Patents

Literature

41 results about "Suspended organic matter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Suspended organic matter. floating particles derived from the breakdown of seaweeds, plankton, fish and other organisms, typically occurring with bacteria and other micro-organisms. Found on http://www.seafriends.org.nz/books/glossary.htm.

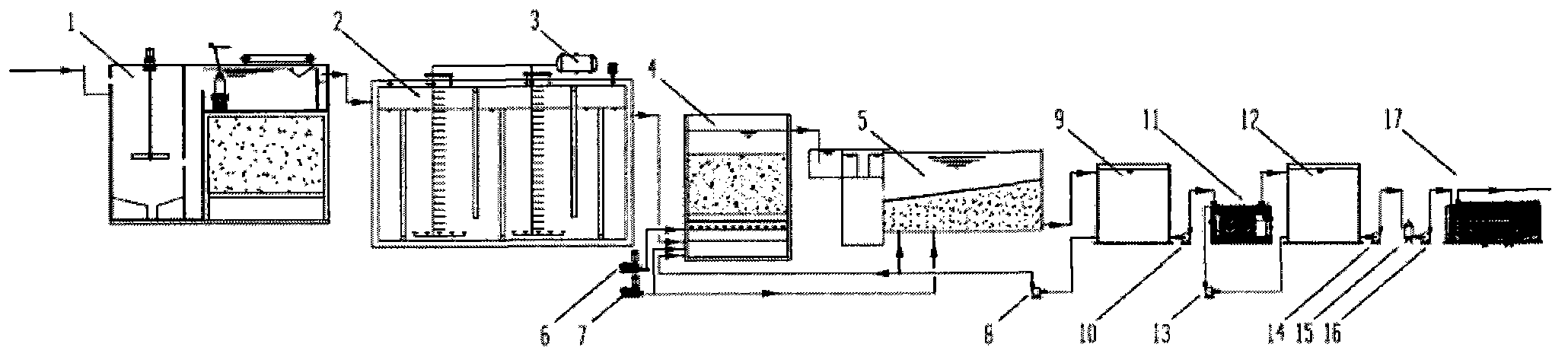

Advanced treatment and recycling process and apparatus for sewage reaching standard

InactiveCN103626352AReduced ozone reaction loadIncrease dissolved oxygen concentrationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSuspended organic matterWater source

The invention relates to an advanced treatment and recycling combined apparatus with petrochemical sewage reaching the standard as a water source. The apparatus comprises an air floatation filter tank, an ozone reaction tank, an immobilized microorganism biological aerated filter, a V-shaped filter tank, an ultrafilter and a reverse osmosis filter, which are successively connected. The invention also provides a process for advanced treatment and recycling of the sewage by using the apparatus so as to obtain circulating water supplemental water. The process comprises the following steps: allowing the sewage to enter into the air floatation filter tank at first so as to remove oil, lightweight floc and suspended solids in the sewage; then allowing the sewage to enter into the ozone reaction tank to degrade organic matters difficult to degrade, thereby improving biodegradability of the sewage; allowing the sewage to enter into the immobilized microorganism biological aerated filter to remove organic matters and ammonia nitrogen in the sewage; allowing the sewage to enter into the V-shaped filter tank to remove suspended solids and suspending organic matters in the sewage; then allowing effluent of the V-shaped filter tank to enter into the ultrafilter so as to remove suspended solids and colloidal organic matters; and allowing effluent of the ultrafilter to enter into the reverse osmosis filter for reverse osmosis so as to remove salt and finally, delivering effluent to water consumption sites of circulating water supplemental water.

Owner:BEIJING JIUZHANG ENVIRONMENTAL ENG CO LTD

Process for the preparation of metal oxide coated organic material by microwave deposition

InactiveUS7459182B2Pretreated surfacesLiquid/solution decomposition chemical coatingSuspended organic matterSolvent

A process for the preparation of organic material comprising an organic substrate and at least one dielectric layer consisting of one or more oxides of a metal selected from groups 3 to 15 of the periodic table, which comprises the steps of:(a) suspending the organic material in an aqueous solution of fluorine scavenger;(b) adding an aqueous solution of one or more fluorine containing metal complexes which are the precursors of the desired metal oxide coating; and(c) subjecting said suspension to microwave radiation to deposit the metal oxide onto said organic material, wherein steps (b) and (c) can optionally be repeated using different fluorine containing metal complexes to produce one or more metal oxide layers.The substrate can be optionally dissolved with solvent to yield free metal oxide or mixed metal oxides that have a plane-parallel structure.

Owner:CIBA SPECIALTYCHEM

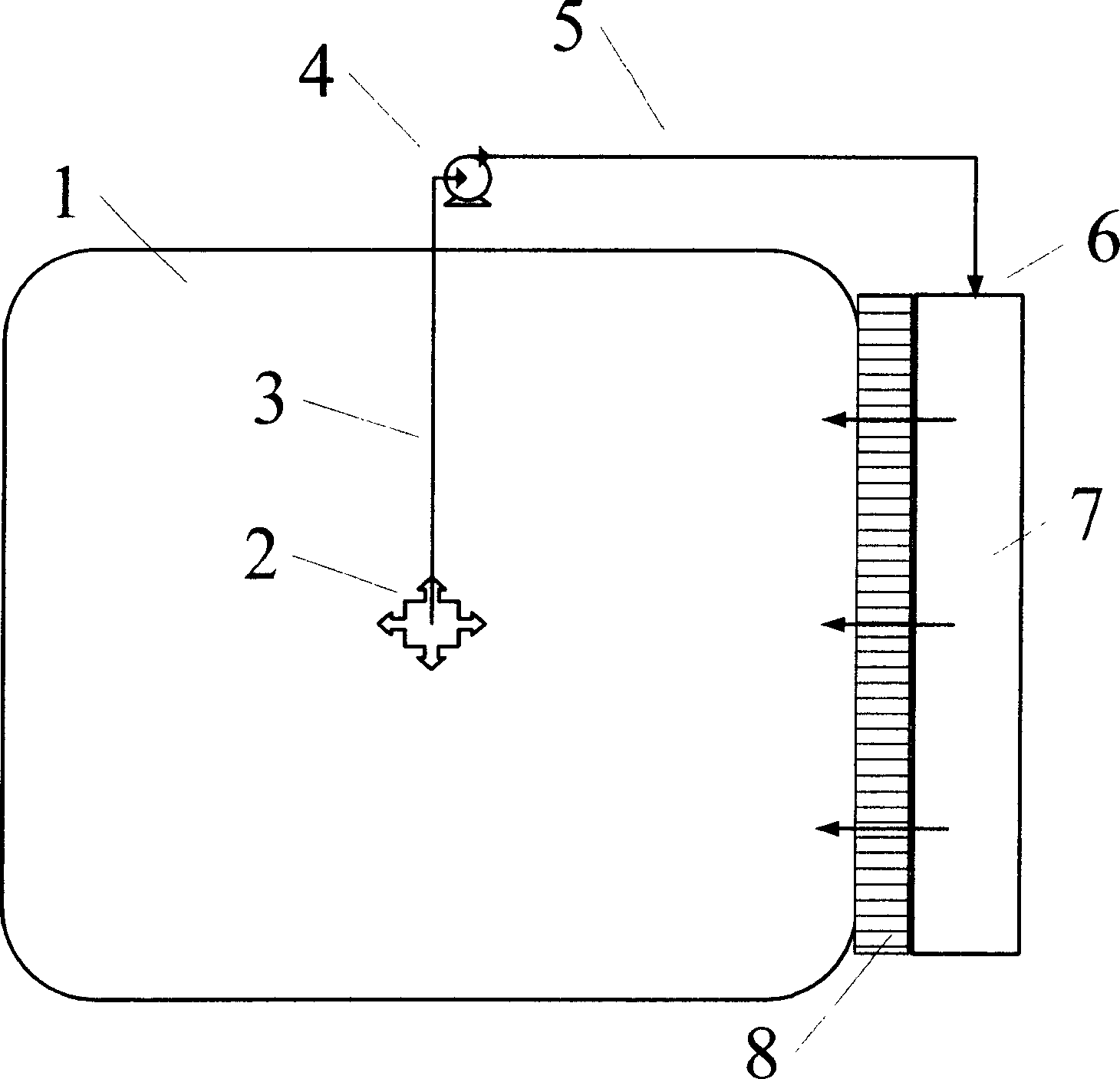

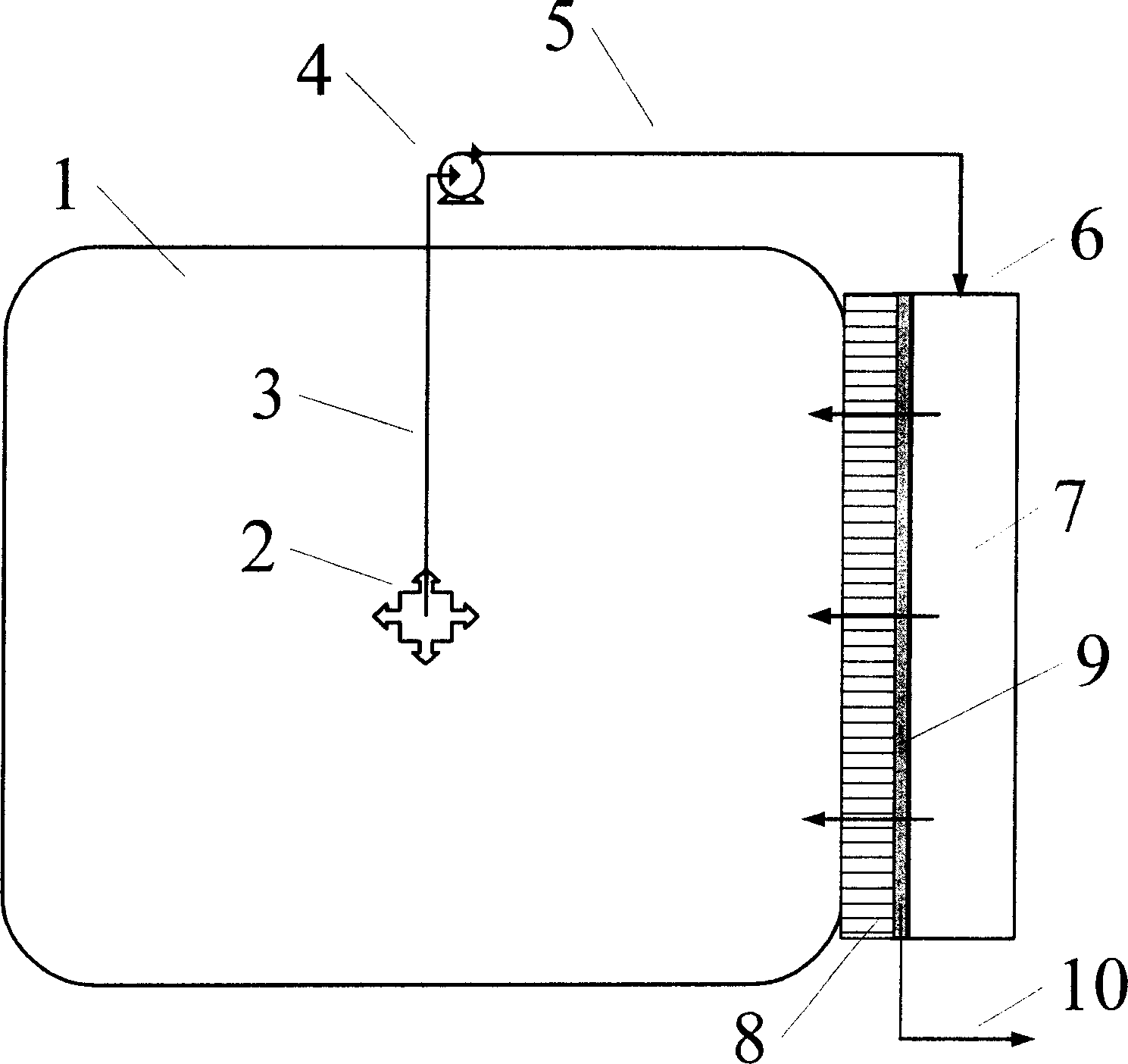

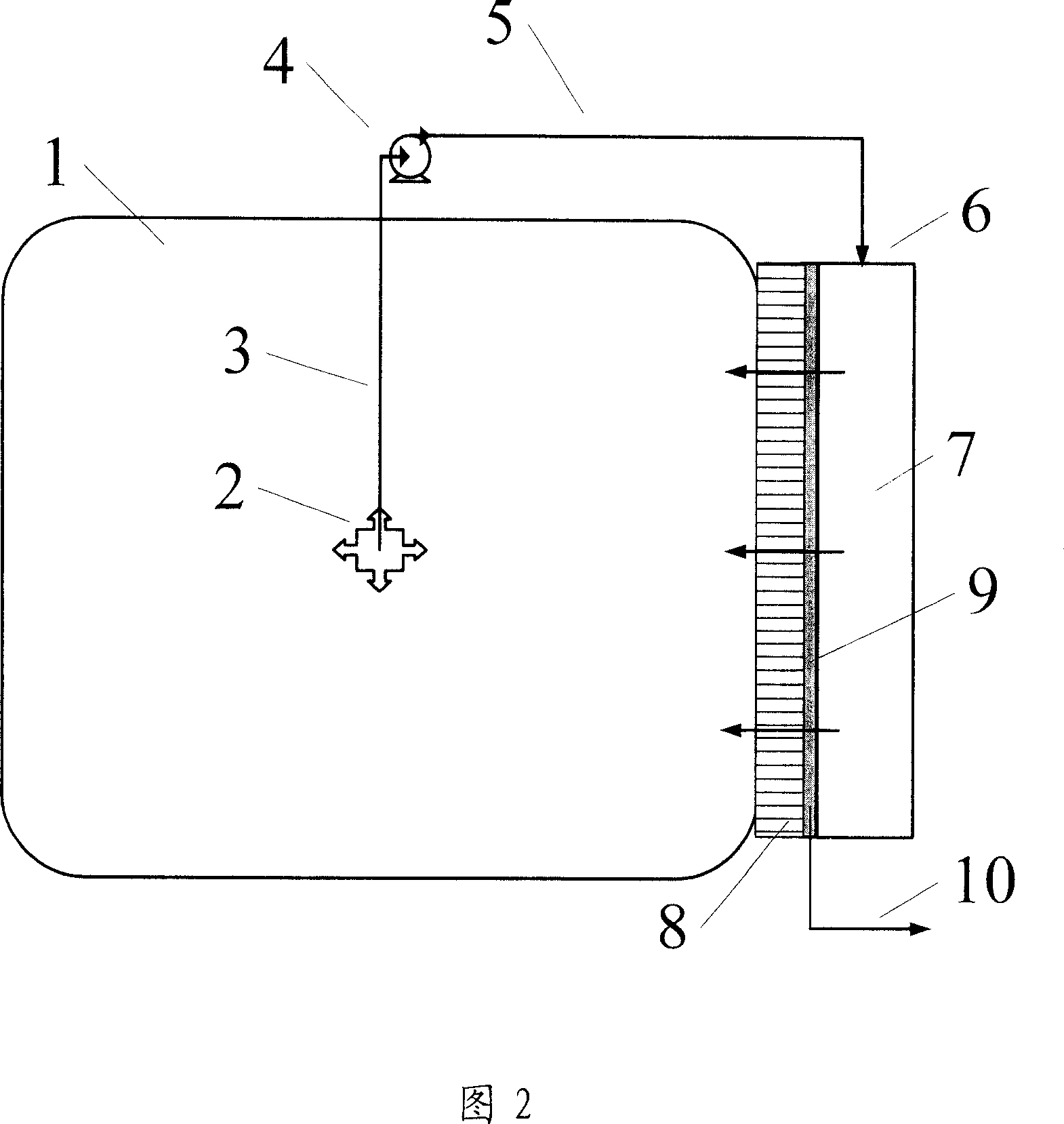

Water purifying method for cultivation pond

InactiveCN1847167AGood effectImprove environmental conditionsPisciculture and aquariaWater/sewage treatment by oxidationSuspended organic matterCatalytic oxidation

