Process for treating chemical wastewater by phenolphthalein coagulation

A technology for chemical wastewater and phenolphthalein, which is applied in the fields of flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc. higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

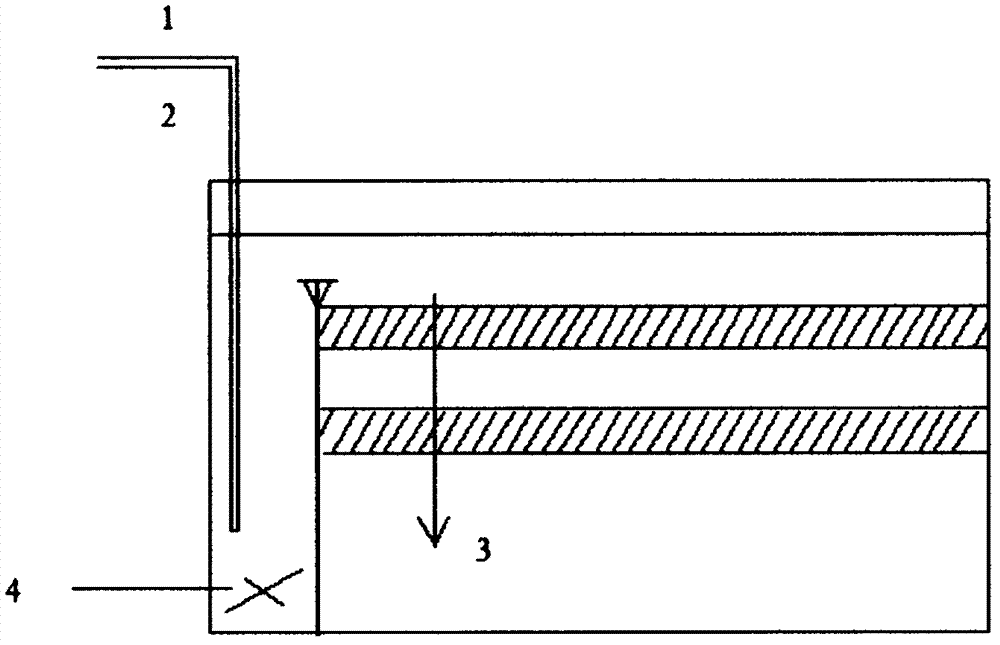

[0011] see figure 1 , first add 6% lime water lye 2 to the chemical wastewater to adjust the pH range of the wastewater to 9-10, then add 10% phenolphthalein 2 solution, and add 0.6% coagulant FeSO 4 1 and 0.03% coagulant PAM1, after fully stirring, the suspended solids in the sewage are fully aggregated into flocculent sediments, and separated by the secondary sedimentation tank, so that a large amount of organic matter in the sewage can be removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com