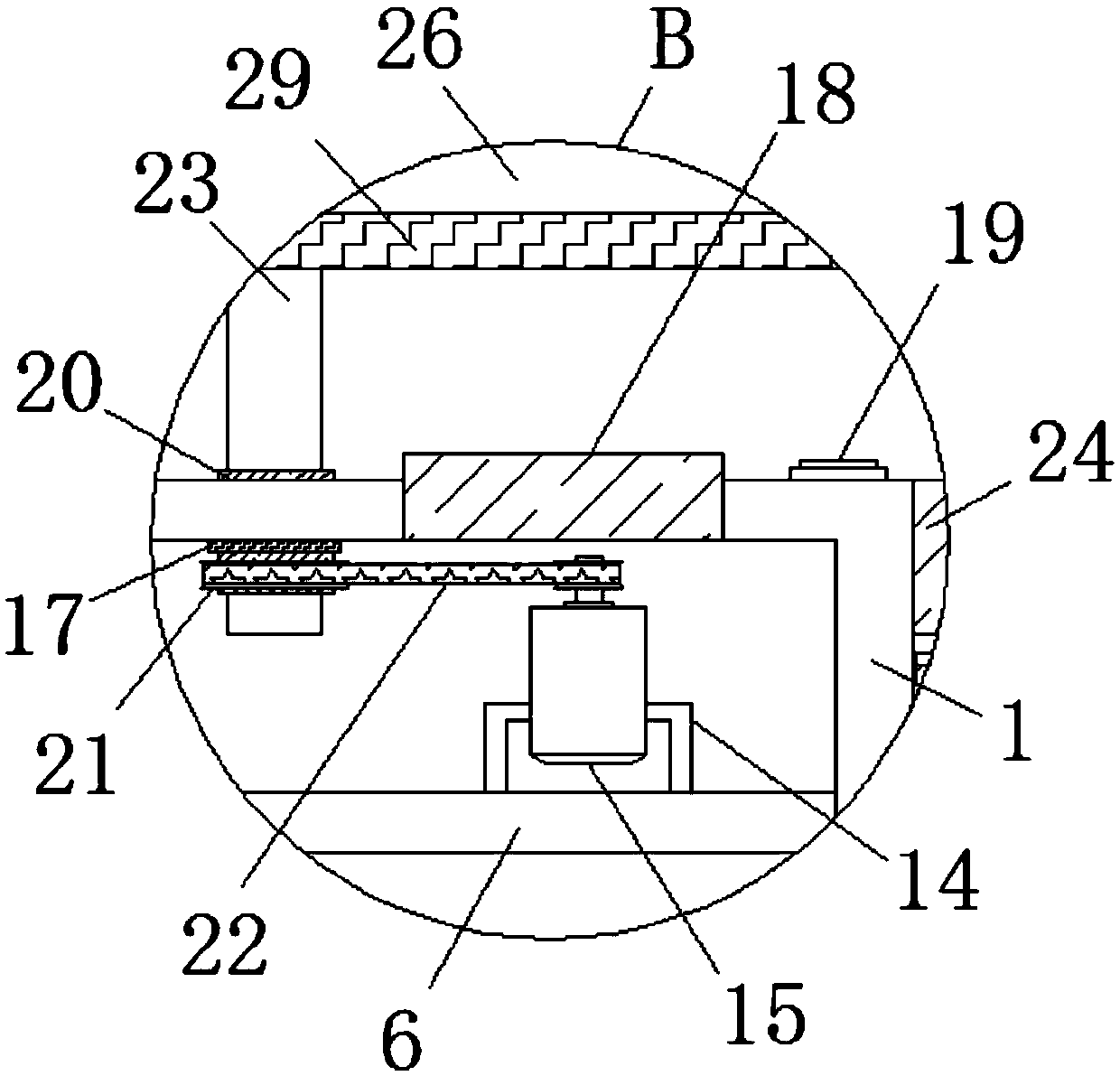

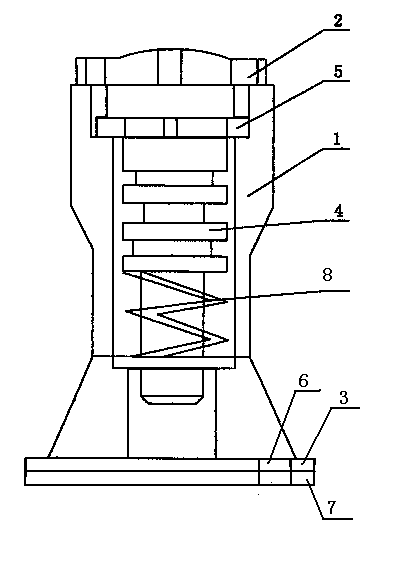

Hydraulic buffering device when automobile being bounced

InactiveCN101125539AIncrease impact forcePrevent sprayingLiquid based dampersBumpersEngineeringPiston cylinder

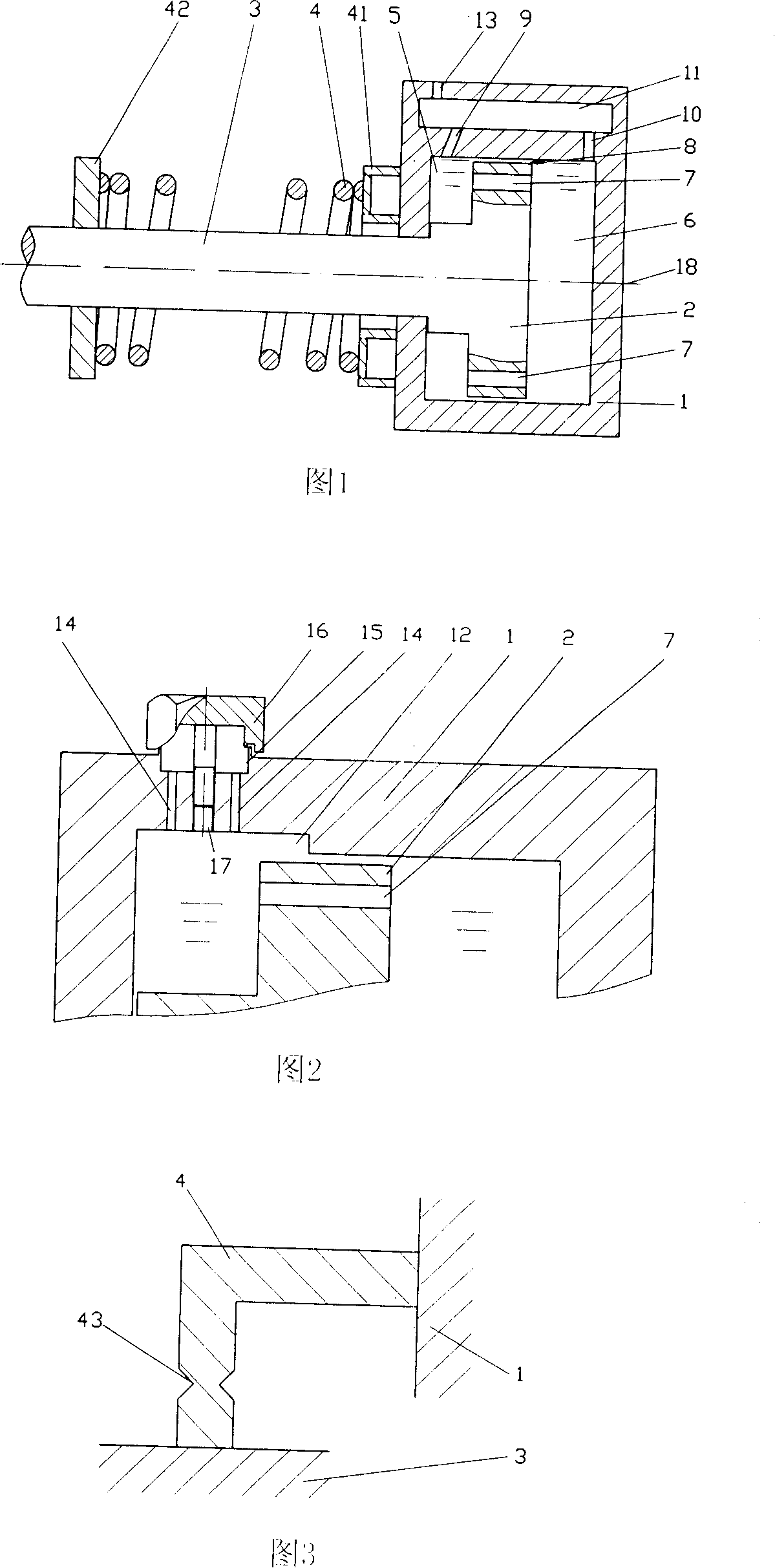

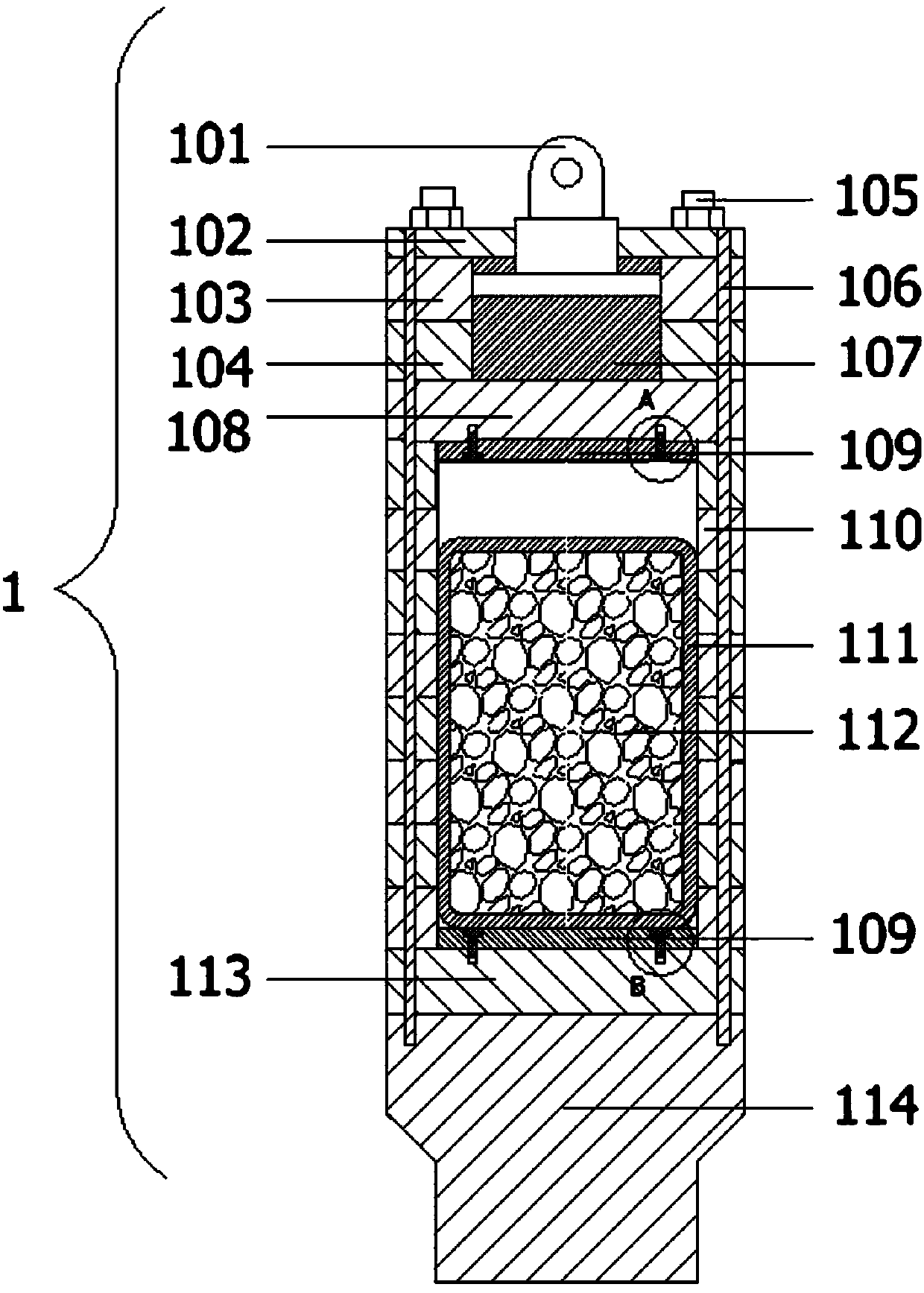

The present invention relates to a hydraulic buffering device when the car is hit and consists of a piston cylinder, a piston, a piston rod and a buffering starting device. The coordination of the piston cylinder and the piston rod and the piston are movable fit. The piston cavity that is filled with oil is divided into a front cavity and a back cavity that are communicated by the piston. The oil can not fill the whole space that is communicated with the piston cavity before buffering force of the hydraulic buffering device reaches the maximum design buffering force. The buffering starting device is used for fixing the relative positions of the piston and the piston cylinder. The hydraulic buffering device is actuated and starts the buffering action when the impact of the vehicle reaches a certain design value. The discharged oil in the rear cavity can automatically flow back after the buffering is reset. Better buffering effect can be achieved when the piston cylinder is provided with a vent hole that is communicated with the front cavity and the outside and measures are taken to prevent the oil being discharged out from the vent hole; utilizing spring as the buffering actuating device can realize slow reset of the hydraulic buffering device and the second buffering of the spring.

Owner:李正才

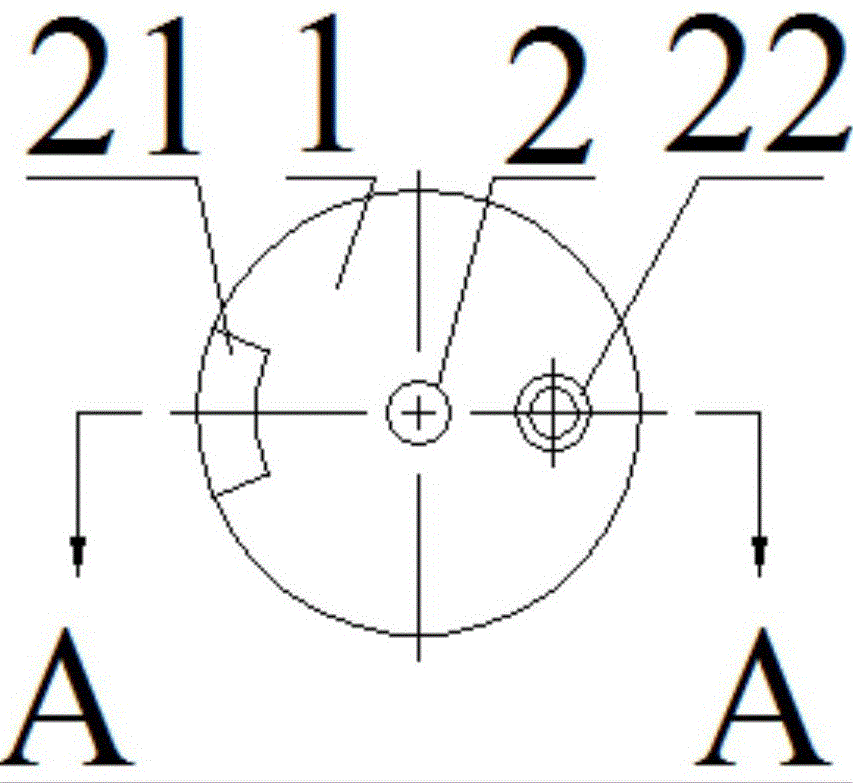

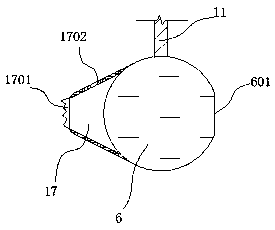

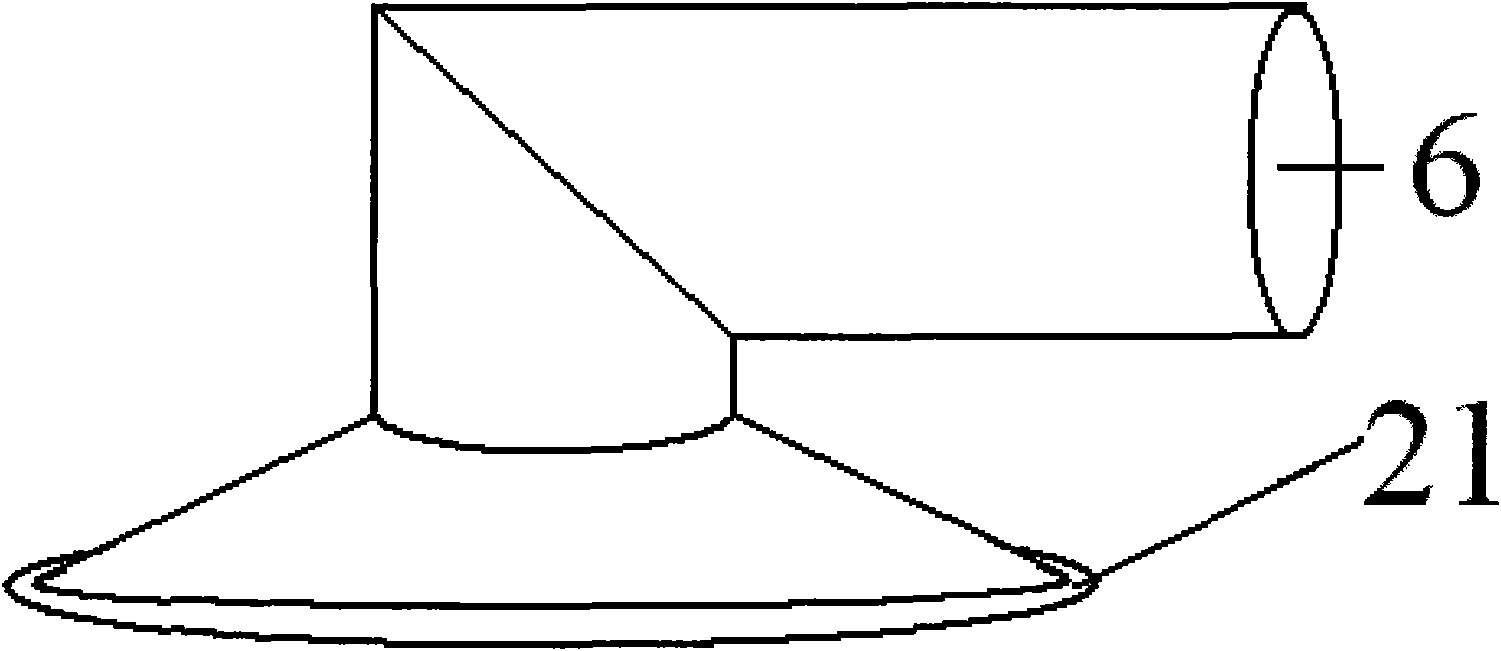

Impeller, superfine mill and superfine milling system

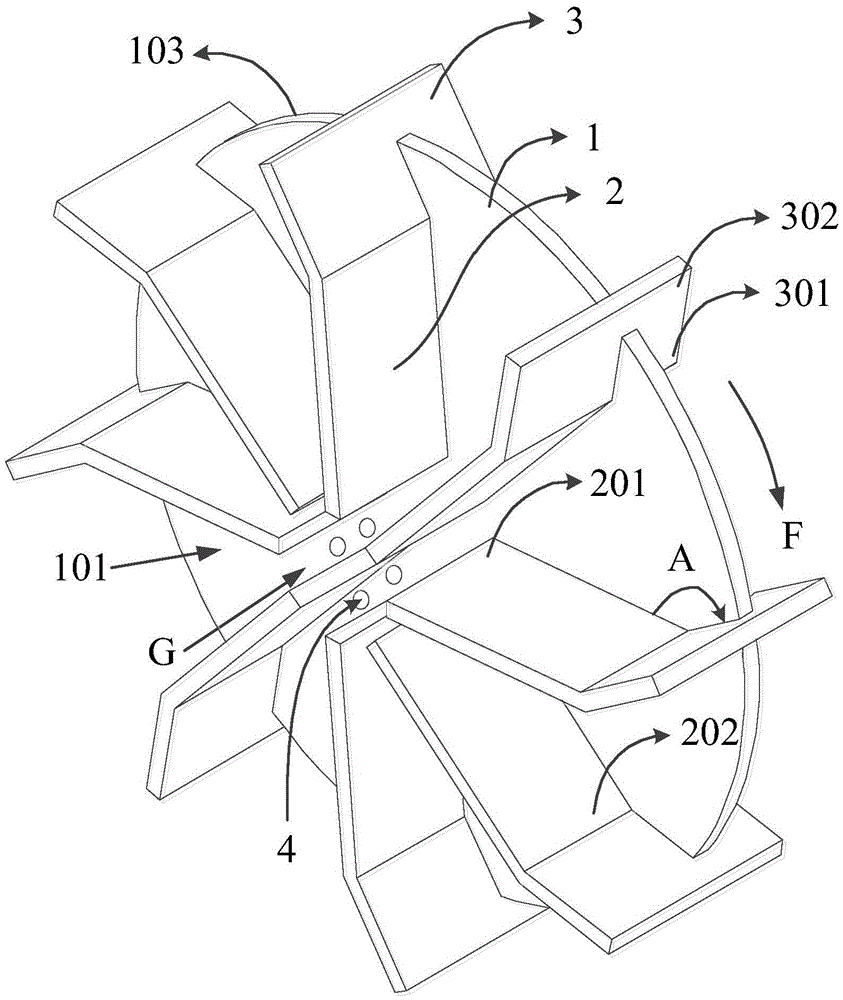

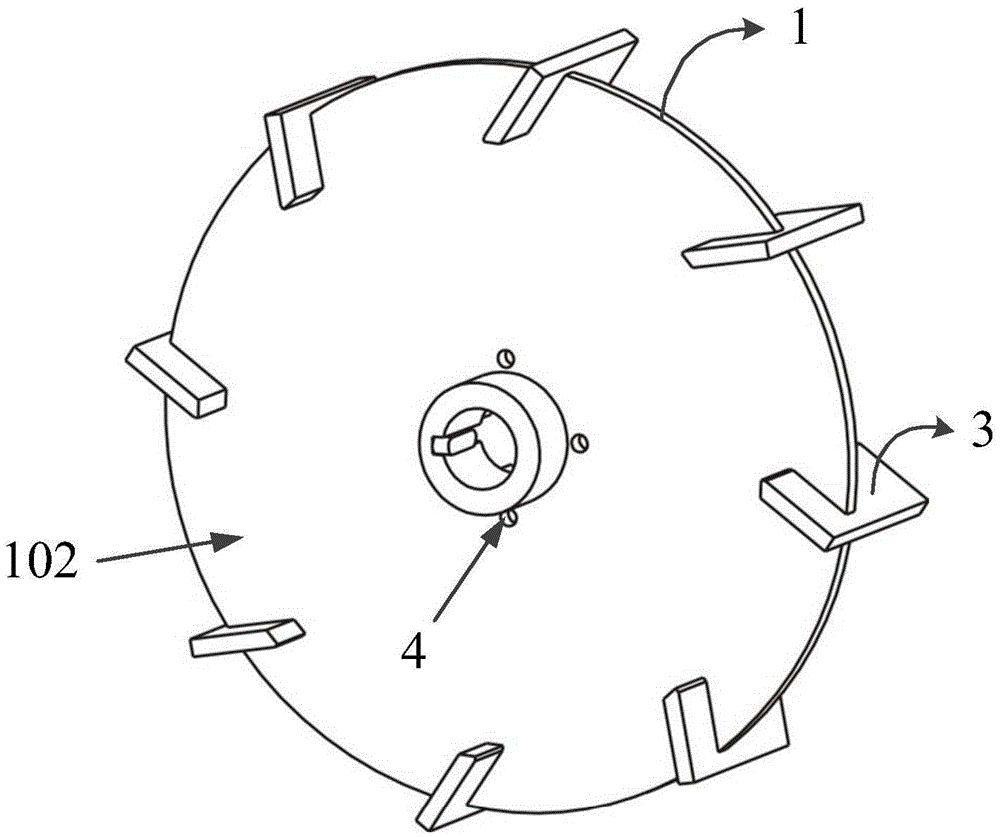

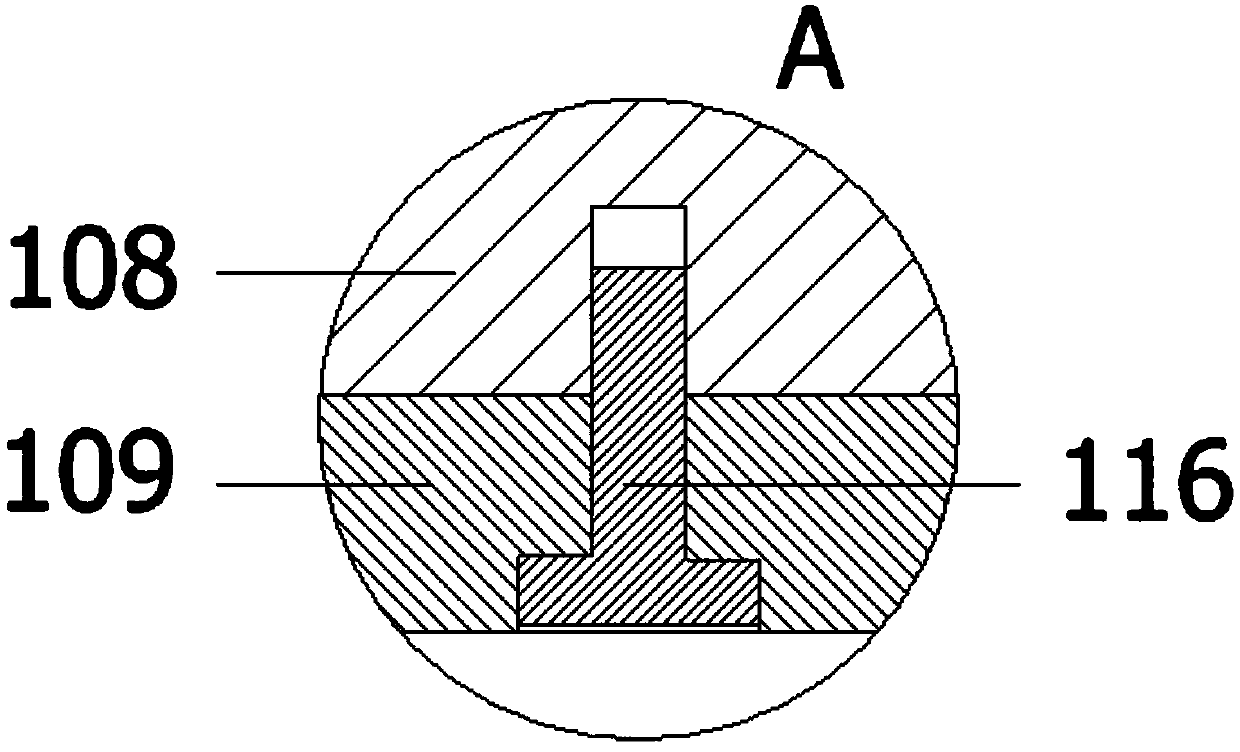

The invention provides an impeller, a superfine mill applying the impeller and a superfine milling system comprising the superfine mill. The impeller comprises a wheel disc, straight surface type blades and straight surface type impact plates, and an abrasion-resistant layer is adhered to the surface of each straight surface type blade. The straight surface type blades are multiple and uniformly arranged on the wheel disc in the radial direction. The tail end of each straight surface type blade is provided with one corresponding straight surface type impact plate in the extension direction of the center of the wheel disc to the outer diameter edge of the wheel disc, and a first included angle is formed between each straight surface type blade and the corresponding straight surface type impact plate. The tail ends of the straight surface type blades are located within the outer diameter edge of the wheel disc. The initiating end of each straight surface type impact plate is connected with the tail end of the corresponding straight surface type blade. The tail ends of the straight surface type impact plates exceed the outer diameter edge of the wheel disc. According to the impeller, the superfine mill applying the impeller and the superfine milling system comprising the superfine mill, high-hardness nonmetal or metal can be milled into superfine powder; in addition, abrasion of equipment parts is small, and the function of particle size classification is achieved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