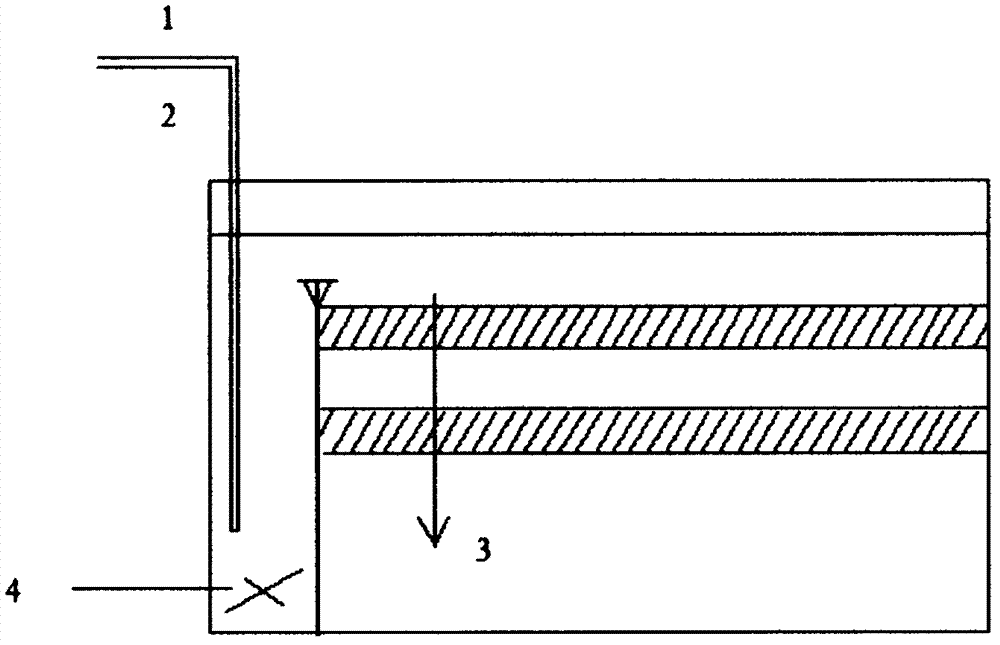

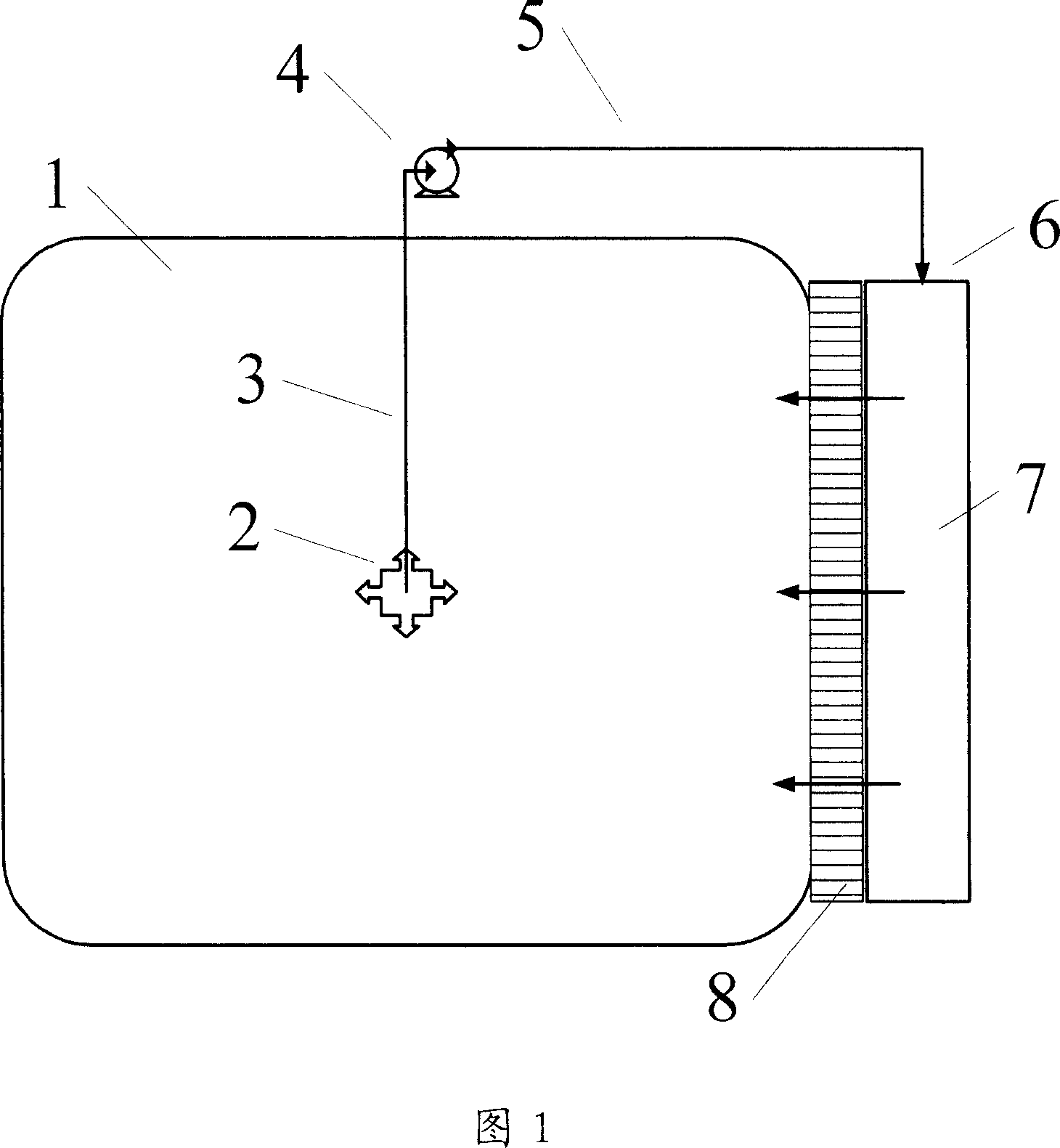

The present invention discloses water purifying method for cultivation pond. The method is one water circulating process including pumping cultivation waste water from the bottom of pond center to one water trough; separating suspended organic matter from water in the water trough; natural photochemically catalytic oxidation of water; and returning the treated water to the pond. The method of the present invention can eliminate water pollution for aquatic cultivation in relatively low cost, improve the physical, chemical and biological conditions of cultivation water, and raise the water environment stability of cultivation water, and is suitable for pond cultivation with both sea water and fresh water.

Owner:海南省环境科学研究院 +1

Recovery and utilization method for copper bearing spent acid solution from sodium saccharin production process

InactiveCN1541955AHigh purity powderHigh purityMultistage water/sewage treatmentSuspended organic matterDistillation

The present invention provides one waste copper containing acid solution recovering and utilizing process in saccharin sodium production. The waste copper containing acid solution recovering and utilizing process includes filtering to eliminate suspended organic matter, oxidizing the filtrate with mixed oxidant of sodium hypochlorite and potassium hypermanganate to eliminate low boiling point organic matter, decompression distilling the solution in vacuum to obtain dilute hydrochloric acid solution, further extraction and concentrating distillation to obtain hydrochloric acid solution of 30 % concentration, burning residue after decompression distilling to eliminate organic matter and obtain high purity copper sulfate and powder of other inorganic salts. The said process can recover the useful matter from waste acid solution and avoid environmental pollution effectively.

Owner:SHANGHAI JIAO TONG UNIV

Standard quality process method for synthetic wastewater of industrial park

InactiveCN101269896AImprove biodegradabilityMultistage water/sewage treatmentWater/sewage treatment by neutralisationActivated sludgeSuspended organic matter

The invention discloses a mark reaching treatment method of packaged wastewater in an industrial park. Aiming at the characteristics that the source of the packaged wastewater in the industrial part is wide, the components are complex, and the mark reaching treatment is not reliable by adopting the general biochemistry technology, firstly, the packaged wastewater in the industrial park is adjusted the pH value by mixing isotrope, and the impact load of the water quality and quantity is reduced; secondly, the biochemical property can be improved through the oxidation pretreatment, the removal rate of the organic matter is about 10-40 percent, the COD is reduced to 400-1000 mg / L, the biochemical property (B / C) can be improved by more than 0.3; thirdly, 0.01-0.1 percent of active carbon is added into a polytype main biochemical treatment system of activated sludge and biomembrane to form a PACT system, the removal rate of the organic matter is about 70-90 percent, the COD can be reduced to 120-150 mg / L; fourthly, suspended organic matter and inorganic matter are removed by coagulating sedimentation, the removal rate of the organic matter is about 10-30 percent, the COD can be stabilized under 100 mg / L, and the requirement (the COD is less than 100 mg / L) of the sewage complex discharge national standard (GB 8978-1996) is achieved.

Owner:NANJING UNIV +1

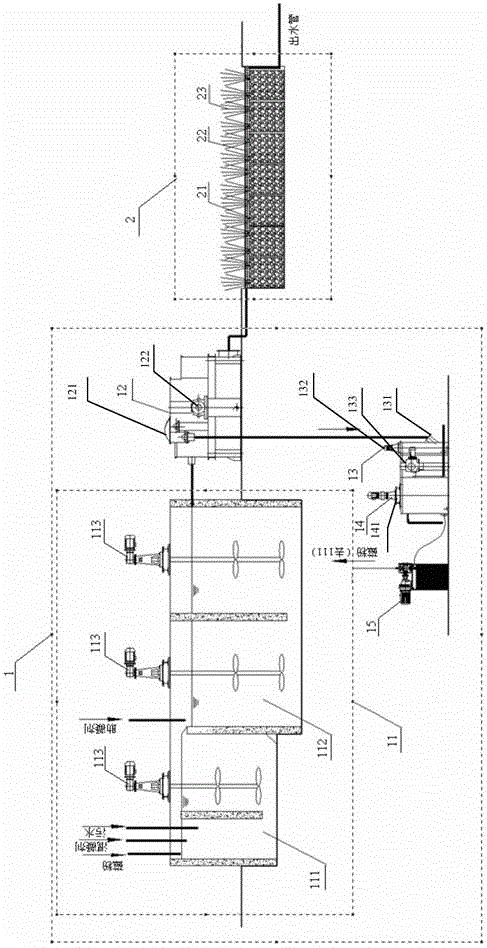

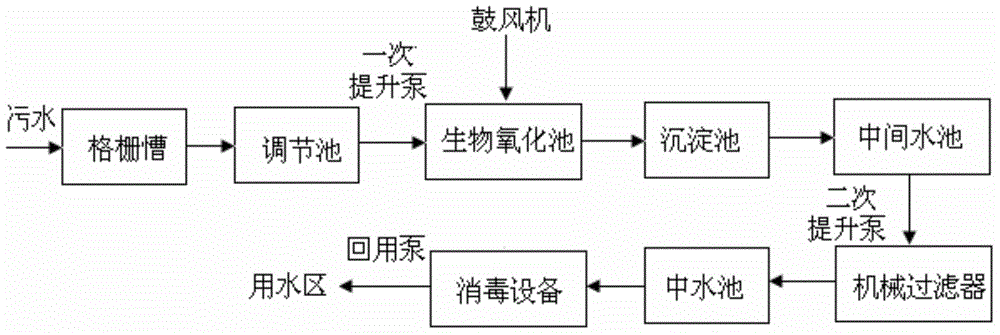

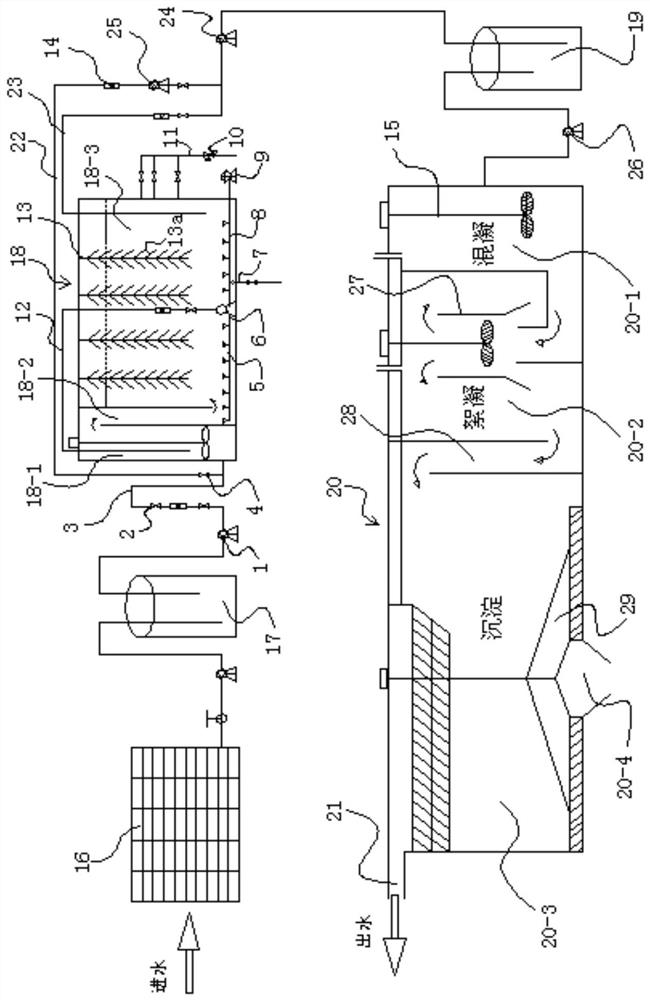

Northern residential district sewage processing system and method

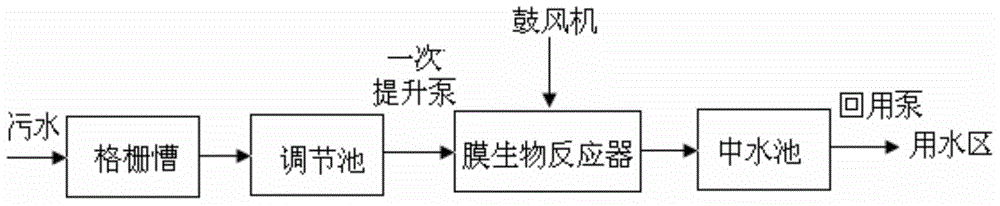

InactiveCN105130123AAchieve in situ useAchieve energy savingMultistage water/sewage treatmentConstructed wetlandGrating

The invention discloses a northern residential district sewage processing system and method. The system comprises a grating tank, an adjusting tank, a magnetic separation water purification unit and a constructed wetland unit. The grating tank, the adjusting tank, the magnetic separation water purification unit and the constructed wetland unit are connected in order through water pipes. According to water quality characteristics of northern residential district sewage, the sewage processing system combined with a magnetic separation water purification technology and a modularized constructed wetland technology is provided, processing advantages of the magnetic separation water purification technology and the modularized constructed wetland technology to pollutants are utilized fully, processing quota of the two novel technologies are distributed reasonably, removal of suspended organic matters, suspensions and total phosphor in sewage is mainly finished during the magnetic separation water purification technology process, and removal of the total nitrogen, ammonia nitrogen and dissolved organic matters is finished by the modularized constructed wetland. The problems are solved that a constructed wetland technology unit is employed alone, the land occupation area is large, obstruction is easy to happen inside the wetland, and ammonia nitrogen and total nitrogen are difficult to meet the water quality standard.

Owner:ENG DESIGN & RES INST OF GENERAL ARMAMENTS DEPT

Method for removing biochemical process tail water organic matters in wastewater by ultraviolet combined with chlorine

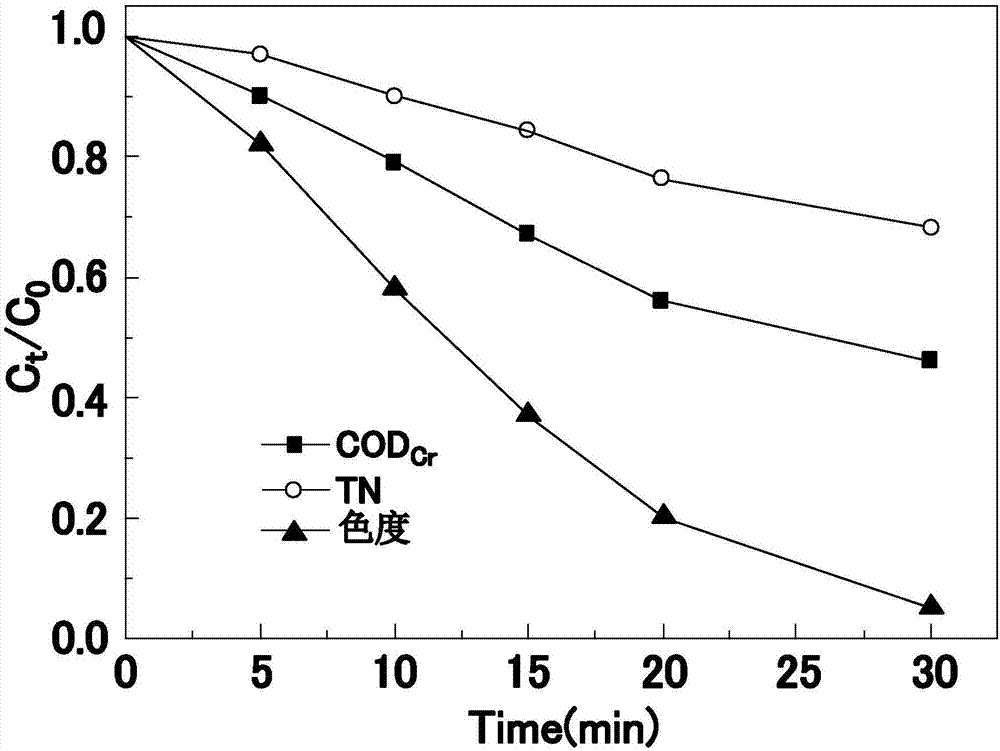

InactiveCN107098524AWater treatment parameter controlWater/sewage treatment by irradiationSuspended organic matterUltraviolet

The invention belongs to the field of deep treatment and reuse of biochemical process tail water and particularly relates to a method for removing biochemical process tail water organic matters in wastewater by ultraviolet combined with chlorine. According to the technical scheme, the method is characterized by comprising the steps of I, adding a chlorine oxidant to wastewater biochemical process secondary effluent that is subjected to coagulating sedimentation to remove suspended organic matters, and stirring, wherein 5-350 mg / L of active chlorine generated by the chlorine oxidant is added; II, irradiating with ultraviolet for 1-60 min. According to the above scheme, the method degrades and mineralizes EfOM (effluent organic matters) through strong oxidizing power of hydroxyl radicals (HO.) and active chlorine (Cl., Cl.<-> and ClO.) by the aid of their co-oxidizing effect.

