Patents

Literature

76results about How to "High purity powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

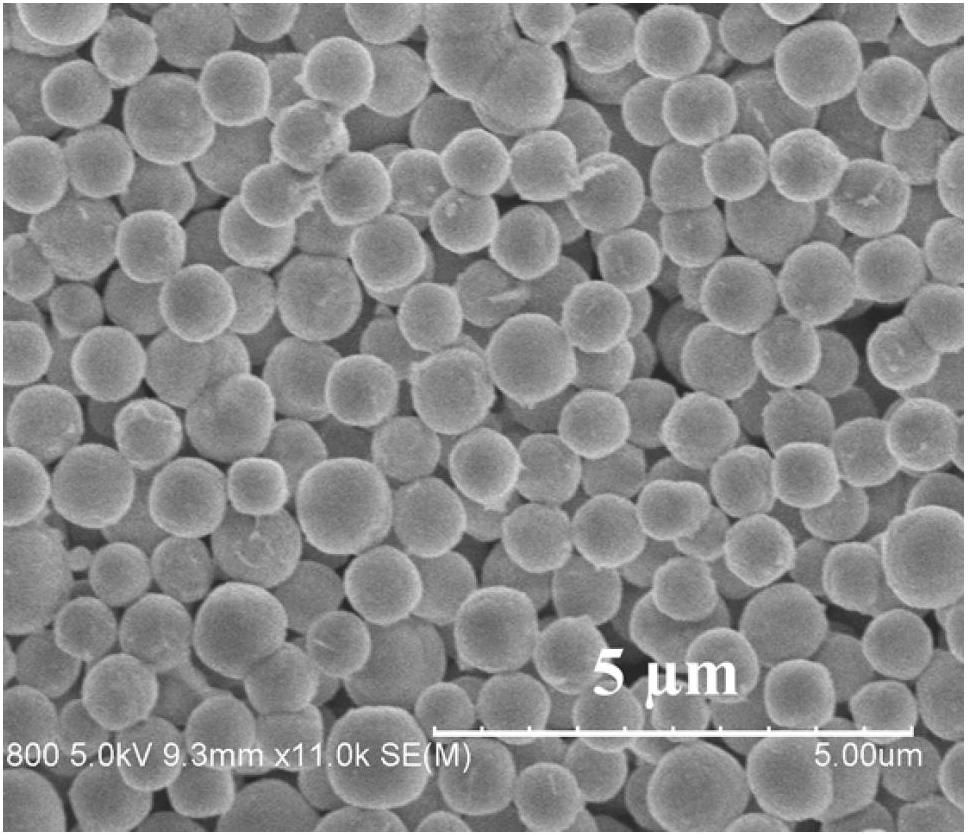

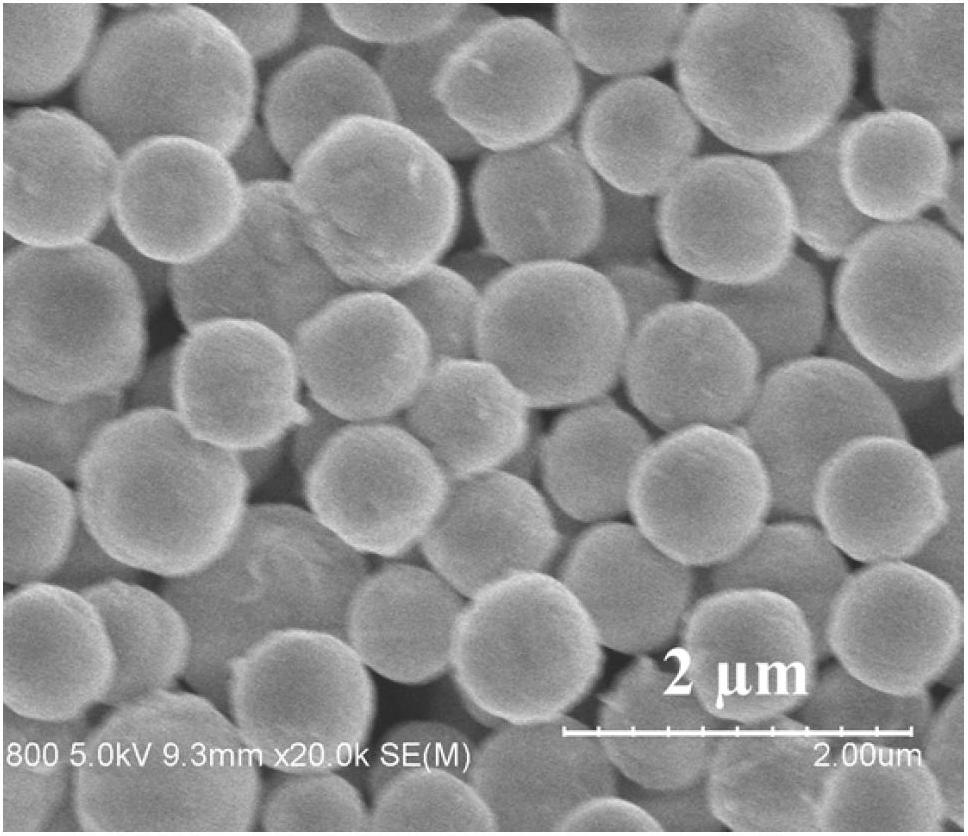

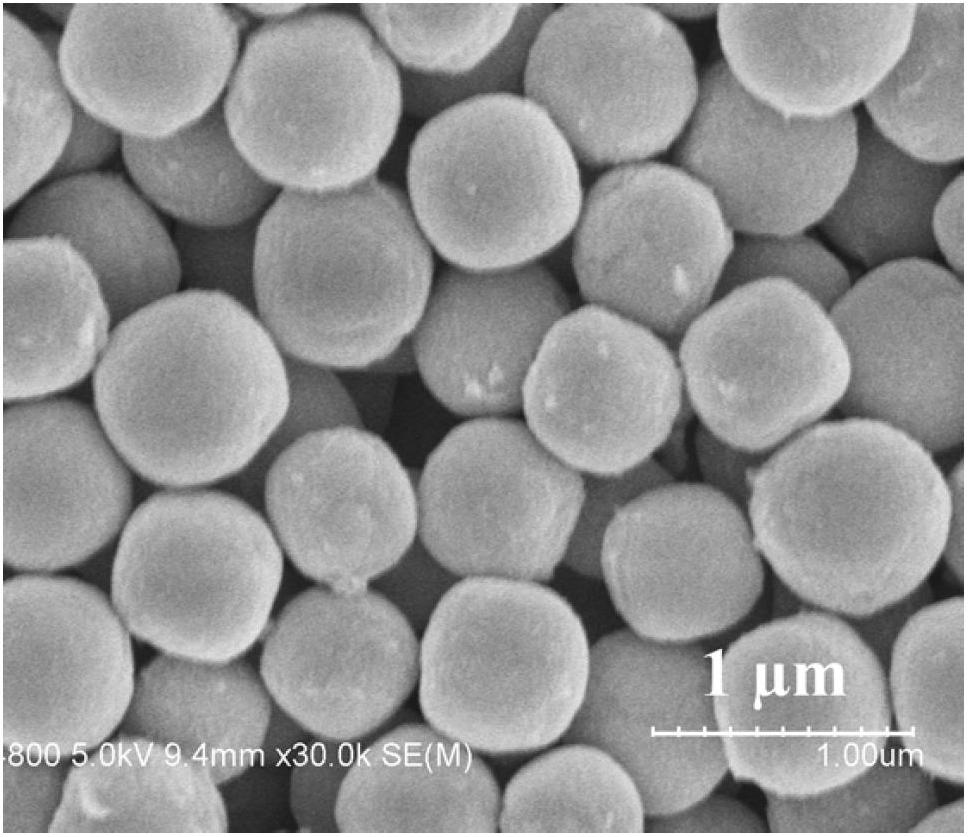

Preparation method of porous nickel oxide/tin dioxide micro/nano spheres

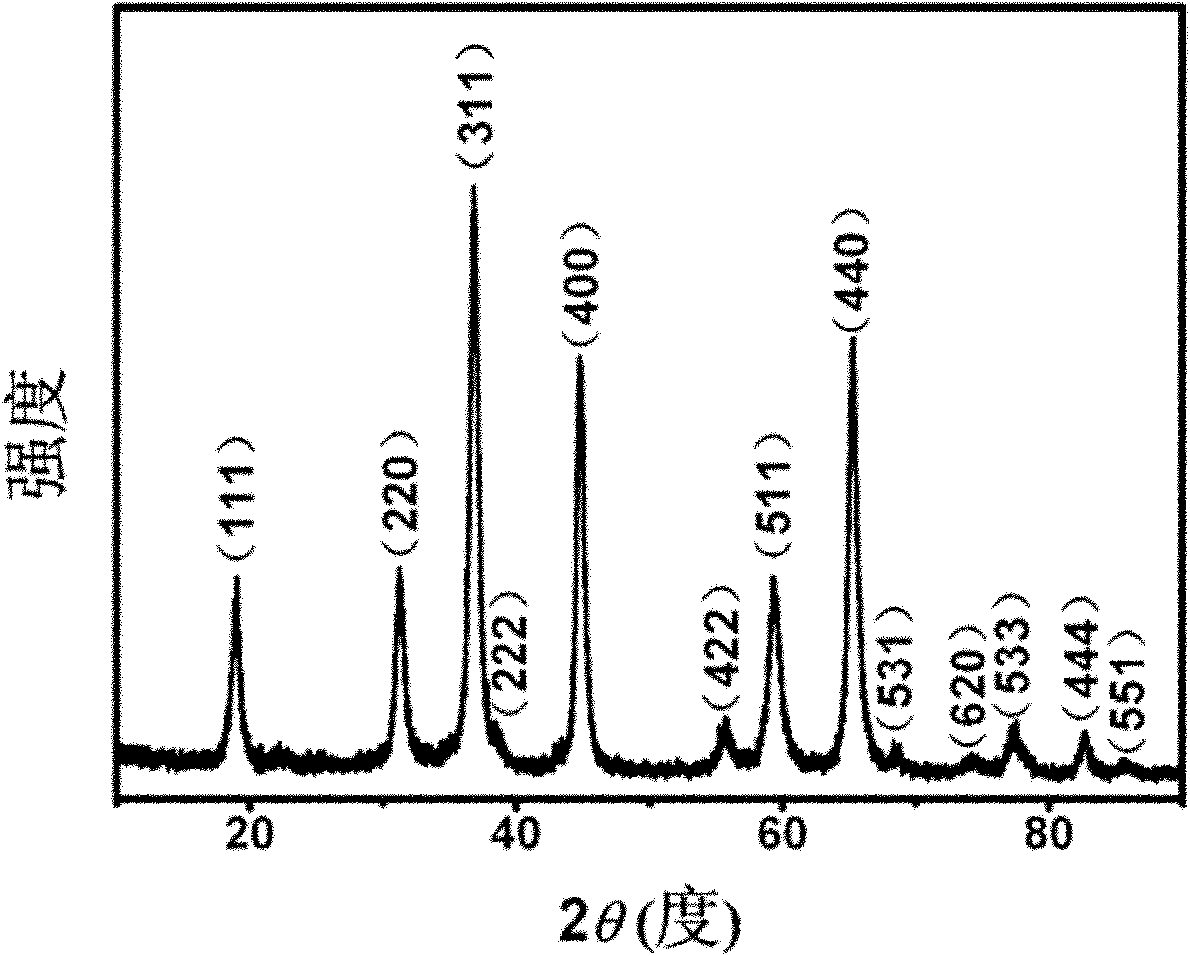

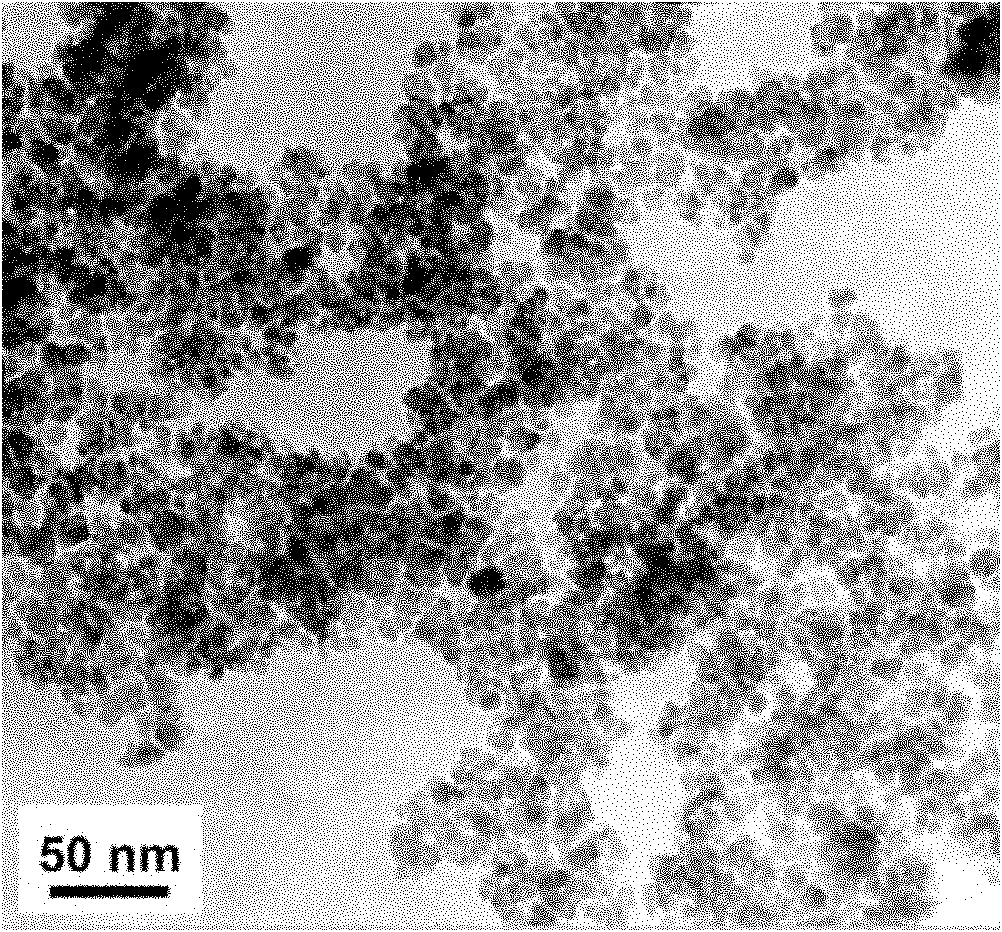

InactiveCN102680539AHigh purity powderPorous pore size distribution is uniformMaterial resistanceTin dioxideMicro nano

The invention discloses a preparation method of porous nickel oxide / tin dioxide micro / nano spheres, which comprises the following steps: stirring tin tetrachloride pentahydrate, nickel sulfate hexahydrate, sodium hydroxide and ammonia water which are used as raw materials, heating, separating, washing, drying and the like to obtain micro / nano spherical hydroxy nickel stannate; and roasting a micro / nano spherical NiSn(OH)6 precursor at high temperature, and cooling to respectively obtain porous micro / nano spherical NiO / SnO2 powder. The micro / nano spherical NiO / SnO2 product prepared by the method disclosed by the invention is light green powder, and has the advantages of large specific area and good product quality. The impedance gas sensing element prepared from the micro / nano spherical NiO / SnO2 powder has high sensitivity, and the sensitivity S value for 100ppm methylbenzene and formaldehyde gases is respectively up to 19.8 and 27.6.