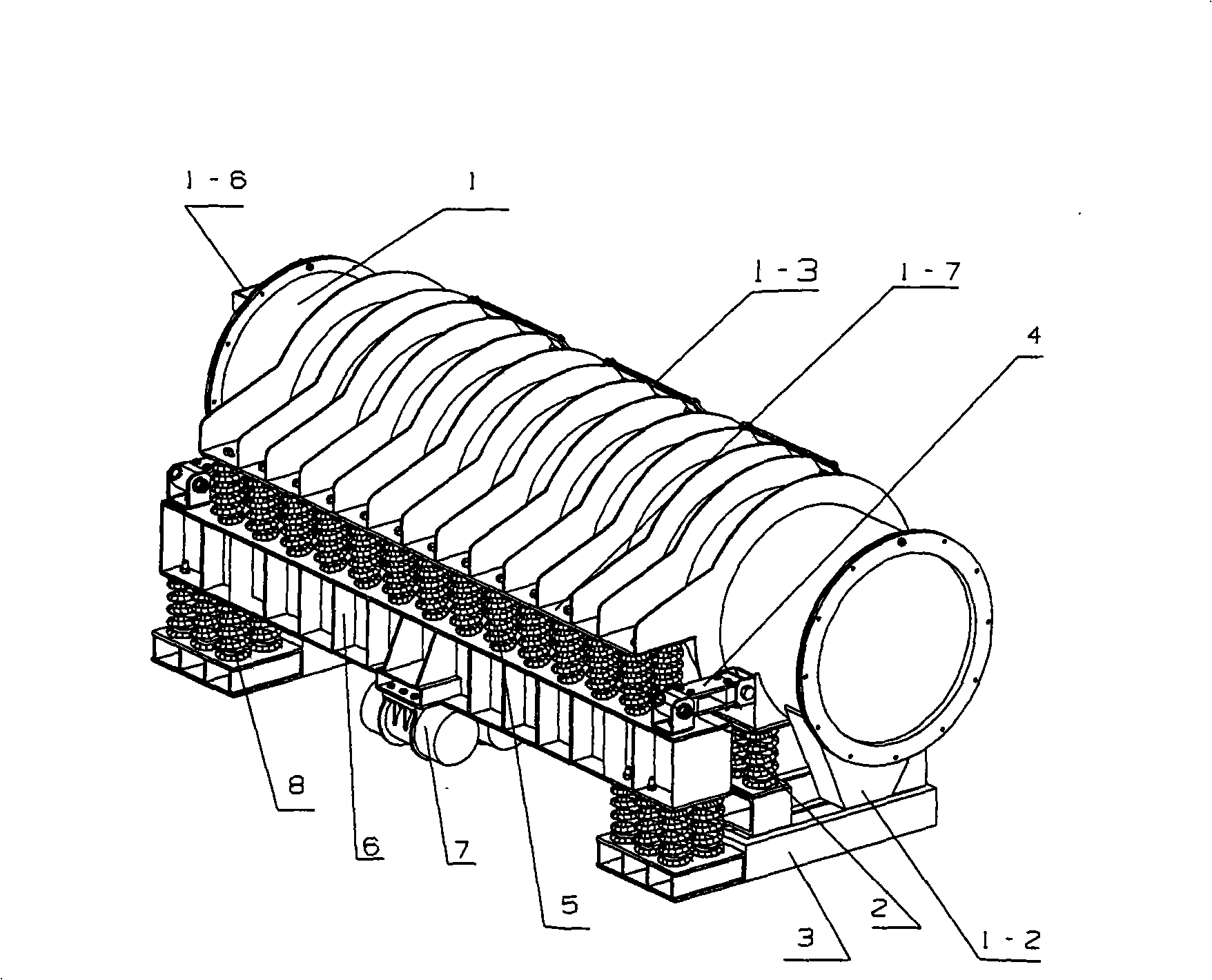

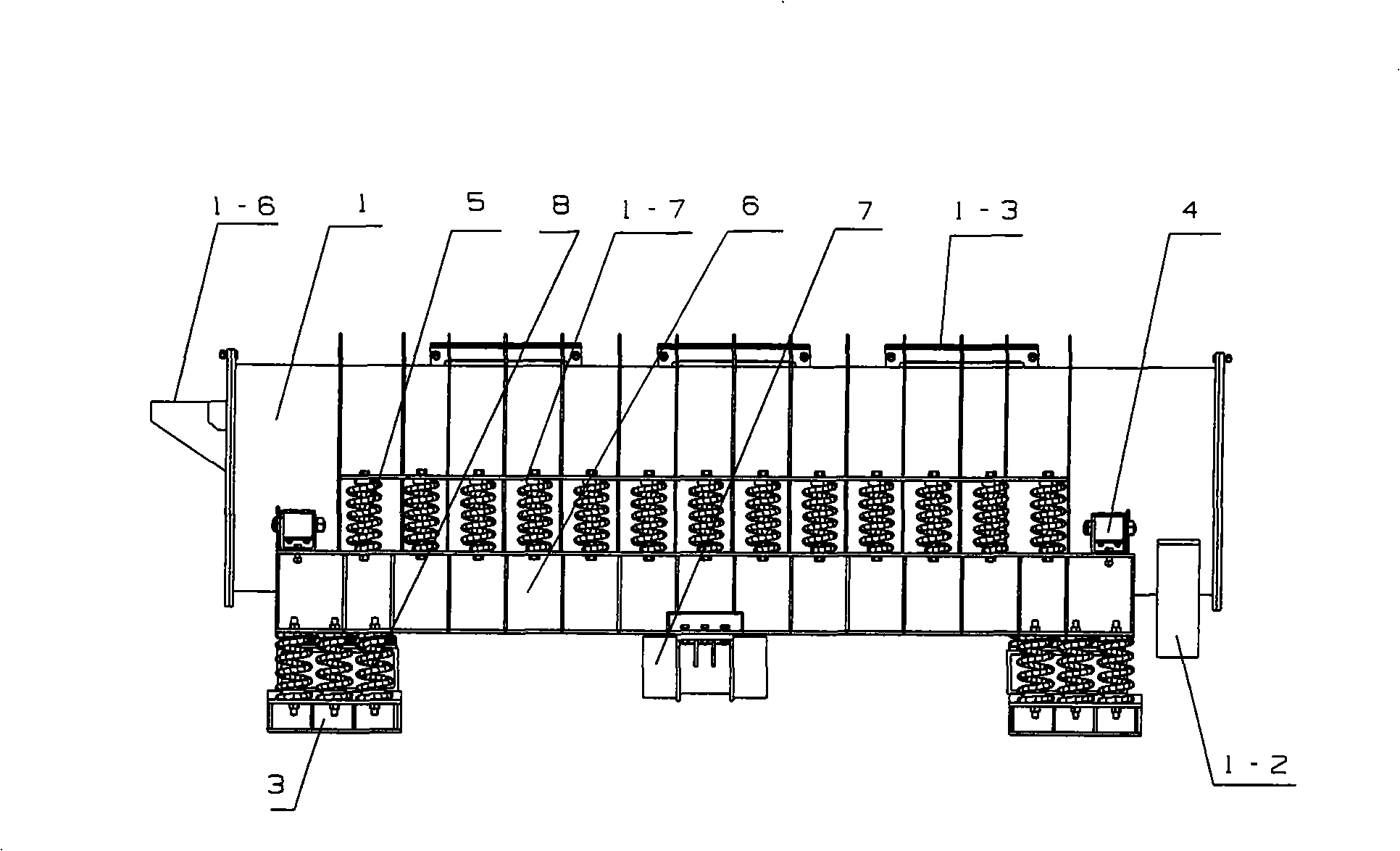

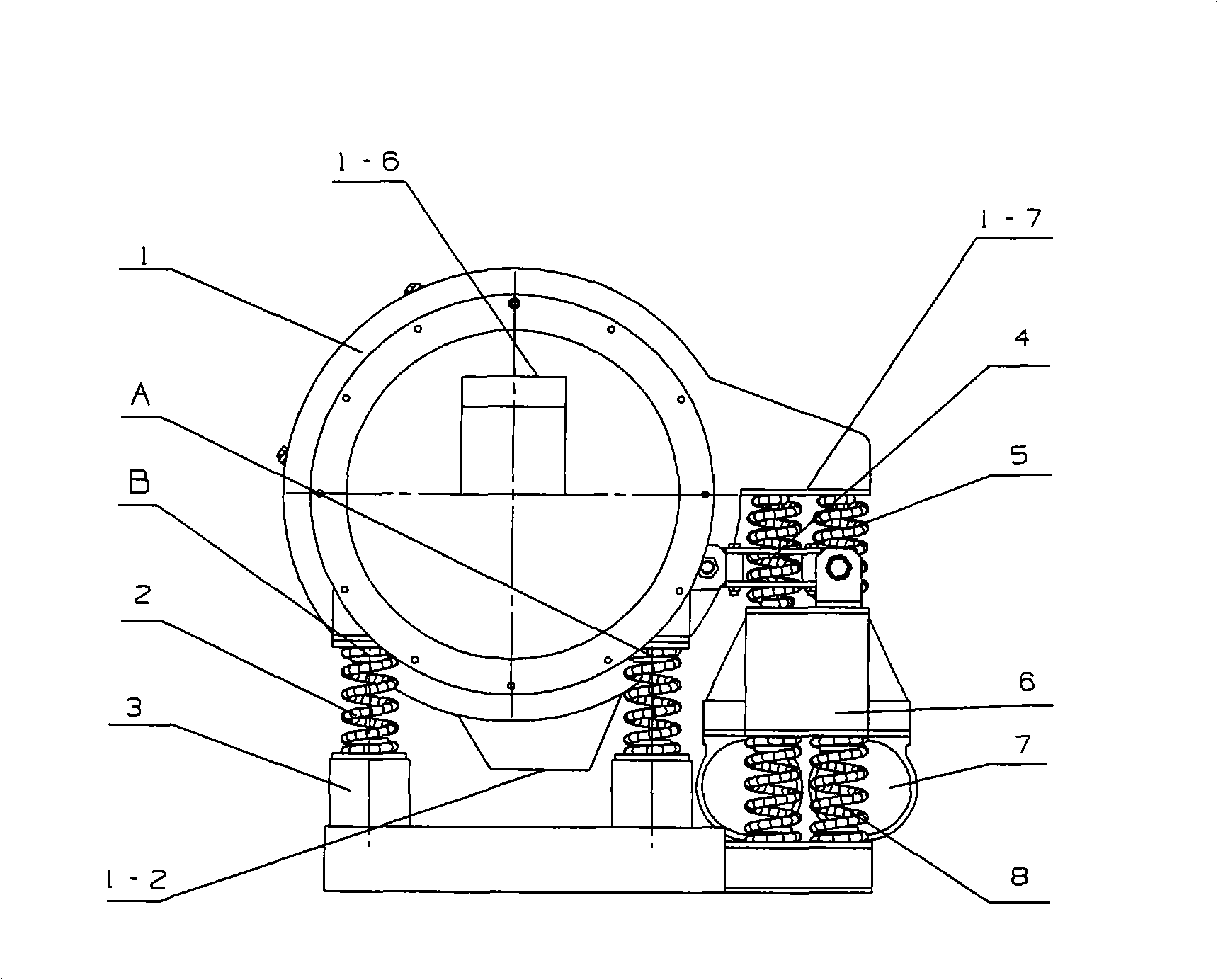

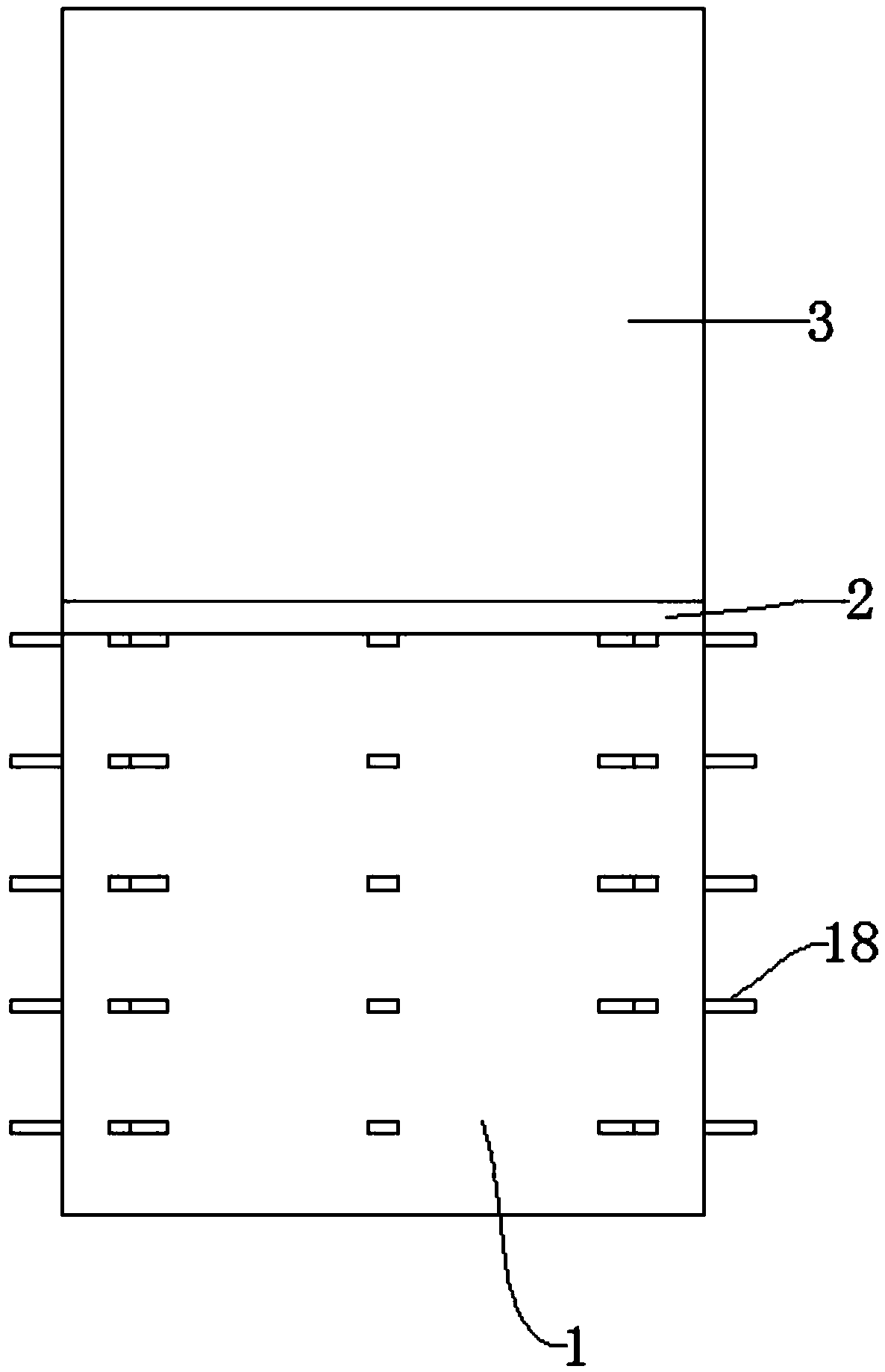

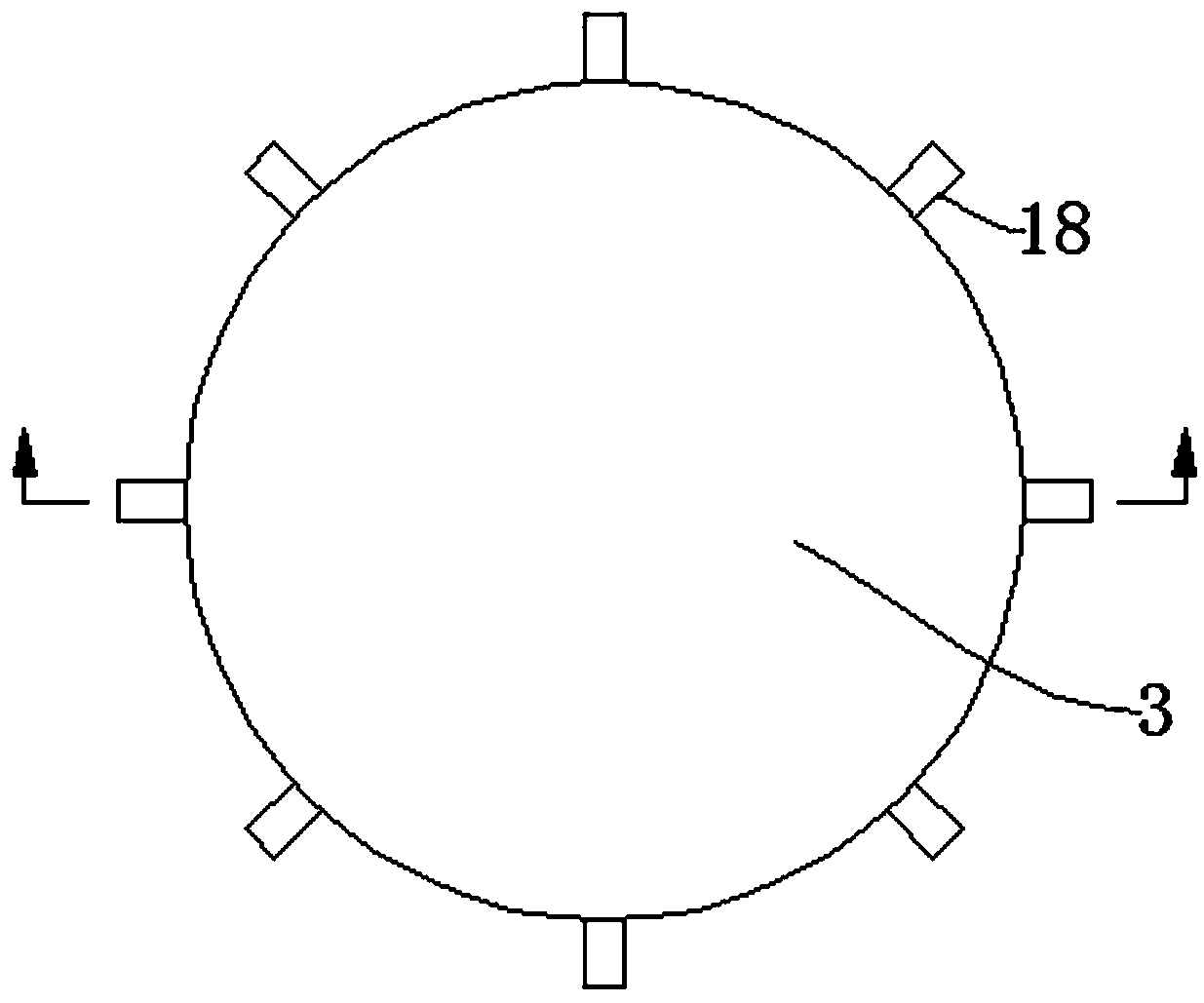

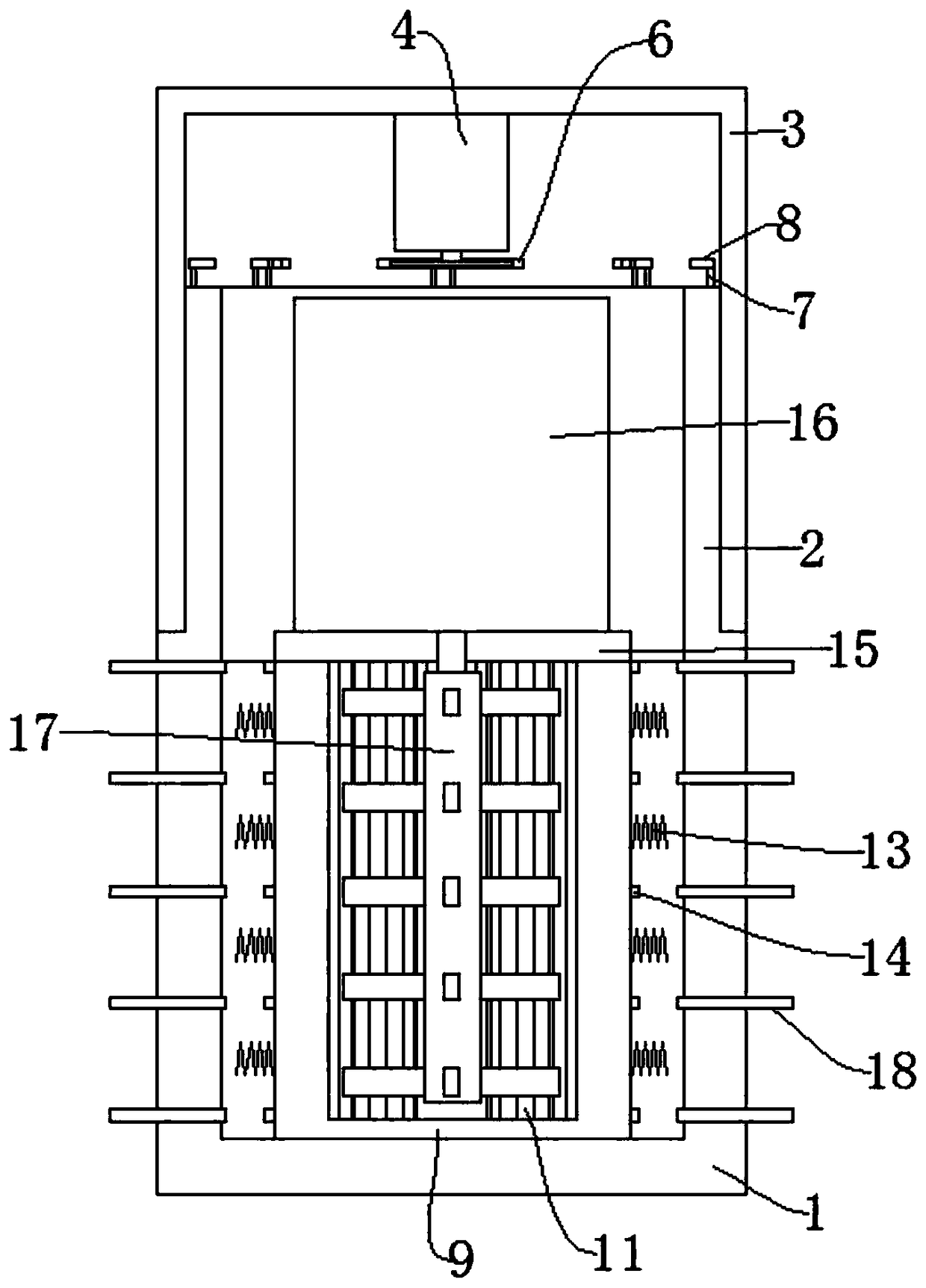

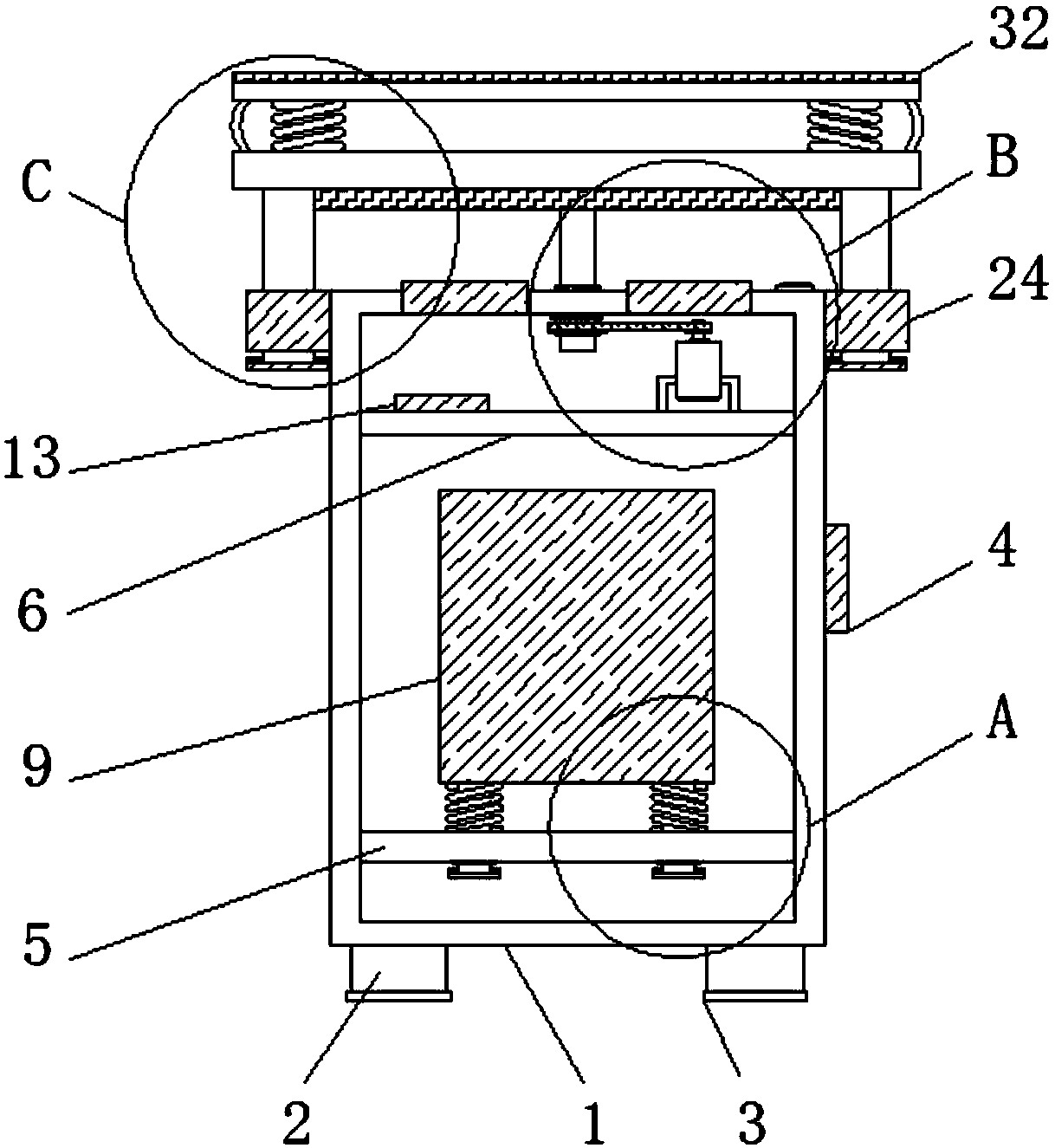

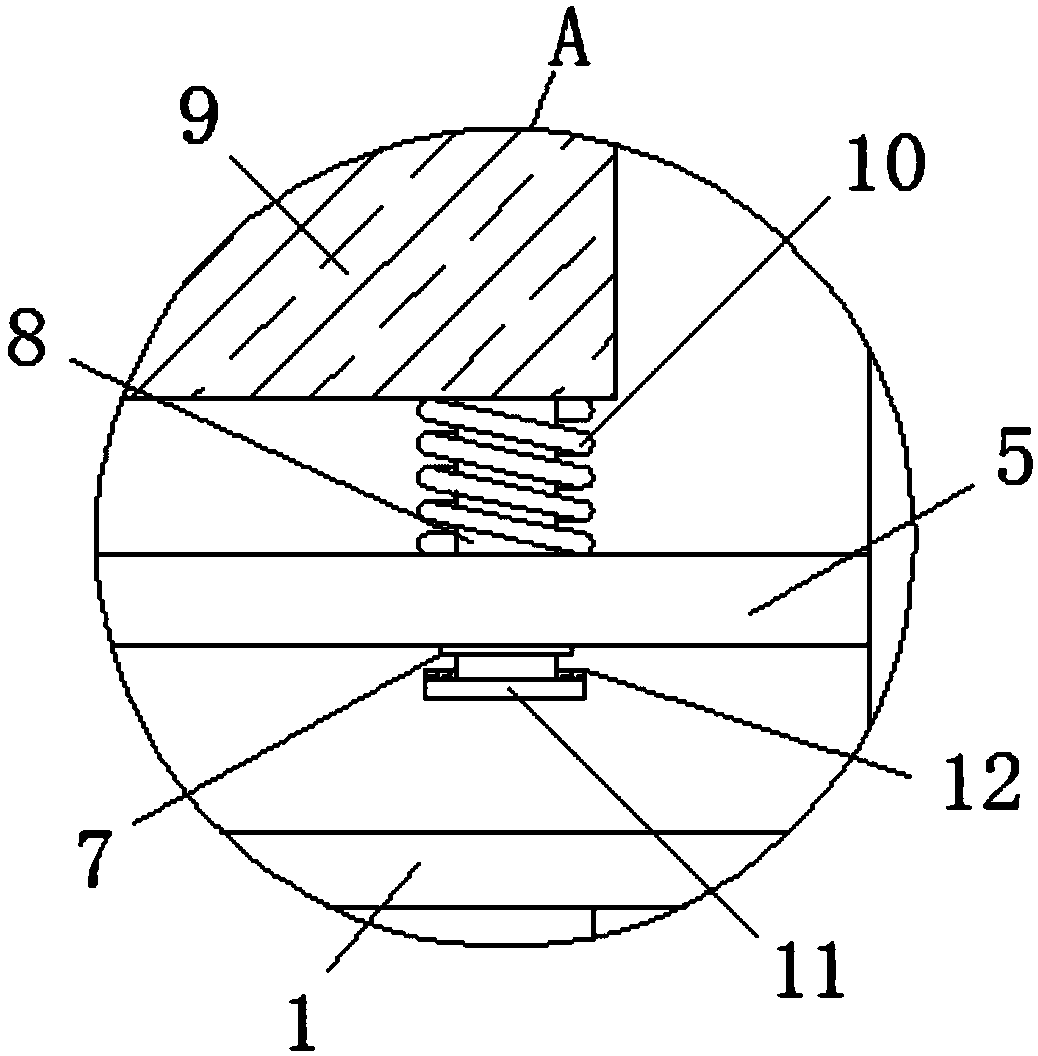

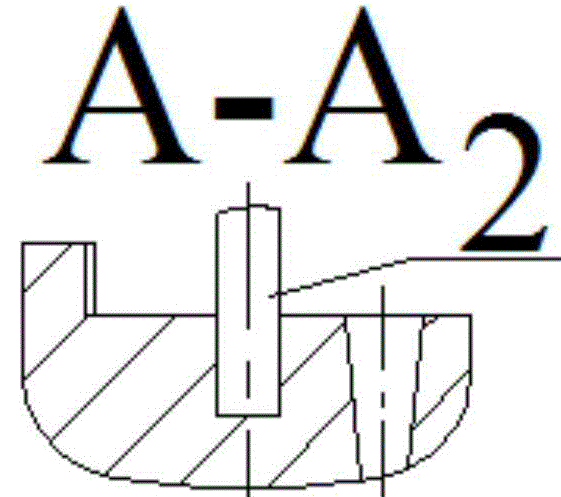

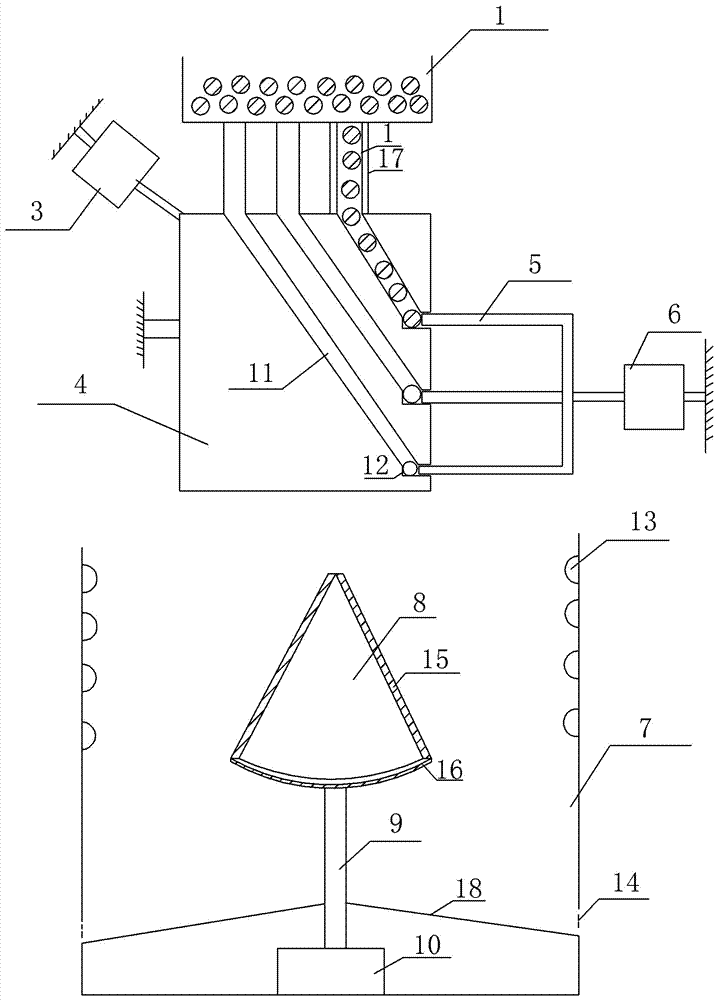

Double-mass asymmetric vibration ball mill

The invention relates to a ball mill, in particular to a double-mass asymmetrical vibratory ball mill. The ball mill comprises a cylinder body, a supporting spring, a machine base, a connecting bar, a master vibration spring, a vibration body, a vibration motor and an isolation spring, wherein the vibration motor and the vibration body are fixed into a whole; the cylinder body and the machine base are connected through the supporting spring; a master vibration spring connecting plate on one side of the cylinder body and the vibration body are connected through the master vibration spring; the vibration body and the machine base are connected through the isolation spring; the cylinder body and the vibration body are connected through the connecting bar; the cylinder body is partitioned into a plurality of compartments in the axial direction; and each compartment is filled with certain number of grinding balls. The ball mill can be used for grinding operation, is characterized in low manufacturing cost, small occupied area and good energy saving effect, and has the prospect of replacing rotary ball mills.

Owner:张二洪

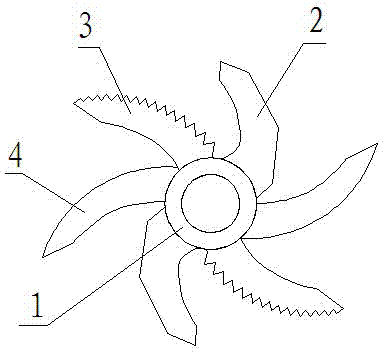

Novel rimer

The invention provides a novel rimer which comprises two sets of blades, wherein each set of blades comprises three blades; the tail ends of the three blades are connected with a central ring; the two sets of blades are uniformly arranged along the circumference of the central ring; each set of blades comprises a fold-type blade, a sawtooth type blade and an arc-shaped blade which are sequentially arranged. When the rimer rotates, the three kinds of blades take turns to cut and divide meat; if a bone is not removed, the cutting edges of the fold-type blades are continuously bent straight lines, and the time that the bone is contacted with different straight lines is different, so that the straight lines bump against the bone discontinuously so as to increase the impact force to the bone and enhance the chopping capacity to the bone; the cutting edges of the sawtooth type blades are sawtooth type and can powerfully cut tendons with stronger tenacity; the arc-shaped blades can cut common meat fiber; the three kinds of blades take turns to cut meat, so that better segmentation and cutting of meat can be realized.

Owner:WUXI YANGGONG MACHINERY MFG

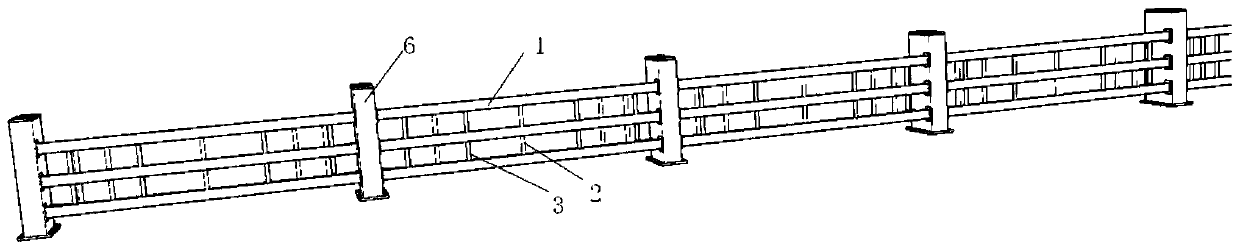

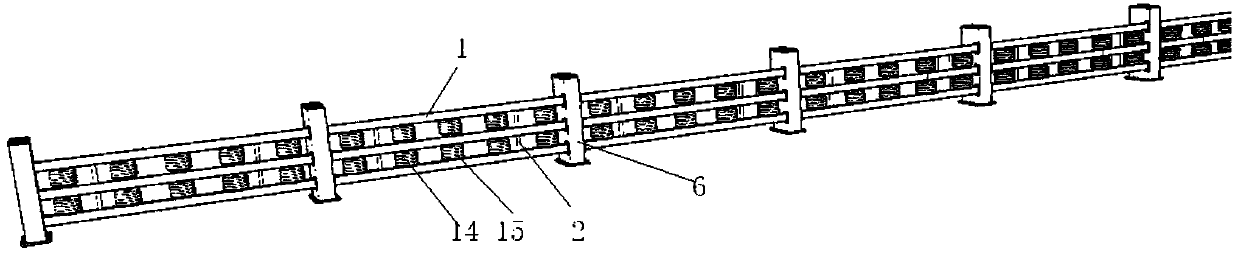

A bridge anti-collision guardrail and a construction method thereof

InactiveCN109056523AIncrease impact forcePlay a protective effectBridge structural detailsBridge erection/assemblyCushioningArchitectural engineering

