Stable hydraulic pie driving equipment for buildings

A kind of piling equipment and construction technology, applied in construction, sheet pile wall, foundation structure engineering, etc., can solve the problems of repeated piling operation, difficulty, etc., and achieve the effect of improving efficiency and reducing the probability of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

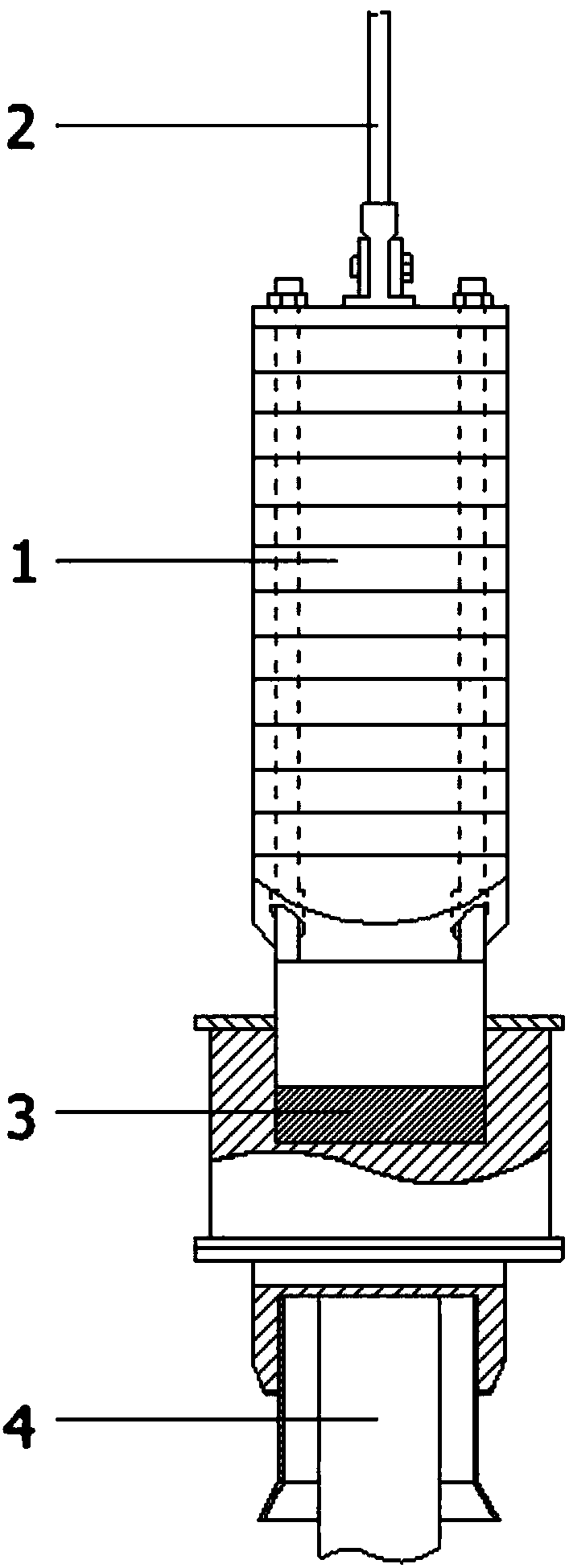

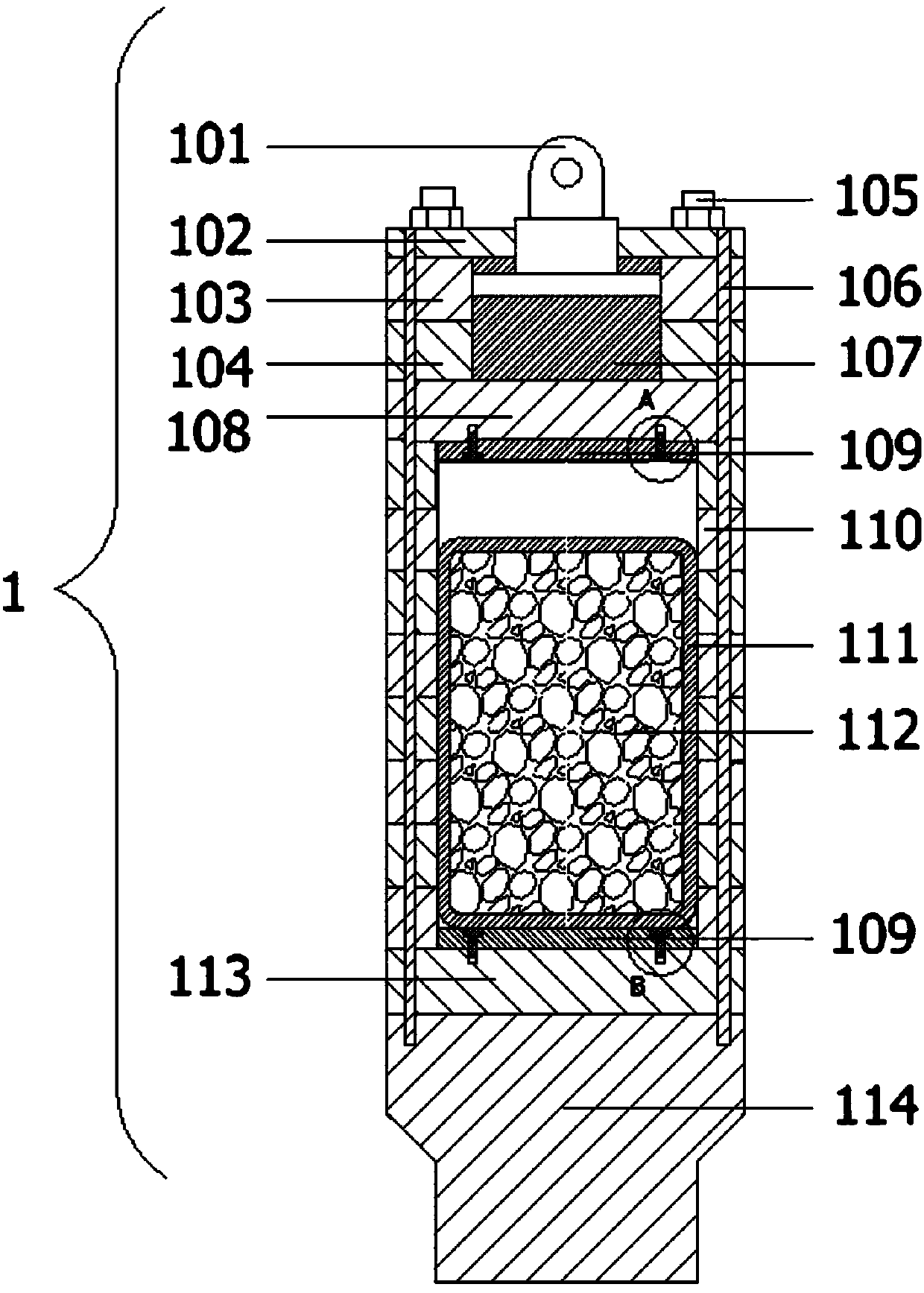

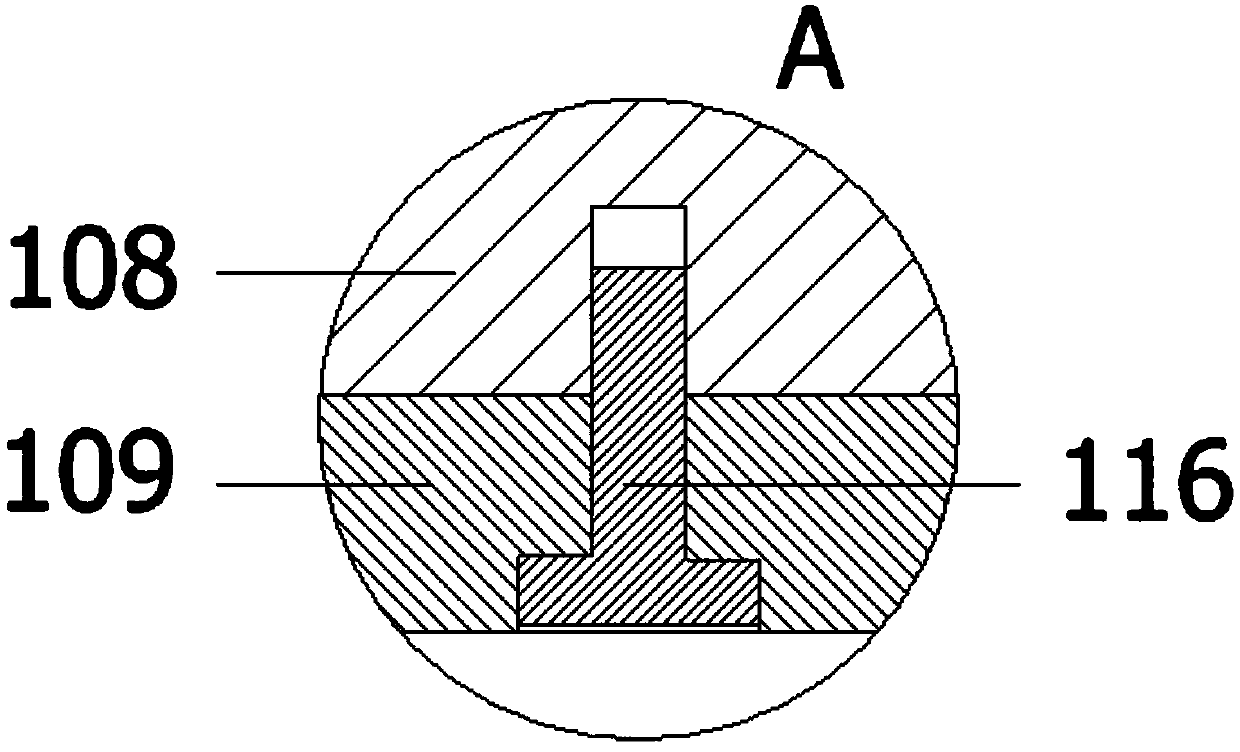

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034]The present invention provides stable hydraulic piling equipment for construction, comprising hydraulic pile driver hammer head mechanism 1, cylinder piston rod 2, hammer pad 3, pile 4, oil cylinder connection seat 101, fixed pressure plate 102, upper ring block 103, lower ring block 104, Bolt 105, fixed bolt 106, buffer pad 107, upper pressing plate 108, buffering protection pad 109, ring pressure block 110, steel wire mesh cover 111, metal particle filler 112, lower pressing plate 113, impact head 114, lock nut 115 and fixing Bolt 116; the top of the hammer head mechanism 1 of the hydraulic pile driver is fixedly connected with the cylinder piston rod 2, and the bottom of the hammer head mechanism 1 of the hydraulic pile driver contacts the hammer pad 3, and the pile 4 is below the hammer pad 3; the hydraulic pile driver The hammer head mechanism 1 is composed of an oil cylinder connecting seat 101, a fixed pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com