Large touch panel with through holes and manufacture method thereof

A touch panel, large-scale technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve electronic mechanism failures, affect the operation of the touch panel, easy to generate air bubbles, load changes and Newton Ring and other problems, to achieve the effect of improving support force, penetrating force and sensitivity, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

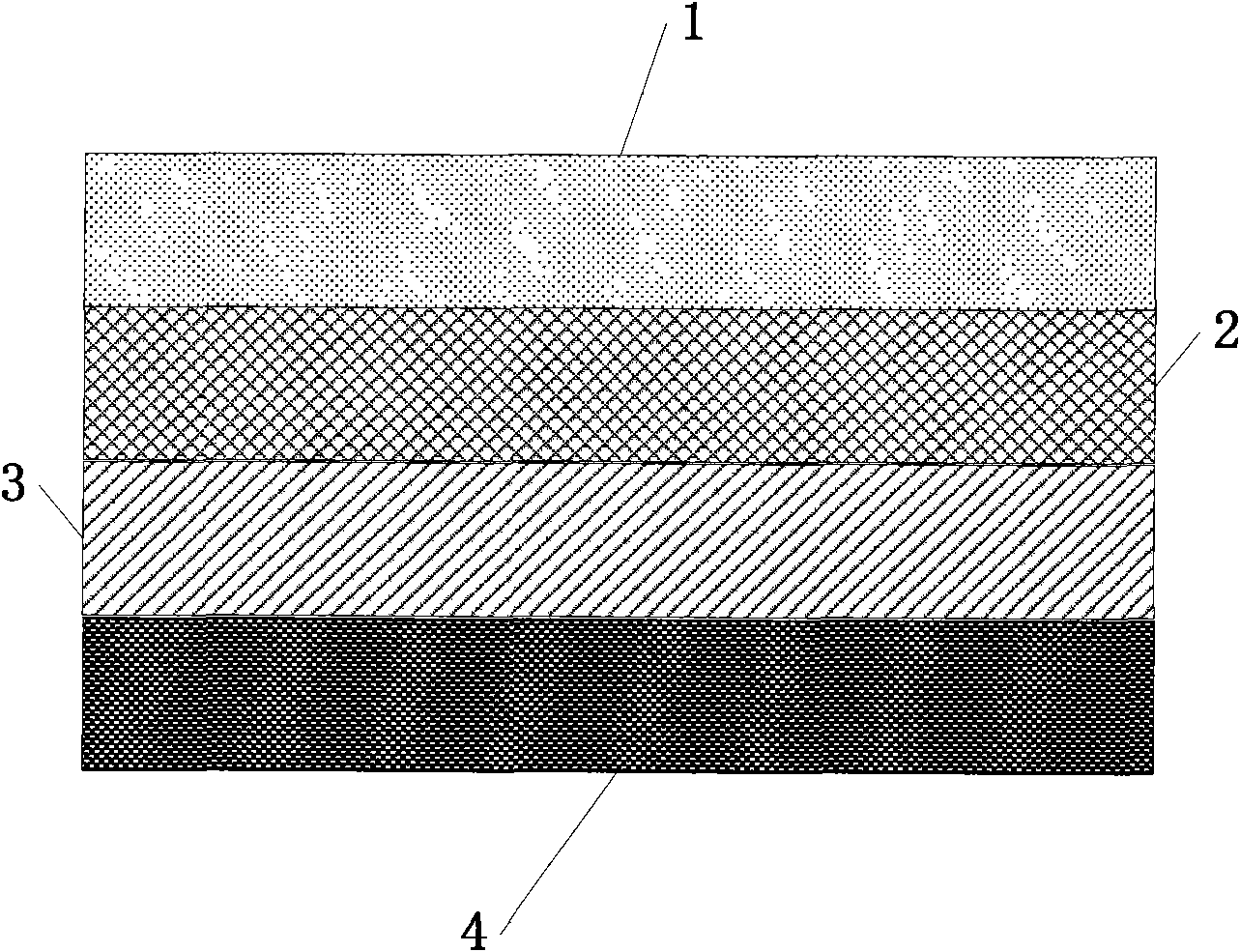

[0027] The thickness of the nameplate layer 1 is 0.125 mm; the thickness of the upper conductive pattern layer 2 and the lower conductive pattern layer 3 is 0.045 mm; the thickness of the substrate layer 4 is 0.3 mm, and the substrate layer 4 is hardened glass.