The invention discloses a bridge anti-collision guardrail and a construction method thereof, Collision barriers include columns, An upper rail and a low rail are respectively sleeved with a buff cylinder and a swirling ring on that upright column, the two ends of the upright column are fix on the upper rail through a limiting seat, the lower rail is provided with a fixing ring on the upright column, the fixing ring is in contact with the limiting seat located below, an L-shaped mounting plate is provided on the upper rail, an L-shaped mounting plate is provided with an anti-collision plate, and a cushioning guardrail plate is provided on the anti-collision plate; The construction method comprises the following steps: (a) route marking; (b) Post positioning; (c) Installation of lower railings; (d) installation of an upper railing; (e) Installation of cushion shields; (f) Installation of bumper plates; (g) Installation of remaining uprights. The anti-collision guardrail of the inventionhas the advantages of high stability, convenient installation, cushioning and anti-collision, high safety, easy operation, orderly and reasonable construction, fast and convenient construction, time and labor saving, low construction intensity and convenient maintenance in the later period. The invention has the advantages of high stability, convenient installation, cushioning and anti-collision,high safety, easy operation, orderly and reasonable construction method, fast and convenient construction, and low construction intensity.

Owner:ZHEJIANG COLLEGE OF CONSTR

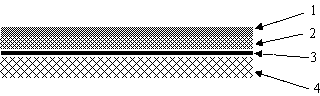

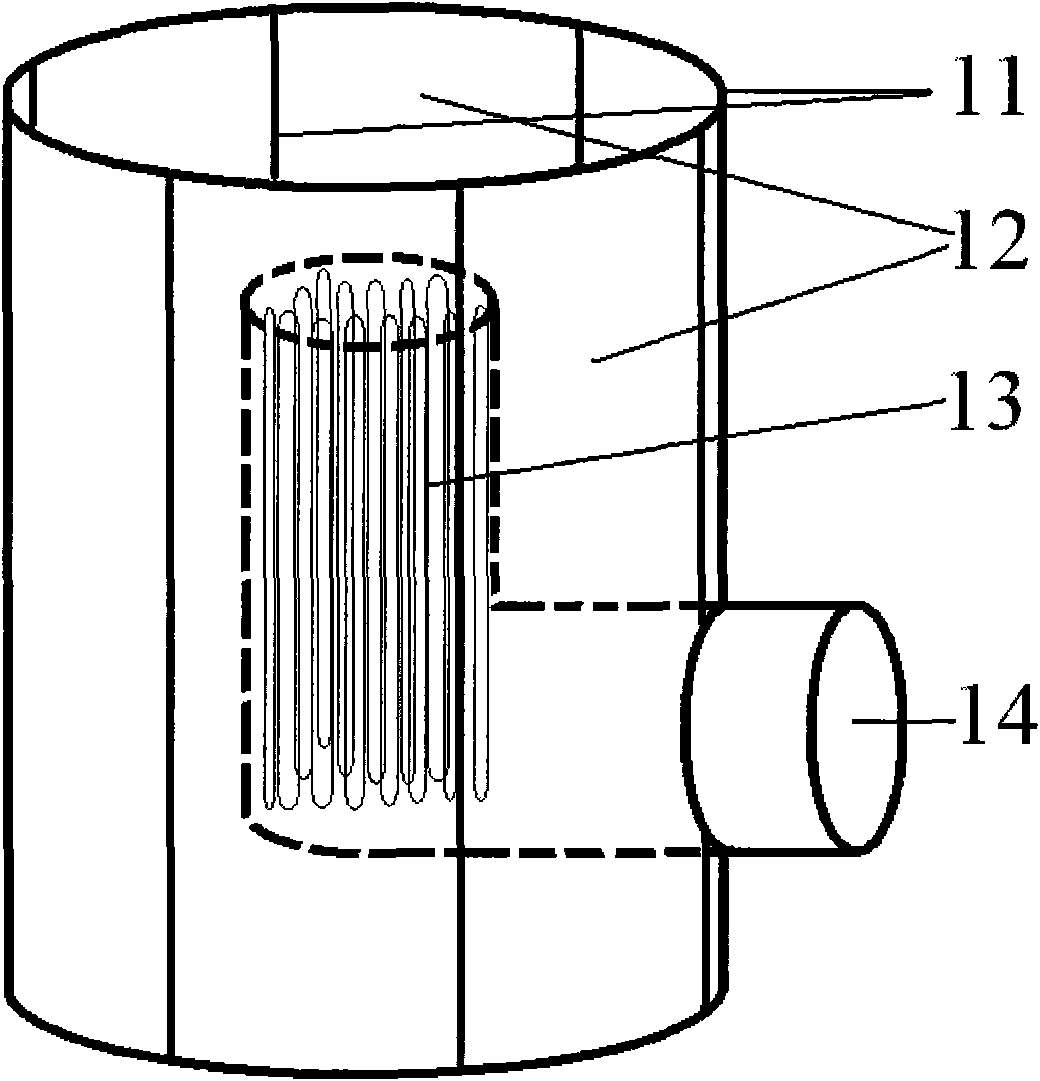

Filtering material for dedusting and low-temperature denitration, and preparation method and application thereof

ActiveCN103170182AGood dimensional stabilityIncreased repeated frictionDispersed particle filtrationLayered productsFiberSurface layer

The invention discloses a filtering material for dedusting and low-temperature denitration, and an application of the filtering material. The filtering material consists of a dust layer, a catalyst layer, a middle fabric enhancement layer and a non-filtering surface layer, wherein the dust layer, the middle fabric enhancement layer and the non-filtering surface layer are formed by thermally resistant fibers with average diameters being 5-30 microns, strength being more than 3.0CN / dtex and elongation being less than 50%, and the catalyst layer is formed by a thermally resistant fiber net adhered with catalyst granules. The filtering material has the functions of dedusting and denitration, and the denitration efficiency can reach more than 85% at the temperature being less than 190 DEG C; and besides, the filtering material has the characteristics of good mechanical strength and long service life.

Owner:CHINESE TEXTILE ACAD

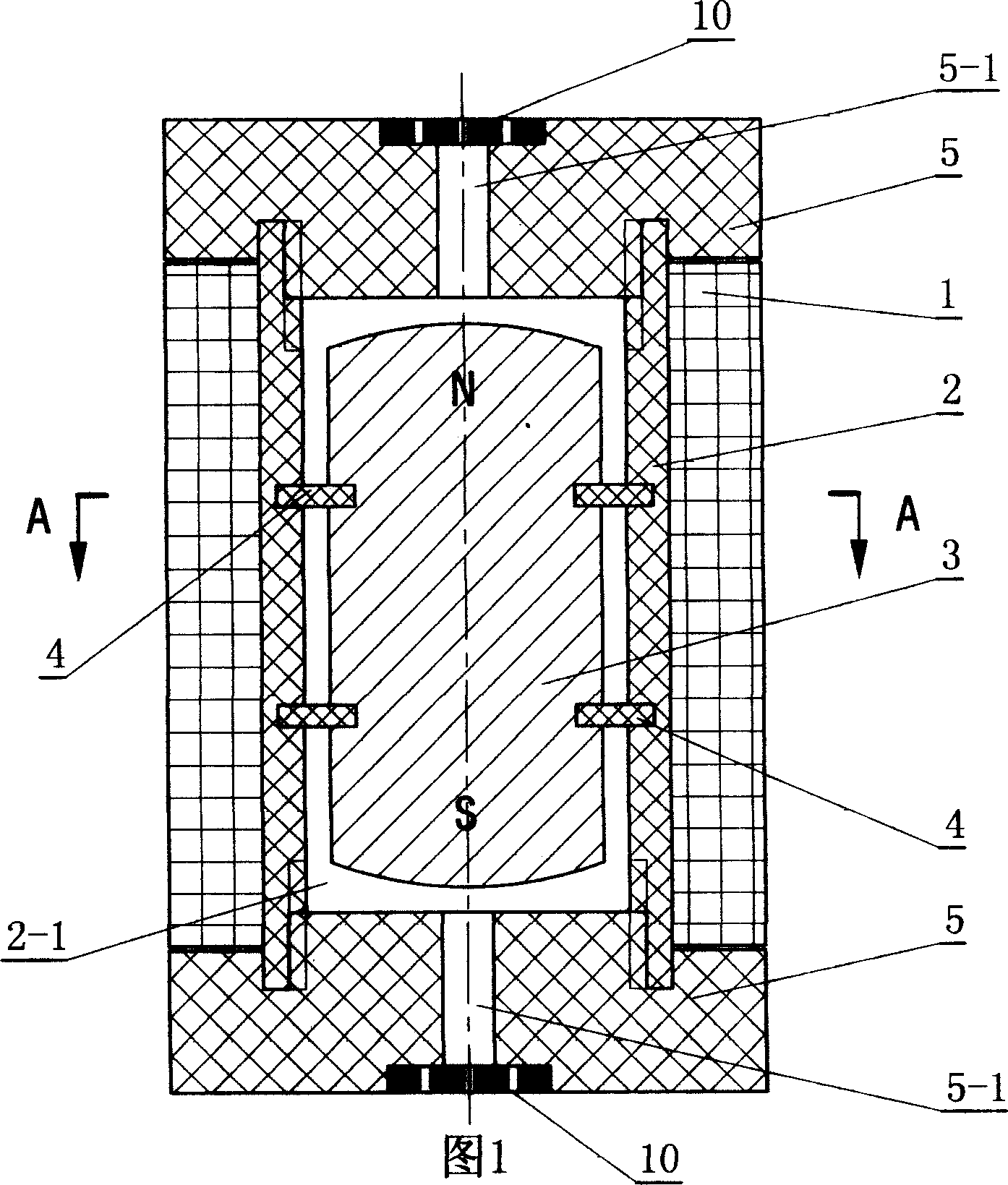

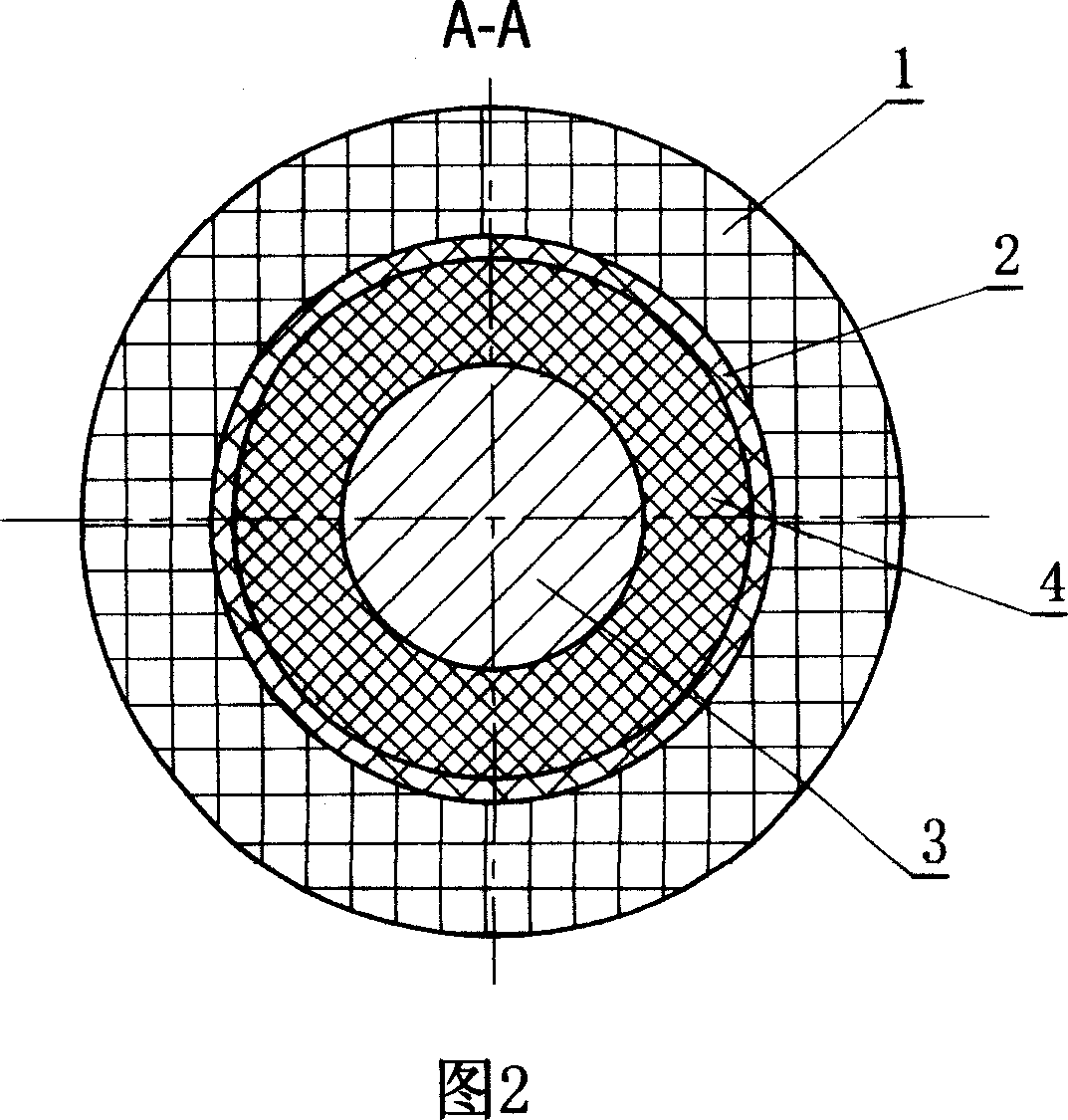

Artificial vibrator

InactiveCN101051774ARealistic vibrationSo as not to damageMechanical energy handlingReciprocating motionEngineering

Being applicable to apparatus in video game, simulated training, motion effect cinema, and the simulated vibrator includes shell, winding, and magnetic hammer. The shell supports winding. The magnetic hammer is installed in cavity of the shell. Through elastic piece, the magnetic hammer is connected to the shell body flexibly. End plates are installed on two ends of the shell body. When doing reciprocal motion, the magnetic hammer contacts end plates or vibration transmission pieces. Advantages are: directivity of vibration, high simulation capability, and obvious collision effect, vivid effect. When multiple simulated vibrators are utilized together can simulate most of vibration situation in reality.

