Hydraulic buffering device when automobile being bounced

A hydraulic buffer, automotive technology, applied in the direction of liquid shock absorbers, bumpers, etc., can solve the problems of increasing the failure probability of hydraulic buffer devices, complex structure of hydraulic buffer devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

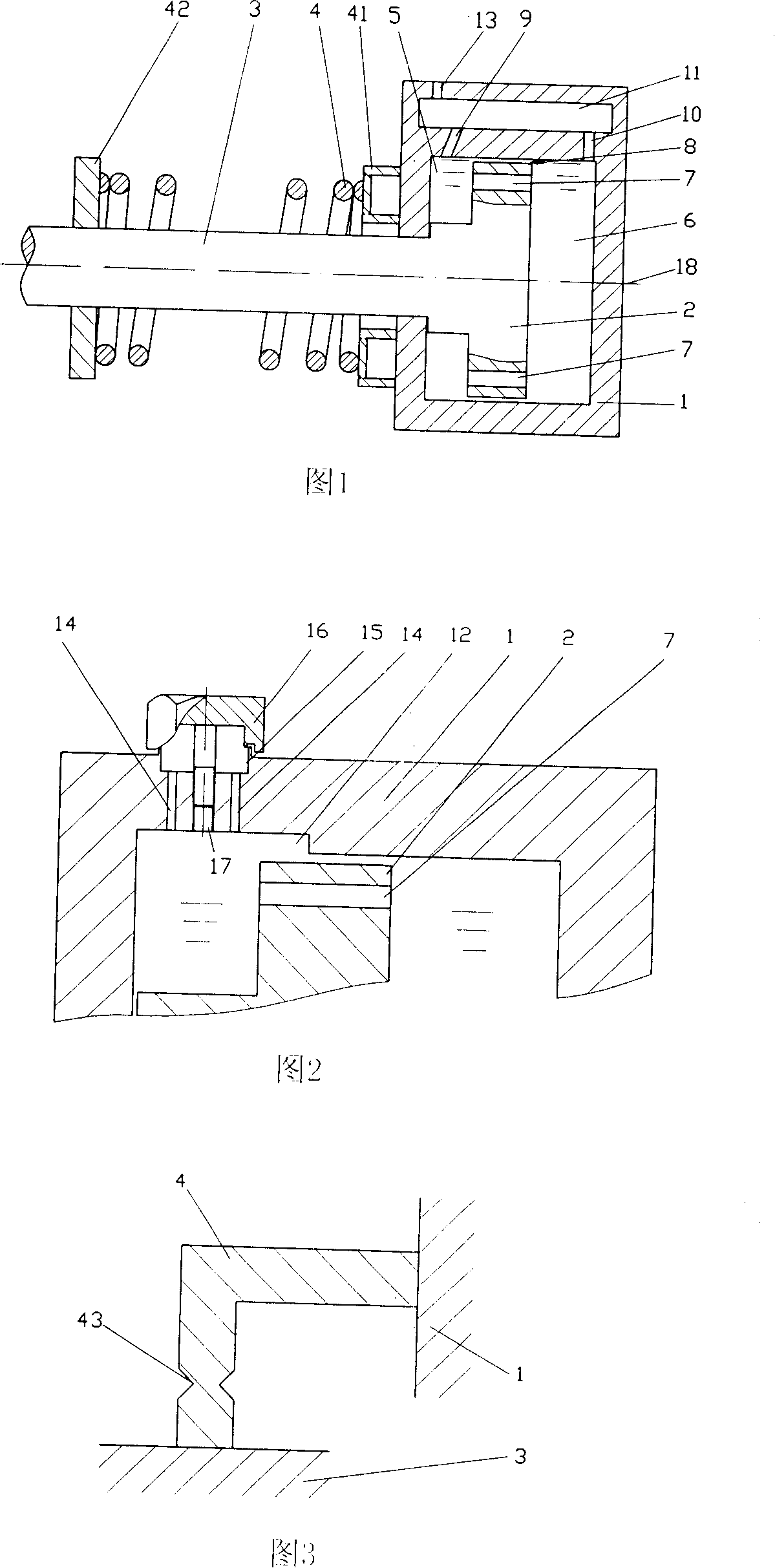

[0013] 1 is a schematic structural diagram of a hydraulic buffer device according to a preferred embodiment of the present invention. The piston cylinder is actually a device assembled from multiple components and sealing materials. The assembly method does not belong to the content of the present invention. For simplicity, Draw it as a whole in the figure. The section through the center line 18 of the piston 2 connected with the piston rod 3 is a convex shape, the piston 2 is placed in the piston cylinder 1, and the cooperation between the piston cylinder 1 and the piston rod 3 is a dynamic fit with an oil sealing function, There is a large gap 8 where the piston cylinder 1 and the piston 2 cooperate, and the internal space formed by the piston cylinder 1, the piston 2 and the piston rod 3 is called the piston cavity. The piston 2 divides the piston cavity into a front cavity 5 and a rear cavity 6. Four communication holes 7 are drilled on the piston 2 at symmetrical position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com