Owner:ANHUI NORMAL UNIV

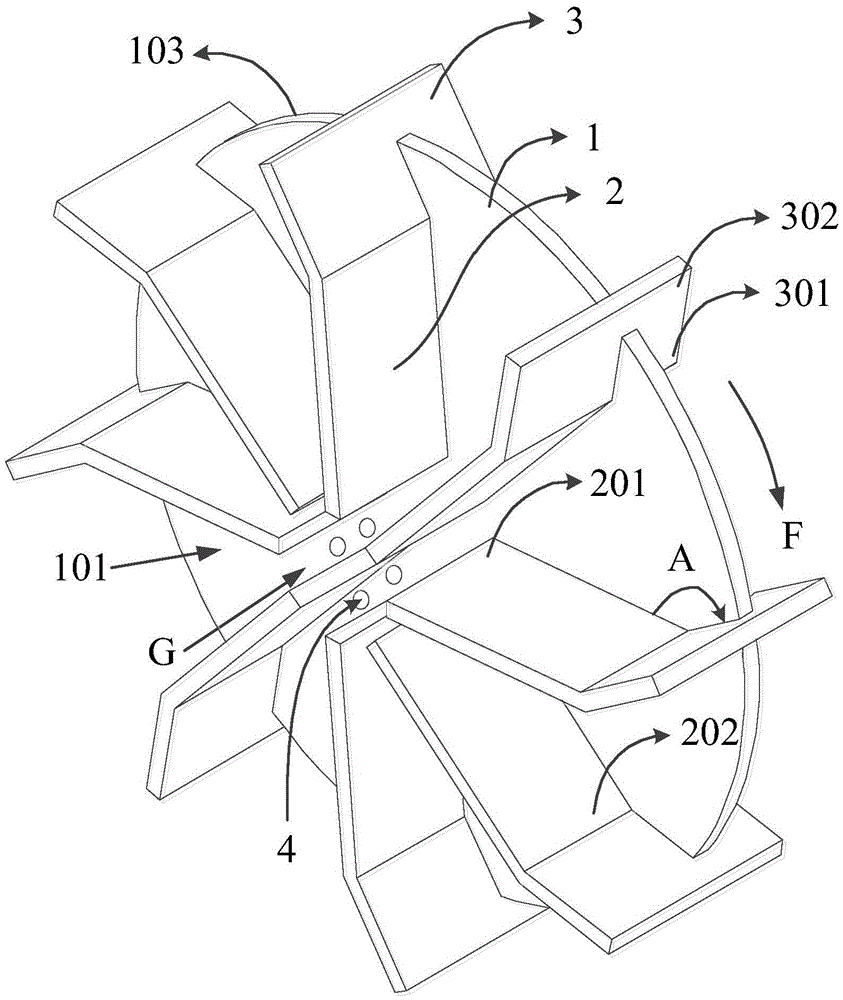

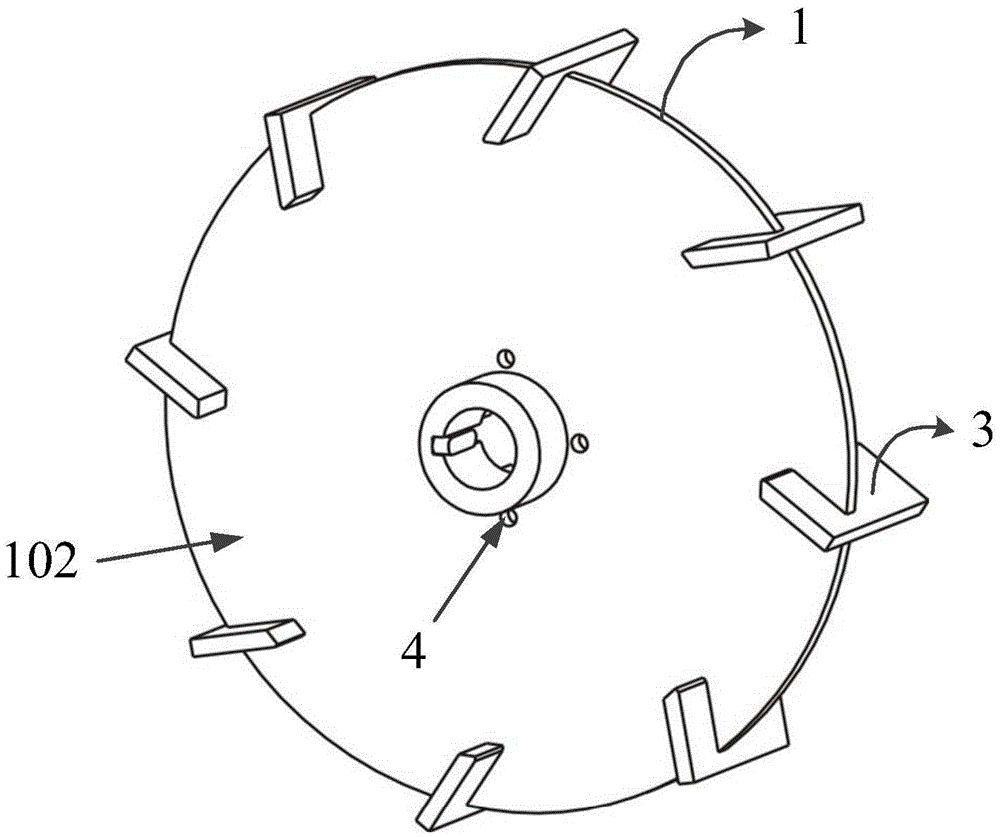

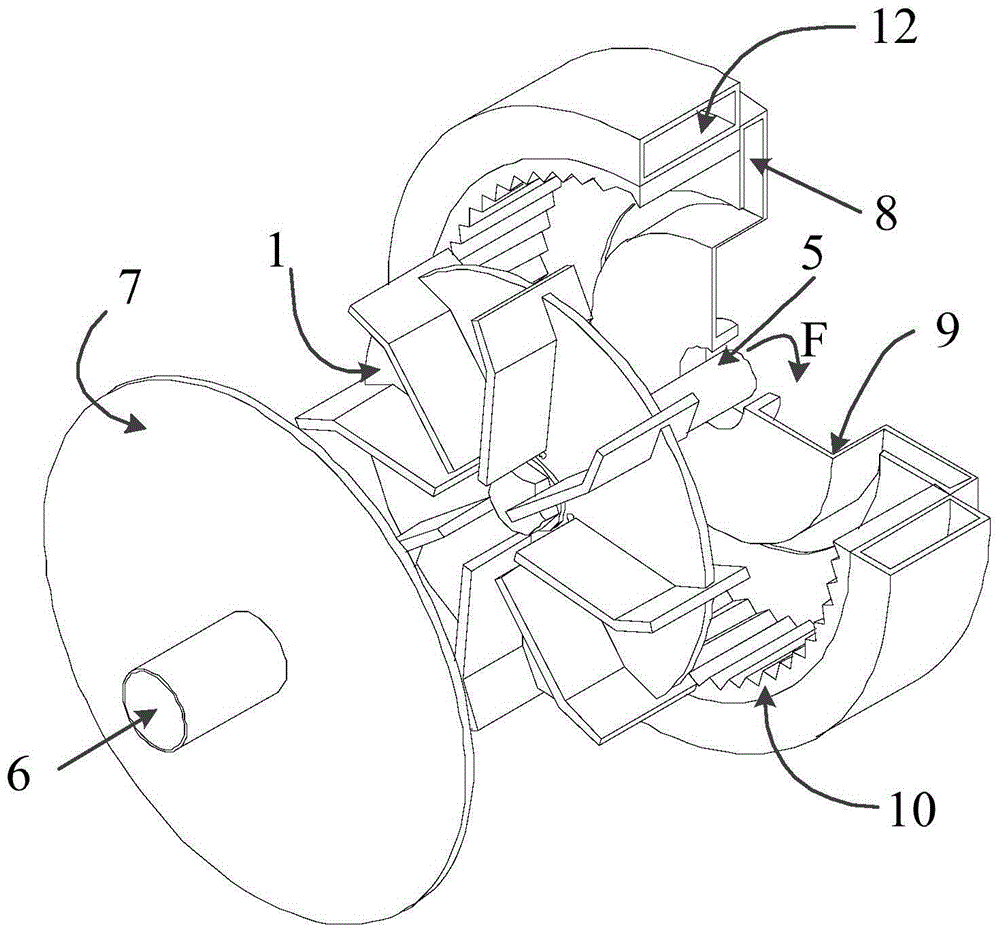

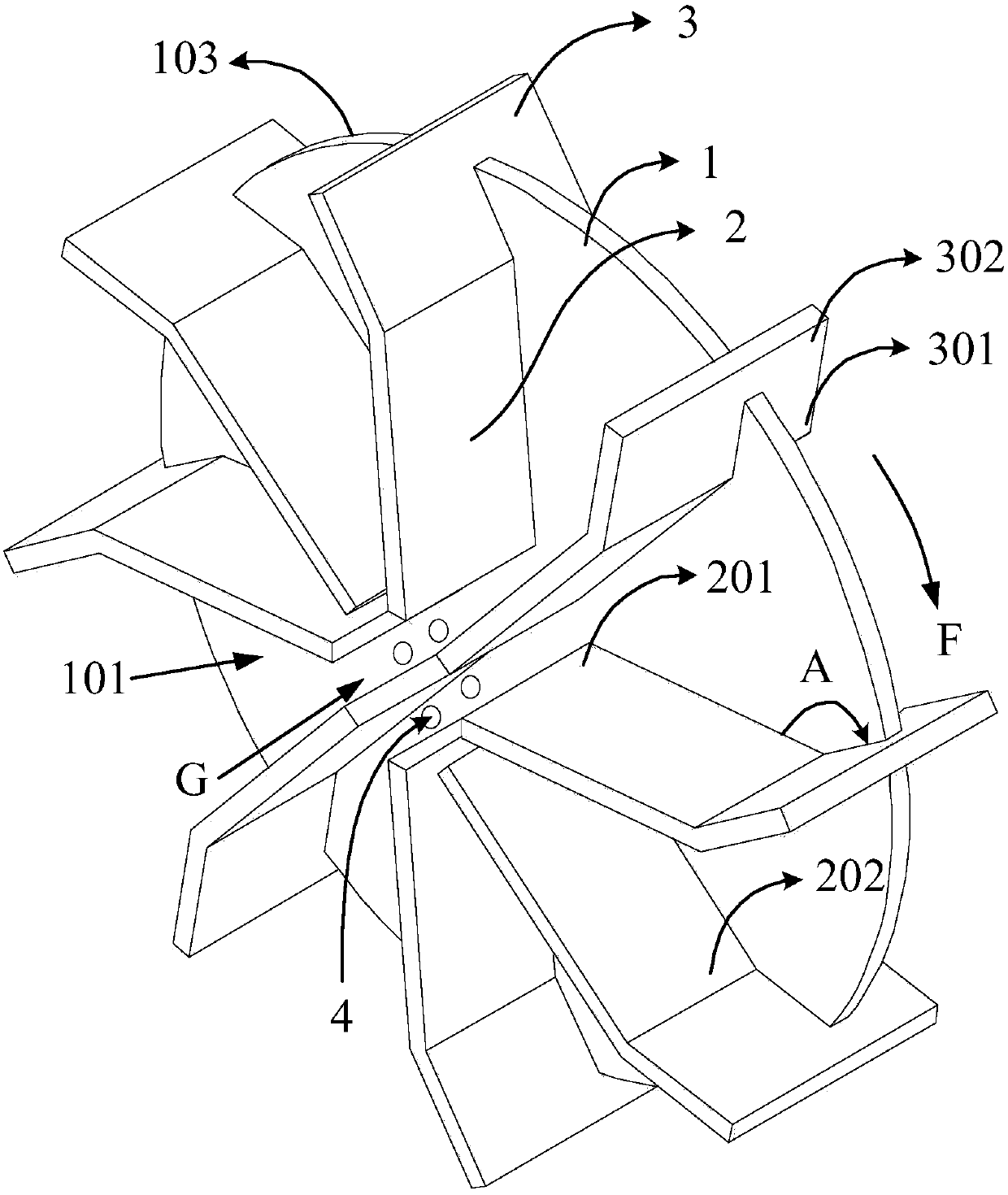

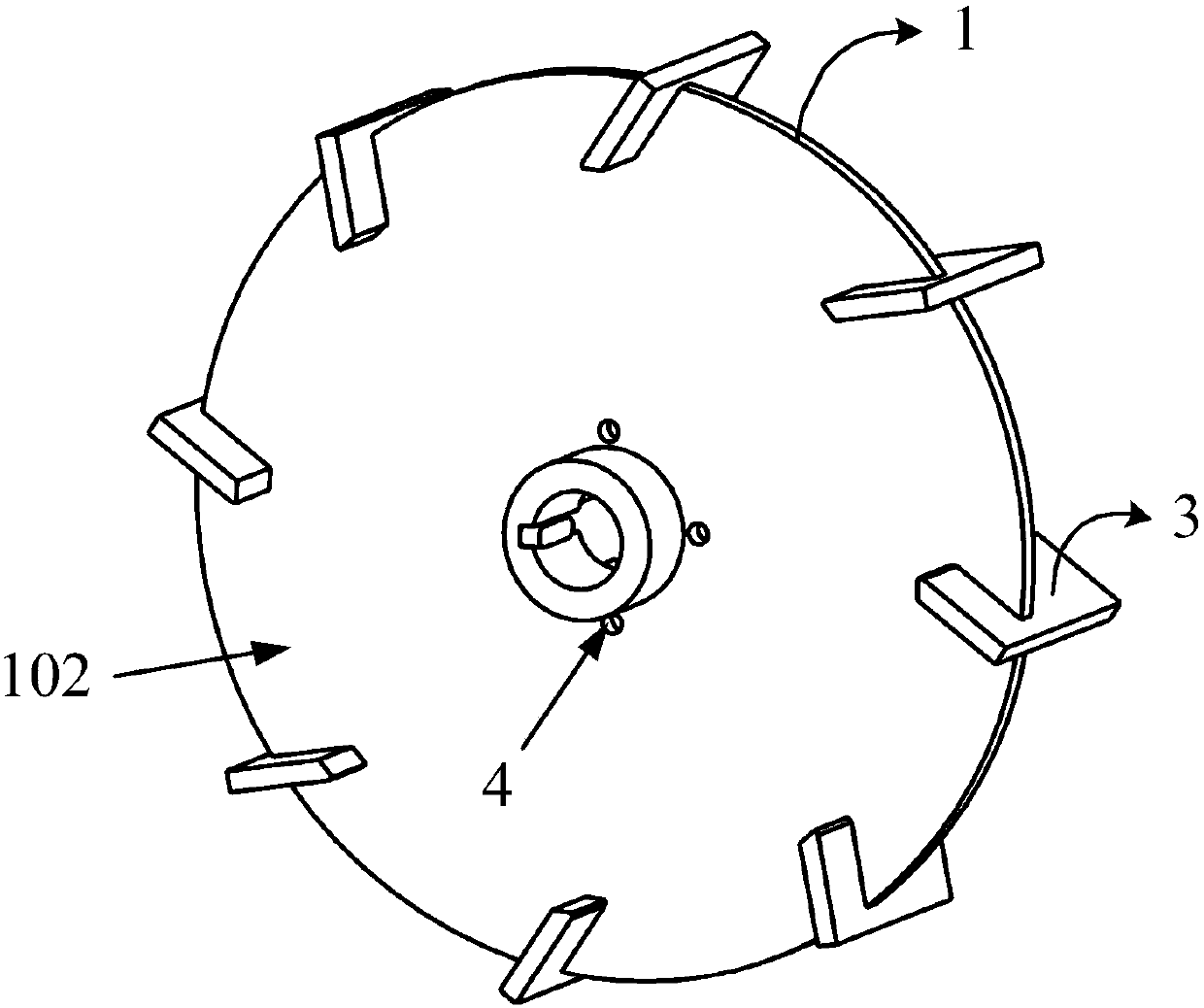

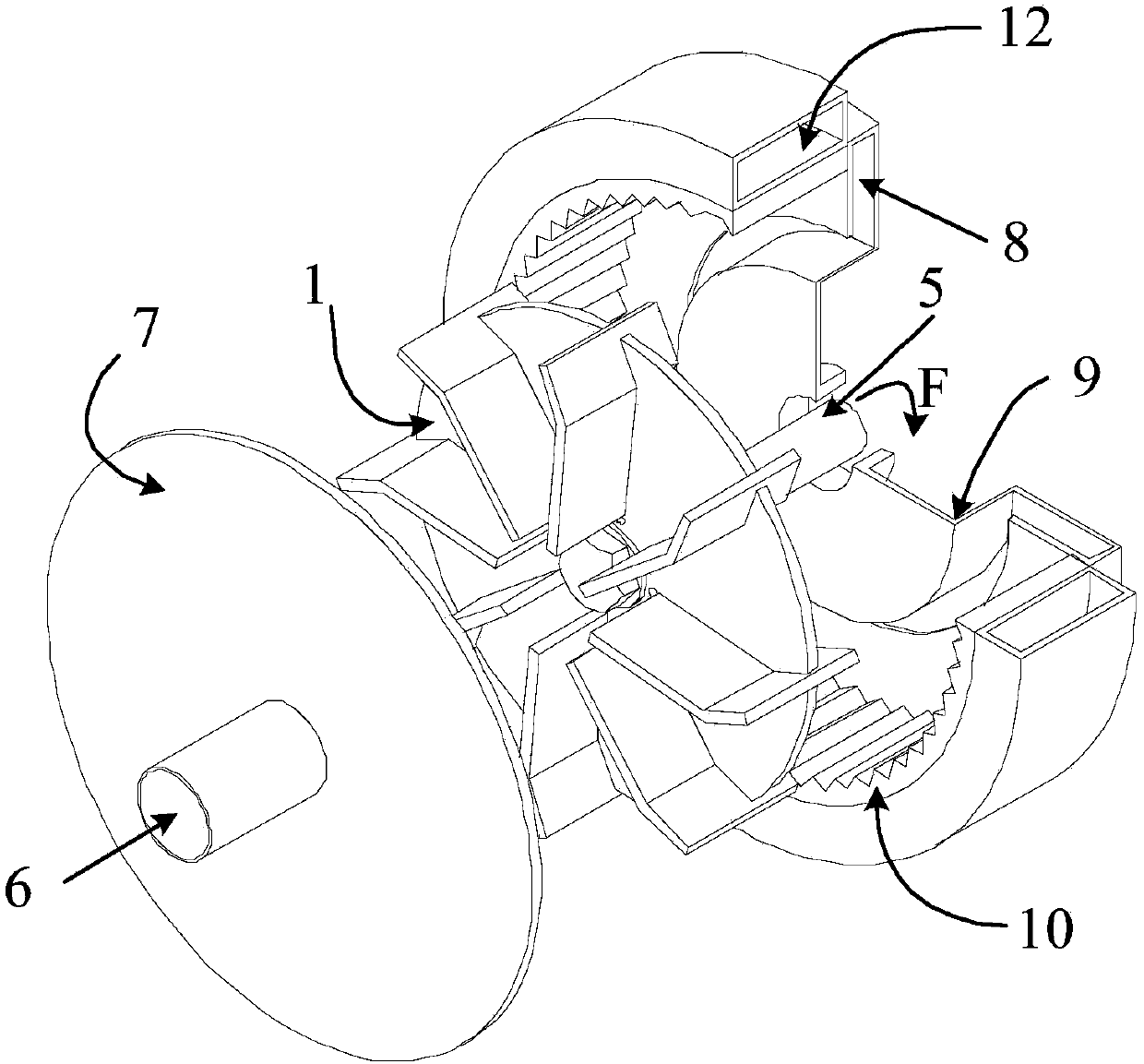

Impeller, superfine mill and superfine milling system

The invention provides an impeller, a superfine mill applying the impeller and a superfine milling system comprising the superfine mill. The impeller comprises a wheel disc, straight surface type blades and straight surface type impact plates, and an abrasion-resistant layer is adhered to the surface of each straight surface type blade. The straight surface type blades are multiple and uniformly arranged on the wheel disc in the radial direction. The tail end of each straight surface type blade is provided with one corresponding straight surface type impact plate in the extension direction of the center of the wheel disc to the outer diameter edge of the wheel disc, and a first included angle is formed between each straight surface type blade and the corresponding straight surface type impact plate. The tail ends of the straight surface type blades are located within the outer diameter edge of the wheel disc. The initiating end of each straight surface type impact plate is connected with the tail end of the corresponding straight surface type blade. The tail ends of the straight surface type impact plates exceed the outer diameter edge of the wheel disc. According to the impeller, the superfine mill applying the impeller and the superfine milling system comprising the superfine mill, high-hardness nonmetal or metal can be milled into superfine powder; in addition, abrasion of equipment parts is small, and the function of particle size classification is achieved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

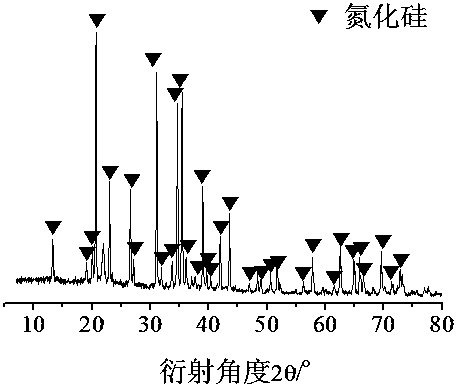

Silicon nitride powder based on catalytic nitridation and preparation method thereof

The invention relates to a silicon nitride powder based on catalytic nitridation and a preparation method thereof. The technical scheme is as follows: the method comprises the following steps: mixing a dispersing agent, silicon powder and distilled water in a mass ratio of 1:200:(10000-16000), stirring, and carrying out ultrasonic dispersion to obtain a suspension; adding 0.88 mol / L water-soluble chromium salt into the suspension according to the Si:Cr2O3 mass ratio of 1:(0.005-0.050) to obtain a mixed solution; adding a precipitant into the mixed solution until the pH value is 7.5-8.5, and stirring for 0.5-1 hour; carrying out vacuum filtration and vacuum drying to obtain a powder mixture; and putting the powder mixture into a tubular atmosphere furnace, heating to 1250-1400 DEG C in a nitrogen atmosphere, and keeping the temperature for 2-8 hours to obtain the silicon nitride powder based on catalytic nitridation. The method has the characteristics of low synthesis temperature, short period, simple technique and high yield, and is easy to control. The silicon nitride powder based on catalytic nitridation has the advantages of high purity and small particle size, and is partially crystal whiskers.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