Owner:WENZHOU UNIVERSITY

Method for preparing isooctyl thioglycolate by adopting tail liquid in the production process of O-alkyl-N-alkyl sulfide expelling carbamate

The invention discloses a method for preparing isooctyl thioglycolate by adopting tail liquid in the production process of O-alkyl-N-alkyl sulfide expelling carbamate, comprising the following steps:a. acidifying and purifying tail liquid, removing separated suspending organic matters; b. extracting the acidified liquid by an extracting agent, esterifying to obtain rough ester; c. carrying out reduced pressure distillation on the rough ester and obtaining the isooctyl thioglycolate. The method is characterized in that: in the extraction and esterification processes, isooctane is firstly takenas the extracting agent to extract and esterify the acidified liquid to obtain organic mixture; the organic mixture is taken as an extracting agent to extract and esterify the new acidified liquid; and the obtained organic mixture after extraction and esterification is taken as an extracting agent to extract and esterify the new acidified liquid at least once. The invention has the advantages ofreasonable production process, raw material saving, low production cost and high product quality and is a reasonable method for recycling the tail liquid in the production process of the O-alkyl-N-alkyl sulfide expelling carbamate.

Owner:WEIFANG JIAHUA CHEM

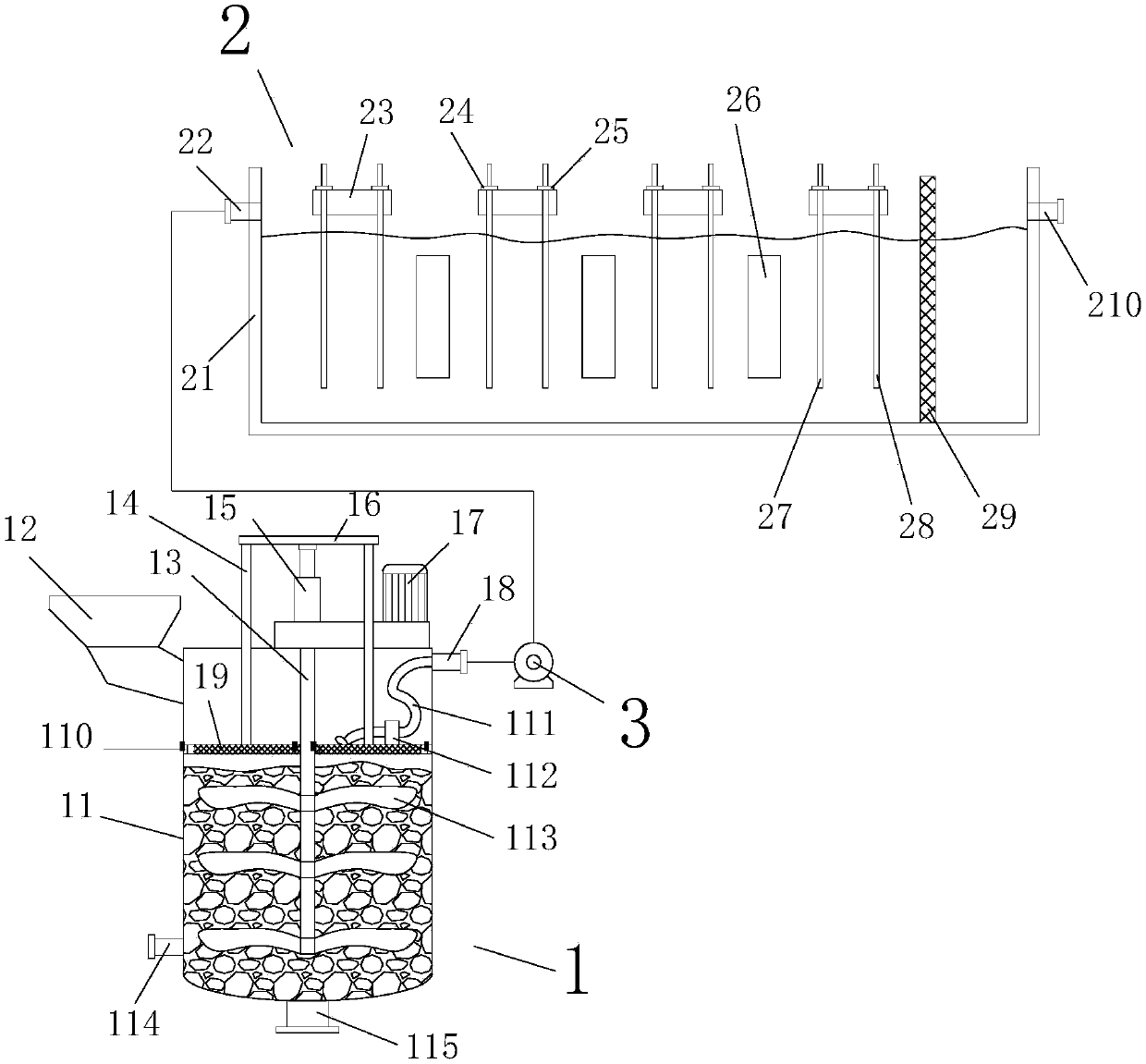

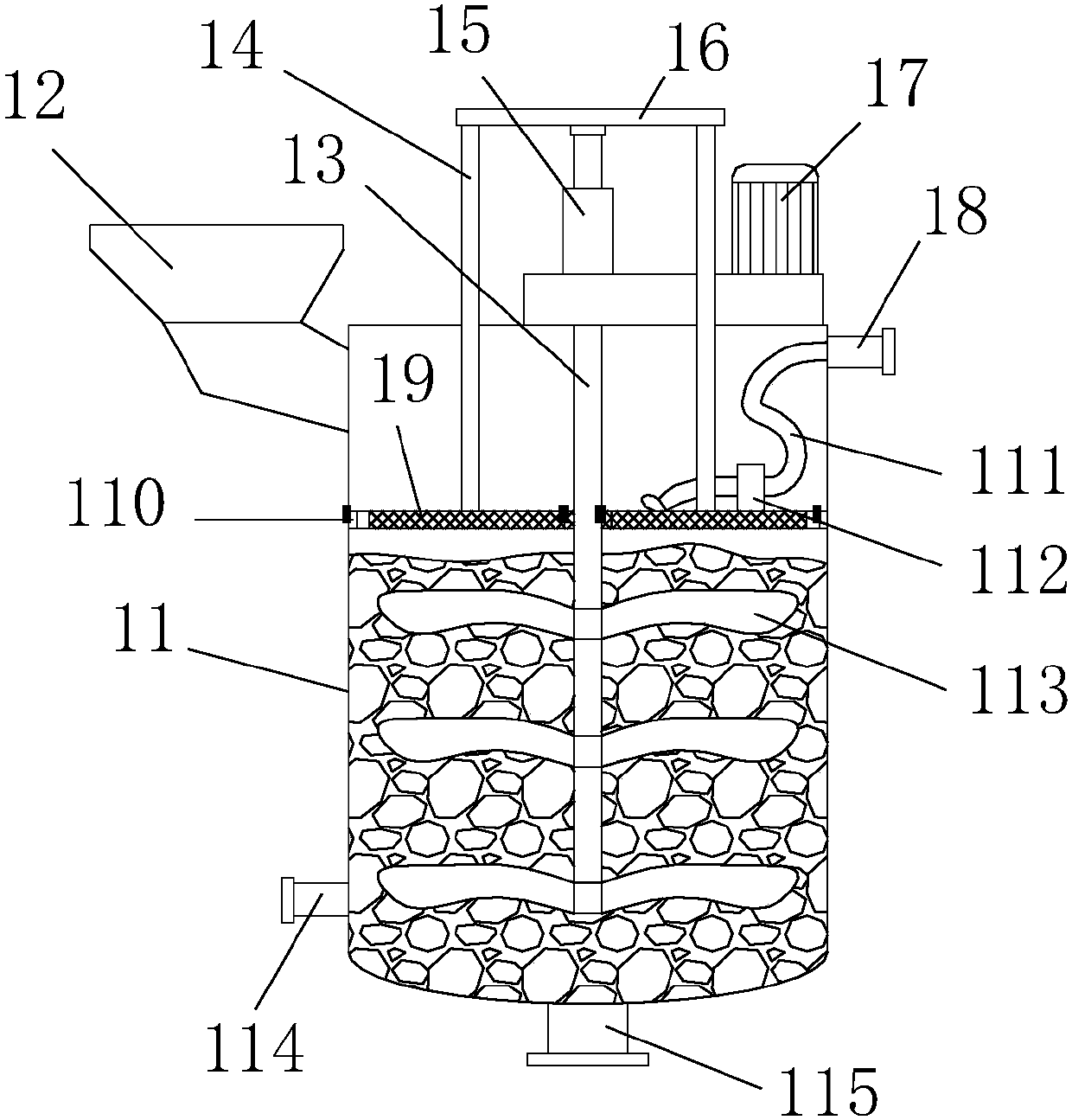

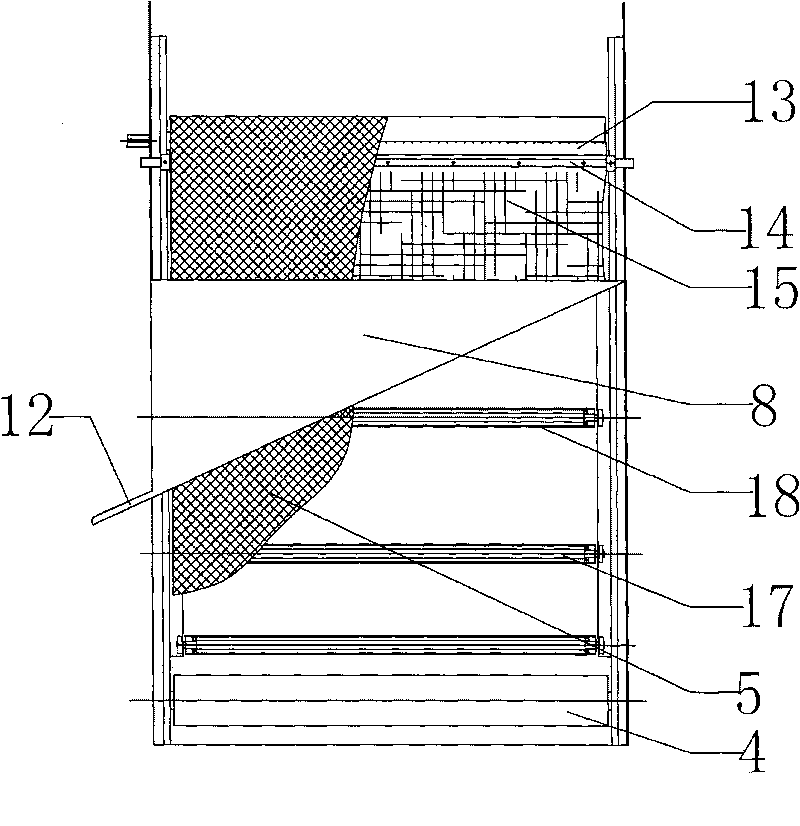

Recycling method and equipment of textile, printing and dyeing wastewater

InactiveCN107555684AEasy to recycleEasy to reuseMultistage water/sewage treatmentWaste water treatment from textile industryTextile printerSuspended organic matter

The invention discloses a method and equipment for recycling textile printing and dyeing wastewater. The equipment includes an initial adsorption mechanism and an electrochemical catalysis mechanism. There is a cylinder cover, a reducer is installed in the middle of the cylinder cover, the output end of the reducer is connected with a stirring shaft extending into the inside of the mixing cylinder, and stirring blades for stirring the coke layer are distributed on the stirring shaft; the electrochemical catalytic mechanism includes The waste water treatment tank body is provided with a water inlet on the left end side wall of the waste water treatment tank body, and a water outlet is arranged on the right end side wall of the waste water treatment tank body. The inside of the waste water treatment tank body is located between the water inlet and the water outlet. An anode electrode plate and a cathode electrode plate are assembled, the process layout of the invention is reasonable, the decolorization effect on the printing and dyeing wastewater is good, the suspended organic matter in the wastewater can be effectively removed, and the decomposition and treatment efficiency of the macromolecular organic matter is high.

Owner:郑州栾信科技有限公司

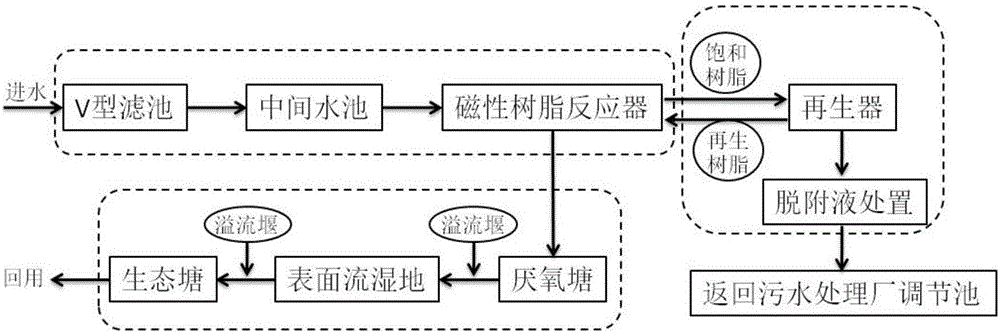

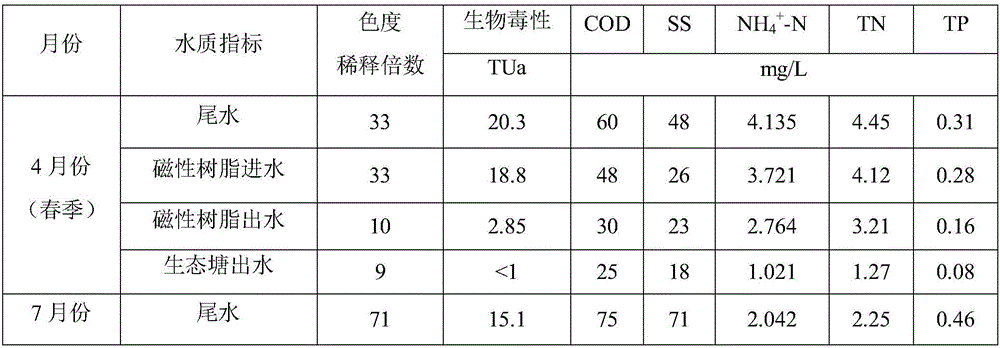

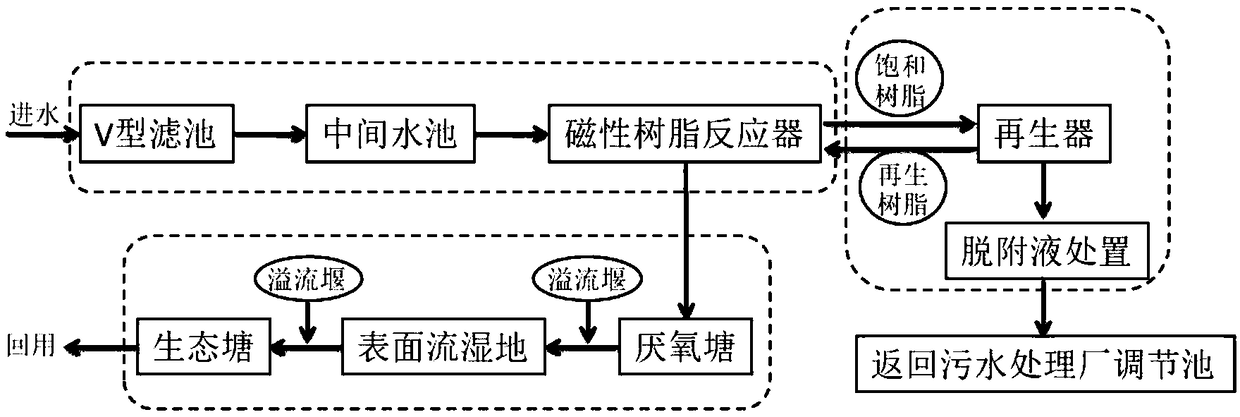

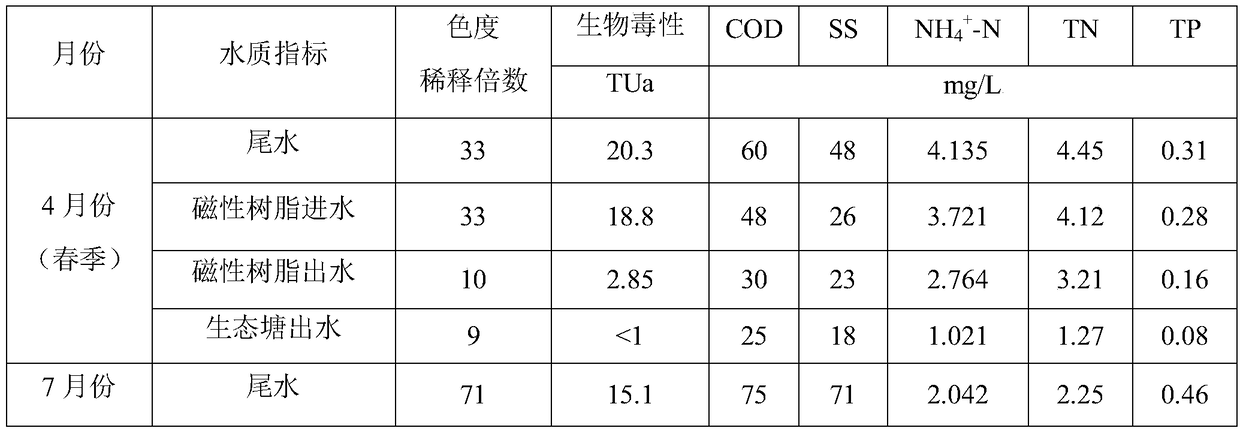

Toxicity reduction and recycling system and treatment method for biotreated effluent in printing and dyeing industry

