Method for deicing by using power circuit deicing device

A technology for power lines and deicers, used in cable installation, electrical components, overhead installation, etc., can solve problems such as the weakening of the bearing capacity of line towers or poles, endangering the safety of operators, and the collapse of line towers or poles. , to achieve the effect of large impact force, good deicing effect and large deicing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

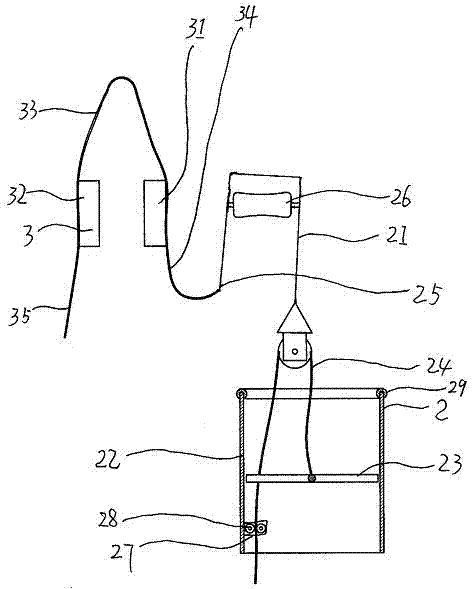

[0040] The structure and operating principle of the power line deicer of the present invention will be further described in detail below in conjunction with the accompanying drawings.

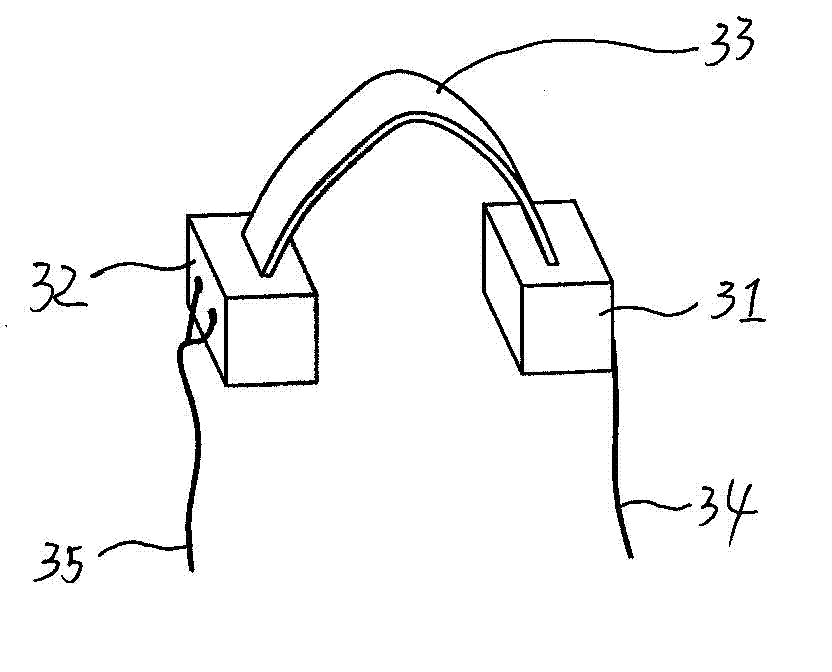

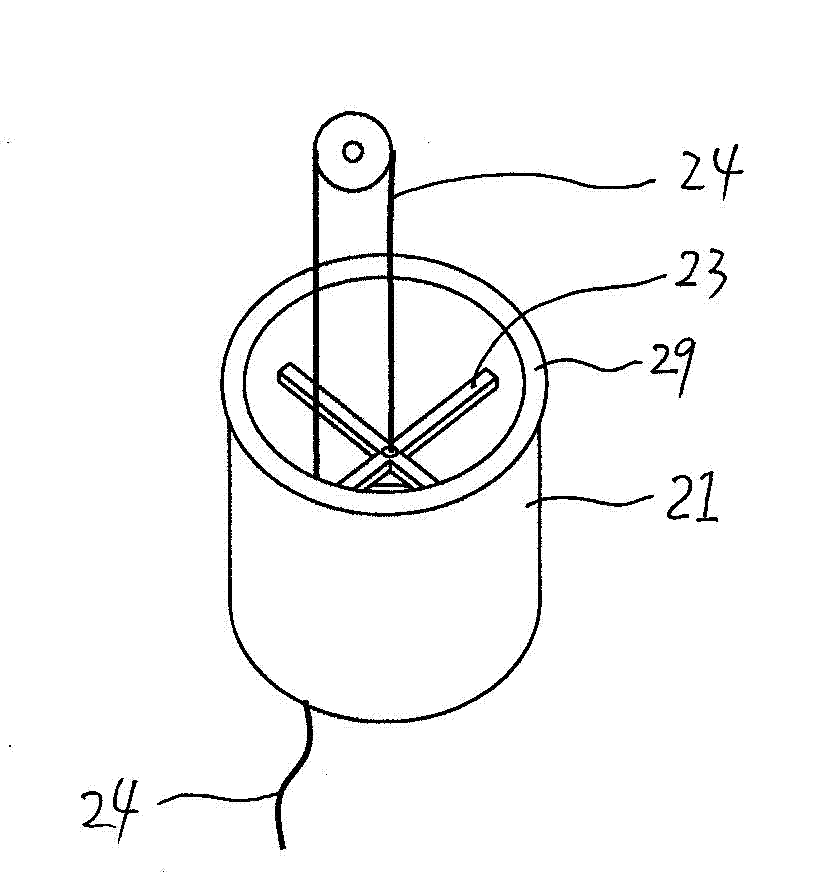

[0041] Such as figure 1 , figure 2 with image 3 As shown, the structure diagram of the power line deicer of the present invention includes a hanging point removal mechanism 3 and a deicing mechanism 2, and the hanging point removal mechanism 3 includes two hanging point removal hammers 31, 32, and the two hanging point removal hammers 31 , 32 are provided with connecting rope 33, are connected with sag rope 34,35 below hanging point removal hammer 31,32, and deicing mechanism 2 comprises somersault block 21 and deicing cylinder 22, closes in deicing cylinder 22 The middle position is provided with a suspension bracket 23, and the suspension bracket 23 is fixed with a stay rope 24 that bypasses the somersault block 21. The suspension end 25 of the somersault block 21 is connected with the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com