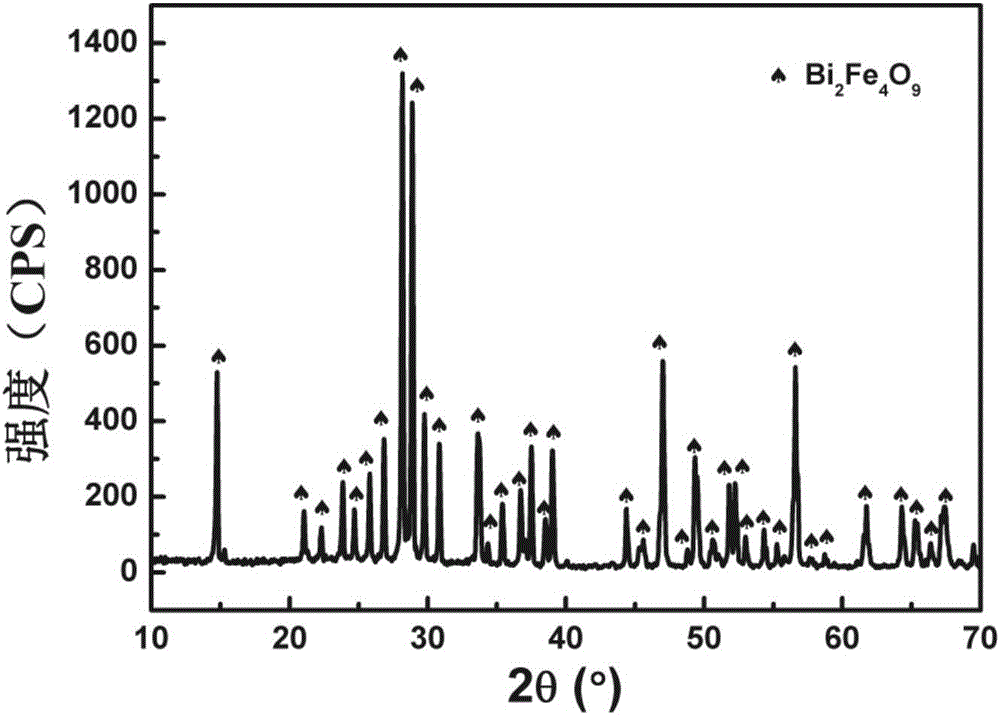

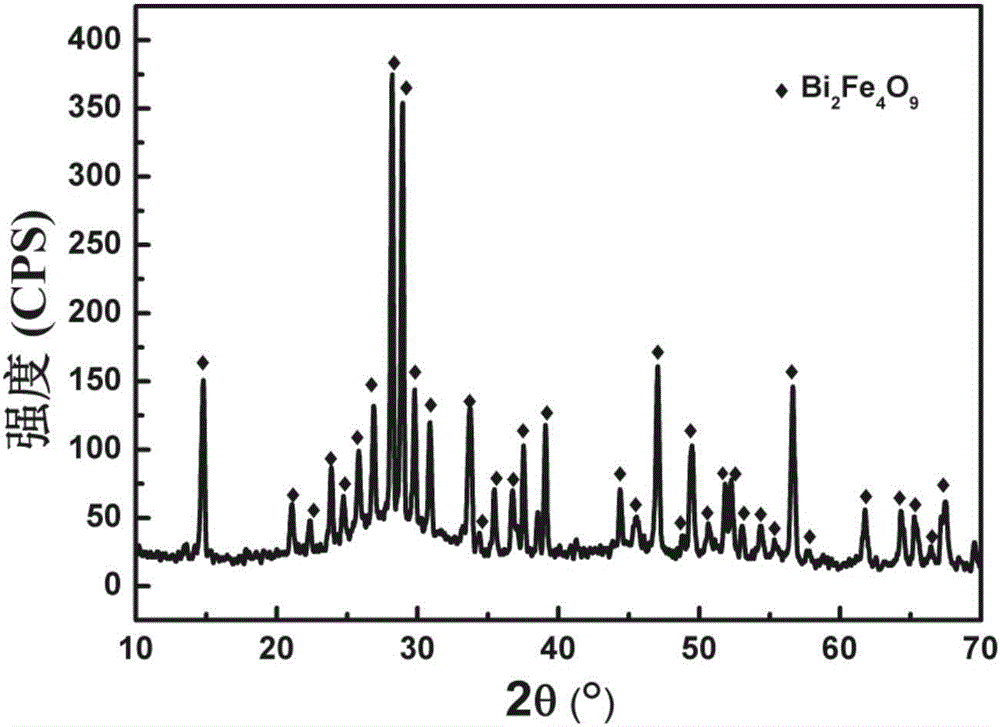

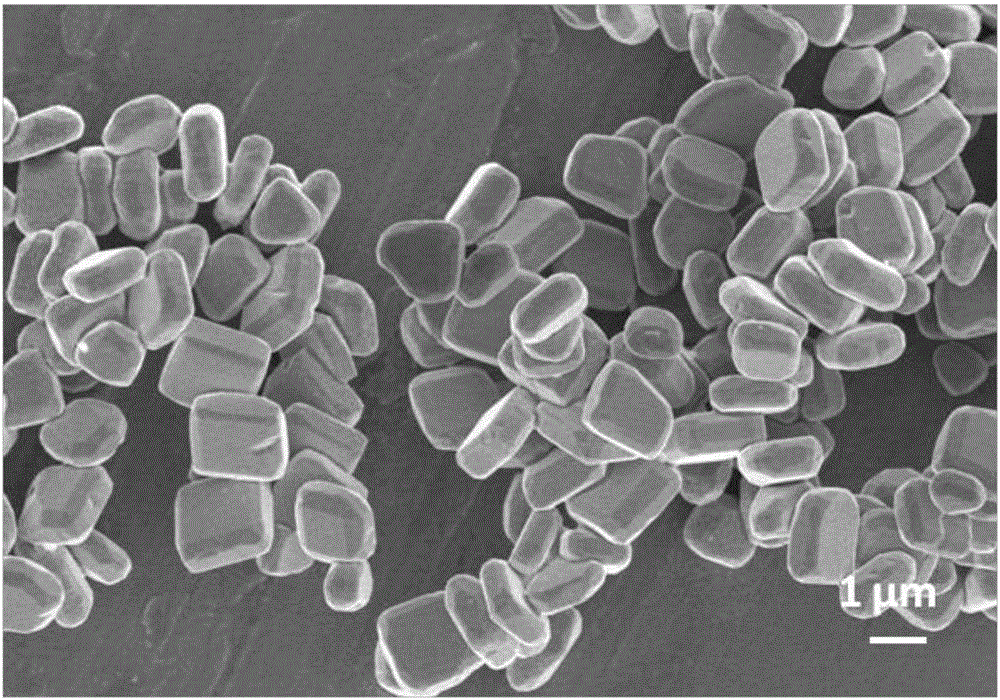

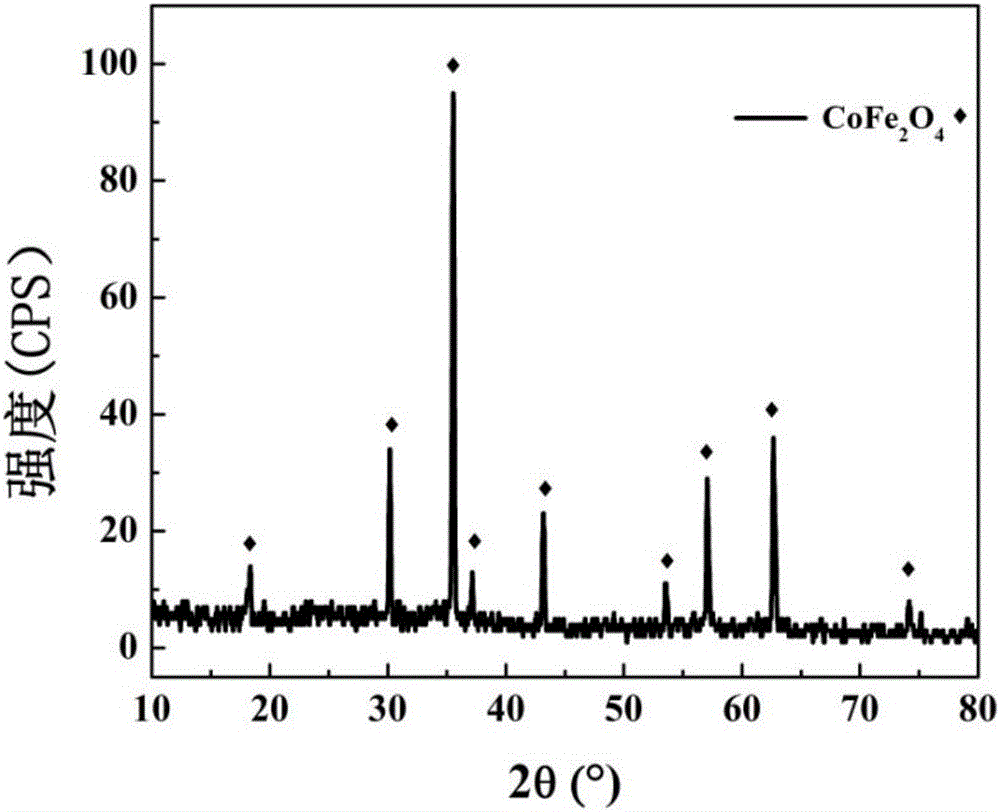

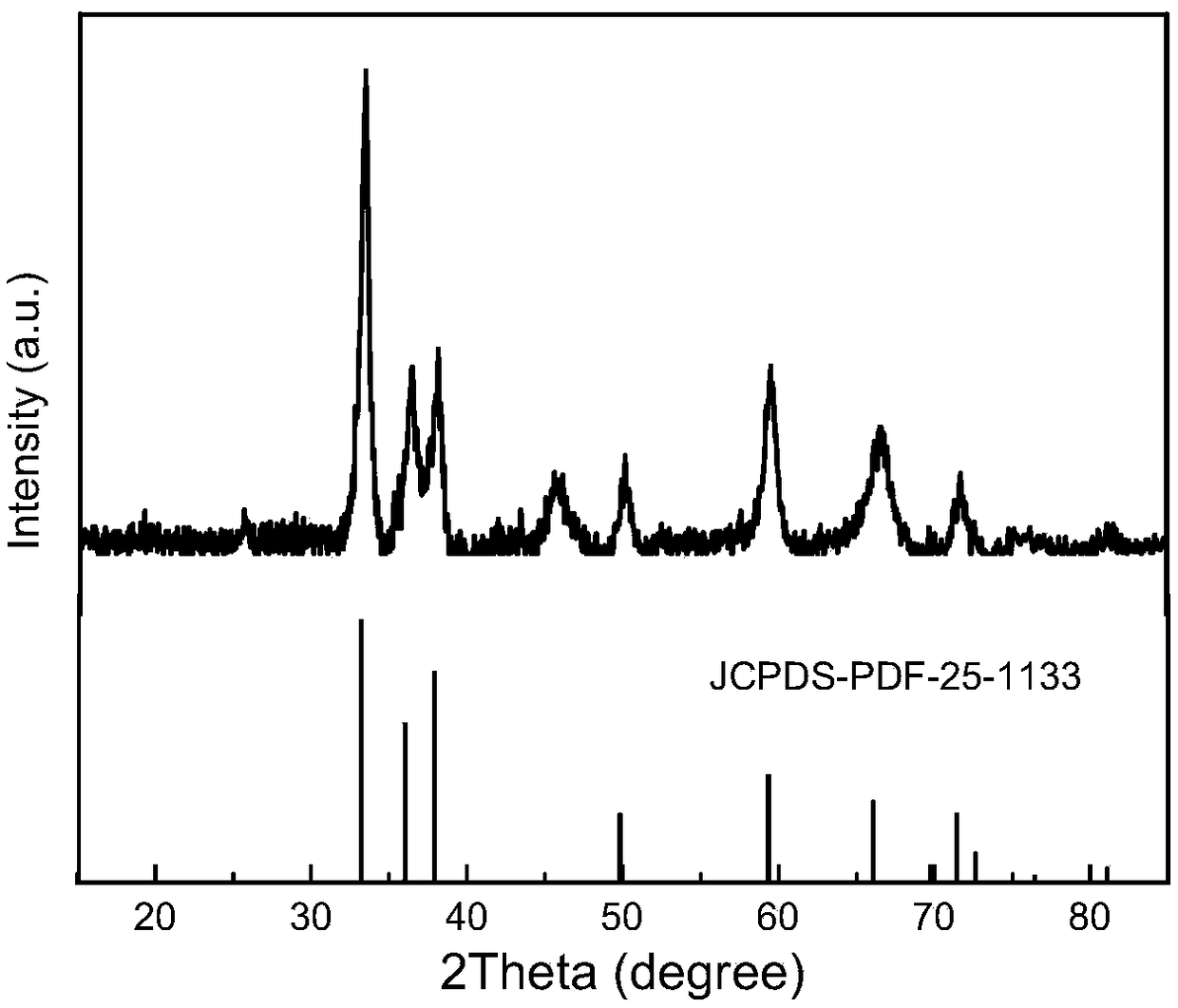

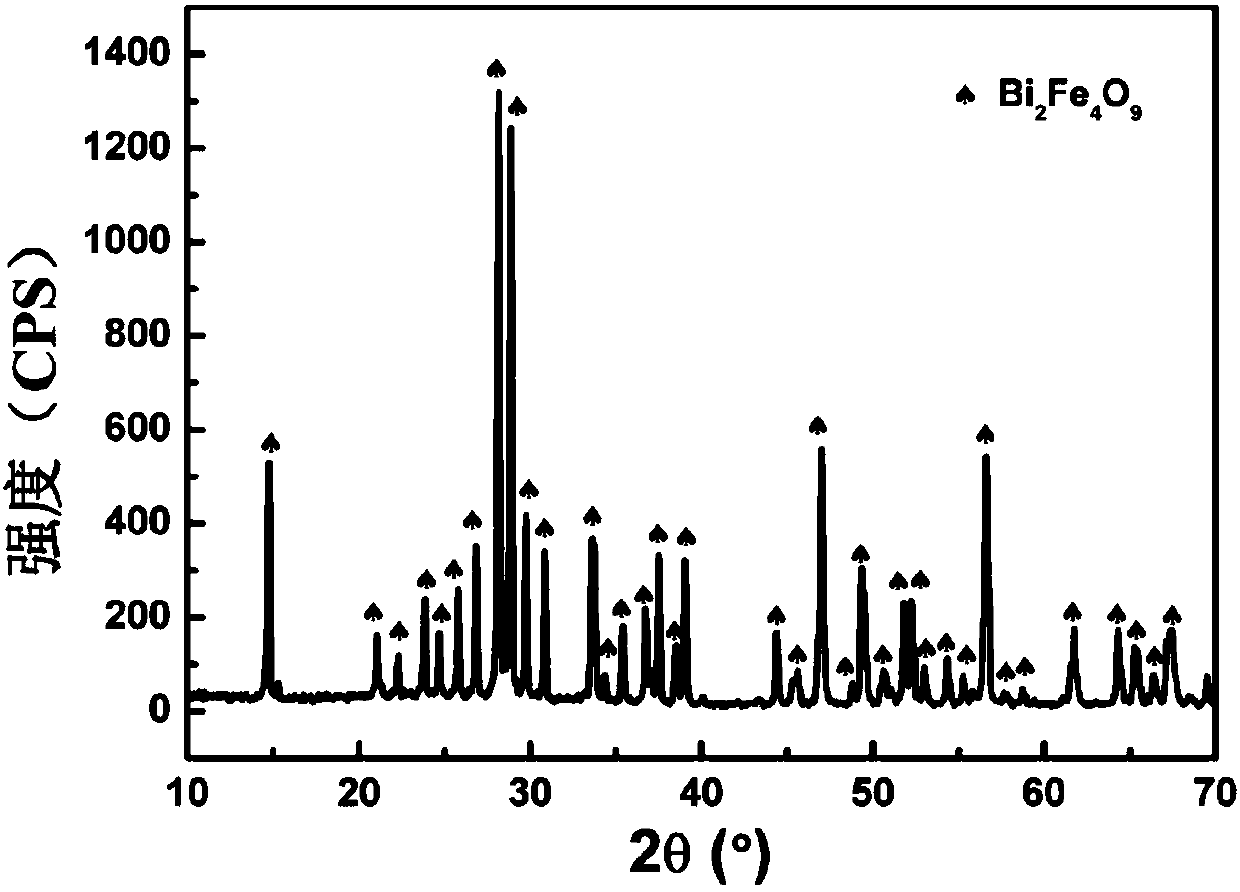

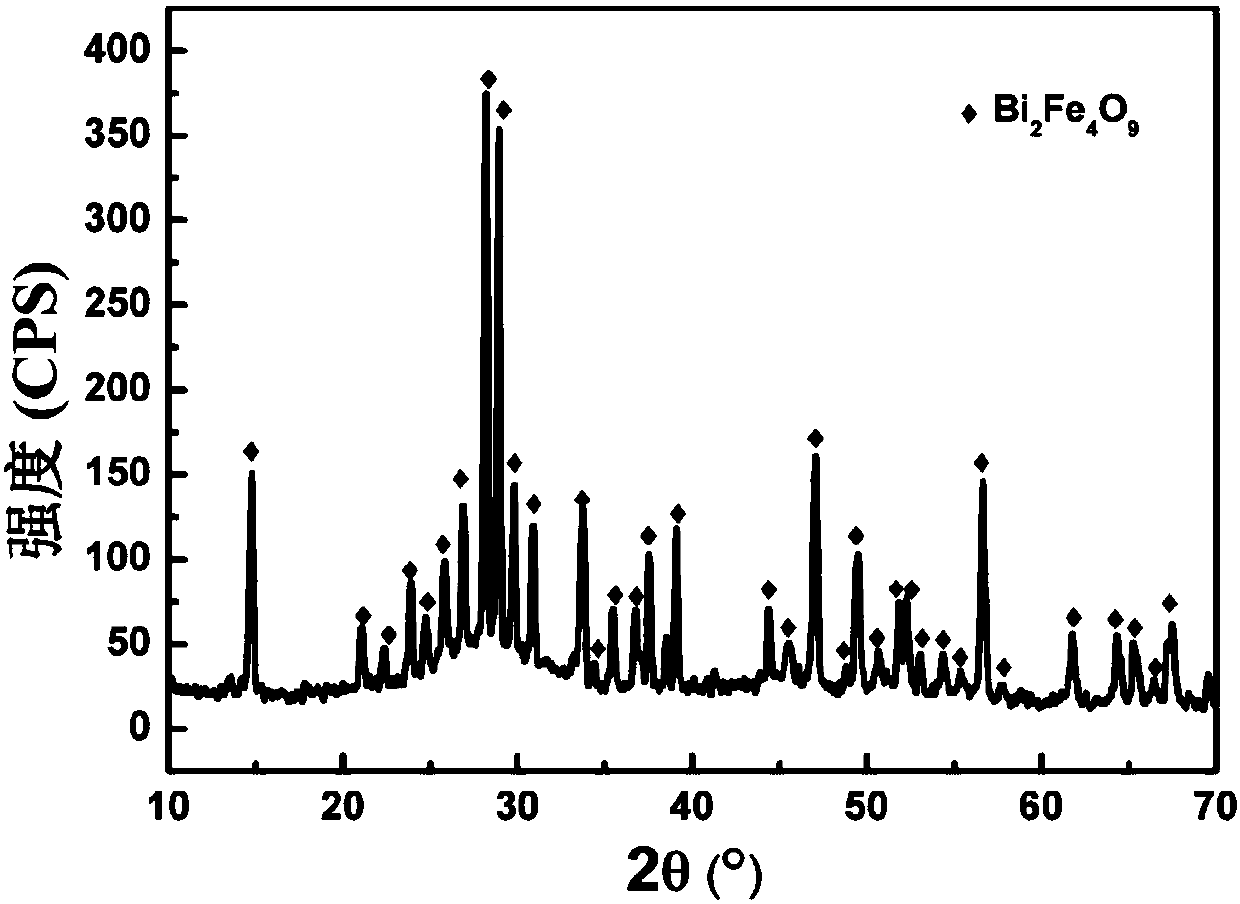

Three-dimensional flower-shaped bismuth ferrite powder and preparation method thereof

ActiveCN106698521ALarge specific surface areaEvenly dispersed grainsMaterial nanotechnologyIron compoundsSolventCrystallite

The invention discloses three-dimensional flower-shaped bismuth ferrite powder and a preparation method thereof. The preparation method comprises the following steps: taking Bi(nO3)3.5H2O and Fe(NO3)3.9H2O as starting materials, preparing blocky bismuth ferrite powder by adopting a hydrothermal method, then mixing the bismuth ferrite powder, a corrosive solvent, a reducing agent and a complex agent under the protective atmosphere, and obtaining three-dimensional porous bismuth ferrite flower balls by adopting a one-step corrosion method. According to the invention, a thick flaky Bi2Fe4O9 powder raw material is prepared by adopting the hydrothermal method, grains are uniform in size and shape and are better in dispersibility, a corrosion technology is adopted, preparation technological operation is simple, and the period is short; and the prepared flower-shaped bismuth ferrite has the diameter being about 1-2mu m, sizes are uniform, a specific surface area is relatively large due to a porous structure, and performances of all the aspects are respectively improved.

Owner:SHAANXI UNIV OF SCI & TECH

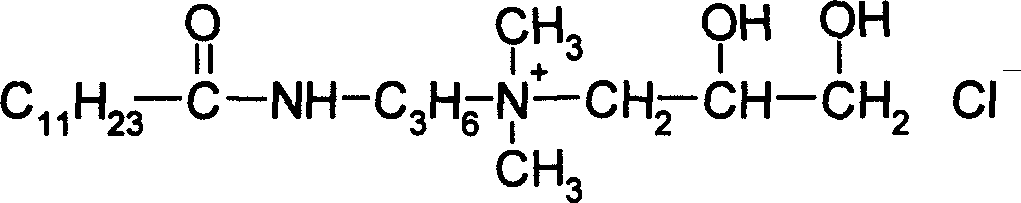

Method for preparing nanometer sulfides powder

A process for preparing sulfide nano-particles includes such steps as preparing the solution of metal salt, adding quaternary ammonium salt, dripping the solution of sodium sulfide in it to generate deposit, filter, water washing, removing the ions of impurities, drying and calcining.

Owner:SHANGHAI UNIV

Method for preparing copper-based powder with low oxygen content and low apparent density through atomization

The invention discloses a method for preparing copper-based powder with low oxygen content and low apparent density through atomization, which comprises the following steps: melting metallic coppers into liquid copper; atomizing the liquid copper; carrying out absorption and filtration on the atomized liquid copper so as to obtain the copper-based powder. The invention is characterized in that in the process of atomization, two nozzles are arranged below the liquid copper, and arranged in a same vertical line so as to form two focuses; the diameter of an orifice is 1.2 to 1.5mm; and atomized vertical angles are respectively 28 to 32 degrees and 18 to 22 degrees. The copper-based powder prepared by using the method of the invention has the advantages of low oxygen content, low apparent density and good metallurgical properties.