ActiveCN106348551ALow running costLow biological toxicityWater treatment parameter controlSpecific water treatment objectivesToxicity reductionSolubility

The invention discloses a toxicity reduction and recycling system and a treatment method for biotreated effluent in the printing and dyeing industry, and belongs to the technical field of deep treatment of printing and dyeing wastewater. The system comprises a V-shaped filtering pond, a middle water pond, a magnetic resin reactor, an anaerobic pond, a surface flow wetland and an ecological pond, wherein the magnetic resin reactor is reasonably combined with ecosystems such as the ecological pond and a constructed wetland; the filtering pond is used for removing suspended organic matters in the biotreated effluent by filtering in order to lower turbidity; magnetic resin is used for adsorbing soluble organic pollutants in the biotreated effluent in order to lower chromaticity and biological toxicity. An alternative anaerobic-aerobic process is formed by a pond-wetland-pond combination to further lower the concentration of organic matters, nitrogen, phosphorus and toxic pollutants in a water body in order to form a set of biotreated effluent recycling method which runs stably, makes effluent be up to surface water IV and US EPA (Environmental Protection Agency) wastewater biological toxicity standards, has a landscape function and is suitable for printing and dyeing textile zones.

Owner:NANJING UNIV +1

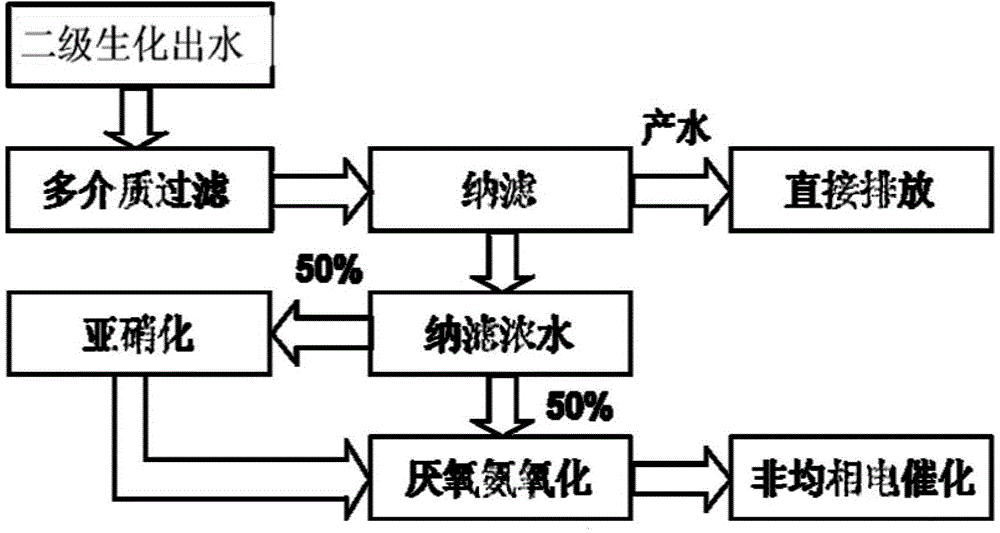

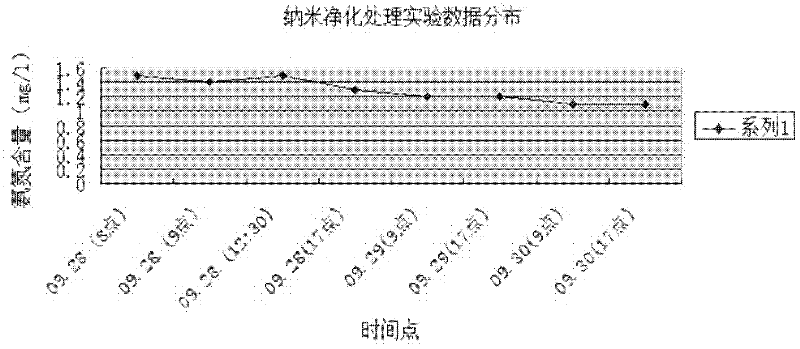

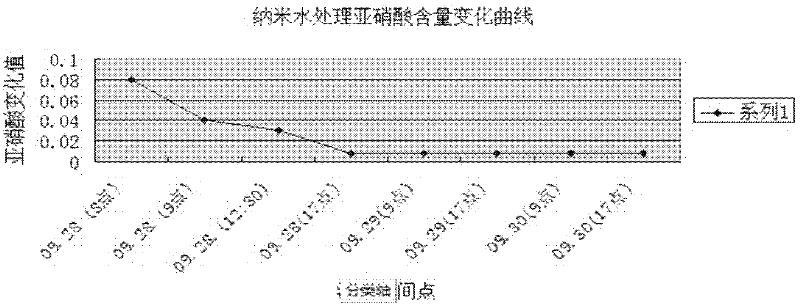

Acrylon wastewater deep treatment method based on dry method

InactiveCN104961298AEfficient removalImprove water qualityMultistage water/sewage treatmentNature of treatment waterSuspended organic matterFiltration

The invention belongs to the technical field of industrial wastewater treatment and particularly relates to an acrylon wastewater deep treatment method based on a dry method. The acrylon wastewater deep treatment method based on the dry method comprises the steps that acrylon wastewater to be treated is pretreated through multi-medium filtration, so that suspension organic matter is removed; then the acrylon wastewater enters a nanofiltration system, recalcitrant organic matter and ammonia nitrogen in the wastewater are separated and concentrated so that produced water can be directly discharged according to the standard; denitrification treatment continues to be conducted on concentrated water generated by the nanofiltration system through a nitrosification-anaerobic ammonia oxidation system, then water subjected to denitrification treatment enters a heterogeneous-phase electro-catalysis unit to be subjected to an oxidation reaction, so that recalcitrant organic matter in the concentrated water is removed, and nanofiltrated concentrated water is discharged according to the standard. According to the acrylon wastewater deep treatment method based on the dry method, pollutants in the acrylon wastewater can be effectively degraded and removed, and technical feasibility is provided for acrylon wastewater deep treatment based on the dry method.

Owner:SHENYANG RES INST OF CHEM IND +1

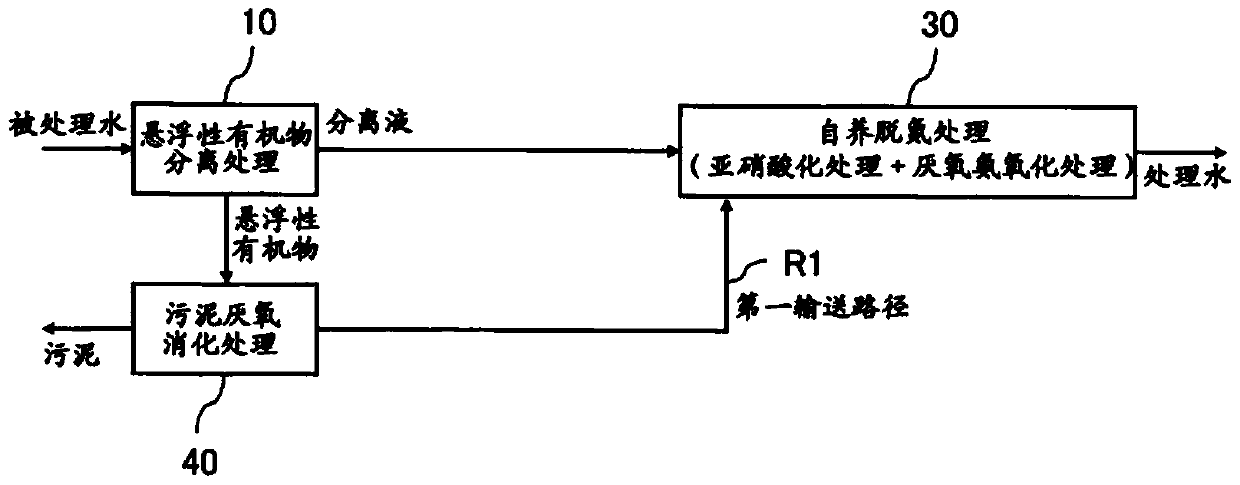

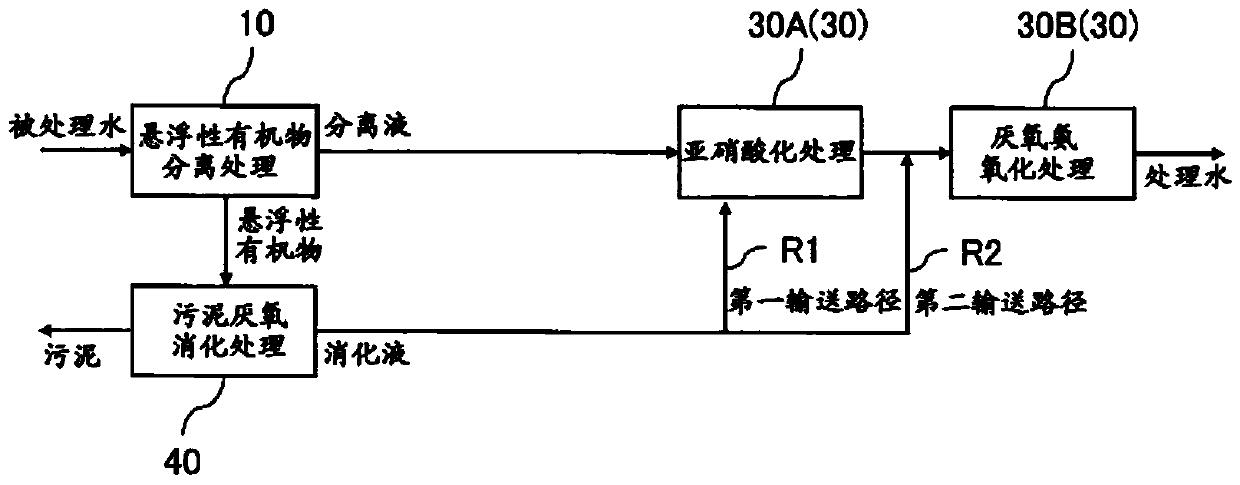

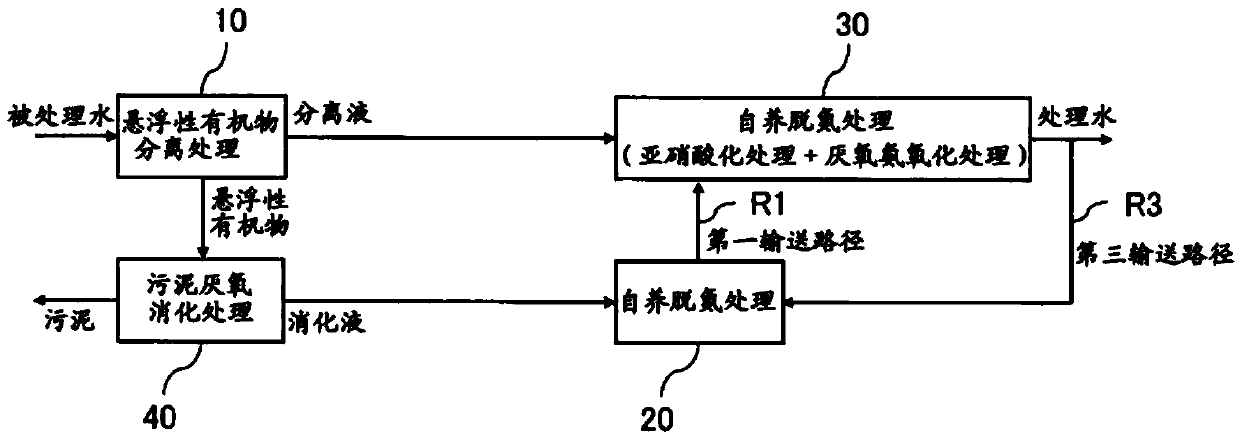

Processing system and processing method for nitrogen-containing organic waste water

InactiveCN103827046AEffective treatmentBiological sludge treatmentBiological water/sewage treatmentSuspended organic matterElectron donor

A processing system for nitrogen-containing organic waste water, configured by: comprising an autotrophic denitrifying device (30) that denitrifies by performing nitrification, whereby ammonia contained in water to be treated is oxidized into nitrous acid by autotrophic microbes under aerobic conditions, and anaerobic ammonia oxidation by autotrophic microbes under anaerobic conditions, using ammonia nitrogen as an electron donor and nitrate nitrogen as an electron receptor; comprising, at the stage before the autotrophic denitrifying device (30), a suspended organic matter separation device (10) that separates suspended organic matter contained in the water to be treated, and a sludge anaerobic digestion device (40) that anaerobically digests the suspended organic matter separated by the suspended organic matter separation device (10); and comprising a first transfer path (R1) that supplies digestive fluid from the sludge anaerobic digestion device (40) to the autotrophic denitrifying device (30). The processing system for nitrogen-containing waste water efficiently performs anaerobic ammonia oxidation using autotrophic microbes, even if the waste water has a low ammonia concentration and includes suspended organic matter.

Owner:KUBOTA LTD

Method for preparing high-quality mercaptoacetic acid from tail solution from O-alkyl-N-alkyl thinocarbamate production

ActiveCN105254547AHigh recovery rateHigh purityOrganic chemistryOrganic compound preparationGlutaric acidSuspended organic matter

The invention discloses a method for preparing high-quality mercaptoacetic acid from a tail solution from O-alkyl-N-alkyl thinocarbamate production. The method comprises the following steps: (1) performing acidizing treatment on the tail solution by using an inorganic acid, and controlling the pH value to be 0.5-1.5; (2) leaving to stand for 6-48 hours, separating suspended organic matters, extracting by using an organic solvent, and extracting by using an extraction agent, thereby obtaining an extraction liquid, wherein the volume ratio of the total amount of the organic solvent to an acidifying liquid is (2.5:0.01)-(2.5:0.1), the organic solvent consists of 40-60wt% of glutaric acid diethyl ester and 40-060wt% of ethyl malonic acid diethyl ester, the volume ratio of the total amount of the extracting agent to a new acidifying liquid is (2:0.1)-(2:2), and the extracting agent is prepared by mixing n-amyl ether, isoamyl ether and sec-butyl methyl ether in a mass ratio of (1-3):(1-3):(1-3); (3) removing the solvent and water from the extraction liquid, thereby obtaining crude acid; (4) performing flash evaporation on the crude acid. The method is high in recycling rate, high in product purity, good in quality and simple in process.

Owner:QINGDAO LNT CHEM

Water quality purification spraying agent and application thereof as well water quality purification method

InactiveCN102553561AImprove the living environmentGood purification effectWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsPurification methodsPhoto irradiation

The invention discloses a water quality purification spraying agent, which contains nano zinc oxide and a dispersant for enabling nano zinc oxide to form a multiphase flow in a solution, wherein nano zinc oxide has particle size d less than 100 nm. By adding nano zinc oxide to the water quality purification spraying agent, the water quality purification spraying agent can carry out photocatalysis effect under illumination and has strong oxidizing property. Serving as a strong oxidizer, the water quality purification spraying agent completes degradation of organic matters (or chlorine-containing substances), thereby degrading organic matters in bottom sludge and organic matters suspended in water of a culture pond and purifying water quality. Nano zinc oxide can generate conduction band electrons and valence band cavities under the illumination condition, and can react with surface adsorbed H2O or OH<-> ion to form hydroxyl with strong oxidizing property, thereby killing cells. At present, the turtle culture industry comprises two culture modes, namely greenhouse culture and earthen pond external pool culture. The nano zinc oxide water quality purification spraying agent not only can improve culture water bodies, but also has excellent purification action on the whole culture greenhouse, thereby integrally improving turtle living environment.

