Advanced treatment method for carbonization wastewater

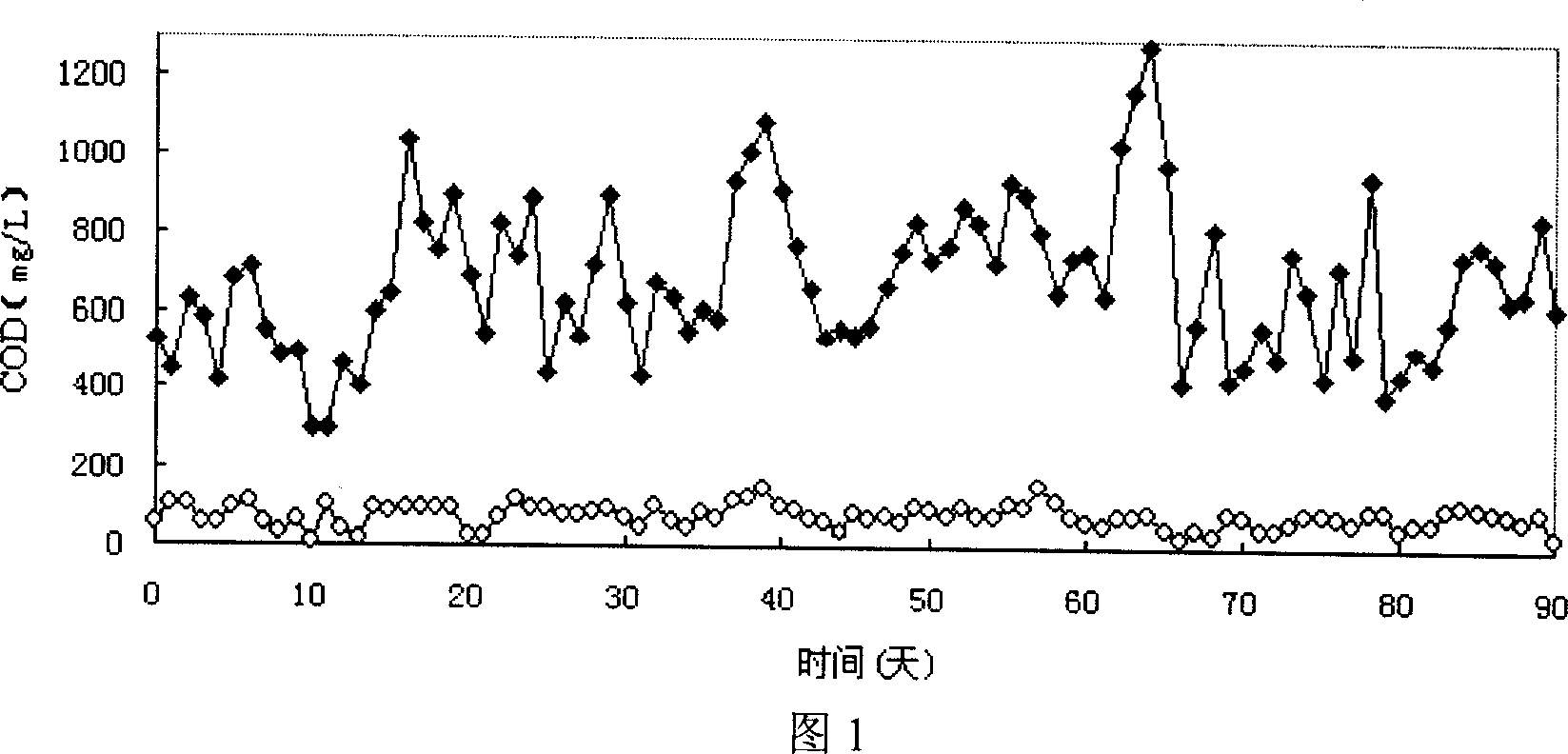

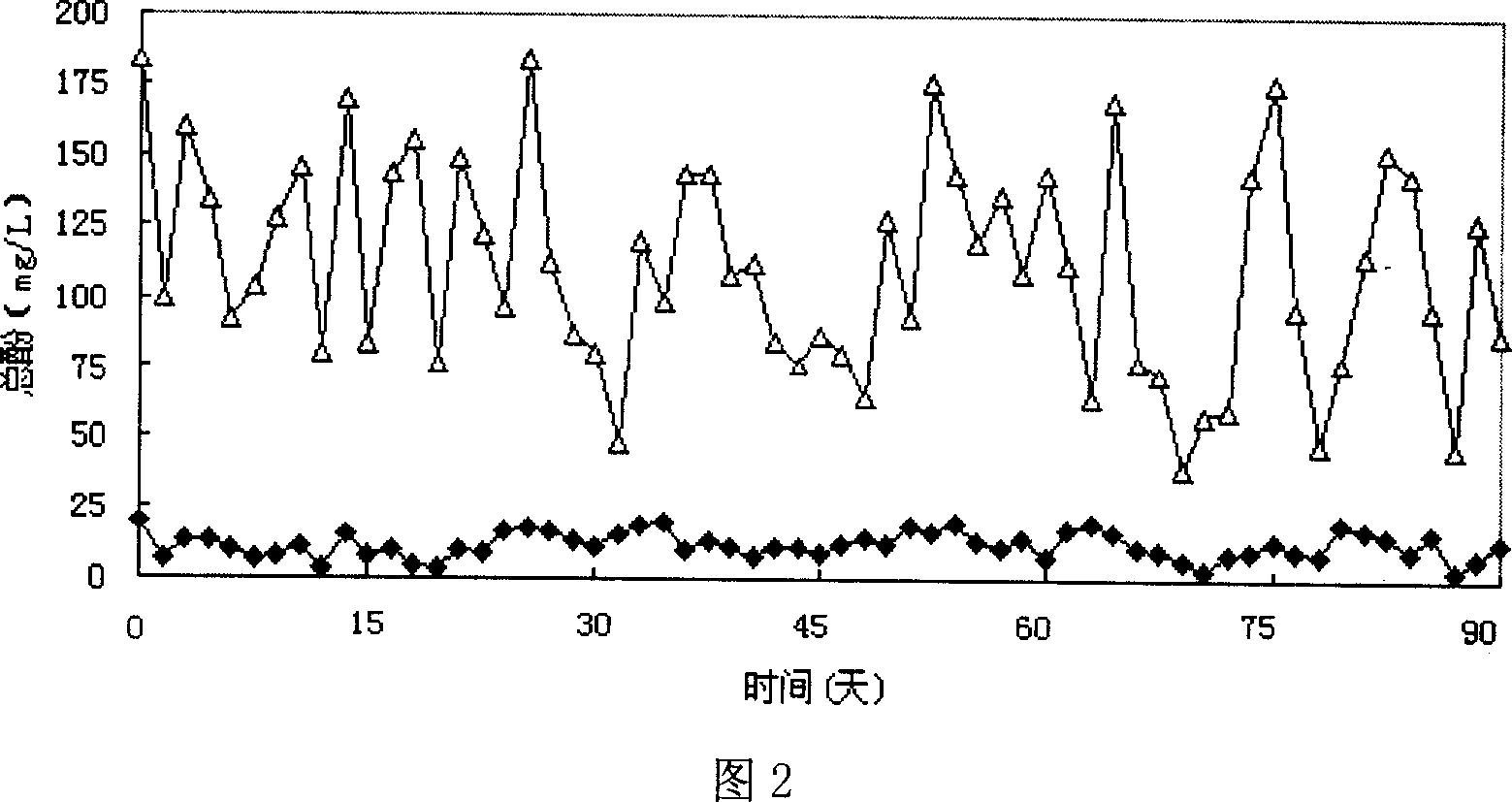

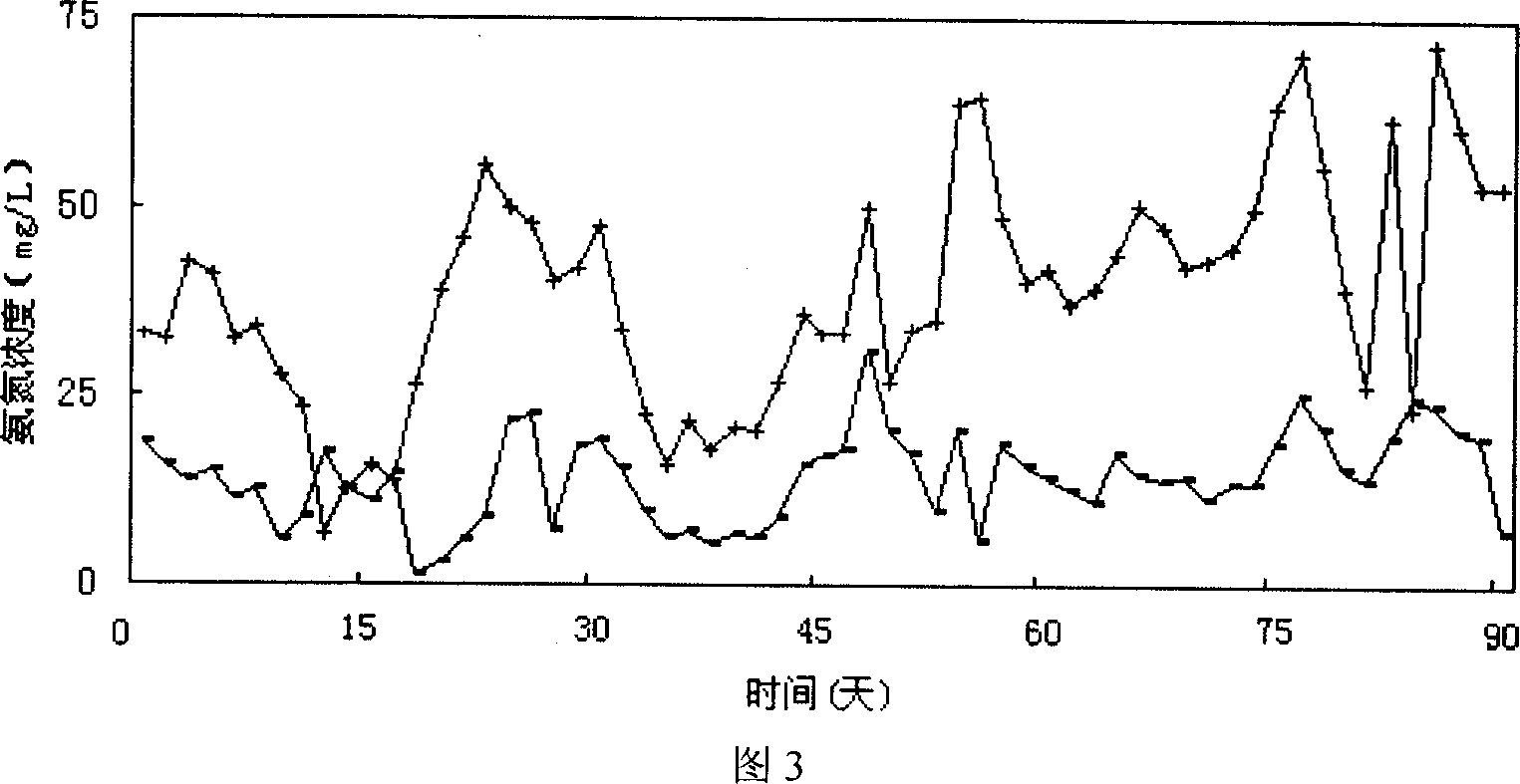

A coking wastewater and advanced treatment technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, biological water/sewage treatment, etc., can solve the problems of COD, total phenol and ammonia nitrogen pollutants failing to meet the discharge standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0005] Specific Embodiment 1: The advanced treatment of coking wastewater in this embodiment is carried out according to the following steps: (1) the coking wastewater that has been generally treated is passed into the flocculation tank to add chemical-biological composite