Owner:铜陵铜基粉体科技有限公司

Low temperature solid phase preparation method of indium tin oxide nano particle powder

InactiveCN103318949APrevents the formation of aggregatesAvoid formingMaterial nanotechnologyGallium/indium/thallium compoundsIndiumCalcination

The invention discloses a low temperature solid phase preparation method of indium tin oxide nano particle powder. The low temperature solid phase preparation method of the indium tin oxide nano particle powder comprises the following steps of: dissolving metal indium with inorganic acid to form an initial solution or dissolving metal salt of indium into water to prepare the initial solution, then adding metal salt of tin to form a mixed solution, then adding water soluble inorganic salt into the mixed solution, then adding ammonia water into the mixed solution, and finally generating an indium tin oxide precursor; and drying a reaction system, grinding to obtain mixed powder, then calcining the mixed powder, washing calcined products to remove the inorganic salt, and then drying, thus the indium tin oxide nano particle powder is obtained finally. By adopting the low temperature solid phase preparation method of the indium tin oxide nano particle powder, the indium tin oxide nano particle powder can be prepared at a lower calcining temperature (300-500 DEG C), the problems that energy consumption is high and particle aggregation is serious which are caused by high temperature calcination treatment can be overcome, an operation process is simple, and the used raw materials are cheap and can be recycled, so that the low temperature solid phase preparation method of the indium tin oxide nano particle powder is applicable to industrialization scale production.

Owner:CHANGAN UNIV

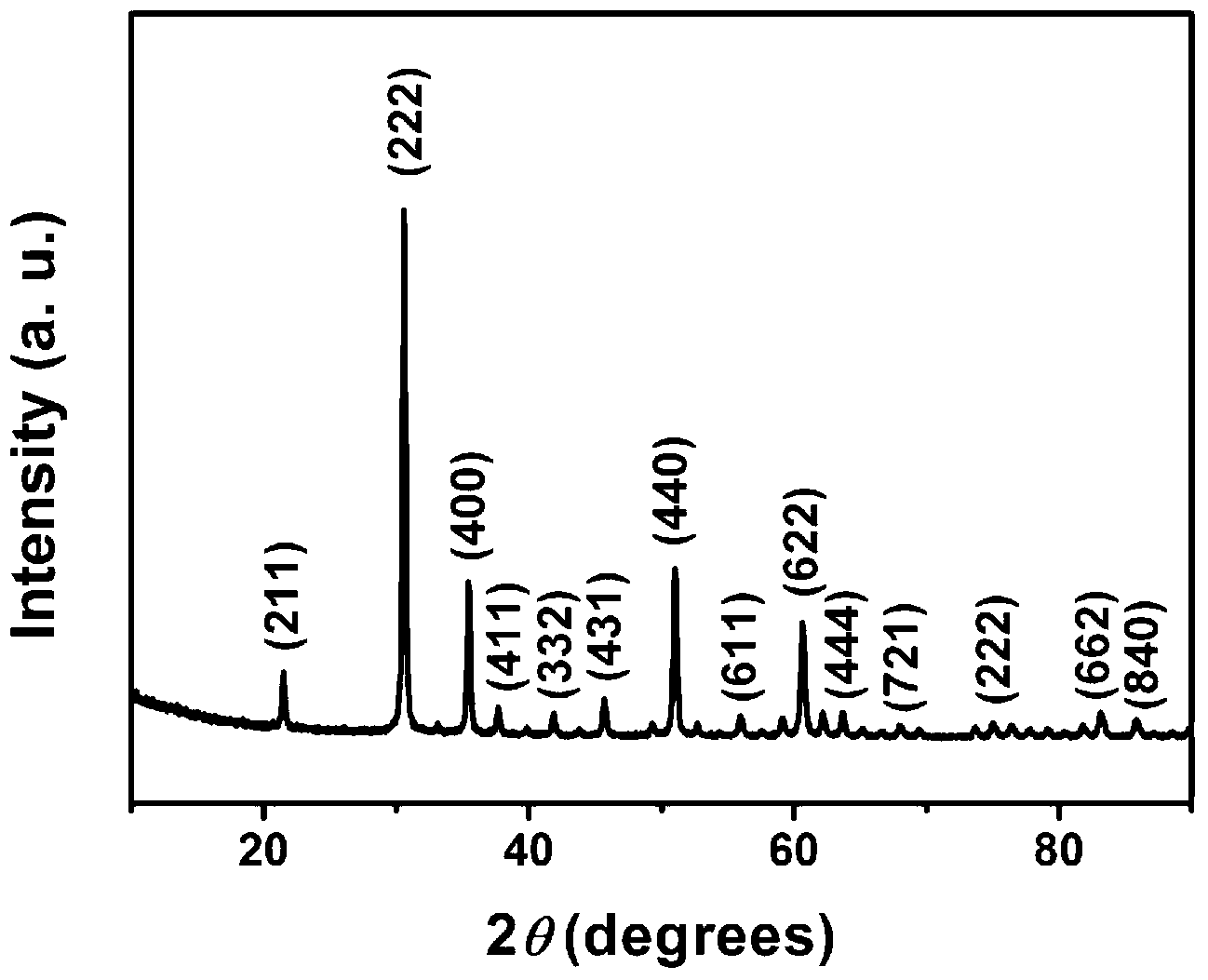

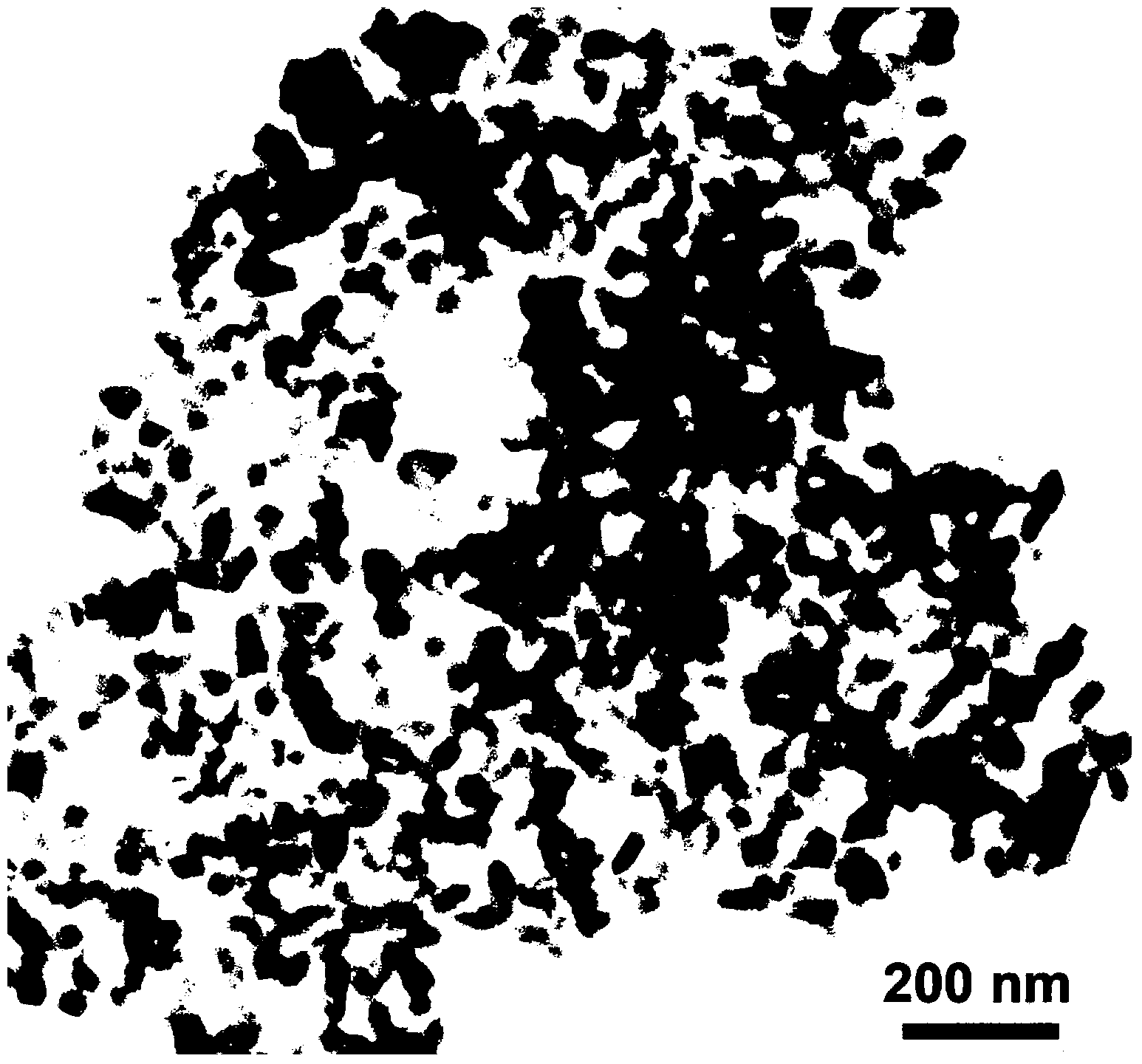

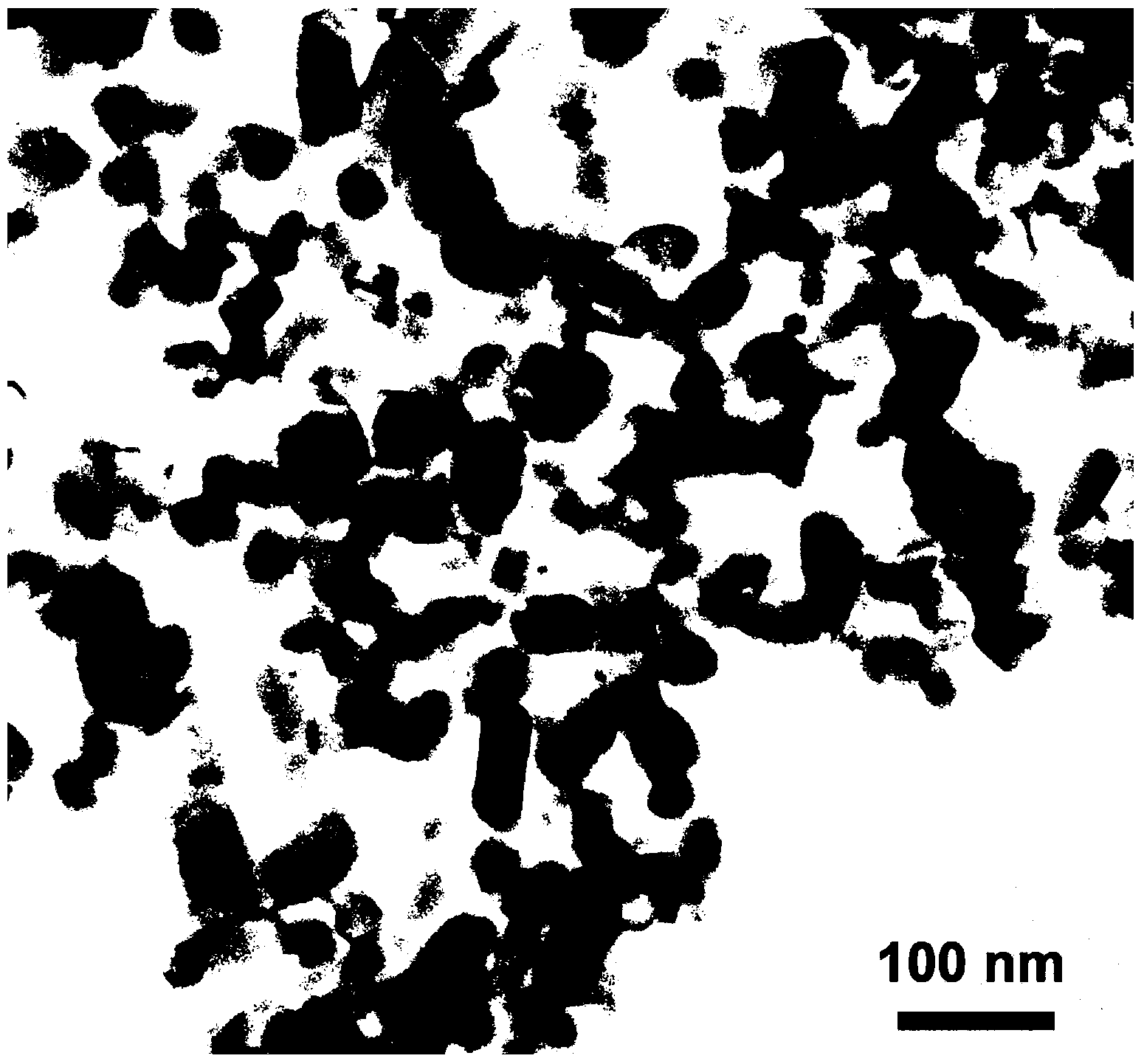

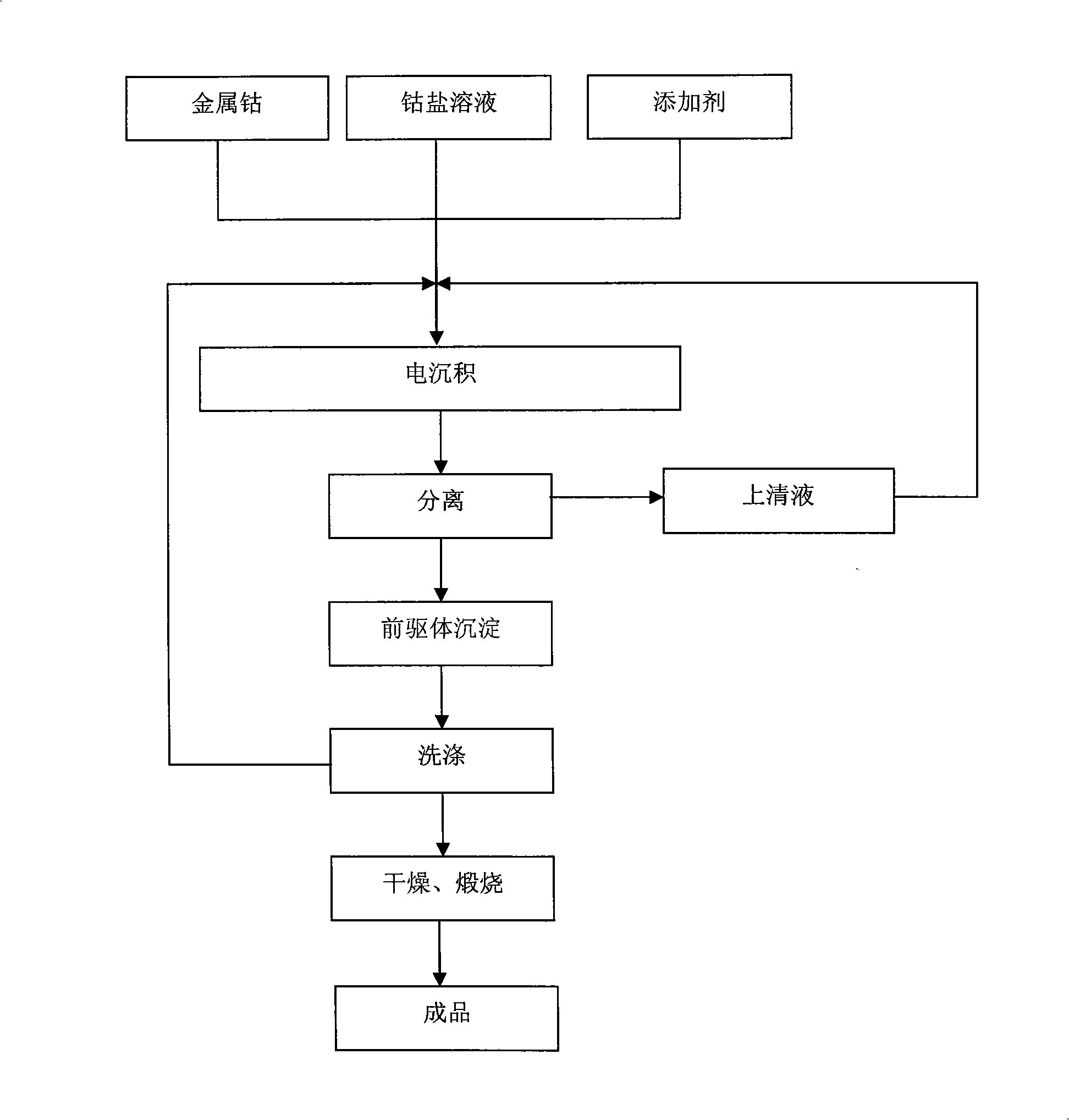

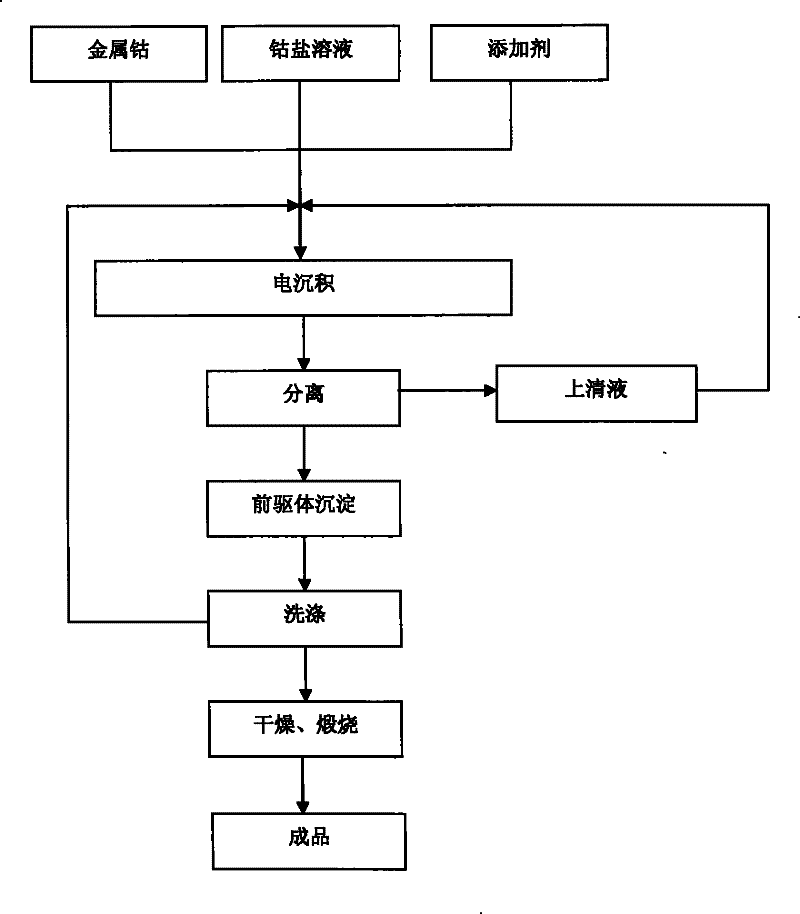

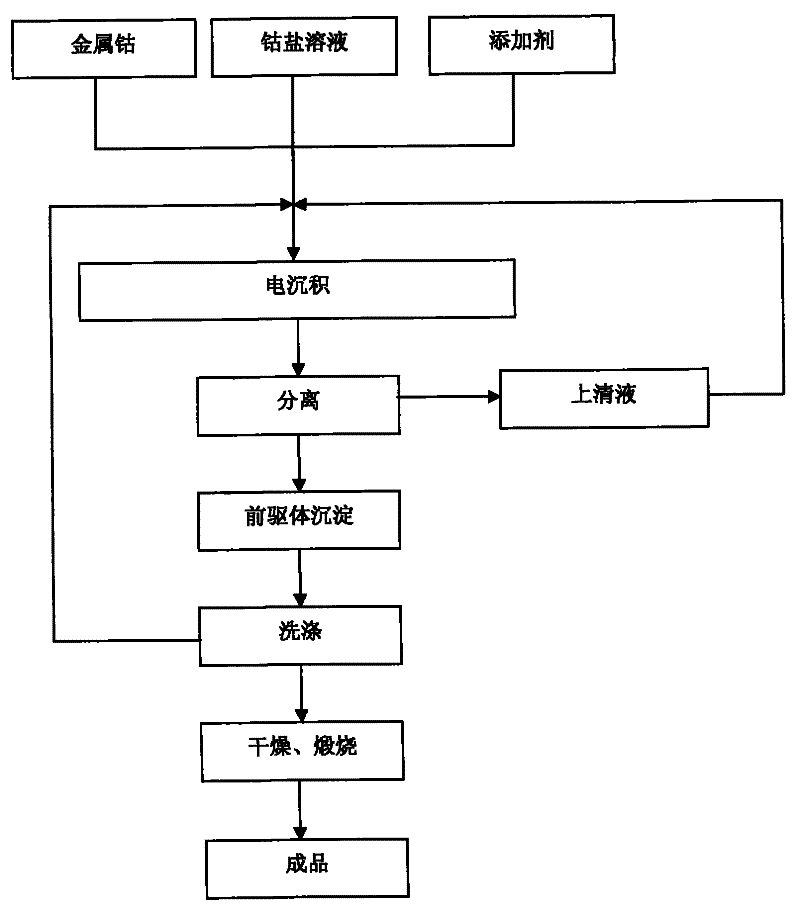

Clean production method for high-purity cobaltosic oxide powder

InactiveCN101525752ASmooth responseNarrow particle size distributionElectrolysis componentsChemistryDecomposition

The invention discloses a clean production method for high-purity cobaltosic oxide powder. The method comprises the following steps: using metal cobalt as an electrolytic anode, using soluble cobalt salt as electrolyte main salt and adding additives; adopting an electrochemical method to prepare a cobaltosic oxide precursor sediment; and then, drying and calcining the precursor sediment to obtain the cobaltosic oxide powder. The cobaltosic oxide powder produced by the method and the process can achieve the purity more than 99.7 percent, no additional precipitator is needed in the whole technological process, the added additives are all easy to wash without decomposition, and electrolyte and washing water can be recycled so as to avoid discharging sewage and generating waste gas. The method can adjust and control the appearance and the grain diameter distribution of the cobaltosic oxide powder by controlling the composition of the electrolyte, the cathode current concentration, the electrodeposition time and the calcining temperature and has the advantages of high product quality, simple production procedures, energy saving, environmental protection, and the like.