Owner:FUJIAN JIUDING BIOTECH

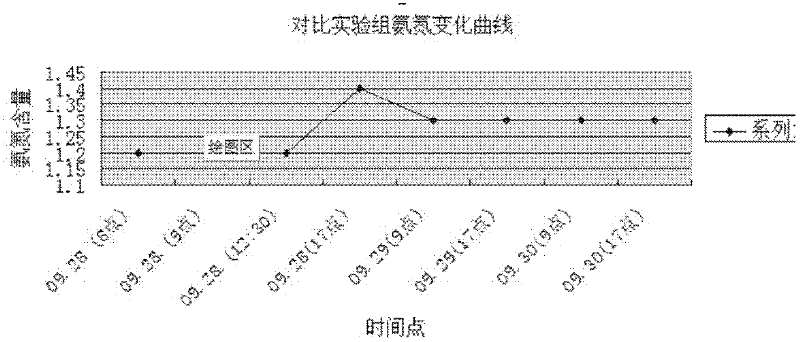

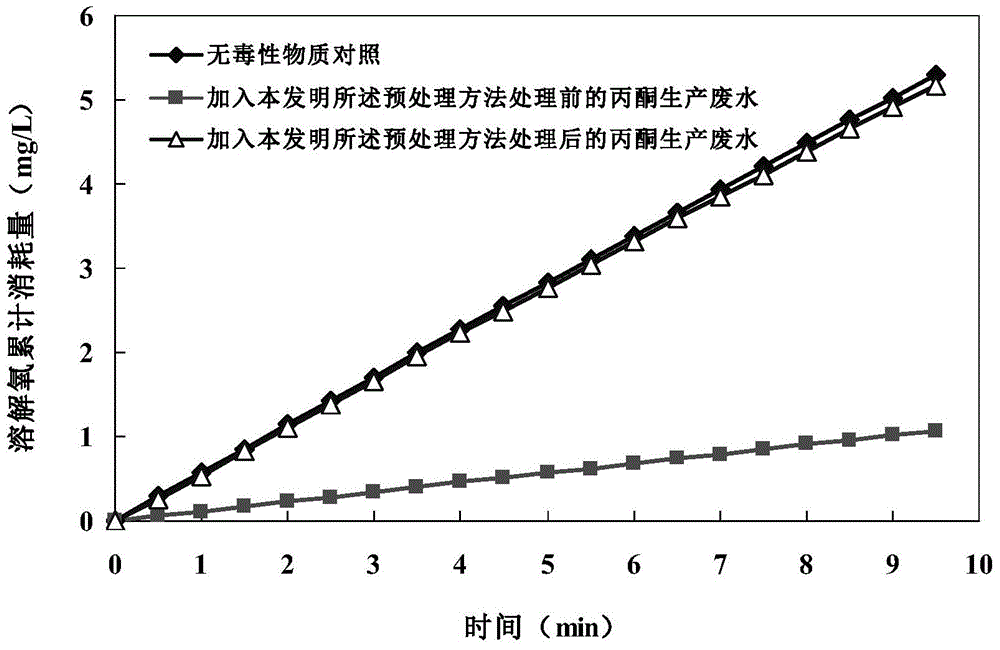

Method for treating wastewater generated in acetone production process

InactiveCN104355501ALow toxicityLow oxygen consumption rateTreatment using aerobic processesWater treatment compoundsChemical oxygen demandSludge

The invention discloses a method for treating wastewater generated in an acetone production process, which comprises the following steps: (1) wastewater pretreatment: (2) aerobic biological treatment: adding a nitrogen source nutrient substance, a phosphorus source nutrient substance and a trace nutrient substance into the pretreated wastewater, and carrying out aerobic biological treatment; and (3) suspended organic matter removal: sending the wastewater subjected to aerobic biological treatment into a precipitation tank or floatation tank to perform sludge-water separation, wherein no acetone is detected in the effluent water, and the COD (chemical oxygen demand) content is lowered to 100 mg / L below. The method disclosed by the invention has the advantages of high treatment load, stable operation and low treatment cost.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Process and device for the treatment of water, particularly for ships

InactiveUS6875363B2Reduce bacteria countReduce in quantitySeawater treatmentSelf-bailing equipments/scuppersSuspended organic matterFiltration

A process for the treatment of water comprises: a) Adding to the water an oxidizing agent in a stunning concentration, wherein the detention time of said agent between adding it to water and the subsequent steps of filtration and / or irradiation is up to about 90 seconds; b) filtering the oxidized water by a filtration system having a filtering size larger than the average size of suspended organic matter in the water; and c) exposing the oxidized and filtered water to irradiation.

Owner:ARKAL FILTRATION SYST C S

Sludge-containing wastewater treatment method

InactiveCN107459214AHigh emissionsSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesActivated sludgeSuspended organic matter

Owner:江苏科力特环保科技有限公司

Low-cost waste water phosphorus fertilizer production technology

InactiveCN105084943AReduce the amount of alkaliReduce contentAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSuspended organic matterMagnesium ammonium phosphate

The invention provides a low-cost waste water phosphorus fertilizer production technology, and belongs to the field of water pollution control and resource regeneration. A low-cost waste water phosphorus fertilizer production device is composed of four treatment units including a first-stage blowing stripping pond, a first-stage settlement pond, a second-stage blowing stripping reaction pond and a second-stage settlement pond. The technology includes the following steps that biogas slurry waste water from an anaerobic pool is firstly subjected to CO2 blowing stripping in the first-stage blowing stripping pond, and the blowing stripping pH value is controlled; then, the waste water enters the first-stage settlement pond in a self-flowing mode, and suspended organic matter, colloid and part of precipitates are separated and removed; outflow water of the first settlement pond enters the second blowing stripping reaction pond for deep aerated blowing stripping and magnesium ammonium phosphate (MgNH4PO4.6H2O) crystallization reaction, and the pH value of the reaction is controlled; the waste water enters the second-stage settlement pond in a self-flowing mode for gravity settling, solid and liquid are separated, and magnesium ammonium phosphate precipitates are recycled. The waste water phosphorus fertilizer production technology can greatly reduce the amount of alkali thrown during waste water magnesium ammonium phosphate production, and the content of impurities in the product is reduced. Meanwhile, the problem that water pumps, pipe accessories and other facilities scale is effectively solved.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