Owner:吴志恒

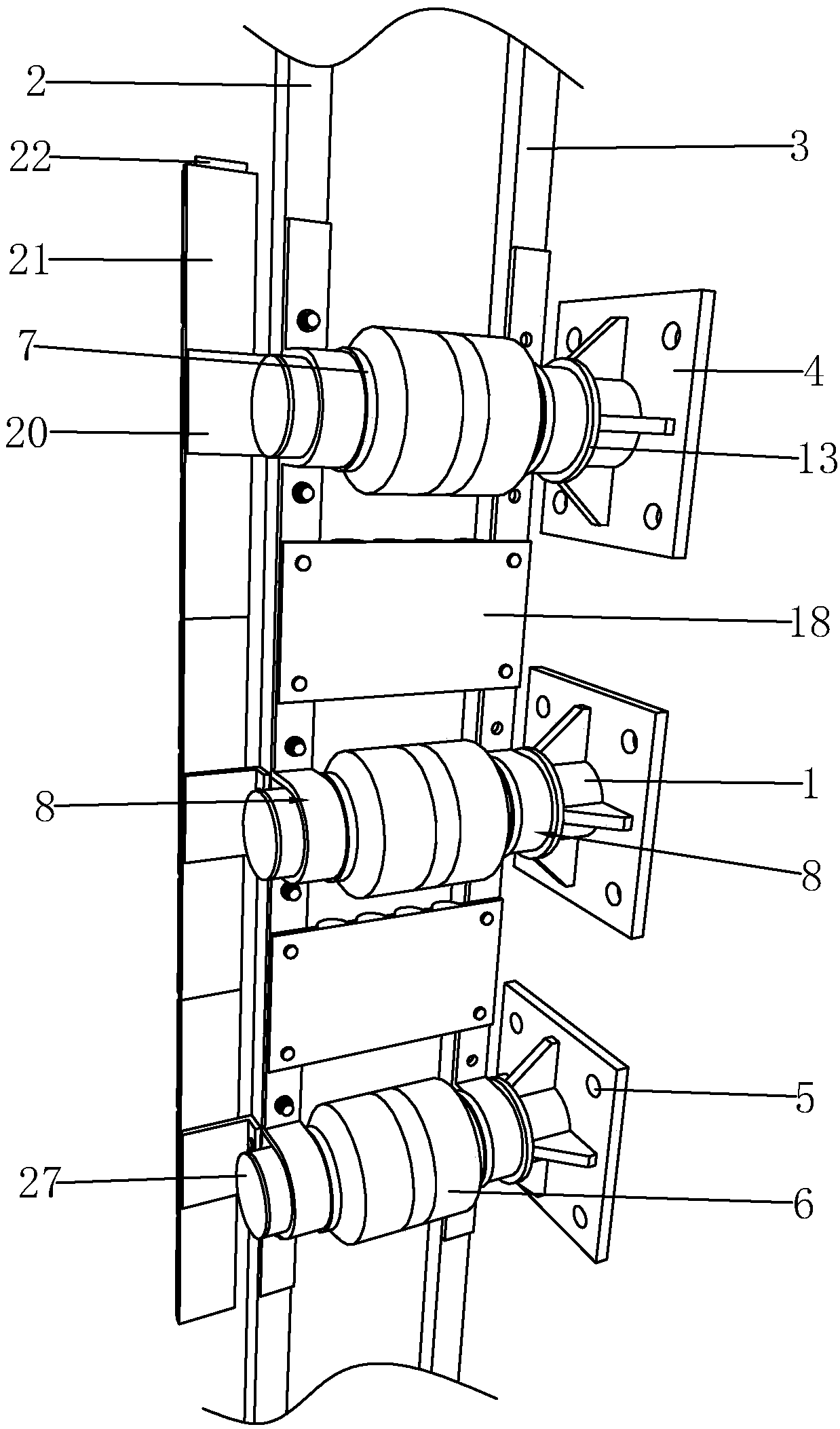

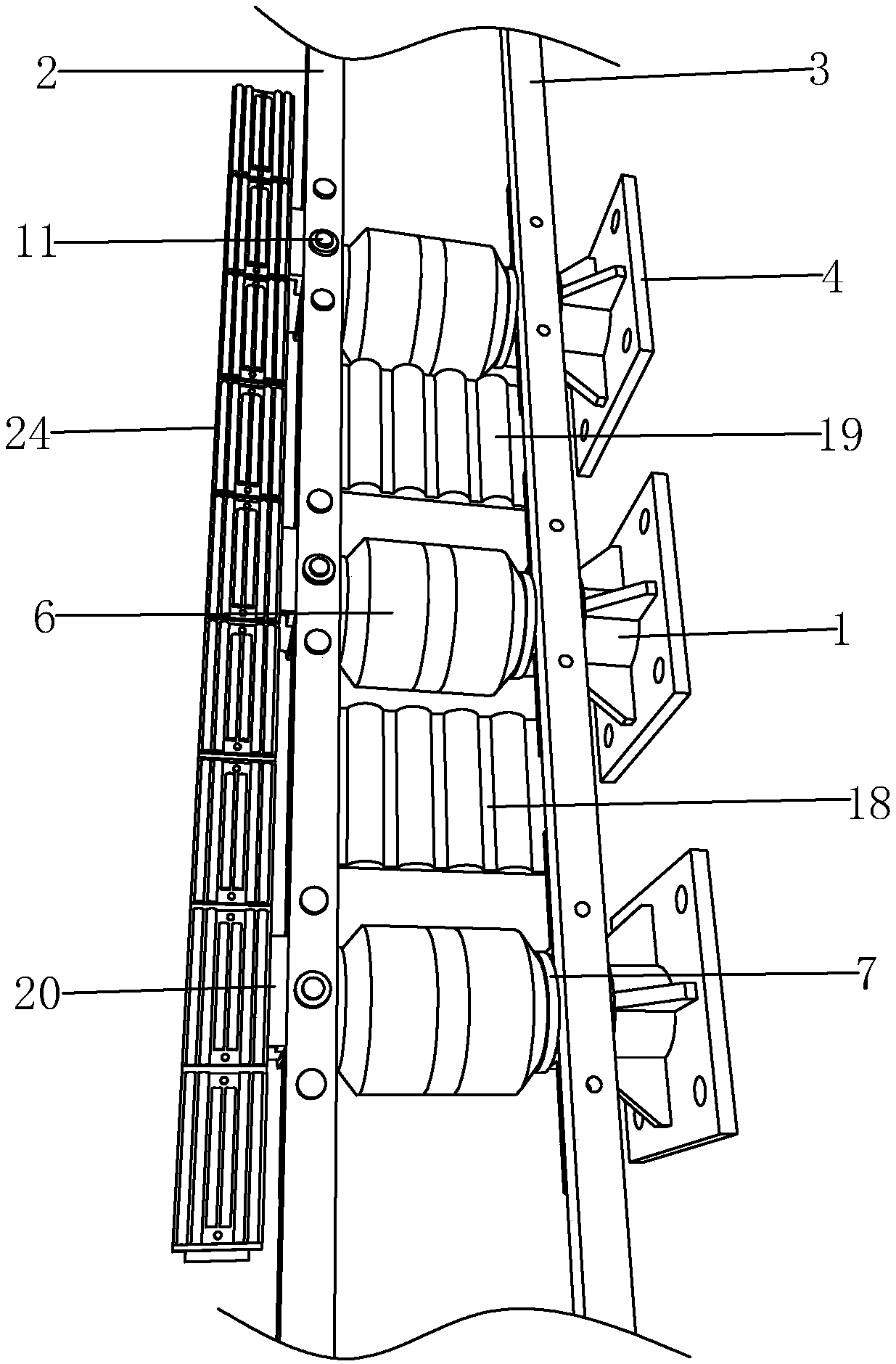

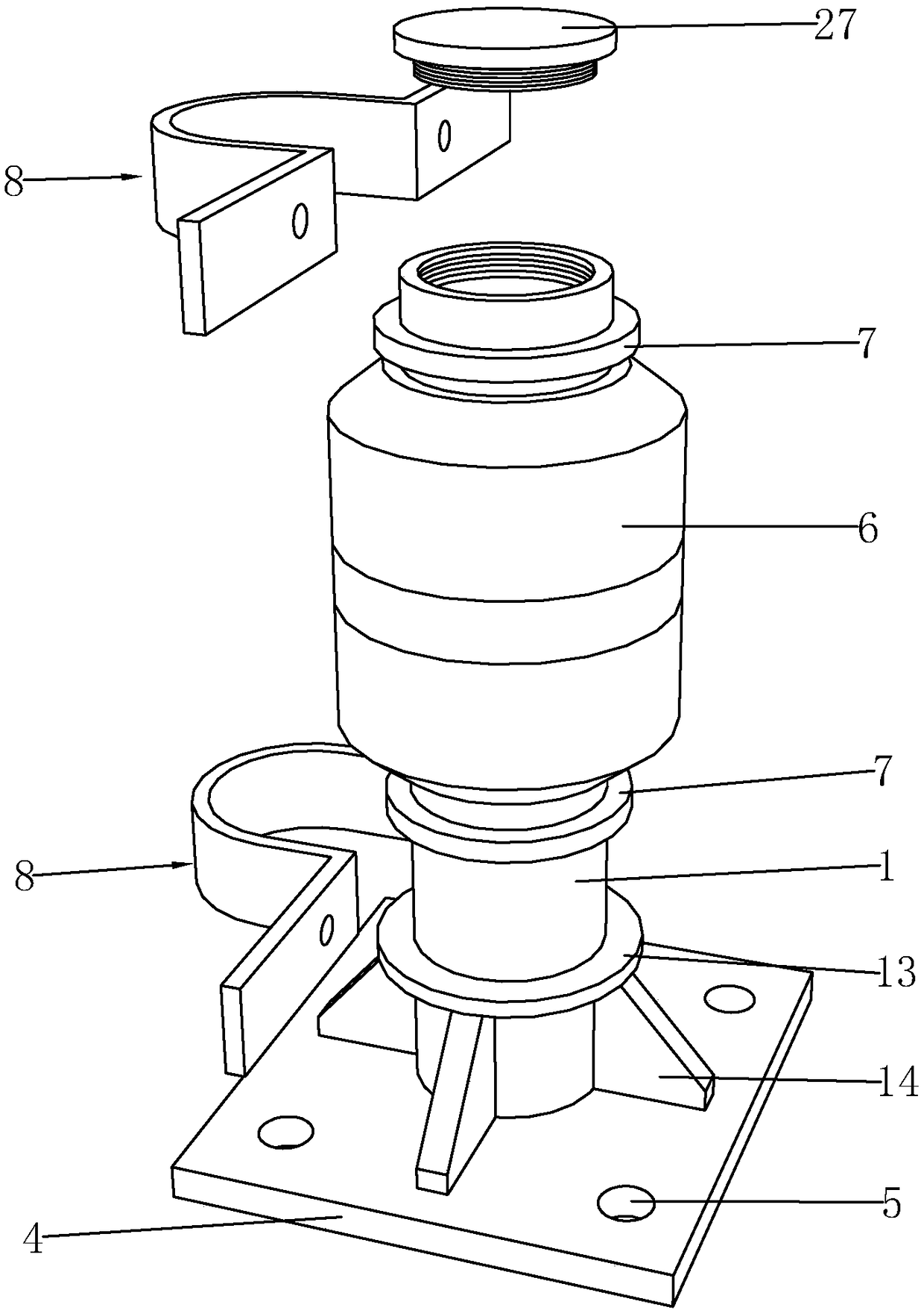

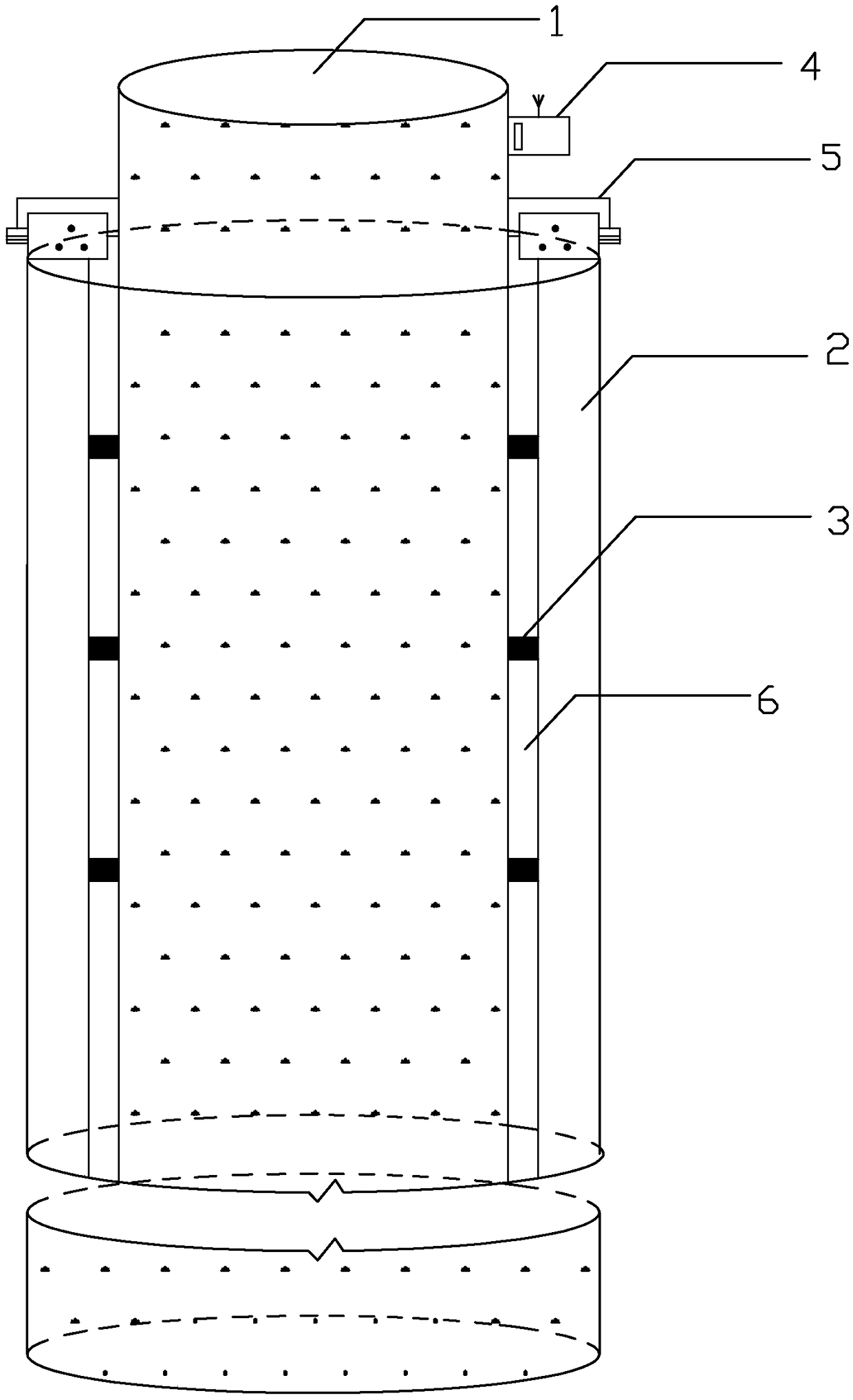

Bridge pier anti-collision structure

PendingCN108708351AExtended service lifeIncrease impact forceClimate change adaptationBridge structural detailsMarine engineeringIdler-wheel

The invention discloses a bridge pier anti-collision structure. The bridge pier anti-collision structure comprises a cylindrical pier and a sleeve arranged outside the cylindrical pier in a sleeving mode. The sleeve wall of the sleeve comprises an outer layer component and an inner layer component which are integrally formed. Idler wheels are arranged on the outer wall of the cylindrical pier. Theinner layer component makes contact with the idler wheels. The sleeve can rotate around the central axis of the cylindrical pier. Through the above design, when a ship collides with the pier, the sleeve rotates, accordingly, the pier forms a guiding inclined angle through impact of the ship, thus direct collision of the ship and the pier is effectively avoided, the collision strength borne by thesleeve is also effectively enhanced, and the great buffer effect on the ship colliding with the ship due to the fact that the ship is out of control can also be achieved. According to the bridge pieranti-collision structure, the maintenance cost of collision between the ship and the pier is effectively reduced, the service life of the pier is prolonged, and the bridge pier anti-collision structure is effective, has wide market application prospects and is worth popularizing energetically.

Owner:FOSHAN UNIVERSITY

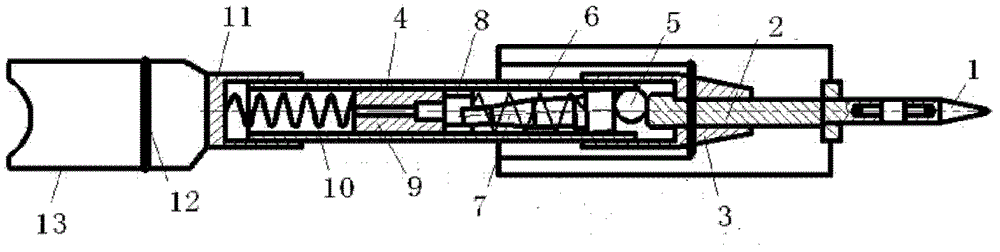

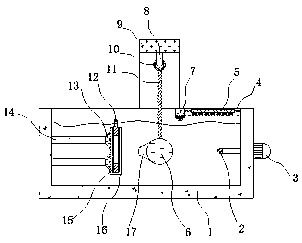

Breaking and dismantling device for rescue

A breaking and dismantling device for rescue comprises a barrier breaking puncher pin. The barrier breaking puncher pin is mounted at one end tip of an impacting rod 2, and the other end of the impacting rod penetrates through a guide bush and is connected with an eccentric steel ball. The guide bush is fixed at one end of a sleeve, and the eccentric steel ball is connected with a check ring through an impacting needle and a return spring which is arranged on the impacting needle in a sleeved mode. The check ring is mounted on one side of an impacting block, and the other side of the impacting block is connected with the bottom of a spring route adjusting rear cover through a force application spring. The spring route adjusting rear cover is connected with one end of the sleeve. The eccentric steel ball, the return spring, the impacting needle, the check ring, the impacting block and the force application spring are located in the sleeve. The spring route adjusting rear cover is mounted on a handle which is connected with a gun stock. When the breaking and dismantling device for the rescue is used, the handle on the spring route adjusting rear cover is held, the barrier breaking puncher pin abuts against a masonry barrier to be broken and is pushed forward to compress the springs, and after being compressed to certain distances, the springs are released abruptly to generate large enough impact force which can break through the masonry barrier. The breaking and dismantling device for the rescue has the advantages of being capable of being operated manually, convenient to carry and use, high in efficiency and capable of being used in all directions.

Owner:XIAN SIYUAN UNIV

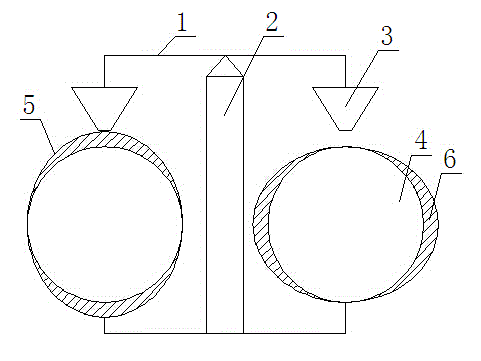

Knocking device for double drums

ActiveCN104457211AReduce volumeVolume weightDrying machines with non-progressive movementsDrying solid materialsArchitectural engineeringCopper

The invention discloses a knocking device for double drums. The knocking device comprises a balancing rod, a supporting platform, two circular-truncated-cone-shaped knocking copper blocks and two circular drums, wherein the middle of the balancing rod is movably connected with the supporting platform; the two knocking copper blocks are respectively fixed at the two ends of the balancing rod through two connecting rods; the two circular drums are respectively arranged at the lower parts of the two knocking copper blocks; oblong impacting rings are fixed on the outer surfaces of the two circular drums; when the device works, the impacting rings on the two drums respectively cooperate with the corresponding knocking copper blocks to sequentially and circularly knock the impacting rings of the two drums. The knocking device can sequentially and circularly knock the two drums under the cooperation of the two drums.