Owner:HUNAN UNIV

Recovery and utilization method for copper bearing spent acid solution from sodium saccharin production process

InactiveCN1541955AHigh purity powderHigh purityMultistage water/sewage treatmentSuspended organic matterDistillation

The present invention provides one waste copper containing acid solution recovering and utilizing process in saccharin sodium production. The waste copper containing acid solution recovering and utilizing process includes filtering to eliminate suspended organic matter, oxidizing the filtrate with mixed oxidant of sodium hypochlorite and potassium hypermanganate to eliminate low boiling point organic matter, decompression distilling the solution in vacuum to obtain dilute hydrochloric acid solution, further extraction and concentrating distillation to obtain hydrochloric acid solution of 30 % concentration, burning residue after decompression distilling to eliminate organic matter and obtain high purity copper sulfate and powder of other inorganic salts. The said process can recover the useful matter from waste acid solution and avoid environmental pollution effectively.

Owner:SHANGHAI JIAO TONG UNIV

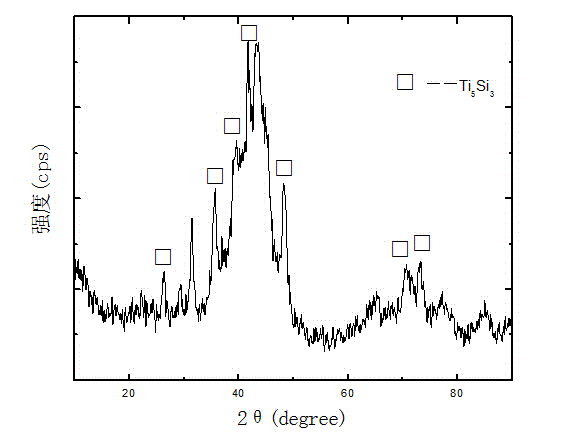

Method for preparing Ti5Si3 intermetallic compound powder by mechanical alloying

InactiveCN104475741APrecise control of stoichiometric ratioHigh purity powderTetrachlorideHigh energy

The invention relates to a method for preparing Ti5Si3 intermetallic compound powder by mechanical alloying, and belongs to the field of inorganic compound manufacturing. According to the method, Ti and Si powder mechanical alloying is carried out mainly by a high-energy ball mill method, tetrachloromethane is used as a process control agent, the ball mill process parameters such as the ball material ratio, the ball mill time and the ball mill rotating speed are optimized, ultra-fine highly dispersed Ti5Si3 powder is obtained. The method has the advantages that the mechanical alloying method is used for preparing the Ti5Si3 intermetallic compound powder, the energy consumption is low, the scaled production can be easily realized, the prepared powder can be used in the field of high-temperature structure materials and electric equipment devices, and good market prospects are realized.

Owner:YANGZHOU UNIV

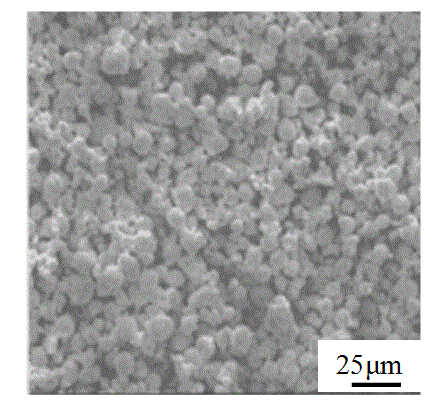

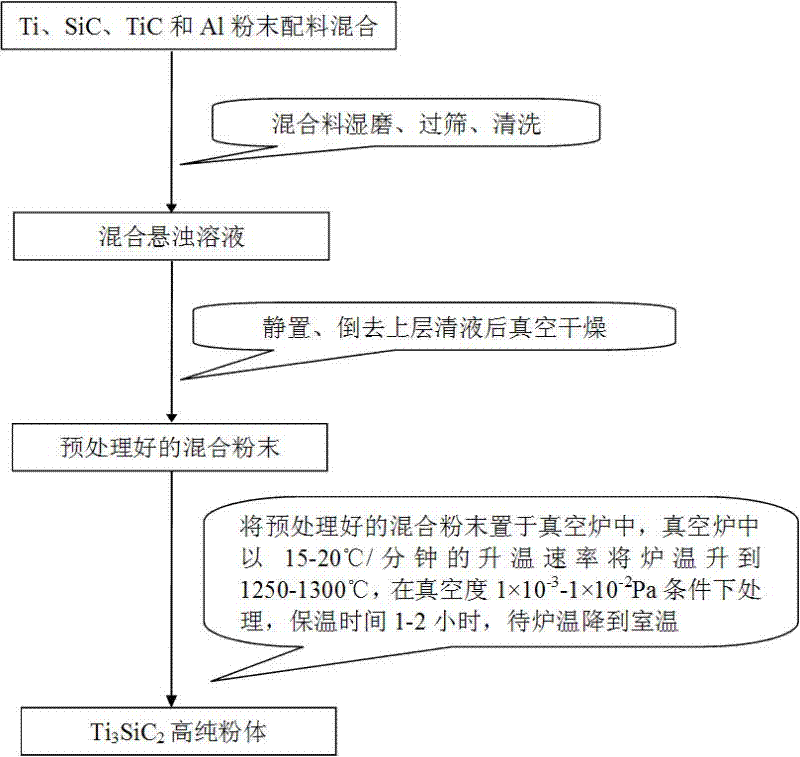

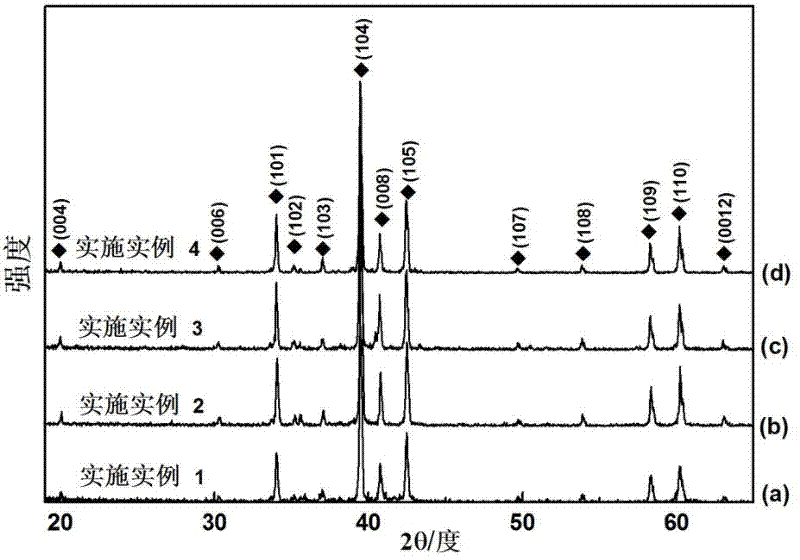

Method for synthetizing Ti3SiC2 high-purity powder

The invention relates to a method for synthetizing Ti3SiC2 high-purity powder. The method comprises the following steps: 1) proportioning: selecting Ti powder, SiC powder and TiC powder as raw materials and Al powder as a synthesizing accelerator wherein the molar ratio of Ti to SiC to TiC to Al is (4-4.1): (2-2.1): (1-1.1): (0.2-0.3); mixing the Ti powder, SiC powder, TiC powder and Al powder to obtain a mixture; 2) performing wet grinding on the mixture, sieving, washing to obtain a mixed suspension; 3) standing the mixed suspension, pouring out the supernatant, performing vacuum drying to obtain pretreated mixed powder; and 4) placing the pretreated mixed powder in a vacuum furnace to heat to 1250-1300 DEG C in a heating rate of 15-20 DEG C / min, treating under the condition that the vacuum degree is 1*10<-3>-1*10<-2>Pa, keeping the temperature for 1-2 hours, and obtaining the Ti3SiC2 high-purity powder under the condition that the furnace temperature is reduced to the room temperature. The Ti3SiC2 powder synthetized by the method has high purity and does not require purification treatment; the process is greatly simplified, the technological parameters are stable, the cost is low, the growth of grains is good; and the method is very suitable for mass production.

Owner:WUHAN UNIV OF TECH

Method for synthesizing aluminium-titanium carbonate ceramic powder

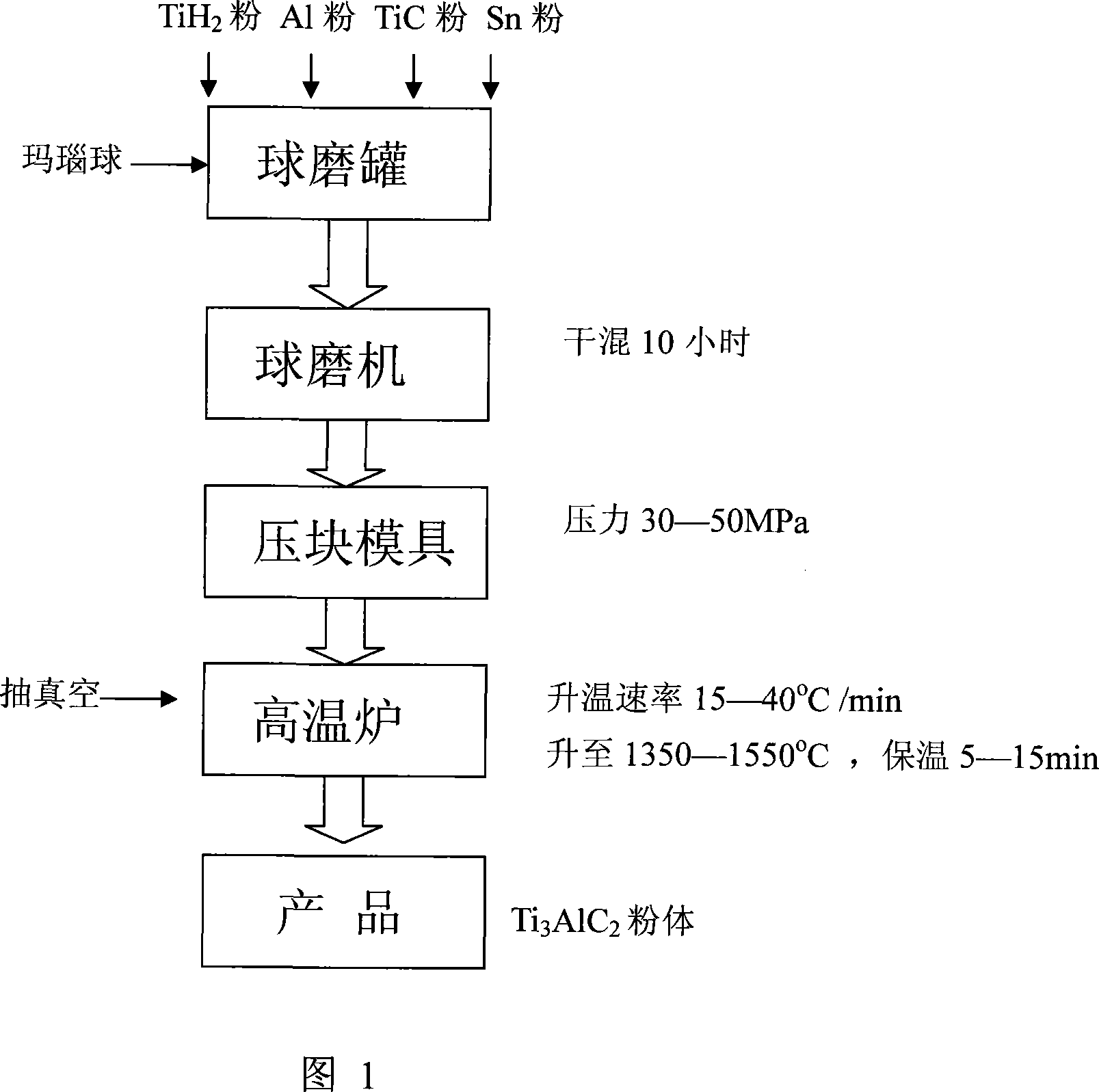

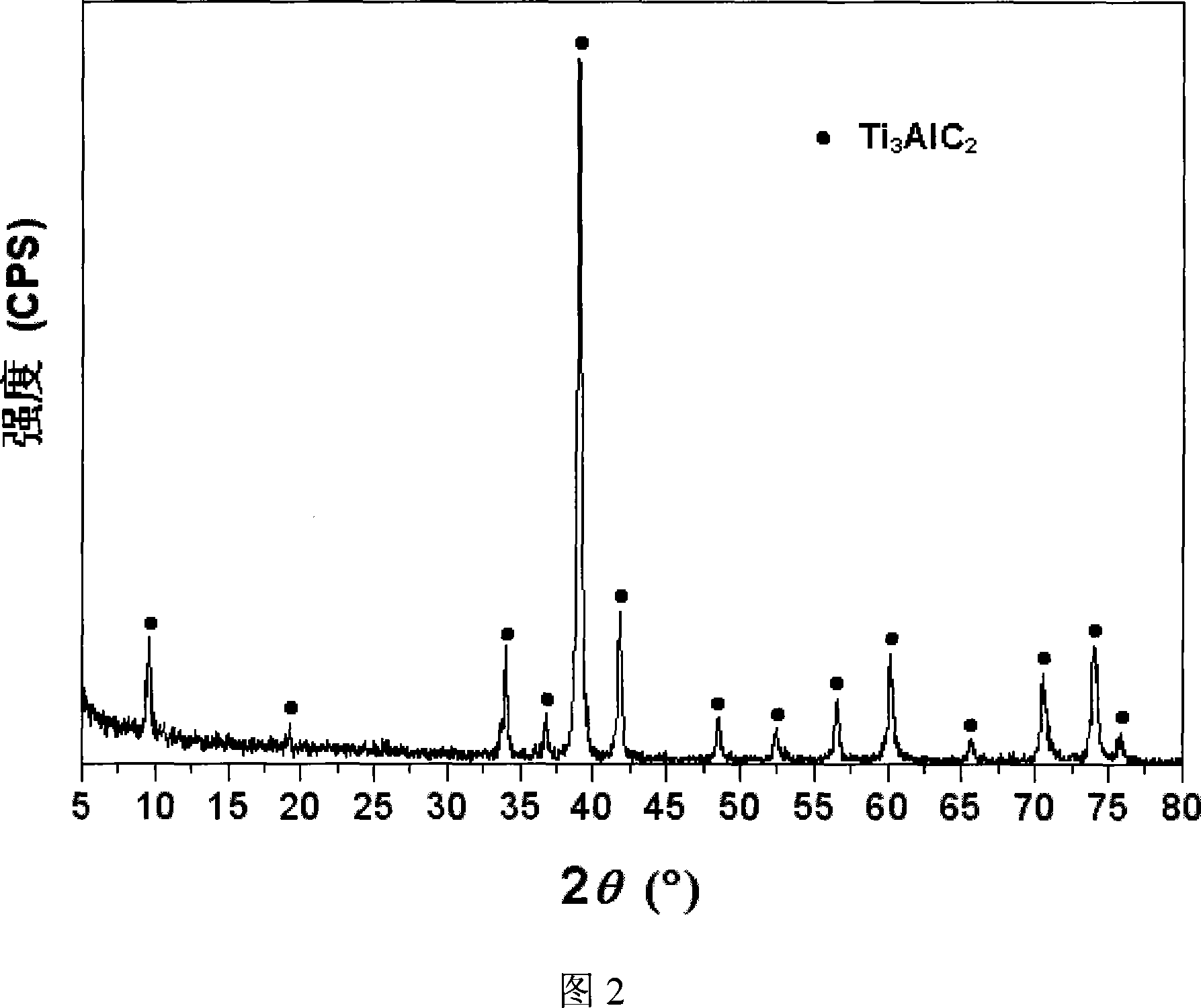

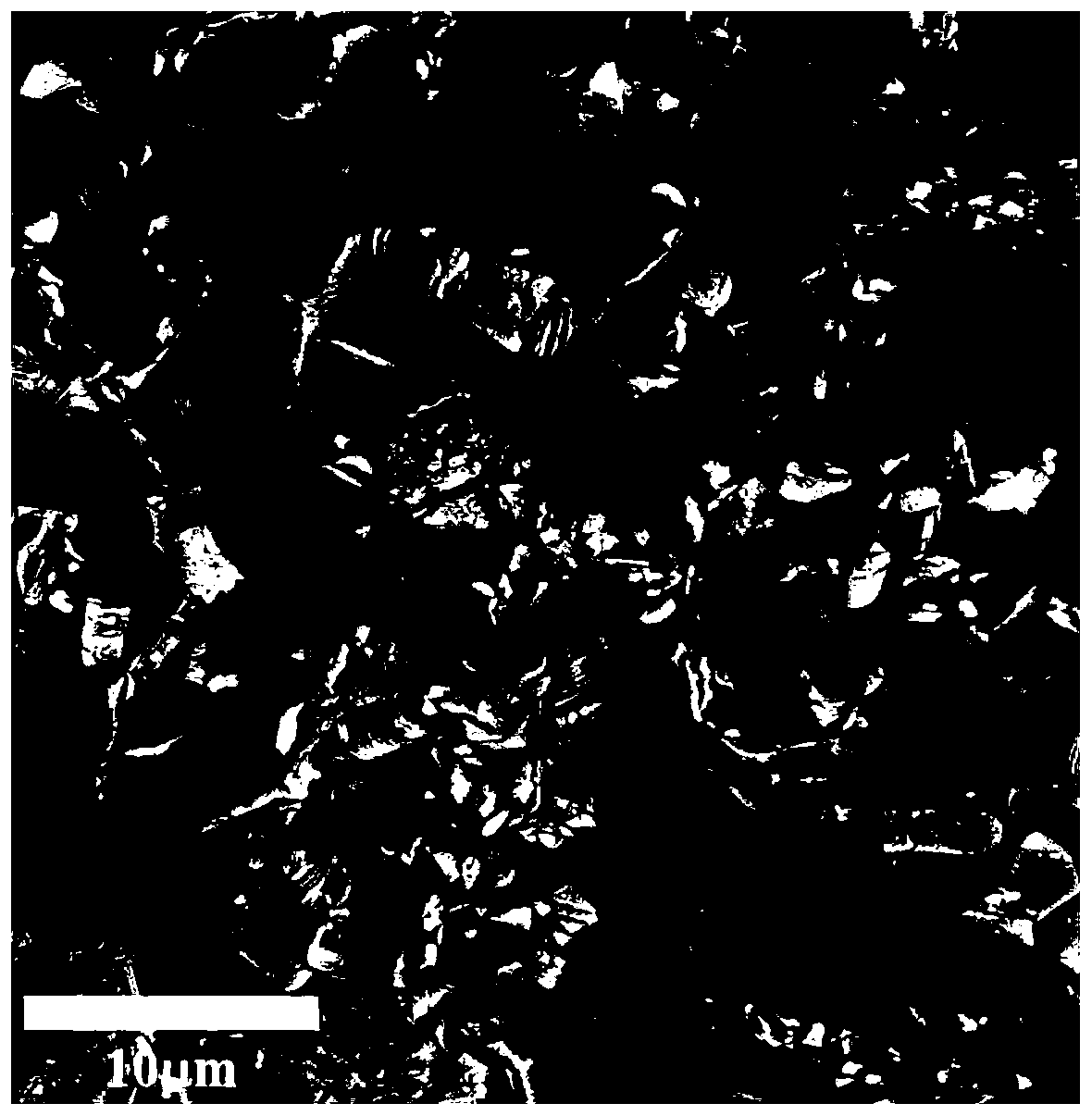

This invention relates to a synthetic method of aluminium carbide titanium ceramic powder. The invention takes TiH2 powder, Al powder and TiC powder as raw material, add Sn as accessory ingredient, dyr mix the raw materials acoording to mol ratio of TiH2:TiC:Al:Sn=1:1:1:0.1 for 10 hours, execute piece under 30 to 50 pressure, then put at high temperature furnace, under vacuum atmosphere rise the furnace temperature to 1350 to 1550 deg by rate of 15 to 40 deg per minute, holding time for 5 to 15min, execute low cost high-purity Ti3AlC2 powder.