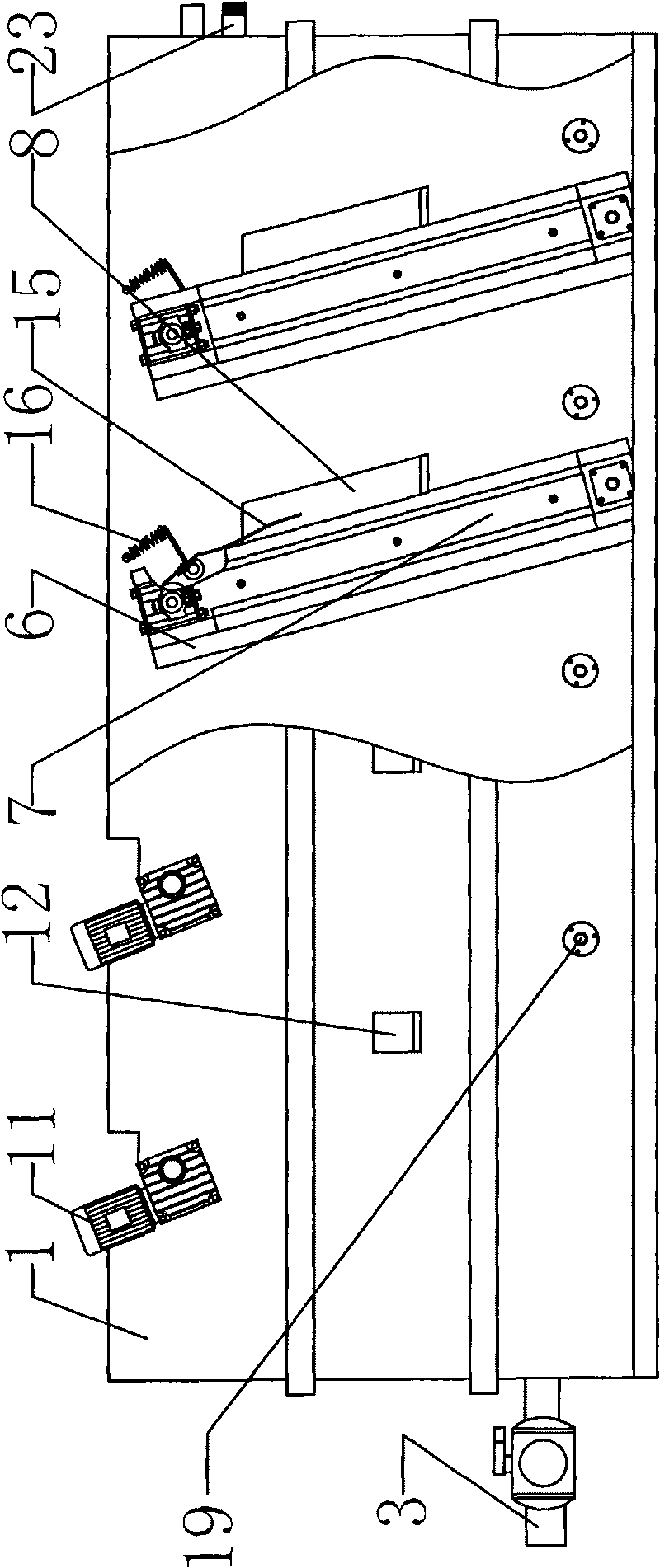

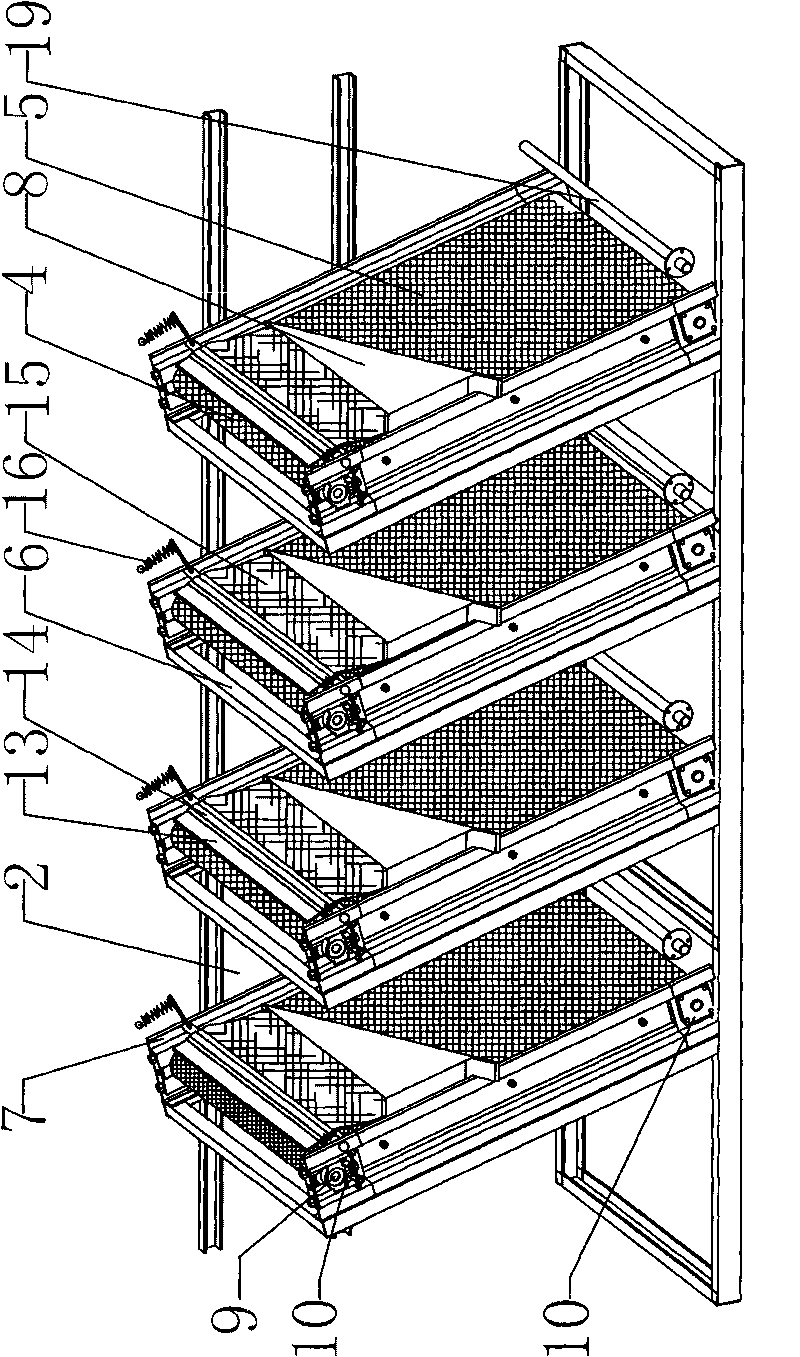

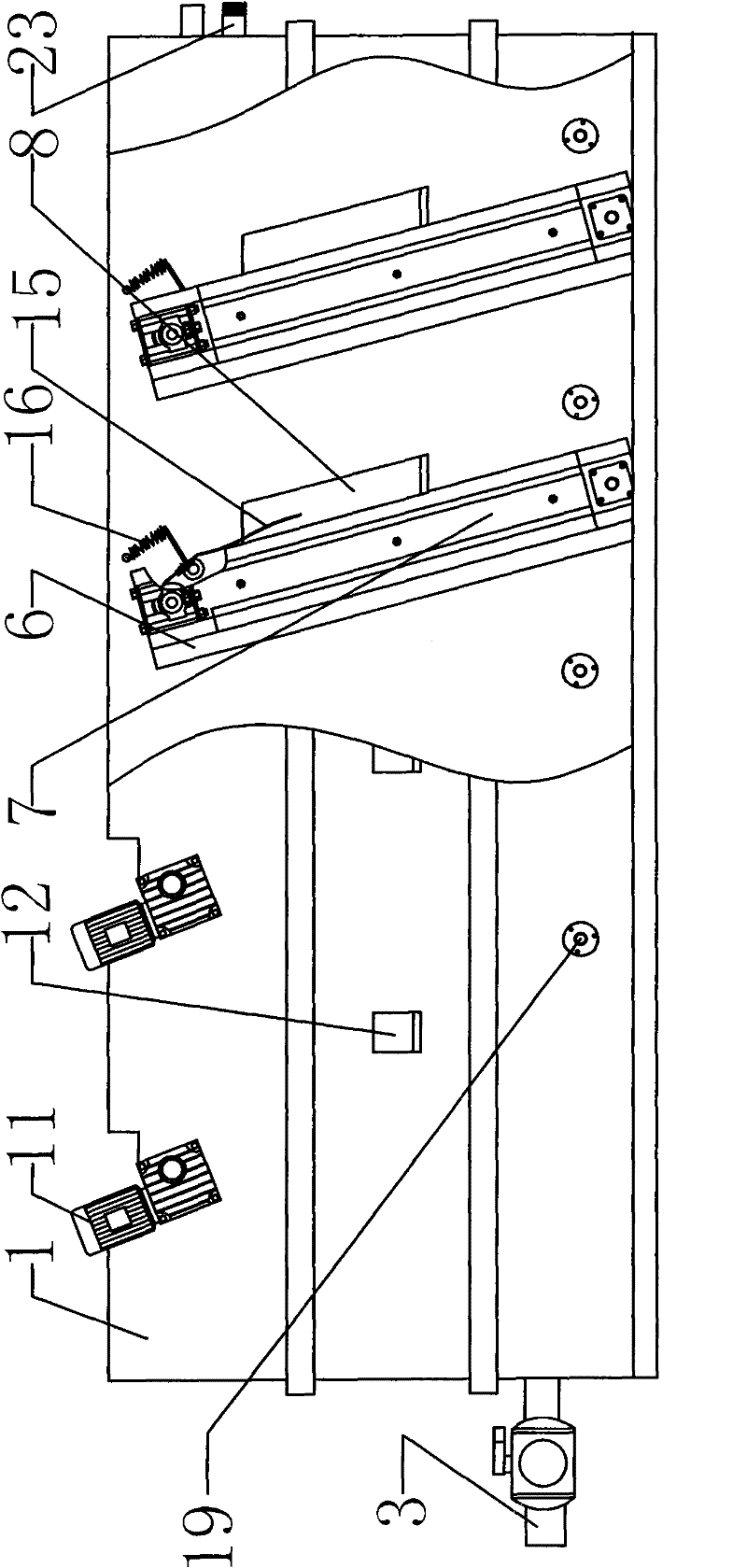

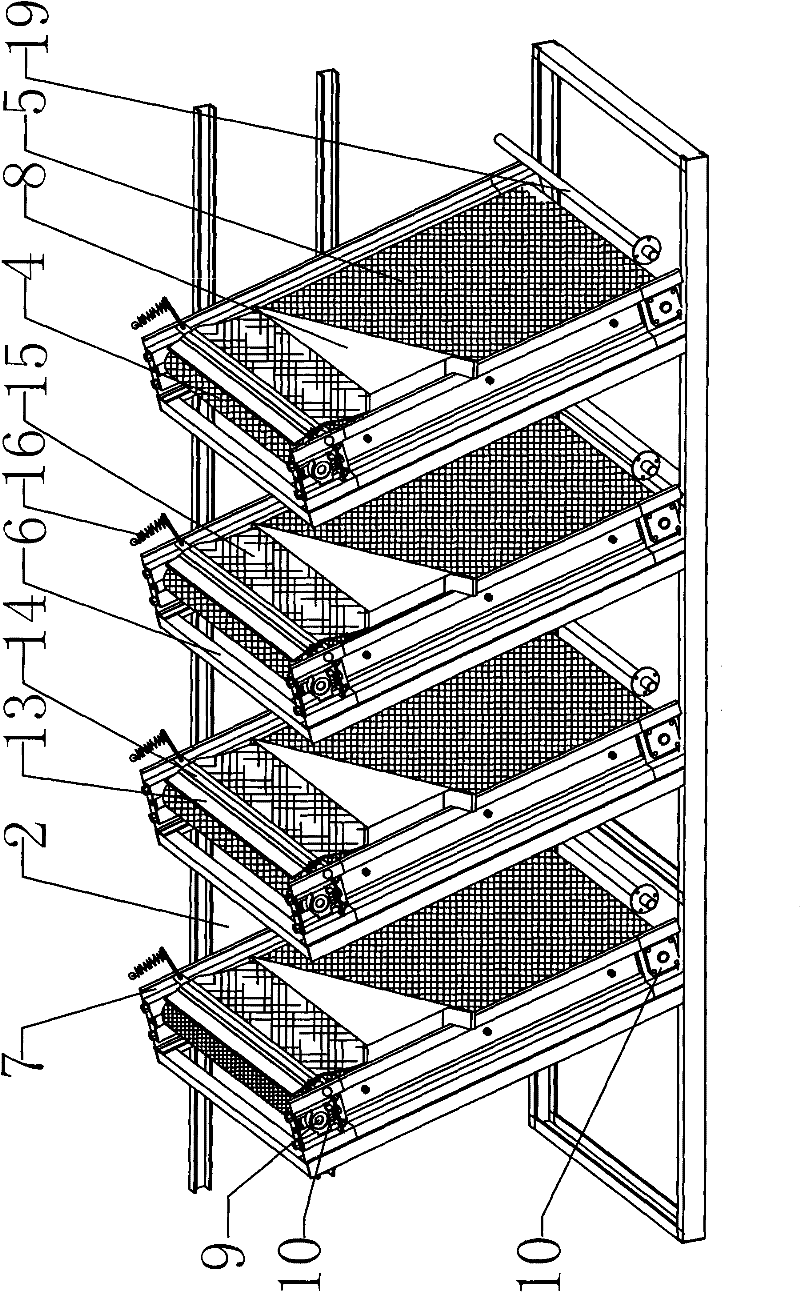

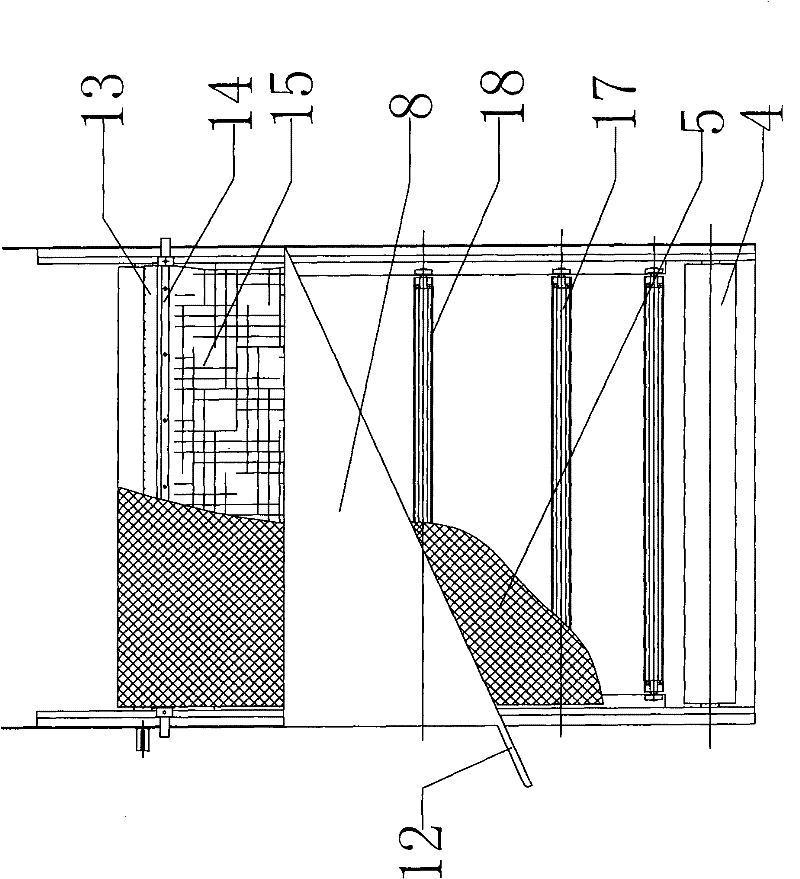

Machine for processing biogas residues and biogas slurry

InactiveCN101708909AHigh filtration rate of suspended organic matterMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSuspended organic matterSlurry

The invention relates to a machine for processing biogas residues and biogas slurry, which is characterized in that: a filtering device comprises rollers, a filter screen, a filter screen frame, side boards, a dirt discharge groove and a residue removal mechanism; both side walls of a box body are respectively and fixedly provided with the side boards; the side boards on the two side walls are fixedly connected with the side face of the filter screen frame from the side in a length direction of the box body; the two rollers are respectively fixed on bearing pedestals at upper and lower ends of the side boards of both sides through bearings; the rollers at the upper ends of the side boards are connected with a motor fixed on the box body through the bearings; a plurality of rotatable carrier roller components are uniformly arranged on the side boards of both sides between the upper and the lower rollers; the filter screen is sleeved between the upper and the lower rollers; the filter screen is arranged on the outer sides of the carrier roller components; the dirt discharge groove with a sewage draining exit on the side face of the box body is fixed on the side face of the side board opposite to the filter screen frame; and the residue removal mechanism is arranged between the tops of the two side boards on one side of the dirt discharge groove. The processing machine for the biogas residues and the biogas slurry has the advantages of durability, reliability and high filtering rate of suspended organic matter.

Owner:JIANGSU XINGNONG ENVIRONMENT PROTECTION TECH CO LTD

A biochemical tail water toxicity reduction and reuse system and treatment method in the printing and dyeing industry

ActiveCN106348551BLow running costLow biological toxicityWater treatment parameter controlSpecific water treatment objectivesConstructed wetlandSolubility

The invention discloses a toxicity reduction and recycling system and a treatment method for biotreated effluent in the printing and dyeing industry, and belongs to the technical field of deep treatment of printing and dyeing wastewater. The system comprises a V-shaped filtering pond, a middle water pond, a magnetic resin reactor, an anaerobic pond, a surface flow wetland and an ecological pond, wherein the magnetic resin reactor is reasonably combined with ecosystems such as the ecological pond and a constructed wetland; the filtering pond is used for removing suspended organic matters in the biotreated effluent by filtering in order to lower turbidity; magnetic resin is used for adsorbing soluble organic pollutants in the biotreated effluent in order to lower chromaticity and biological toxicity. An alternative anaerobic-aerobic process is formed by a pond-wetland-pond combination to further lower the concentration of organic matters, nitrogen, phosphorus and toxic pollutants in a water body in order to form a set of biotreated effluent recycling method which runs stably, makes effluent be up to surface water IV and US EPA (Environmental Protection Agency) wastewater biological toxicity standards, has a landscape function and is suitable for printing and dyeing textile zones.

Owner:NANJING UNIV +1

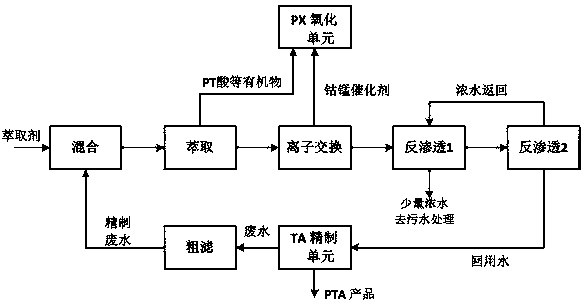

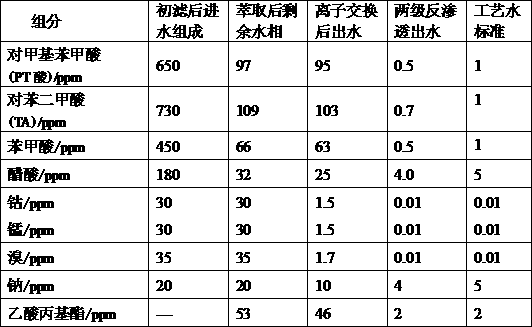

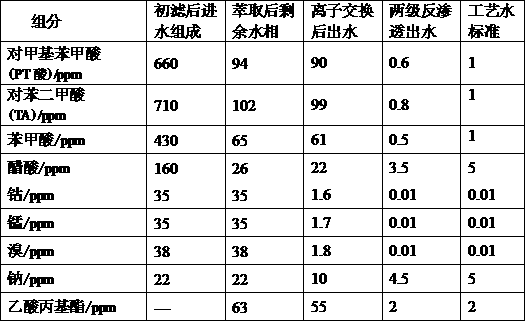

A kind of pta production waste water comprehensive treatment reuse method

ActiveCN105585212BAvoid secondary pollutionReduce consumptionWater/sewage treatment by ion-exchangeTreatment with anaerobic digestion processesSuspended organic matterFiltration

The invention discloses a comprehensive treating and recycling method for PTA (purified terephthalic acid) production wastewater. According to the method, a primary filtration-extraction-ion exchange-reverse osmosis integrated process is adopted to treat the PTA production wastewater. The method comprises the following steps: the wastewater from a refining unit of a PTA device is subjected to primary filtration, and solid aromatic acid organic matters which are filtered out return to an oxidation unit for use; refined wastewater after filtration is subjected to extraction with a carboxylic acid alkyl ester extracting agent in a mixer, and extracted substances return to the oxidation unit for use; a raffinate phase enters an ion exchange system and is subjected to resin adsorption and ion exchange for recovery of a cobalt and manganese metal catalyst, and the recovered metal catalyst returns to the oxidation unit for use; finally, through two stages of reverse osmosis systems, penetrated water is taken as process water to return to the refining unit for use; a small amount of concentrate is sent to a sewage treatment system for treatment. The water treating and recycling rate reaches 70%-85%. The method has the advantages of little investment, low energy consumption, high wastewater treating and recycling rate and the like and has remarkable economic benefit.

Owner:NANJING POLYTECHNIC INSITUTE

Recovery and utilization method for copper bearing spent acid solution from sodium saccharin production process

InactiveCN1218890CHigh purity powderHigh purityMultistage water/sewage treatmentDistillationSuspended organic matter

The present invention provides one waste copper containing acid solution recovering and utilizing process in saccharin sodium production. The waste copper containing acid solution recovering and utilizing process includes filtering to eliminate suspended organic matter, oxidizing the filtrate with mixed oxidant of sodium hypochlorite and potassium hypermanganate to eliminate low boiling point organic matter, decompression distilling the solution in vacuum to obtain dilute hydrochloric acid solution, further extraction and concentrating distillation to obtain hydrochloric acid solution of 30 % concentration, burning residue after decompression distilling to eliminate organic matter and obtain high purity copper sulfate and powder of other inorganic salts. The said process can recover the useful matter from waste acid solution and avoid environmental pollution effectively.