Owner:嘉善县魏塘资产管理有限公司

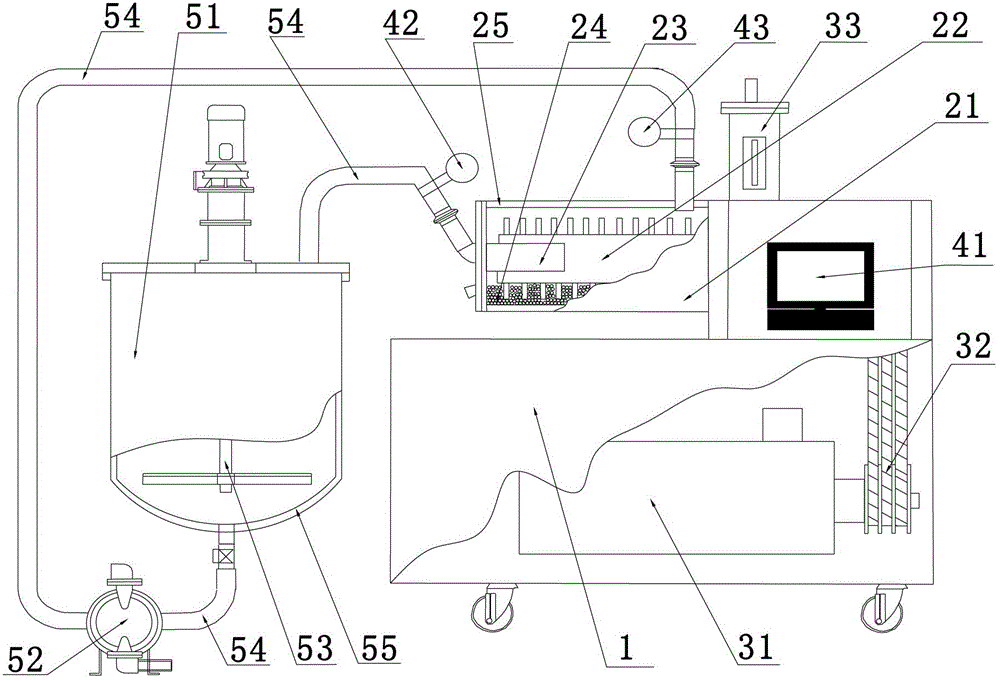

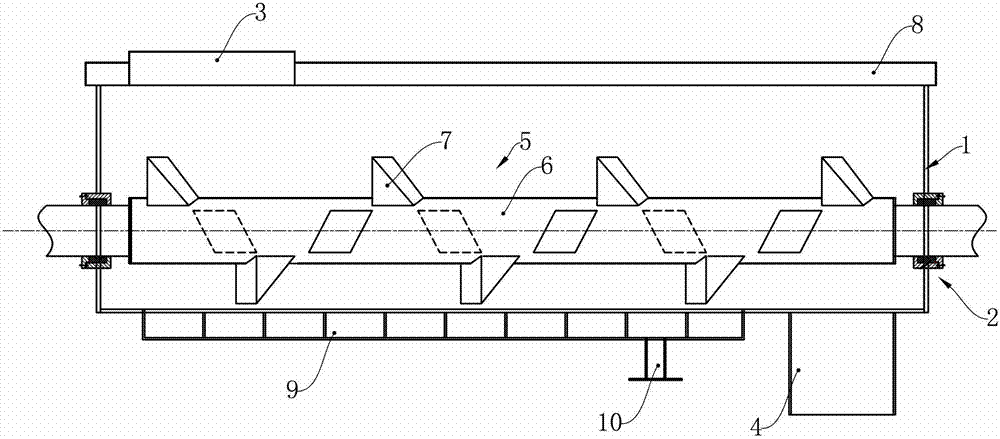

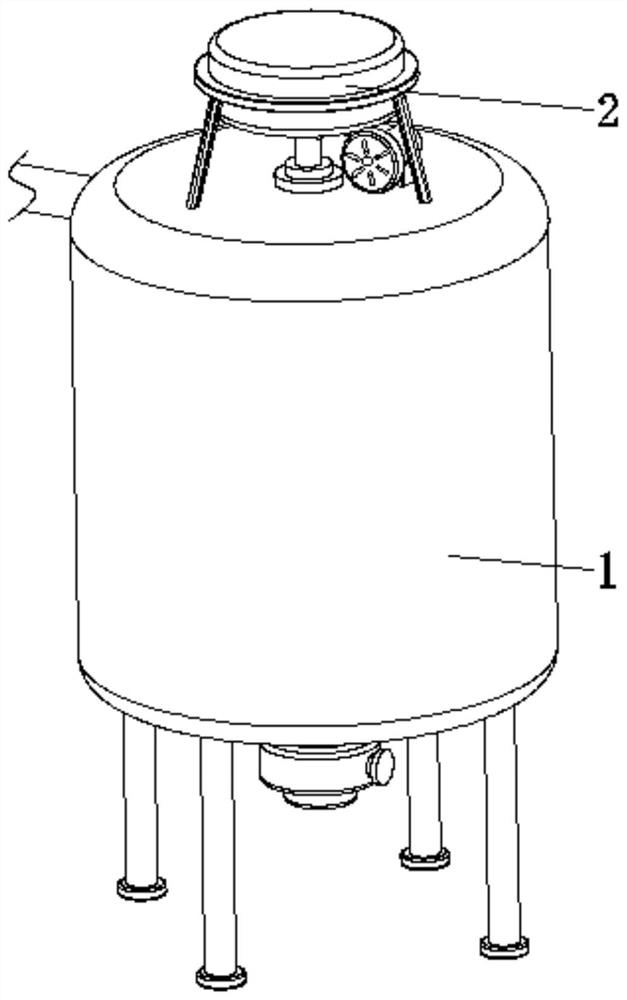

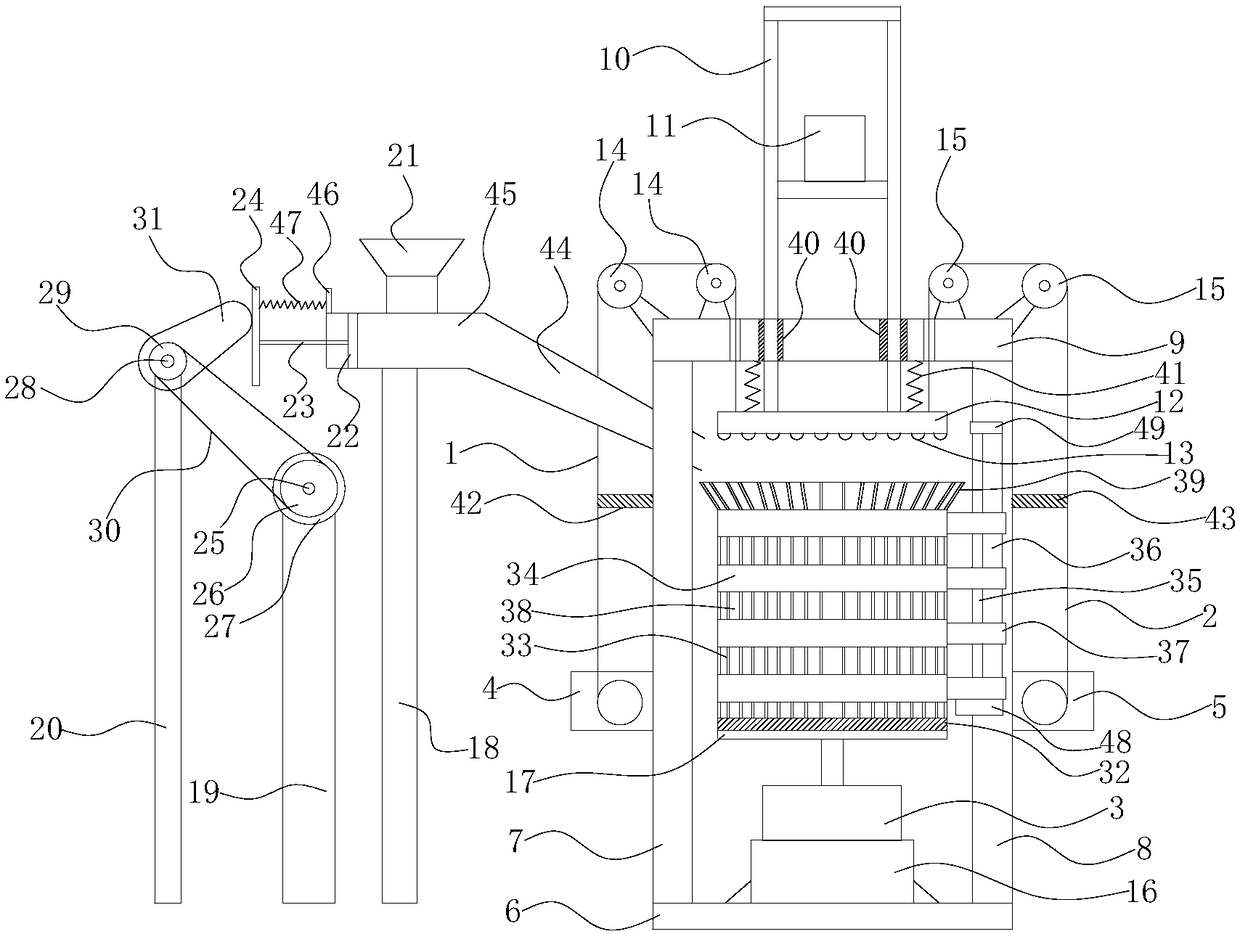

Grinding device and grinding process for grinding heat transfer printing color paste

The invention provides a grinding device for grinding a heat transfer printing color paste. The grinding device comprises a base rack, wherein the base rack is fixedly provided with a sand mill, a control assembly and a power assembly; the power assembly comprises a motor, and the sand mill comprises a grinding barrel and a plurality of grinding media positioned in the grinding barrel. The grinding device further comprises a circulating assembly, wherein the circulating assembly comprises a circulating barrel, a circulating pump and a plurality of conduits. The discharge port of the grinding barrel is communicated with the feed port of the circulating barrel by virtue of the conduit, and the feed port of the grinding barrel and the discharge port of the circulating barrel are respectively connected with the outlet and inlet of the circulating pump. The invention further provides a grinding process utilizing the grinding device. The grinding device provided by the invention has the characteristics of simple structure, favorable heat dissipation effect, low noise, capability of continuous production, low production cost, high grinding efficiency, and high quality of grinded products.

Owner:ZHUHAI FREE TRADE ZONE NEOJET APOLLOJET IMAGING MATERIALS

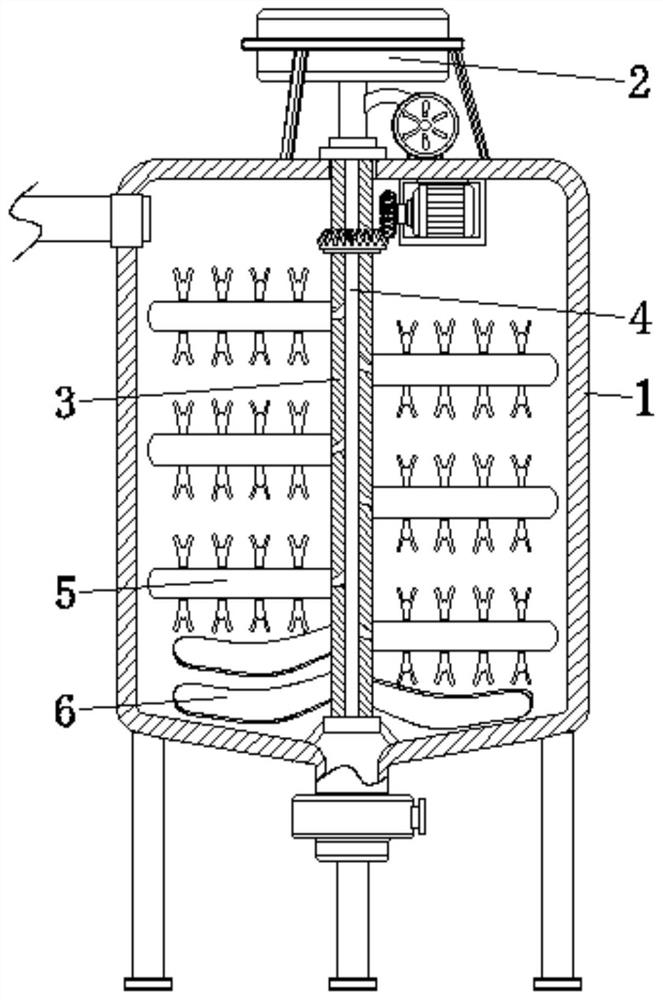

Efficient vertical agitating ball mill for cemented carbide production and manufacture

ActiveCN109201214AQuick grindingImprove grinding efficiencyGrain treatmentsElectric machineryEngineering

The invention discloses an efficient vertical agitating ball mill for cemented carbide production and manufacture. The efficient vertical agitating ball mill comprises a grinding outer cylinder, a machine cylinder is installed at the upper end of the grinding outer cylinder in a disassembled mode, and a cylinder cover is tightly arranged at the upper end of the machine cylinder in a covered mode.An electric rotating machine is vertically and fixedly mounted at the center of the top surface of the inner side of the cylinder cover, a mounting bracket is mounted on an output shaft at the lower end of the electric rotating machine, and a conductive arc is mounted at the end, away from the electric rotating machine, of the mounting bracket. The efficient vertical agitating ball mill has the beneficial effects that the efficient vertical agitating ball mill for cemented carbide production and manufacture can realize fast and efficient grinding of cemented carbide powder, has high grinding efficiency, can achieve a better grinding effect without long-time grinding, and has good practicability.

Owner:蓬莱市超硬复合材料有限公司

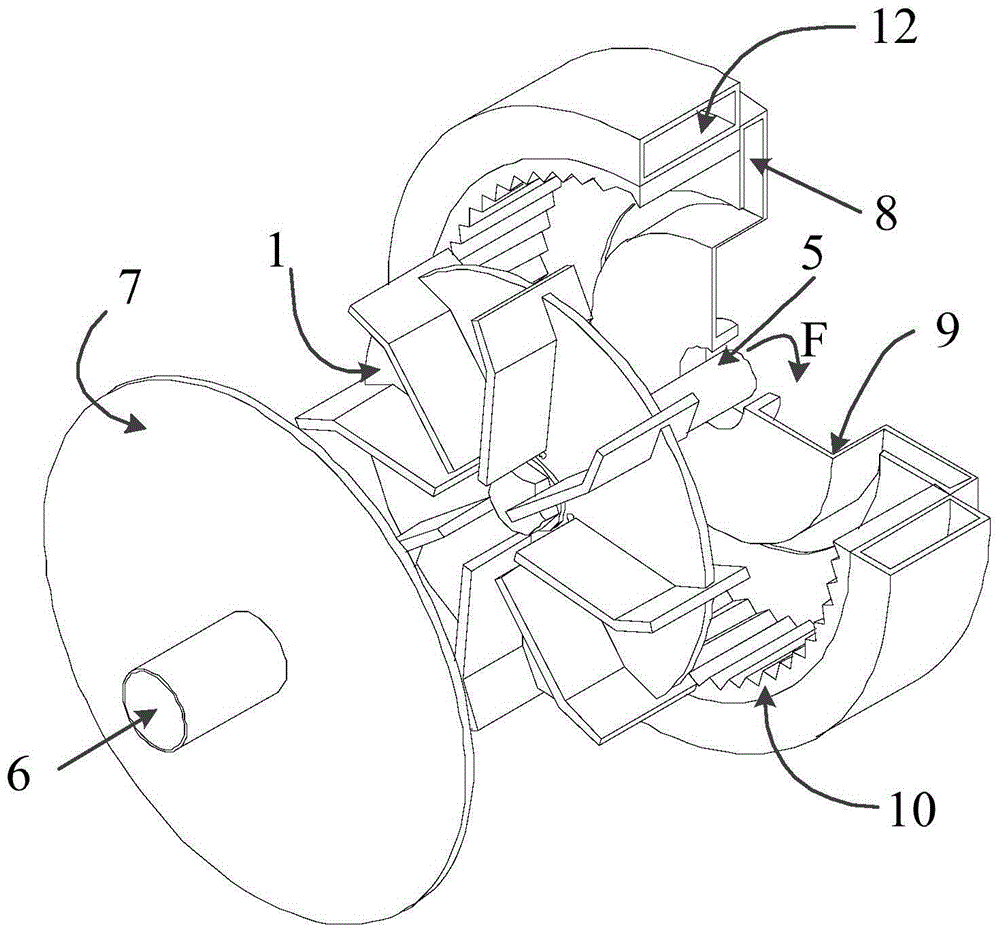

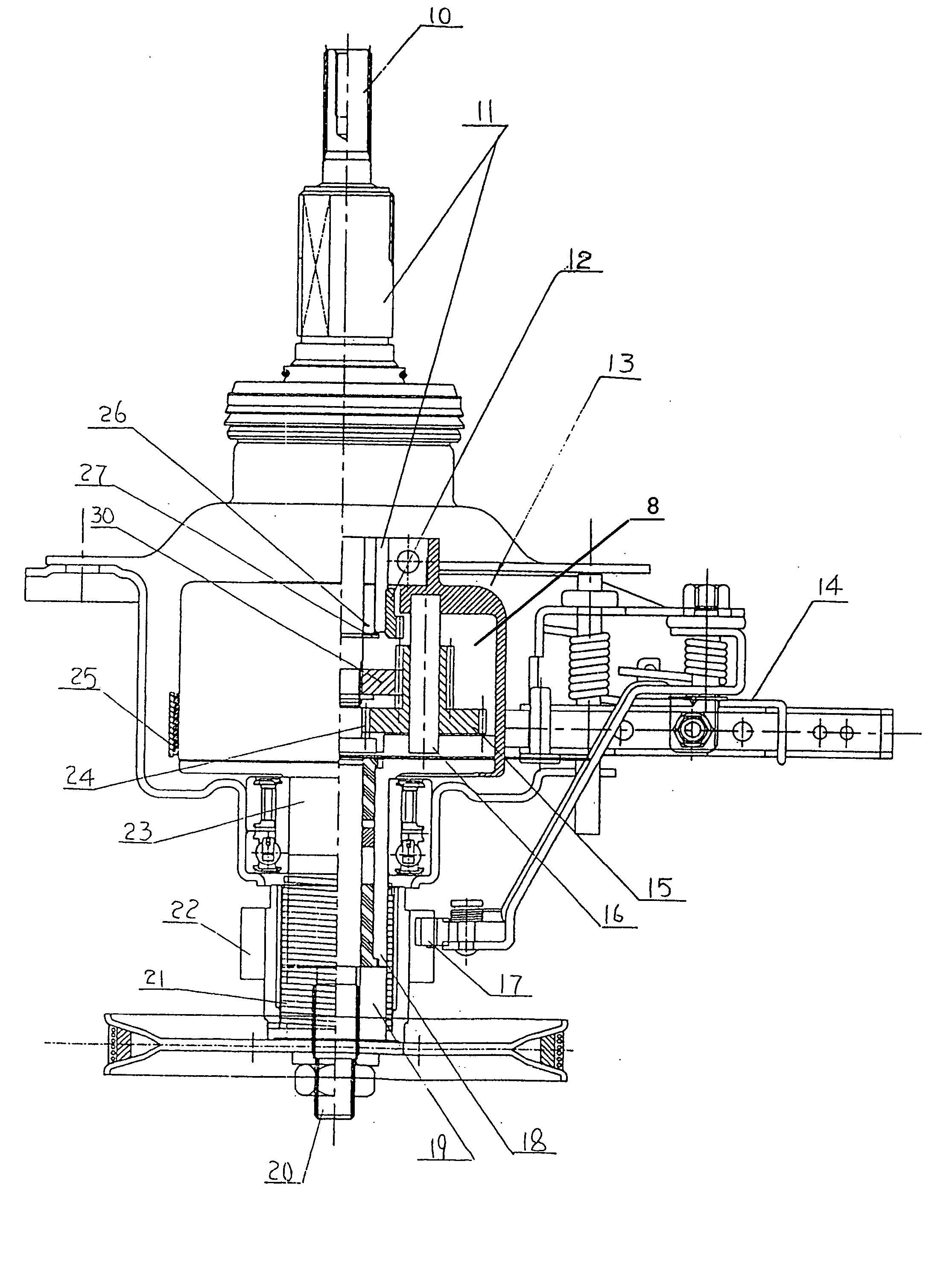

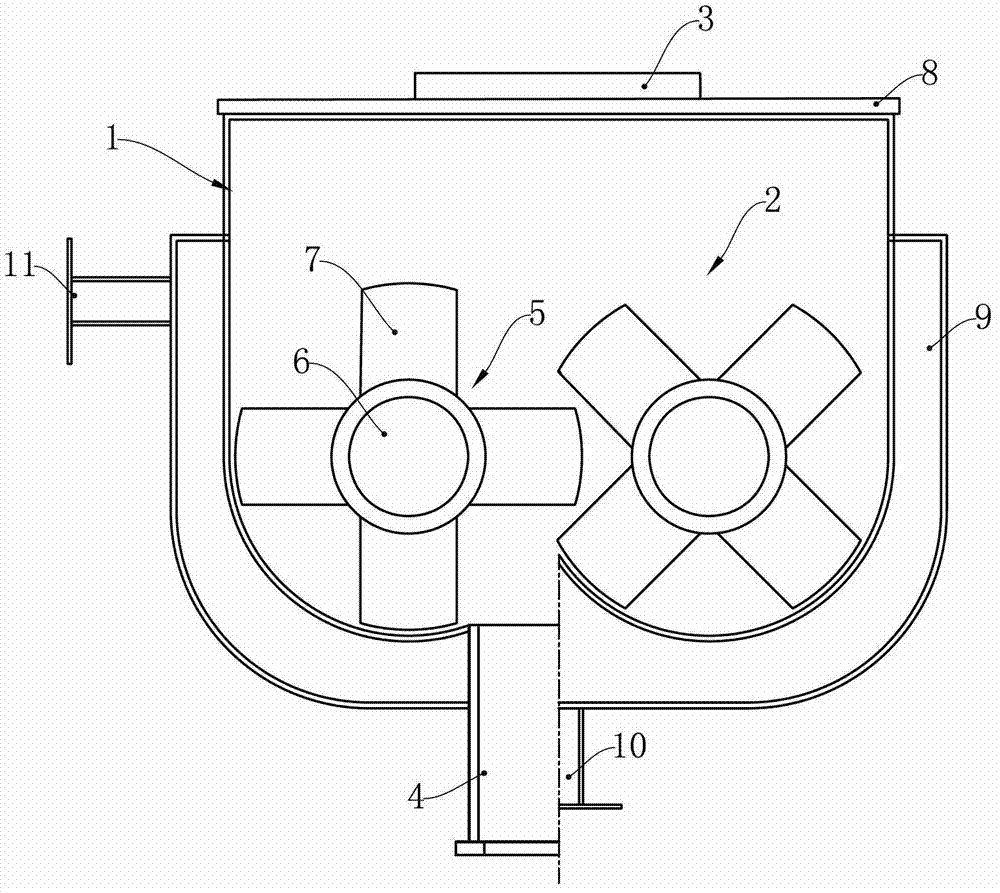

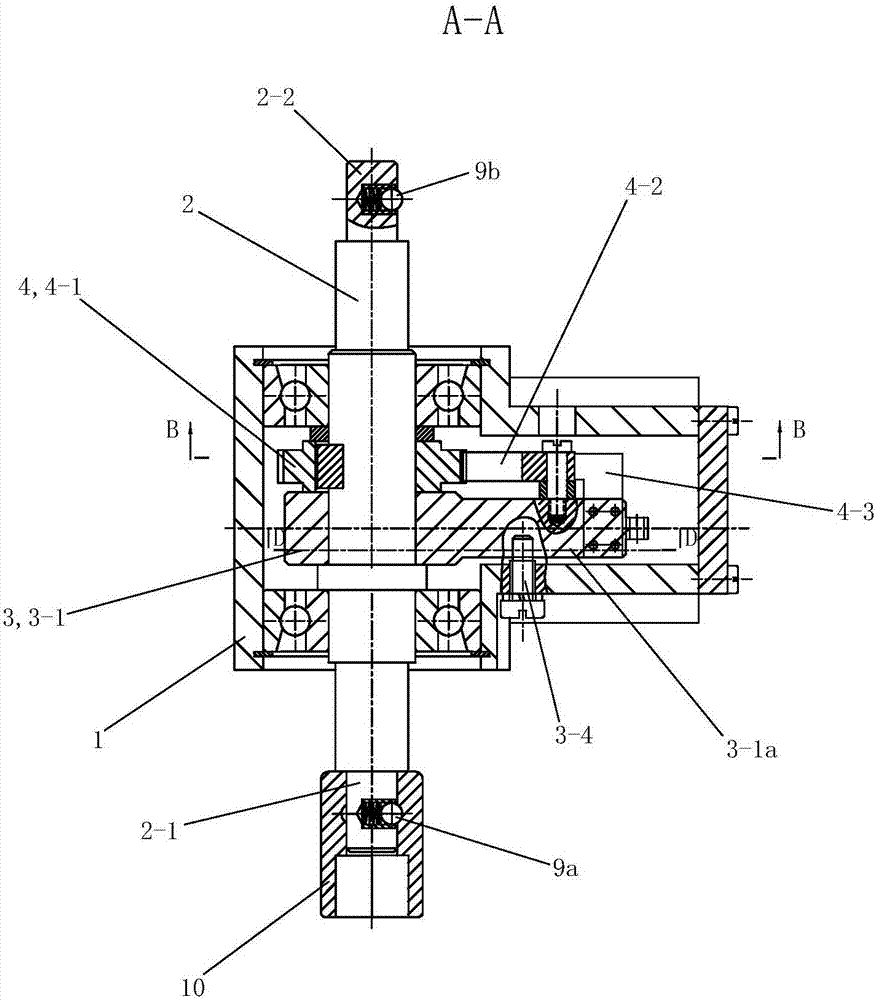

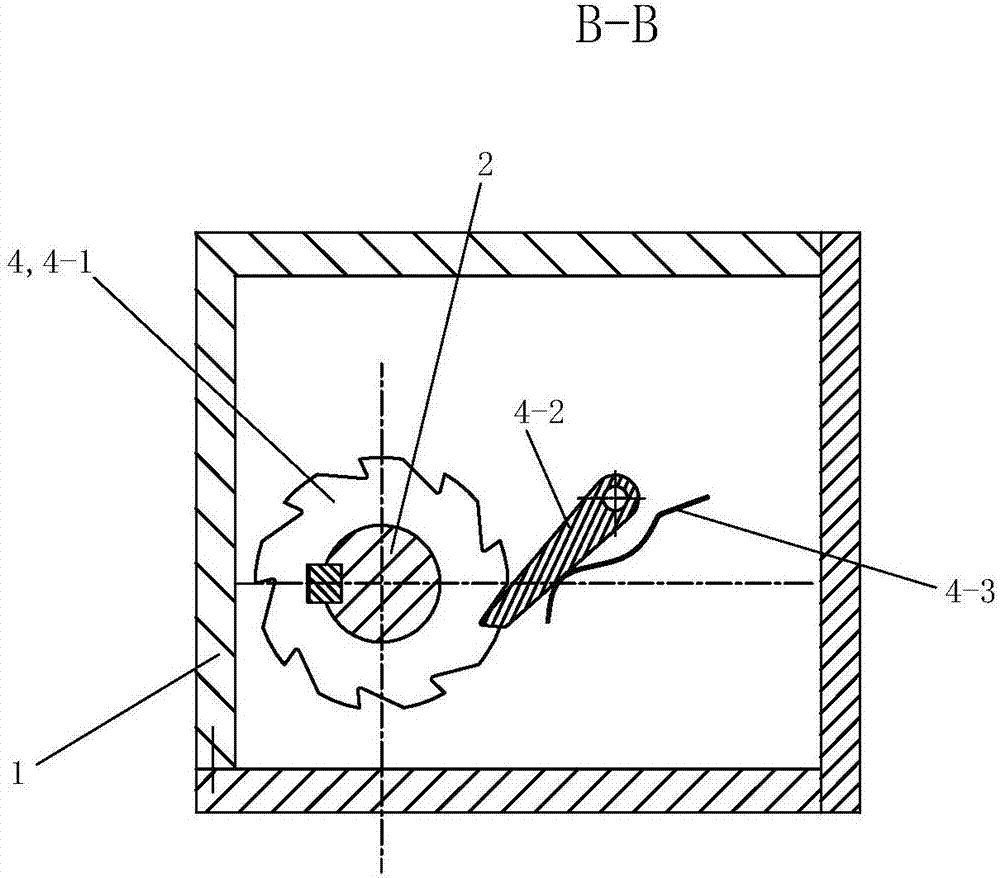

Counter-rotation wash method and transmission machine

InactiveUS20050039496A1Compact structureSmall volumeOther washing machinesWashing machine with receptaclesLaundry washing machineControl engineering

A transmission mechanism suitable to be used in a washing machine for creating dual-direction driving comprises a drive power input end and two drive power output ends, in which one of drive power output ends is connected to an agitator shaft (10) to drive the agitator shaft rotating in a first direction; while the other of drive power output ends is connected with an inner basket shaft (11) to drive the inner basket shaft rotating in a second direction opposed to the first direction. A washing machine for creating dual-direction washing and a washing method for creating dual-direction washing in a washing machine are disclosed in the present invention. Furthermore, an agitator and an inner basket suitable to be used in the washing machine are disclosed in the present invention.

Owner:HAIER GRP AN HAIER ELECTRIC APPLIANCES INT

Electric power cabinet having waterproof function

InactiveCN107658746AWith waterproof functionExtended service lifeSubstation/switching arrangement casingsAnti-seismic devicesTester deviceEngineering

The invention discloses a power cabinet with waterproof function, which comprises a cabinet body, a humidity tester is fixedly connected to one side of the outer wall of the cabinet body, and a fixing rod is fixedly connected to the inside of the cabinet body, and the tops of the fixing rods are respectively fixed from left to right The controller and the motor are connected, and the inner cavity on the top of the cabinet is fixedly connected with a bearing. The inner part of the bearing is fixedly sleeved with a nut, and the outer part of the bottom of the nut is fixedly sleeved with a wheel. The outer wall of the wheel is connected to the output shaft of the motor through a belt drive. The outer wall of the nut, the inner thread of the nut is sleeved with a threaded rod. The power cabinet with waterproof function, through the cooperation between the humidity tester, controller, motor, bearings, nuts, belts and threaded rods, can ensure that no matter how heavy the rainwater is, it will not float into the power cabinet and keep the inside of the cabinet. Dry to ensure that the circuit inside the cabinet will not be short-circuited by rain, thereby reducing the loss of the circuit inside the cabinet and improving the service life of the power cabinet.

