All-oxide ferroelectric photodiode and preparation method thereof

A technology of photodiodes and oxides, used in circuits, electrical components, ion implantation plating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1. Base cleaning

[0056] STO was used as the substrate, and each process was ultrasonically cleaned in acetone, absolute ethanol, and deionized water for 15 minutes, and then dried with high-purity nitrogen.

[0057] 2. Preparation of LSMO layer

[0058] 1) Configuration of precursor solution

[0059] Mix according to the volume ratio of glacial acetic acid: deionized water = 1:1, and add equal mass of polyethyleneimine (PEI) and ethylenediaminetetraacetic acid (EDTA) to the above mixed solvent, according to the molar ratio La: Sr: Mn=7:3:10 weighing (CH 3 COOH) 3 La, (CH 3 COOH) 2 Sr and (CH 3 COOH) 2 Mn was added to a mixed solvent containing PEI and EDTA, and mixed evenly to obtain a precursor solution. The concentration of LSMO in the precursor solution was 0.1 mol / L, and the concentrations of PEI and EDTA in the precursor solution were equal, both 0.03 g / L ml;

[0060] 2) Preparation of monolayer film

[0061] (100) SrTiO 3 The substrate is placed in a ...

Embodiment 2

[0079] Prepare the device according to the method of Example 1, the difference is: when preparing the LSMO layer, the O in the furnace during the heat treatment process 2 The flow rate is 0.5 L / min.

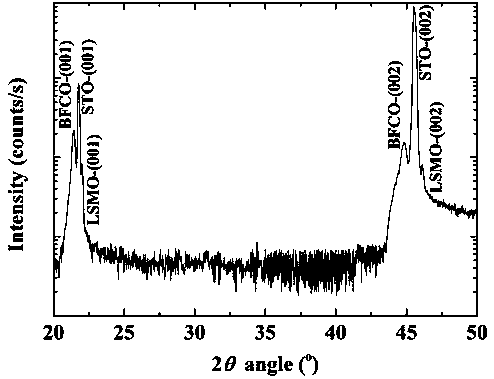

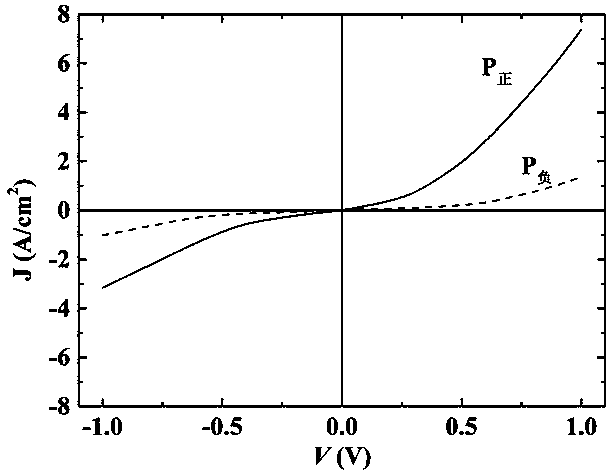

[0080] The materials of the LSMO layer and the BFCO layer in the obtained device have better epitaxial growth, and the crystallinity of the ITO layer is still good. For the device under light (AM1.5G, 100 mW cm -2 ) and the current and voltage performance under dark conditions were tested, and the test method was the same as in Example 1. The on-off ratio under dark conditions and positive and negative remanent polarization is 4.8:1; under positive and negative remanent polarization, the maximum open circuit voltage of the device under light conditions is 52 mV, and the short circuit current is 630 μA / cm 2 .

Embodiment 3

[0082] Prepare the device according to the method of Example 1, the difference is: when preparing the BFCO layer, the temperature in the furnace during the heat treatment N 2 The flow rate is 1 L / min.

[0083] The materials of the LSMO layer and the BFCO layer in the obtained device have better epitaxial growth, and the crystallinity of the ITO layer is still good. For the device under light (AM1.5G, 100 mW cm -2 ) and the current and voltage performance under dark conditions were tested, and the test method was the same as in Example 1. The on-off ratio under dark conditions and positive and negative remanent polarization is 4.6:1; under positive and negative remanent polarization, the maximum open circuit voltage of the device under light conditions is 43 mV, and the short circuit current is 520 μA / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com