Method for synthetizing Ti3SiC2 high-purity powder

A powder and high-purity technology, which is applied in the field of synthesizing Ti3SiC2 high-purity powder, can solve problems such as high price of Ti powder, accelerated equipment aging, and reduced service life, and achieve the effects of improving product purity, shortening production cycle, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

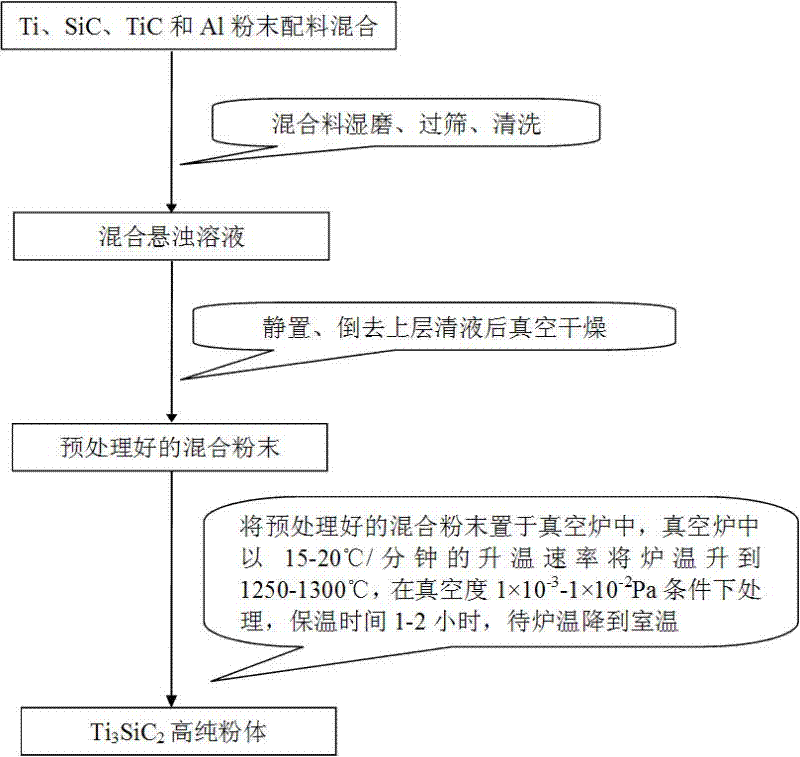

[0034] Such as figure 1 As shown, a synthetic Ti 3 SiC 2 The method for high-purity powder, it comprises the steps:

[0035] 1) Ingredients: Ti powder, SiC powder and TiC powder are used as raw materials, Al powder is used as a synthesis accelerator, and 113.88 grams of Ti powder, 46.52 grams of SiC powder, 36.47 grams of TiC powder and 3.13 grams of Al powder, a total of 200g; Ti powder, SiC powder, TiC powder and Al powder are mixed to obtain a mixture;

[0036] 2) Put the above-mentioned mixture, appropriate amount of alcohol and steel ball milling balls in a steel ball milling tank, and wet mill them in a ball mill for 2 hours, wherein: the speed of the ball mill is 100 rpm, and the mass ratio of balls to materials is 5:1;

[0037] 3) After sieving and cleaning the ball milling balls, the mixed suspension solution was obtained and left to stand for 5 minutes, the supernatant liquid was poured off, and vacuum-dried to obtain the pretreated mixed powder, wherein the vacuu...

Embodiment 2

[0044] Such as figure 1 As shown, a synthetic Ti 3 SiC 2 The method for high-purity powder, it comprises the steps:

[0045]1) Ingredients: Ti powder, SiC powder and TiC powder are used as raw materials, Al powder is used as a synthesis accelerator, and 56.13 grams of Ti powder, 24.50 grams of SiC powder, 17.42 grams of TiC powder and 1.95 grams of Al powder, a total of 100g; Ti powder, SiC powder, TiC powder and Al powder are mixed to obtain a mixture;

[0046] 2) Put the above-mentioned mixture, appropriate amount of alcohol and steel ball milling balls in a steel ball milling tank, and wet mill them in a ball mill for 5 hours, wherein: the speed of the ball mill is 50 rpm, and the mass ratio of balls to materials is 5:1;

[0047] 3) After sieving and cleaning the ball milling balls, the mixed suspension solution was obtained and left to stand for 10 minutes, the supernatant liquid was poured off, and vacuum-dried to obtain the pretreated mixed powder, wherein the vacuum-...

Embodiment 3

[0052] Such as figure 1 As shown, a synthetic Ti 3 SiC 2 The method for high-purity powder, it comprises the steps:

[0053] 1) Ingredients: Ti powder, SiC powder and TiC powder are used as raw materials, Al powder is used as a synthesis accelerator, and 84.00 grams of Ti powder, 36.05 grams of SiC powder, 27.58 grams of TiC powder and 2.37 grams of Al powder, a total of 150g; Ti powder, SiC powder, TiC powder and Al powder are mixed to obtain a mixture;

[0054] 2) Put the above-mentioned mixture, appropriate amount of alcohol and steel ball milling balls in a steel ball milling tank, and wet mill them in a ball mill for 3 hours, wherein: the speed of the ball mill is 90 rpm, and the mass ratio of balls to materials is 5:1;

[0055] 3) After sieving and cleaning the ball milling balls, the mixed suspension solution was obtained and left to stand for 8 minutes, the supernatant liquid was poured off, and vacuum-dried to obtain the pretreated mixed powder, wherein the vacuum-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com