Owner:郑艳峰

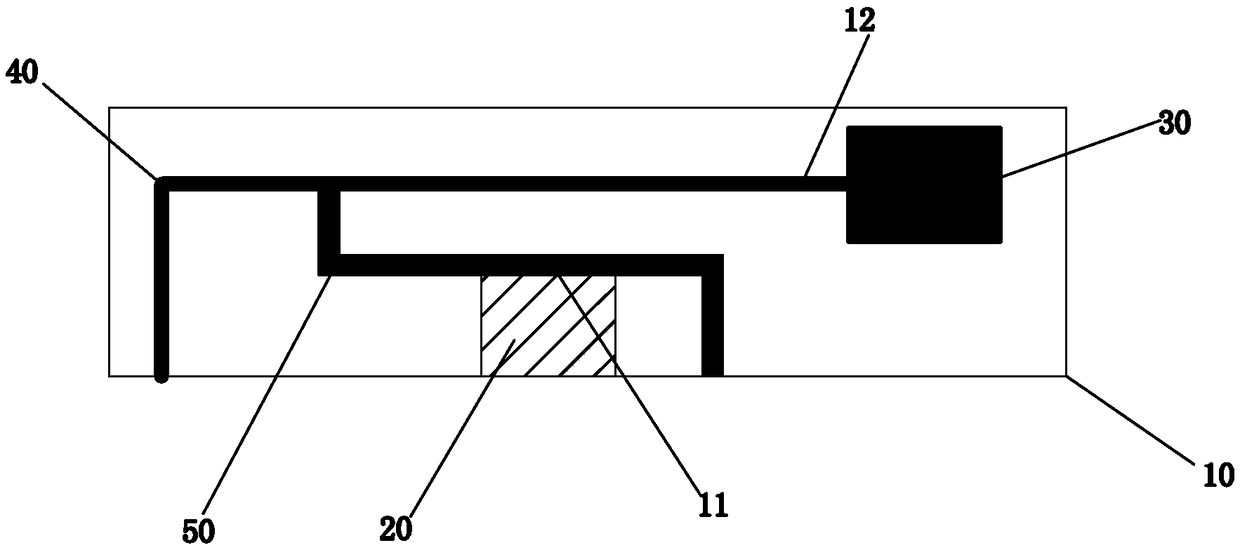

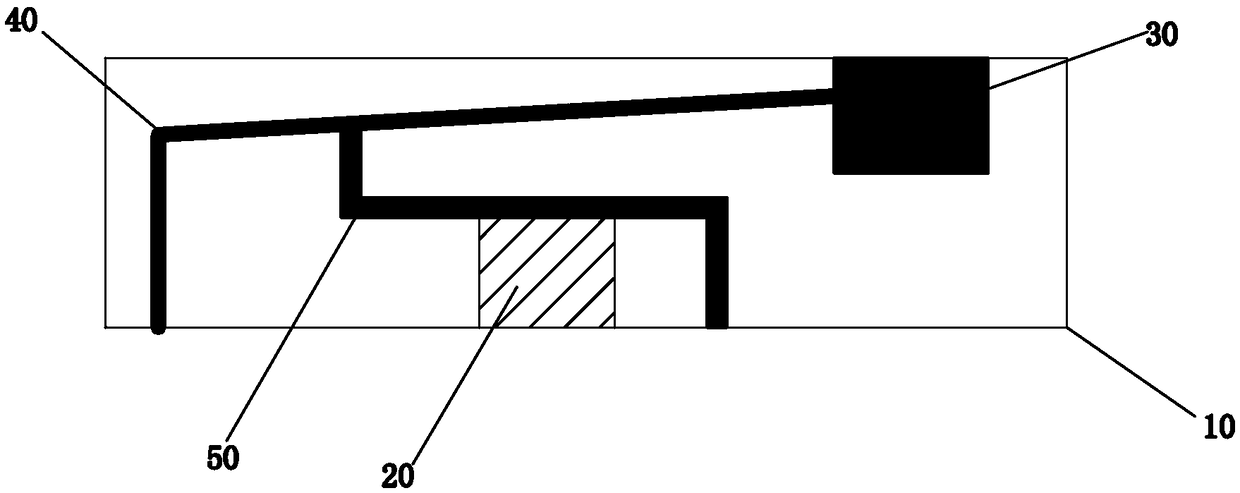

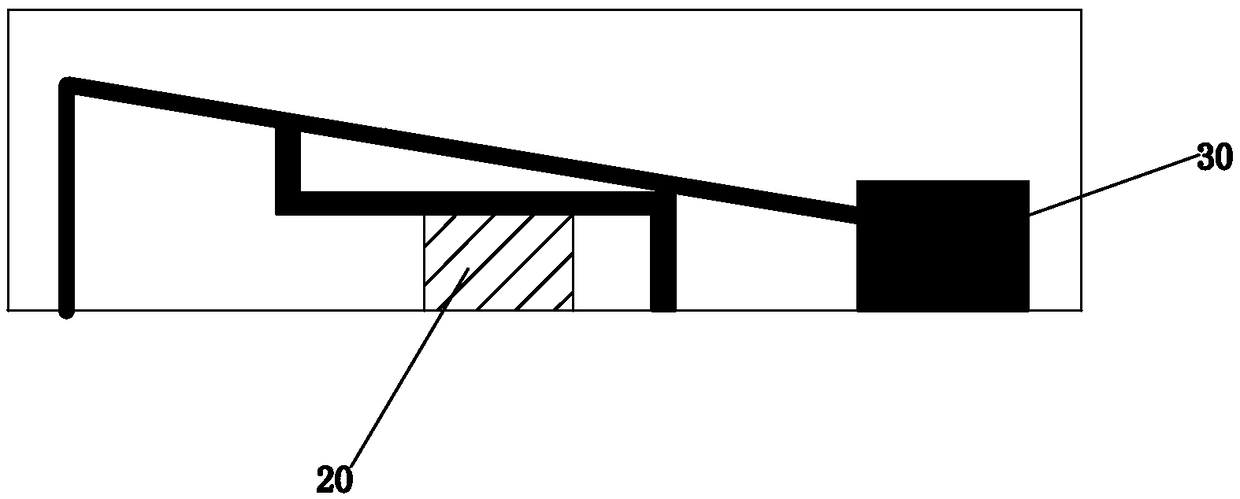

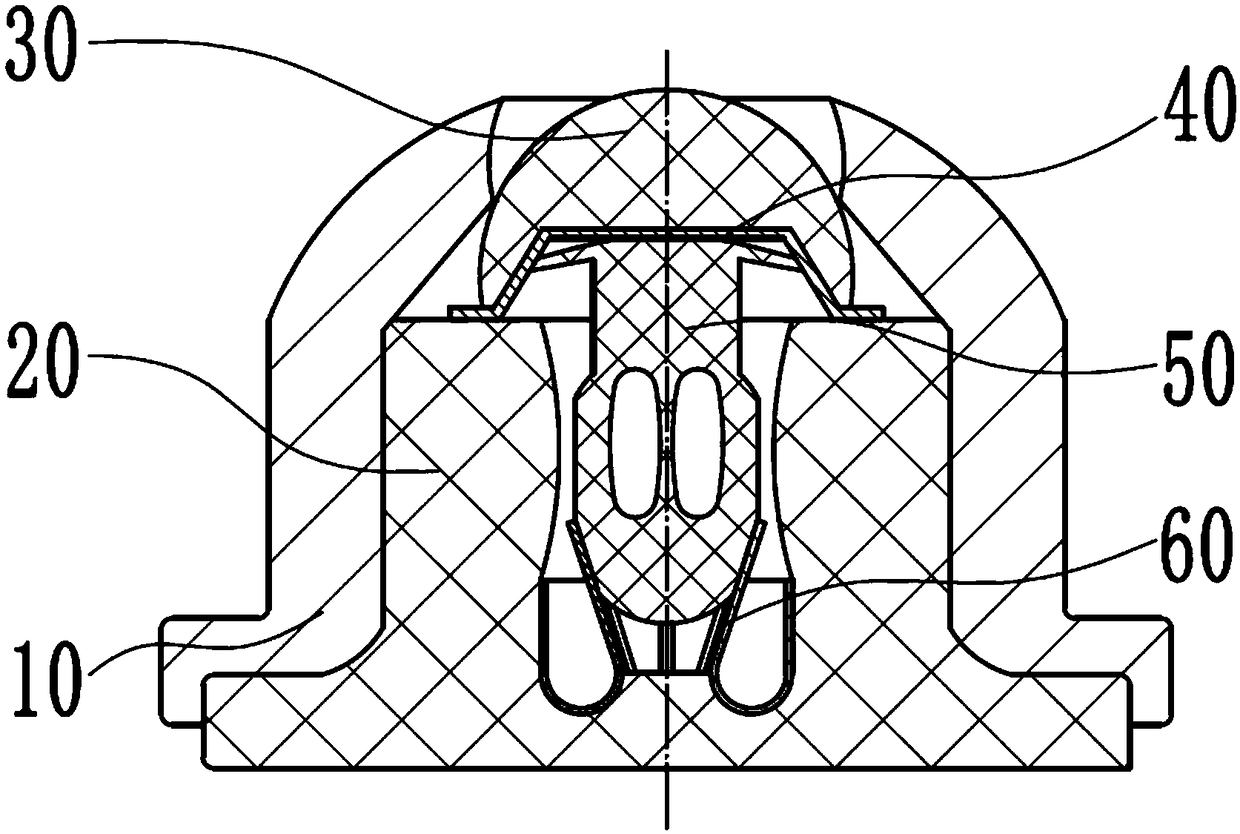

Lever-type haptic feedback device

ActiveCN109005268ALow excitation voltageIncrease energy densityInput/output for user-computer interactionGraph readingElectricityVibration amplitude

A lever-type haptic feedback device. A longitudinal extension of the laminate piezoelectric ceramics is carryed out once so as to drive the swing end to swing upward through the driving end of the lever-type elastic transmission member so as to drive the mass block to directly impact the inner top surface of the shell, and the mass block moves downward under the elastic action of the lever-type elastic transmission member and the rebound force after the impact until the mass block directly strikes the bottom surface of the shell, then the mass is restored to the initial state by the elastic action of the lever-type elastic transmission member and the rebound force after the impact, and the laminated piezoelectric ceramics are longitudinally retracted to the initial state during the upwardmovement of the mass. The whole device is simple in structure and good in technicality, which is advantageous to the effective propagation of vibration. The vibration amplitude of laminated piezoelectric ceramics can be amplified by using lever-type elastic transmission parts, and the problem of small vibration amplitude of existing vibrators is solved.

Owner:HUAQIAO UNIVERSITY

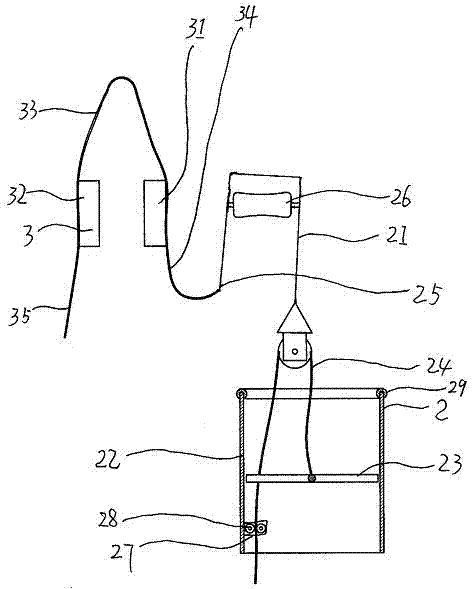

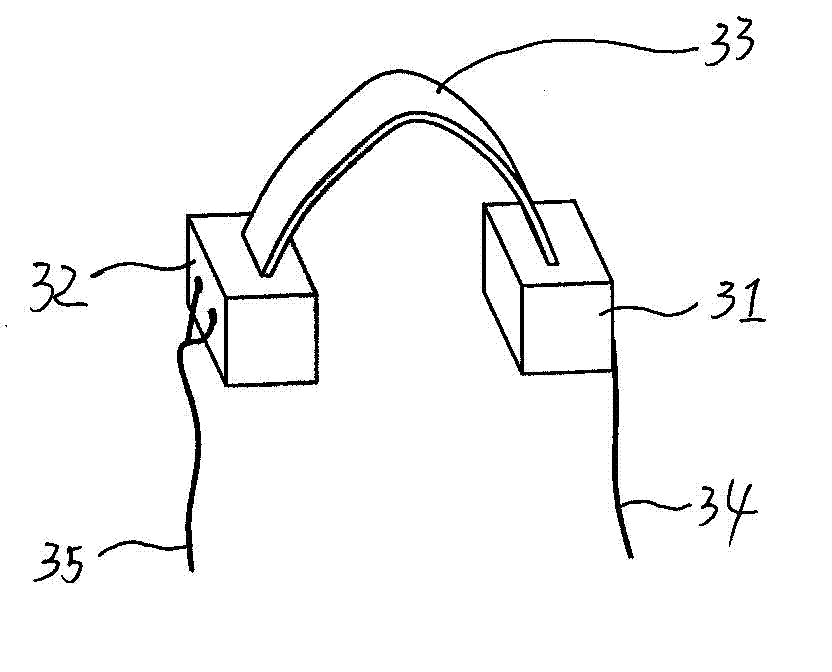

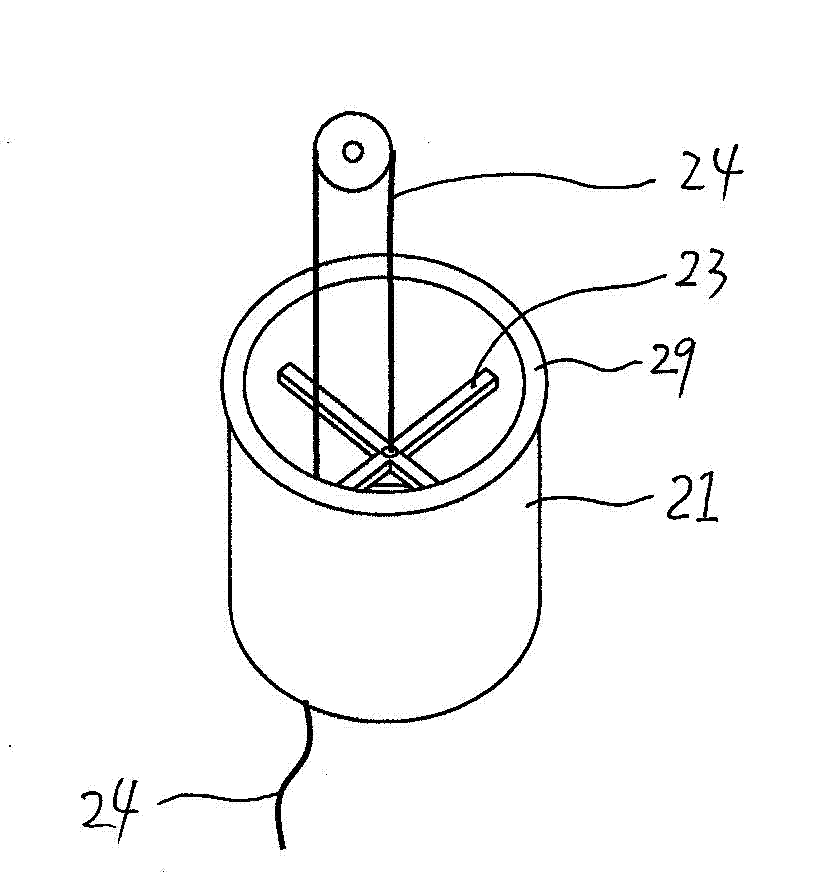

Method for deicing by using power circuit deicing device

The invention belongs to the technical field of methods for removing ice coated on a lead, and discloses a method for deicing by using a power circuit deicing device. The device is mainly and technically characterized by comprising a mount point cleaning mechanism and a deicing mechanism, wherein the mount point cleaning mechanism comprises two mount point cleaning hammers and a connecting rope, and an arc hanging rope is connected below each mount point cleaning hammer; the deicing mechanism comprises a following tackle and a deicing barrel, wherein a hanging bracket is arranged at a position close to the middle part in the deicing barrel, a pull rope which can bypass the following tackle is fixedly arranged on the hanging bracket, and a hanging end of the following tackle is connected with the arc hanging rope of one mount point cleaning hammer; the method comprises the steps that: firstly, ice coated on a mount point can be removed by using the mount point cleaning hammers; secondly, a running wheel of the following tackle is hung on the mount point, and the coated ice is forcefully impacted by using the deicing barrel, so that the deicing area is large, and the deicing speed is fast; and the mount point, the connecting rope, the deicing barrel and the like can be conveniently carried, all operations can be finished by an operator on the ground, and the safety factor is high.

Owner:STATE GRID CORP OF CHINA +2

Particle shaping equipment

ActiveCN102755857APrevent adhesion formationBreak up fullyGranulation in stationary drums/troughsEngineeringSilicon

The invention discloses particle shaping equipment, which is arranged between particle forming equipment and cooling equipment and comprises a trough and a stirring device, wherein the trough is used for receiving a solid material led out by the particle forming equipment and is provided with a feed port and a discharge port; and the stirring device is used for scattering the solid material and conveying the solid material to the discharge port, is arranged in the trough and comprises at least two helical stirring paddles which are arranged in the trough in parallel. According to the particle shaping equipment, the solid material can be effectively prevented from being adhered into large blocks due to rapid cooling, cooling and subsequent sieving and crushing are easy, and the particle quality of inorganic silicon is improved.

Owner:山东龙港硅业科技有限公司

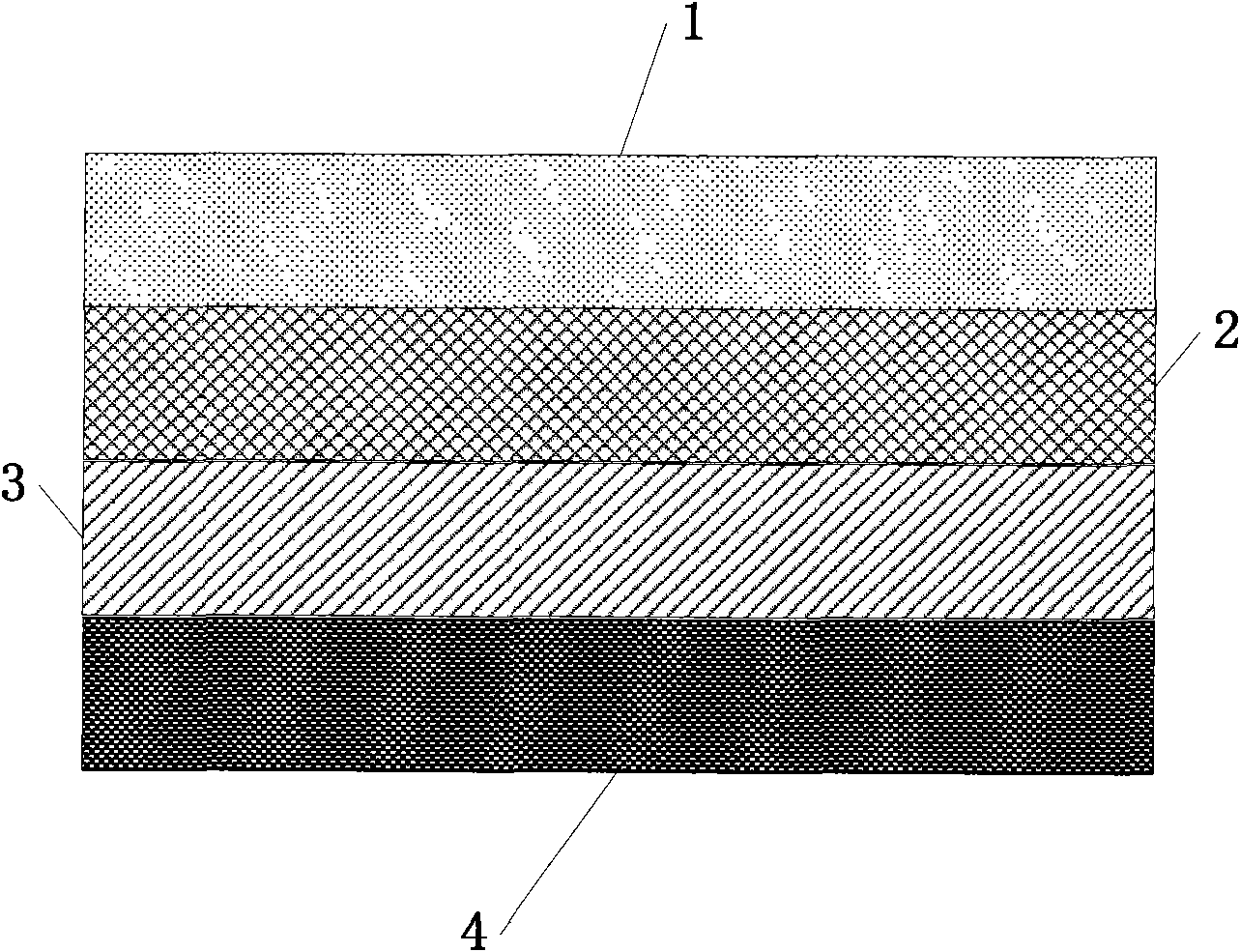

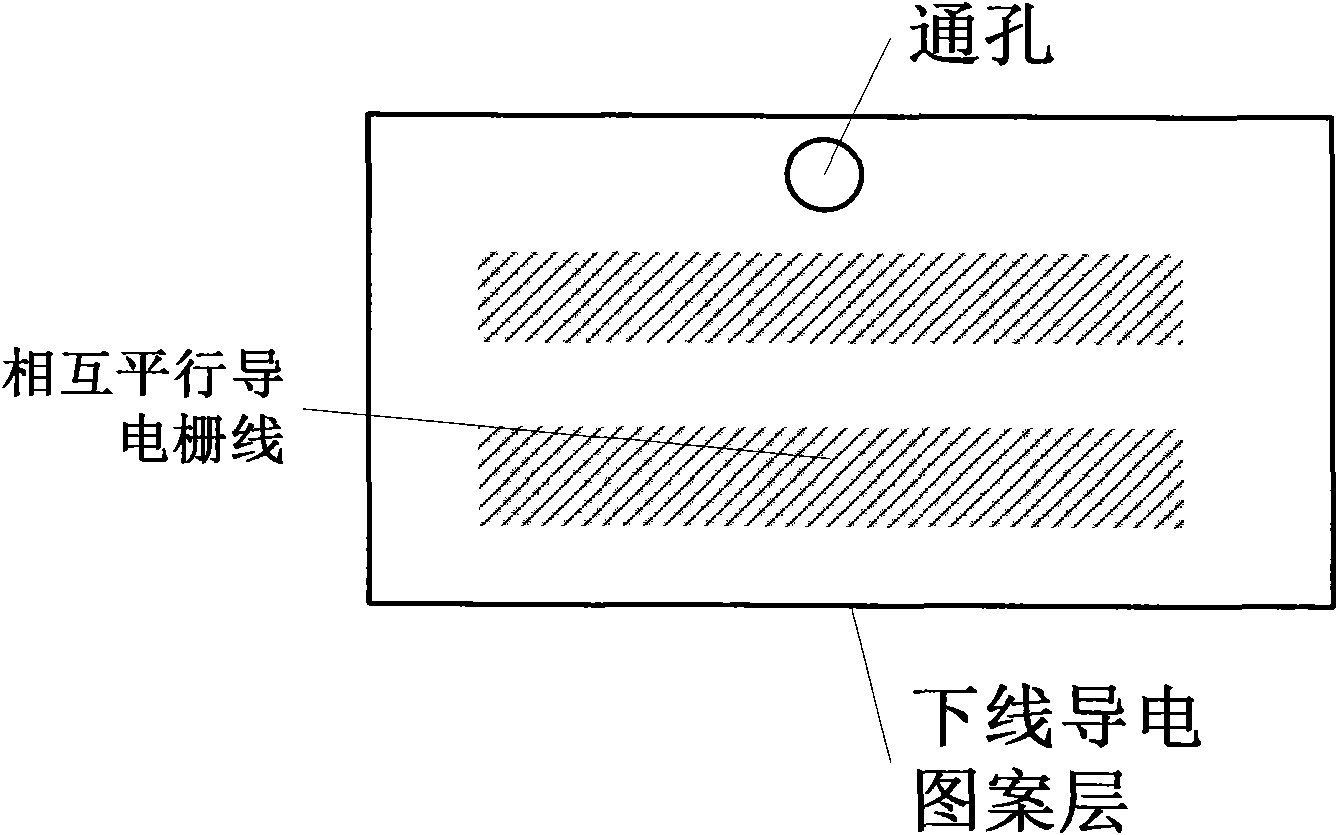

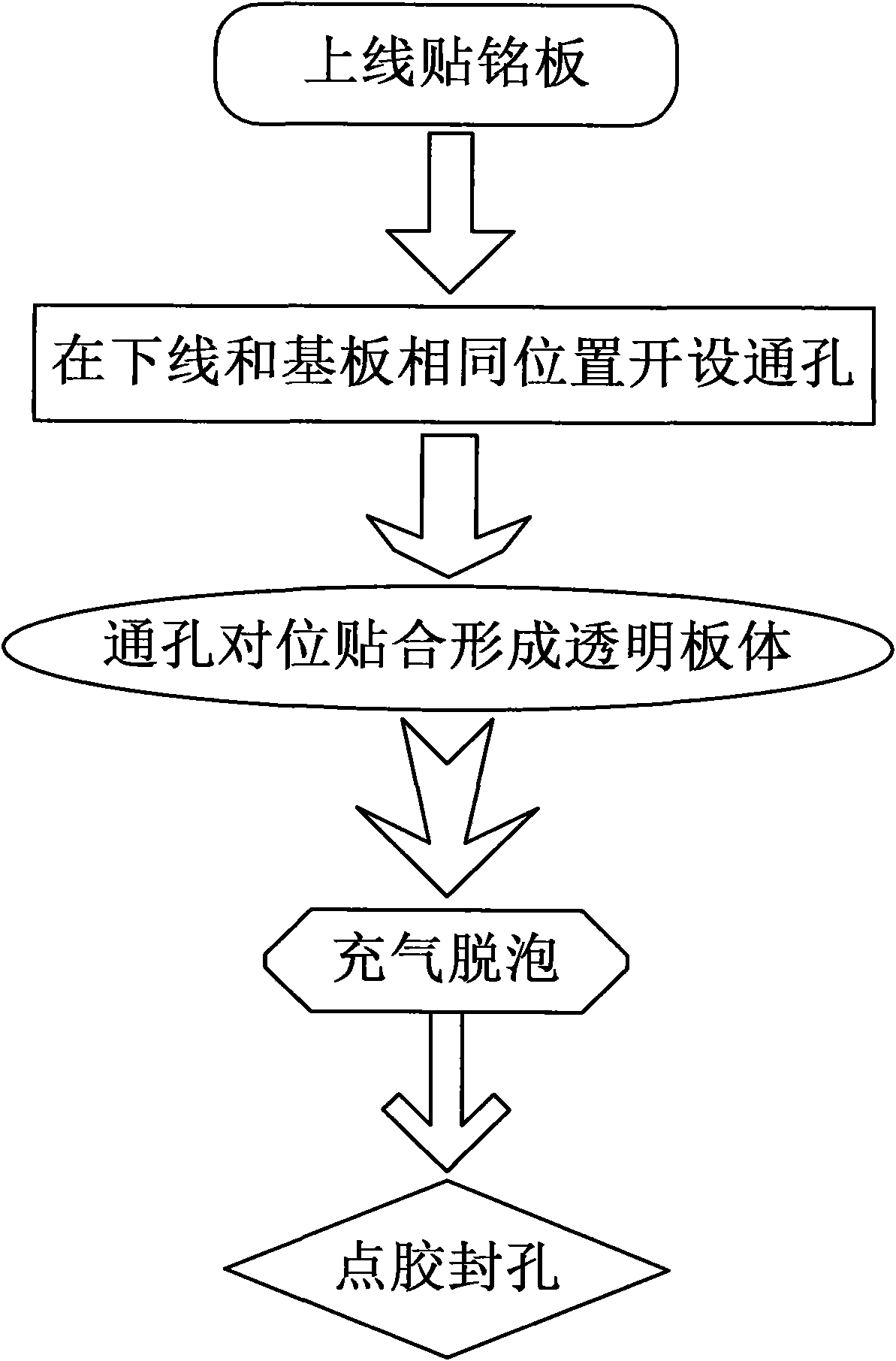

Large touch panel with through holes and manufacture method thereof

InactiveCN101901078AReduce manufacturing costStrong penetrating powerInput/output processes for data processingNewton's ringsEngineering

The invention discloses a large touch panel with through holes and a manufacture method thereof, belonging to the technical field of touch panel composite layer structures and manufacture processes thereof. The large touch panel with through holes comprises a first layer as a nameplate layer, a second layer as a top thread conducting pattern layer, a third layer as a bottom thread conducting pattern layer and a fourth layer as a substrate layer, wherein through holes are arranged at the same positions on the peripheries of the bottom thread conducting pattern layer and the substrate layer. The touch panel is provided with the through holes to realize the sealing state of inner air of the touch panel body and eliminate adverse phenomena of bubbles, load changes, the Newton's ring, and the like which are generated in the touch panel body.

