Fluorescent powder and preparation method thereof, and luminescent device comprising fluorescent powder

A technology of light-emitting devices and phosphors, which is applied in the field of phosphors, can solve the problems of decreased luminous intensity of phosphors and many defects on the surface of phosphors, and achieve the effect of avoiding the reduction of luminous intensity and volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

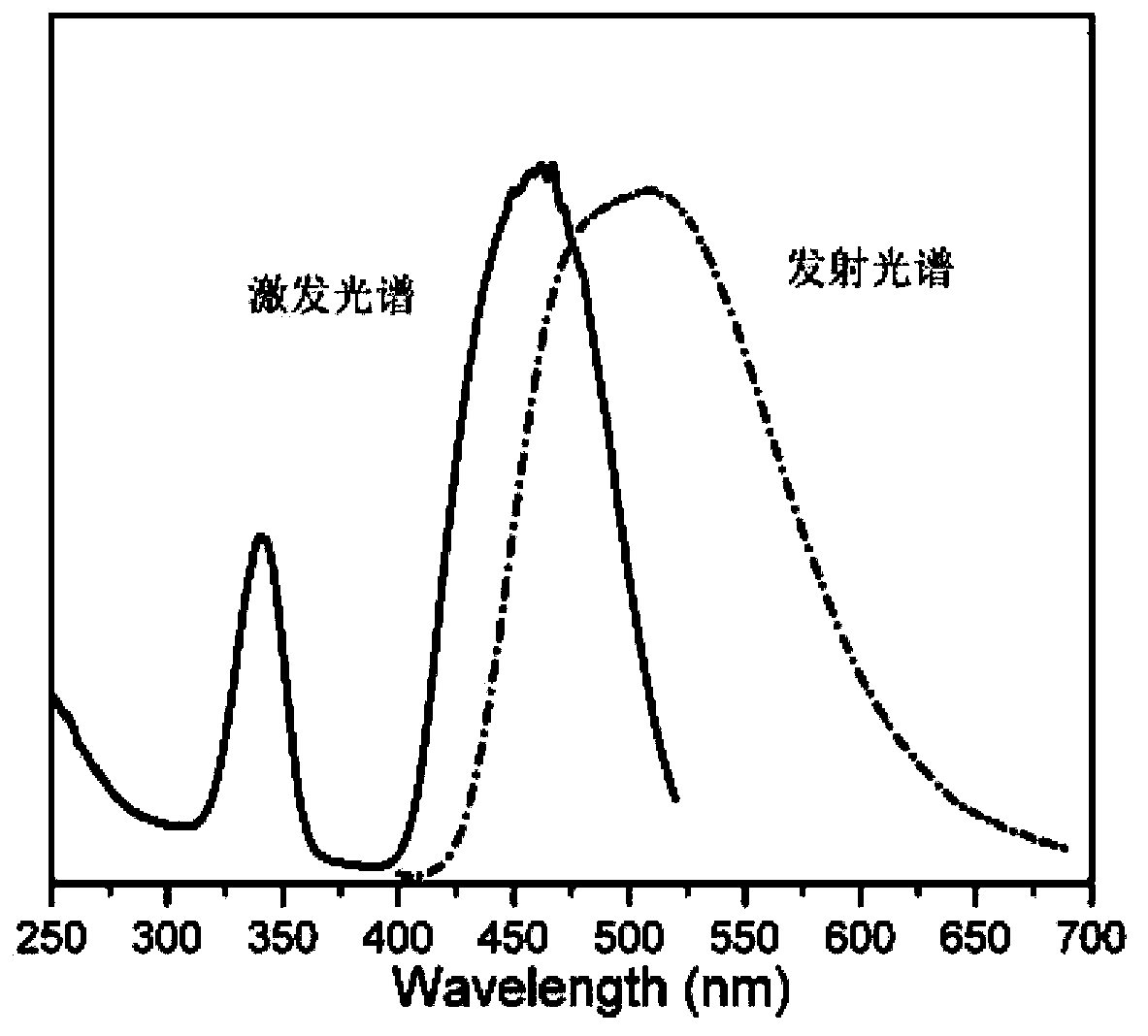

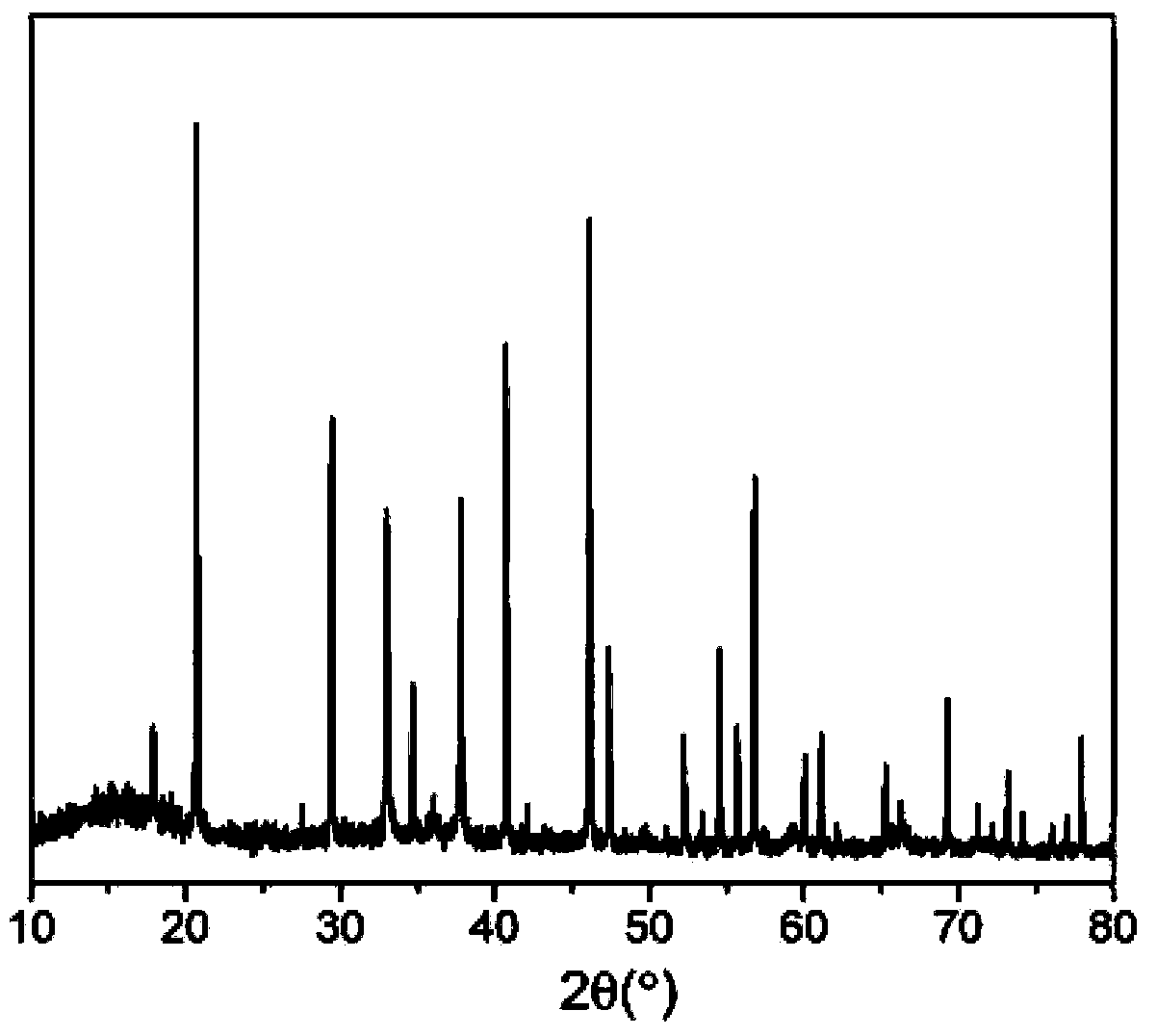

[0030] Example 1 The chemical composition of the fluorescent powder is Na 2.8 Y 0.11 Ce 0.09 Al 2 Li 2.8 Al 0.2 f 11.4 N 0.2 o 0.4

[0031] Raw materials are NaF (analytical pure), YF 3 (analytical pure), CeF 3 (analytical pure), AlF 3 (analytical pure), AlN (analytical pure), LiF (analytical pure) and Al 2 o 3 (analytically pure), the molar ratio is 2.80:0.110:0.090:1.733:0.200:2.800:0.133. Grind and mix the raw materials and place them in an alumina container (it can also be zirconia or boron nitride), and sinter at a temperature of 1450°C for 4 hours. The sintering atmosphere is a mixture of nitrogen and hydrogen (the sintering atmosphere is a mixture of hydrogen, nitrogen and hydrogen gas, ammonia or carbon monoxide), the sintered powder is taken out from the container, crushed, classified and treated with hydrochloric acid with a molar concentration of 3 moles per liter, and the average particle size of the synthesized phosphor is Adjust the diameter to 15 μ...

