Filtering material for dedusting and low-temperature denitration, and preparation method and application thereof

A filter material and low-temperature denitrification technology, applied in chemical instruments and methods, separation methods, filtration separation, etc., can solve the problems of reduced denitrification efficiency, reduced service life of filter materials, and impact on filter strength, etc., to achieve long service life and mechanical High strength and good filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

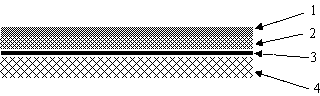

Image

Examples

Embodiment 1

[0036] Preparation of upper layer dust and non-filter surface layer: use polyphenylene sulfide fibers with an average diameter of 14.5μm, a strength of 4.5CN / dtex, and an elongation of 28% to process into a fiber web through opening, carding, laying, and pre-needling Respectively as the dust layer and the non-filter surface layer;

[0037] Preparation of the intermediate fabric reinforcement layer: use polyphenylene sulfide fibers with an average diameter of 14.5μm, a strength of 4.5CN / dtex, and an elongation of 28% to be spun, heat-set, and woven into a plain weave fabric as the intermediate fabric reinforcement layer;

[0038] Preparation of the catalytic layer: The catalyst particles composed of manganese salts and cobalt salts were hot-pressed on the polyphenylene sulfide fibers at a temperature of 350 °C for 15 minutes, and then the polyphenylene sulfide fibers with the above catalyst particles attached After opening, carding, laying, and pre-needling, it is processed int...

Embodiment 2

[0041] Preparation of dust-facing layer and non-filtering surface layer: fibers obtained by mixing polyphenylene sulfide with an average diameter of 14.5 μm, a strength of 4.1 CN / dtex, and an elongation of 35% and meta-aramid are opened and carded , Laying, pre-acupuncture and processing into fiber nets are used as dust-facing layer and non-filtering surface layer respectively;

[0042] Preparation of middle fabric reinforcement layer: mix polyphenylene sulfide fiber with average diameter of 14.5μm, strength of 4.1CN / dtex, and elongation of 35% with meta-aramid fiber, then spin, heat-set, and weave into plain weave fabric as an intermediate fabric reinforcement;

[0043] Preparation of the catalytic layer: The catalyst particles composed of manganese salt and cerium salt were hot-pressed on the fiber mixed with polyphenylene sulfide and meta-aramid at a temperature of 400°C for 8 minutes, and then attached The fiber of above-mentioned catalyst particle is processed into fiber...

Embodiment 3

[0047] Preparation of dust-facing layer and non-filtering surface layer: use polyphenylene sulfide fibers with an average diameter of 17.5μm, a strength of 4.8CN / dtex, and an elongation of 30% to process into a fiber web through opening, carding, web laying, and pre-needling Respectively as the dust layer and the non-filter surface layer;

[0048] Preparation of the intermediate fabric reinforcement layer: use polyphenylene sulfide fibers with an average diameter of 17.5μm, a strength of 4.8CN / dtex, and an elongation of 30% to be spun, heat-set, and woven into a plain weave fabric as the intermediate fabric reinforcement layer;

[0049] The preparation of the catalytic layer: firstly, the polyphenylene sulfide fiber is opened, carded, laid, and pre-needled to obtain a polyphenylene sulfide fiber web, and then the catalyst particles composed of manganese salt, molybdenum salt and zinc salt are heated at a temperature of Under the conditions of 350°C and 12min, hot pressing is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com