Owner:牧东光电科技有限公司

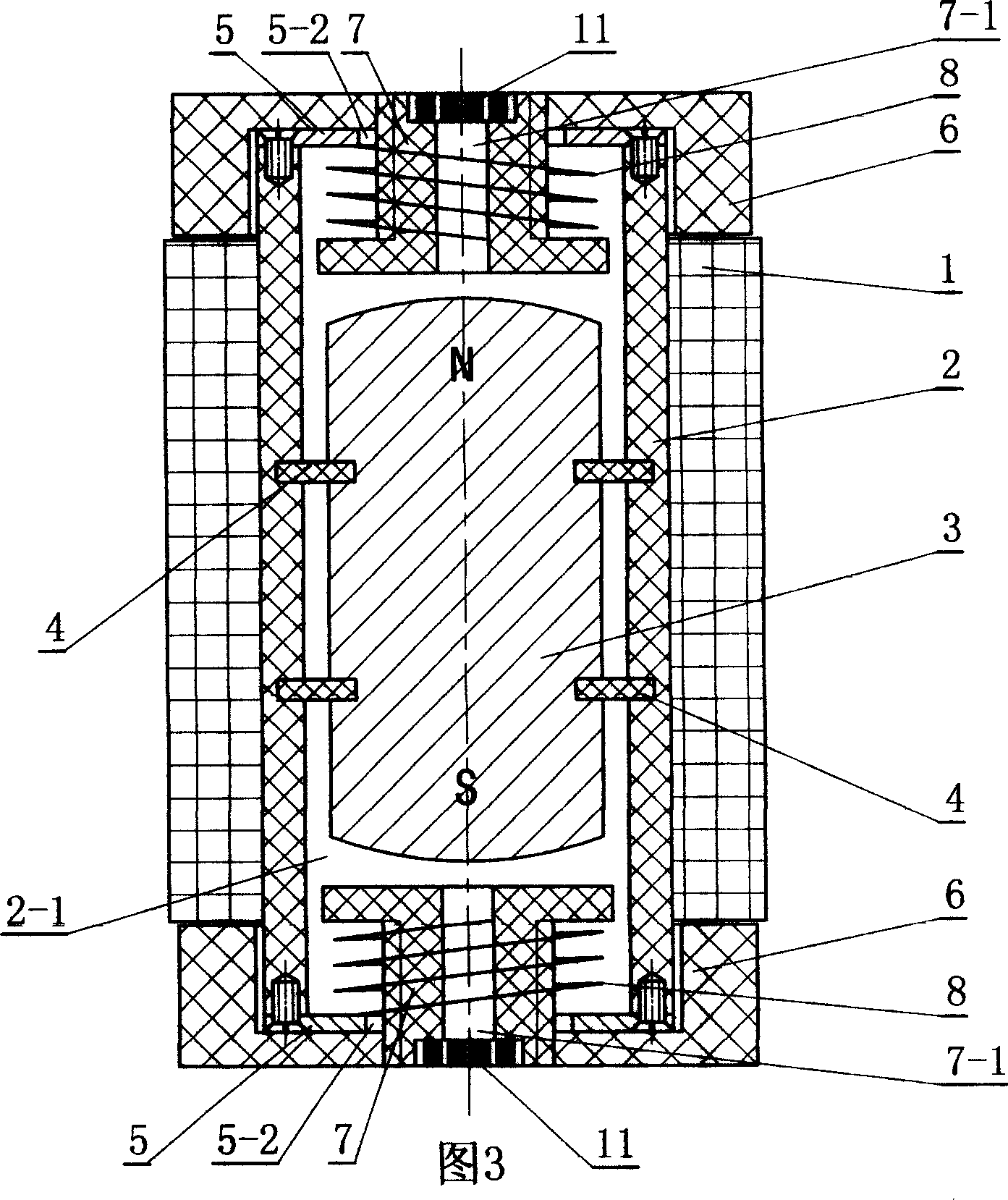

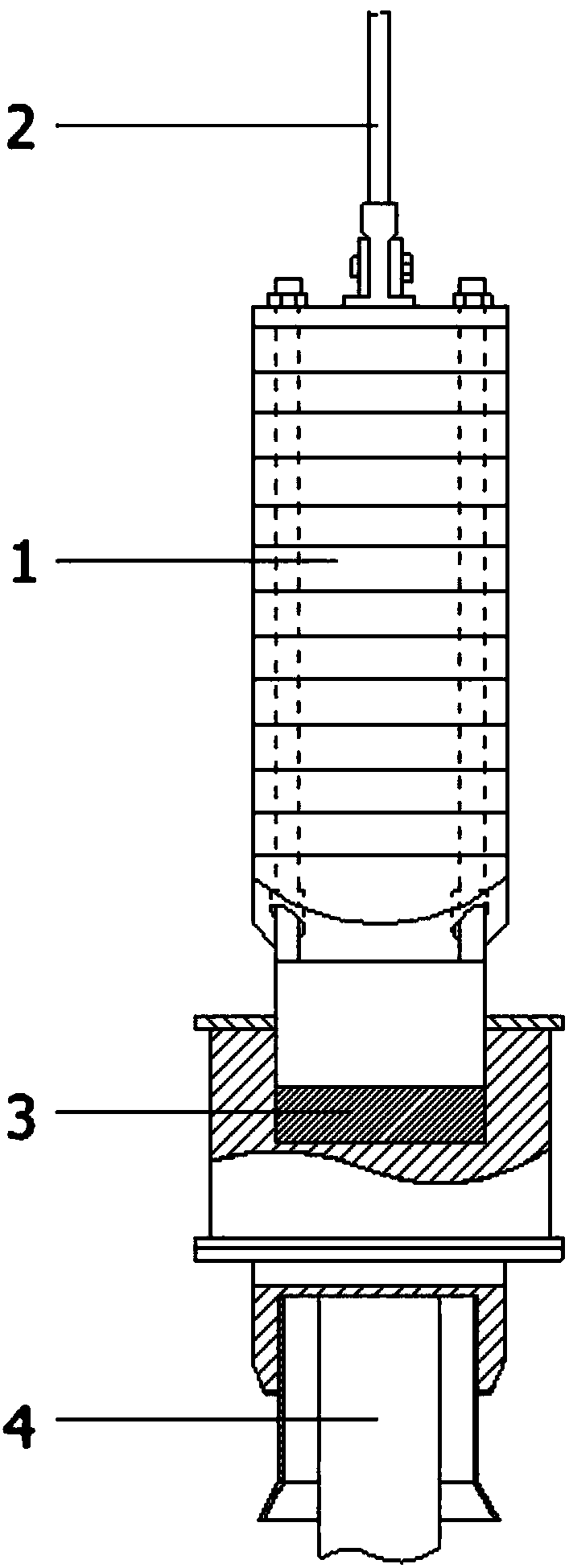

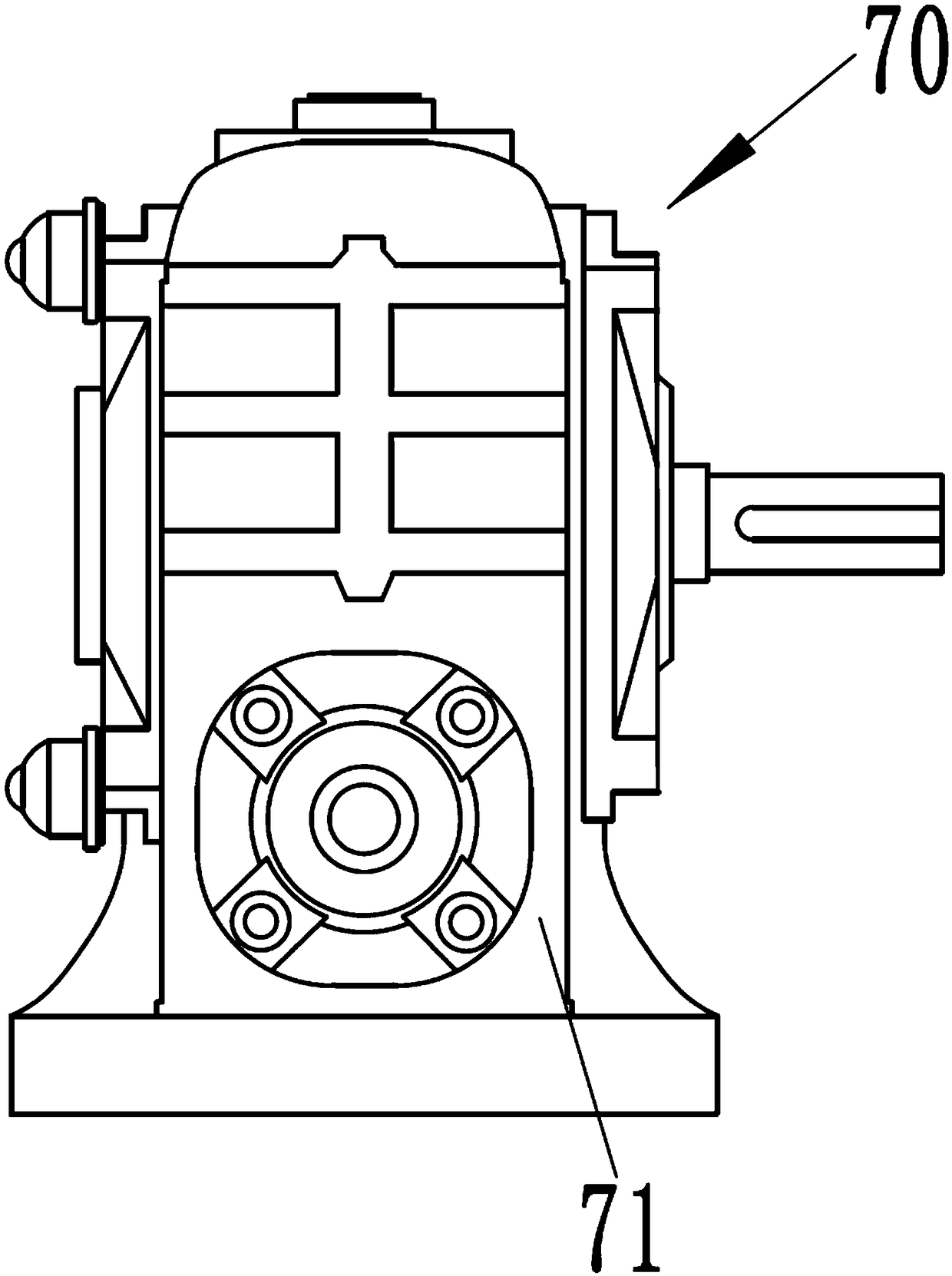

Damping and denoising air hammer

The invention provides a damping and denoising air hammer. The conventional air hammer has the defects of high noise, high vibration and large damages to walls of equipment in a hammering process. The damping and denoising air hammer comprises a shell (1), wherein the upper end of the shell is connected with an air inlet cover (2); the lower end of the shell is connected with a back substrate (3); an impact piston (4) is arranged inside the shell; the upper end of the impact piston absorbs a magnetic substrate (5) through electromagnetic force; the back substrate is provided with an exhaust opening (6); and the outer end of the back substrate is provided with a rubber pad (7). The damping and denoising air hammer is taken as a forging machine.

Owner:JIANGSU FUJIE HIGH-END EQUIP MFG (GRP) CO LTD

Vibration grinding method with active impact and rotational grinding of grinding medium

InactiveCN106345570AParticipating mass is smallReduce starting powerPreparing sample for investigationGrain treatmentsEngineeringSpring force

The invention relates to a vibration grinding method with active impact and rotational grinding of a grinding medium. A stepless speed regulation motor is used to drive an oscillating shaft, a grinding medium is arranged at the lower end of the oscillating shaft which is provided with an eccentric block, and the grinding medium and the eccentric block are fixed in a proper position of the oscillating shaft at a certain included angle, so that the excitation force mainly acts on the horizontal surface; and the grinding medium and the eccentric block rotate with the stepless speed regulation motor through a transmission device, and actively impact on a material under the action of the excitation force in a grinding chamber and generate rotational grinding with the rotation of the motor. The vibration grinding method provided by the invention has the advantages of high grinding efficiency, low energy consumption, fine grinding size, good spring force condition, and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Stable hydraulic pie driving equipment for buildings

InactiveCN107761730AAvoid damageRealize secondary piling operationBulkheads/pilesContact padEngineering

The invention provides stable hydraulic pile driving equipment for buildings. The stable hydraulic pile driving equipment comprises a hydraulic pile driver hammer mechanism and fixing bolts, wherein an oil cylinder piston rod is fixedly connected to the top of the hydraulic pile driver hammer mechanism, the bottom of the hydraulic pile driver hammer mechanism is in contact with a hammer pad, and apile is arranged under the hammer pad; a buffering protection pad with the same diameter as the inner rings of annular pressure blocks is fixedly mounted at the axis of the bottom of an upper pressing plate through two fixing bolts; and a buffering protection pad with the same diameter as the inner rings of the annular pressure blocks is fixedly mounted at the axis of the top of a lower pressingplate through two fixing bolts. The number of the annular pressure blocks is but not limited to eight groups and can be adjusted through increase / reduction. The height of a hollow cavity is changed bychanging the number of the annular pressure blocks, so that a steel wire mesh sleeve is temporarily separated from the bottom end surface of the hollow cavity when a hitting head descends to hit, andthen the top end surface of the hollow cavity exerts a stronger hitting force onto the steel wire mesh sleeve to facilitate improvement of the pile driving efficiency.

Owner:陈佳敏

Walnut shelling equipment

The invention relates to the field of food processing, and in particular relates to walnut shelling equipment, comprising a frame, a telescopic cylinder, a material filling bucket, a shell breaking mechanism and a shell removing mechanism, wherein the shell breaking mechanism comprises a shell breaking block, a shell breaking rod and a push-and-pull cylinder; the shell breaking block is hinged onto the frame; the telescopic cylinder is hinged with the shell breaking block; a channel is arranged in an inclined mode in the shell breaking block, the bottom of the channel is vertically arranged, the outlet diameter of the channel is smaller than the inlet diameter of the channel, and the inlet of the channel is communicated with the material filling bucket; the shell removing mechanism comprises a collecting box, a cone-shaped body, a baffle plate, a motor and a support bar, the motor is fixed to the frame, one end of the support bar is fixedly connected with the motor, the other end of the support bar is fixedly connected with the bottom of the cone-shaped body, a ribbed plate is arranged on the peripheral wall of the cone-shaped body, the baffle plate is arranged below the cone-shaped body, and an opening is arranged where the baffle plate is in contact with the side wall of the collecting box. The technical scheme can ensure that different sizes of walnut shells can be crushed, and simultaneously the shells can be sufficiently separated from the walnut meat.

Owner:仁怀市龙井葫芦种植专业合作社

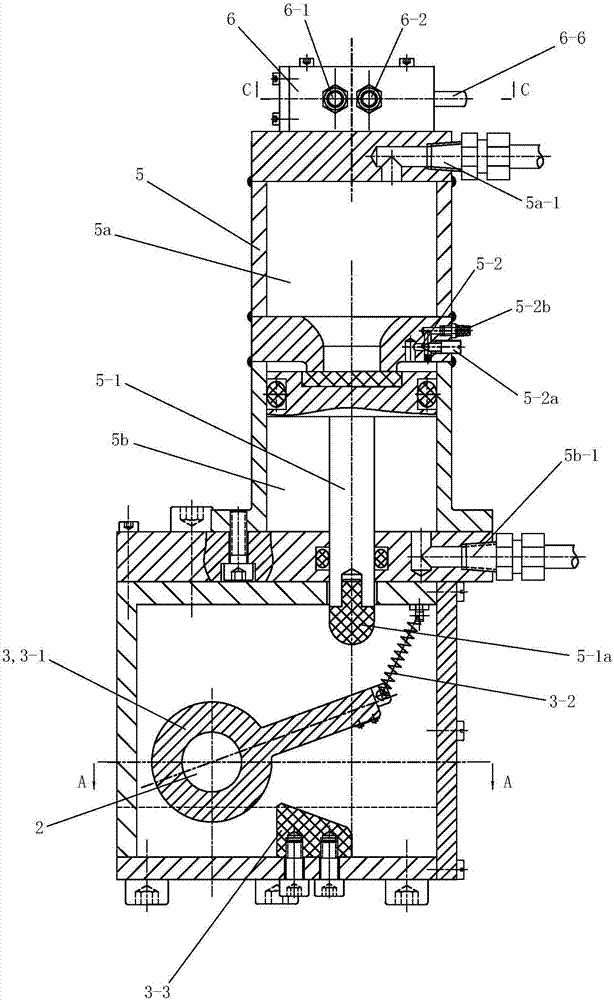

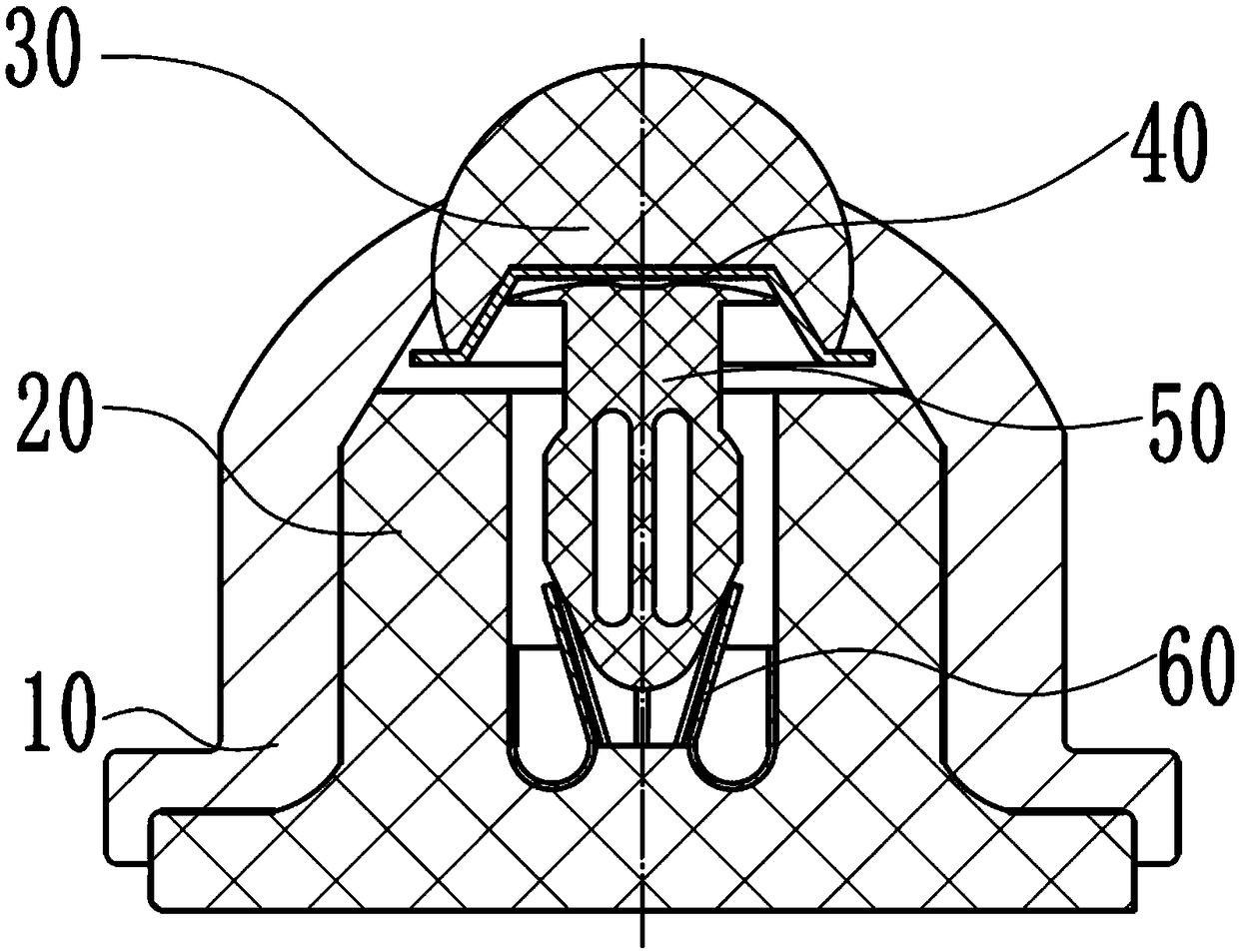

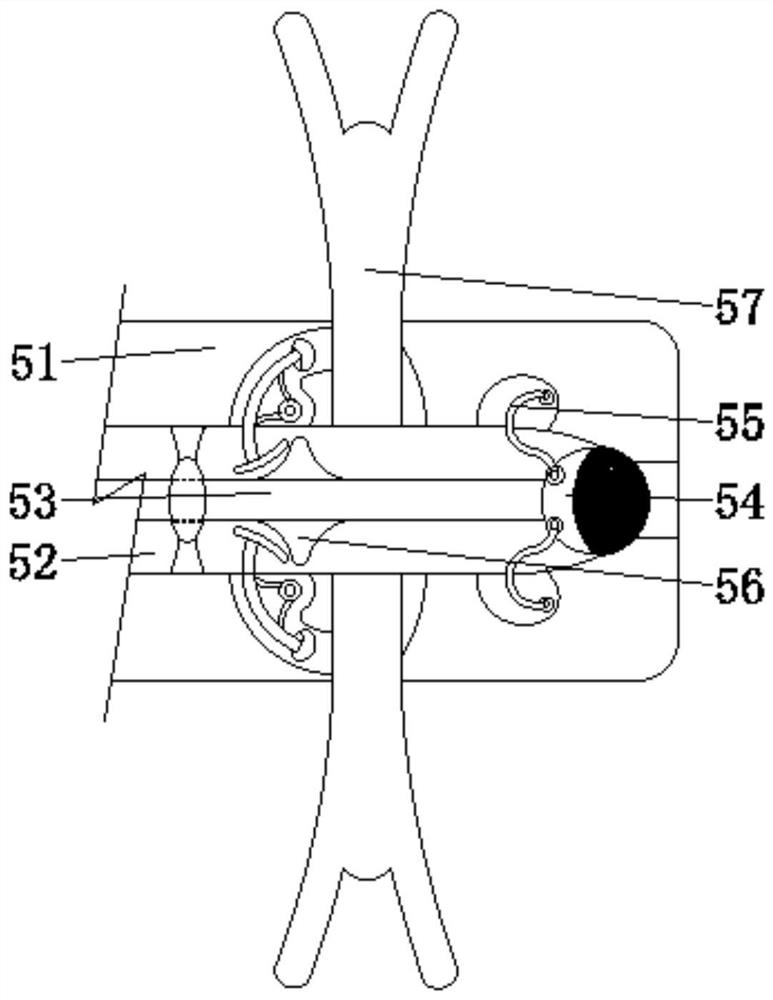

Pneumatic wrench

ActiveCN107962523AOvercome the defect of small torqueCompact structureSpannersWrenchesDrive shaftEngineering

The invention discloses a pneumatic wrench. The pneumatic wrench is characterized by comprising a shell, a transmission shaft, a driving mechanism, a ratchet mechanism, an impacting cylinder and a control device; the transmission shaft is rotationally arranged in the shell through a bearing correspondingly arranged in the shell; the two ends of the transmission shaft both stretch out of the shell;the front end of the transmission shaft is provided with a first square connection part capable of being provided with a corresponding replaceable sleeve; the rear end of the transmission shaft is provided with a second square connection part capable of being provided with a corresponding replaceable sleeve; a piston rod of the impacting cylinder impacts the driving mechanism; the driving mechanism drives the transmission shaft to rotate clockwise in one way through the ratchet mechanism; and the control device controls the impacting cylinder to work.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Speed reducer protection device

ActiveCN108662128AExtended service lifeReduce impact forceNon-rotating vibration suppressionGearing detailsReducerEngineering

The invention provides a speed reducer protection device which is glued to the outer surface of a reduction gearbox body of a speed reducer through glue. The protection device comprises a rubber base,a protection shell, a bearing part, a bee wing elastic part and a rubber body, the rubber base is sleeved with the protection shell, the bearing part installed in the rubber base, the lower portion of the bee wing elastic part abuts against the bearing part, the upper portion of the bee wing elastic part stretches out of the upper end face of the rubber base to extend upwards, the rubber body isplaced on the upper portion of the bee wing elastic part, and the rubber body penetrates through the upper portion of the protection shell to extend out of the protection shell. According to the speedreducer protection device, by adopting the structure, the surface of the speed reducer can be protected and prevented from being damaged, and therefore the service life of the speed reducer can be prolonged.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

Building sewage chemical treatment device

InactiveCN112957953AImprove responseEasy to handleRotary stirring mixersTransportation and packagingChemical treatmentArchitectural engineering

The invention discloses a building sewage chemical treatment device which comprises a machine body and an agent adding device, the agent adding device is fixed to the center of the top of the machine body, a driving rotating shaft, a conveying channel, a mixing device and a spiral blade are arranged in the machine body, and the driving rotating shaft is rotationally connected between two corresponding sides of the inner wall of the machine body and located in the center; and the top end of the driving rotating shaft is connected with the agent adding device in a matched mode through a rotating connector, the conveying channel is formed in the center of the interior of the driving rotating shaft, the mixing device is fixed to the surface of the driving rotating shaft, the agent adding device communicates with the mixing device through the conveying channel, and the spiral blade is fixed to the bottom of the surface of the driving rotating shaft. The invention relates to the technical field of sewage treatment. According to the chemical treatment device for the building sewage, the purpose of uniform mixing is achieved, reaction reagents can be rapidly and uniformly mixed, treatment of heavy metals in the sewage is facilitated, the sewage treatment effect is good, and the purification efficiency and the use performance are improved.