flocculant; (2) pumped into the sand filter column; (3) ) to aerate the sand-filtered waste water, and then pass it into the immobilized bioactivated carbon reactor to stay for 30-40 minutes, and the water can be discharged; step (3) the immobilized bioactivated carbon reactor is provided with an immobilized bioactivated carbon column, fixed Engineering bacteria were immobilized on the activated carbon column.

[0006] In this embodiment, a chemical-biological composite flocculant is added to the flocculation tank. The biological flocculant in the composite flocculant is a metabolite produced by microorganisms, and its main components are glycoprotein, polysaccharide, protein, cellulose and DNA. The use of c...

specific Embodiment approach 2

[0007] Embodiment 2: The difference between this embodiment and Embodiment 1 is: the chemical-biological composite flocculant in step (1) is composed of chemical flocculant and biological flocculant; 80-120 mg of chemical flocculant is added per liter of waste water agent and 7~13mg bioflocculant. Other steps are the same as those in Embodiment 1.

specific Embodiment approach 3

[0008] Specific embodiment three: The difference between this embodiment and specific embodiment one is: the chemical-biological composite flocculant in step (1) is composed of chemical flocculant and biological flocculant; 90-110 mg chemical flocculant is added per liter of waste water Agent and 8 ~ 12mg bioflocculant. Other steps are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com