Treatment method of preserved mustard wastewater

A technology of pickled mustard wastewater and treatment methods, which is applied in the direction of food industry wastewater treatment, water/sewage treatment, water treatment parameter control, etc., and can solve the problem of reduced stability and reliability of biochemical treatment equipment, short duration of bioaugmentation effect, and inapplicability Mustard mustard wastewater treatment and other issues have achieved the effect of achieving stable and up-to-standard discharge, realizing resource utilization, and realizing resource exchange and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

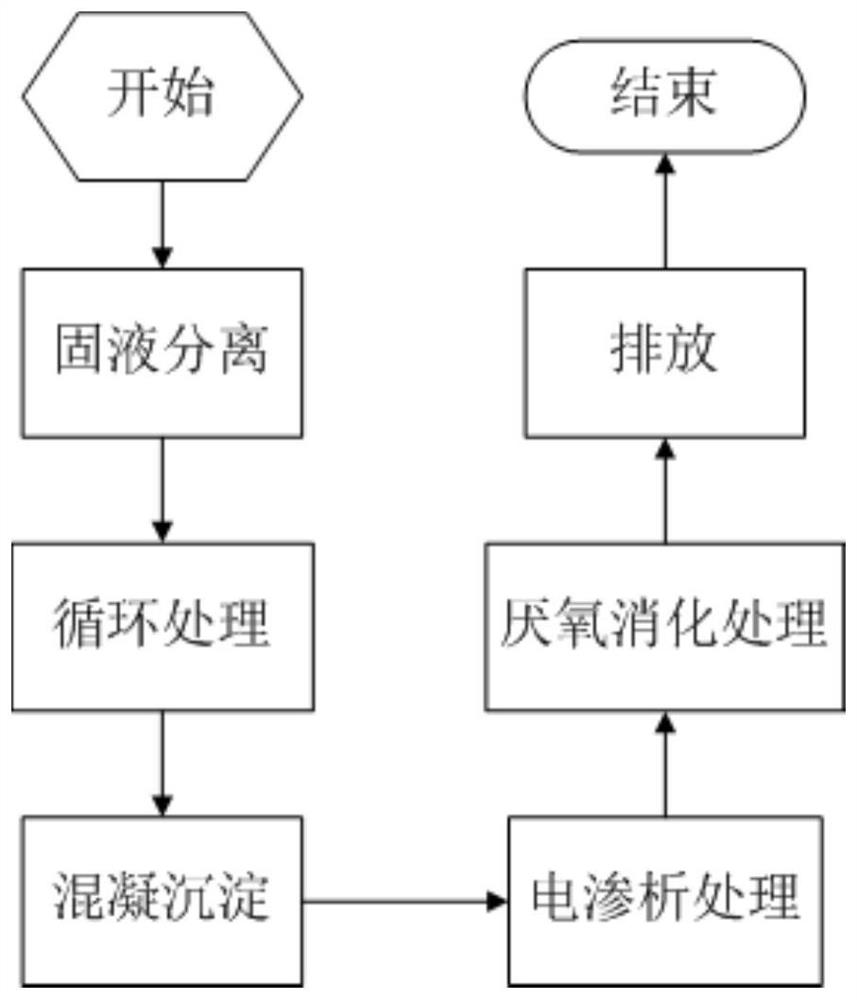

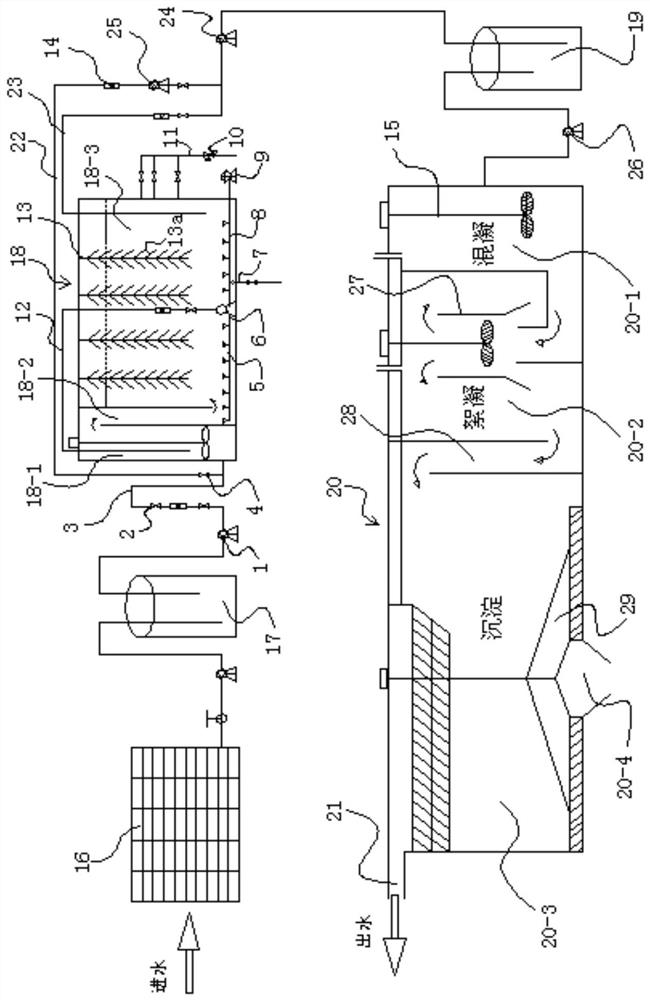

Method used

Image

Examples

Embodiment 1

[0063] Adopt the present invention to process the mustard mustard wastewater of a mustard mustard factory in Fuling, Chongqing according to the above steps, and the COD and NH in the mustard mustard wastewater 4 + -N and SS water quality are 14380~14410, 441~453 and 218~230mg / L respectively, and the salinity is 7%;