Owner:SHANGHAI JIAOTONG UNIV

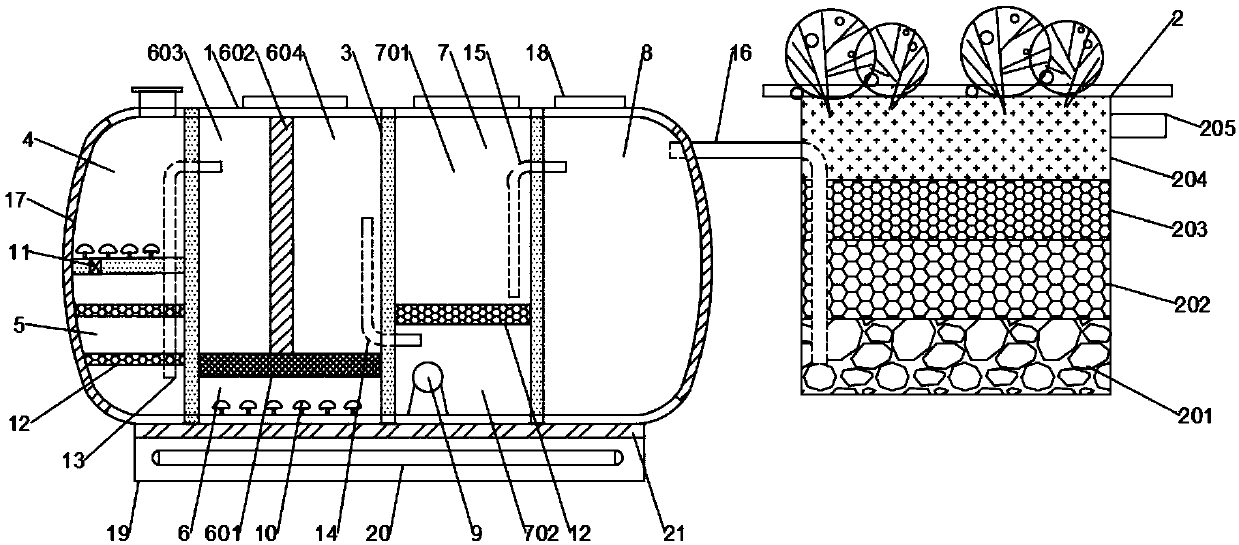

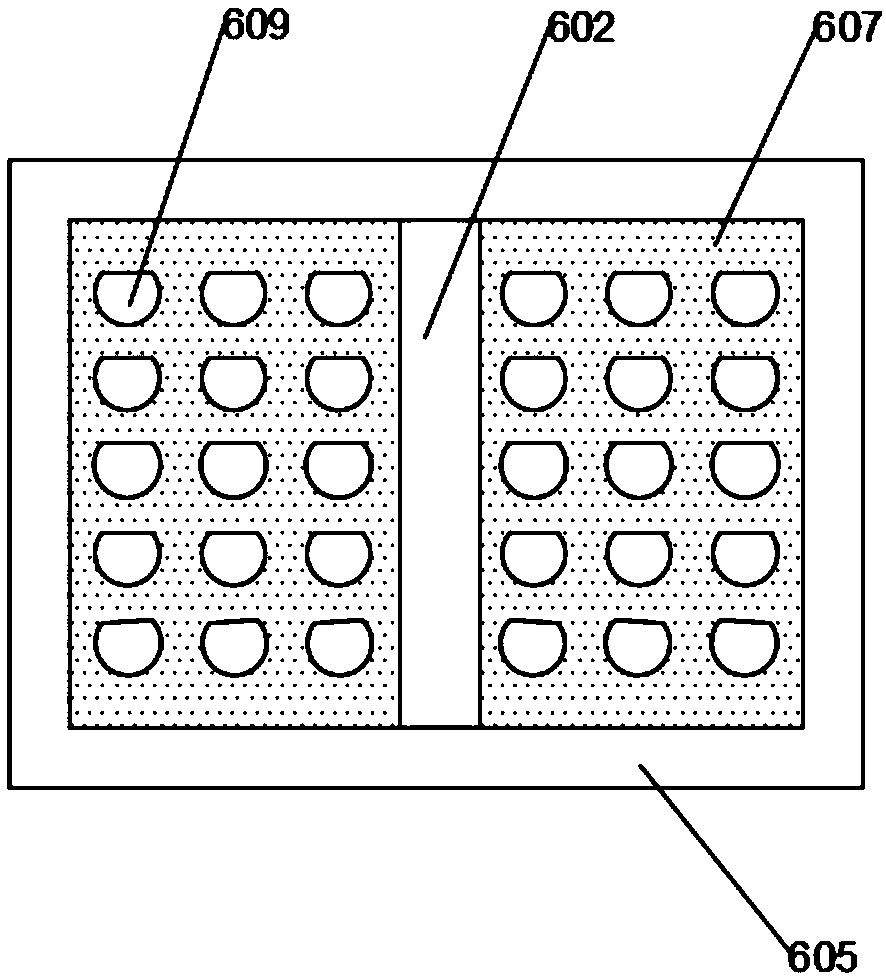

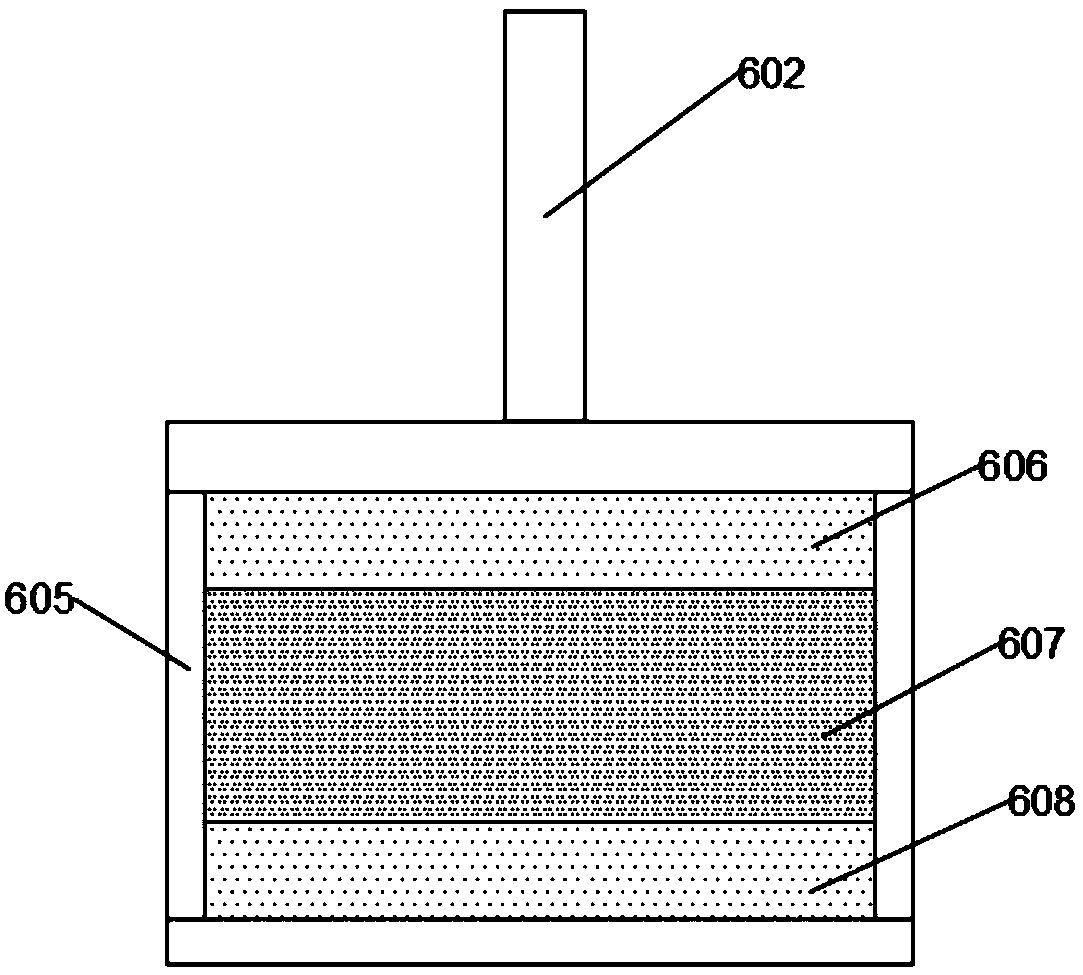

Buried sanitary sewage processing device

InactiveCN109626753AImprove sewage treatment capacityEasy to handleSpecific water treatment objectivesWater contaminantsSuspended organic matterSewage

The embodiment of the invention discloses a buried sanitary sewage processing device. The device comprises a purification box, the purification box is connected with a deep purification cultivating tank through a pipeline, and partition plates are arranged in the purification box; the inside of the purification box is partitioned by the partition plates into an adjusting tank, a first filtering sedimentation tank, an anaerobic fermentation tank, a second filtering sedimentation tank and a disinfecting tank which are successively connected, the disinfecting tank is connected with the deep purification cultivating tank through a pipeline, the lower portion of the second filtering sedimentation tank is provided with a circulating pump, and the circulating pump is connected with the adjustingtank through a pipeline; a biological membrane plate is arranged in the anaerobic fermentation tank, the anaerobic fermentation tank is partitioned into upper and lower portions by the biological membrane plate, a partition plate is arranged on the upper area of the biological membrane plate, and the upper area of the biological membrane plate is partitioned into a liquid inlet area and a liquid outlet area through the partition plate; aeration devices are arranged on the lower area of the biological membrane plate and at the bottom of the adjusting tank. The device utilizes the principle of combining sedimentation and anaerobic fermentation for removing suspended organic matter in sanitary sewage and has the advantages that the sewage processing capacity is high, and the efficiency is high.

Owner:湖南湘星环保水处理设备有限公司

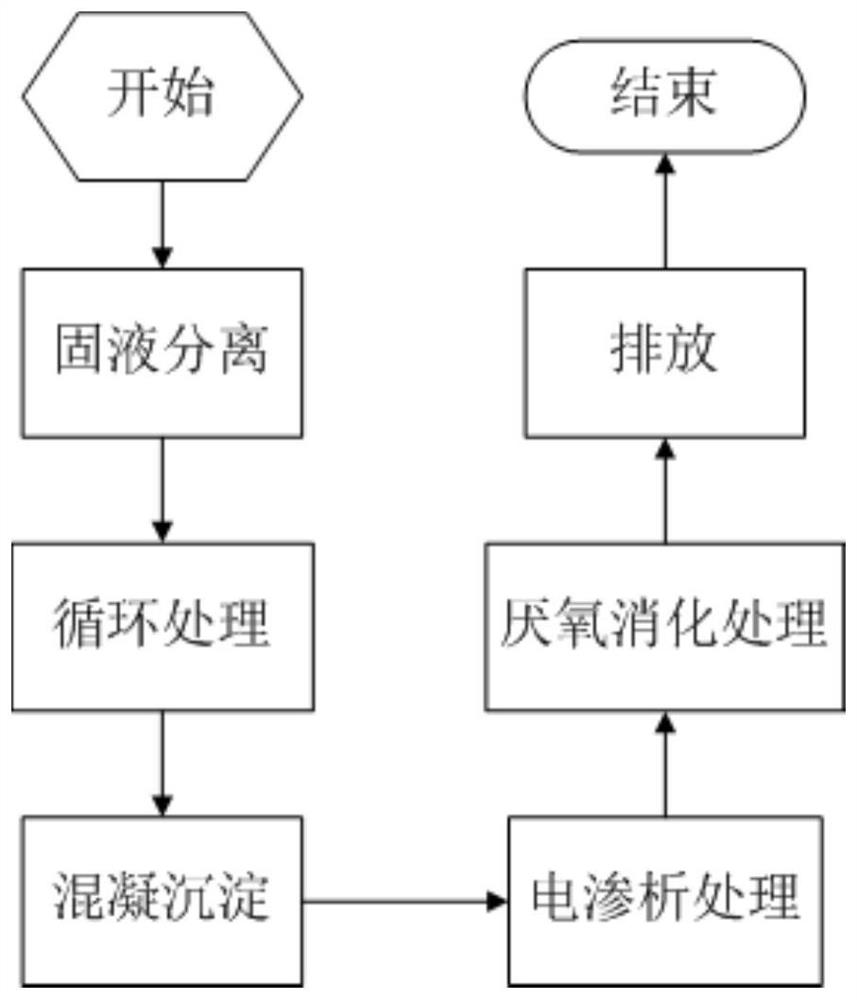

Treatment method of preserved mustard wastewater

PendingCN112624519AAvoid cloggingReduce lossesWater treatment parameter controlTreatment using aerobic processesDigestion TreatmentSuspended organic matter

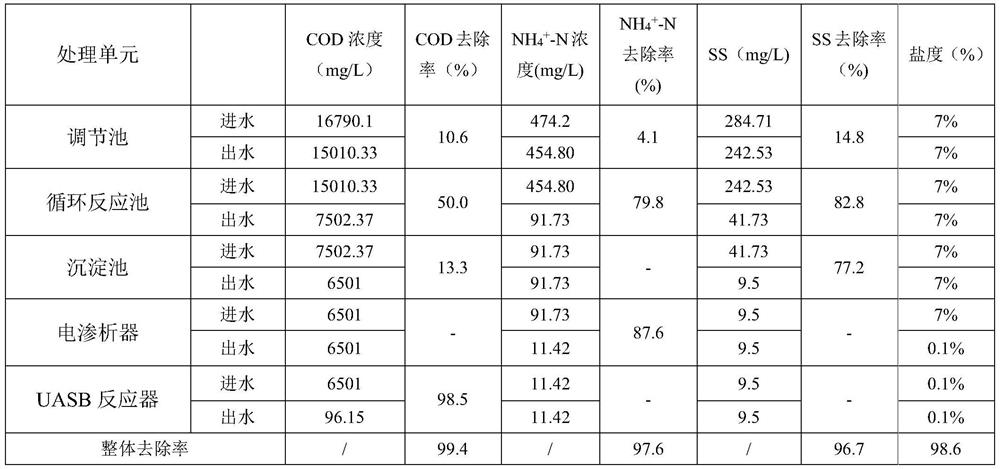

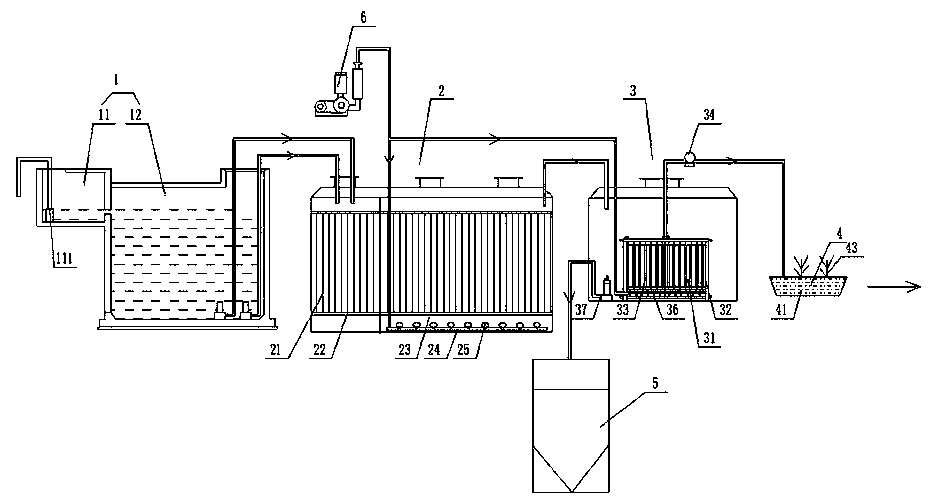

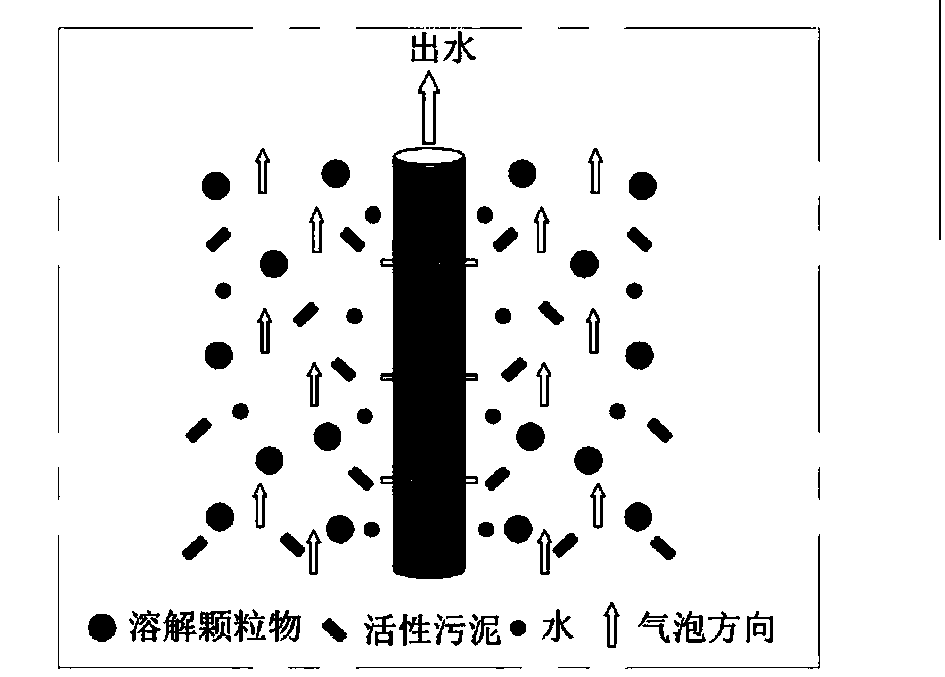

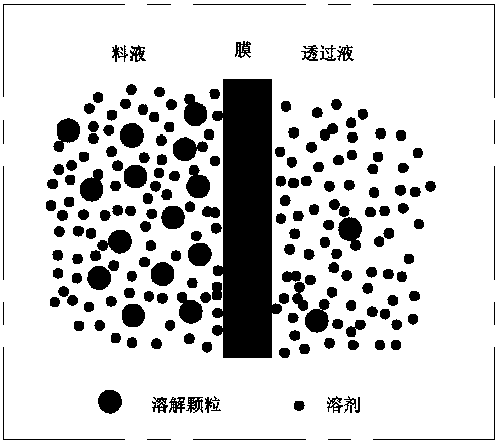

The invention discloses a treatment method of preserved mustard wastewater, which comprises the steps of 1) filtering high-salt preserved mustard wastewater through a solid-liquid separation unit, enabling waste liquid to enter an adjusting unit, and adjusting the pH value of the waste liquid to 6.5-8; 2) enabling the waste liquid to enter a circular reaction tank to remove organic matters, ammonia nitrogen, total nitrogen and total phosphorus in the waste liquid; 3) enabling effluent circularly treated by the circular reaction tank to enter a coagulating sedimentation unit for precipitating insoluble organic matters and fine particle suspended matters in the waste liquid; 4) enabling effluent treated by the coagulating sedimentation unit to enter an electrodialysis treatment unit, and separating sodium ions and chloride ions of NaCl in the waste liquid by adopting a membrane separation method to reduce the salinity of the waste liquid; and (5) enabling the effluent of the electrodialysis treatment unit to enter an anaerobic digestion treatment unit, enabling anaerobic microorganism compound strains added into the waste liquid to be in full contact with the waste liquid, and then discharging. After the suspended organic matters and inorganic matter particles are removed, more than 90% of salt in the wastewater is removed by utilizing electrodialysis equipment, so that the energy consumption and the cost of wastewater treatment are effectively reduced.

Owner:CHONGQING UNIV OF TECH

Three-effect fused rural ecological sewage treatment system and three-effect fused rural ecological sewage treatment method

PendingCN110002674AMeet irrigationImprove the water effectWater contaminantsWater/sewage treatment bu osmosis/dialysisConstructed wetlandActivated sludge

The invention discloses a three-effect fused rural ecological sewage treatment system and a three-effect fused rural ecological sewage treatment method. The system comprises a pre-treatment unit, a LJ-BL treatment unit, a LJ-MB treatment unit, a LJ-EL treatment unit and a sludge treatment unit. The pre-treatment unit removes suspended organic matters in household sewage by means of a precipitationand anaerobic fermentation principle, the BJ biochemical treatment unit degrades CODcr and BOD5 in the wastewater through an anaerobic pool and an aerobic tank, the MB treatment unit is used for treating sewage by combining efficient membrane separation with an activated sludge method, and the LJ-EL treatment unit further eliminates organic matters, heavy metals and nitrogen and phosphorus through an artificial wetland. The system has a good effluent effect, can meet afforestation and farm irrigation and can be directly reclaimed as the content of effluent suspended solids and turbidity are close to zero. Compared with a conventional treatment system, 40% of a land occupied area can be saved, and the landscape in a plant is good.