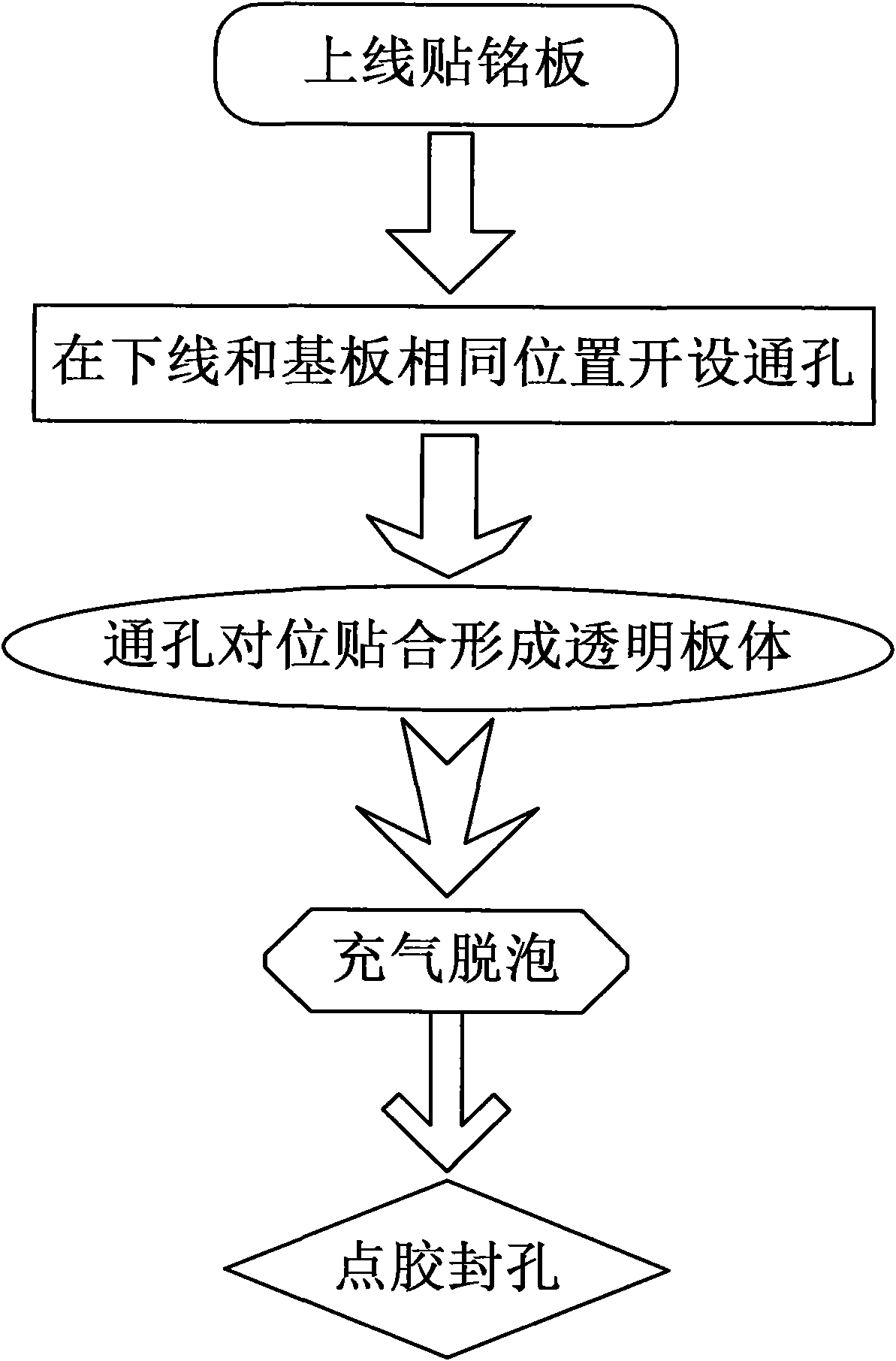

[0028] The method for manufacturing a large-size touch panel with a through hole, the following steps are carried out under dust-free and dry conditions:

[0029] Step 1: The nameplate layer 1 is attached to the upper line conductive pattern layer 2;

