Method for preparing Ti5Si3 intermetallic compound powder by mechanical alloying

A mechanical alloying, titanium metal technology, applied in the field of inorganic compound manufacturing process, can solve the problems of low yield, pollution, complex processing technology, etc., and achieve the effects of uniform distribution, high powder purity and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh Si powder and Ti powder as raw materials according to the molar ratio of 3:5, and weigh ZrO according to the ball-to-material ratio of 20:1 (mass ratio). 2 Ceramic balls are used as grinding balls; carbon tetrachloride, which is 0.3 times the volume of the ball mill jar, is used as a process control agent. Put the weighed raw materials, grinding balls and process control agent into the ball mill jar, use Ar gas as the protective gas, put the sealed ball mill jar into the high-energy planetary ball mill, set the speed at 500 rpm, and the milling time at 40 Hour. The obtained ball mill slurry is vacuum-dried and ground, and passed through a 130-mesh sieve to obtain Ti 5 Si 3 Powder.

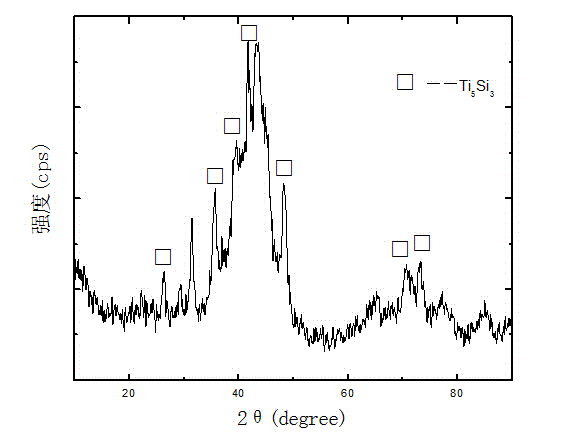

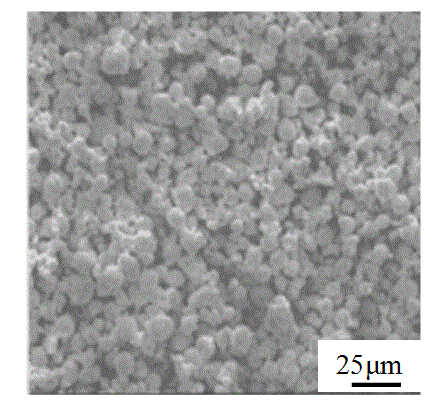

[0017] The powder obtained by the above process only contains Ti 5 Si 3 Phase, the particle size is on the order of microns and uniformly distributed, see figure 1 and 2 .

Embodiment 2

[0019] Weigh Si powder and Ti powder as raw materials according to the molar ratio of 3:5, and weigh ZrO according to the ball-to-material ratio (mass ratio) of 10:1. 2 Ceramic balls are used as grinding balls; carbon tetrachloride, which is 0.1 times the volume of the ball mill jar, is used as a process control agent. Put the weighed raw materials, grinding balls and process control agent into the ball mill jar, use Ar gas as the protective gas, put the sealed ball mill jar into a high-energy planetary ball mill, set the speed at 300 rpm, and the milling time at 50 Hour. The obtained ball mill slurry is vacuum-dried and ground, and passed through a 130-mesh sieve to obtain Ti 5 Si 3 Powder.

[0020] The powder obtained by the above process only contains Ti 5 Si 3 Phase, the particle size is on the order of microns and uniformly distributed, see figure 1 and 2 .

Embodiment 3

[0022] Weigh Si powder and Ti powder as raw materials according to the molar ratio of 3:5, and weigh ZrO according to the ball-to-material ratio (mass ratio) of 15:1. 2 Ceramic balls are used as grinding balls; carbon tetrachloride, which is 0.2 times the volume of the ball mill jar, is used as a process control agent. Put the weighed raw materials, grinding balls and process control agent into the ball mill jar, use Ar gas as the protective gas, put the sealed ball mill jar into the high-energy planetary ball mill, set the speed at 400 rpm, and the milling time at 45 Hour. The obtained ball mill slurry is vacuum-dried and ground, and passed through a 130-mesh sieve to obtain Ti 5 Si 3 Powder.

[0023] The powder obtained by the above process only contains Ti 5 Si 3 Phase, the particle size is on the order of microns and uniformly distributed, see figure 1 and 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com