Owner:BEIJING JIAOTONG UNIV

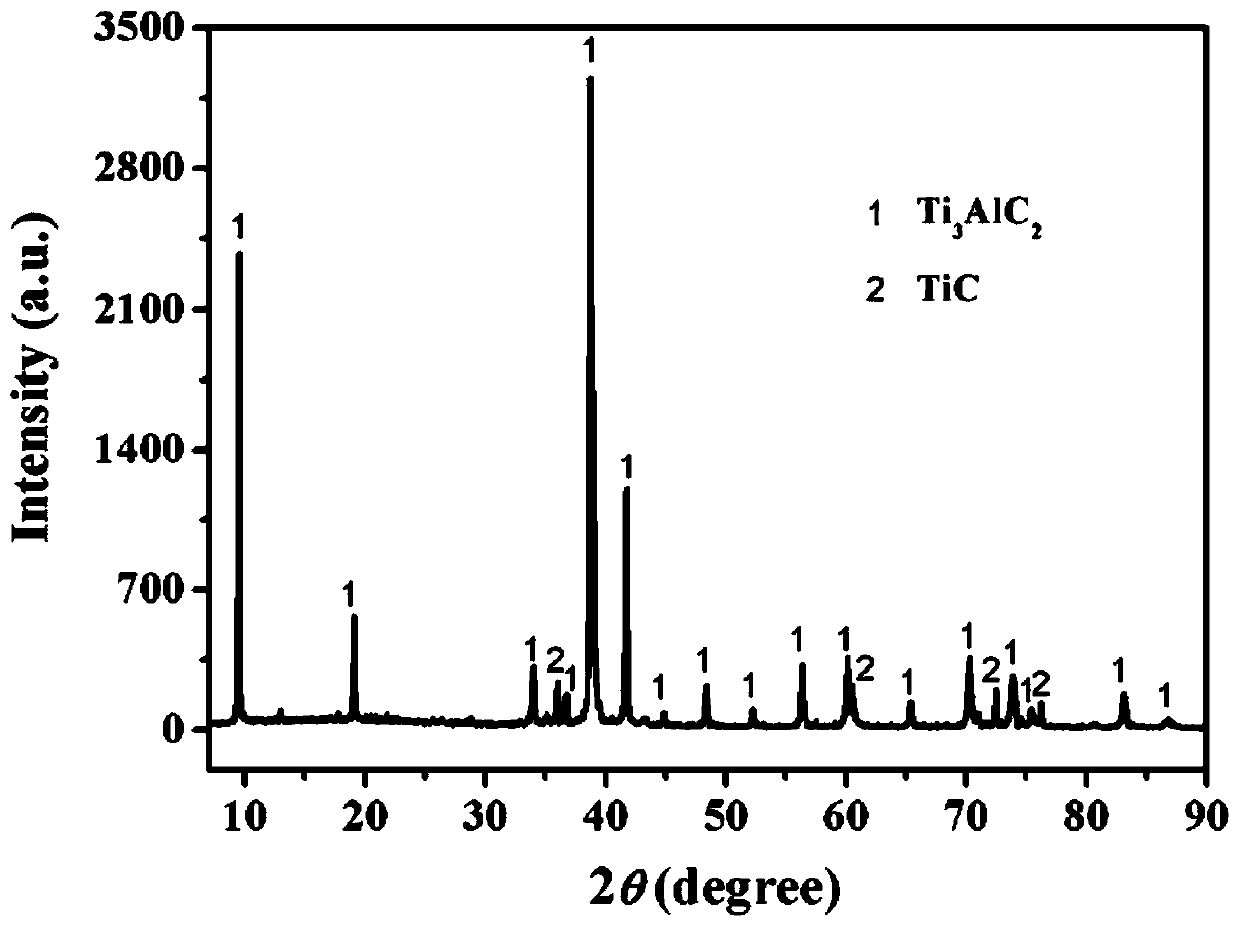

Ti3AlC2 powder and preparation method thereof

PendingCN110817875AAdequate responseIncrease profitCarbon compoundsThermal insulationArgon atmosphere

The invention relates to Ti3AlC2 powder and a preparation method thereof. The preparation method comprises the steps: taking titanium powder, aluminum powder and graphite as reaction materials, takingsodium chloride and potassium chloride as molten salt media, performing ball milling on the reaction materials and the molten salt media, putting a ball-milled ball abrasive into an aluminum oxide crucible, putting the aluminum oxide crucible into a thermal insulation structure sagger, filling a gap between the thermal insulation structure sagger and the aluminum oxide crucible with silicon carbide powder, and putting the thermal insulation structure sagger into a microwave oven; sequentially heating to 440-460 DEG C, 590-610 DEG C and 900-1200 DEG C at three heating rates in an argon atmosphere, carrying out heat preservation for 5-60 min under a condition of the temperature of 900-1200 DEG C, and carrying out furnace cooling to room temperature; and finally, grinding, washing with water, carrying out suction filtration and drying to obtain the Ti3AlC2 powder. The method has the characteristics of high raw material utilization rate, short production period, low energy consumption andhigh production efficiency, and the prepared Ti3AlC2 powder is high in purity and suitable for mass production.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing nano ZnO by virtue of metallurgy

InactiveCN102910669AHigh purityUniform particle sizeHydrogenZinc oxides/hydroxidesHydrogenWater vapor

The invention provides a method for preparing nano ZnO by virtue of metallurgy. The method comprises the following steps of: reducing zinc ores by adopting hydrogen to form a zinc liquid, evaporating the zinc liquid at high temperature, and then introducing water vapor for reaction to form ZnO powder and hydrogen which is recycled. According to the method, not only can nano ZnO with good quality be prepared, but also the hydrogen can be generated and recycled. The ZnO powder prepared by the method is high in purity and uniform in particle size; and the cost of the whole method is low, the use equipment is simple, the industrial production is easy, and the method is a novel and high-efficiency technology for preparing the nano ZnO powder and recycling the hydrogen.

Owner:KUNMING UNIV OF SCI & TECH

Processing method for increasing blueberry anthocyanidin content and purity

The invention relates to a processing method for increasing blueberry anthocyanidin content and purity. The processing method comprises the following steps: accurately weighting 20g of blueberry fresh fruit, washing by distilled water, air drying the moisture on the surface, crushing, homogenating, placing in a triangular flask, taking 2% of hydrochloric acid-methanol as an extraction solvent, setting the ratio of the solvent to fresh fruit as 5-20, extracting the pH value as 1.5-2.5, wherein cellulase accounts for 1-4% of the fresh fruit, and the enzymatic hydrolysis temperature is 40-70 DEG C, and performing an enzymatic hydrolysis reaction for 1 hour. The water-bath extraction is completed and then pumping filtration is carried out, the obtained filtrate enables rotary evaporation, and is performed with freeze drying to obtain a blueberry anthocyanidin crude extract. The blueberry anthocyanidin content is 5.15-5.65mg / 100g through high performance liquid chromatography determination. The blueberry anthocyanidin content is 3.65mg / 100g after the blueberry anthocyanidin is treated by a traditional solvent adding extraction method. The method for processing blueberry anthocyanidin has the advantages of simple operation, low cost, less pollution and high product content. the loss of blueberry anthocyanidin active components is far lower than that of the blueberry anthocyanidin active components by a solvent adding processing technology, and the purity of the obtained blueberry anthocyanidin powder is far higher than that of the blueberry anthocyanidin product on shelf.

Owner:BEIJING FORESTRY UNIVERSITY

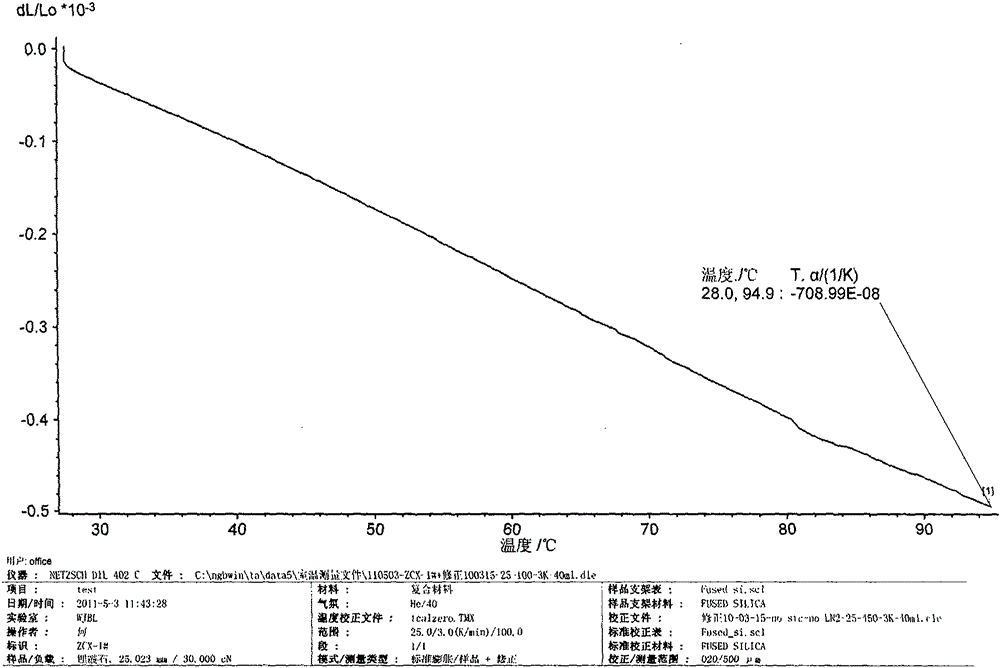

Simple, convenient and environment-friendly preparation method for beta-eucryptite powder

InactiveCN106379908ASimple preparation processLow equipment requirementsAluminium silicatesLithium carbonateSolid phases

The invention relates to a solid-phase preparation method for beta-eucryptite powder. The preparation method comprises the following steps: 1) weighing lithium carbonate, silica and alpha-alumina according to equimolar proportion; 2) subjecting the raw materials weighed in the step 1) to grinding and mixing in a rapid grinding device; and 3) filling an alumina saggar with the raw materials ground and mixed in the step 2), placing the alumina saggar in a high-temperature furnace and carrying out calcining so as to obtain desired beta-eucryptite powder. The preparation method is simple in process, low in equipment requirement, nontoxic and pollution-free; the prepared beta-eucryptite powder has high purity; and the preparation method is suitable for batch production.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD

Preparation method of special magnesium oxide for grain-oriented silicon steel sheet

The invention relates to a preparation method of special magnesium oxide for grain-oriented silicon steel sheet, belonging to the technical field of the preparation special magnesium oxide. The methodcomprises the following steps: reacting magnesium compound solution with the mixed solution of sodium carbonate and sodium hydroxide at a temperature to prepare a mixture of intermediate product containing magnesium carbonate and magnesium hydroxide, filtrating, washing, drying, calcining at high temperature, and grinding to obtain the special magnesium oxide for grain-oriented silicon steel sheet. The method has the advantages that the raw material is accessible, the cost is low, the production process is simple, the facility request is low, the method is applicable to industrialized production; the intermediate product is easy for separation and purification and is easy to wash, the washing loss of the product is low, the product yield is high; the product is special magnesium oxide powder, the powder has high purity, the grain size is small, and the average grain size is 1-2mu m and has a certain distribution range. The method is especially suitable for the preparation of special magnesium oxide for grain-oriented silicon steel sheet.

Owner:上海实业振泰化工有限公司

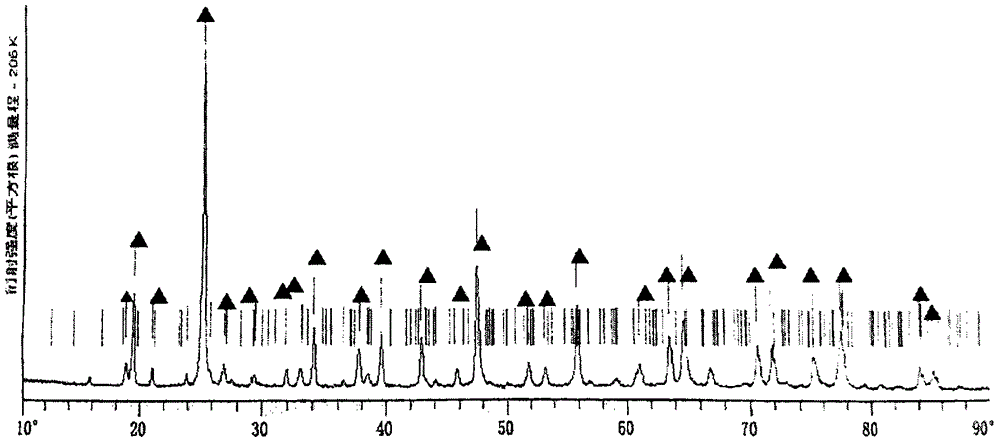

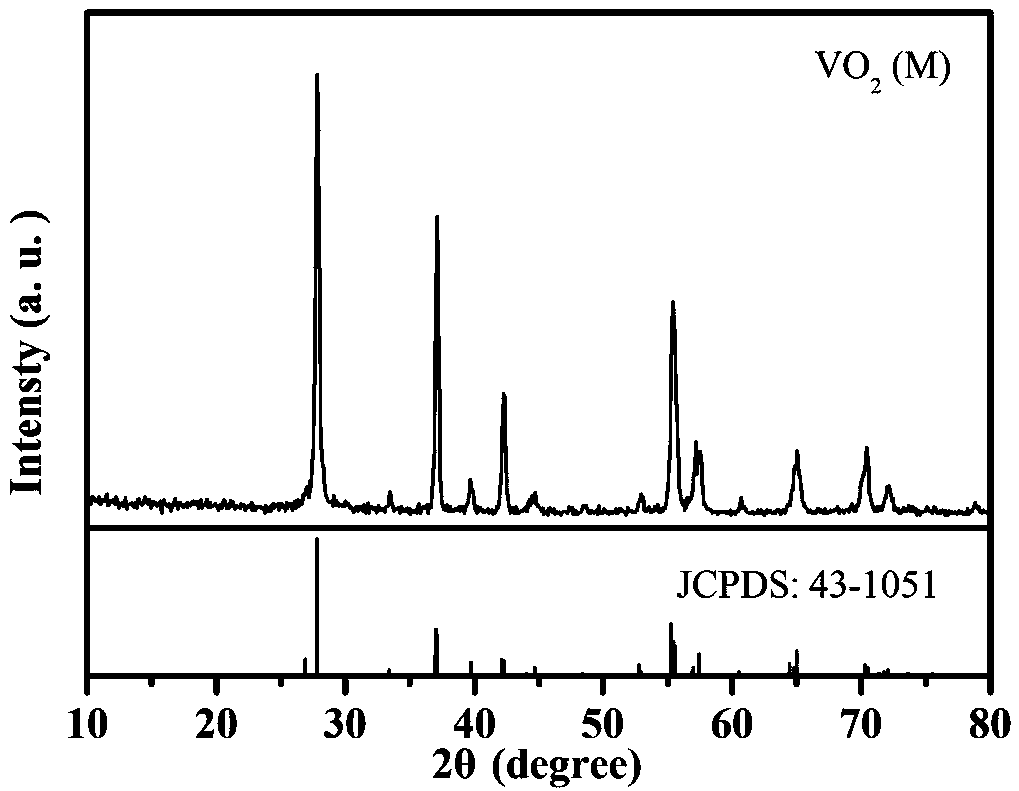

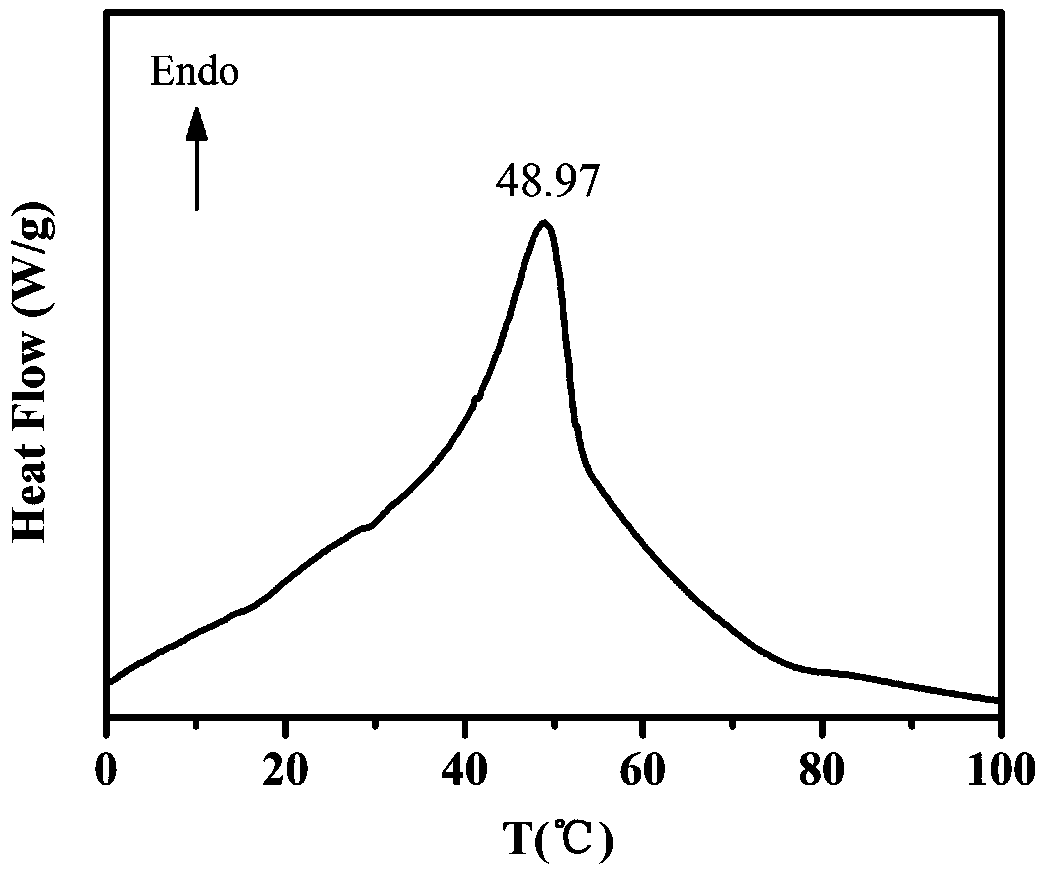

One-step hydrothermal method for preparing molybdenum-doped VO2 (M) powder by aid of tartaric acid used as reducing agent

