Walnut shelling equipment

A walnut shelling technology, which is applied in the field of walnut shelling equipment, can solve the problems that the walnut shell cannot be guaranteed, and the complete separation of the shell and the pulp cannot be achieved, so as to achieve the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

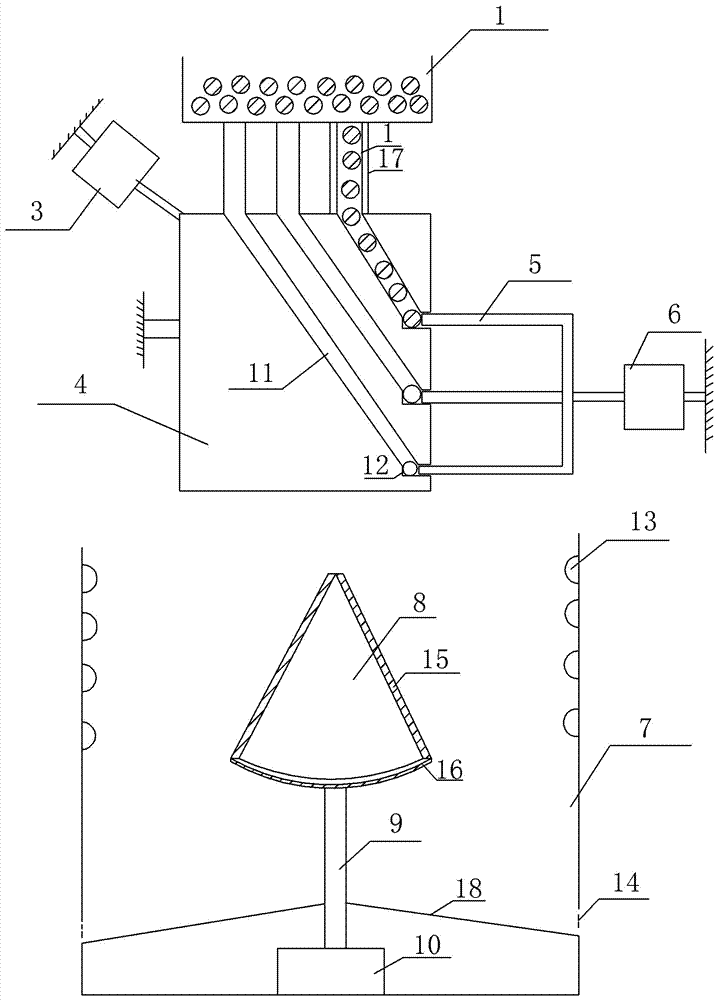

[0016] like figure 1 The shown walnut shelling equipment is provided with a frame, a hopper 1, a corrugated pipe 2, a telescopic cylinder 3, a shell breaking block 4, a shell breaking rod 5, a push-pull cylinder 6, and a collection chamber 7 from top to bottom. , Conical body 8, support rod 9, motor 10. The broken shell block 4 is hinged on the frame, and there are three channels 11 of different sizes inclined to the lower right in the broken shell block 4, the channel bottom 12 is vertically arranged, the channel bottom 12 is provided with a blower, the channel 11 exit is horizontally arranged, and the channel 11 The outlet diameter is smaller than the channel 11 inlet diameter. The hopper 1 is welded on the frame, the bottom of the hopper 1 is provided with an opening, and the opening is connected with the entrance of the channel 11 through the corrugated tube 2, and the corrugated tube 2 is covered with a plastic sleeve 17. The telescopic cylinder 3 is fixedly connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com