Embodiment 2

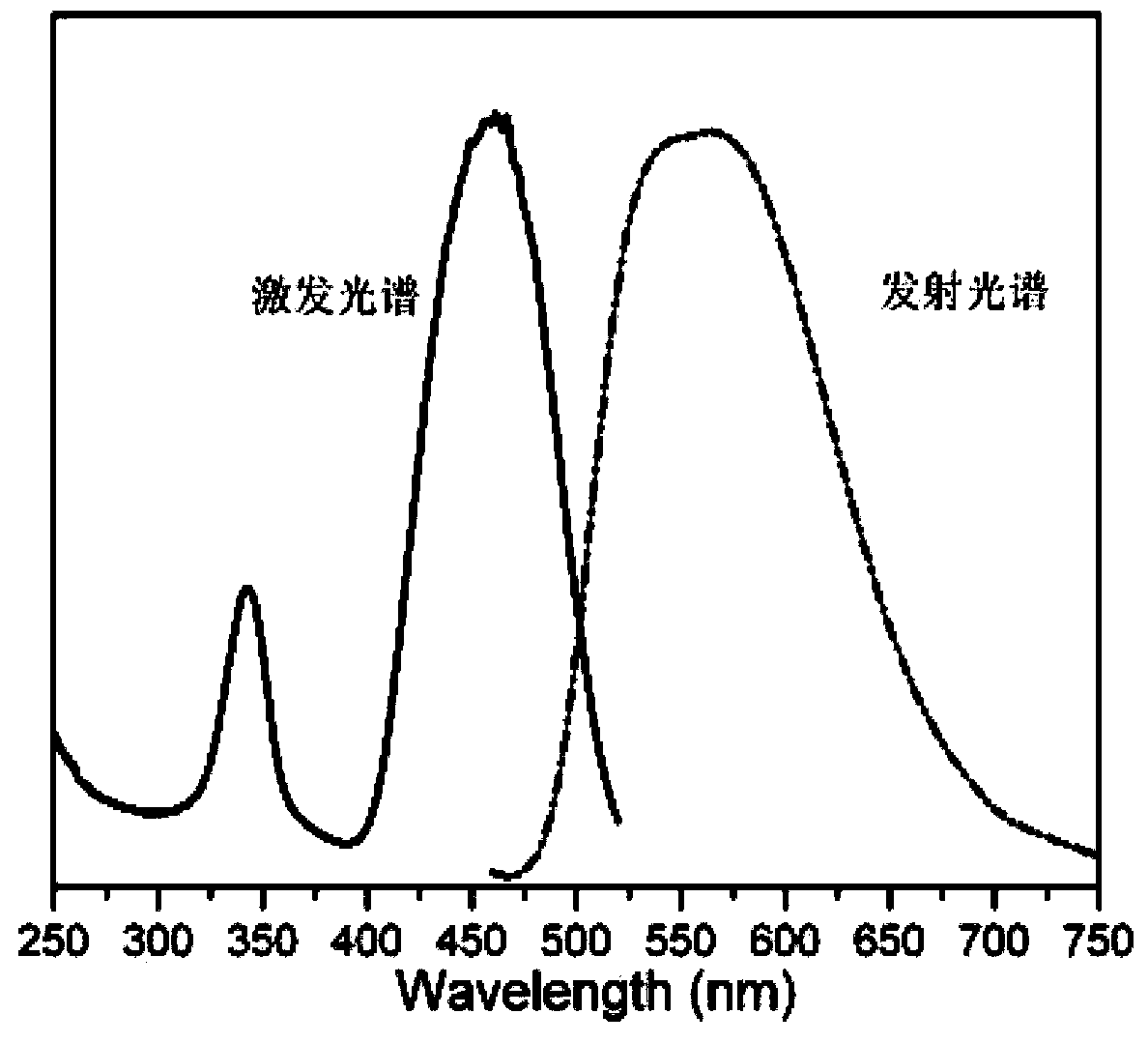

[0032] Example 2 The chemical composition of phosphor powder is NaY 1.91 Ce 0.09 Al 2 LiAl 2 f 4.4 N 0.4 o 7.2

[0033] Raw materials are NaF (analytical pure), Y 2 o 3 (analytical pure), CeF 3 (analytical pure), AlF 3 (analytical pure), AlN (analytical pure), LiF (analytical pure) and Al 2 o 3 (analytically pure), the molar ratio is 1.000:0.955:0.090:0.710:0.400:1.000:1.445. Grind and mix the raw materials and place them in a zirconia container (it can also be alumina or boron nitride), and sinter at a temperature of 1250°C for 4 hours. The sintering atmosphere is a mixture of nitrogen and hydrogen (the sintering atmosphere can be hydrogen, nitrogen and hydrogen One or more of mixed gas, ammonia or carbon monoxide), the pressure is 3 atmospheres. The sintered powder is taken out from the container, crushed, graded, and treated with hydrochloric acid with a molar concentration of 3 moles per liter, and the average particle size of the synthesized phosphor is adjus...

Embodiment 3

[0034] Example 3 The chemical composition of phosphor powder is NaY 1.91 Ce 0.09 Al 2 LiAl 2 f 5.5 N 1.5 o 5

[0035] Raw materials are NaF (analytical pure), Y 2 o 3 (analytical pure), CeF 3 (analytical pure), AlF 3 (analytical pure), AlN (analytical pure), LiF (analytical pure) and Al 2 o 3 (analytically pure), the molar ratio is 1.000:0.955:0.090:1.077:1.500:1.000:0.716. After grinding and mixing the raw materials, place them in an alumina container (or zirconia or boron nitride), and sinter at a temperature of 1200°C for 4 hours. The sintering atmosphere is a mixture of nitrogen and hydrogen, and the pressure is 3 atmospheres. The sintered powder is taken out from the container, crushed, graded, and treated with hydrochloric acid with a molar concentration of 3 moles per liter, and the average particle size of the synthesized phosphor is adjusted to 15 μm, and then the phosphor is washed repeatedly with distilled water to medium properties, and then put the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com