Owner:赵明兵

Steel strength detection device applied to ocean exploration ships near polar circles

ActiveCN109142096AIncrease authenticityDeformation size is easy to detectMaterial strength using single impulsive forceSurface oceanOcean exploration

The invention discloses a steel strength detection device applied to ocean exploration ships near polar circles. The device comprises a detection tank, wherein two ends of the top of the detection tank are connected with the same portal frame through bolts, the middle of the inner wall of the top of the portal frame is connected with a fixing ring through bolts, a connecting ring is arranged inside the circumference of the fixing ring in a sleeving manner, a swing rope is connected with the outer wall of the circumference of the connecting ring through a bolt, a pendulum bob is connected withthe end, away from the connecting ring, of the swing rope through a bolt, a beating block is welded on one side of the pendulum bob, a beating motor is connected with the middle of the outer wall of one side of the detection tank through bolts, and a beating bulging block is in bolt connection with one end of an output shaft of the beating motor. Detection authenticity is increased, the deformation size of a steel plate is convenient to detect, the detection accuracy rate of the deformation amount of the steel plate is improved, the pendulum bob is prevented from flying out of the detection tank or deviating and colliding with the inner wall of the detection tank, and accordingly, safety is improved.

Owner:安徽振瀚建设工程有限公司

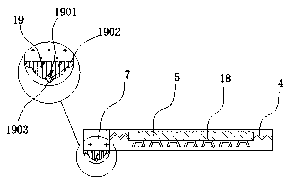

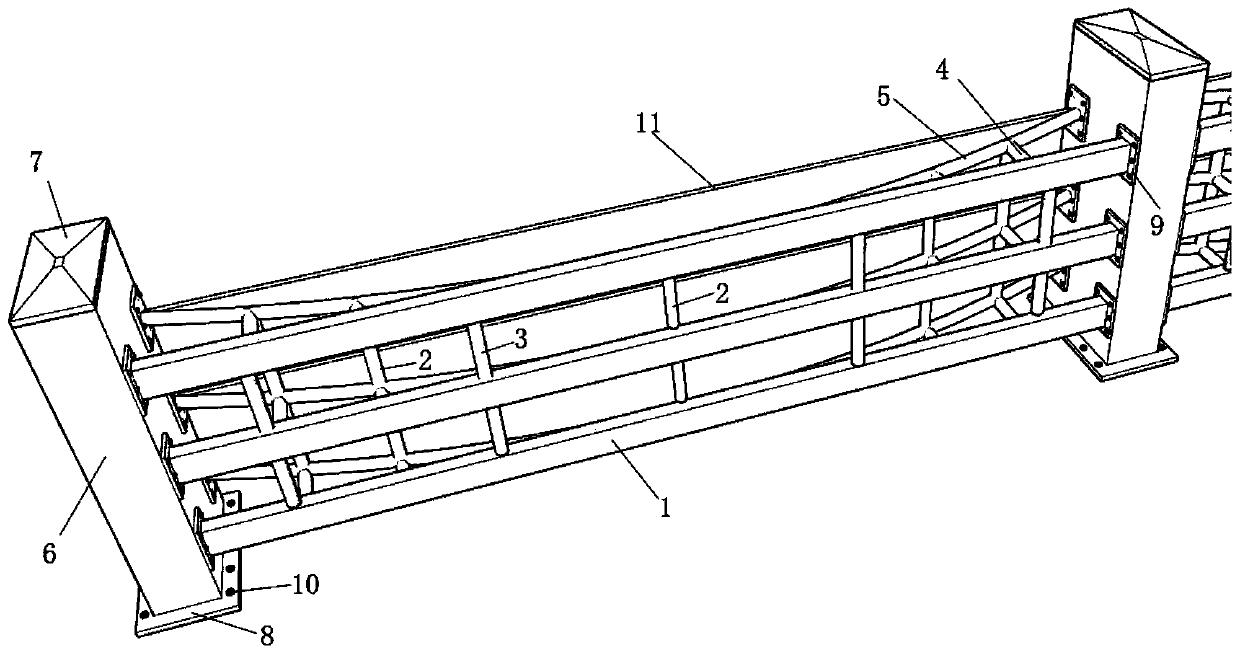

Semi-rigid bridge anti-collision guardrail

ActiveCN110578294ARelative displacement is smallIncrease impact forceBridge structural detailsBridge deckClerestory

The invention discloses a semi-rigid bridge anti-collision guardrail. The anti-collision guardrail comprises a plurality of guardrail steel framework structures which are sequentially connected, and the plurality of guardrail steel framework structures which are sequentially connected form a multiple arch structure; the guardrail steel framework structures comprise steel longitudinal beams, archedsteel pipes and two steel vertical columns, the two ends of the steel longitudinal beams are fixedly connected with the two steel stand columns respectively, and the two ends of the arched steel pipes are fixedly connected with the two steel vertical columns respectively; inhaul cables are anchored between the steel vertical columns at the two ends of the multiple arch structure; in the steel longitudinal beams, the arched steel pipes and the inhaul cables, the steel longitudinal beams are arranged close to one side of a bridge deck in the direction of the width of the bridge deck; the archedsteel pipes are arranged at a position,away from the bridge deck relative to the steel longitudinal beams; the arch tops of the arched steel pipes face one side of the bridge deck, steel pipe columnsfor transmitting force are connected between the arched steel pipes and the steel longitudinal beams, and the inhaul cables are arranged at a position far away from the bridge deck relative to the arched steel pipes. The problem that the anti-collision performance of the anti-collision guardrail is insufficient in the prior art is solved.

Owner:CHANGAN UNIV

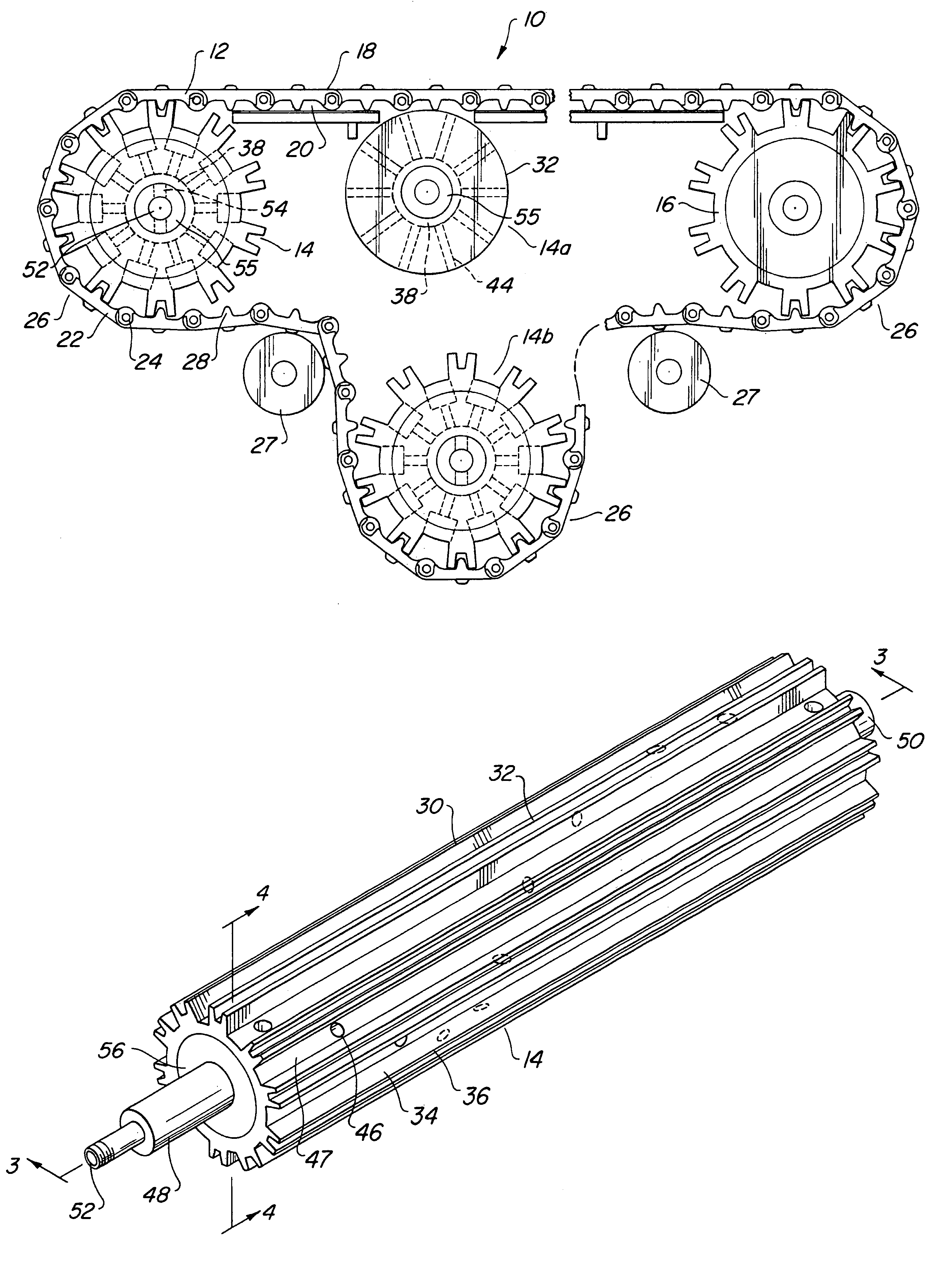

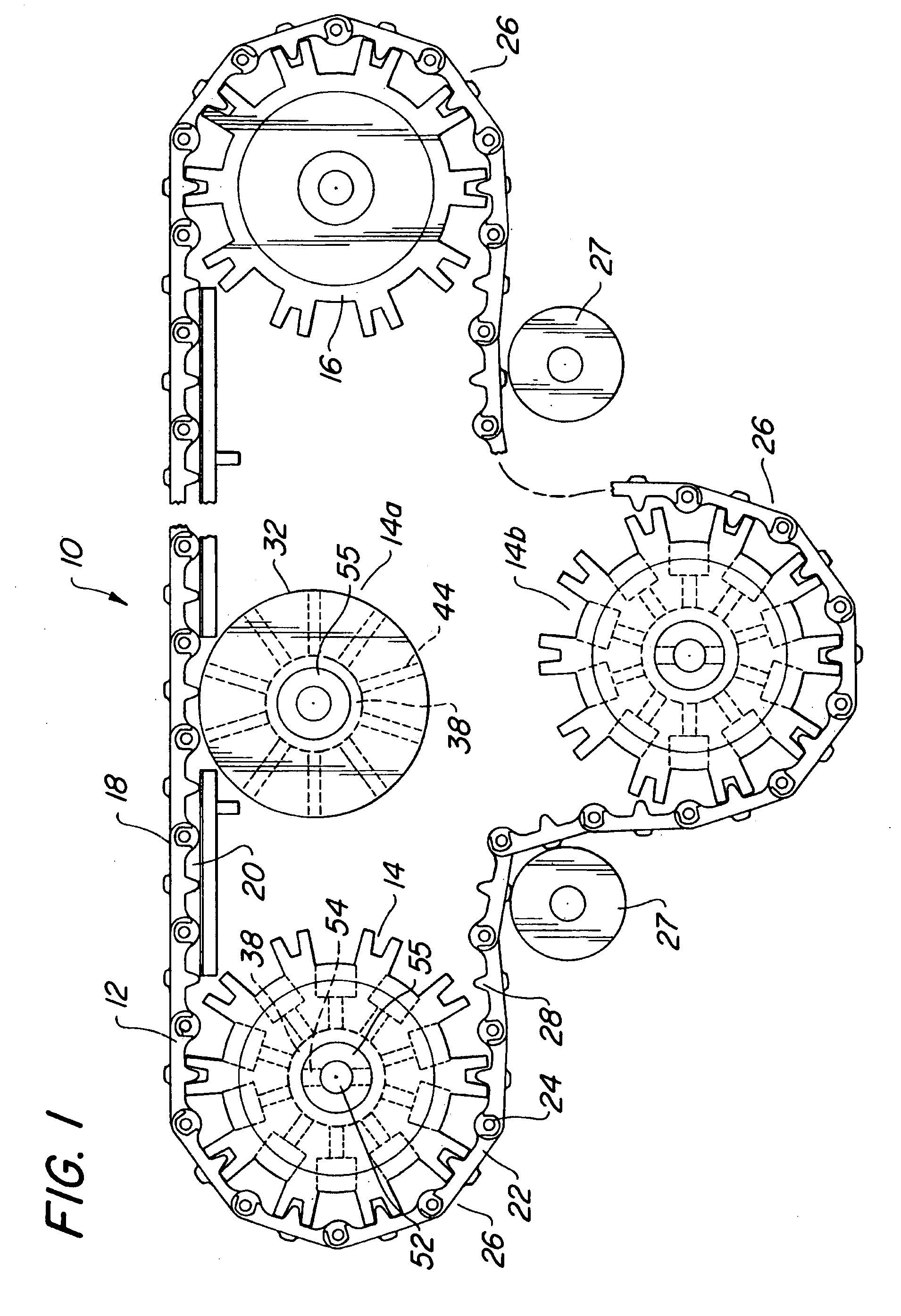

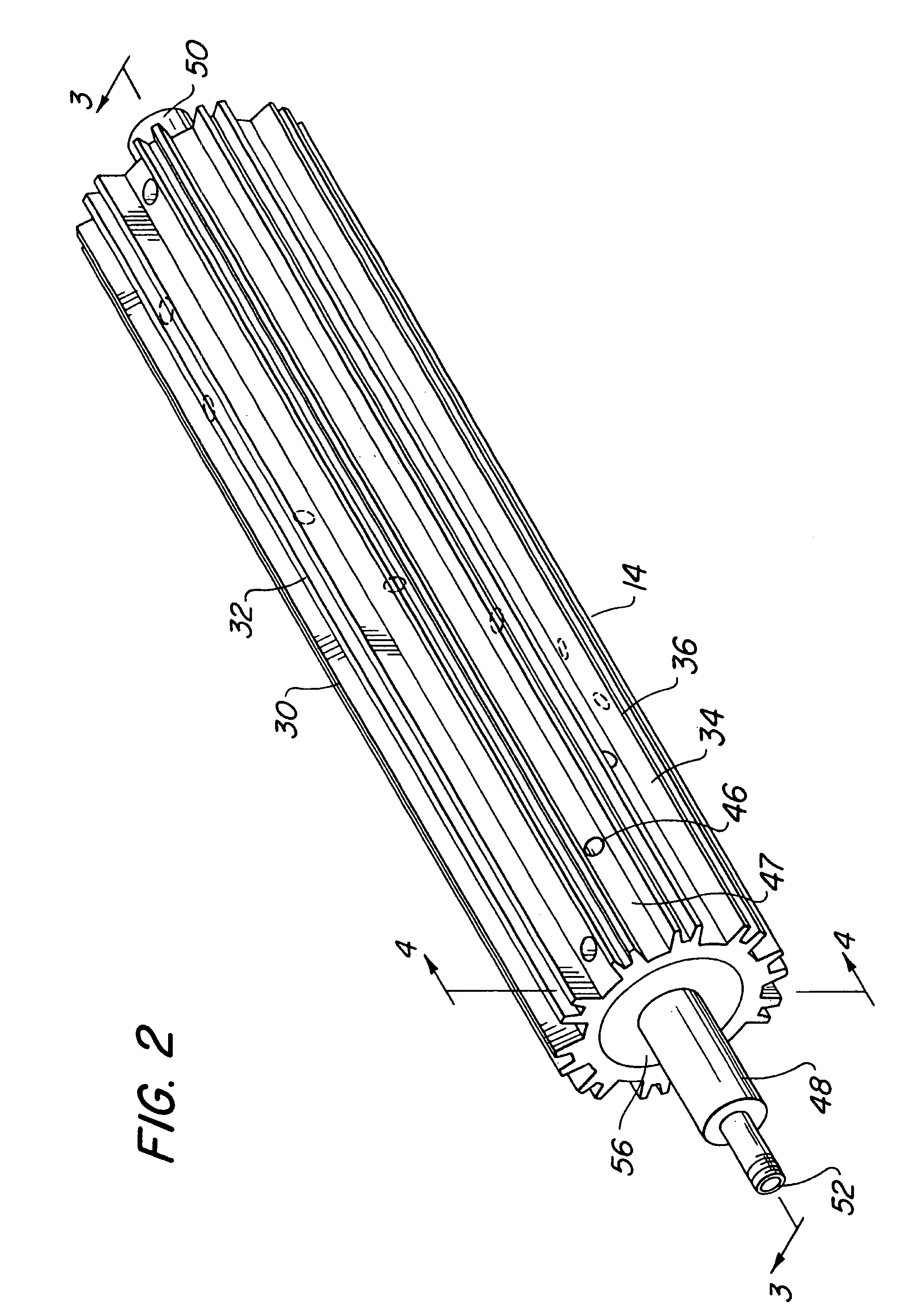

Conveyor and conveyor belt cleaning sprocket

A sprocket for an endless conveyor is disclosed having a plurality of fluid outlet passages arranged radially between the center of the sprocket and its outer circumferential surface. The outlet passages are positioned along the length of the sprocket in a helical path and are in fluid communication with an annular fluid conduit extending lengthwise along the center of the sprocket. A fluid inlet connected to the conduit supplies fluid under pressure to the conduit, the fluid spraying radially outwardly through the outlet passages to impinge on the inside surface of the endless conveyor and remove any accumulated debris. Nozzles are positioned within the outlet passages to control the fluid spray.

Owner:MONTGOMERY PRESTON D

Improved automatic crushing system for iron ore

The invention discloses an improved automatic crushing system for iron ore. The improved automatic crushing system comprises a box body, a first rope member, a second rope member, a first cylinder, afirst motor, a second motor, a crushing frame, a feeding system, wherein the box body comprises a lower plate, a left plate, a right plate, an upper plate, a front plate and a rear plate. The upper plate is provided with an impact frame in an inserted mode, the impact frame is provided with a gravity body, an impact plate is mounted at the bottom of the impact frame, and the impact plate is provided with a breaking hammer. One end of the first rope member is fixedly connected to the left side of the impact plate, and the other end of the first rope member is fixedly connected to the side wallof an output shaft of the first motor. One end of the second rope member is fixedly connected to the right side of the impact plate, and the other end of the second rope member is fixedly connected tothe side wall of an output shaft of the second motor. A left guide wheel is mounted on the left side of the upper plate, a right guide wheel is mounted on the right side of the upper plate, and a push plate is connected to the top of a telescopic rod of the first cylinder. The improved automatic crushing system can fully crush the iron ore to provide better preparation for resource extraction work in the iron ore.

Owner:郭文英

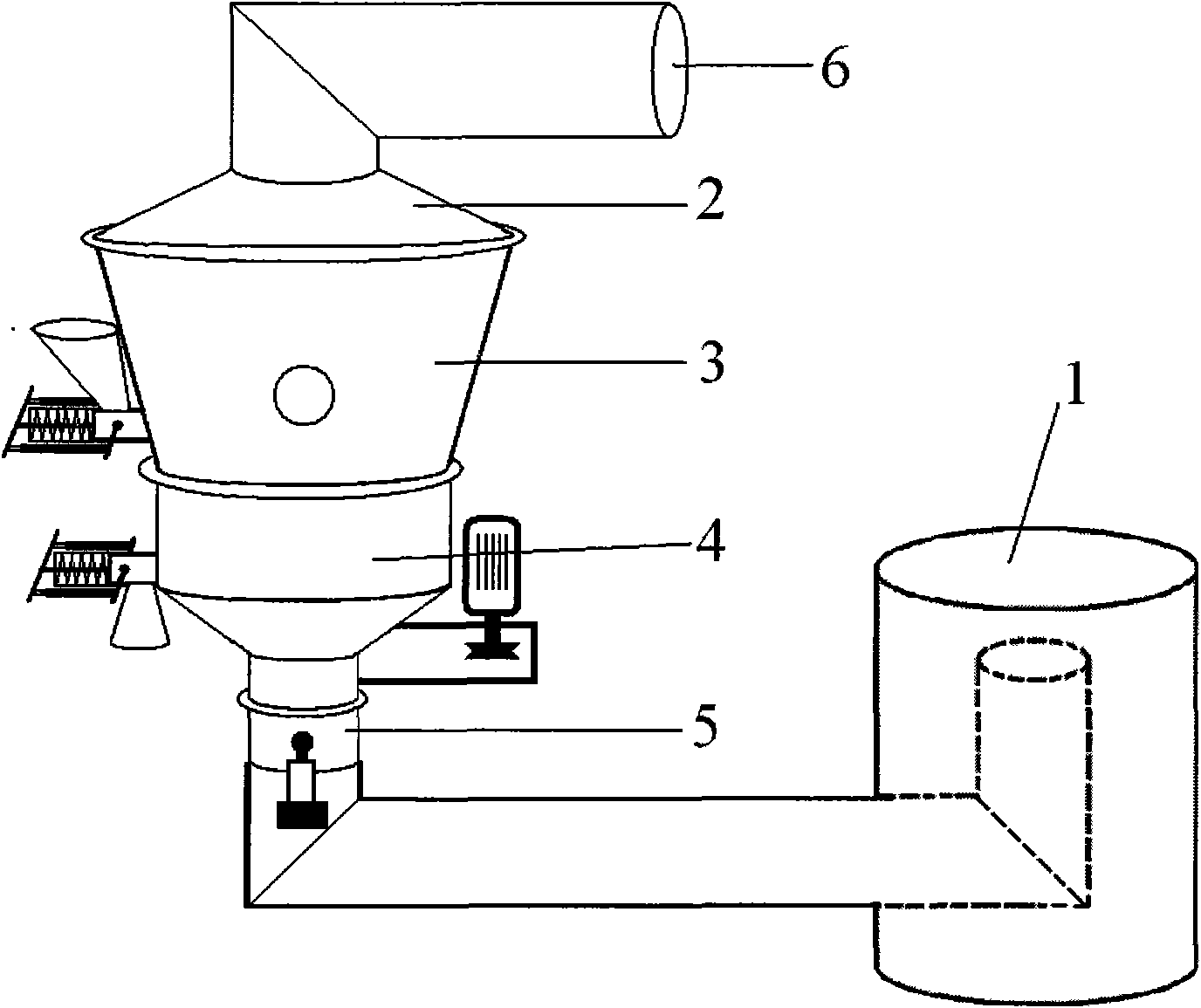

Rotary plate-type fluidization coating equipment

InactiveCN102107126ASpraying speed is fastGood sustained release effectGranulation by powder suspensionEngineeringViscosity

The invention relates to rotary plate-type fluidization coating equipment which is characterized in that: the effective air intake area of a heat source air inlet of the fluidization coating equipment is increased, so that the intensity of a fluidizing air flow of the fluidization coating equipment is increased; and the driving force of a rotary plate on coated particles is enhanced and simultaneously the impact force of a wall of a coating chamber on the coated particles is enhanced, so as to reduce the adhesion between the coated particles, as a result, although the viscosity of a coating liquid is high, the coating quality of the coated particles is guaranteed. The adaptation of the fluidization coating equipment to the coating liquids with different performances can be maximally improved; and the coatings of the coated particles are intact and have good slow release properties, which can effectively increase the coating efficiency.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com