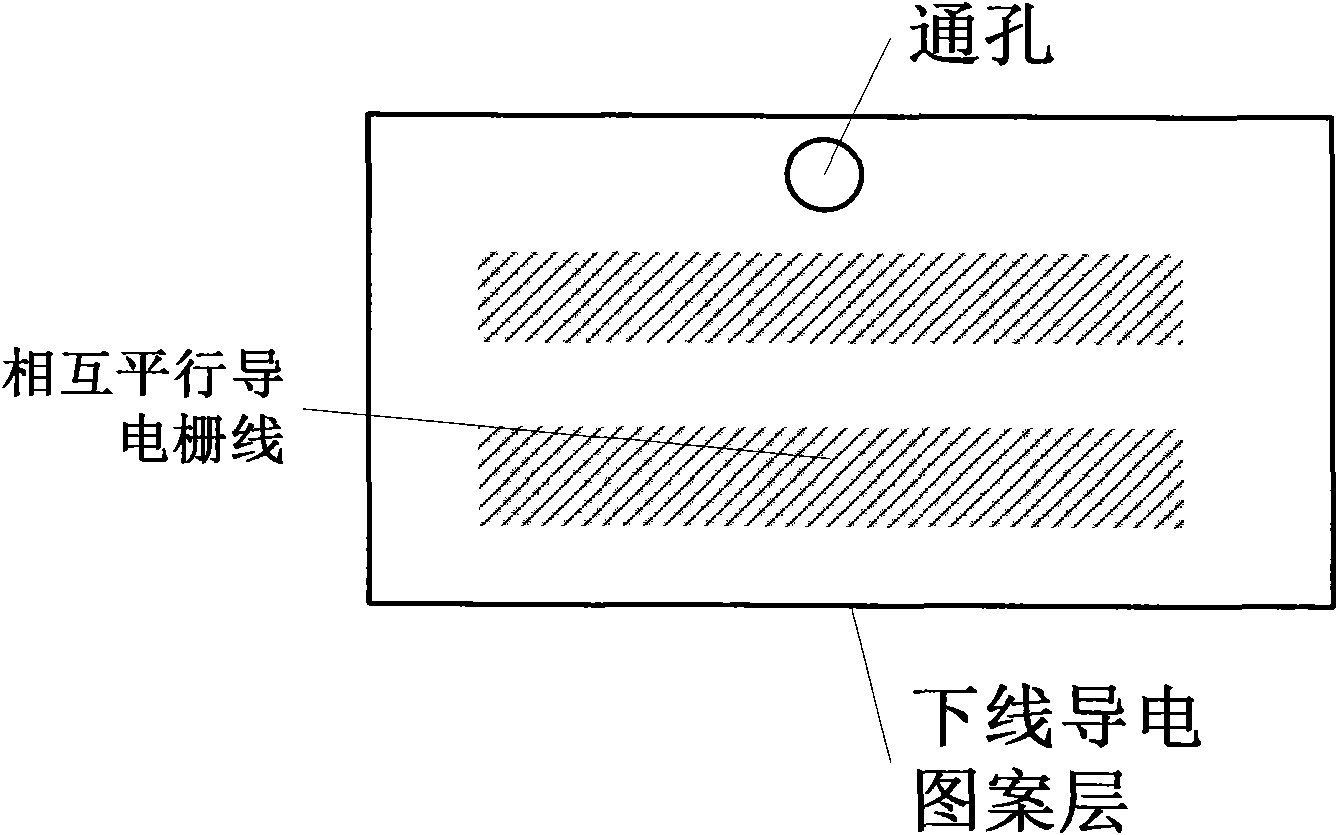

[0030] Step 2: Through the middle position of the lower conductive pattern layer 3 and the peripheral part of the substrate layer 4, the laser laser obtains a through hole; the through hole of the lower conductive pattern layer 3 and the through hole of the substrate layer 4 are aligned, and the lower conductive pattern layer 3 and the through hole of the substrate layer 4 are aligned. Lamination of substrate layer 4;

[0031] Step 3: The lower-line conductive pattern ...

Embodiment 2

[0035] The thickness of the nameplate layer 1 is 0.188 mm; the thickness of the upper conductive pattern layer 2 and the lower conductive pattern layer 3 is 0.188 mm; the thickness of the substrate layer 4 is 2.5 mm, and the substrate layer 4 is polycarbonate resin.

[0036] The method for manufacturing a large-size touch panel with a through hole, the following steps are carried out under dust-free and dry conditions:

[0037] Step 1: The nameplate layer 1 is attached to the upper line conductive pattern layer 2;

[0038] Step 2: Through the middle position of the lower conductive pattern layer 3 and the peripheral part of the substrate layer 4, the laser laser obtains a through hole; the through hole of the lower conductive pattern layer 3 and the through hole of the substrate layer 4 are aligned, and the lower conductive pattern layer 3 and the through hole of the substrate layer 4 are aligned. Lamination of substrate layer 4;

[0039] Step 3: The lower-line conductive pat...

Embodiment 3

[0043] The thickness of the nameplate layer 1 is 0.158 mm; the thickness of the upper conductive pattern layer 2 and the lower conductive pattern layer 3 is 0.128 mm; the thickness of the substrate layer 4 is 1.8 mm, and the substrate layer 4 is hardened glass.

[0044] The method for manufacturing a large-size touch panel with a through hole, the following steps are carried out under dust-free and dry conditions:

[0045] Step 1: The nameplate layer 1 is attached to the upper line conductive pattern layer 2;

[0046] Step 2: Through the middle position of the lower conductive pattern layer 3 and the peripheral part of the substrate layer 4, the laser laser obtains a through hole; the through hole of the lower conductive pattern layer 3 and the through hole of the substrate layer 4 are aligned, and the lower conductive pattern layer 3 and the through hole of the substrate layer 4 are aligned. Lamination of substrate layer 4;

[0047] Step 3: The lower-line conductive pattern ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com