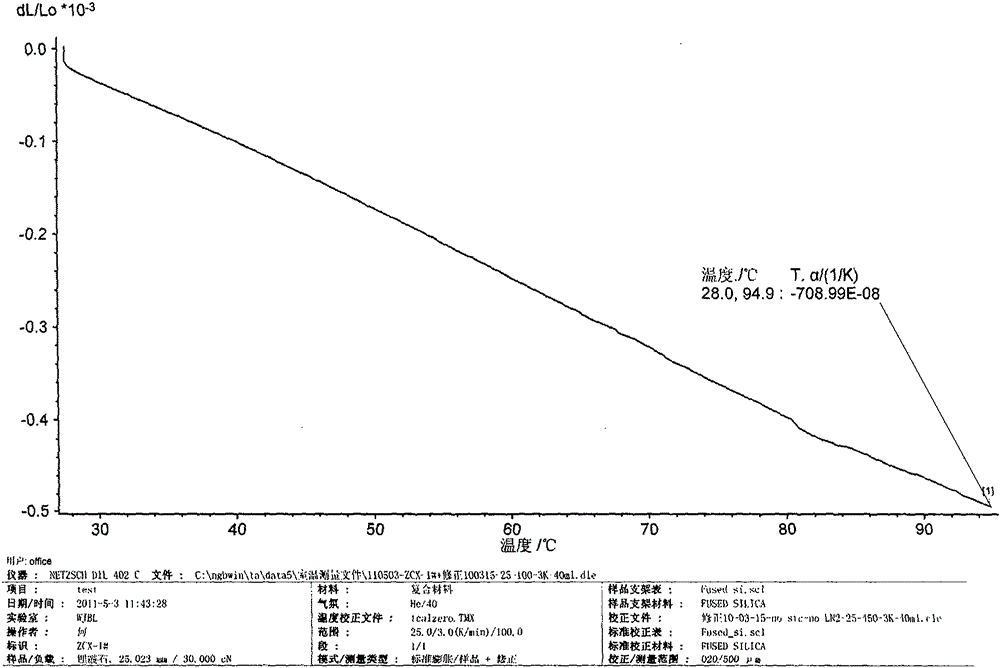

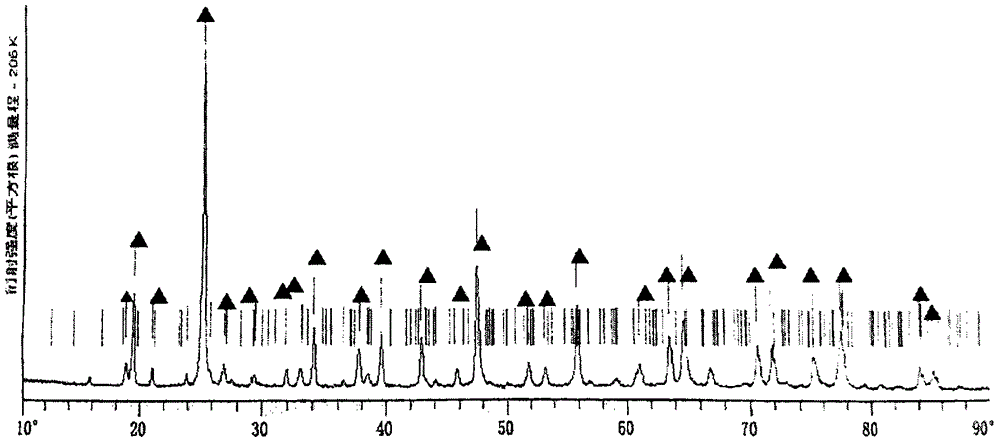

Simple, convenient and environment-friendly preparation method for beta-eucryptite powder

A technology of eucryptite powder and eucryptite, which is applied in the direction of aluminum silicate, silicate, etc., can solve the problems of unsuitable large-scale production, long preparation period of sol-gel method harmful to health, environmental pollution, etc., and meet the equipment requirements Low, large negative expansion coefficient, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment one: the preparation steps of β-eucryptite in the present embodiment are as follows: take analytically pure lithium carbonate, silicon dioxide and α-alumina in an equimolar ratio, put the above-mentioned complex into a quick mill, and Grinding the mixed materials in the rapid mill for 1-3 hours, putting the mixed raw materials into an alumina sagger, placing them in a high-temperature furnace and calcining at 1200°C-1300°C for 1-3 hours to prepare β-eucryptite.

specific Embodiment approach 2

[0009] Embodiment 2: This embodiment differs from Embodiment 1 in that the calcination temperature is 1200°C-1300°C, the calcination time is 4-8 hours, and other steps are the same as Embodiment 1.

specific Embodiment approach 3

[0010] Embodiment 3: This embodiment differs from Embodiment 1 in that the calcination temperature is 1300°C-1350°C, the calcination time is 4-6 hours, and other steps are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com