Polarization-doped InN-based tunneling field effect transistor and manufacturing method thereof

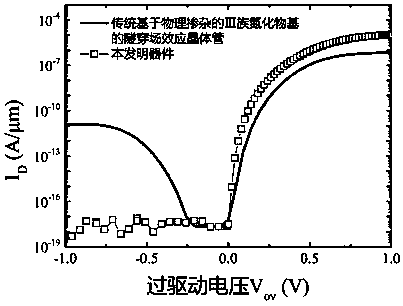

A technology of tunneling field effect and polarization doping, which is applied in the direction of diodes, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of increased process complexity, reduced device reliability, and reduced device performance Threshold swing, improved reliability, improved modulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

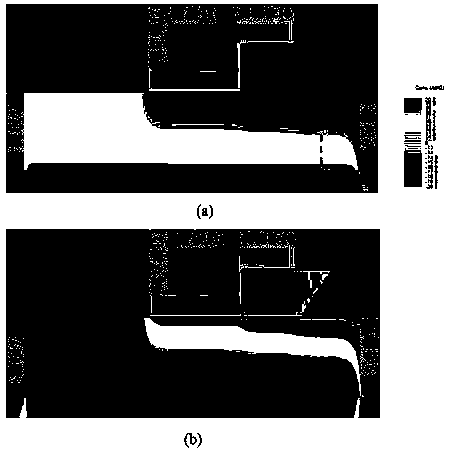

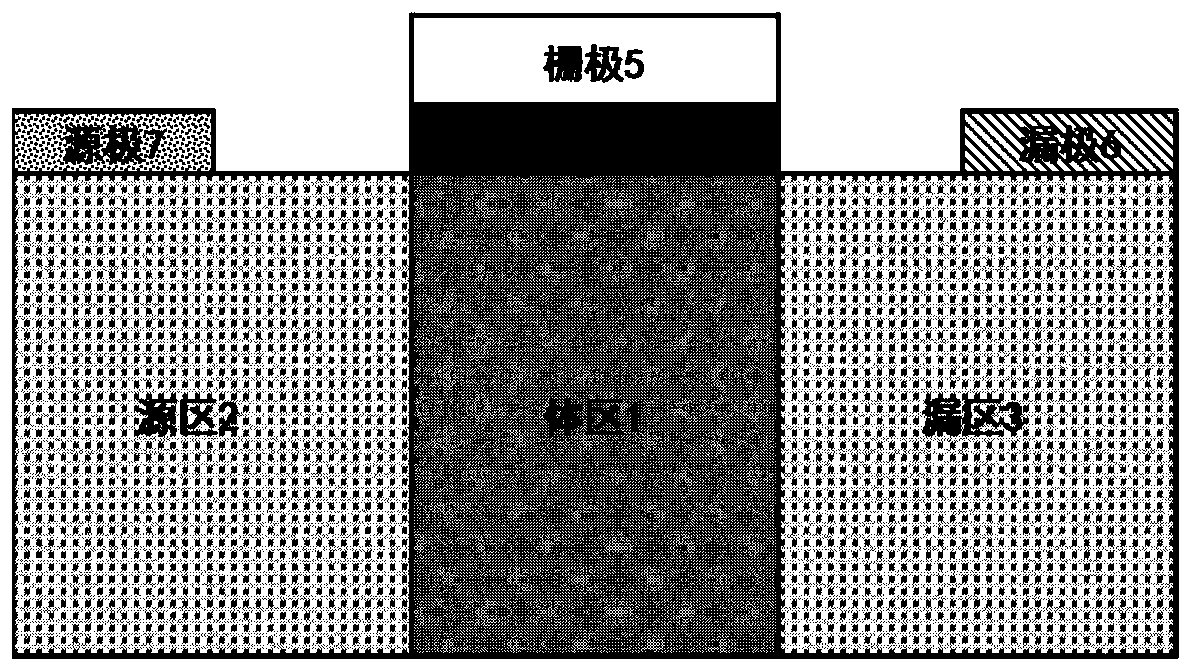

[0062] Embodiment 1: Fabricate a polarization-doped InN-based tunneling field-effect transistor with a polarization inversion layer thickness of 24 nm.

[0063] Step 1. Make a drift layer 2 on the substrate 1, such as image 3 b.

[0064] Using sapphire as the substrate 1, metal organic chemical vapor deposition technology is used to epitaxially unintentionally doped GaN semiconductor material with a thickness of 1000nm in the [0001] crystal direction on the substrate 1 to form a drift layer 2, wherein the process used for epitaxy The conditions are: the temperature is 950° C., the pressure is 40 Torr, the hydrogen gas flow rate is 4000 sccm, the ammonia gas flow rate is 4000 sccm, the gallium source flow rate is 100 μmol / min, and the epitaxy time is 2 h.

[0065] Step 2. Make body region 3, such as image 3 c.

[0066] On the buffer layer 2, the unintentionally doped InN semiconductor material with the [0001] crystal orientation is epitaxed by molecular beam epitaxy techno...

Embodiment 2

[0088] Embodiment 2: Fabricate a polarization-doped InN-based tunneling field-effect transistor with a polarization inversion layer thickness of 10 nm.

[0089] Step 1. Make drift layer 2 on substrate 1, such as image 3 b.

[0090] Using silicon carbide as the substrate 1, metal organic chemical vapor deposition technology is used on the substrate 1 at a temperature of 950°C, a pressure of 40 Torr, a hydrogen flow rate of 4000 sccm, an ammonia gas flow rate of 4000 sccm, and a gallium source flow rate of 100 μmol / min. The drift layer 2 is formed by epitaxially using the unintentionally doped GaN semiconductor material with a thickness of 750 nm in the [0001] crystal orientation under the process condition of an epitaxial time of 1.5 h.

[0091] Step 2. Make body region 3, such as image 3 c.

[0092] On the buffer layer 2, use molecular beam epitaxy technology at a vacuum degree of less than or equal to 1.0×10 -10 mbar, the RF power is 400W, and the reactant is N 2 1. A ...

Embodiment 3

[0114] Embodiment 3: Fabricate a polarization-doped InN-based tunneling field-effect transistor with a polarization inversion layer thickness of 1.2 nm.

[0115] Step A. Make a drift layer 2 on the substrate 1, such as image 3 b.

[0116] GaN material is used as the substrate 1, and the unintentionally doped GaN semiconductor material with a thickness of 500nm in the [0001] crystal orientation is epitaxially used on the substrate 1 by metal-organic chemical vapor deposition technology to form a drift layer 2, wherein the epitaxy adopts The process conditions are: temperature 950°C, pressure 40Torr, hydrogen flow rate 4000sccm, ammonia flow rate 4000sccm, gallium source flow rate 100μmol / min, epitaxy time 1h.

[0117] Step B. Make body region 3, such as image 3 c.

[0118] On the buffer layer 2, use the molecular beam epitaxy technique to epitaxy the unintentionally doped InN semiconductor material with the [0001] crystal orientation to form the bulk region 3 with a thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com