Owner:山西绿洁环保有限公司

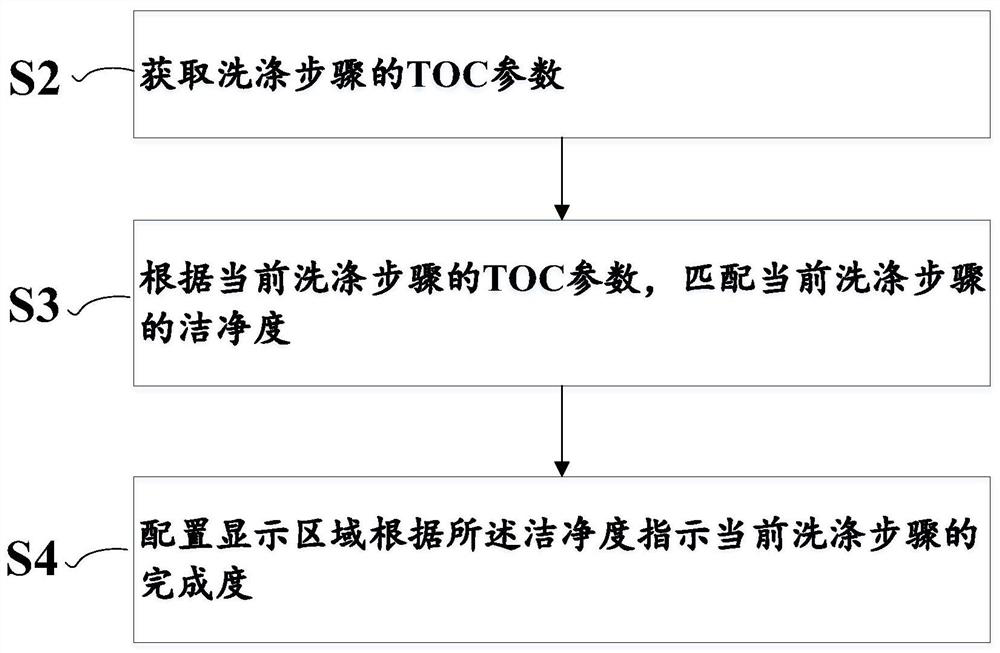

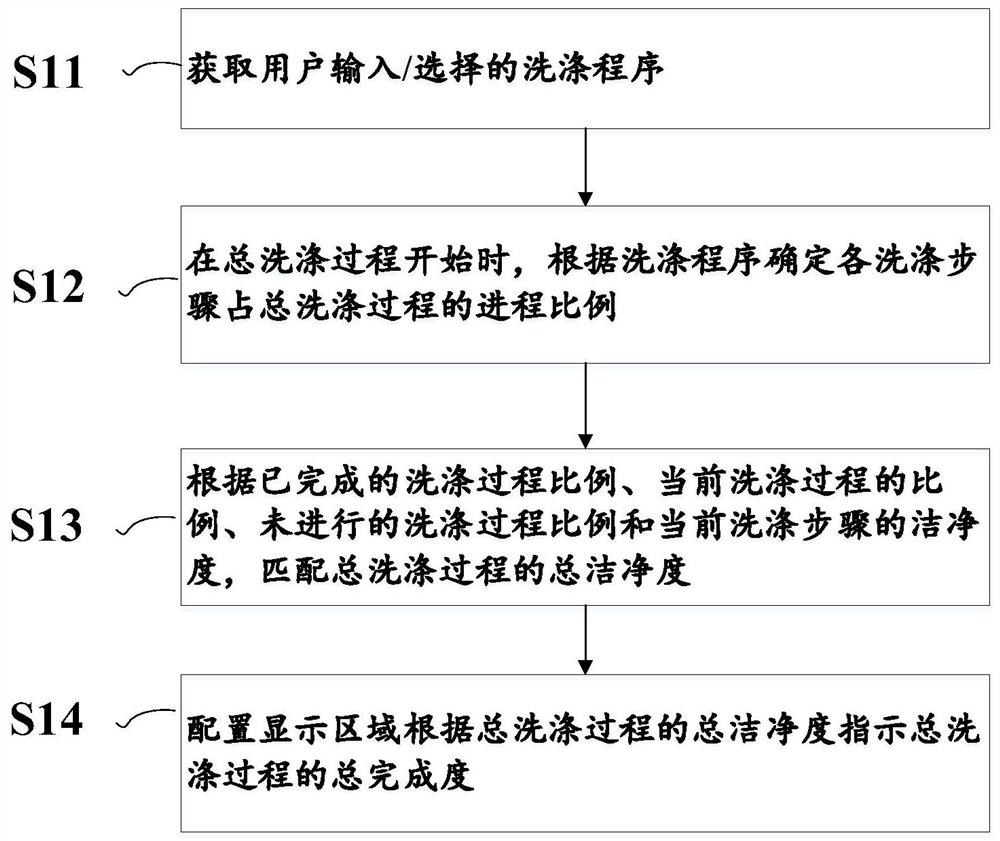

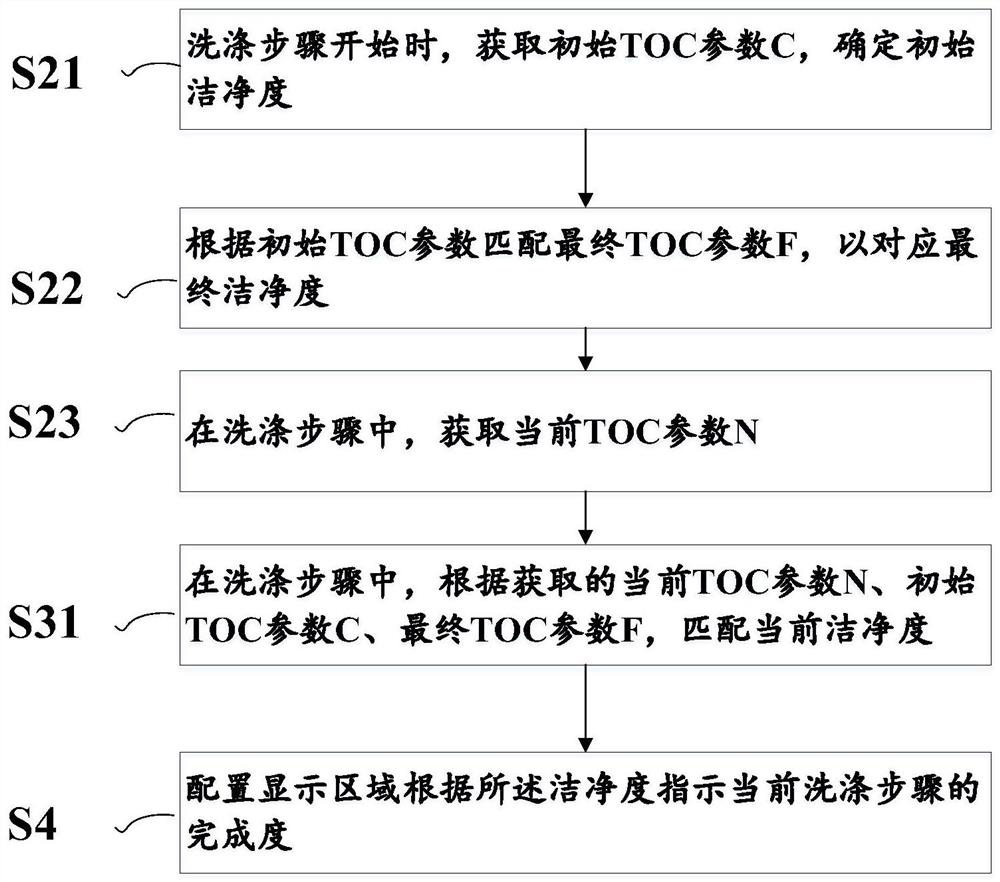

Clean state indication method and system, storage medium and washing device

ActiveCN114875619AImprove experienceAccurate understandingControl devices for washing apparatusTextiles and paperSuspended organic matterProcess engineering

The invention relates to a clean state indicating method for a washing process. The clean state indicating method comprises the following steps: acquiring TOC parameters of a washing step; matching the cleanliness of the current washing step according to the TOC parameter of the current washing step; the configuration display area indicates the completion degree of the current washing step according to the cleanliness; the content of organic matters in water can be accurately reflected, not only can suspended organic matters be detected, but also most of general pigments, food stains, organic additives and detergents which are soluble in water can be detected, and the amount of dirt in washing water can be reflected through TOC detection, so that the cleanliness can be judged. The cleanliness can correspondingly indicate the completion degree of the washing step in the display area; a user can obviously and accurately know the washing process, the washing completion degree can be visually known, and finally the user experience is improved; in addition, the invention also relates to a corresponding system, a storage medium and a washing device.

Owner:YUNMI HULIAN TECH (GUANGDONG) CO LTD

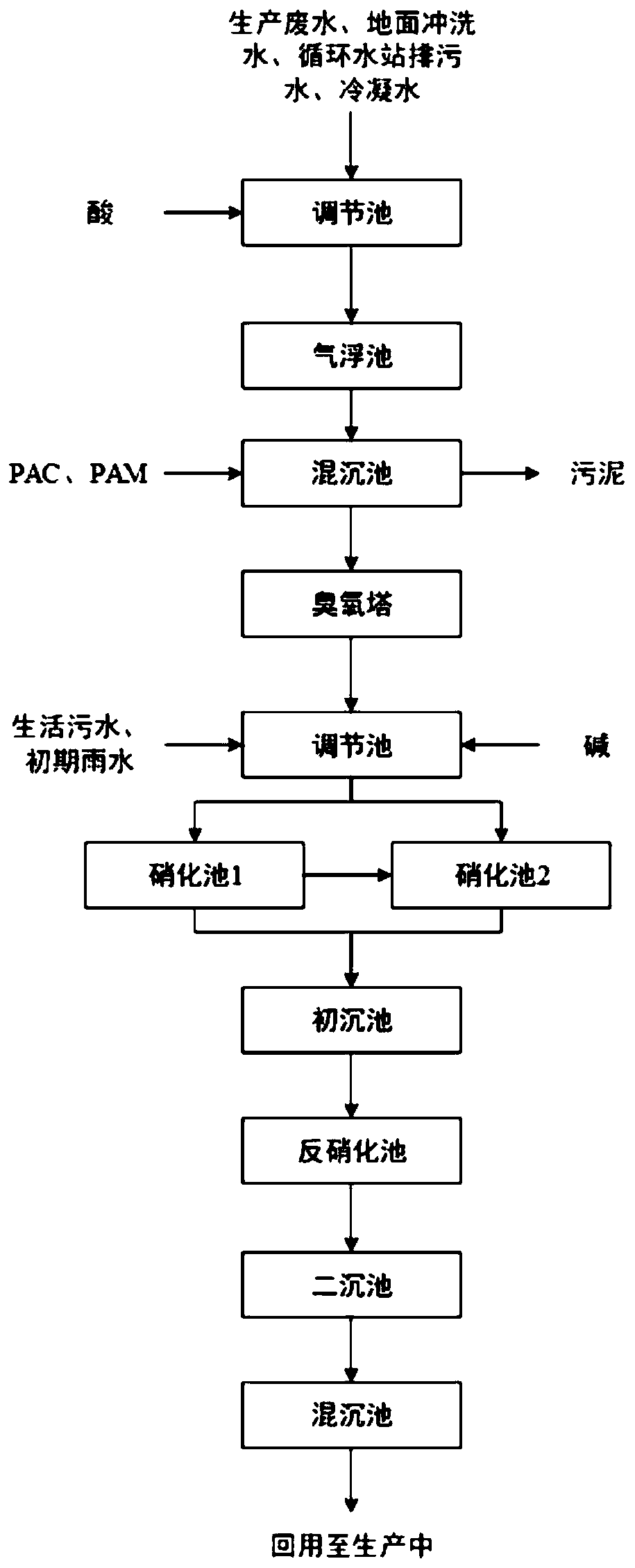

Treatment method of rubber processing wastewater difficult to biodegrade

InactiveCN111470722AImprove biodegradabilityAchieving zero emissionsWater treatment parameter controlWater contaminantsWater useSuspended organic matter

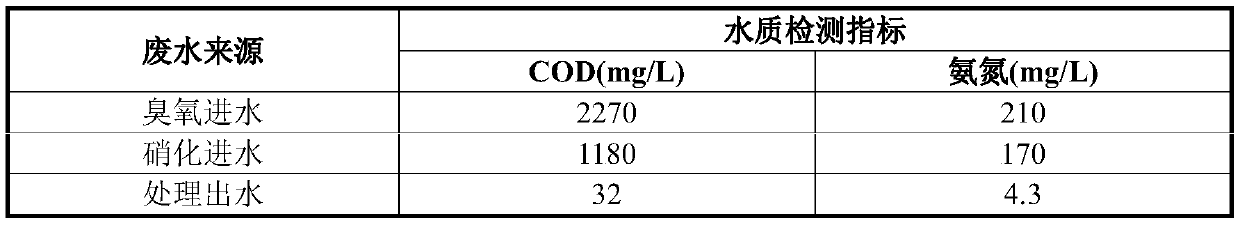

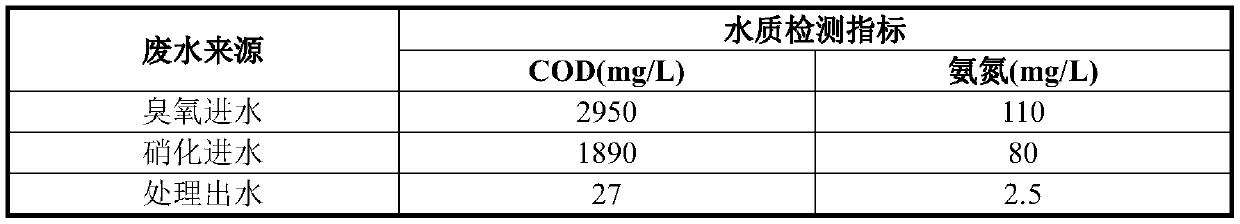

The invention discloses a treatment method of low-concentration rubber processing wastewater difficult to biodegrade, and belongs to the technical field of chemical wastewater treatment. The inventionprovides a treatment method of rubber processing wastewater difficult to biodegrade. The method comprises the following steps: mixing production wastewater to be treated, removing floating oil organic matters through air floatation treatment, removing colloid organic matters through flocculent precipitation, carrying out catalytic ozonation on the wastewater, mixing effluent with domestic sewageand initial rainwater, carrying out nitrification and denitrification treatment, finally feeding into a coagulating sedimentation tank, carrying out secondary coagulating sedimentation, and discharging. The wastewater is pretreated to remove floating oil and a large amount of suspended organic matters, and the molecular structure of the non-biodegradable organic matters is further destroyed through catalytic ozonation, so that the biodegradability of the wastewater is improved, and the COD and ammonia nitrogen of the wastewater are reduced through nitrification and denitrification treatment, so that the effluent reaches the enterprise reuse water standard, and zero emission of enterprises is realized.

Owner:江苏南大华兴环保科技股份公司

Process for treating chemical wastewater by phenolphthalein coagulation

InactiveCN102951712AIncrease concentrationReduce dosageWater contaminantsWater/sewage treatment by flocculation/precipitationPhenolphthaleinSuspended organic matter

The invention provides a process for treating chemical wastewater by phenolphthalein coagulation, belonging to the field of energy conservation and environment protection. The process comprises the steps as follows: firstly, feeding an amount of alkali liquor to sewage to regulate the pH value of the sewage to 9-10 and feeding a phenolphthalein solution prepared from alcohol, wherein phenolphthalein is intrinsically easily soluble in the alcohol and is insoluble in water, and when the phenolphthalein solution is fed to the sewage, phenolphthalein is separated out greatly to form plenty of colloidal insoluble substances due to the effect that the alcohol is soluble in the water; then, feeding 0.3-1.2% of coagulant FeSO4 and 0.01-0.03% of aided mixer polyacrylamide (PAM) and then stirring uniformly to form a lot of high-density flocculent easily-settled complexes; and settling the sewage by an inclined-tube sedimentation tank, thereby removing suspended organic matters in the sewage. According to the process, the treatment efficiency can be improved by 10-20% in general; and meanwhile, as an amount of phenolphthalein with low cost is fed, the concentration of the suspended matters in the sewage is increased and the addition of the coagulant is reduced; and therefore, the operating cost can be saved by 5-10%.

Owner:天津滨海鼎昇环保科技工程有限公司

Water purifying method for cultivation pond

InactiveCN100335423CGood effectImprove environmental conditionsPisciculture and aquariaWater/sewage treatment by oxidationSuspended organic matterCatalytic oxidation

The present invention discloses water purifying method for cultivation pond. The method is one water circulating process including pumping cultivation waste water from the bottom of pond center to one water trough; separating suspended organic matter from water in the water trough; natural photochemically catalytic oxidation of water; and returning the treated water to the pond. The method of the present invention can eliminate water pollution for aquatic cultivation in relatively low cost, improve the physical, chemical and biological conditions of cultivation water, and raise the water environment stability of cultivation water, and is suitable for pond cultivation with both sea water and fresh water.

Owner:海南省环境科学研究院 +1

Biogas residue biogas slurry processor

InactiveCN101708909BHigh filtration rate of suspended organic matterMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationBiochemical engineeringSuspended organic matter

The invention relates to a processing machine for biogas residue and biogas slurry, which is characterized in that: the filter device includes a drum, a filter screen, a filter screen frame, a side plate, a sewage tank and a slag removal mechanism, and side walls are respectively fixed on the two side walls of the box body. The side plate is fixedly connected to the side of the filter frame on one side in the length direction of the box body. The two rollers are respectively fixed on the bearing seats at the upper and lower ends of the side plates on both sides through bearings. The motors fixed on the box body are connected, and a plurality of rotatable roller parts are evenly arranged on the side plates on both sides between the upper and lower rollers, and a filter screen is set between the upper and lower rollers. The net is placed on the outside of the idler; the sewage tank with a sewage outlet on the side of the box is fixed on the side of the side plate opposite to the filter frame, and the slag removal mechanism is set between the tops of the side plates on the side of the sewage tank. The invention has the advantages of: a durable and reliable biogas residue biogas slurry processor with high filtration rate of suspended organic matter.

Owner:JIANGSU XINGNONG ENVIRONMENT PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com