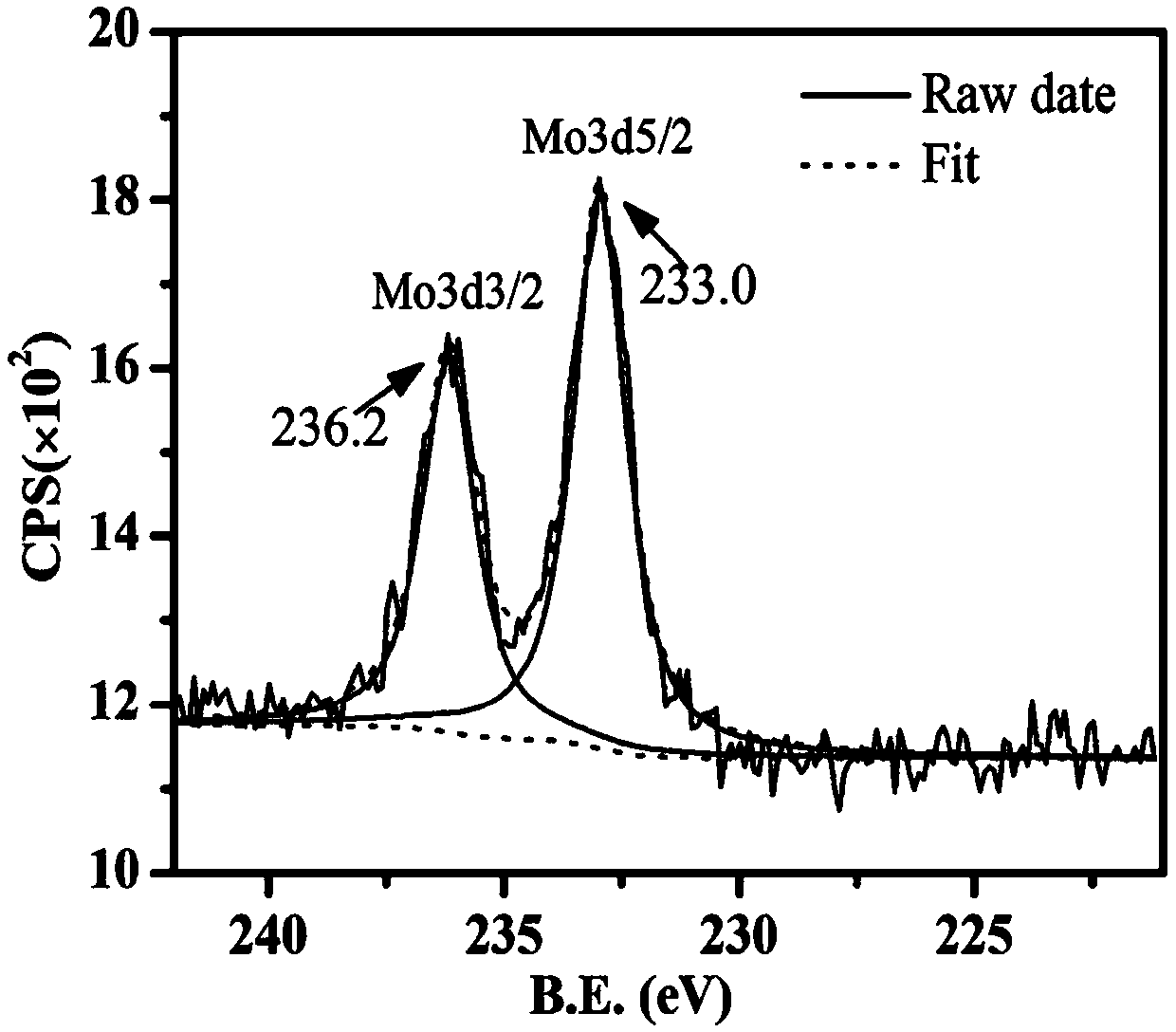

The invention relates to a one-step hydrothermal method for preparing molybdenum-doped VO2 (M) powder by the aid of tartaric acid used as a reducing agent. The one-step hydrothermal method mainly includes steps of uniformly stirring certain quantities of vanadium pentoxide, the tartaric acid, doping agents and deionized water at the room temperature to obtain mixtures, then transferring the mixtures into a high-pressure reaction kettle and carrying out hydrothermal reaction in the temperature ranges of 180-240 DEG C for the reaction time of 24-72 hours; naturally cooling reaction products until the temperatures of the reaction products reach the room temperature, repeatedly centrifugally washing obtained precipitates and ultimately drying the precipitates to obtain the molybdenum-doped VO2(M) powder. The one-step hydrothermal method has the advantages that the pure-phase molybdenum-doped VO2 (M) powder can be prepared by the aid of one-step hydrothermal processes at the low reaction temperatures for the short reaction time, and accordingly the problems of particle aggregation and influence on the thermochromism performance due to VO2 (M) powder prepared by the aid of hydrothermalprocesses and annealing heat treatment processes can be solved; the molybdenum-doped VO2 (M) powder prepared by the aid of the one-step hydrothermal method is high in purity and good in crystallinity,and the phase change temperatures can be controlled.

Owner:SICHUAN UNIV

Biological method for preparing ferrite-bismuth ferrite composite fluorescent material

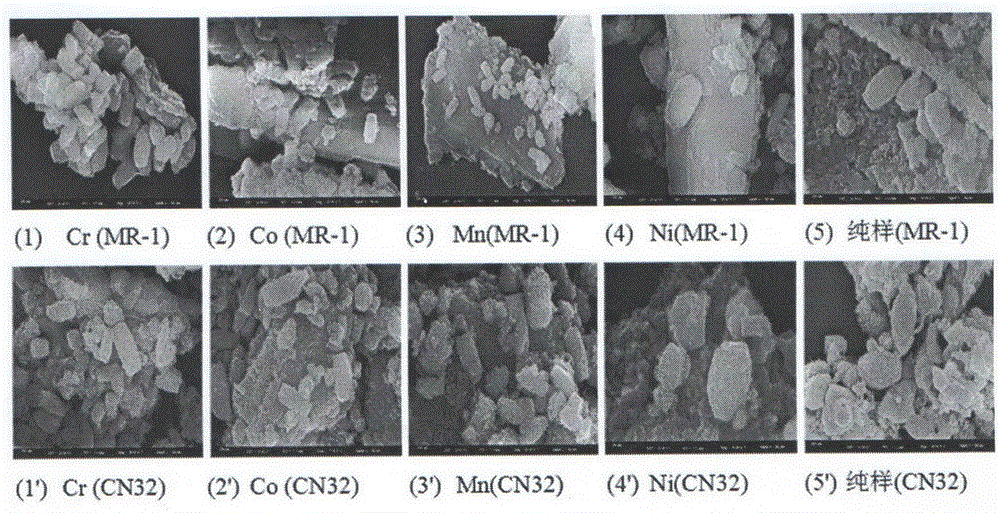

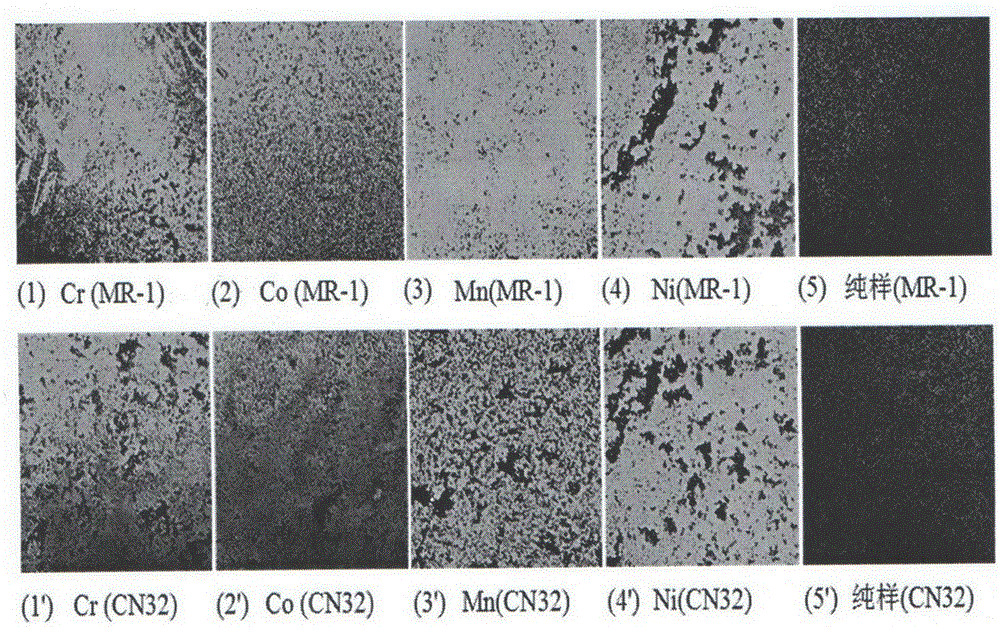

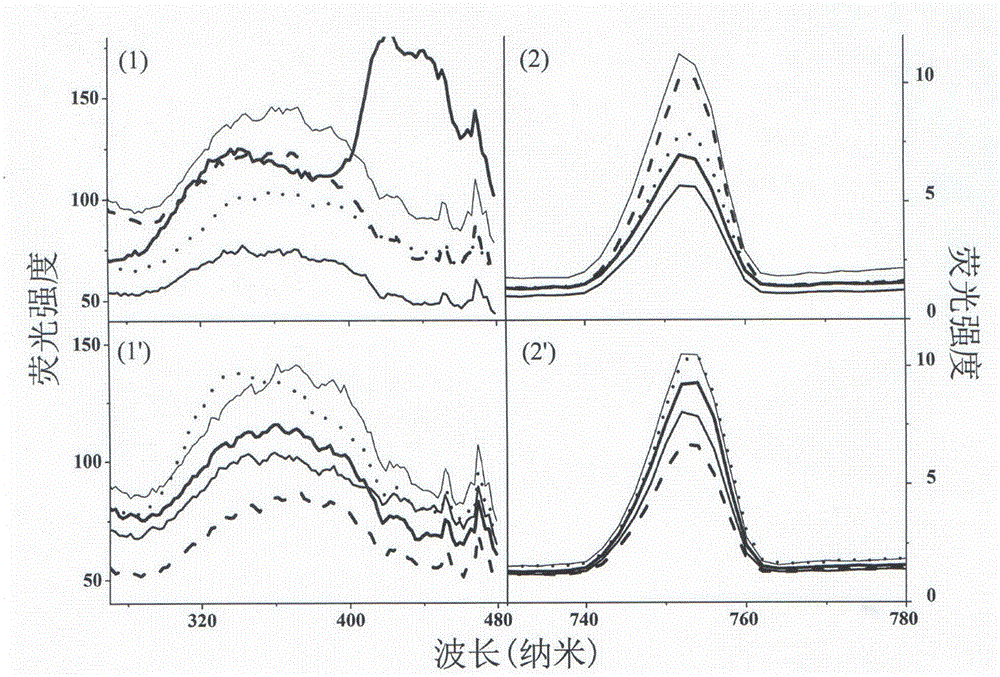

InactiveCN105062478AHigh recovery rateHigh purity powderFermentationLuminescent compositionsShewanella putrefaciensIron reduction

The present invention relates to a biological method for preparing a ferrite-bismuth ferrite composite fluorescent material. The biological method comprises three steps of: step I: in a tryptone soy broth culture medium, respectively culturing 30 g / L shewanella putrefaciens MR-1 and 30 g / L iron-reducing bacteria CN-32; step II: using a peptization reflow technique to prepare transition metal single-doped iron oxide hydroxide; and step III: under an aerobic condition at the room temperature, adding the single-doped iron oxide hydroxide and bismuth ferrite respectively into the shewanella putrefaciens MR-1 and the iron reduction bacteria CN-32, standing and layering to obtain the ferrite-bismuth ferrite nano composite fluorescent material respectively prepared from the shewanella putrefaciens MR-1 and the iron-reducing bacteria CN-32. Compared with the current conditions, the biological method for preparing the ferrite-bismuth ferrite composite fluorescent material has the advantages of a low price, a simple process, less pollution, and a high recovery rate. The ferrite-bismuth ferrite composite fluorescent material powder obtained by the method is high in purity, complete in topography, and uniform in thickness, has good fluorescent properties and can be applied to the fields of magnetic resonance imaging, targeting drug delivery, magnetic hyperthermia, and the like.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Method for extracting pure ammonium rhenate from rhenium-contained extracting liquid

ActiveCN108300858AEasy to produceHigh recovery rateProcess efficiency improvementRheniumHydrometallurgy

The invention discloses a method for extracting pure ammonium rhenate from rhenium-contained extracting liquid, belongs to the field of ammonium rhenate purification in wet metallurgy, and solves theproblems of complex operation in preparation of ammonium rhenate, lower recovery rate and higher cost in the prior art. The method comprises the steps of reverse extraction by hydrochloric acid, introduction of chlorine, generation of precipitations by adding ammonium chloride, washing of the precipitations through ammonium-contained hydrochloric acid, washing by ethanol solution after filtrationof the precipitations, drying of powder after washing of chlorine ions, and obtaining of high-purity ammonium rhenate powder. The method is simple in process, mild in reaction, simple in operation, low in cost, high in yield and easy to realize scale production; and meanwhile, the product is powder with high purity to achieve subsequent preparation of high-purity rhenium powder.

Owner:JINCHUAN GROUP LIMITED

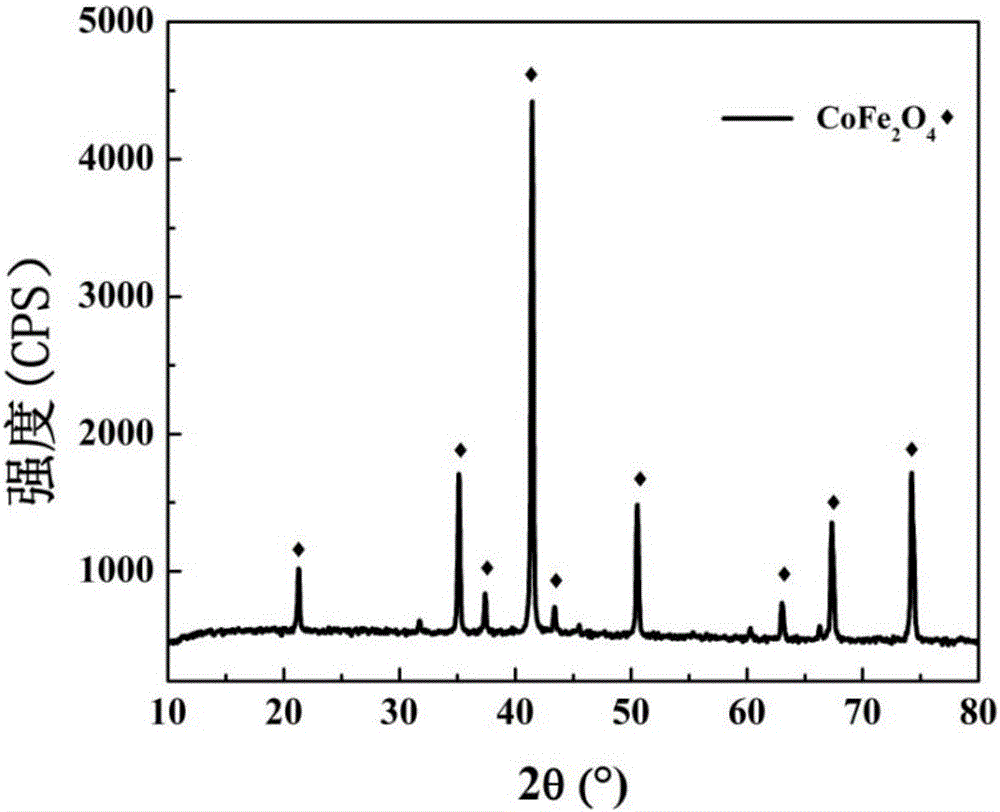

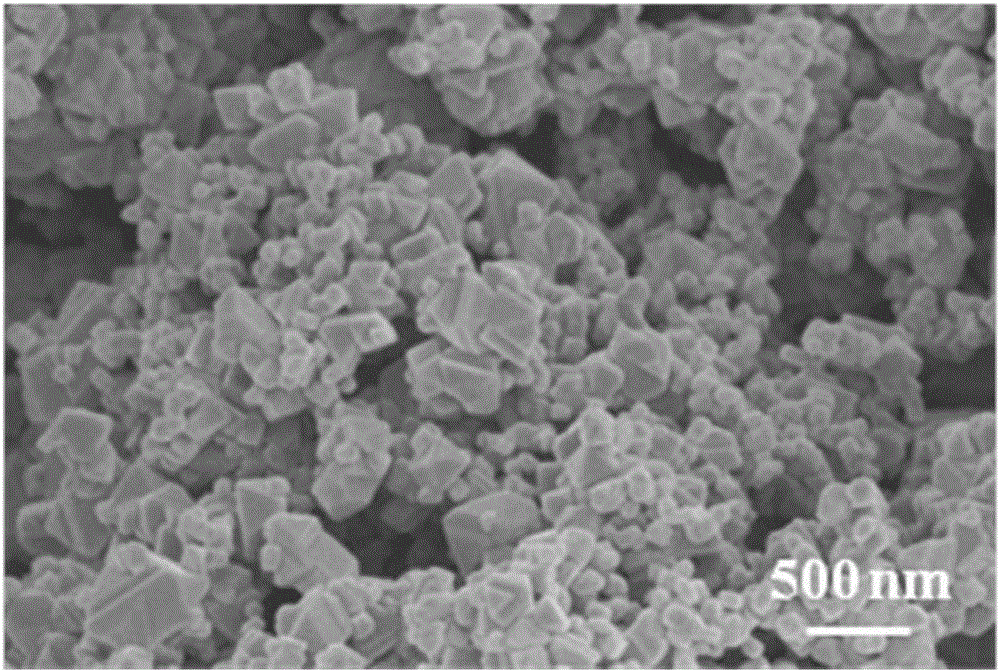

Rod-like cobalt ferrite powder and preparation method thereof

ActiveCN106830100AUniform shape and sizeLarge specific surface areaCobalt compoundsAcetic acidNitrogen

The invention discloses rod-like cobalt ferrite powder and a preparation method thereof. The preparation method comprises the following steps: taking Co(NO3)2.6H2O and Fe(NO3)3.9H2O as raw materials, preparing granular cobalt ferrite powder by adopting a sol-gel method, then taking N,N-dimethyl formamide as a solvent, hydrazine hydrate as a reducing agent and methyl mercaptoacetate as a complexing agent, and under the protection of nitrogen, further corroding the cobalt ferrite powder by adopting a one-step corrosion method, so that cobalt ferrite with a rod-like structure is obtained. The rod-like cobalt ferrite powder disclosed by the invention has the advantages that preparation process is simple in operation, and the period is short; and the prepared rod-like cobalt ferrite has the diameter about 90-100nm and the length about 600-700nm and is uniform in size, and the rod-like structure enables the specific surface area of cobalt ferrite to be increased.

Owner:西安方科新材料科技有限公司

Method for preparing AlN powder

InactiveCN109264679AHigh purity powderHigh purityMaterial nanotechnologyNitrogen compoundsAir atmospherePhenanthroline

The invention discloses a method for preparing AlN powder. The method includes first dissolving an aluminum source and a nitrogen source completely in a solvent according to the Al:N molar ratio of 1:1-1:35, mixing evenly, drying the solvent by evaporating, roasting an obtained solid mixture at 500-1000 DEG C for 1-9h in a roasting atmosphere, and then decarburizing the mixture at 200-750 DEG C for 1 to 5h in an air atmosphere to obtain the high-purity AlN powder. The aluminum source is aluminum chloride hydrate, aluminum lactate, aluminum glycinate, aluminum stearate and the like; the nitrogen source is guanidine hydrochloride, guanidine acetate, chitosan, 1,10-phenanthroline; the solvent is any one of deionized water, methanol, ethanol, ethyl acetate, acetone, diethyl ether, benzene andtoluene; the roasting atmosphere is one or two of nitrogen, ammonia, argon and helium. Compared with the conventional AlN preparation method, the method has the advantages of wide reactant range, environmentally-friendly process, simple operation, high product purity and low cost.

