Advanced treatment and recycling process and apparatus for sewage reaching standard

A technology for advanced treatment and sewage, applied in the field of ultrafiltration-reverse osmosis combined process, which can solve problems such as unfavorable microbial growth and degradation of organic matter, poor treatment effect of organic pollutants and ammonia nitrogen, organic matter and microbial contamination, etc., to achieve system adaptation. It has strong performance and practicability, improves the effect of low microbial concentration and is not easy to be lost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

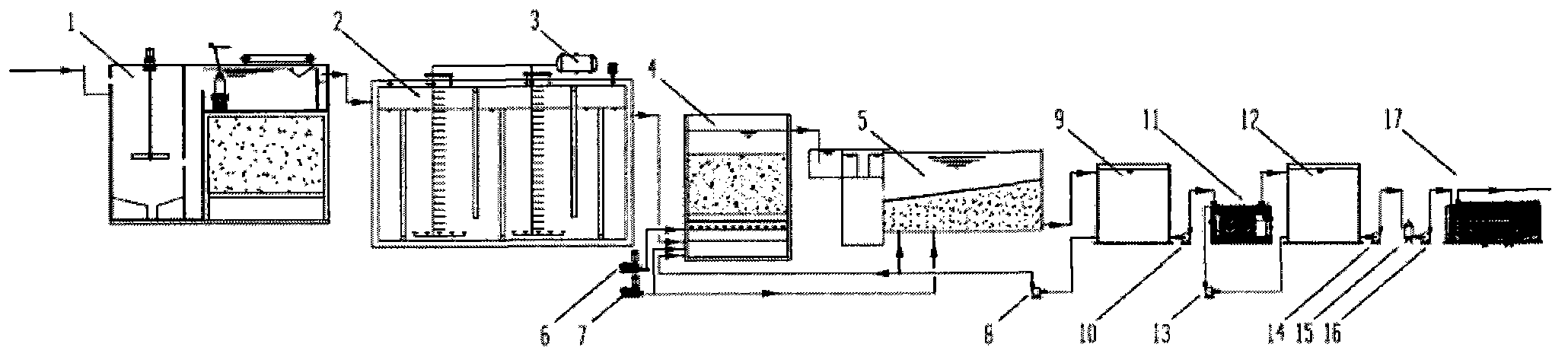

Image

Examples

example

[0061] The raw water is the standard sewage from a petrochemical enterprise, and the water quality meets the first-level standard in the national standard of the People's Republic of China "Sewage Comprehensive Discharge Standard" (GB8978-1996). Add mutant bacteria and enzyme preparations at a ratio of 4 to 10 g bacterial agent / L, and acclimatize. Controlling COD of Immobilized Microbes in Biological Aerated Filters at the Initial Stage of Cultivation Cr The concentration is 500-600mg / L, and the DO concentration is controlled at 3-5mg / L. After 3-5 days of stuffy exposure, the sewage that reaches the standard will enter the sewage advanced treatment and reuse device in order to realize continuous water inflow and outflow of the entire process system.

[0062] The standard sewage enters the air flotation filter to remove oil, light flocs and suspended solids in the water. Dosing polyaluminum chloride and polyacrylamide before the air flotation filter, the dosing concentration i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com