[0064] Through the grille, go to the adjustment tank to adjust the pH of the solution to 6.5-8.5, enter the circulating reaction tank for bioaugmentation treatment, and activate the halophilic bacteria agent (5%-10% inoculum) liquid to expand culture, add medium to make it grow to the optimal concentration) 3d, set HRT=12h sequential batch type intermittent water change, drainage ratio is 1 / 3, aeration intensity is 1000L / h, sludge concentration is 3200mb / L; after coagulation, flocculation, and sedimentation treatment, the coagulation and flocculation residence time is set to 0.7h, the dosage of coagulant is 70mg / L, and the dosage of flocculation is 4mg / L, and th...

Embodiment 2

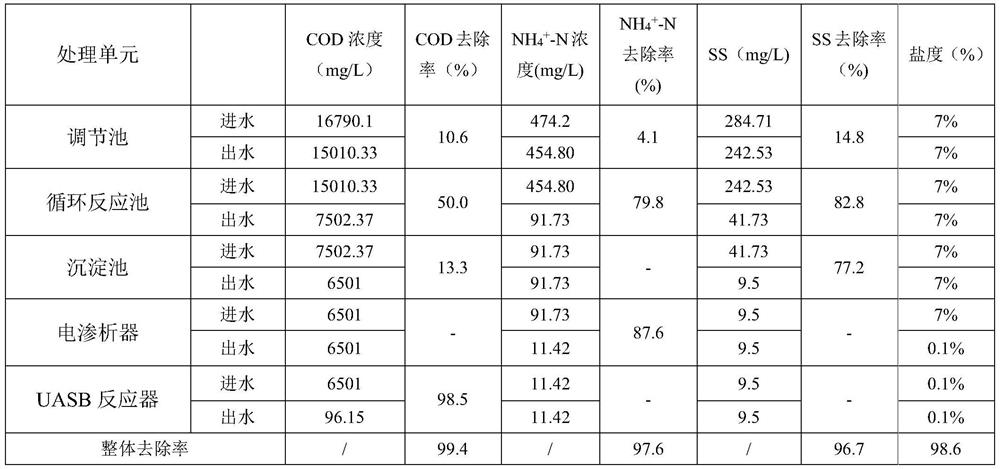

[0070] According to the above steps, the present invention is used to treat the mixed liquid of comprehensive waste water and pickled mustard waste water produced in the production process of a mustard plant in Banan District, Chongqing City, and then the mixed liquid passes through a high-salt mustard waste water pretreatment device, an electrodialyzer, and a UASB in sequence. After the reactor, the final effluent can meet the discharge standard, and the specific treatment conditions are shown in Table 2.

[0071] Table 2

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com