Owner:SHAANXI UNIV OF SCI & TECH +1

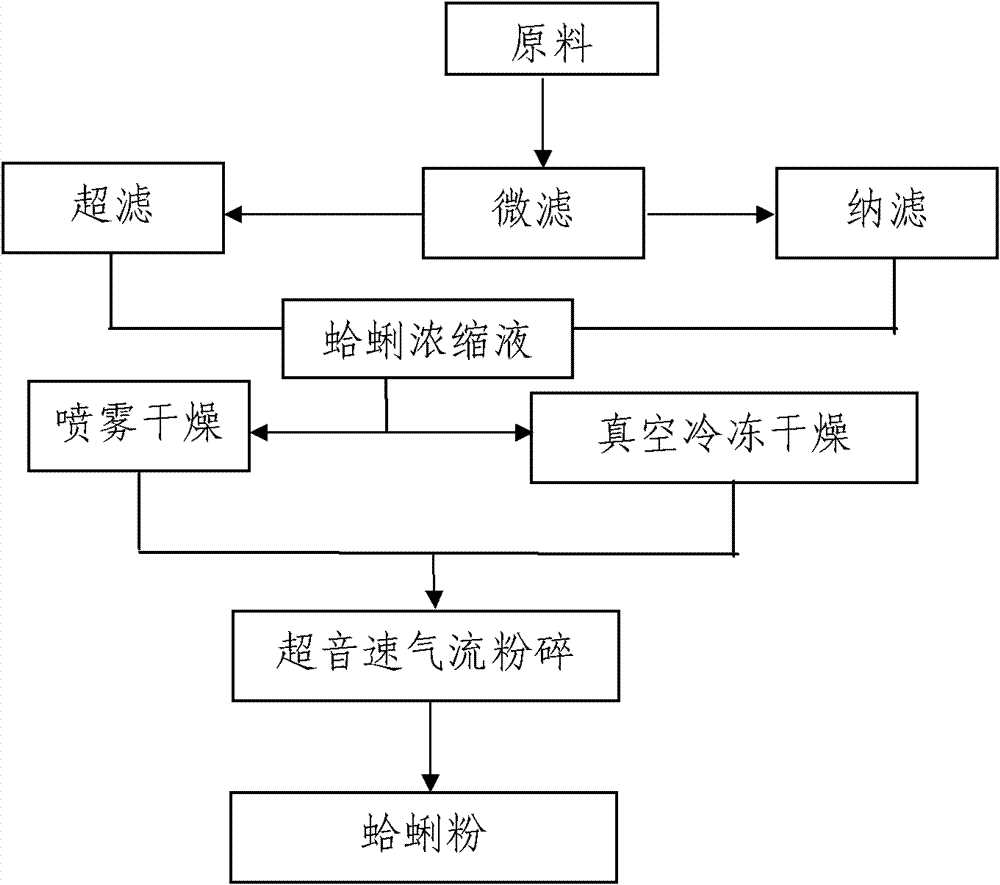

Clam concentrated liquid or clam powder, and production method thereof

The invention relates to an aquatic product deep processing technology, and specifically relates to clam concentrated liquid or clam powder, and a production method thereof. According to the invention, clam steaming and boiling liquid obtained during a clam processing process is adopted as a raw material; impurities are removed by micro-filtration; and salt and part of water content are removed by ultra-filtration or nano-filtration, such that the clam concentrated liquid is obtained. Measured according to standard, every 100g of the concentrated liquid comprises the components of: 5-30g of protein, 0.5-5g of fat, 2-15g of total sugar, 5-20g of an ash content, and balance of water. The clam concentrated liquid is subjected to vacuum lyophilization or spray-drying, such that crude clam powder is obtained; the crude clam powder is crushed by using a supersonic jet mill, such that clam powder is obtained. Every 100g of the clam powder comprises the components of: 20-65g of protein, 2-15g of fat, 3-20g of total sugar, 5-20g of an ash content, and 3-10g of water.

Owner:大连利明海洋生物食品有限公司

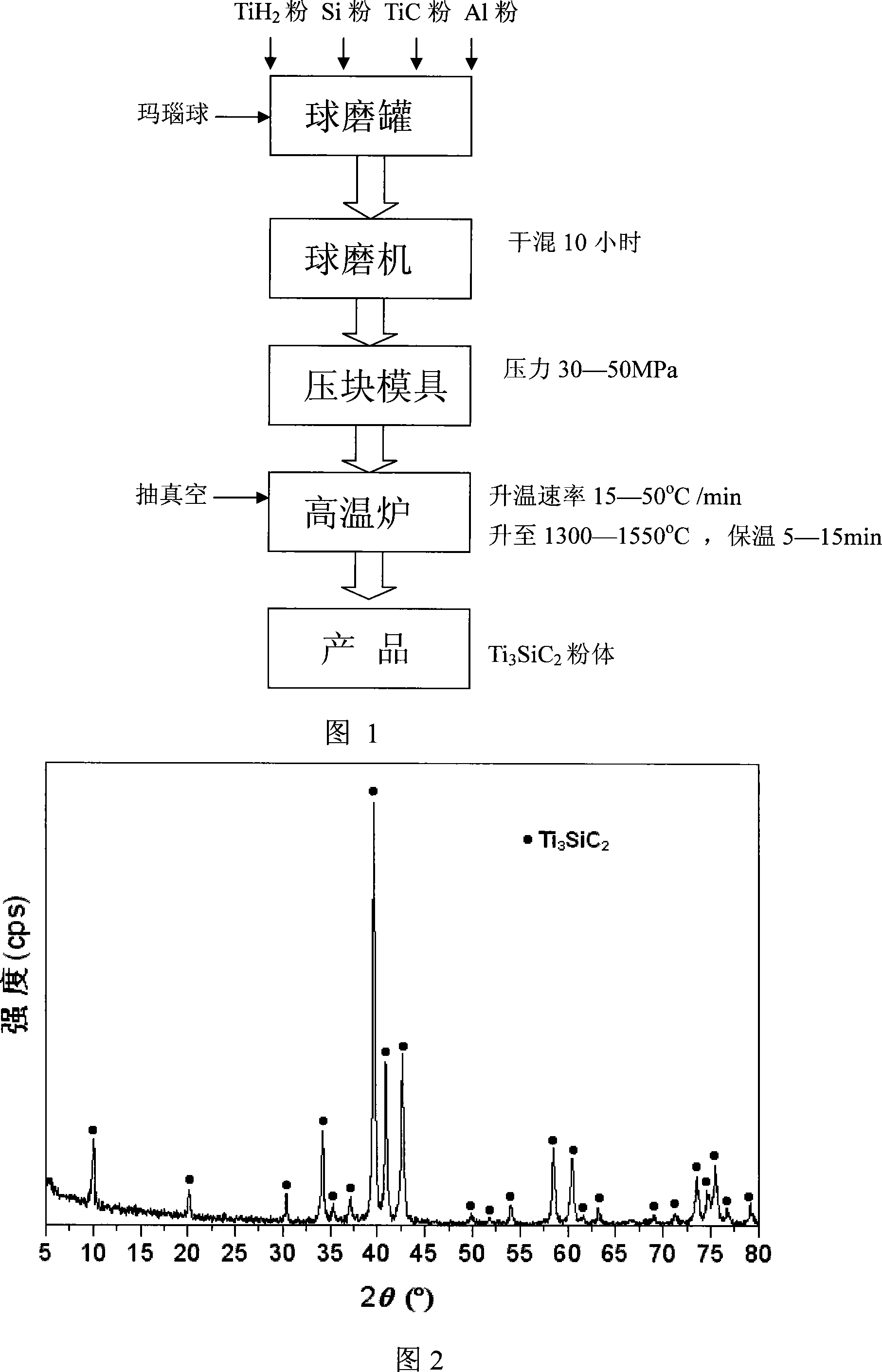

Atmospheric synthesizing method for silicon carbide titanium ceramic powder

The invention relates to a synthesis method of sic ceramic powder at ordinary pressure. The invention is made from the following materials that are TiH2 powder, Si powder, and TiC powder, and the using of Al which is used as reaction promoter. The materials, according to a certain mole ratios of Ti: Si: TiC: Al of 1:1: (1.8-2): (0.15-0.25), are mixed dryly together for 10 hours, and then are compacted into briquetting under the pressure of 30-50 MPa. Then the briquetting is put into high temperature furnace at vacuum condition. Next in a heating increasing rate of 15-50 DEG C / min, the temperature in furnace is increased to 1300-1550 DEG C and is kept for 5-15min, then the Ti3SiC2 powder of high purity and low cost is obtained. The invention is characterized by short synthesis time of Ti3SiC2 powder, high purity, low cost, simple equipment, and stable technical parameter, and being suitable for large scale production.

Owner:BEIJING JIAOTONG UNIV

Clean production method for high-purity cobaltosic oxide powder

InactiveCN101525752BNarrow and uniform particle size distributionGood dispersionElectrolysis componentsElectrolysisDecomposition

The invention discloses a clean production method for high-purity cobaltosic oxide powder. The method comprises the following steps: using metal cobalt as an electrolytic anode, using soluble cobalt salt as electrolyte main salt and adding additives; adopting an electrochemical method to prepare a cobaltosic oxide precursor sediment; and then, drying and calcining the precursor sediment to obtainthe cobaltosic oxide powder. The cobaltosic oxide powder produced by the method and the process can achieve the purity more than 99.7 percent, no additional precipitator is needed in the whole technological process, the added additives are all easy to wash without decomposition, and electrolyte and washing water can be recycled so as to avoid discharging sewage and generating waste gas. The method can adjust and control the appearance and the grain diameter distribution of the cobaltosic oxide powder by controlling the composition of the electrolyte, the cathode current concentration, the electrodeposition time and the calcining temperature and has the advantages of high product quality, simple production procedures, energy saving, environmental protection, and the like.

Owner:HUNAN UNIV

Batch preparation method of pentatitanium trisilicate intermetallic compound powder

InactiveCN108165794APrecise control of stoichiometric ratioHigh purity powderHigh energyShielding gas

The invention relates to a batch preparation method of pentatitanium trisilicate intermetallic compound powder. Si powder and Ti powder are weighed according to a mole ratio of 3: 5 as sintering raw materials; a Ti5Si3 compound is synthesized by adopting a vacuum sintering process; the sintering process comprises the following steps: the Si powder and the Ti powder, uniformly mixed, are put in a vacuum furnace, are heated to 1350-1450 DEG C for insulation, and are cooled to the room temperature along with the furnace; the sintering materials are added in anhydrous ethanol, and are put in a ball milling tank; Ar gas is used as shielding gas; the sealed ball milling tank is put in a high-energy planet ball mill; a wet ball milling method is used for refining; and vacuum drying and grinding are performed on obtained ball milling pulp to pass through a sieve of 130 meshes to obtain Ti5Si3 powder. The method overcomes the defects of easy generation of pollutions, complex machining process,low yield and the like in a casting method, a powder press sintering method, a quick solidification method and a self-propagating combustion method. No by-product is generated in the reaction process;the powder purity is high; meanwhile, the chemical ratios of products can be precisely controlled; the energy consumption is low; the particle sizes of the products are fine and uniformly distributed; the activity is high; the products can be prepared in batches; no pollution is generated; and the cost is reduced.

Owner:YANGZHOU UNIV

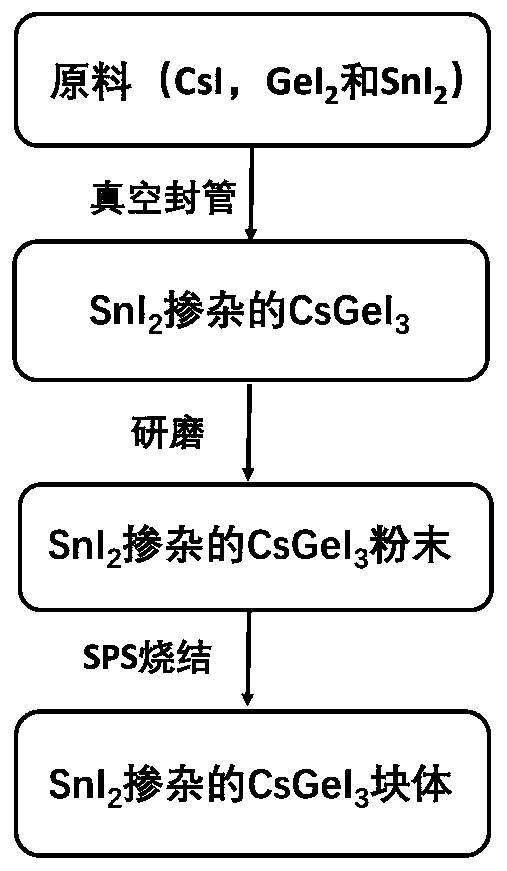

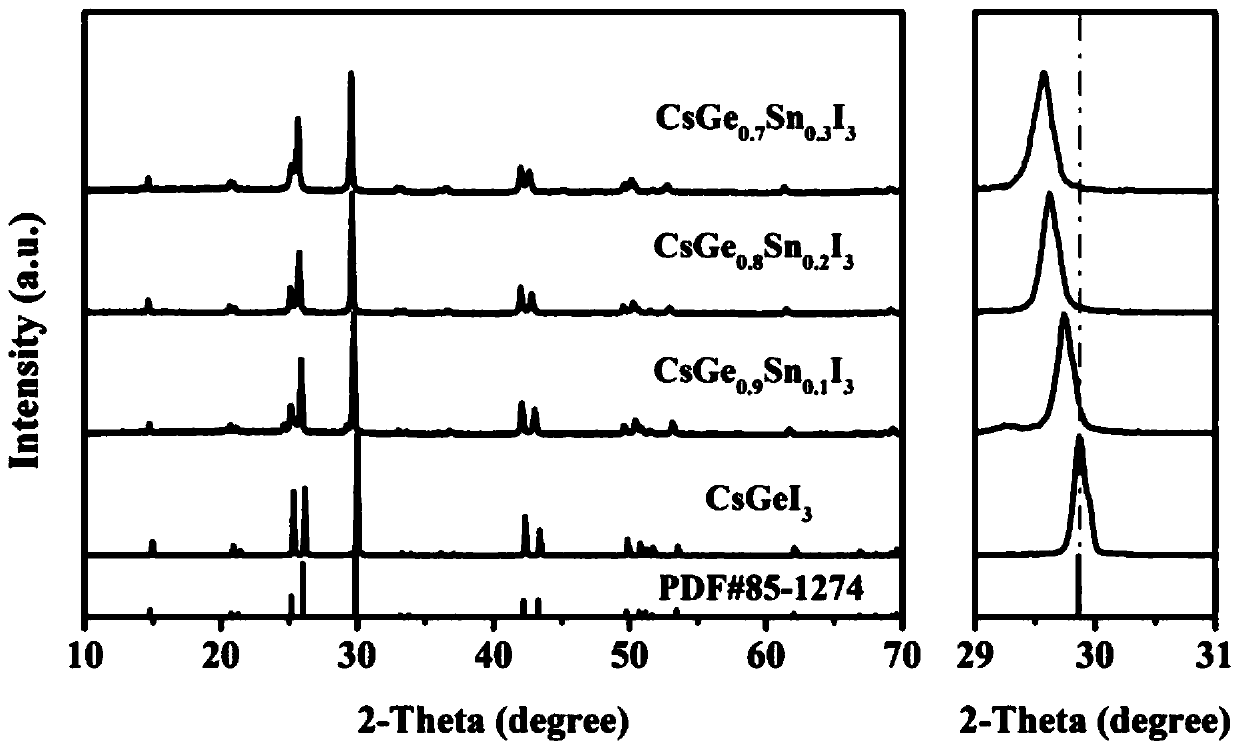

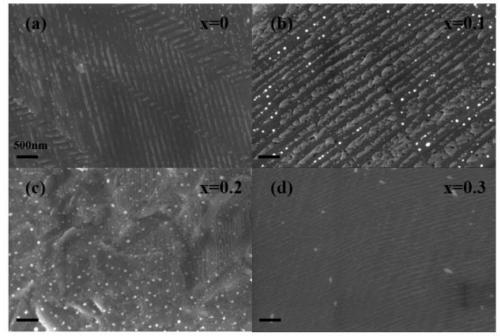

SnI2 doped CsGeI3 perovskite type thermoelectric material and preparation method thereof

InactiveCN111048658AHigh purity powderHigh block densityThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsPlasma technology

The invention discloses a SnI2 doped CsGeI3 perovskite type thermoelectric material and a preparation method thereof and belongs to the technical field of new energy material preparation. The preparation method comprises the steps of powder preparation and block preparation. According to the powder preparation, CsI, SnI2 and GeI2 are added into a quartz tube proportionally, after the quartz tube is vacuumized, the quartz tube is filled with high-purity argon, and the tube is sealed; the quartz tube containing the raw materials is arranged in a sintering furnace, the quartz tube is heated to 450-550 DEG C at a speed of 2-5 DEG C / min, is subjected to heat preservation for 12-24 hours, and then is cooled to 200-350 DEG C at a speed of 2-5 DEG C / min; and an obtained block is taken out and ground in a glove box for 10-15 min, so that SnI2 doped CsGeI3 powder can be obtained. According to the block preparation, the SnI2 doped CsGeI3 powder is sintered through a spark plasma technology; the powder is poured into a graphite mold; and the powder is sintered for 5-30 min under temperature of 200-400 DEG C and pressure intensity of 5-40 MPa, and a block material is obtained. With the method adopted, the perovskite type thermoelectric material SnI2 doped CsGeI3 block can be prepared; and the obtained block is high in density. The method has the advantages of low preparation temperature andshort preparation time.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing magnesium-aluminum spinel nano particle powder

InactiveCN102001696AReaction raw materials are readily availableCalcination temperature is lowAluminium oxides/hydroxidesAluminateNanoparticle

The invention discloses a method for preparing magnesium-aluminum spinel nano particle powder, which comprises the following steps of: preparing water soluble aluminate into an aqueous solution with the Al3<+> concentration of 0.05-1mol / L; then adding alkali; filtering aluminium hydroxide; after washing, carrying out drying treatment and grinding into fine powder in 200-1,000 meshes; adding the ground fine powder into a magnesium sulfate aqueous solution; after fully stirring, carrying out drying treatment to obtain the mixed powder of aluminium hydroxide and magnesium sulfate; calcining the mixed powder at 800-950 DEG C for 2-5 hours; and after washing a calcined product with water and removing magnesium sulfate, carrying out drying treatment under the condition of 80-100 DEG C. The invention discloses an environmental-friendly and energy-saving method for producing high-purity agglomeration-free magnesium-aluminum spinel nano particle powder at an industrial scale.

Owner:CHANGAN UNIV

A kind of impeller and ultrafine grinding machine, ultrafine grinding system

The invention provides an impeller, a superfine mill applying the impeller and a superfine milling system comprising the superfine mill. The impeller comprises a wheel disc, straight surface type blades and straight surface type impact plates, and an abrasion-resistant layer is adhered to the surface of each straight surface type blade. The straight surface type blades are multiple and uniformly arranged on the wheel disc in the radial direction. The tail end of each straight surface type blade is provided with one corresponding straight surface type impact plate in the extension direction of the center of the wheel disc to the outer diameter edge of the wheel disc, and a first included angle is formed between each straight surface type blade and the corresponding straight surface type impact plate. The tail ends of the straight surface type blades are located within the outer diameter edge of the wheel disc. The initiating end of each straight surface type impact plate is connected with the tail end of the corresponding straight surface type blade. The tail ends of the straight surface type impact plates exceed the outer diameter edge of the wheel disc. According to the impeller, the superfine mill applying the impeller and the superfine milling system comprising the superfine mill, high-hardness nonmetal or metal can be milled into superfine powder; in addition, abrasion of equipment parts is small, and the function of particle size classification is achieved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

A kind of three-dimensional flower-shaped bismuth ferrite powder and preparation method thereof

ActiveCN106698521BUniform shape and sizeGood dispersionMaterial nanotechnologyIron compoundsIron powderThree dimensional shape

The invention discloses three-dimensional flower-shaped bismuth ferrite powder and a preparation method thereof. The preparation method comprises the following steps: taking Bi(nO3)3.5H2O and Fe(NO3)3.9H2O as starting materials, preparing blocky bismuth ferrite powder by adopting a hydrothermal method, then mixing the bismuth ferrite powder, a corrosive solvent, a reducing agent and a complex agent under the protective atmosphere, and obtaining three-dimensional porous bismuth ferrite flower balls by adopting a one-step corrosion method. According to the invention, a thick flaky Bi2Fe4O9 powder raw material is prepared by adopting the hydrothermal method, grains are uniform in size and shape and are better in dispersibility, a corrosion technology is adopted, preparation technological operation is simple, and the period is short; and the prepared flower-shaped bismuth ferrite has the diameter being about 1-2mu m, sizes are uniform, a specific surface area is relatively large due to a porous structure, and performances of all the aspects are respectively improved.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com